Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

175results about How to "Reduce volume fraction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

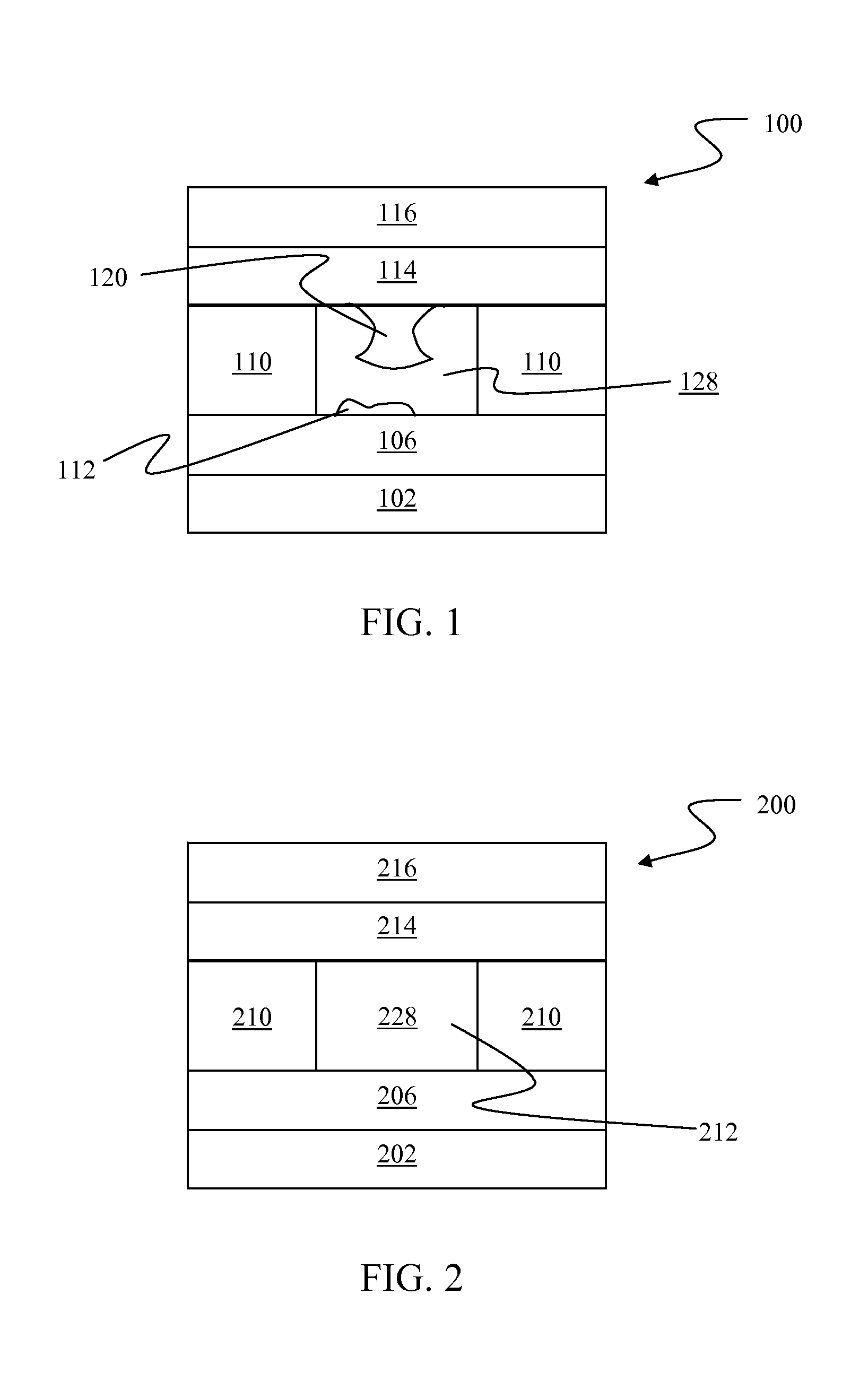

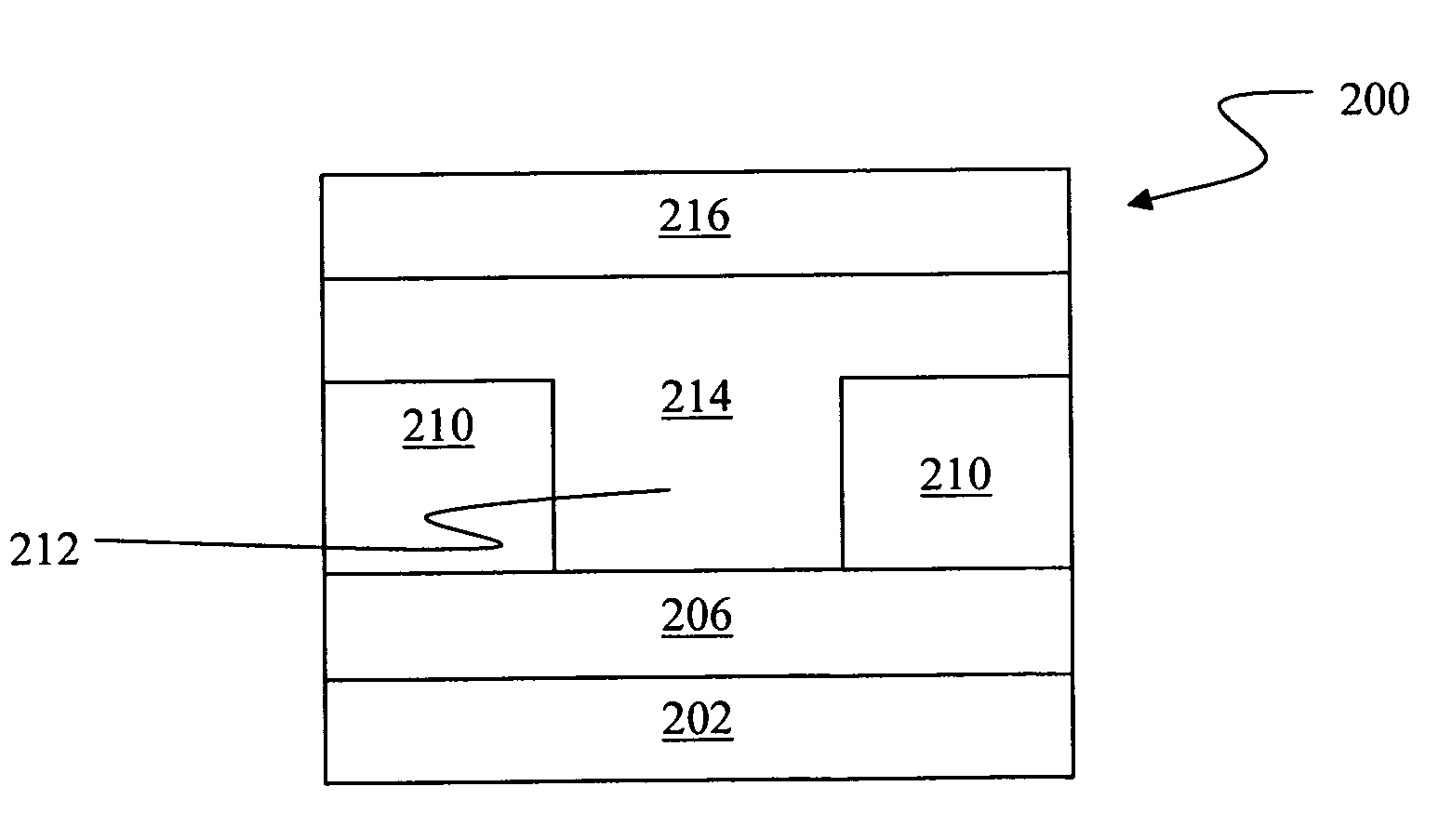

Oxide-rich liner layer for flowable CVD gapfill

ActiveUS20120142192A1Reduce volume fractionIncrease deposition rateSemiconductor/solid-state device detailsSolid-state devicesSilicon oxideOxygen content

The formation of a gap-filling silicon oxide layer with reduced volume fraction of voids is described. The deposition involves the formation of an oxygen-rich less-flowable liner layer before an oxygen-poor more-flowable gapfill layer. However, the liner layer is deposited within the same chamber as the gapfill layer. The liner layer and the gapfill layer may both be formed by combining a radical component with an unexcited silicon-containing precursor (i.e. not directly excited by application of plasma power). The liner layer has more oxygen content than the gapfill layer and deposits more conformally. The deposition rate of the gapfill layer may be increased by the presence of the liner layer. The gapfill layer may contain silicon, oxygen and nitrogen and be converted at elevated temperature to contain more oxygen and less nitrogen. The presence of the gapfill liner provides a source of oxygen underneath the gapfill layer to augment the gas phase oxygen introduced during the conversion.

Owner:APPLIED MATERIALS INC

Porous cordierite ceramic honeycomb article with improved strength and method of manufacturing same

ActiveUS20070119133A1Reduce the amount requiredIncrease volume fractionCombination devicesAuxillary pretreatmentCordieritesSilicon dioxide

