Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

53results about How to "Add Brownian motion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

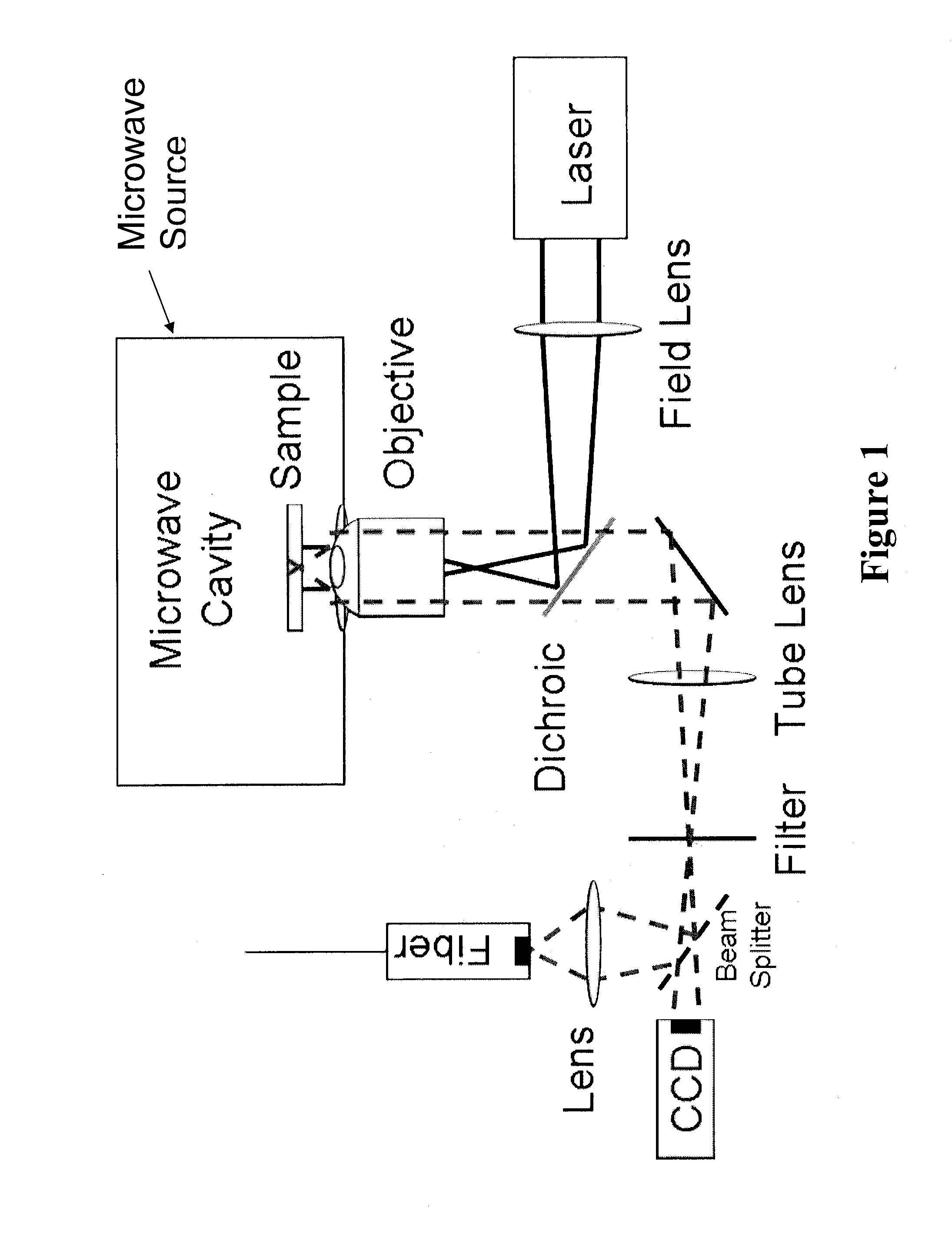

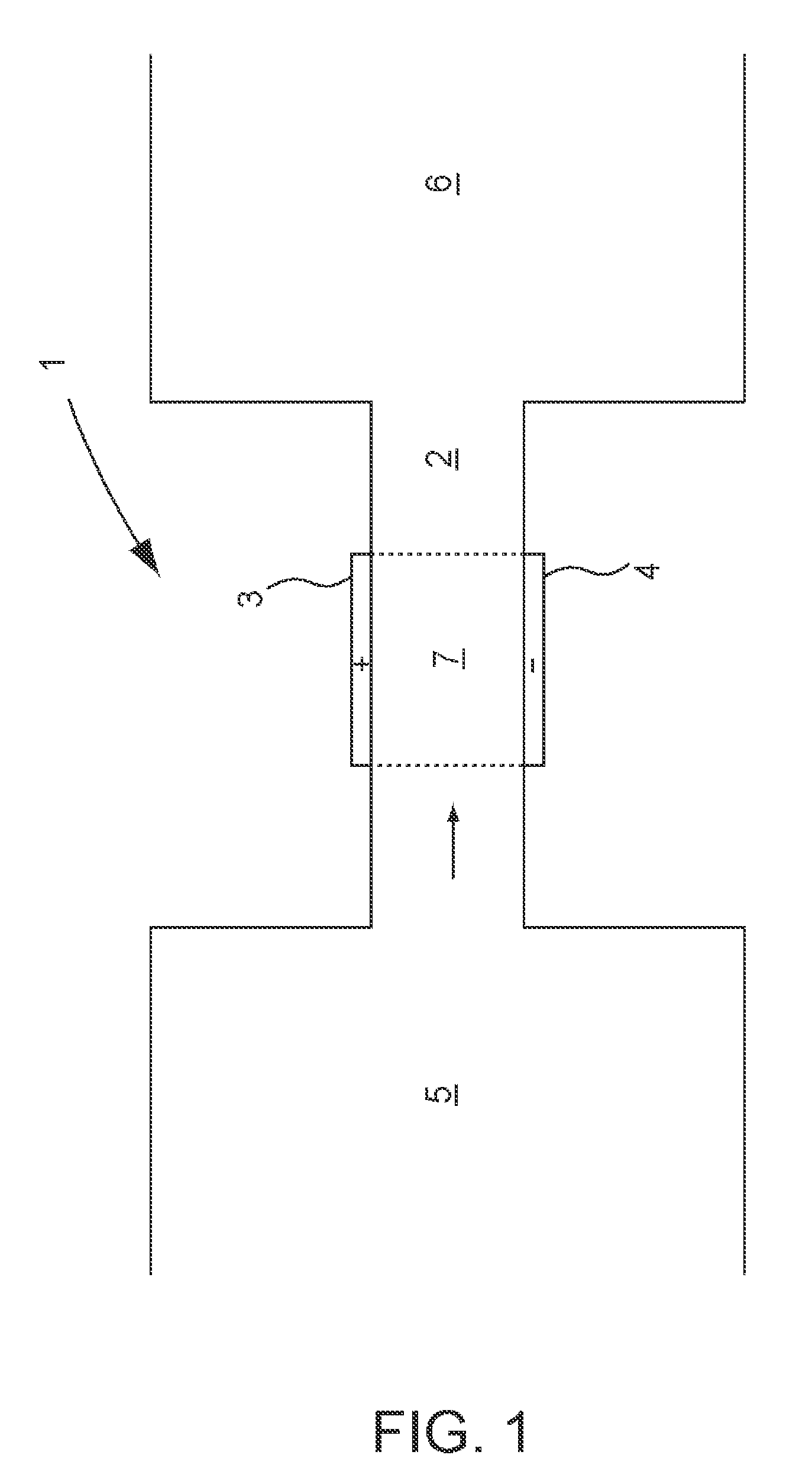

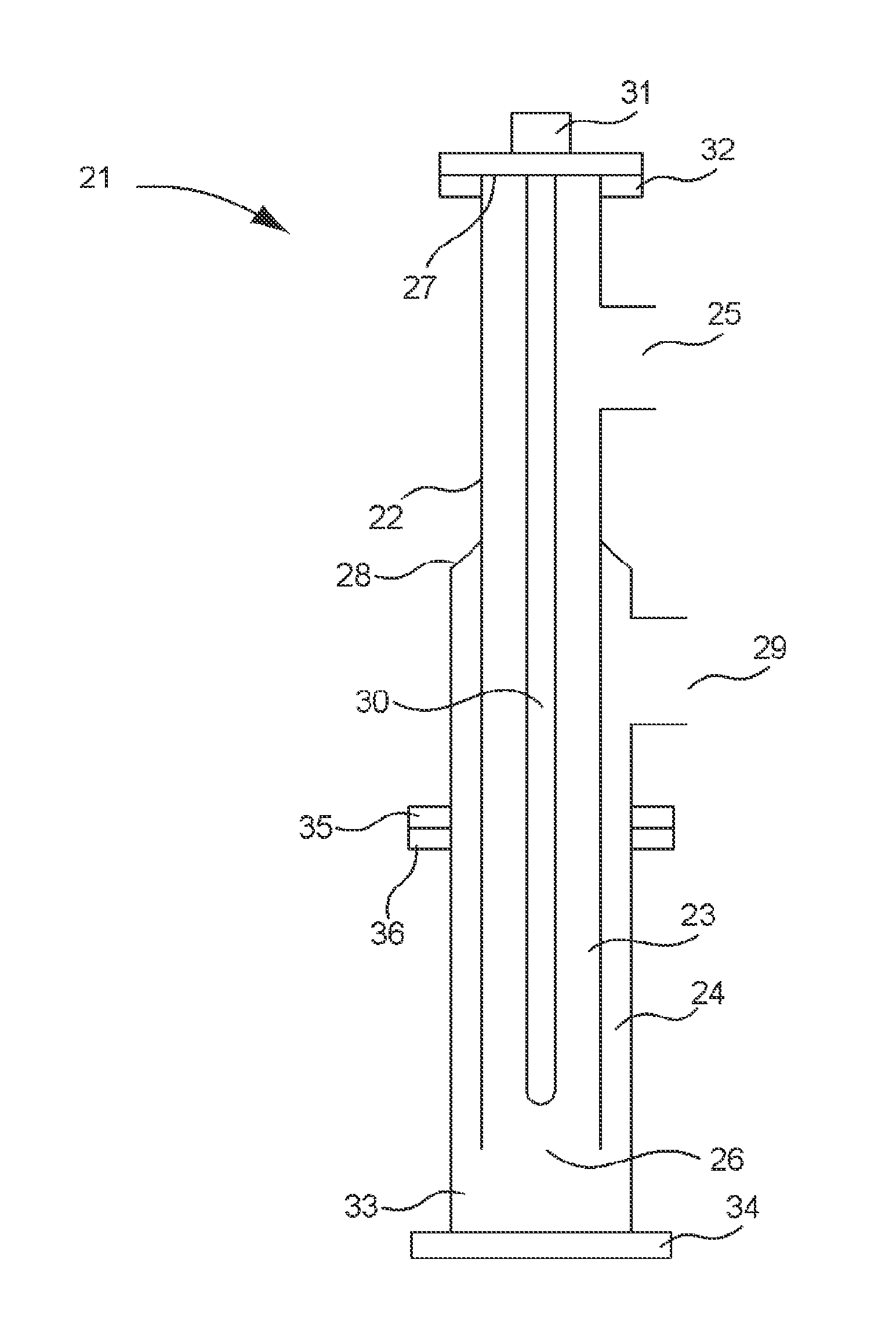

Fluorescence microscope in a microwave cavity

ActiveUS20100209937A1Prolong chemical reaction timeSolve the lack of resolutionBioreactor/fermenter combinationsBiological substance pretreatmentsMicrowave cavityChemical reaction

The present invention relates to an optical imaging system communicatively connected to a microwave energy producing source wherein the combination provides for increases in chemical reaction times and the ability to monitor the reactions in real time with sufficient resolution to view the location of intracellular components labeled with luminescent molecules as well as interaction with other biomolecules and responses to localized environmental variables in living cells and tissues during the application of a microwave field.

