Fiber-reinforced ceramic matrix composite material, preparation method and application thereof

A fiber-reinforced, composite material technology, used in lighting and heating equipment, furnace components, furnaces, etc., to achieve the effect of simple process, excellent interlaminar shear strength, and increased density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

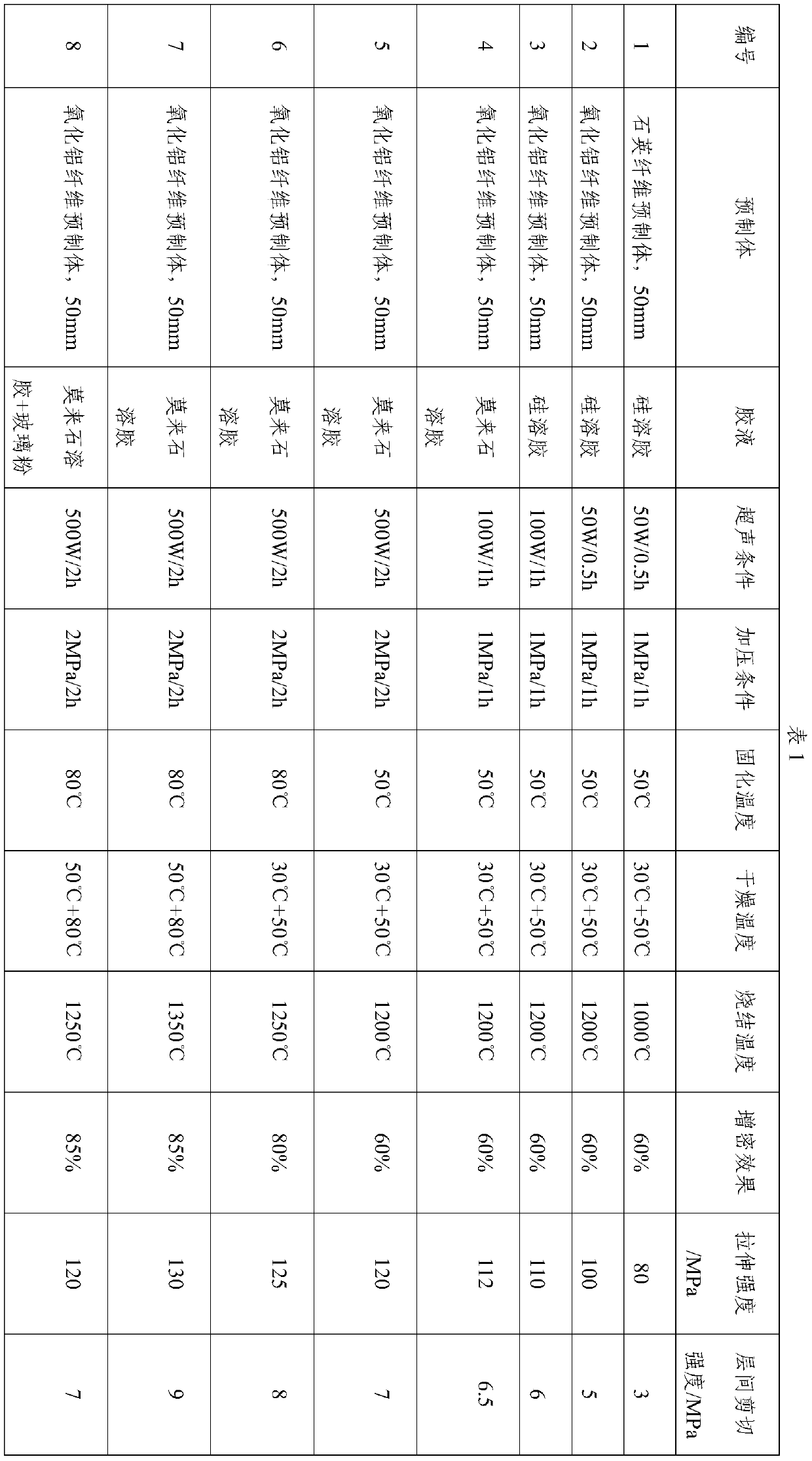

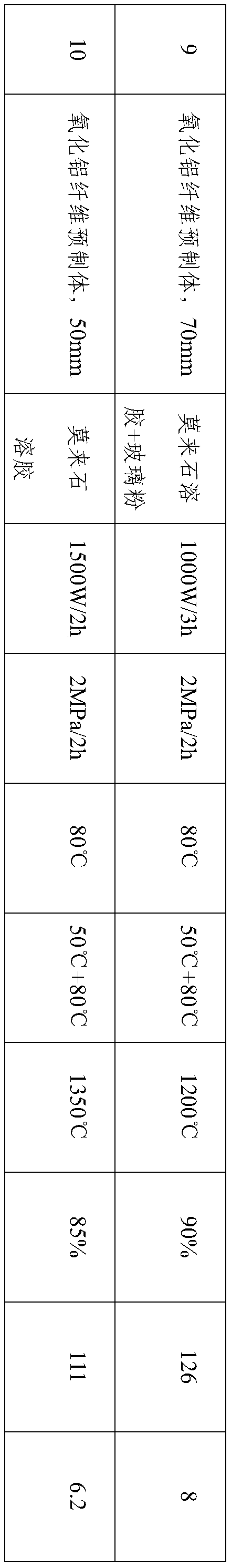

Examples

preparation example Construction

[0042] Specifically, refer to figure 1 , the preparation method of the fiber-reinforced ceramic matrix composite provided by the invention comprises the following steps:

[0043] A step of preparing a glue solution for impregnating the fiber preform;

[0044] The step of vacuum impregnating the fiber preform with the glue solution;

[0045] The step of ultrasonically vibrating the system comprising the fiber preform and the glue for impregnation after vacuum impregnation;

[0046] The step of introducing compressed gas into the environment where the system is located after the ultrasonic vibration is finished;

[0047] a step of curing the pressurized material;

[0048] performing the steps of drying and sintering the cured material in sequence;

[0049] A step of densifying the sintered material.

[0050]In addition, the present invention also optimizes the specific technical parameters in the two steps of ultrasonic vibration and pressurization. Better ultrasonic vibra...

Embodiment 1

[0085] First, a fiber preform made of quartz fiber fabric with a thickness of 50 mm is placed in an impregnation tool, and an ultrasonic device is provided in the impregnation tool for ultrasonic vibration. Vacuum the tooling by 0.1MPa, pump the silica sol into the tooling, and