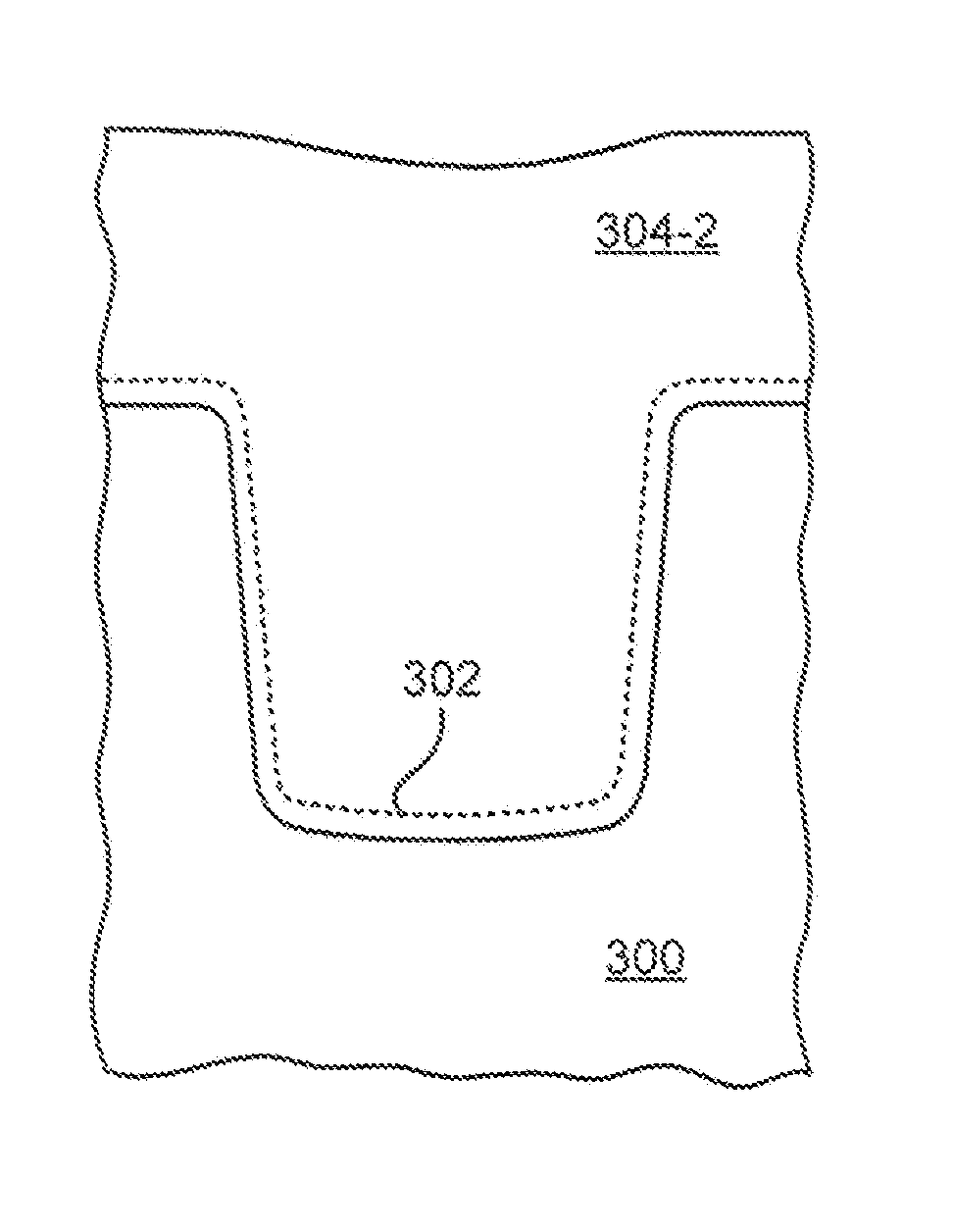

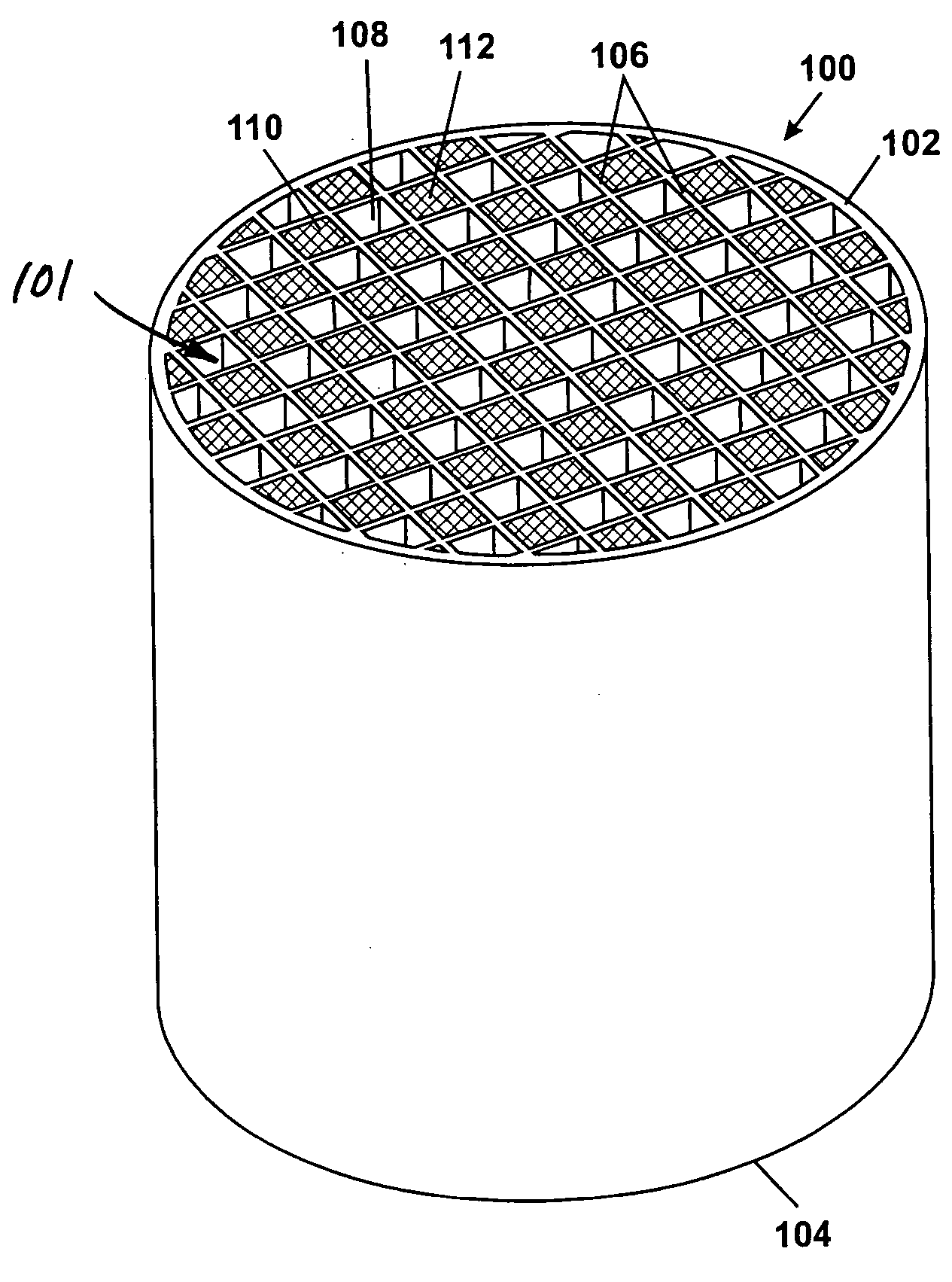

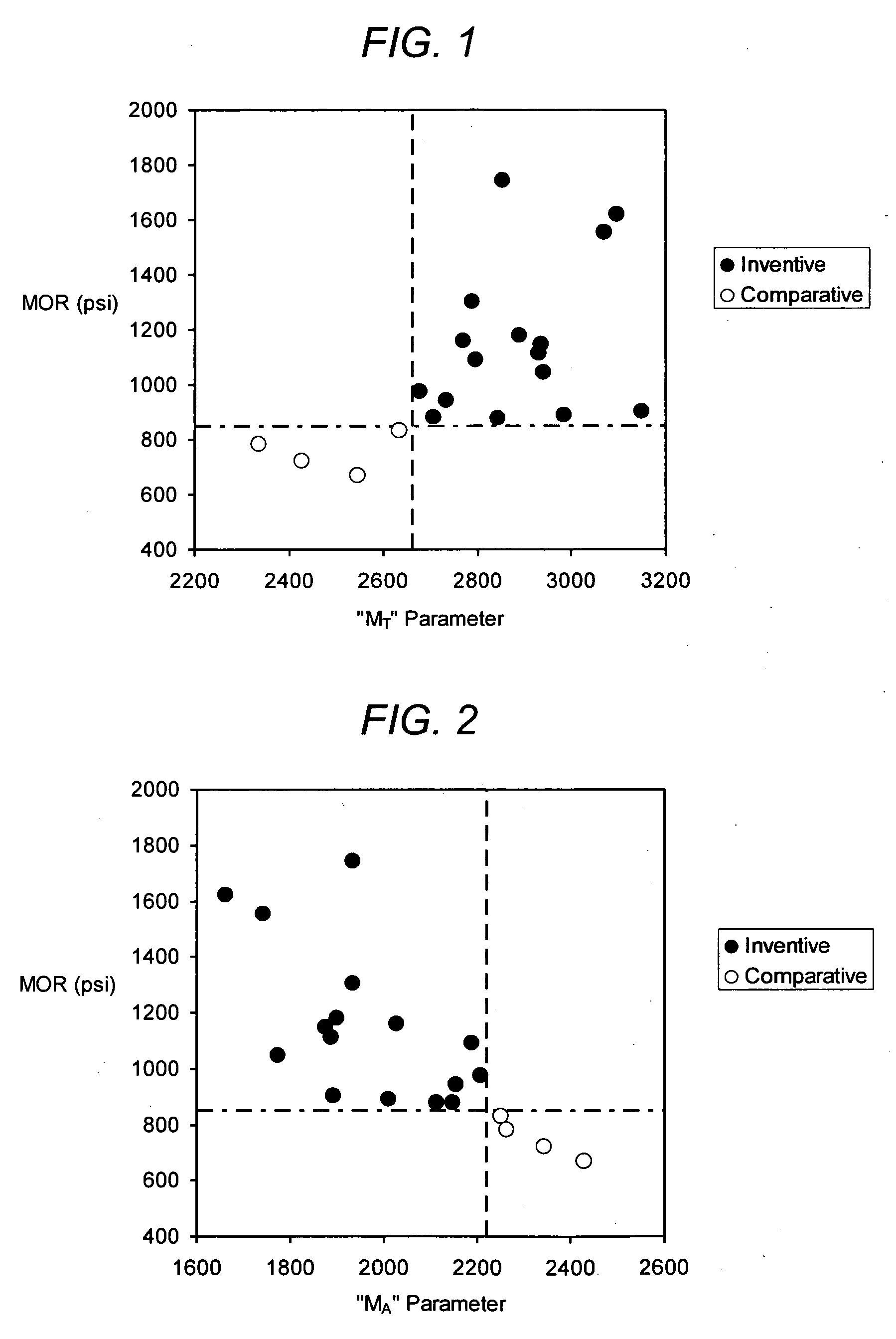

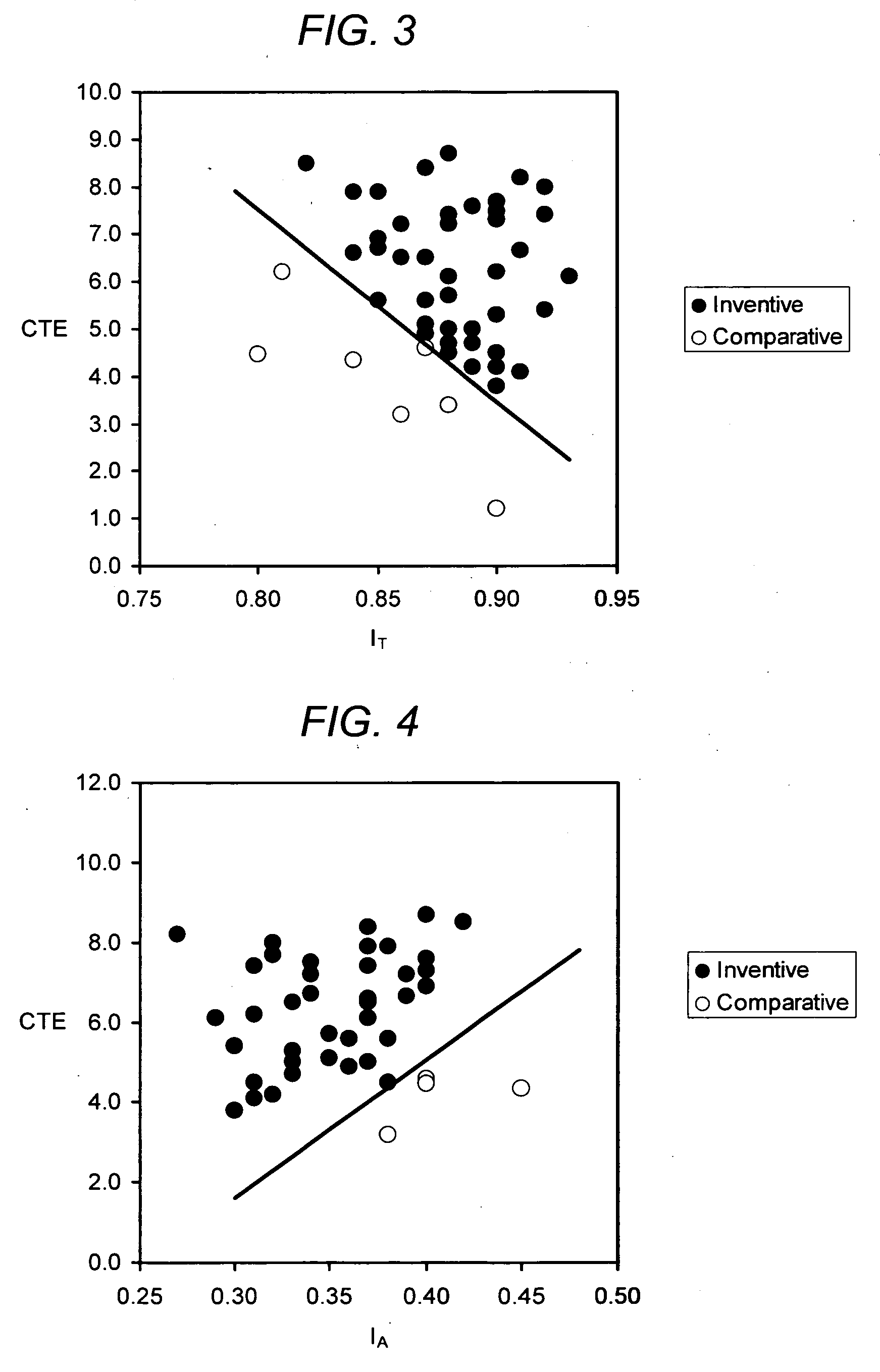

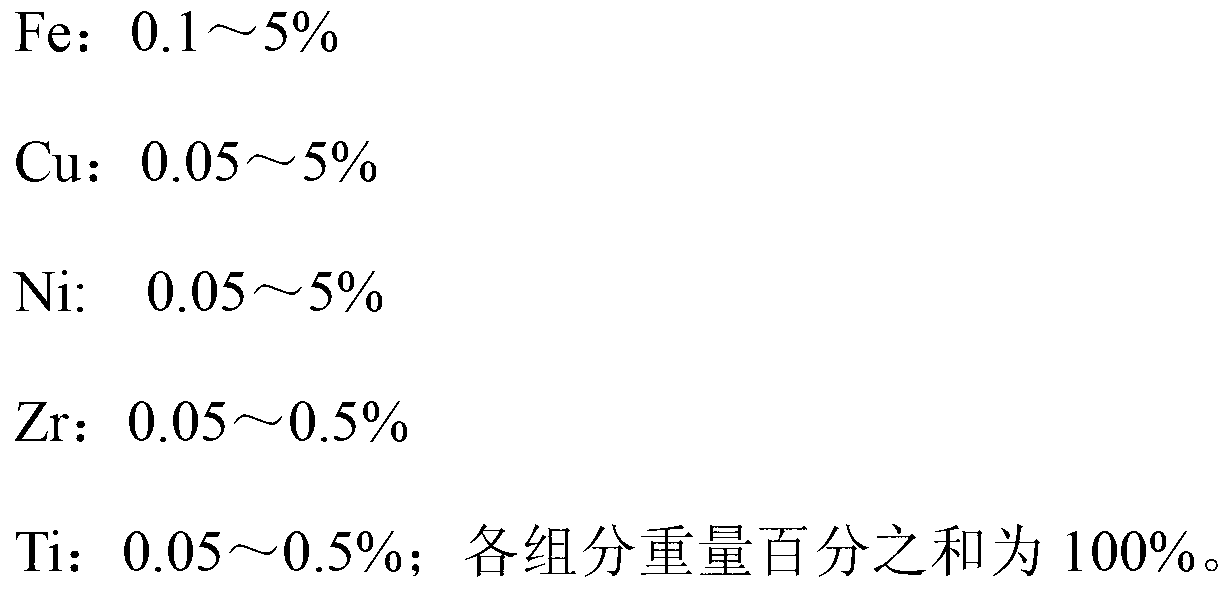

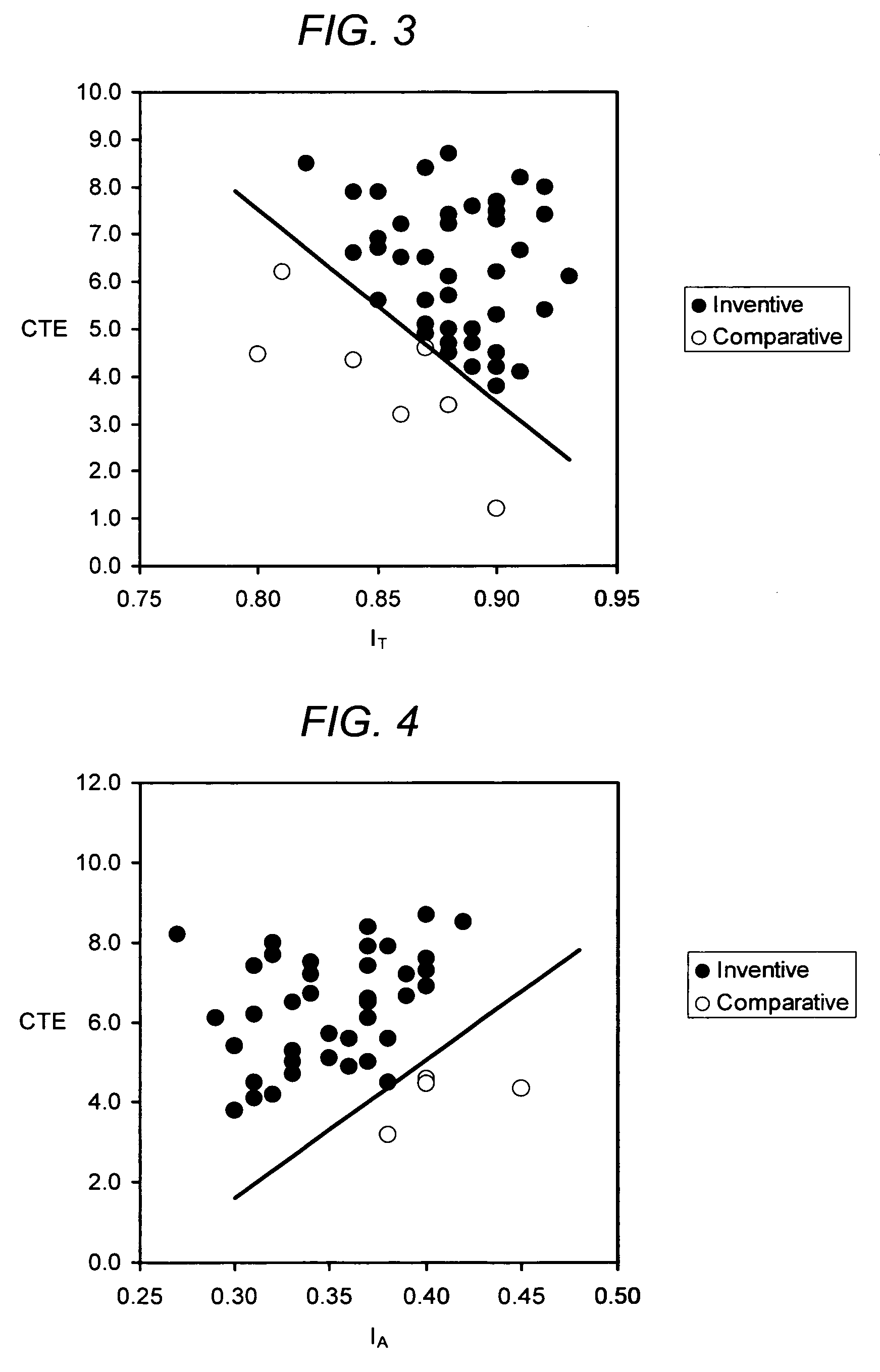

A porous cordierite ceramic honeycomb article with increased mechanical strength and thermal shock resistance. The porous cordierite ceramic honeycomb article has MA<2220, or MT>2660 wherein MA=3645 (IA)−106 (CTE)+19 (d90)+17 (% porosity), MT=4711 (IT)+116 (CTE)−26 (d90)−28 (% porosity), and a CTE≦9×10−7 / ° C. in at least one direction. A method of manufacturing is also disclosed wherein the inorganic raw material mixture contains talc, an alumina-forming source, a silica-forming source, and 0-18 wt. % of a kaolin or calcined kaolin containing not more than 8 wt. % of a fine kaolin source having a median particle diameter of less than 7 μm, wherein the fired porous ceramic cordierite honeycomb article has a porosity<54% . Alternatively, if greater than 8 wt. % of the fine kaolin source is used, then a slow ramp rate is utilized from 1200° C. to 1300° C. of not more than 20° C. / hr.

Owner:CORNING INC

Light and pressure-proof fast-decomposed cast magnesium alloy

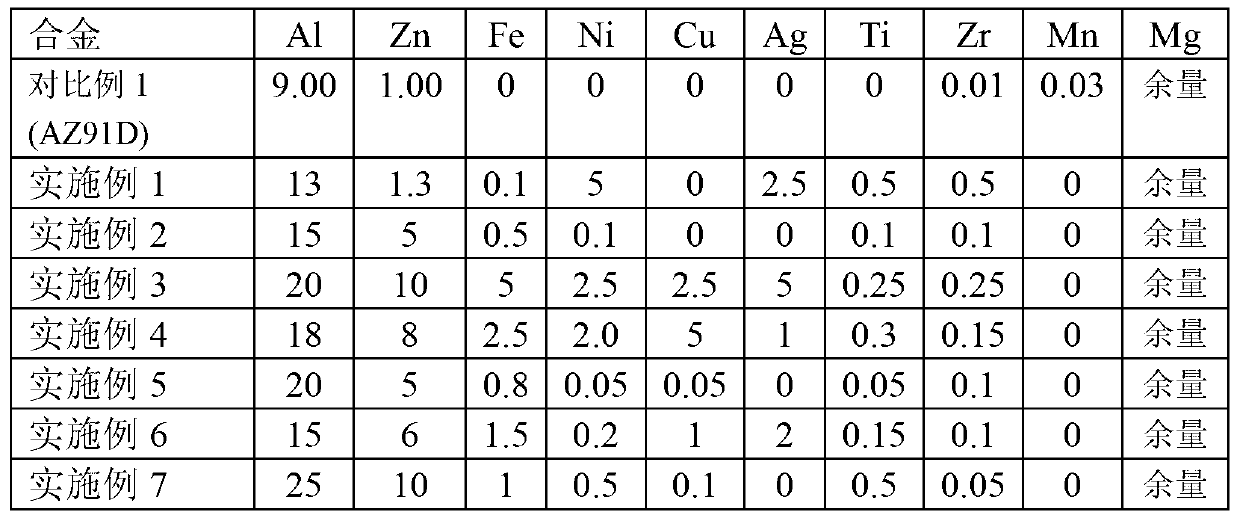

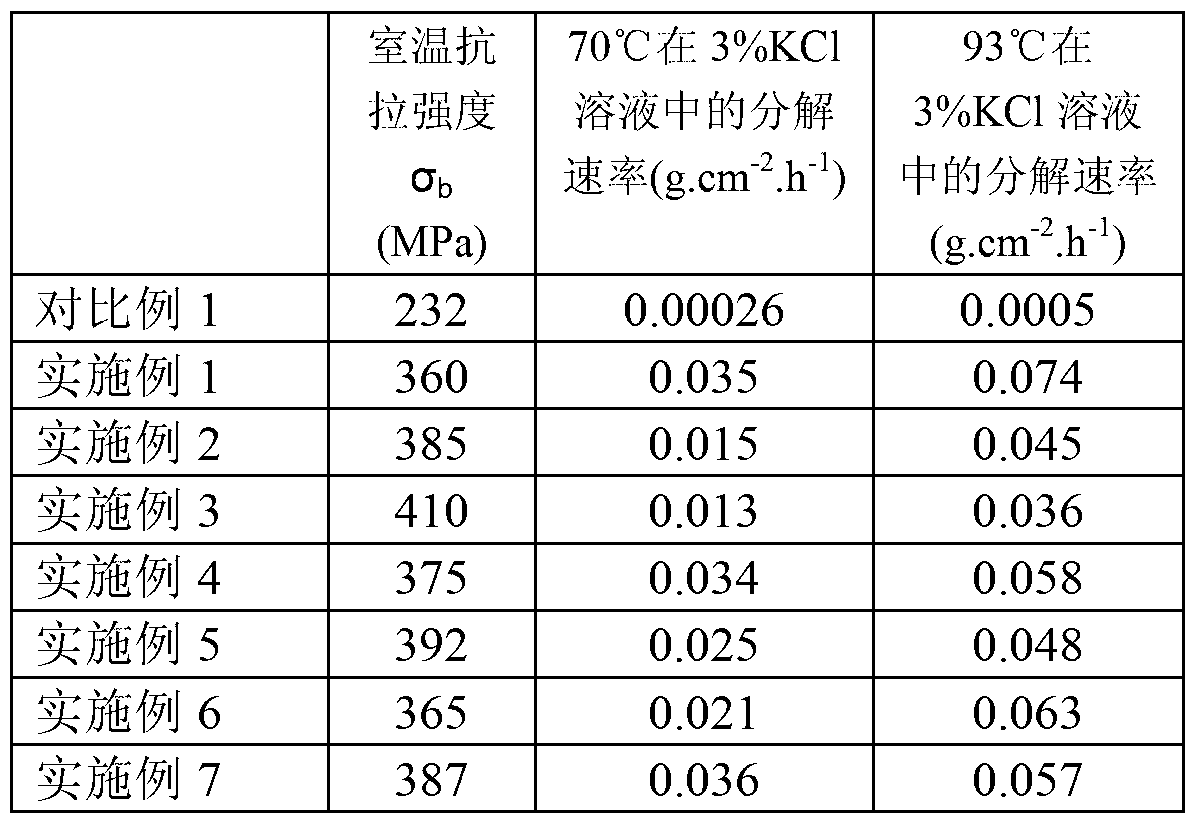

The invention discloses light and pressure-proof fast-decomposed cast magnesium alloy which can be used as a tripping ball material for a multi-stage sliding sleeve staged-fracturing technique. The light and pressure-proof fast-decomposed cast magnesium alloy is prepared from the following components: 13-25% of Al, 2-15% of Zn, 0.1-5% of Fe, 0.05-5% of Cu, 0.05-5% of Ni, 0-5% of Ag, 0.05-0.5% of Zr, 0.05-0.5% of Ti, and the balance of Mg. The preparation method comprises the following steps of: weighing the components according to the designed component ratio of the magnesium alloy; firstly, putting pure magnesium and pure aluminum into a smelting furnace, putting pure zinc and intermediate alloy of other components into magnesium-aluminum alloy melt after melting; refining, degassing, and stewing after warming to melt; then casting in a protective atmosphere. The light and pressure-proof fast-decomposed cast magnesium alloy is reasonable in component ratio, and simple in craft process; the light and pressure-proof fast-decomposed cast magnesium alloy can be obtained by controlling the ingredients of the alloy; the alloy decomposition performance exceeds that of the traditional cast magnesium alloy; the demands of the multi-stage sliding sleeve staged-fracturing technique on the decomposition performance of the tripping ball material can be met; industrialized application can be achieved; application of the magnesium alloy in the field of exploitation of petroleum and gas is expanded.