Owner:UNIV OF MARYLAND BALTIMORE COUNTY

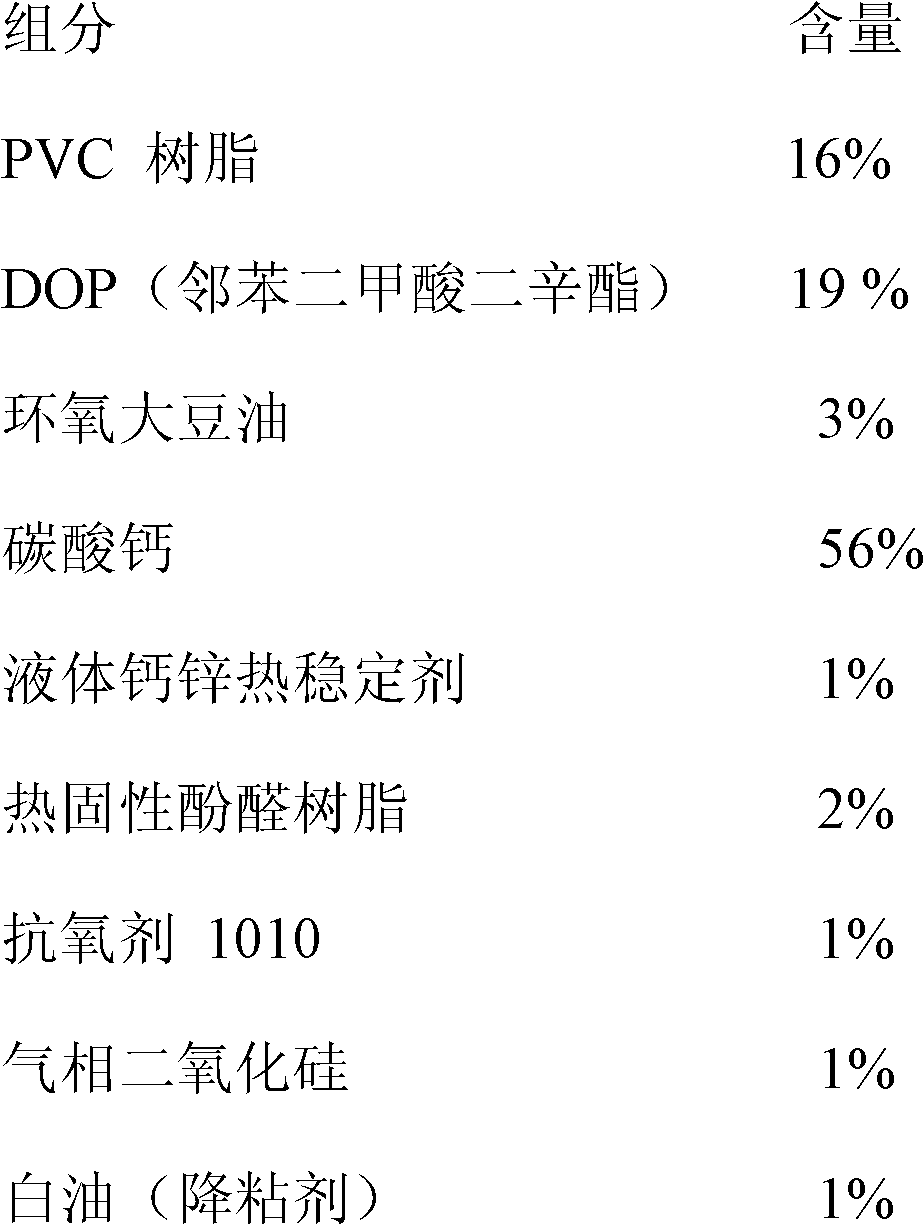

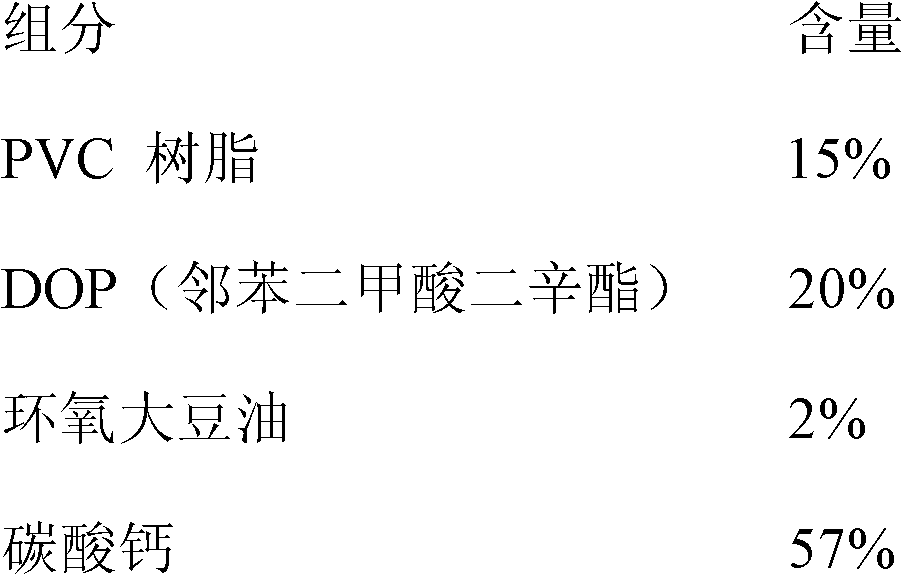

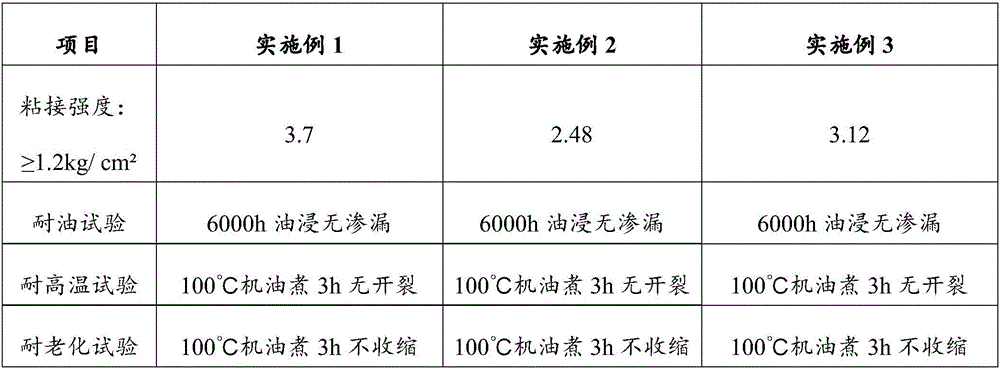

High temperature resistant adhesive for automobile filter

InactiveCN102277105AStrong heat resistanceImprove heat resistanceAldehyde/ketone condensation polymer adhesivesAdhesiveAntioxidant

The invention relates to a high-temperature resistant adhesive for a filter cleaner of an automobile. The adhesive comprises the following raw materials in percentage by weight: 13 to 16 percent of polyvinyl chloride (PVC) resin, 19 to 22 percent of dioctyl phthalate, 2 to 3 percent of epoxidized soybean oil, 55 to 60 percent of calcium carbonate, 0.2 to 1 percent of liquid calcium zinc heat stabilizer, 2 to 5 percent of thermosetting phenolic resin, 0.3 to 1 percent of antioxidant, 1 to 2 percent of thixotropic agent and 0 to 2 percent of white oil. In the high-temperature resistant adhesive, phenolic resin modified polyvinyl chloride is adopted, the thermosetting phenolic resin has high infiltration capacity, so the adhesive is diffused and infiltrated to the surface of a bonding material fully to promote Brownian movement to make polar groups or chain knots on two interfaces get close to each other; and when the distance between the adhesive and adherend molecules is between 5 and 10 angstroms, mutually-attractive force is formed among interface molecules, and the distance among the molecules is further shortened to the maximum stable state, so the adhesive force of the adhesive can be enhanced; and the phenolic resin has the characteristics of high heat resistance, flame retardance and the like, so that the high-temperature resistant performance of the adhesive and filter cleaner products is enhanced.