the slurry is submerged in the fabric to end the glue feeding. Then, start the ultrasonic device to ultrasonically vibrate the fiber prefabricated body and glue in the tooling to break and eliminate the air holes in the fabric. The ultrasonic power is 50W, the ultrasonic frequency is 20KHz, the ultrasonic energy transmission rate is 0.1w / g, and the ultrasonic time is 0.5h. Subsequently, the compressed air is introduced into the tooling so that the inside of the tooling has an air pressure of 1 MPa, and the pressing time is 1 hour. Next, the whole tooling is placed in an oven at 50° C. to initiate a gelation reaction of the slurry in the tooling, so that the slurry inside the preform is solidified and r...

Embodiment 2

[0087] First, a fiber preform made of alumina fiber fabric with a thickness of 50 mm is placed in an impregnation tool, and an ultrasonic device is installed in the impregnation tool for ultrasonic vibration. Vacuum the tooling by 0.1MPa, pump the silica sol into the tooling, and the slurry is submerged in the fabric to end the glue feeding. Then, start the ultrasonic device to ultrasonically vibrate the fiber prefabricated body and glue in the tooling to break and eliminate the air holes in the fabric. The ultrasonic power is 50W, the ultrasonic frequency is 20KHz, the ultrasonic energy transmission rate is 0.1w / g, and the ultrasonic time is 0.5h. Subsequently, the compressed air is introduced into the tooling so that the inside of the tooling has an air pressure of 1 MPa, and the pressing time is 1 hour. Next, the whole tooling is placed in an oven at 50° C. to initiate a gelation reaction of the slurry in the tooling, so that the slurry inside the preform is solidified and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com