Owner:中山市宏镁科技有限公司

Methods for forming electrodes in phase change memory devices

InactiveUS20090029031A1Reduce structural irregularityReduce volume fractionElectrical apparatusCoatingsPhase-change memoryConductive materials

A method for forming electrode materials uniformly within openings having small dimensions, including sublithographic dimensions, or high aspect ratios. The method includes the steps of providing an insulator layer having an opening formed therein, forming a non-conformal conductive or semiresistive material over and within the opening, and mobilizing the conductive material to densify it within the opening. The method reduces the concentration of voids or defects in the conductive or semiresistive material relative to the as-deposited state. The mobilizing step may be accomplished by extrusion or thermal reflow and causes voids or defects to coalesce, collapse, percolate, or otherwise be removed from the as-deposited conductive or semiresistive material.

Owner:OVONYX

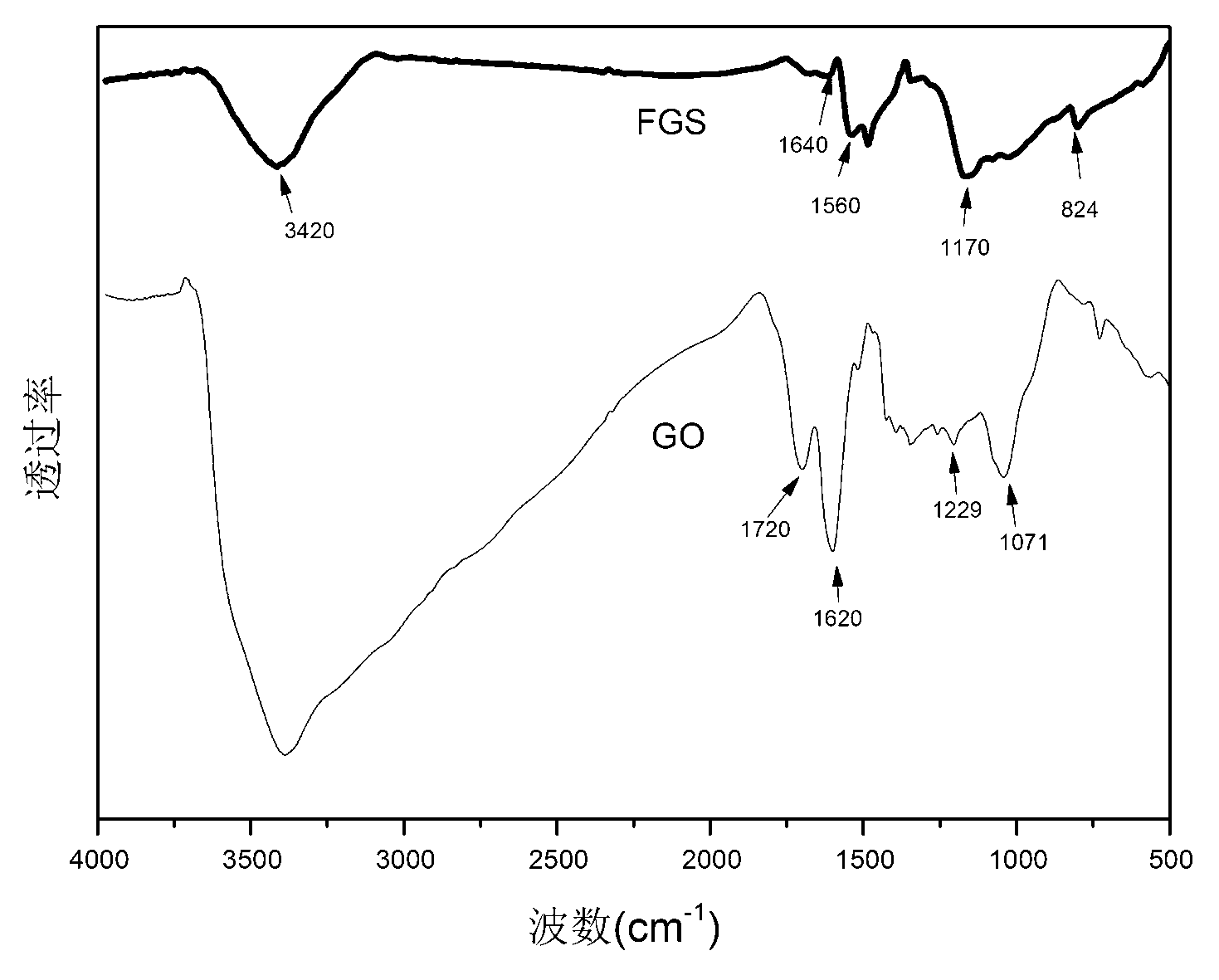

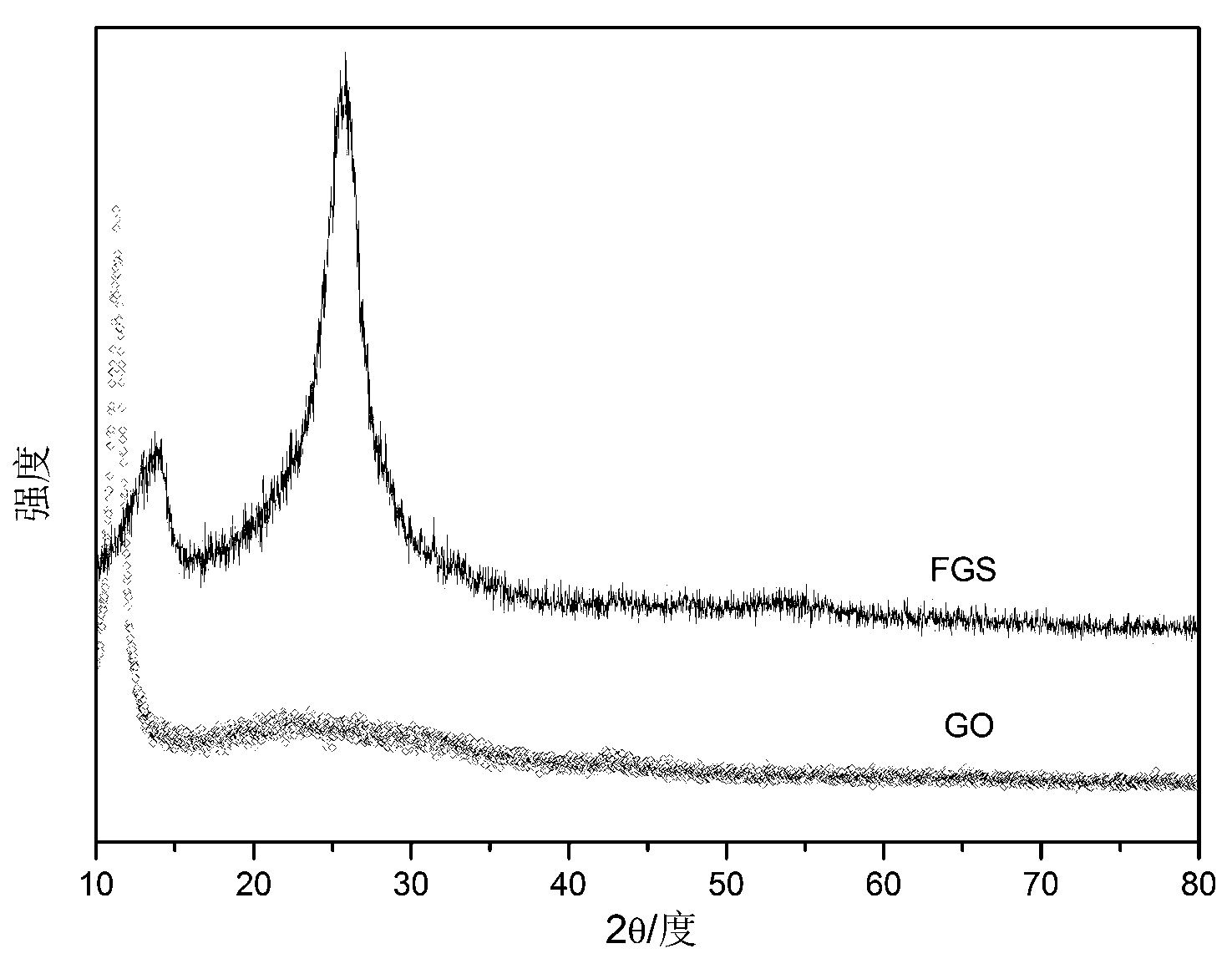

Polyimide high dielectric composite material and preparation method thereof

The present invention relates to a polyimide high dielectric composite material, wherein polyimide is adopted as a matrix phase, modified graphene and nanometer barium titanate are adopted as inorganic phases, components comprise, by mass, 0.5-3.0 w% of modified graphene, 9.6-29.8 w% of nanometer barium titanate, and 69.7-87.4 w% of polyimide, the modified graphene is p-phenylenediamine graft modified graphene, and the surface of the modified graphene contains chemically grafted polyimide. The preparation method comprises the following steps: (1) graphene oxide modification, (2) polyamic acid prepolymer preparation, and (3) composite material thermal cross-linking. According to the preparation method, the functionalized graphene and the polyimide molecules can be combined through a covalent bond form, electric conductivity of the graphene can directly affect dielectric property of the composite material, and a volume fraction of the barium titanate can be effectively reduced. In addition, the conventional solution blending technology is adopted, the preparation process is simple, operation is easy, and the method can be widely promoted and applied.

Owner:EAST CHINA UNIV OF SCI & TECH

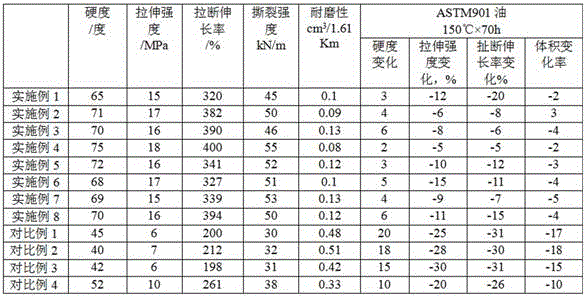

High-performance nitrile rubber sealing material and preparation method thereof

The invention discloses a high-performance nitrile rubber sealing material and a preparation method thereof. The high-performance nitrile rubber sealing material is prepared from the following raw materials in parts by weight: 25 to 35 parts of nitrile rubber, 4 to 7 parts of composite sulfurizing reagent, 4 to 5 parts of anti-aging agent, 8 to 15 parts of activating agent, 25 to 30 parts of reinforcing agent and 2 to 5 parts of heat-resistant additive. By adopting the high-performance nitrile rubber sealing material, the problems of poor wear resistance, low tensile strength and low tearing strength in ordinary nitrile rubber are solved, and the prepared product has high mechanical performance and superior high-temperature performance.

Owner:南阳天一密封股份有限公司

Porous cordierite ceramic honeycomb article with improved strength and method of manufacturing same

ActiveUS7520911B2Reduce the amount requiredIncrease volume fractionCombination devicesAuxillary pretreatmentCordieritesSilicon dioxide

A porous cordierite ceramic honeycomb article with increased mechanical strength and thermal shock resistance. The porous cordierite ceramic honeycomb article has MA<2220, or MT>2660 whereinMA=3645(IA)−106(CTE)+19(d90)+17(% porosity),MT=4711(IT)+116(CTE)−26(d90)−28(% porosity),and a CTE≦9×10−7 / ° C. in at least one direction. A method of manufacturing is also disclosed wherein the inorganic raw material mixture contains talc, an alumina-forming source, a silica-forming source, and 0-18 wt. % of a kaolin or calcined kaolin containing not more than 8 wt. % of a fine kaolin source having a median particle diameter of less than 7 μm, wherein the fired porous ceramic cordierite honeycomb article has a porosity<54% . Alternatively, if greater than 8 wt. % of the fine kaolin source is used, then a slow ramp rate is utilized from 1200° C. to 1300° C. of not more than 20° C. / hr.