Owner:佛山市豹王滤芯制造有限公司

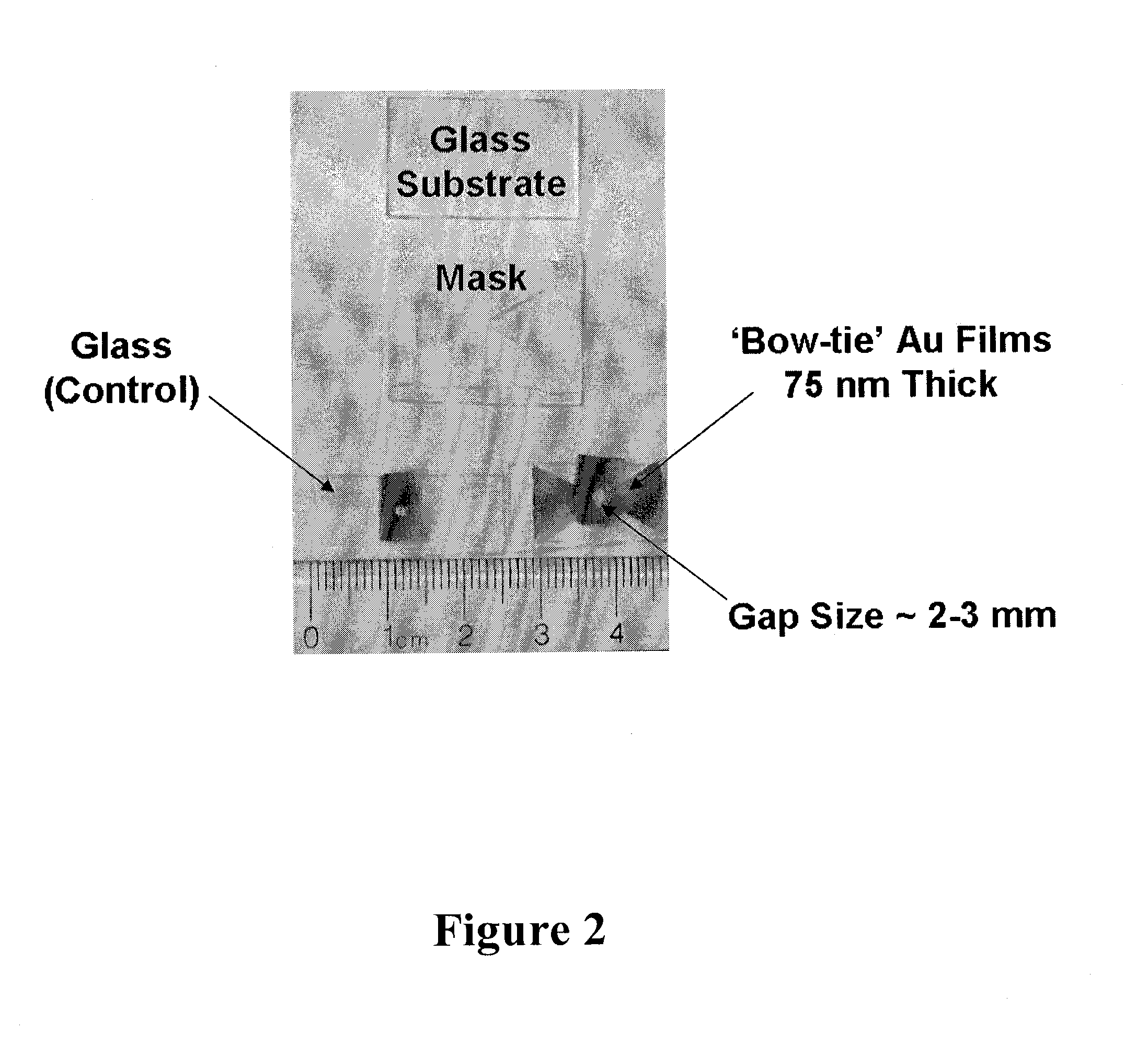

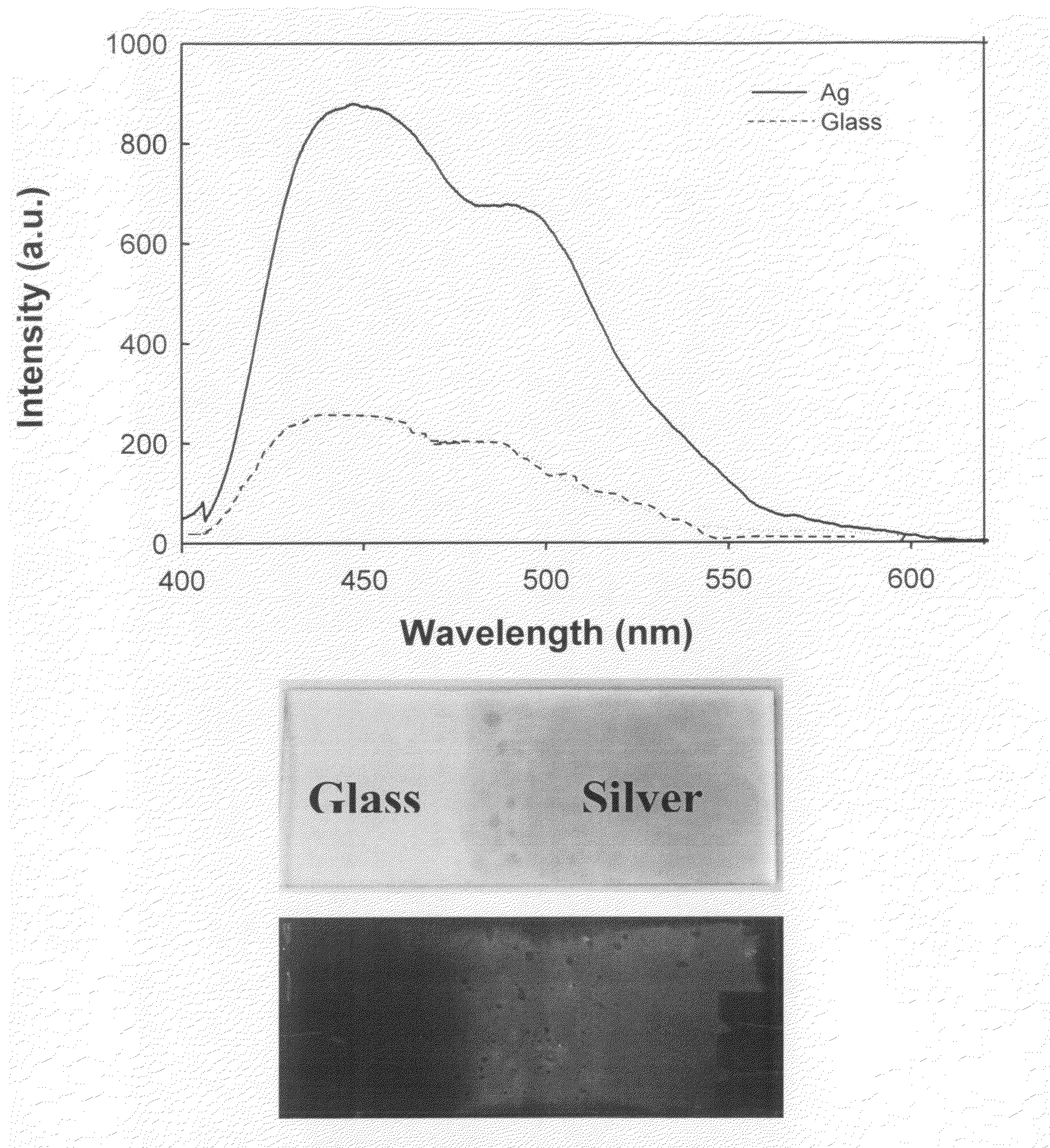

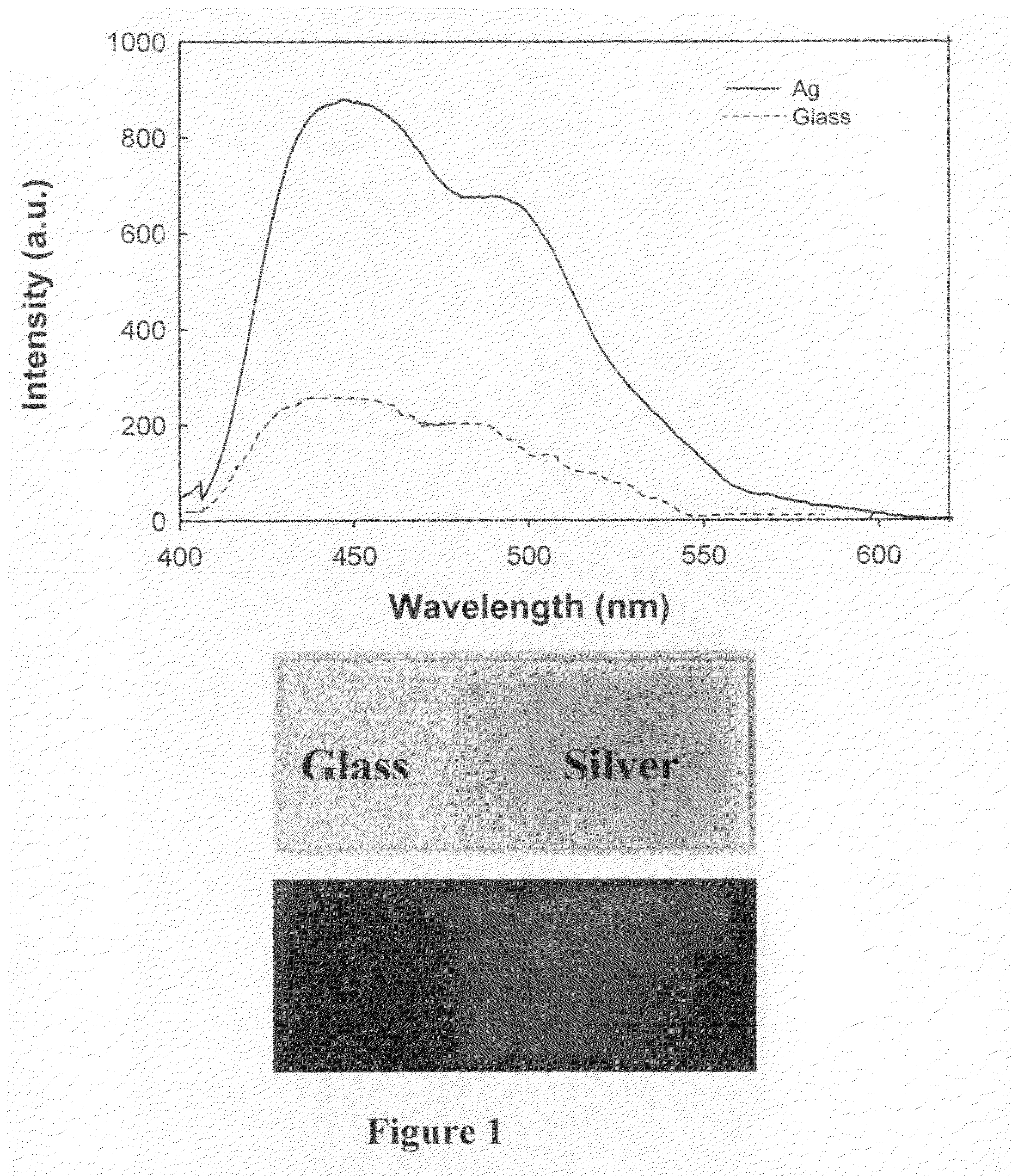

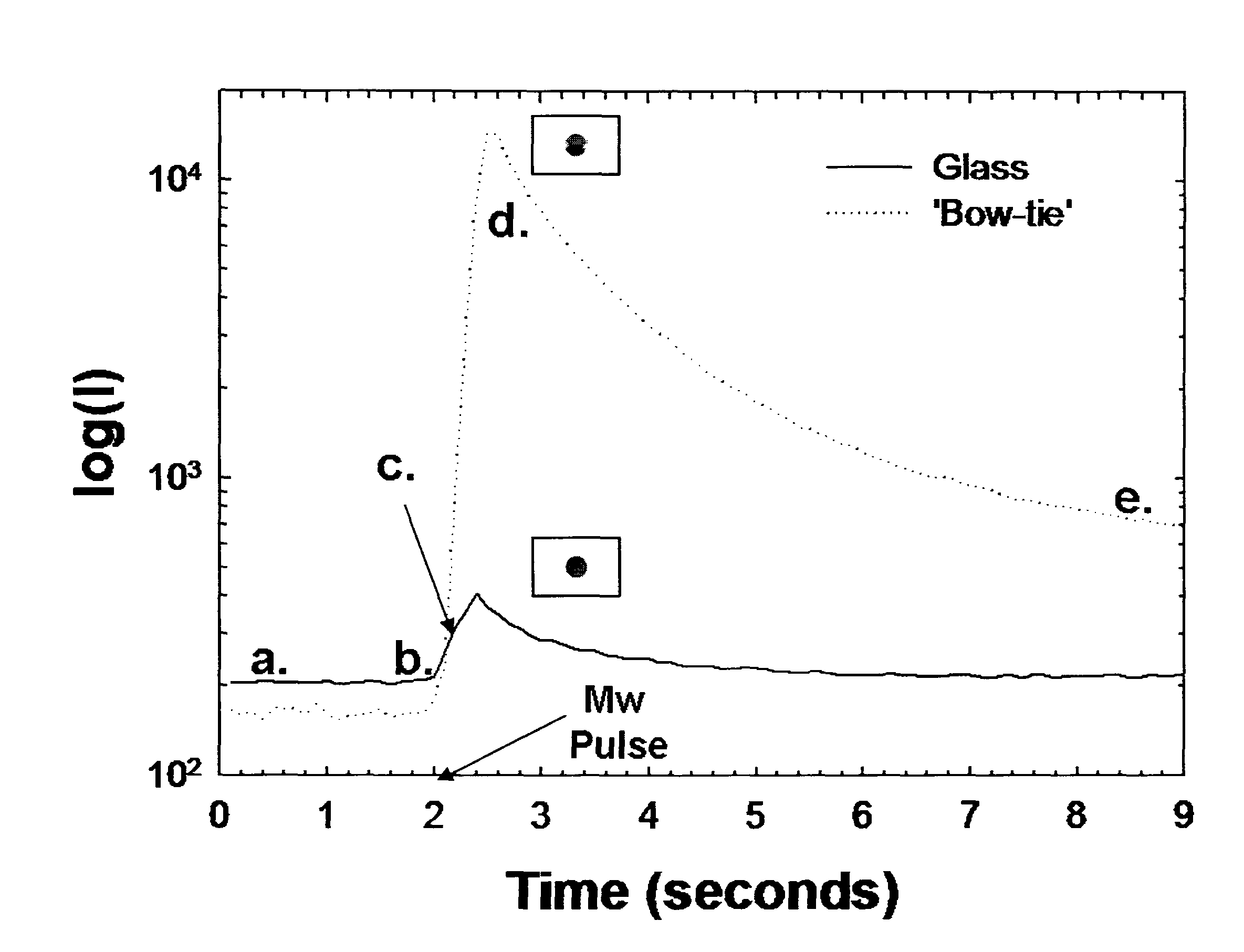

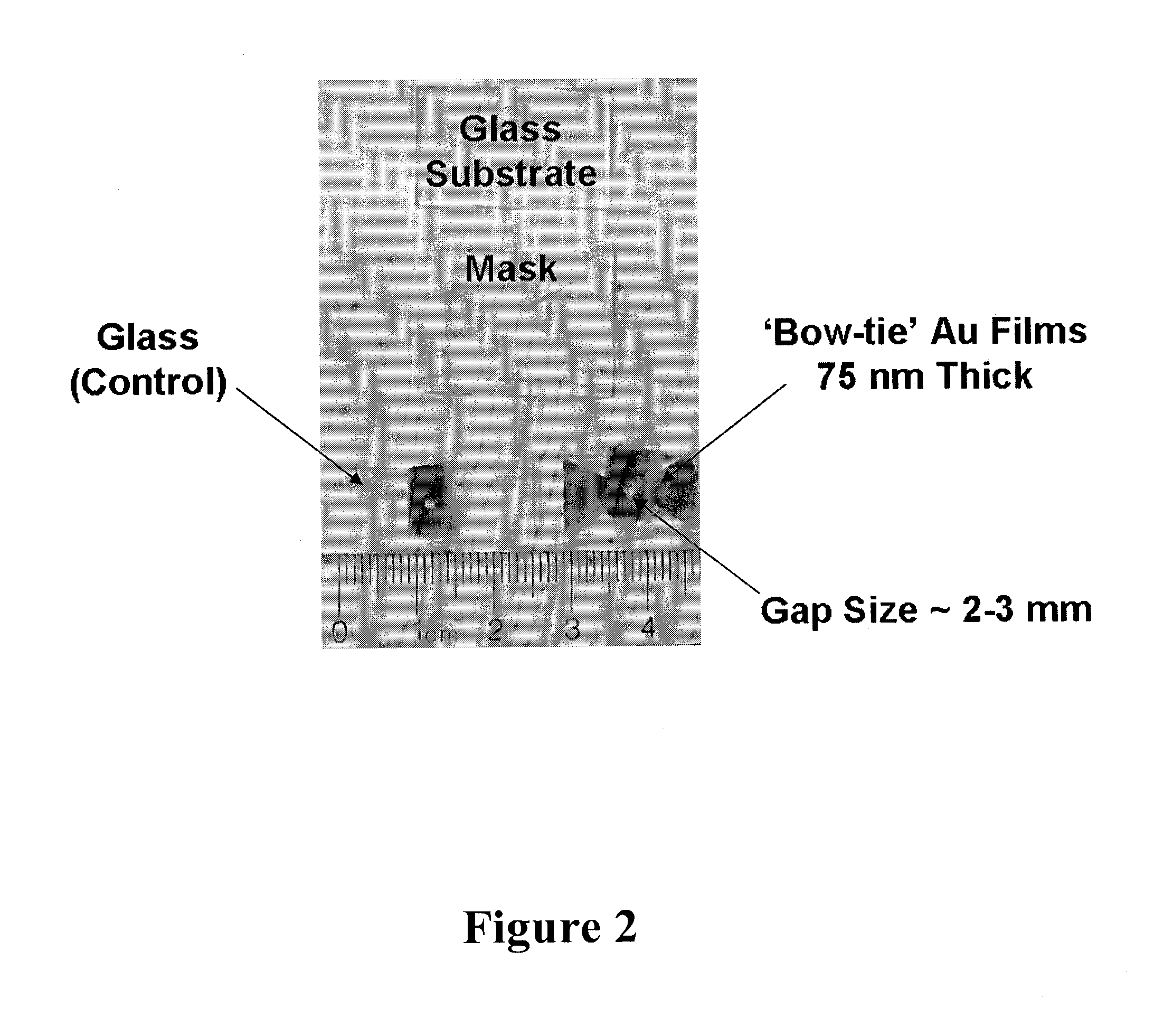

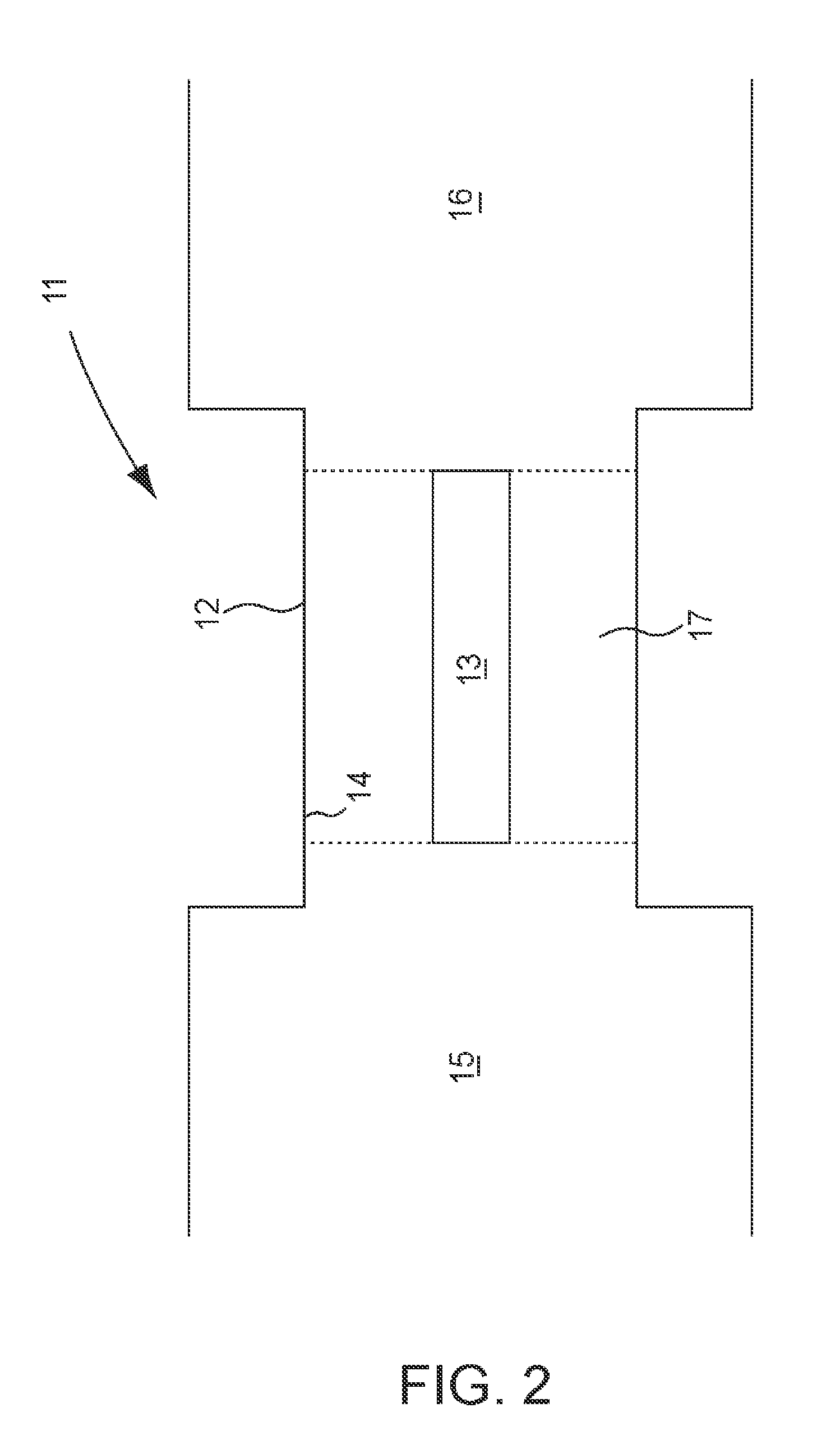

Microwave trigger metal-enhanced chemiluminescence (mt mec) and spatial and temporal control of same

ActiveUS20100003695A1Add Brownian motionHigh emission intensityBioreactor/fermenter combinationsBiological substance pretreatmentsMicrowaveChemical reaction

The present invention relates to a method of imaging structures and features using plasmonic emissions from metallic surfaces caused by chemiluminescence based chemical and biological reactions wherein imaging of the reactions is enhanced by the use of microwave energy and further enhanced by using metallic geometric structures for spatially and temporally controlling the biological and chemical reactions.

Owner:UNIV OF MARYLAND BALTIMORE COUNTY

Fluorescence microscope in a microwave cavity

ActiveUS8404450B2Speed up chemical reactionsSolve the lack of resolutionBioreactor/fermenter combinationsBiological substance pretreatmentsMicrowave cavityChemical reaction

Owner:UNIV OF MARYLAND BALTIMORE COUNTY

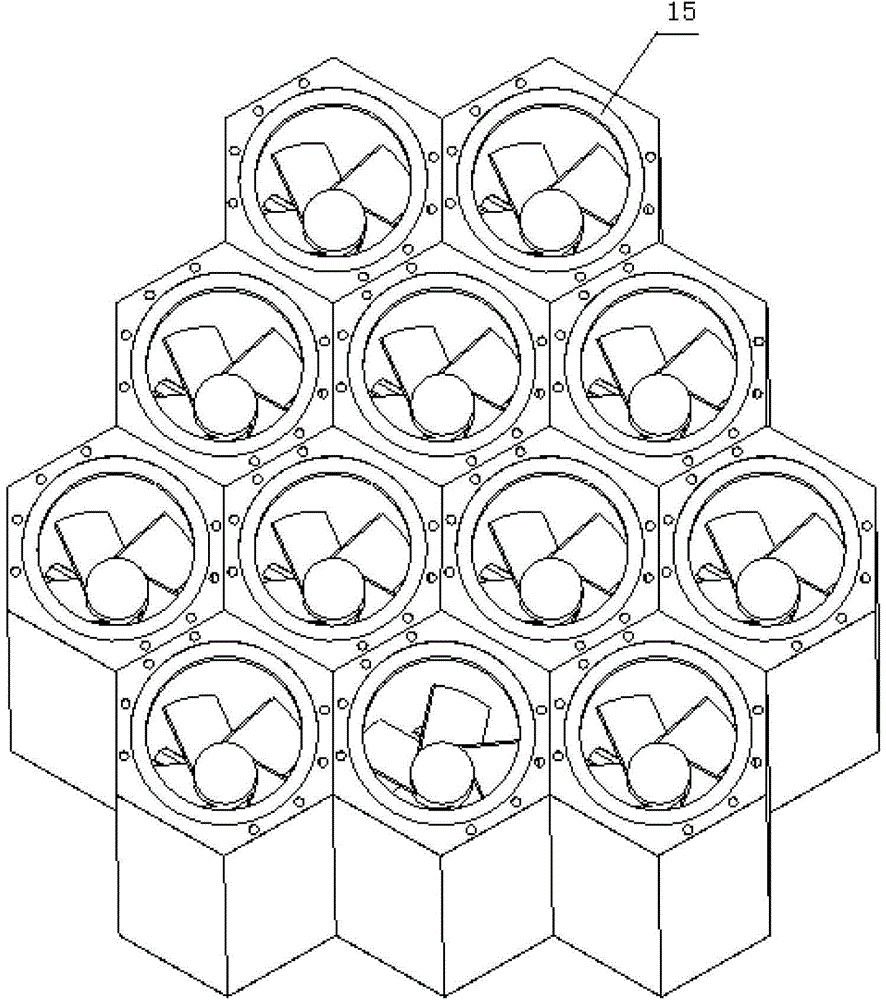

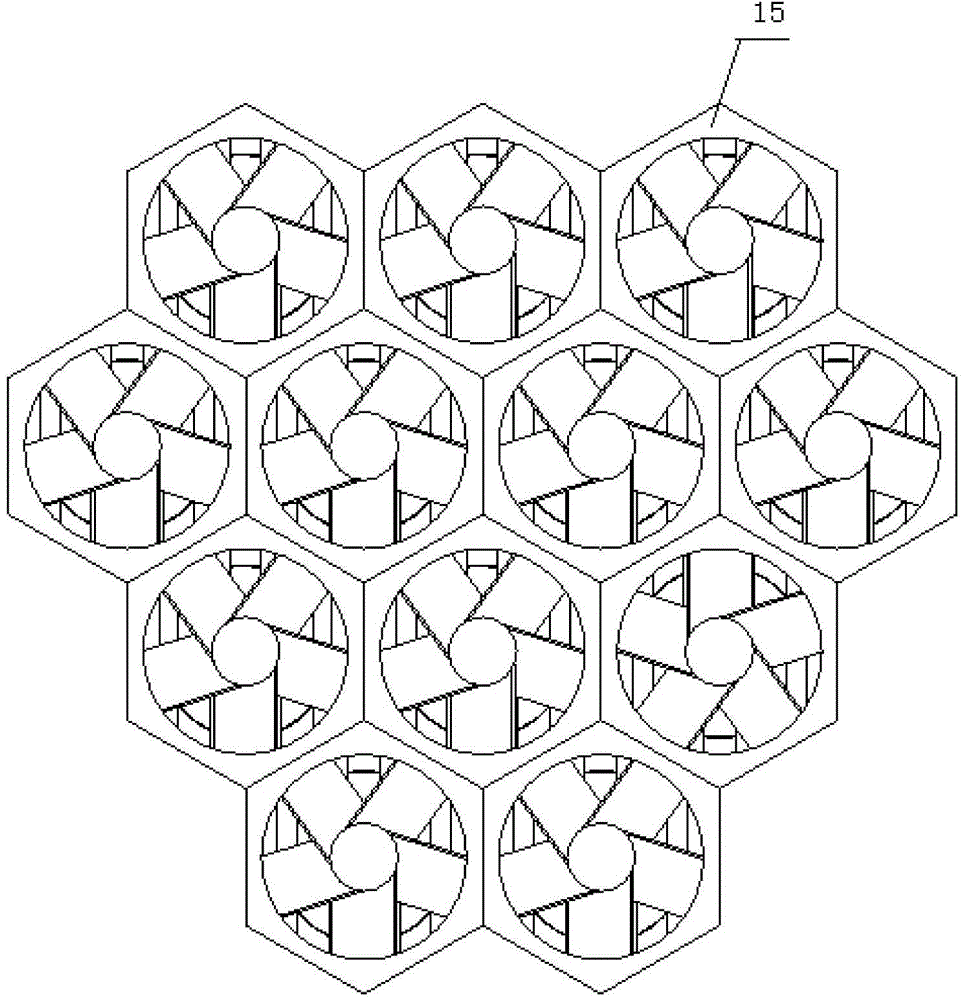

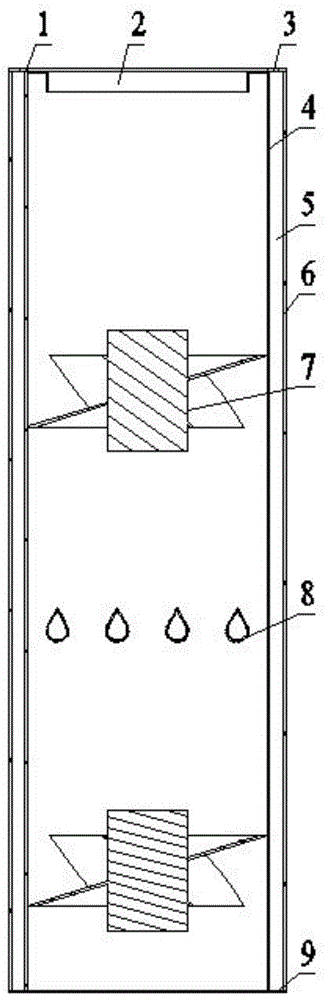

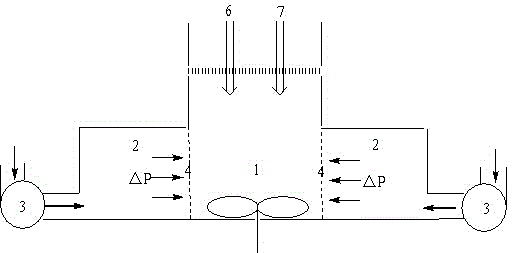

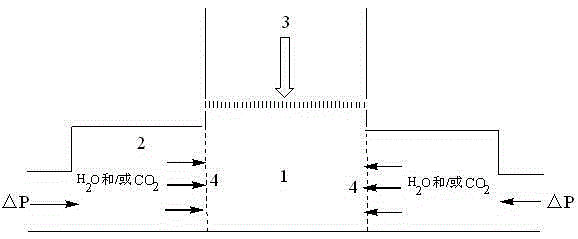

Phase-change dust-removing and mist-removing paralleling device of high-efficiency pneumatic pipe bundle and application

The invention relates to a phase-change dust-removing and mist-removing paralleling device of a high-efficiency pneumatic pipe bundle and an application. The phase-change dust-removing and mist-removing paralleling device comprises a plurality of phase-change dust-removing and mist-removing devices of the high-efficiency pneumatic pipe bundle, which are connected together in parallel; each of the phase-change dust-removing and mist-removing device comprises a hollow drum body with the openings at the two ends, a drum-body upper sealing plate, a drum-body lower sealing plate, a cyclone section, a pipe-bundle type water-mist distributing section and a water blocking section. The paralleling device has the advantages that the plurality of phase-change dust-removing and mist-removing devices are connected together in parallel, so that a user can assemble and adjust according to the treating capability needed practically, single phase-change dust-removing and mist-removing devices can be connected by adopting bonding, welding or hole grooves and the like; the manufacture is convenient and the waste-gas treating range is greatly expanded.