Owner:CORNING INC

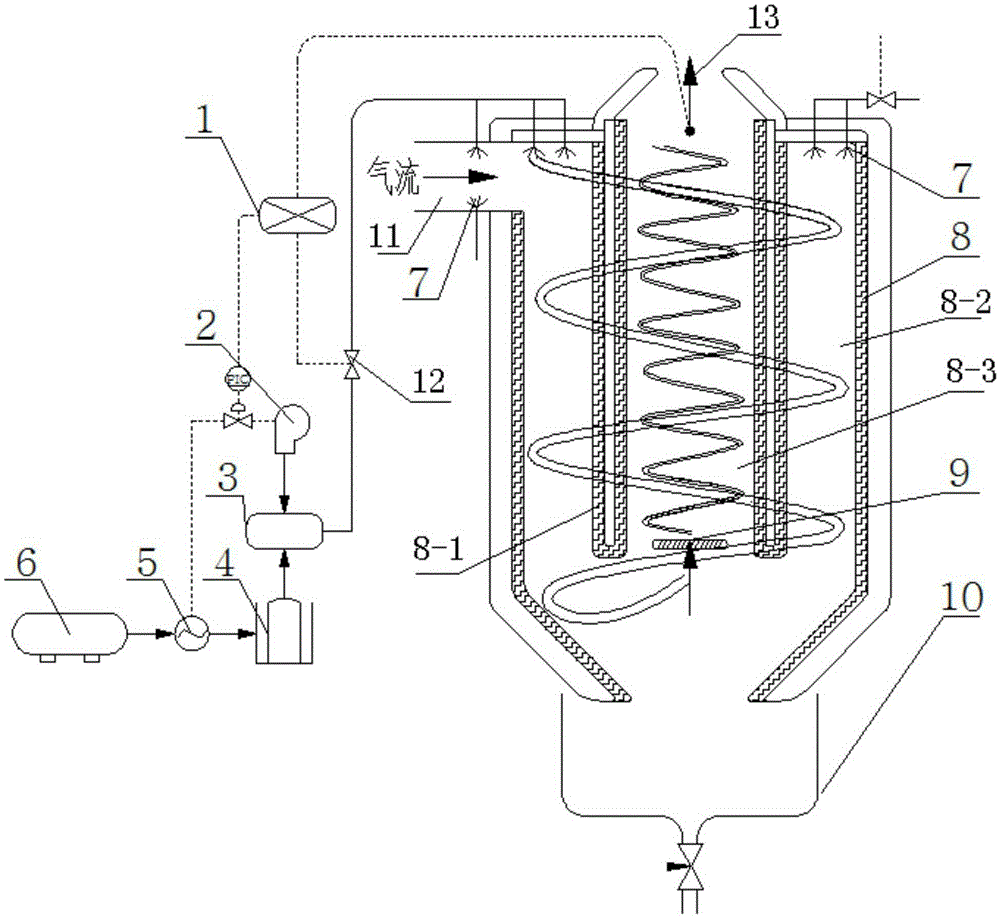

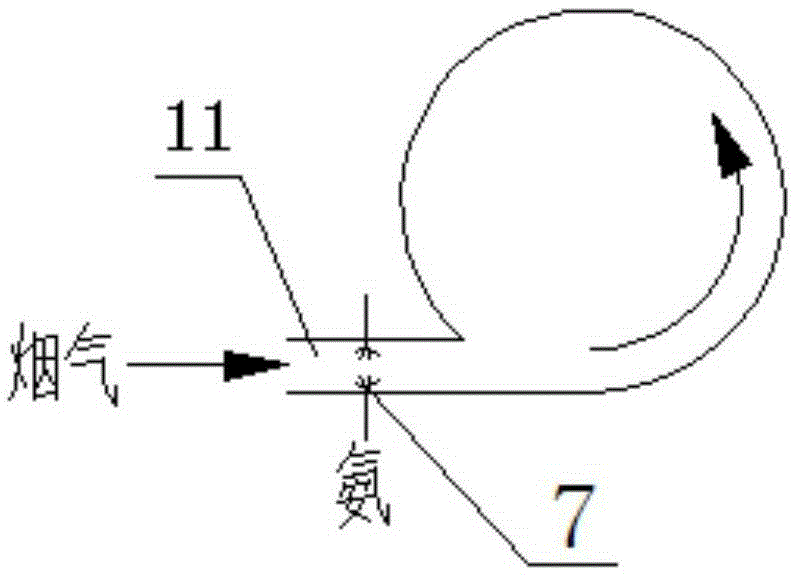

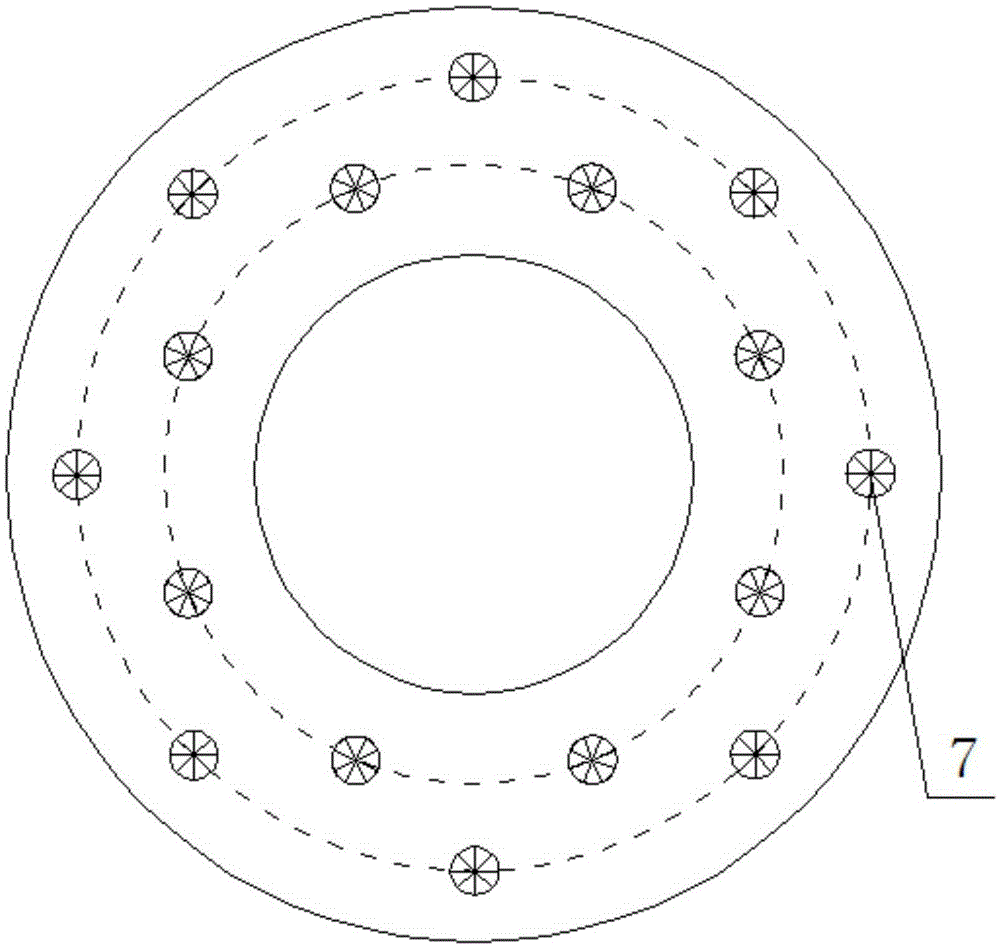

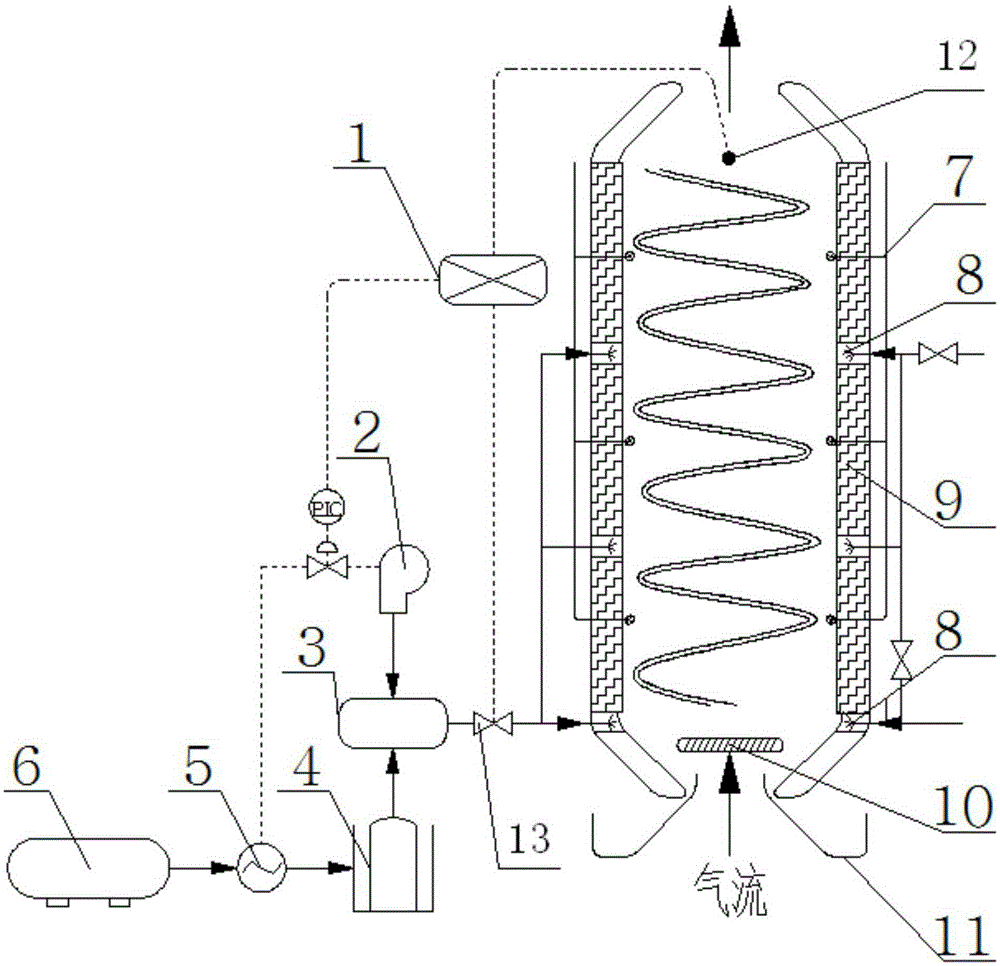

Double-rotation SCR denitration method and apparatus thereof

ActiveCN105289301AImprove denitrification efficiencyIncrease contact timeDispersed particle separationCycloneFlue gas

The invention discloses a double-rotation SCR denitration method and an apparatus thereof. According to the invention, a first eddy flow catalytic reaction chamber and a second eddy flow catalytic reaction chamber are arranged along a denitrating tower body; a flue gas introduction pipeline is arranged on a sidewall of the denitrating tower body; several eddy flow atomizing nozzles are respectively arranged on inner periphery of the flue gas introduction pipeline and the inner periphery at top of the first eddy flow catalytic reaction chamber; when flue gas is introduced into the flue gas introduction pipeline, the flue gas and ammonia gas injected by the eddy flow atomizing nozzle are mixed, and a mixture enables spiral sinking along circumference of the first eddy flow catalytic reaction chamber from up to down in a tangent circle mode, under effect of a cyclone, and then the mixture enable spiral rise along circumference of the second eddy flow catalytic reaction chamber from down to up in the tangent circle mode. Under prerequisite that high efficiency denitration is ensured, catalyst amount is less, operation of technical means is simple and easy, compared with the prior art, a denitrating tower structure is simple, cost of the apparatus is low, denitration efficiency is high, energy consumption is low, escapement ratio of ammonia is reduced, denitration cost is greatly reduced, and economic benefit is obviously increased.

Owner:SOUTH CHINA UNIV OF TECH

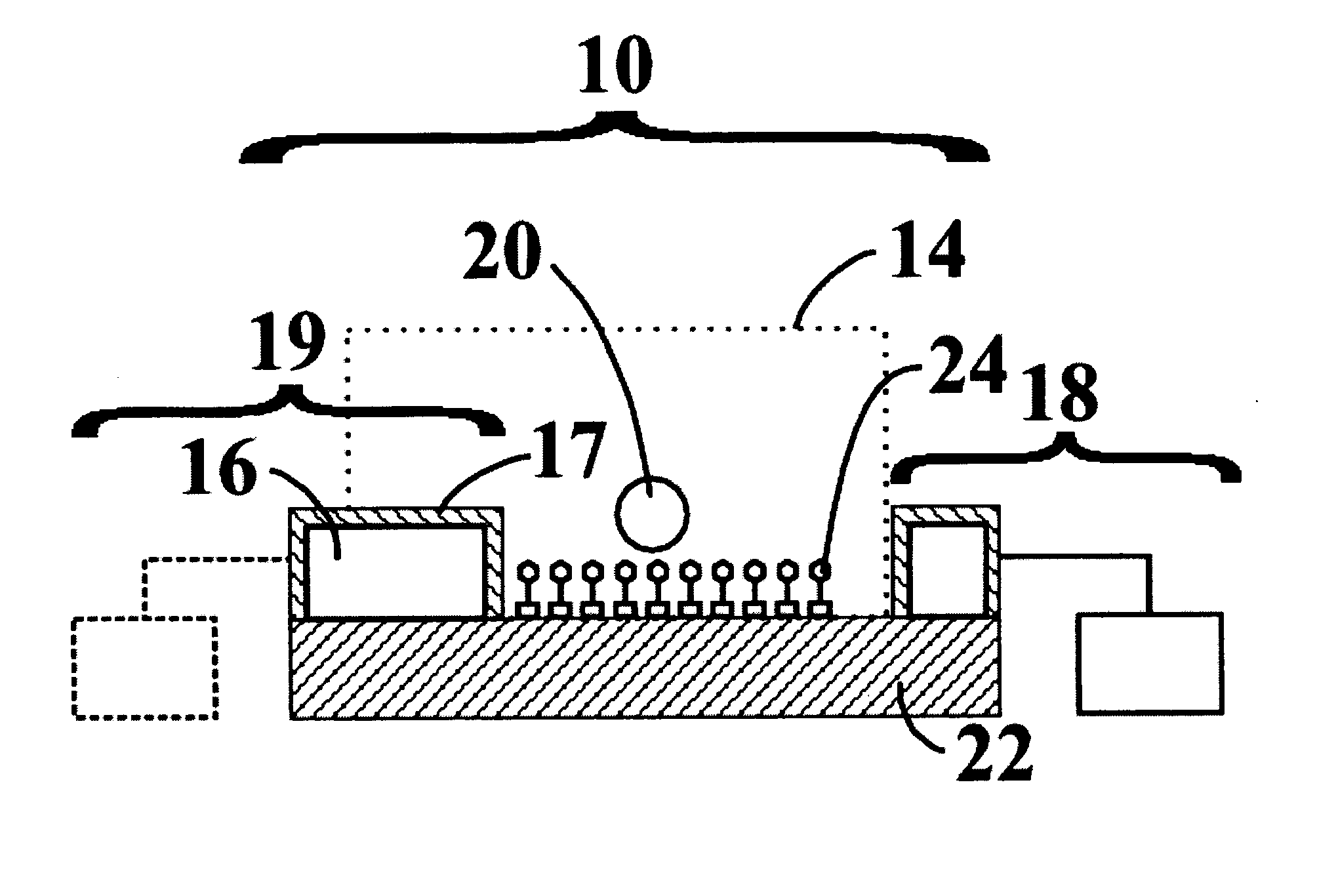

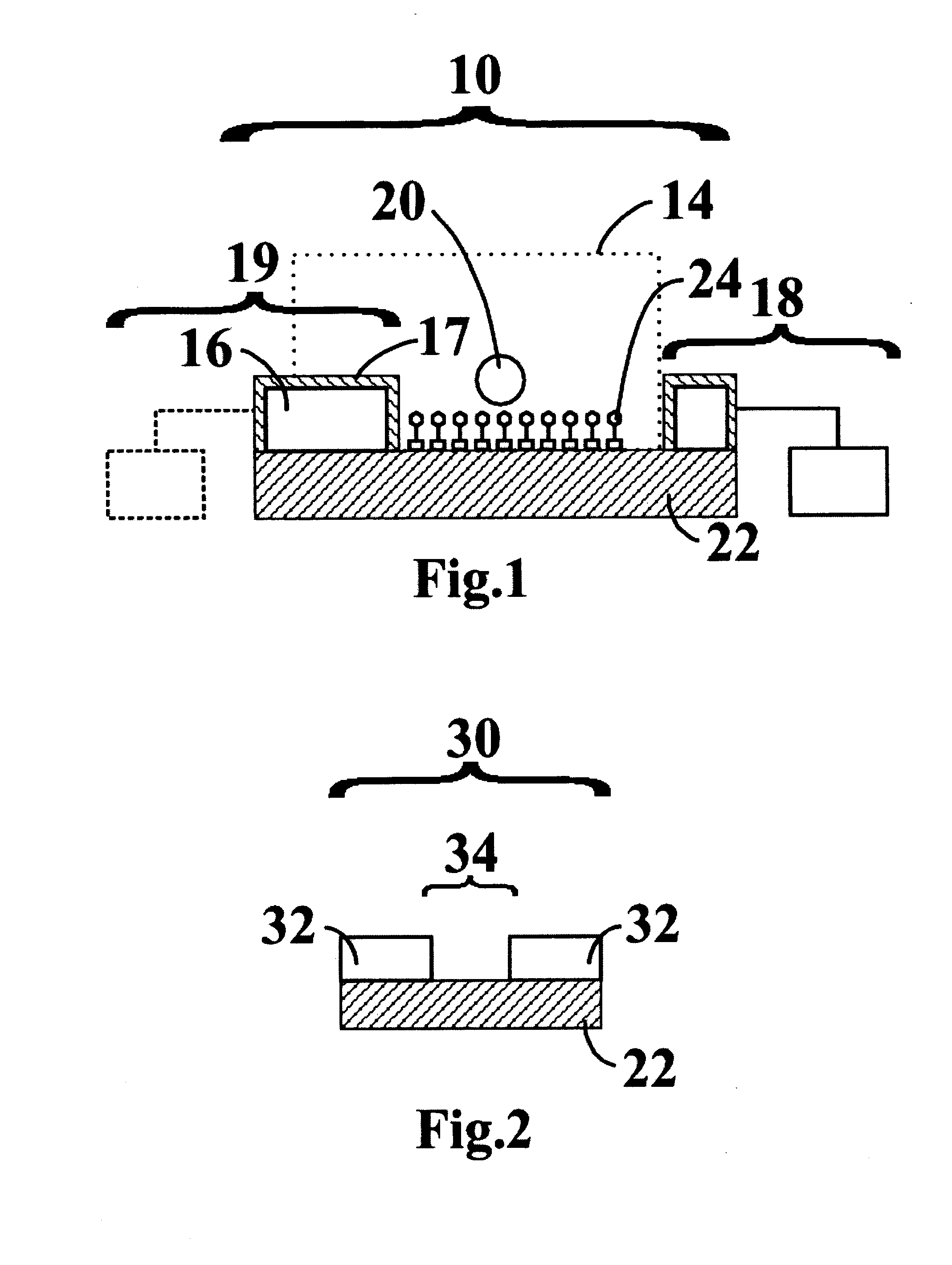

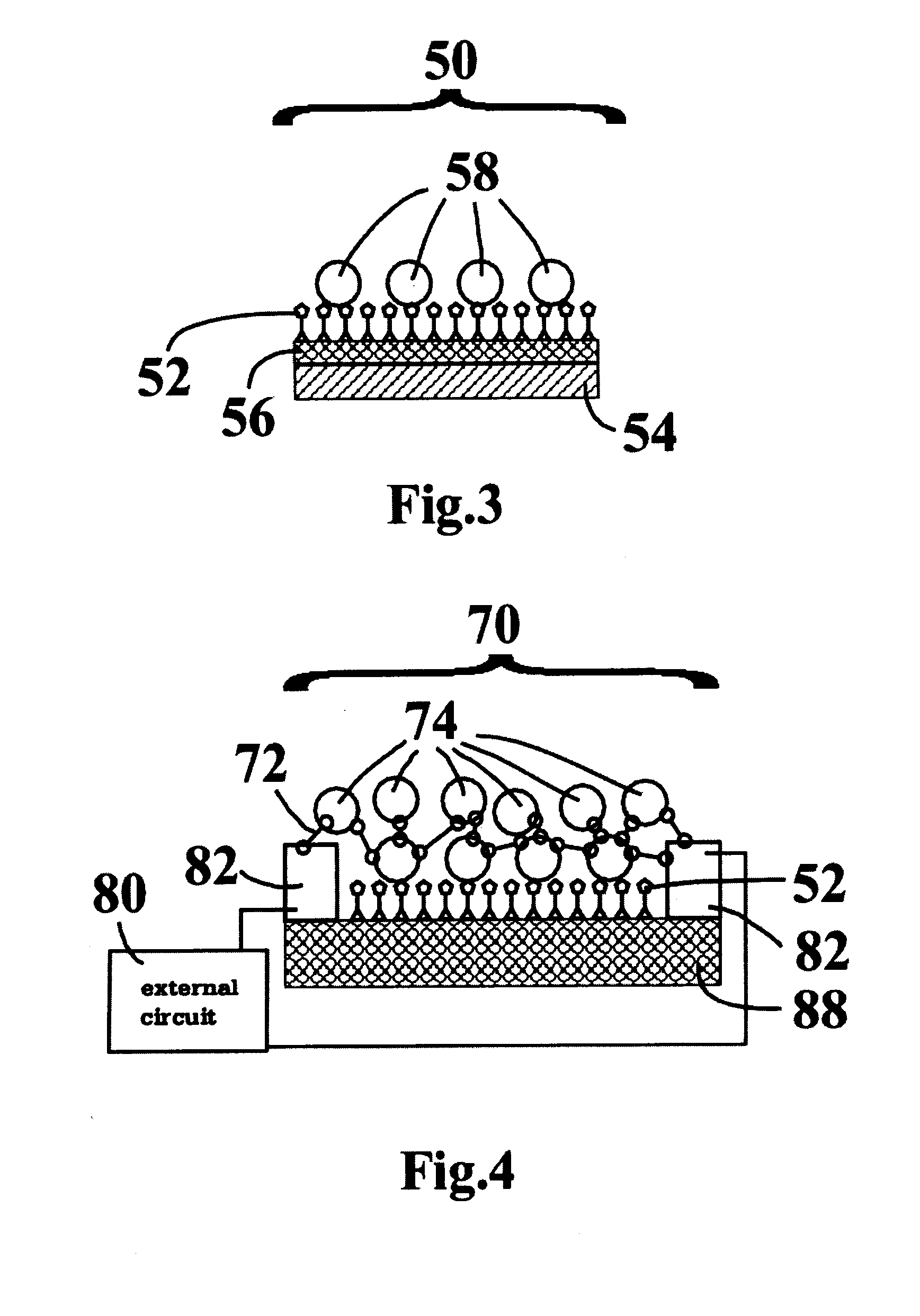

Dielectric Sensing Method and System

InactiveUS20090273354A1Little changeEnsure mechanical stabilityBioreactor/fermenter combinationsBiological substance pretreatmentsCapacitanceDielectric

Sensing device and method for detecting presence and concentration of generic target analytes of interest. The device and method are based on detecting changes in effective dielectric induced by the target analytes of interest. Applications of the invention include, but are not restricted to, detecting and characterizing the presence of chemical and / or biological target analytes of interest as well as detecting and characterizing target analytes of interest from a separation apparatus. In one embodiment of the invention, the device comprises at least two electrodes in a rigid architecture such as a solid surface, where the electrodes have sizes and inter-electrode spacings that are on the order of sizes of target analytes of interest to improve sensitivity of the device. Changes in effective dielectric and, therefore, capacitance induced by a presence of the target analytes of interest are measured electronically. The changes are used to detect the presence of the target analytes of interest and to characterize their presence.