Owner:AEROSPACE ENVIRONMENTAL ENG

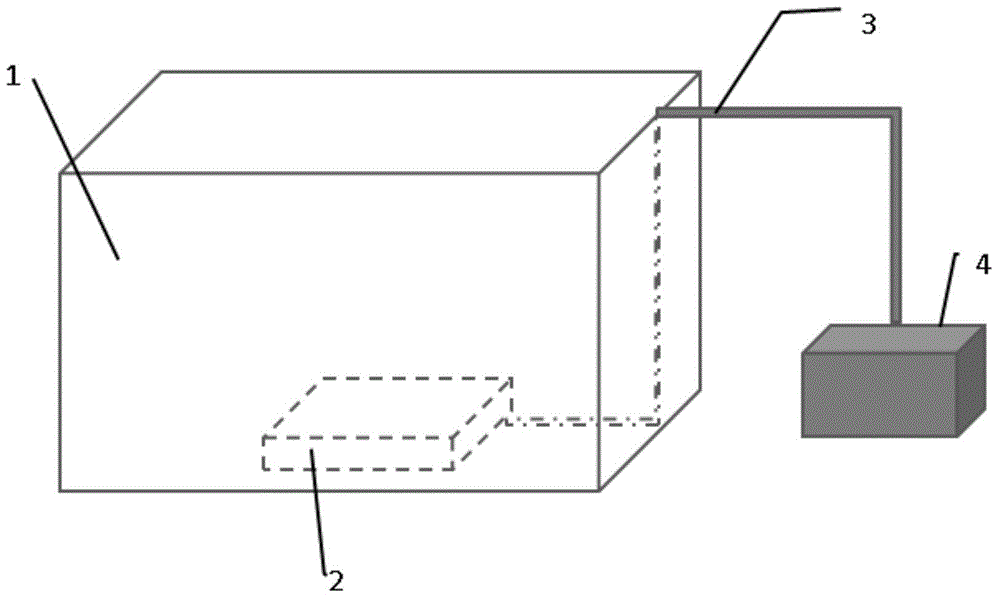

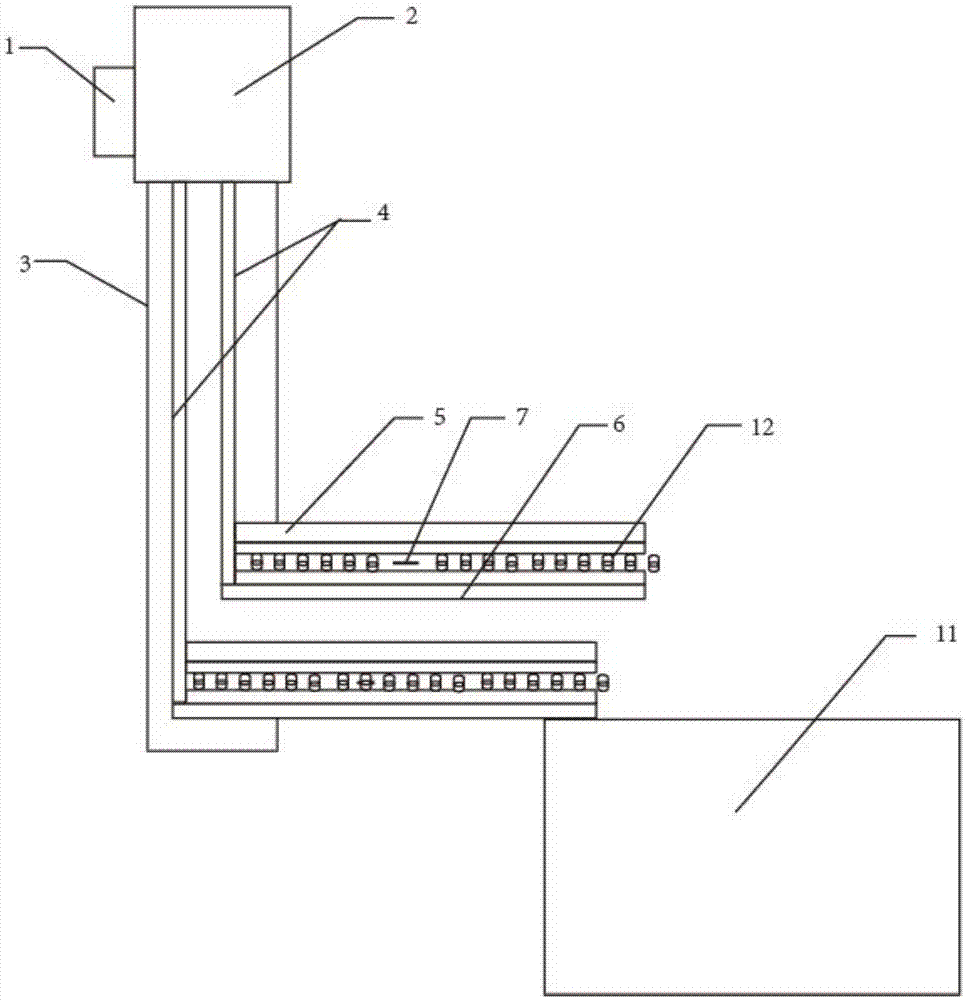

PCB-PTH (Printed Circuit Board-Plated Through Hole) line hole conditioning and activation ultrasonic device and method

InactiveCN104152875AImprove liquidityAdd Brownian motionLiquid/solution decomposition chemical coatingPrinted element electric connection formationEngineeringTemperature difference

The invention discloses a PCB-PTH (Printed Circuit Board-Plated Through Hole) line hole conditioning and activation ultrasonic device and method. The device comprises a hole conditioning or activation solution tank, an ultrasonic generator, a wire and an ultrasonic host, wherein the ultrasonic generator is mounted in the activation solution tank, and the ultrasonic generator is connected with the ultrasonic host via the wire. The PCB-PTH line hole conditioning and activation flow comprises the steps of charging, bulking, recovery, double water washing, glue residue removal, recovery, high neutralization water washing, high double water washing, neutralization, double water washing, hole conditioning, hot water washing, double water washing, microetching, double water washing and the like. According to the invention, ultrasonic energy with the capabilities of compression and expansion can effectively penetrate through fine gaps and small holes due to inertial thrust of liquid, and liquidity of solution in the holes is improved; the difference between colloid particle numbers on a liquid level and at the bottom of the tank can be reduced; palladium colloid molecular dispersion is good; the uniformity of activation of points of a plated board in the tank is improved; the ultrasonic energy generates a micro-stirring force and a temperature difference driving potential which contribute to improving Brownian movement of colloids; and adhesion of hole walls is increased.

Owner:志超科技(遂宁)有限公司

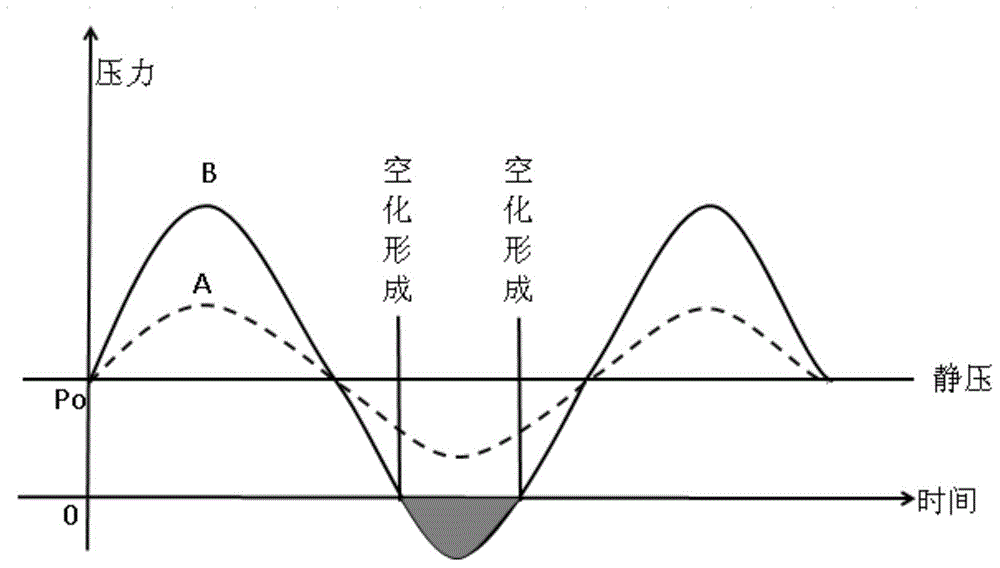

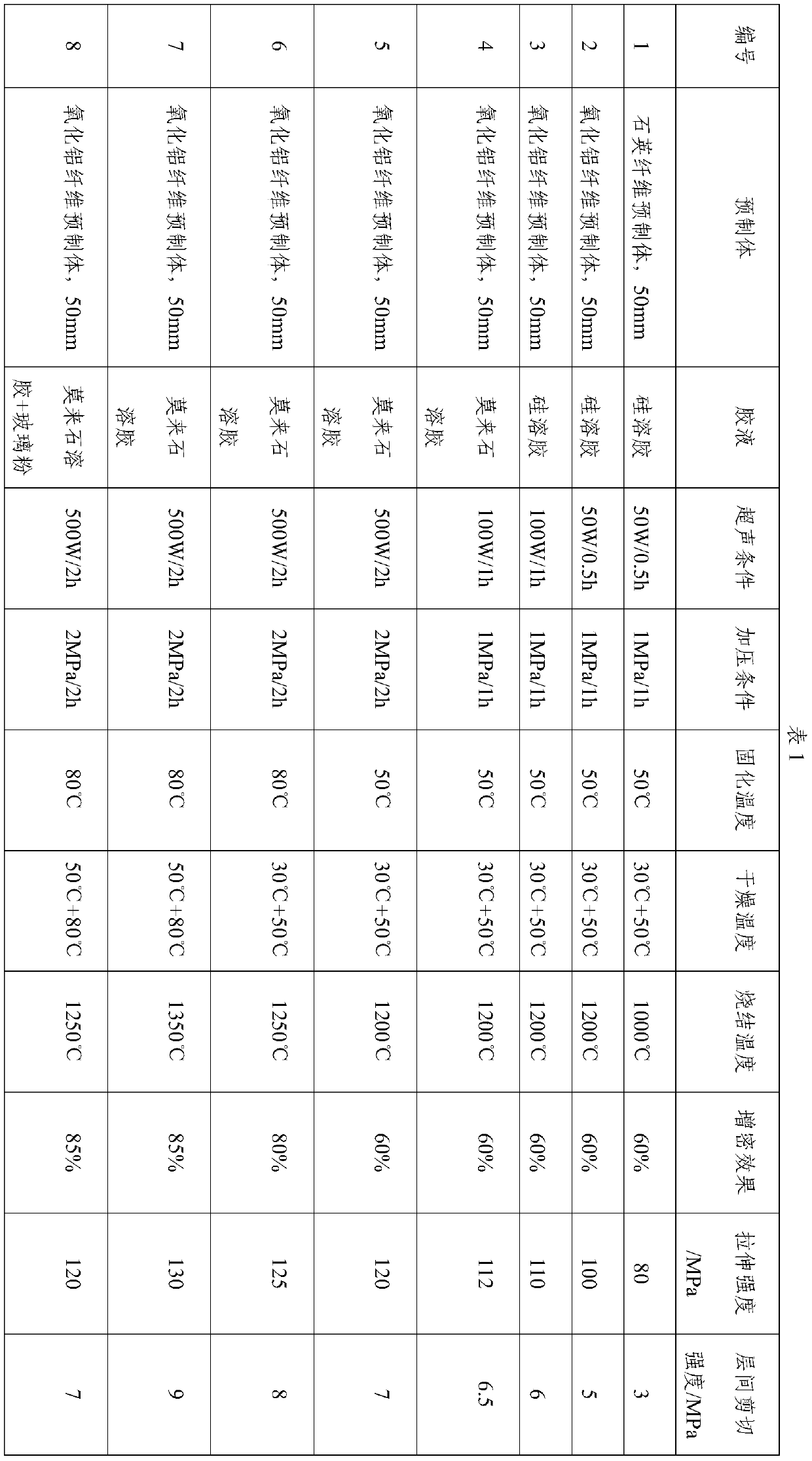

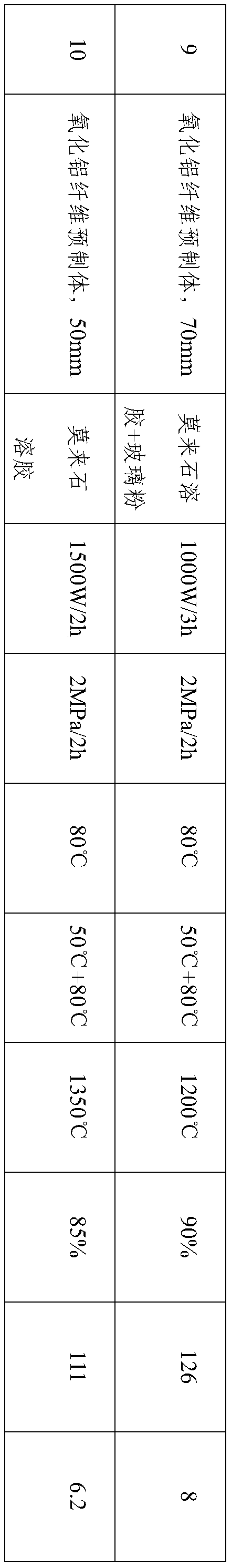

Fiber-reinforced ceramic matrix composite material, preparation method and application thereof

The invention relates to a fiber-reinforced ceramic matrix composite material, a preparation method and application thereof. The preparation method includes: (1) a step of preparation of a glue solution for impregnating a fiber preform; (2) a step of vacuum impregnation; (3) a step of curing; (4) a step of drying and sintering, and (5) a step of densification. Between the step (2) and the step (3), the method also includes the steps of: (i) carrying out ultrasonic vibration on a system containing the fiber preform and the glue solution for impregnation at the end of vacuum impregnation; and (ii) introducing compressed gas into the environment where the system is located at the end of ultrasonic vibration for pressurization, making the pressure of the environment where the system is locatedreach 1-4MPa, and keeping the maintaining time at 1-24h. The preparation method provided by the invention can prepare the fiber-reinforced ceramic matrix composite material which has thickness of 50mm or more and still has high density, excellent tensile strength and interlaminar shear strength.