Owner:LINAK AS +1

Graphene enhanced aluminium-based silicon carbide composite, preparation method and application thereof

ActiveCN106591666AImprove reliabilityImprove thermal conductivitySemiconductor/solid-state device detailsSolid-state devicesThermal diffusivityElectronic packaging

The invention relates to a graphene enhanced aluminium-based silicon carbide composite and a preparation method thereof. The composite comprises the following substances by volume percent: 40% to 70% of silicon carbide and 0.5% to 5% of graphene, and the balance being aluminium alloy. The composite is prepared through the powder metallurgy method and is obtained through the steps of blending, powder mixing, bagging, vacuum degassing and hot iso-hydrostatic forming treatment. The composite has the advantages of high thermal conductivity, high strength, high plasticity, light weight, good thermal diffusivity, isotropy, and the like, and becomes a second-generation electronic packaging material with wide application.

Owner:BEIJING BAOHANG ADVANCED MATERIALS CO LTD

Carbon fiber reinforced aluminum base composite material for brake disc and preparation method of composite material

The invention relates to an aluminum alloy brake disc, and in particular relates to a carbon fiber reinforced aluminum base composite material for the brake disc and a preparation method of the composite material. The carbon fiber reinforced aluminum base composite material for the brake disc is prepared by taking an aluminum-silicon-copper series aluminum alloy as a matrix and micro-nano scale carbon fibers as a reinforcing phase of the aluminum alloy matrix, and performing melt synthesis-compression molding. Compared with the prior art, through carbon fiber reinforcement, the fatigue resistance and wear resistance of the material are improved, and the material is good in braking effect and long in service life and can be applied to brake discs of various motor vehicles.

Owner:JIANGSU UNIV

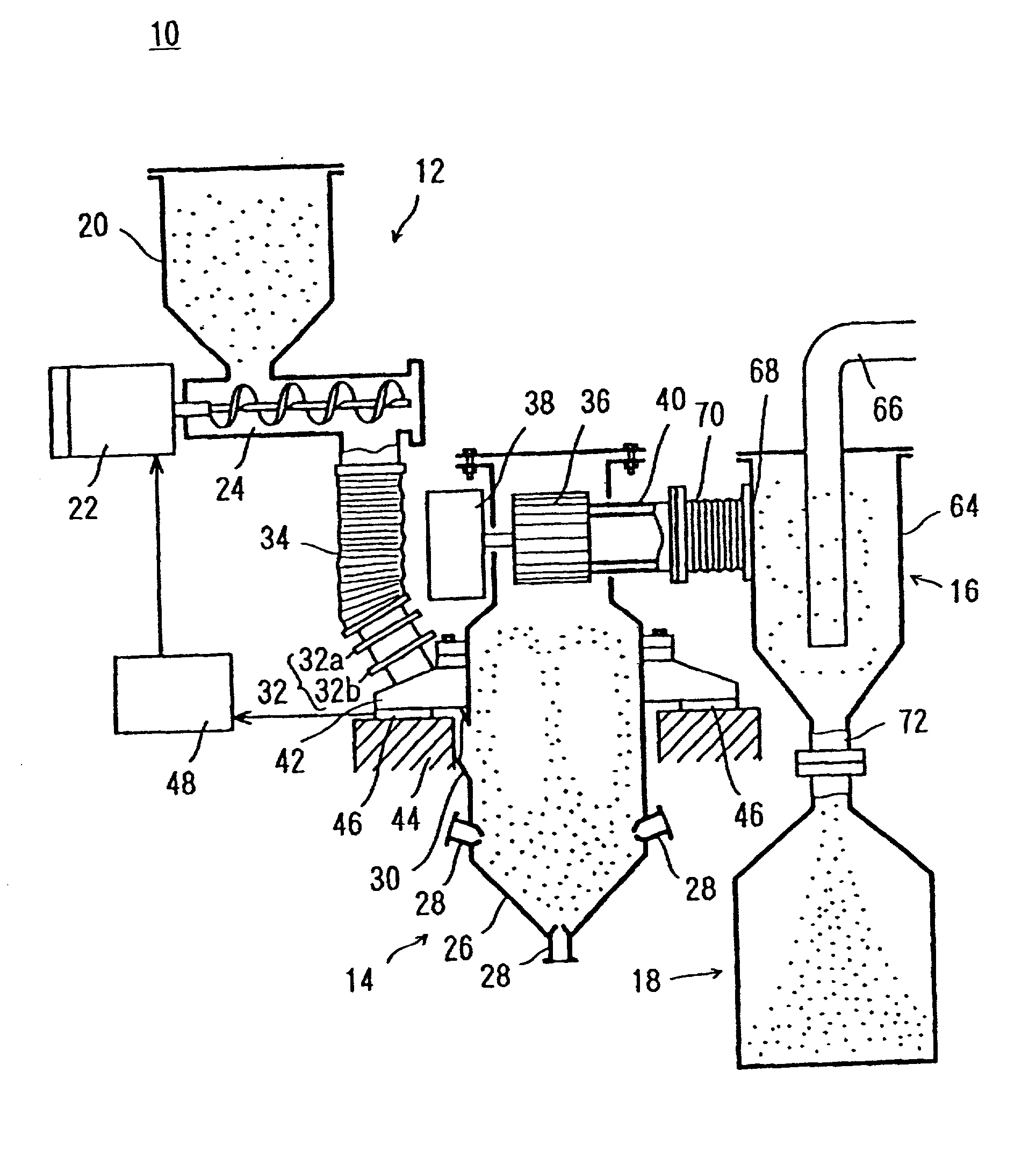

Rare earth magnet and method for producing the magnet

InactiveUS20020129874A1Improve the compaction effectReduce volume fractionTransportation and packagingMetal-working apparatusRare-earth magnetVolume fraction

Owner:HITACHI METALS LTD

Pressure extrusion method for filling features in the fabrication of electronic devices

InactiveUS20090226603A1More consistentReduce structureElectrical apparatusCoatingsAspect ratioPhase-change material

A method of filling high aspect ratio features with active electronic or conductive materials. In one method, high pressure extrusion is used to urge the as-deposited active or conductive material into an incompletely filled opening. In another method, a rapid thermal anneal process is used to induce reflow of the as-deposited active or conductive material into an incompletely filled opening. Both methods are also effective in densifying active or conductive materials within openings by collapsing voids that arise in the as-deposited state. The instant methods provide for more uniform and consistent filling of openings and minimize the variability and impairment of electrical characteristics of active material devices. Active materials include phase-change materials, chalcogenide materials, switching materials, and programmable resistance materials.

Owner:OVONYX

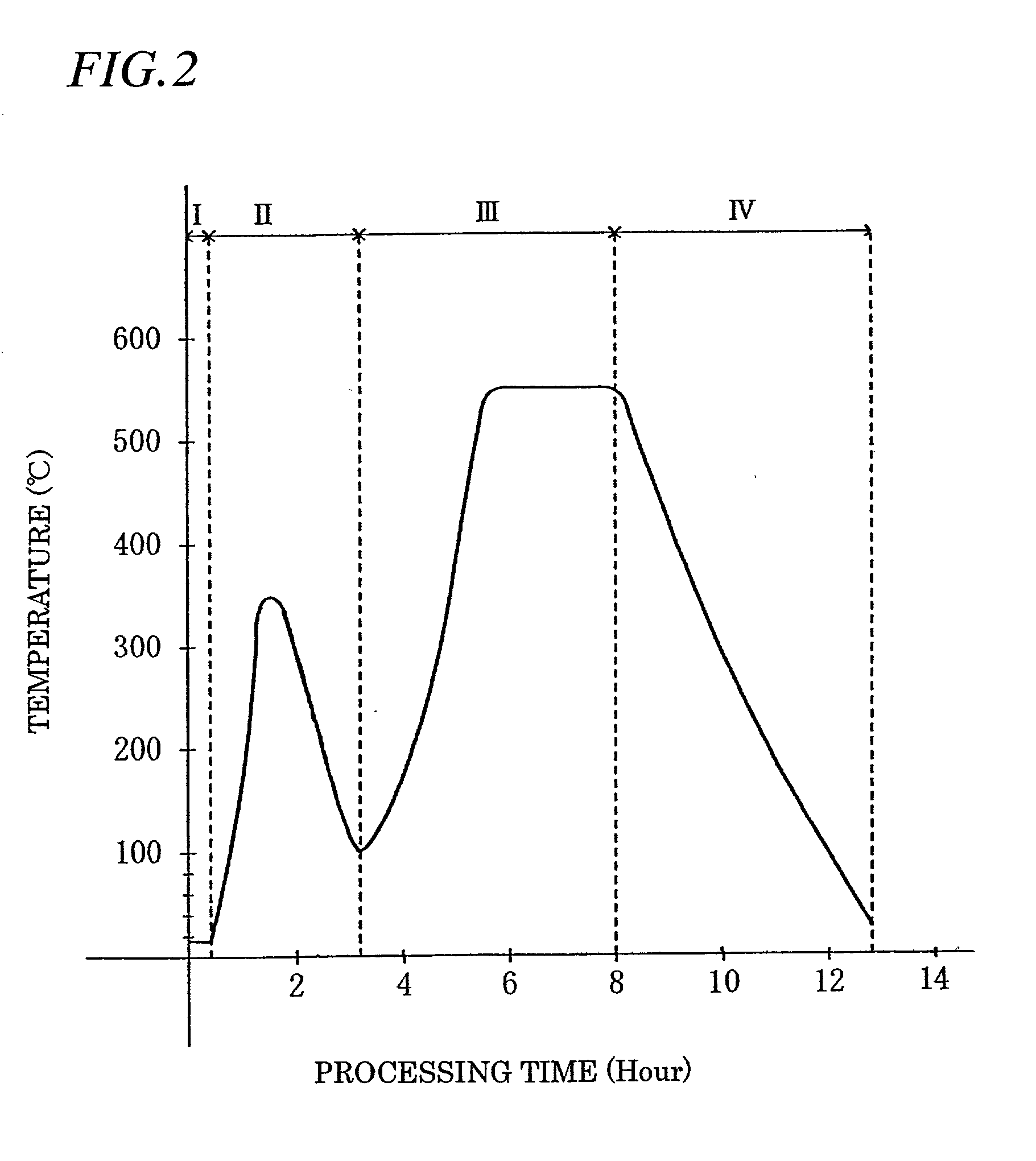

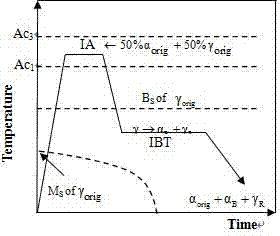

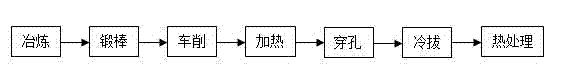

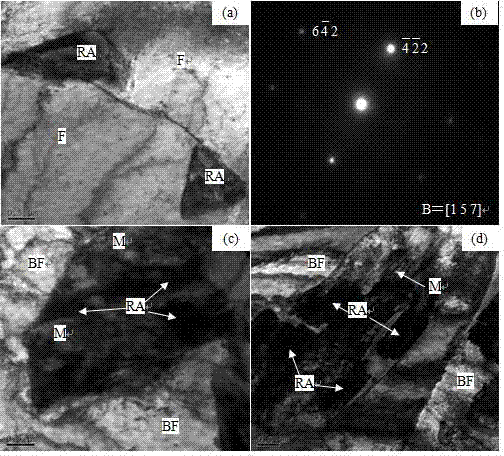

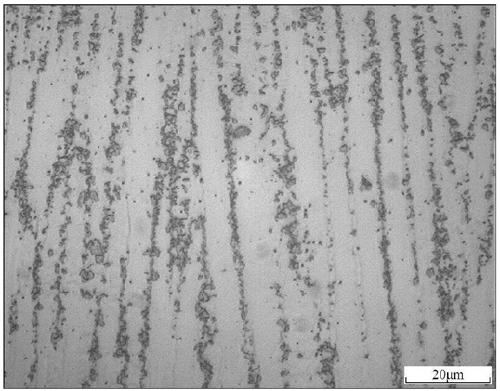

Method for producing transformation induced plasticity (TRIP) seamless tube

InactiveCN102407245AAustempering achievedReduce contentFurnace typesHeat treatment furnacesAustemperingChemical composition

The invention belongs to the field of preparation of steel tubes, and in particular relates to a method for producing a transformation induced plasticity (TRIP) seamless tube. The method comprises the following steps that: a smelted ingot is forged into a rod, turned, heated, punched and subjected to cold drawing to obtain a seamless cold drawing steel tube, and the seamless cold drawing steel tube is placed in a resistor furnace for critical region isothermal annealing for 180-1200 seconds at the temperature of 780-850 DEG C, and then is rapidly placed in a salt bath furnace for bainite region isothermal annealing for 120-1800 seconds at the temperature of 380-470 DEG C so as to obtain the TRIP seamless tube. According to the technical scheme in the invention, the chemical components of common low carbon steel can be used for producing the TRIP seamless tube with good comprehensive mechanical properties, high yield strength up to 580MPa, high tensile strength up to 763MPa and high product of strength and elongation up to 22029MPa.%. The method is easy to realize in industrialized production, has the advantages of relatively stable process and relatively low cost, and is suitable for producing TRIP seamless steel tubes with different chemical components and sizes.

Owner:NORTHEASTERN UNIV LIAONING

Dielectric sensing method and system

InactiveUS8246910B2Maximize fractionImprove concentrationBioreactor/fermenter combinationsBiological substance pretreatmentsDielectricTarget analysis

Sensing device and method for detecting presence and concentration of generic target analytes of interest. The device and method are based on detecting changes in effective dielectric induced by the target analytes of interest. Applications of the invention include, but are not restricted to, detecting and characterizing the presence of chemical and / or biological target analytes of interest as well as detecting and characterizing target analytes of interest from a separation apparatus. In one embodiment of the invention, the device comprises at least two electrodes in a rigid architecture such as a solid surface, where the electrodes have sizes and inter-electrode spacings that are on the order of sizes of target analytes of interest to improve sensitivity of the device. Changes in effective dielectric and, therefore, capacitance induced by a presence of the target analytes of interest are measured electronically. The changes are used to detect the presence of the target analytes of interest and to characterize their presence.

Owner:LINAK AS +1

Production technology of high-strength 7-series aluminum alloy pipe

ActiveCN109355538AHigh strengthIncreased resistance to stress corrosion susceptibilityFurnace typesHeat treatment furnacesIngot castingMechanical property

The invention belongs to the technical field of heat treatment of aluminum alloy, and relates to a production technology of a high-strength 7-series aluminum alloy pipe. An aluminum alloy ingot casting is prepared from the following raw materials according to the mass percentage: 7.5-8.5% of Zn, 1.0-3.5% of Mg, 0.10-0.20% of Cu, 0.05-0.3% of Zr, 0.1-1.5% of Mn, 0.05-0.3% of Cr, 0 .05% of Ti, 0.05%of B, less than or equal to 0.05% of single impurity, less than or equal to 0.15% of impurities in total and the balance Al. The two-stage homogenizing treatment and the two-stage aging heat treatment are adopted in the production technology of the aluminum alloy pipe, wherein according to the two-stage homogenizing system, the heat preservation is carried out for 24 hours at the temperature of 470 DEG C, and the heat preservation is carried out for 10 hours at the temperature of 480 DEG C; and according to the two-stage aging system, the heat preservation is carried out for 7 hours at the temperature of 110 DEG C to 130 DEG C, and the heat preservation is carried out for 10 hours at the temperature of 165 DEG C to 170 DEG C. The overall mechanical property of the high-strength 7-series aluminum alloy pipe is effectively improved.