Owner:AEROSPACE INST OF ADVANCED MATERIALS & PROCESSING TECH

High-efficiency pneumatic pipe bundle phase-change dedusting and demisting device and application

InactiveCN104923020AImprove centrifugal effectHelp to separate and captureCombination devicesElectricityEngineering

The invention relates to a high-efficiency pneumatic pipe bundle phase-change dedusting and demisting device and application. The device comprises a hollow barrel with two ends open, an upper barrel sealing plate, a lower barrel sealing plate, rotational flow sections, pipe-bundle-type water mist distribution sections and a water retaining section, the rotational flow sections of more than two stages are arranged coaxially in the inner-layer barrel from bottom to top at intervals, each pipe-bundle-type water mist distribution section is arranged coaxially between each two corresponding rotational flow sections, and the water retaining section is coaxially arranged on the inner-layer barrel below the upper barrel sealing plate in an outer-edge-sealed manner. The device can effectively remove liquid drops, dust and superfine dust of smoke systems or industrial waste gas systems, is good in demisting and dedusting effect and is lower in energy consumption and more energy saving when compared with wet-type electric dedusting. In addition, by the device, arrangement space is saved, and power equipment is omitted; the device has good dedusting and demisting effect while energy consumption is lowered, and can be applied to dedusting and demisting of industrial tail gas.

Owner:AEROSPACE ENVIRONMENTAL ENG

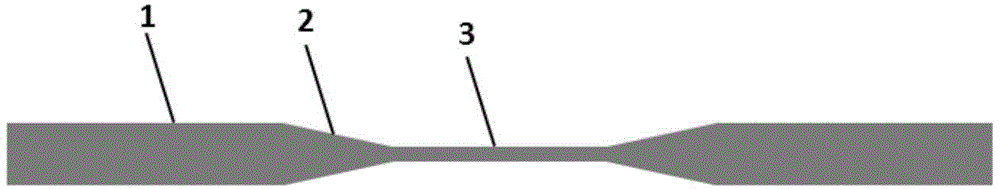

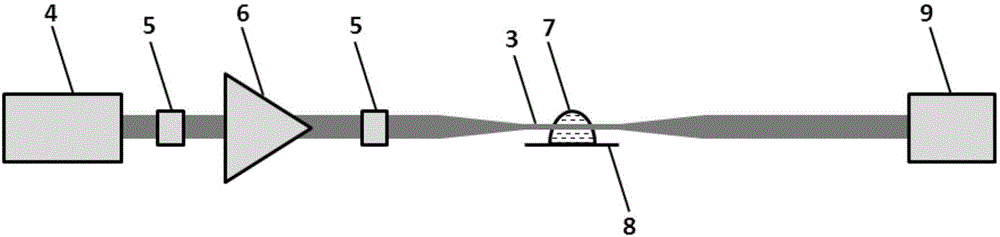

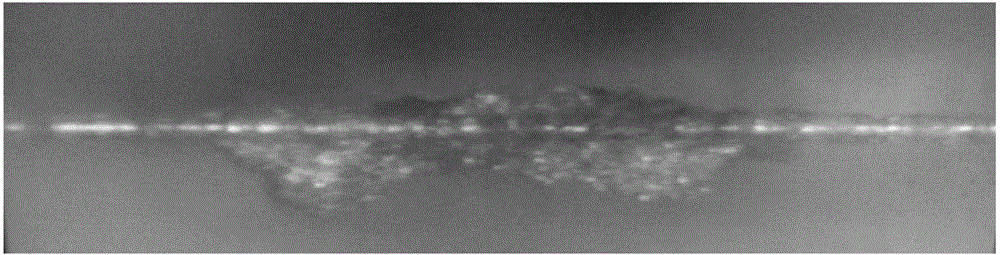

Method for efficient deposition of tungsten sulfide on side surface of tapered optical fiber

ActiveCN104477997AEfficient depositionIncrease deposition rateTungsten compoundsOptical power meterTungsten

A method for efficient deposition of tungsten sulfide on a side surface of a tapered optical fiber comprises steps as follows: a tungsten sulfide dispersion liquid is prepared; the tapered optical fiber is prepared from an ordinary single-mode optical fiber; an optical fiber in a tapering zone is immersed in the tungsten sulfide dispersion liquid; a laser with certain power is input from one end of the optical fiber, and output laser power changes are monitored by a laser power meter at the other end; the amount of the tungsten sulfide deposited on the side surface of the tapered optical fiber is controlled through control on the magnitude of the laser power input to the tapered optical fiber and the laser passing time. According to the method, all that is required is to use tungsten sulfide powder instead of preparing large-area tungsten sulfide materials, so that acting distances between optical fields and the tungsten sulfideare longer, more optical fields can interact with the tungsten sulfide, and the deposition speed and the deposition size of the tungsten sulfide can be significantly increased.

Owner:SHANGHAI JIAO TONG UNIV

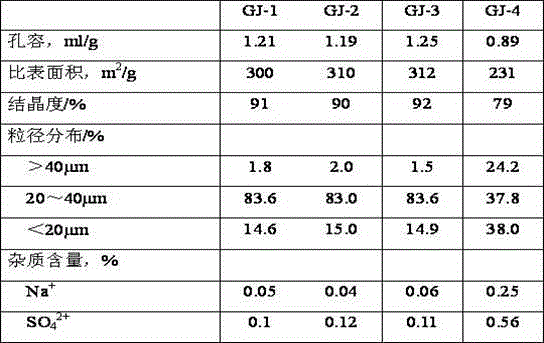

Preparation method of pseudo-boehmite with high purity and high crystallization degree

ActiveCN105585036AConstant concentrationReduce aggregation rateAlkali-metal aluminates/aluminium-oxide/aluminium-hydroxide preparationAluminium oxides/hydroxidesAluminium hydroxideFuel oil

The invention discloses a preparation method of pseudo-boehmite with high purity and high crystallization degree. The method comprises the following steps: (1) bottom water is added into a pressure zone and a reaction zone of a reactor, and a stabilizing agent is added into water in the reaction zone; (2) an aqueous solution of aluminium salts and an alkaline solution are respectively injected into a feed inlet I and a feed inlet II at the upper part of the reaction zone of the reactor, a sol forming reaction is carried out, during the sol forming reaction process, when aluminium hydroxide sol reaches a certain concentration, a pressure pump pumps water in the pressure zone into a reaction zone through a semi-permeable membrane, the sol is kept in a concentration range, and the reaction is continuously carried out for a period of time; (3) after the reaction ends, a stirring paddle at the bottom of the reactor is started, pH value of the reactor is adjusted, temperature is rapidly raised to an aging temperature, after aging, filtering, washing and drying are carried out, the pseudo-boehmite is obtained. The pseudo-boehmite is prepared by a semi-permeable membrane penetration mode, and the obtained pseudo-boehmite has the advantages of high purity, high crystallization degree, and uniform particle size distribution; and the pseudo-boehmite is suitable for preparing carriers and catalysts of hydrotreatment catalysts for wax oil, heavy oil and other inferior raw materials.

Owner:SINOPEC DALIAN RES INST OF PETROLEUM & PETROCHEMICALS CO LTD +1

Automatic reinjection water heating production increasing process of coal-bed gas well

The invention relates to an automatic reinjection water heating production increasing process of a coal-bed gas well. The process comprises the following steps: A, performing precipitation and filtration treatment on produced liquid once or for more times to remove more than 95 percent of solid particles; B, heating the treated clear liquid through solar energy to increase the water temperature to 60-90 DEG C; C, injecting hot water into a shaft through a hot water reinjection pipeline, extending the hot water reinjection pipeline to the space below a coal bed through an oil sleeve annulus and increasing the temperature of the original shaft liquid to over 20 percent; D, circularly performing the steps. The process has the advantages that the heat energy is injected into the shaft liquid in a hot water injection mode and the brownian motion of coal dust in the shaft liquid is increased so as to increase the divergence of the coal dust in the water, favorably reduce the concentration of the coal dust and discharge the coal dust, besides a part of heat energy is transferred to a coal-bed gas storage layer of an immediate vicinity of a wellbore, so that the free energy of the coal-bed gas can be increased to increase the desorption rate of the coal-bed gas, and meanwhile the gas is expanded on heating, so that a seepage passage can be expanded, the permeability of a reservoir stratum is improved and the production increase of the coal-bed gas is realized.

Owner:CNOOC ENERGY TECH & SERVICES

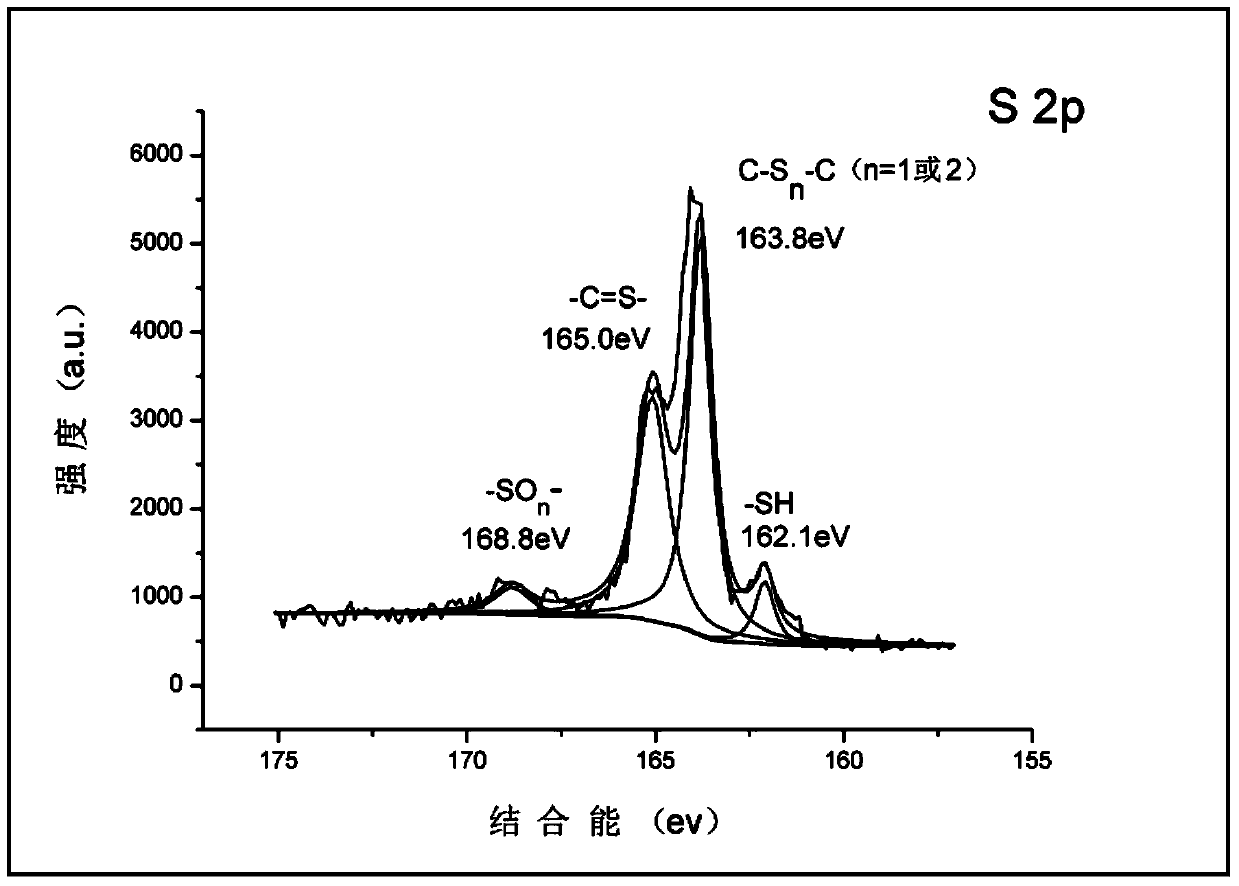

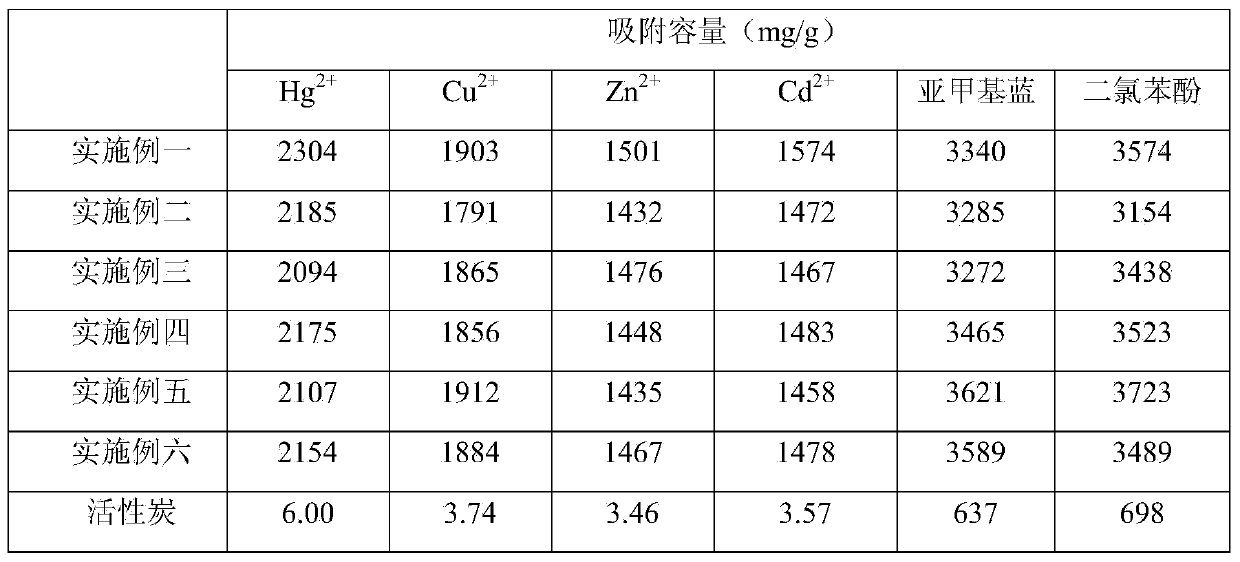

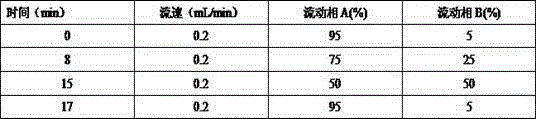

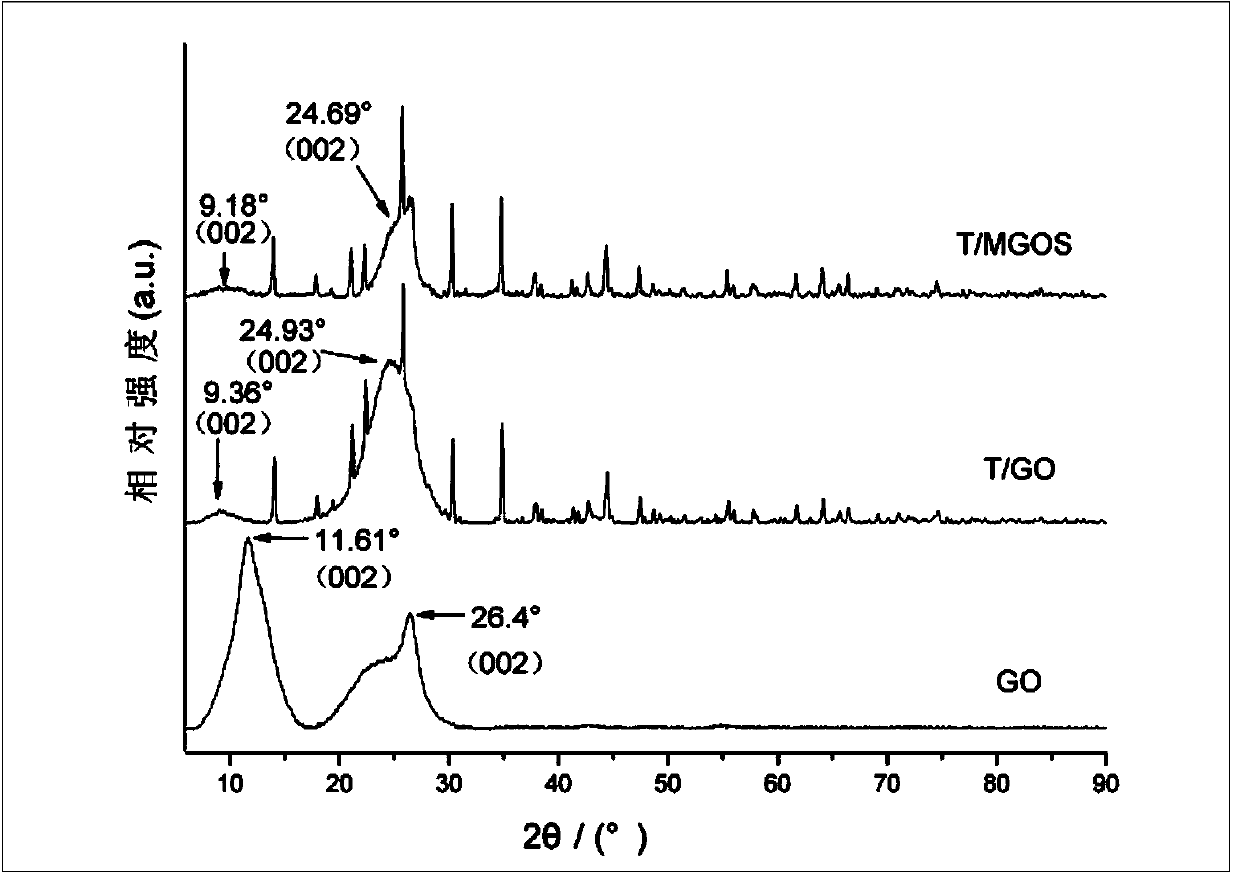

Tourmaline/grafting modified sulfur-containing graphene composite adsorption material and preparation method thereof

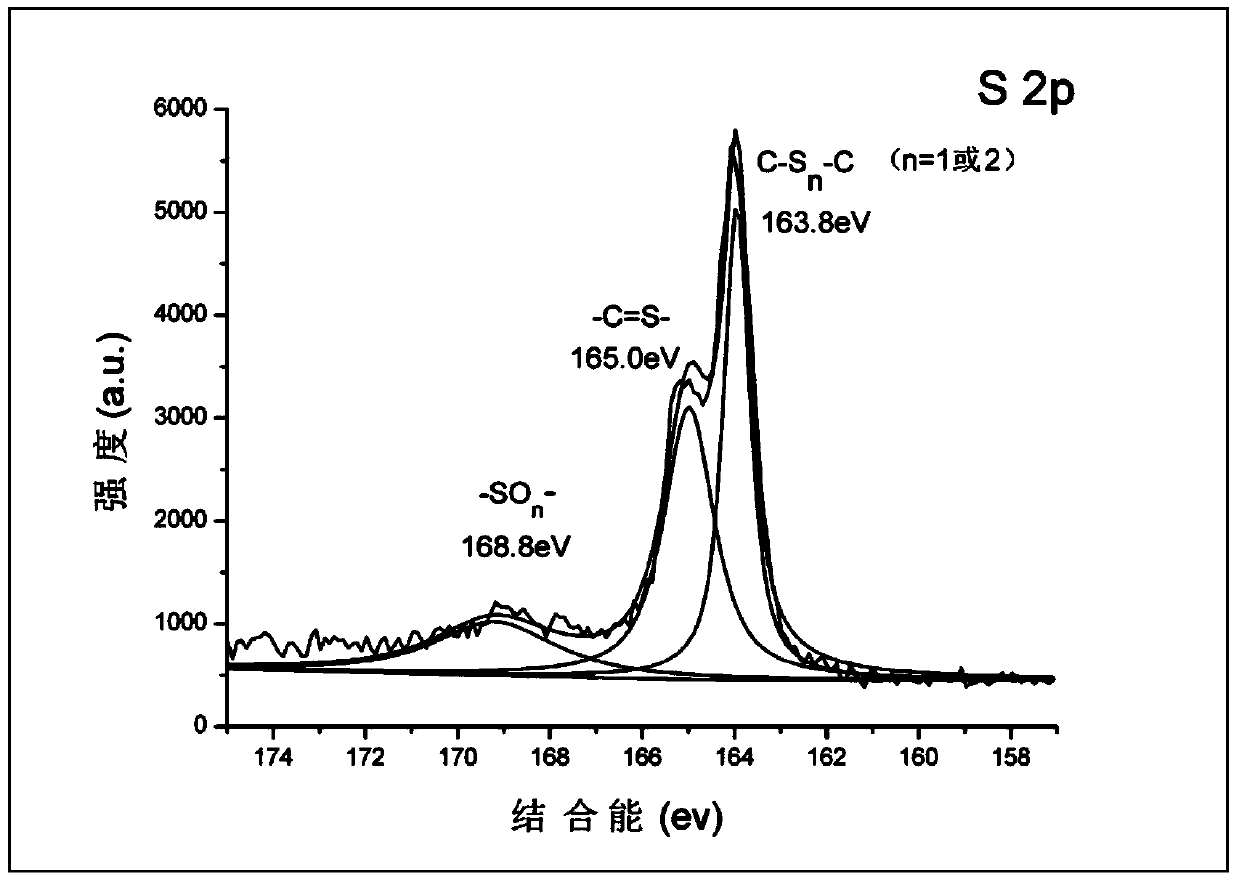

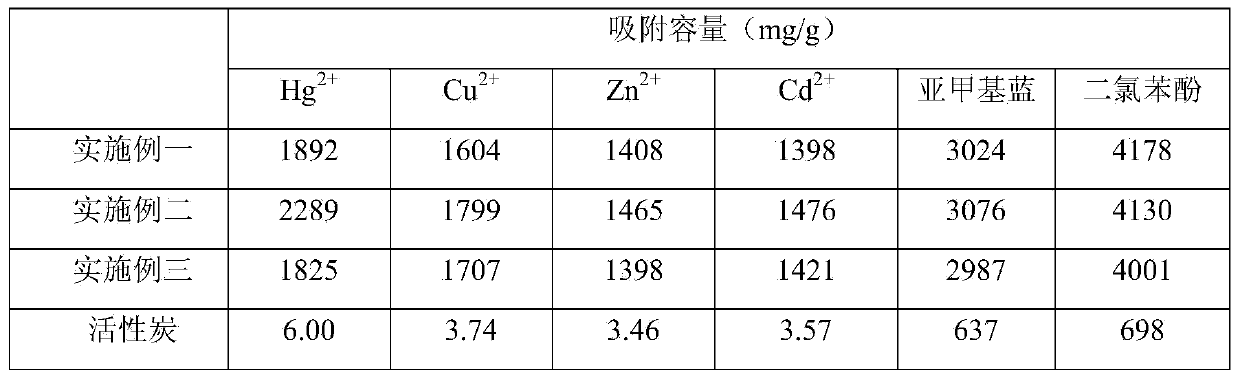

ActiveCN104001475ALarge specific surface areaIncrease movement rateWater/sewage treatment by irradiationOther chemical processesMulti pollutantCvd graphene

The invention discloses a tourmaline / grafting modified sulfur-containing graphene composite adsorption material and a preparation method of the tourmaline / grafting modified sulfur-containing graphene composite adsorption material. According to the method, firstly, oxidized graphene and tourmaline are compounded, grafting modification is carried out on oxidized graphene molecules through Na2S203, and at the same time, the oxidized graphene is reduced, so that functional groups such as -C=S-, -SOn-, C-Sn-C and -SH bonds are grafted to the oxidized graphene molecules successfully, grafting modified sulfur-containing graphene is obtained, and the adsorption performance on heavy metal ions is improved. The grafting modified sulfur-containing graphene molecules and the tourmaline can be combined together organically, the novel efficient composite adsorption material can be prepared and has the good adsorption effect on various contaminants, especially the adsorption performance on the heavy metal ions is improved remarkably, the adsorption capacity on mercury ions can reach up to 2304 mg / g, the preparation method is simple, raw materials are easy to obtain and small in use amount, and environmental protection is achieved.