Owner:CHINA ZHONGWANG

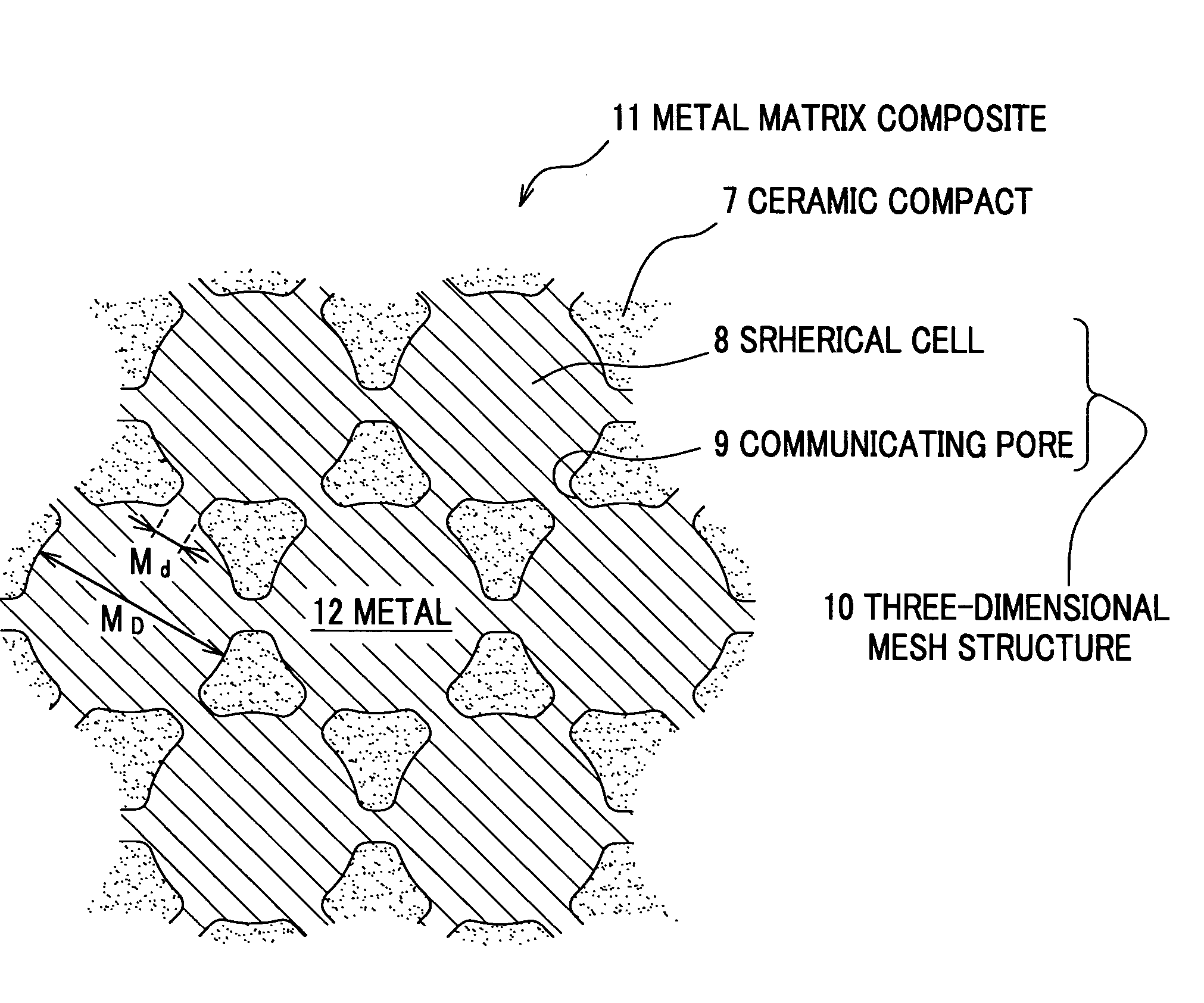

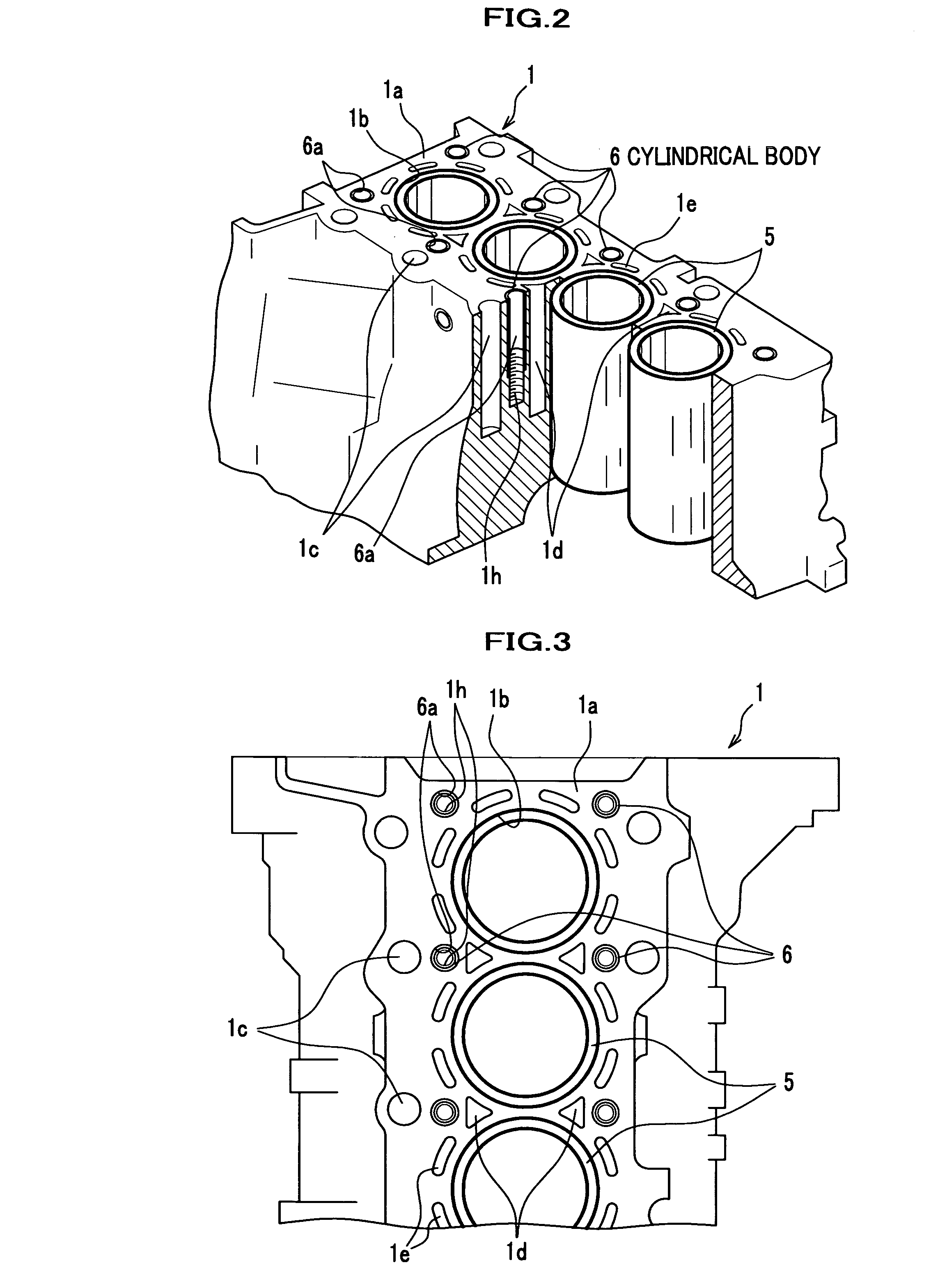

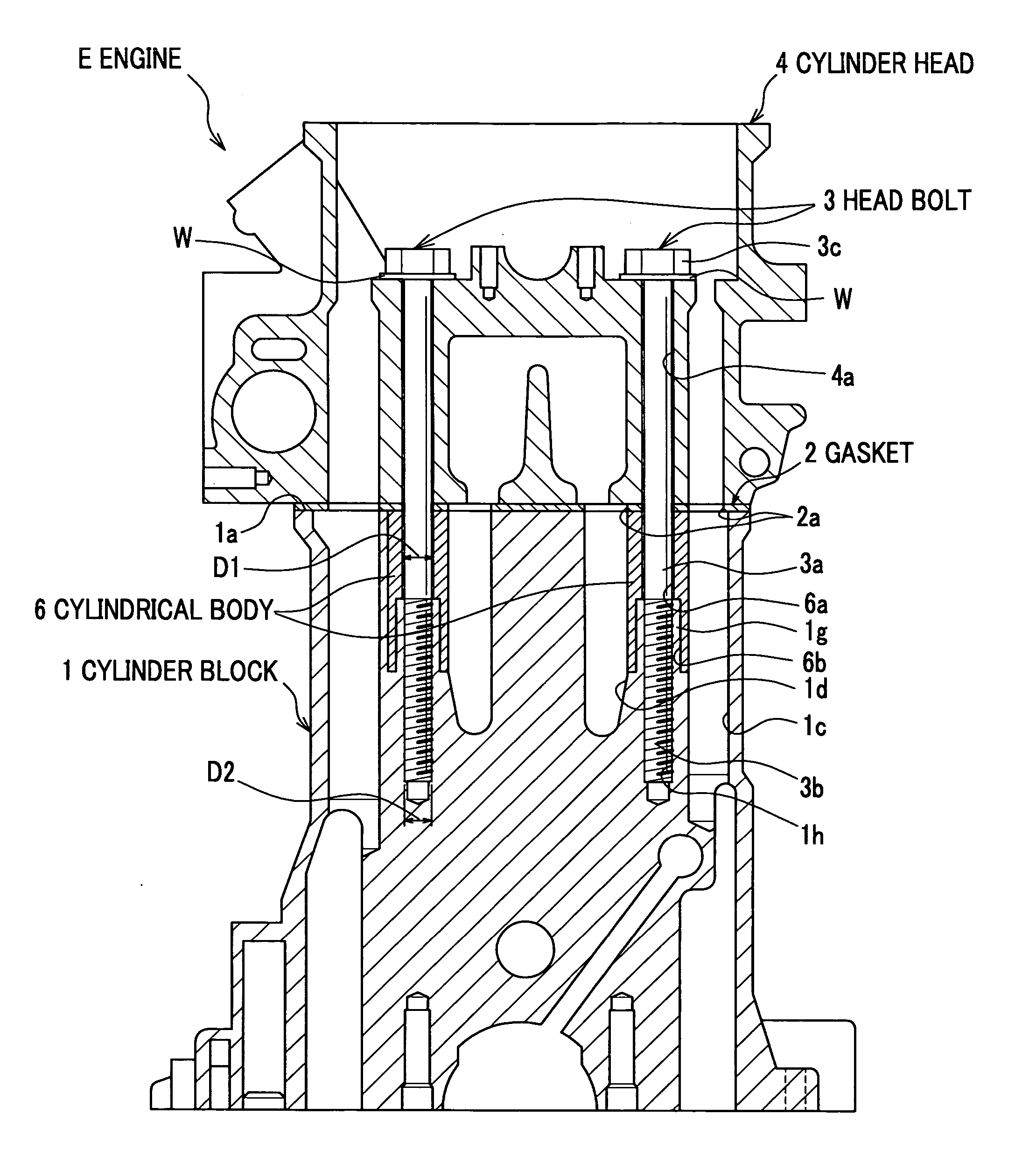

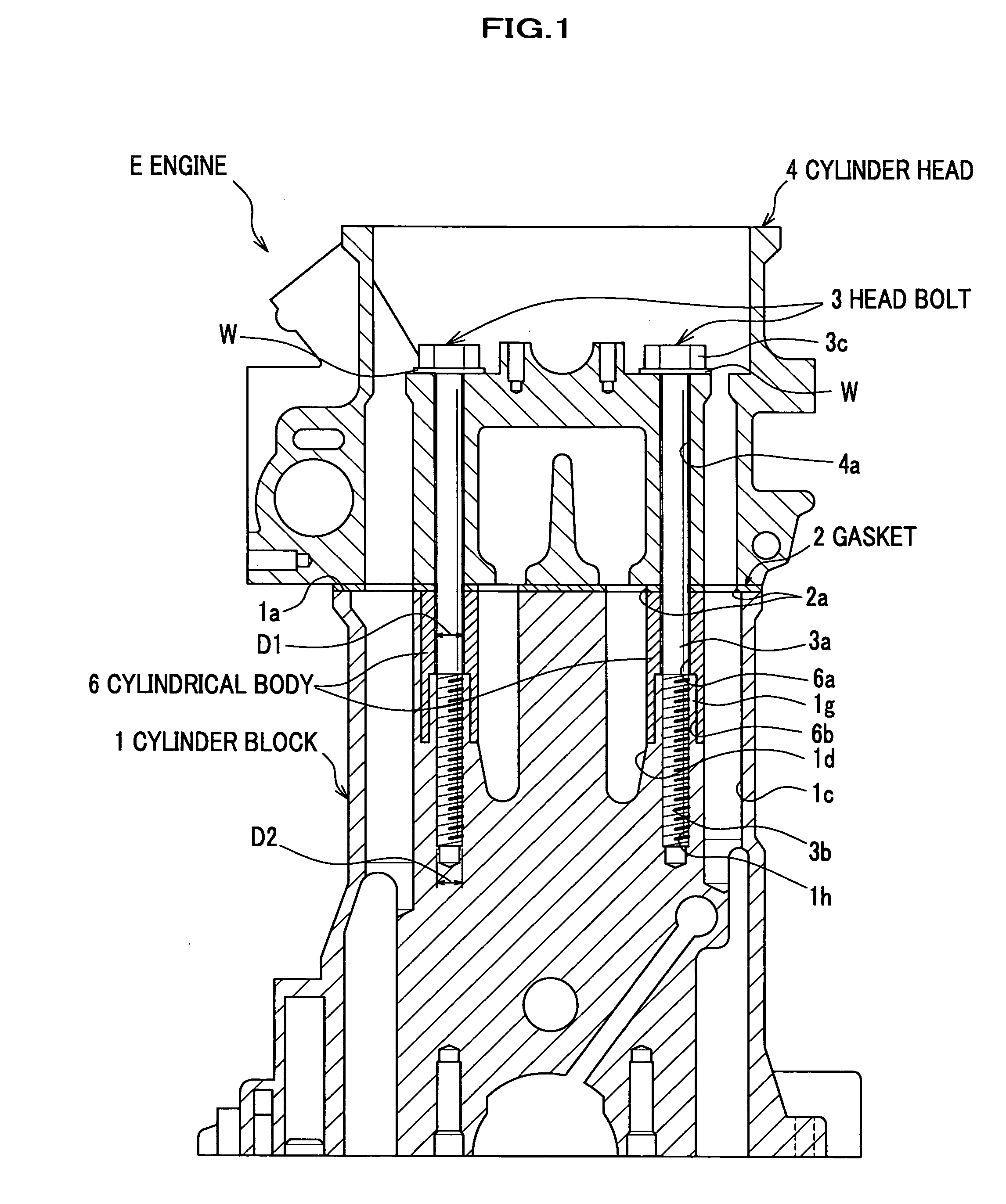

Cylinder block

InactiveUS7073476B2Increase volumeReduce volume fractionCasingsCylinder headsCylinder blockMetal matrix composite

In a cylinder block, at least one member disposed around a bore is made of a metal matrix composite including a ceramic compact having a three-dimensional mesh structure comprised of a plurality of spherical cells and a plurality of communicating pores for allowing adjacent spherical cells to communicate with each other, with the plurality of spherical cells filled with a metal.

Owner:HONDA MOTOR CO LTD

Eliminating method for brittle phase in laser-repaired nickel-base high temperature alloy

ActiveCN109182935AImprove mechanical propertiesInhibit deteriorationMetallic material coating processesSolution treatmentMechanical property

The invention provides an eliminating method for a brittle phase in a laser-repaired nickel-base high temperature alloy, and belongs to the technical field of metal material heat treatment. The eliminating method comprises the steps that the laser-repaired nickel-base high temperature alloy is sequentially subjected to delta aging treatment and delta solution treatment, wherein the temperature ofdelta aging treatment is 850-970 DEG C, and the temperature of delta solution treatment is 1015-1035 DEG C. In the method, delta aging treatment is carried out on the laser-repaired nickel-base high temperature alloy at first, and the Laves brittle phase is eliminated; and then delta solution treatment is carried out at the temperature of 1015-1035 DEG C for eliminating the delta phase separated out in the previous step. Since the temperature of delta solution treatment is lower than the solution temperature for eliminating the Laves phase in conventional heat treatment, damage caused by hightemperature solution on the alloy structure and the mechanical property can be avoided, and the mechanical property of the nickel-base high temperature alloy is obviously improved along with eliminating of the Laves phase.

Owner:NANCHANG HANGKONG UNIVERSITY

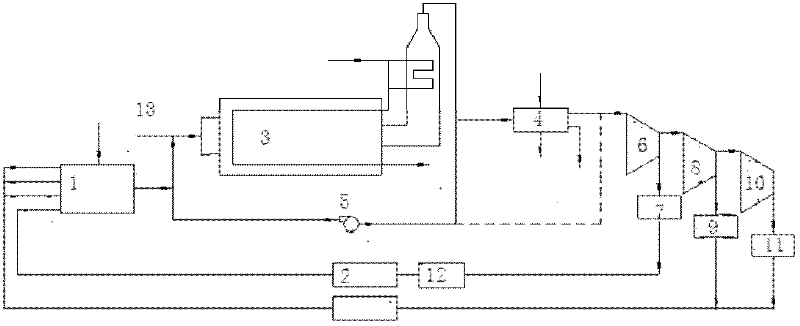

Oxygen-enriched combustion poly-generation process and equipment for steam injection boiler in oil field

InactiveCN102431974AFix storage issuesRealize integrated collaborative removalNitrogen compoundsSulfur compoundsAtmospheric airFuel oil

The invention relates to an oxygen-enriched combustion poly-generation process and equipment for a steam injection boiler in an oil field. According to the invention, air is subjected to deep cooling air separation so as to obtain nitrogen and pure oxygen; the pure oxygen is introduced into a steam injection boiler in an oil field and is mixed and burned with fuel oil so as to obtain CO2-rich flue gas; a part of the CO2-rich flue gas is used as circulation gas and is mixed with the pure oxygen, and mixed gas enters into the steam injection boiler; the rest part of the CO2-rich flue gas is compressed and condensed by using a CO2 liquefaction system so as to obtain high purity CO2, and the high purity CO2 is delivered to an oil displacement system of the oil field; flue gas which has undergone condensation and removal of CO2 enters into a SO2 and NOx recovery system so as to realize condensation and recovery of SO2 and NOx. According to the invention, the technology of oxygen-enriched combustion is introduced into the steam injection boiler, which enables the problem of storage of CO2 to be overcome and allows recovery and treatment of residual flue gas to be realized by using a simple method, thereby realizing integrated simultaneous removal of pollutants and protecting atmospheric environment; since a plurality of byproducts are obtained, considerable economic benefits can be achieved.

Owner:SHANDONG UNIV

Method for producing foamed aluminum products by use of selected carbonate decomposition products

InactiveUS20060243094A1Uniform structureShorten the timeThin material handlingDecompositionReactive gas

A method for producing an aluminum foam product wherein reactive gas producing particles are introduced into an aluminum alloy melt under controlled conditions and subjected to agitation to induce the production of foam-stabilizing by-products, and, under certain conditions, the production of gases used to produce the molten metal foam itself. Foam products produced through this method have intrinsically formed metal oxides and other solid particles dispersed therein and are devoid of the large extrinsically added stabilizing ceramic additions traditionally used in the production of aluminum foams. The invention claims a rapid, single step method for producing an inoculated, foamable melt using low cost precursor materials.

Owner:ARCONIC INC

Self-lubricating aluminum-based composite material and method for preparing same

InactiveCN101328553AControl volume fractionReduce volume fractionFrictional coefficientBoron nitride

The invention provides a self lubrication aluminum based composite material and a preparation method thereof, relating to an aluminum based composite material and a preparation method thereof. The invention solves the problems of high requirement on equipment, high cost, poor material performance and difficult second shaping and mechanical processing of materials in the synthesis of the prior self lubrication aluminum based composite material. The self lubrication aluminum based composite material is prepared from titanium diboride reinforced particles, aluminum particles or aluminum alloy particles, boron nitride particles and matrix aluminum alloy. The preparation method comprises the following steps: 1. raw materials are weighted according to the volume ratio; 2. the materials except for aluminum alloy are subjected to mixing and preliminary shaping to obtain the prefabricated part, and the prefabricated part is put in a mould and heated; 3. the aluminum alloy is heated until the aluminum alloy is melted; 4. the melted aluminum alloy is cast in the mould for pressure infiltration; and 5. the composite material of the invention is obtained after cooling and demoulding. The self lubrication aluminum based composite material of the invention has the advantages of good strength and elastic modulus, low frictional coefficient, high corrosion resistance, good plasticity and the realization of thermo forming. The preparation method of the invention has the advantages of simple method, easy operation and easy process control.

Owner:HARBIN INST OF TECH

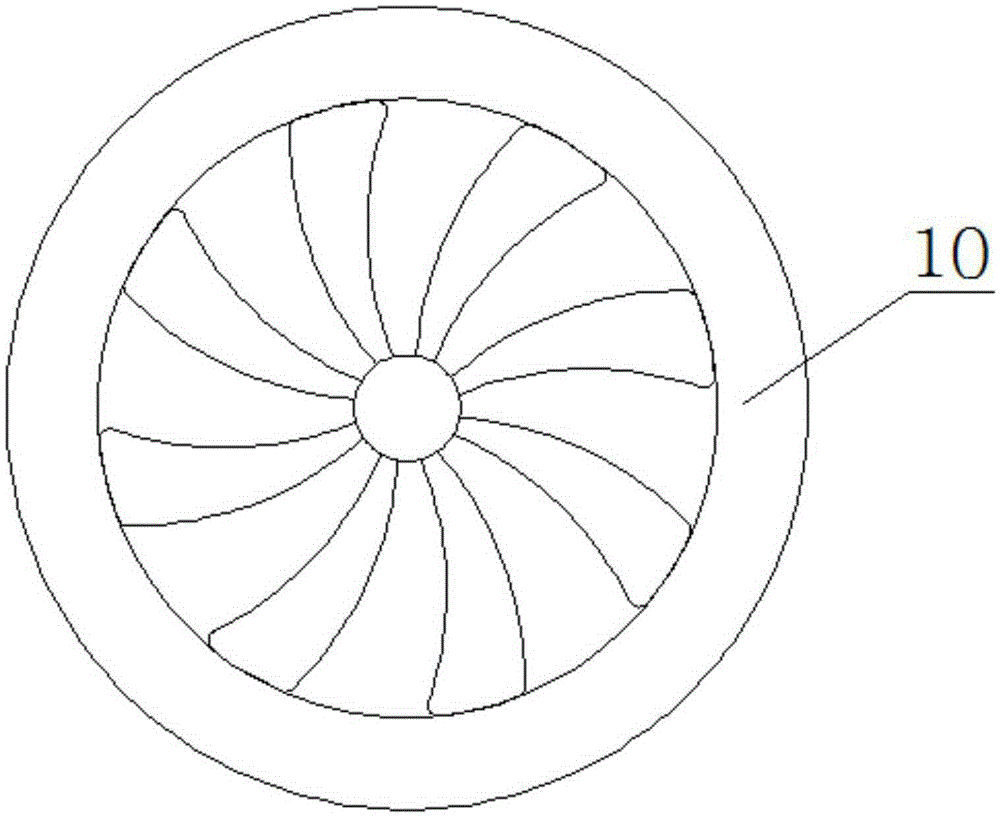

Rotational flow plate type SCR denitration tower and denitration method thereof

ActiveCN105289300AExtended stayThe catalytic reduction reaction is fullyDispersed particle separationFlue gasEscape rate

The invention discloses a rotational flow plate type SCR denitration tower and a denitration method thereof. The denitration tower comprises a denitration tower body and a corrugated plate type catalyst layer arranged along the inner circumference face of the denitration tower body, and the corrugated plate type catalyst layer forms a flue gas channel. A plurality of layers of rotational flow atomizing nozzles performing jetting in the contact circle direction are distributed on the circumference face of the corrugated plate type catalyst layer from bottom to top. When flue gas enters the flue gas channel from the bottom of the denitration tower body, and the flue gas encounters ammonia gas jetted by the whirlwind atomizing nozzles, the flue gas and the ammonia gas are mixed in an entrainment mode and spirally raises in the inner circumference direction of the flue gas channel in a contact circle mode because the ammonia gas is jetted in a rotational flow mode in the contact circle direction. On the premise that efficient denitration is guaranteed, the catalyst use amount of the denitration tower is small, the technical means is easy and convenient to use. Compared with the prior art, the denitration tower is simple in structure, low in manufacturing cost, high in denitration efficiency and low in energy consumption, reduces the ammonia escape rate, makes denitration cost greatly reduced, and remarkably improves economic benefits.

Owner:SOUTH CHINA UNIV OF TECH

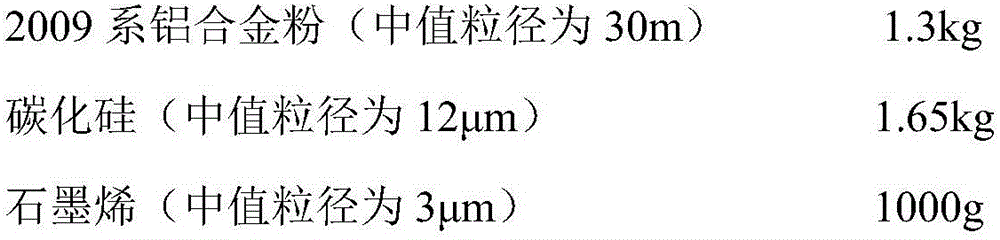

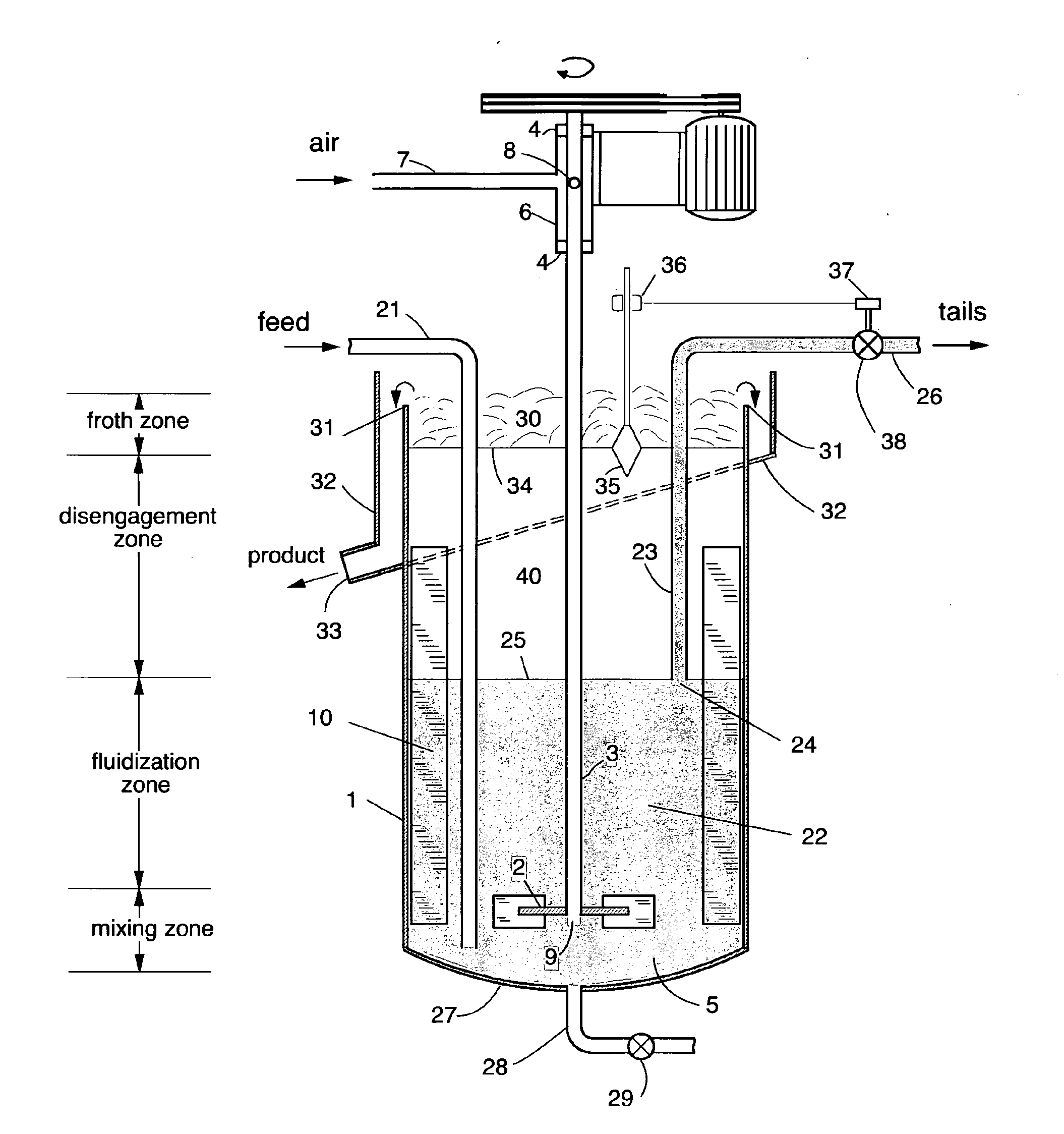

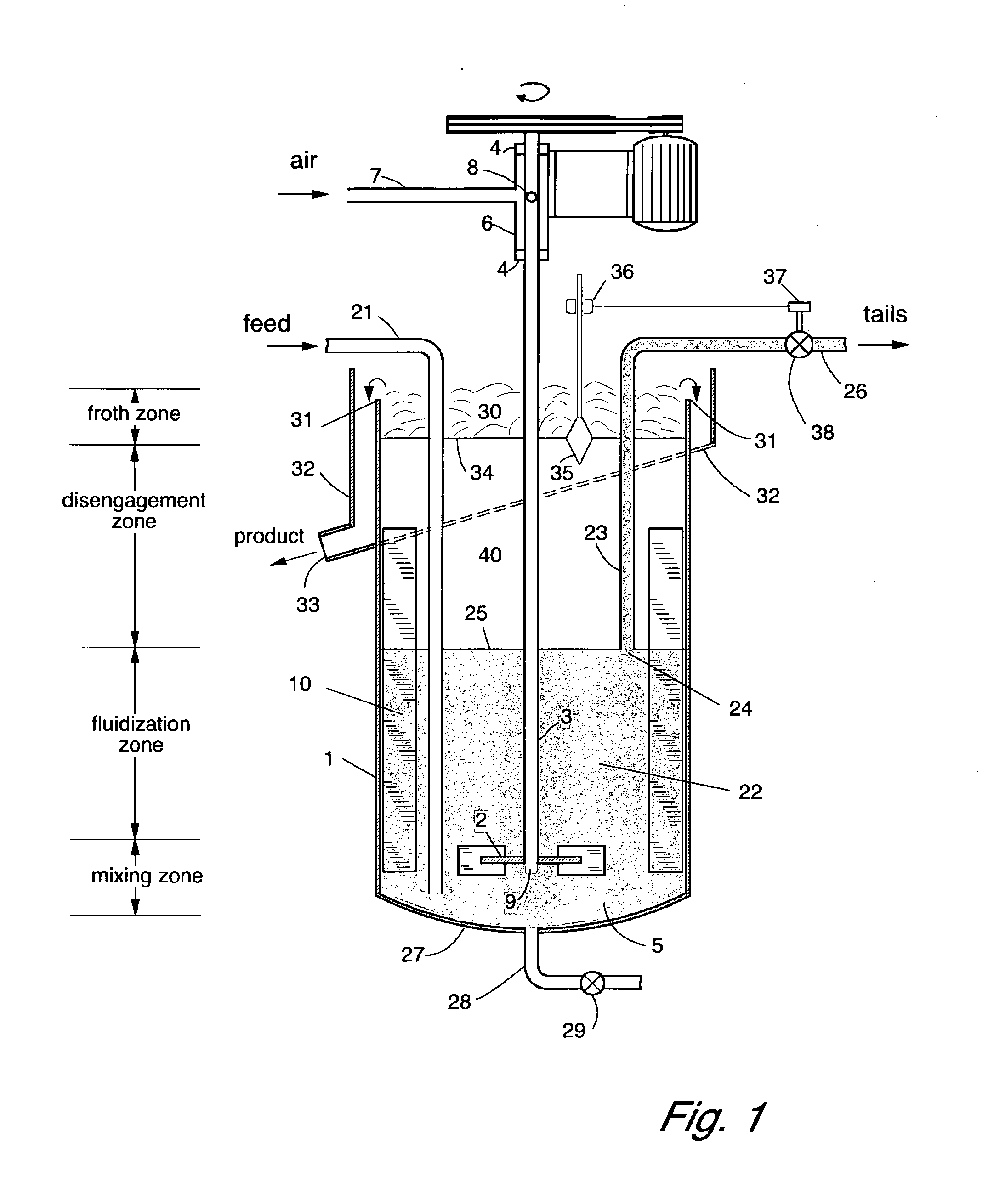

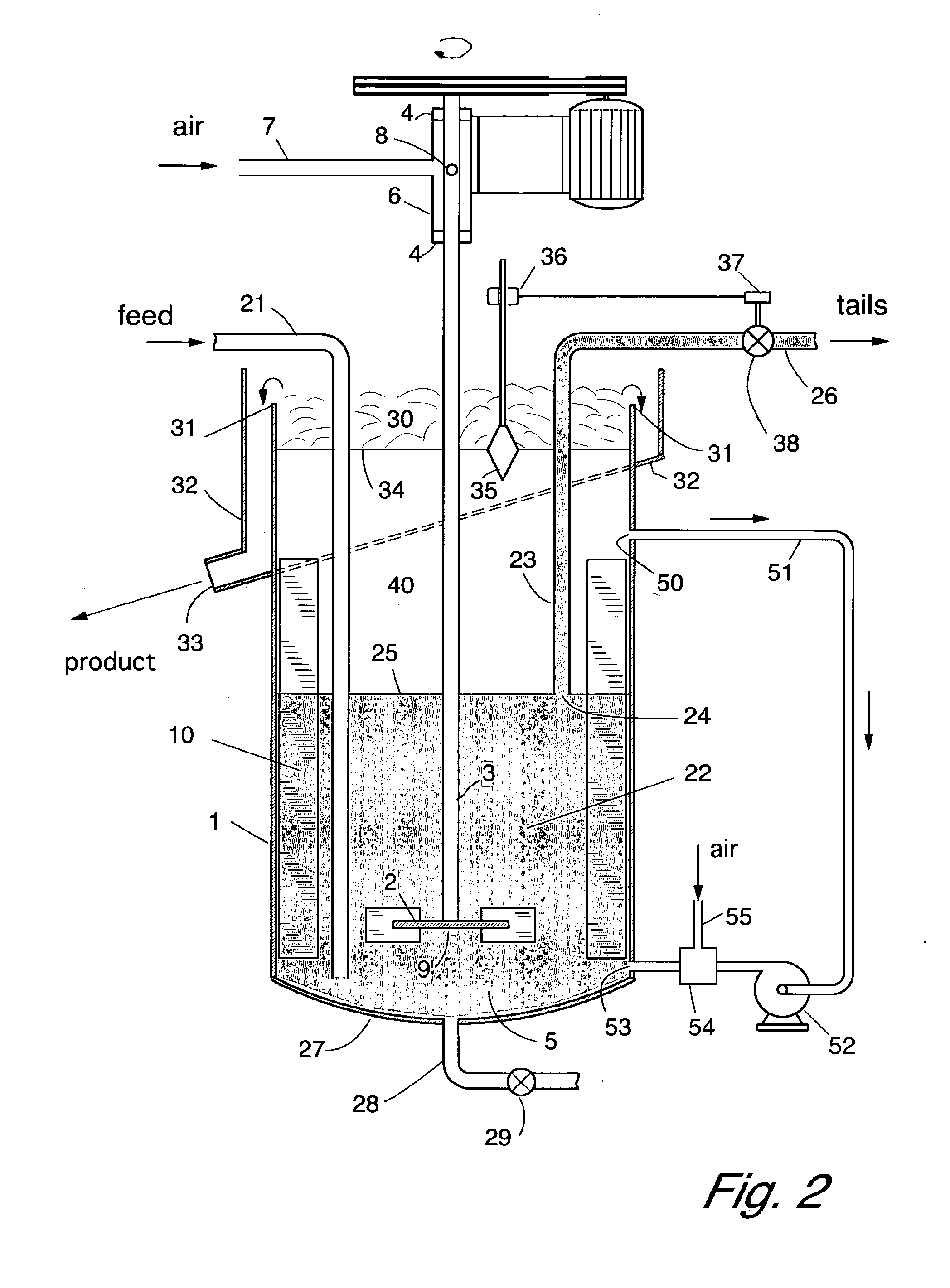

Improved method and apparatus for froth flotation in a vessel with agitation

InactiveUS20120061298A1Reduce volume fractionReduce hydraulic resistanceEvaporators with heating coilsFlotationImpellerFluidized bed

A method of separating mixed particles in a flotation cell uses a fluidized bed within the cell where particles are fluidized in a quiescent zone by liquid moving upwardly through the fluidized bed. The fluidizing liquid may be provided by the feed or by recycling liquid from upper parts of the cell such as from the disengagement zone. Bubbles are introduced into the lower part of the cell through a mechanical impeller which also breaks up any channels in the mixing zone, or by separate aeration in the bottom of the cell or by introduction through a recycle pipe.

Owner:NEWCASTE INNOVATION LTD

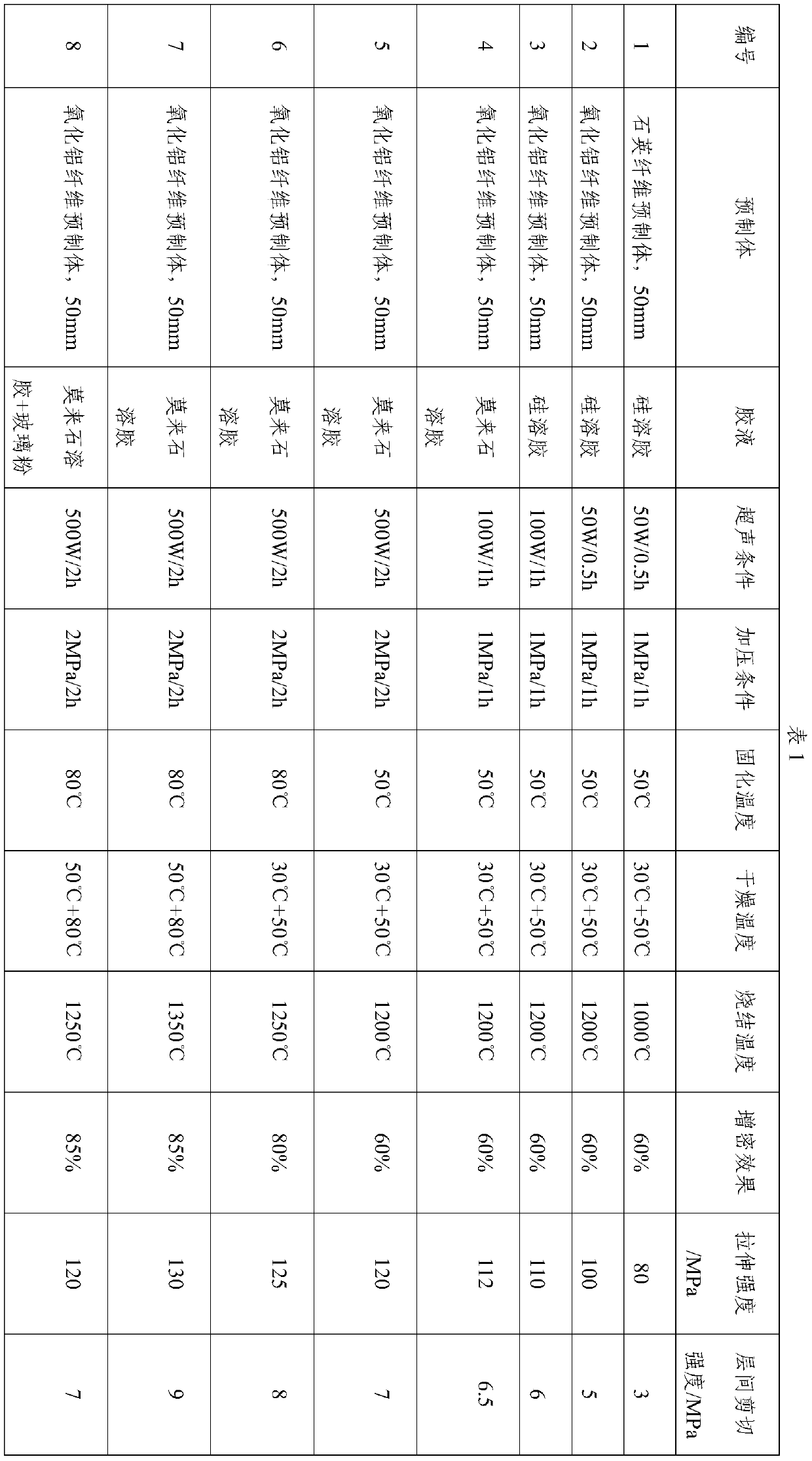

Fiber-reinforced ceramic matrix composite material, preparation method and application thereof

The invention relates to a fiber-reinforced ceramic matrix composite material, a preparation method and application thereof. The preparation method includes: (1) a step of preparation of a glue solution for impregnating a fiber preform; (2) a step of vacuum impregnation; (3) a step of curing; (4) a step of drying and sintering, and (5) a step of densification. Between the step (2) and the step (3), the method also includes the steps of: (i) carrying out ultrasonic vibration on a system containing the fiber preform and the glue solution for impregnation at the end of vacuum impregnation; and (ii) introducing compressed gas into the environment where the system is located at the end of ultrasonic vibration for pressurization, making the pressure of the environment where the system is locatedreach 1-4MPa, and keeping the maintaining time at 1-24h. The preparation method provided by the invention can prepare the fiber-reinforced ceramic matrix composite material which has thickness of 50mm or more and still has high density, excellent tensile strength and interlaminar shear strength.

Owner:AEROSPACE INST OF ADVANCED MATERIALS & PROCESSING TECH

Synchronous laser heat treatment method for laser additive manufacturing nickel-based high-temperature alloy

ActiveCN110315075AImprove coordination and deformation abilityFine and uniform grainAdditive manufacturing apparatusIncreasing energy efficiencyMechanical propertyHeat treated

The invention discloses a synchronous laser heat treatment method for laser additive manufacturing a nickel-based high-temperature alloy. According to the method, morphology size and distribution of Laves phase can be effectively regulated and controlled, the Laves phase is converted into a discrete granular shape from a deposited continuous long strip, and the volume fraction of the Laves phase is obviously reduced along with extension of the laser heat treatment time. According to the laser heat treatment method, synchronous heat treatment in a deposition forming process can be realized, local area Laves phase morphology and distribution can be regulated and controlled under the condition that the tissue performance of a laser repair base material area is not influenced, the granular Laves phase which are fined and dispersion distributed is obtained, so that the overall mechanical property of parts is improved, and effective utilization can be obtained in the repair and remanufacturing of the high-temperature alloy structural member; and in addition, the method can also be applied to the fields of high-temperature alloy material preparation, high-temperature alloy structural member rapid manufacturing and the like.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Carbon nano tube reinforced aluminum alloy composite material prepared through squeeze casting method

The invention discloses a carbon nano tube reinforced aluminum alloy composite material prepared through squeeze casting method, which relates to a preparation method of carbon nano tube reinforced metal composite material. The invention solves the problem that the distribution of the carbon nano tube in the carbon nano tube reinforced aluminum alloy composite material obtained through the existing preparation method is not even, and the interfacial associativity of the carbon nano tube and the metal base body is poor. The method is as follows: 1, the mixed solution is prepared; 2, the mixed solution is processed in ultrasonic way; 3, the step 2 is repeated; 4, the dried precast block is prepared; 5, the sintered precast block is prepared; 6, melting aluminum alloy is infiltrated to holes of the sintered precast block under the pressure role, and is solidified under the pressure role to obtain the carbon nano tube reinforced aluminum alloy composite material. The carbon nano tubes in the carbon nano tube reinforced aluminum alloy composite material obtained in the invention are evenly distributed, and the interfacial associativity is good.

Owner:HARBIN INST OF TECH

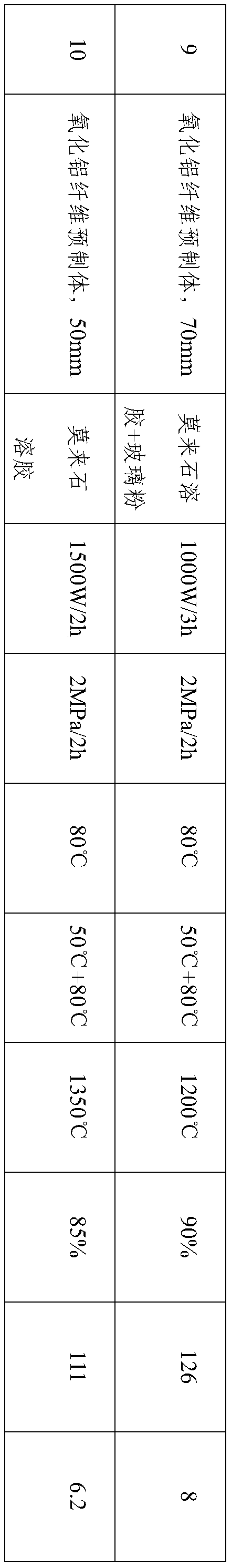

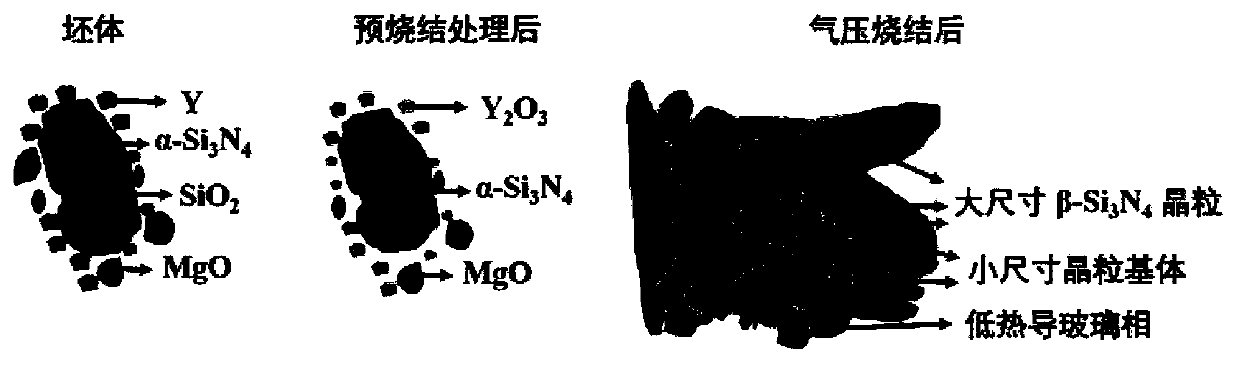

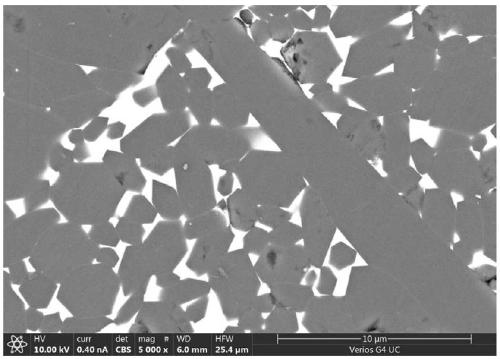

High-strength, high-toughness and high-thermal-conductivity silicon nitride ceramic material and preparation method thereof

The invention relates to a high-strength, high-toughness and high-thermal-conductivity silicon nitride ceramic material and a preparation method thereof. The silicon nitride ceramic material is prepared from the following raw materials: alpha-Si3N4 and a sintering aid, wherein the sintering aid is a rare earth metal simple substance and an alkaline earth metal oxide, and the total content of the sintering aid is 2-12wt%; the rare earth metal simple substance is Y; and the alkaline earth metal oxide is preferably at least one of MgO, CaO and BaO.

Owner:江西中科上宇科技有限公司

Purifying method for recombinant humanized anti-human tumor necrosis factor monoclonal antibody

InactiveCN104098697AReduce volume fractionHigh purityImmunoglobulins against cytokines/lymphokines/interferonsMicroorganism based processesProtein AHamster

The invention relates to the technical field of biological pharmacy, and especially relates to a purifying method for a recombinant humanized anti-human tumor necrosis factor monoclonal antibody. The method comprises: sampling a to-be purified recombinant humanized anti-human tumor necrosis factor monoclonal antibody sample to a balanced cation exchange chromatographic column, and performing washing, leaching, rebalancing and elution, so as to obtain a purified recombinant humanized anti-human tumor necrosis factor monoclonal antibody solution. A preparation method for the to-be purified recombinant humanized anti-human tumor necrosis factor monoclonal antibody sample comprises: getting Chinese hamster ovary cells integrated with humanized anti-human tumor necrosis factor monoclonal antibody gene, culturing, getting a cell culturing supernatant, and employing protein A to perform affinity chromatography, so as to obtain the to-be purified recombinant humanized anti-human tumor necrosis factor monoclonal antibody sample. Leaching in the method means linear gradient elution. A buffer for rebalancing in the method is a citric acid buffer, an acetic acid buffer or a phosphoric acid buffer. Through the leaching step, the purity of the recombinant humanized anti-human tumor necrosis factor monoclonal antibody is successively improved.

Owner:SHANGHAI UNION BIOPHARM +1

Cylinder block

InactiveUS20050279315A1Improve thermal conductivityImprove rigidityCasingsCylinder headsCylinder blockMetal matrix composite

In a cylinder block, at least one member disposed around a bore is made of a metal matrix composite including a ceramic compact having a three-dimensional mesh structure comprised of a plurality of spherical cells and a plurality of communicating pores for allowing adjacent spherical cells to communicate with each other, with the plurality of spherical cells filled with a metal.

Owner:HONDA MOTOR CO LTD

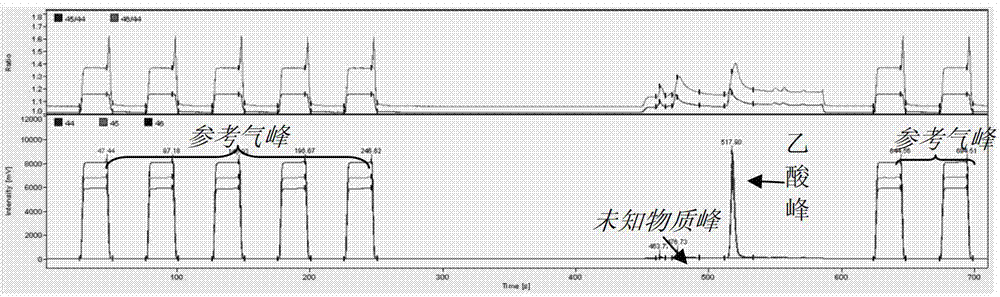

Rapid measuring method for carbon acetate stable isotope in table vinegar

ActiveCN102967669AReduce dosagePromote the advancement of assay technologyComponent separationGc c irmsGas phase

The invention relates to a rapid measuring method for carbon acetate stable isotope in table vinegar. The rapid measuring method uses a gas chromatography-combustion-isotope ratio mass spectrography (GC-C-IRMS) to measure, and comprises a step of adopting alcohol to dilute a table vinegar sample, and a step of using gas chromatograph (GC) to separate acetic acid in the diluted sample. The rapid measuring method disclosed by the invention uses GC-C-IRMS to achieve rapid measurement for carbon acetate stable isotope in table vinegar, thus solving a technical difficulty that a series of pre-treatments are needed for purifying acetic acid before measuring the carbon acetate stable isotope in the table vinegar, improving the carbon acetate stable isotope measuring technology, and providing a technical method for identifying whether cereals vinegar and fruit vinegar products are true or false.

Owner:CHINA NAT RES INST OF FOOD & FERMENTATION IND CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com