Owner:HEBEI UNIV OF TECH

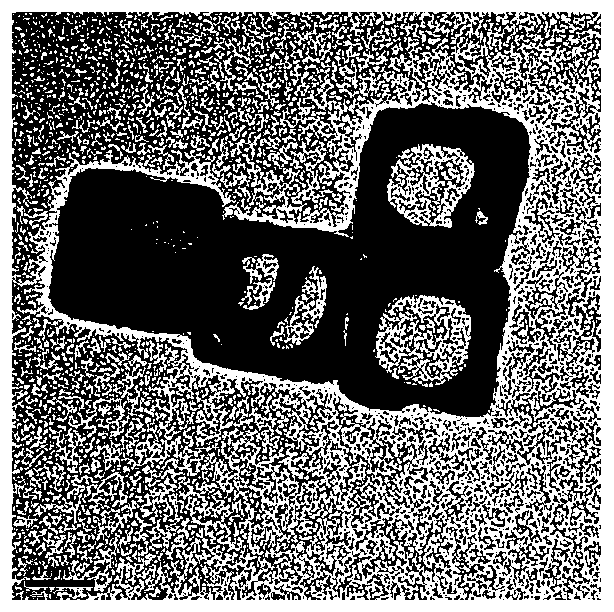

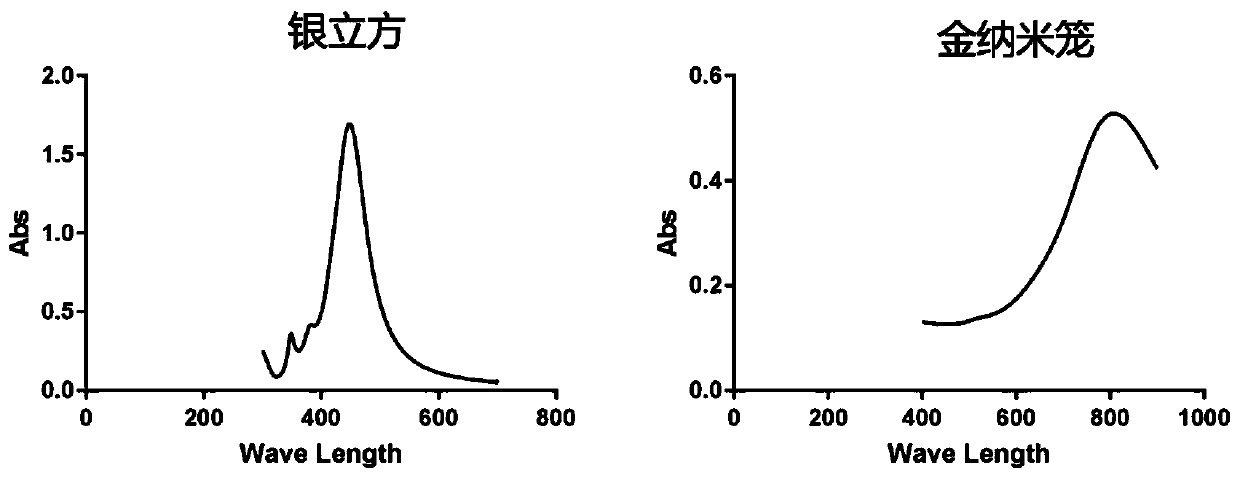

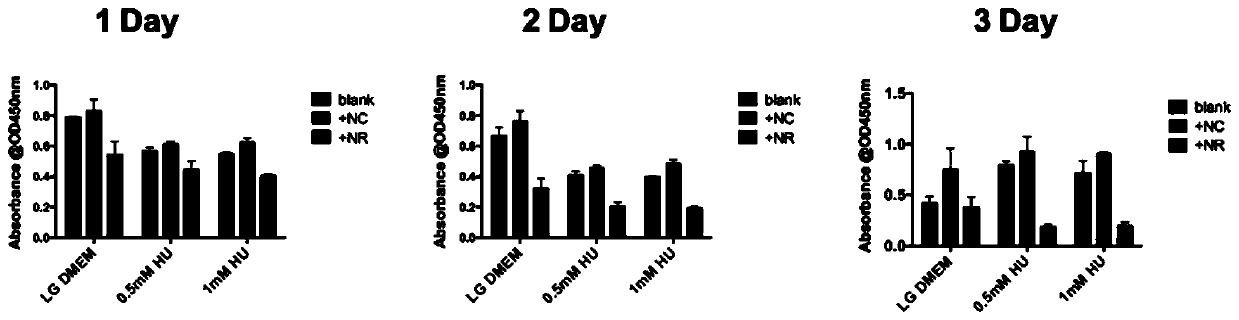

Application of gold nanocages in DAN injury resistance

InactiveCN110200992AAchieve selective releaseGood metabolic efficiency in vivoCosmetic preparationsDrug photocleavageApoptosisUltraviolet

The invention discloses application of gold nanocages in DAN injury resistance. Experiments prove that the gold nanocages help relieve cellular DNA injury induced by active oxygen, chemotherapeutic drugs (such as hydroxyurea) and physical irradiations (such as ultraviolet and X-ray); in manifesting, the gold nanocages promote proliferative activity of cells with DNA injury and inhibit apoptosis ofcells caused by DNA injury; the gold nanocages can evidently inhibit fibroblast apoptosis caused by ultraviolet irradiation and are applicable to the preparation of anti-aging or anti-radiation cosmetics; the gold nanocages as drug carriers feature optothermal release, never stay in the body for long time, and have good biosafety; X-ray irradiation for a mouse model verifies that the gold nanocages can promote reconstruction of the bone marrow blood-producing system, maintain the steady state of the immune system and extend the survival rate, and are applicable to the preparation of drugs toprevent and treat radiation-caused marrow injury or drugs to treat aplastic anemia.

Owner:WUHAN UNIV

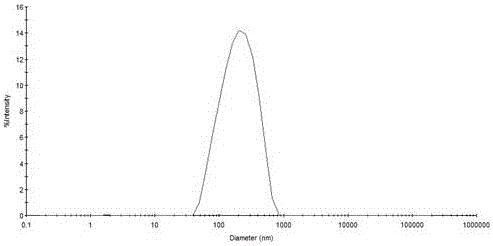

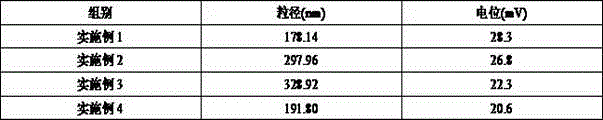

Preparation method and application of blueberry anthocyanin chitosan nanoemulsion

ActiveCN106038484AImprove stabilityLarge specific surface areaSenses disorderPharmaceutical non-active ingredientsFreeze-dryingSolvent

The invention provides a preparation method and application of a blueberry anthocyanin chitosan nanoemulsion, and belongs to the field of nanotechnology. The preparation method comprises the following steps: ultrasonically extracting blueberry pomace to obtain a blueberry anthocyanin extracting solvent; freeze-drying; adding a blueberry anthocyanin crude extract to a chitosan hydrochloride solvent with a concentration of 0.5-0.8mg / mL to obtain a mixed solvent I; dropwise adding a carboxymethyl chitosan solvent with the pH of 6.0 plus or minus 0.1 and a concentration of 0.5-2.0mg / mL to the mixed solvent I to obtain a blueberry anthocyanin chitosan nanoemulsion. The blueberry anthocyanin chitosan nanoemulsion prepared by the method can be used for preparing an eye drop and a blueberry anthocyanin beverage. The preparation method provided by the invention is simple, and the average particle size of the prepared blueberry anthocyanin chitosan nanoemulsion is less than 500nm; meanwhile, the loss rate of anthocyanin in the blueberry anthocyanin chitosan nanoemulsion prepared by the invention is extremely small as the storage time prolongs, and the prepared eye drop and beverage have the characteristics of high anthocyanin content, stable property and the like.

Owner:ANHUI AGRICULTURAL UNIVERSITY

Tourmaline/graft modification sulfur-containing graphene oxide composite adsorption material and preparation method thereof

InactiveCN103990435ALarge specific surface areaIncrease movement rateOther chemical processesWater/sewage treatment by sorptionOxide compositeAbsorption effect

The invention discloses a tourmaline / graft modification sulfur-containing graphene oxide composite adsorption material and a preparation method of the material. The material is prepared from raw materials including tourmaline, graphene oxide and sodium polysulfide, wherein the tourmaline accounts for 1%-2% of the total mass of the raw materials; the graphene oxide accounts for 5%-70% of the total mass of the raw materials; the sodium polysulfide accounts for 5%-94% of the total mass of the raw materials. According to the tourmaline / graft modification sulfur-containing graphene oxide composite adsorption material, the composite absorption material can be prepared by utilizing physical and chemical properties of the components of the composite material, is high in specific surface area and has functional groups such as -C=S-, -Son-, and C-Sn-C with affinity to heavy metal ions; the prepared material is good in absorption effect on a plurality of heavy metal ions and organic matters and particularly has absolute advantages in absorption of heavy metal ions when being compared with active carbon.

Owner:HEBEI UNIV OF TECH

Tourmaline/graft modified sulfur-containing reduction-oxidation graphene composite adsorbing material and preparation method thereof

InactiveCN103990436ALarge specific surface areaIncrease movement rateOther chemical processesWater/sewage treatment by sorptionFatty acidAdsorption effect

The invention discloses a tourmaline / graft modified sulfur-containing reduction-oxidation graphene composite adsorbing material and a preparation method thereof. The method comprises the following steps of firstly, compounding graphene oxide with graphene, carrying out graft modifying on a graphene oxide molecule by using sodium polysulfide, so that functional groups such as -C=S-, -SOn-, C-sn-C bonds, and the like, are successfully grafted on the graphene oxide molecule; and then, reducing the modified graphene oxide by using hydrazine hydrate. According to the invention, the reduction-oxidation graphene molecule and tourmaline are organically combined together to prepare an efficient novel composite adsorbing material which has good adsorbing effect on various pollutants; the reduced graft modified sulfur-containing reduction-oxidation graphene has certain hydrophobicity, can quickly adsorb organic substances which are insoluble in water such as petroleum, benzene, salad oil and fatty acid, particularly improves adsorption effect on heavy metal ions remarkably; moreover, the preparation method is simple, and materials are easily available, small in dosage and environmental friendly.

Owner:HEBEI UNIV OF TECH

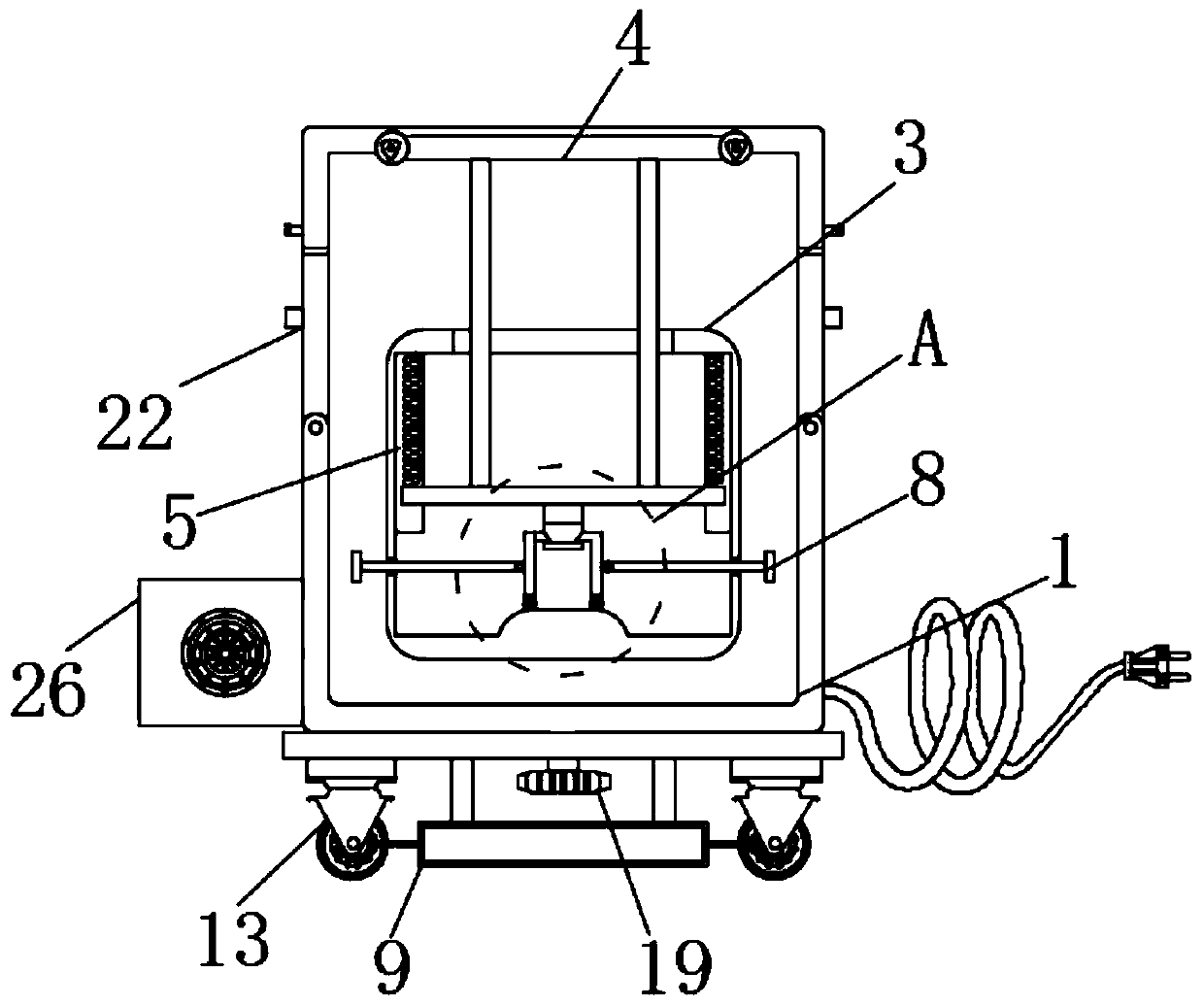

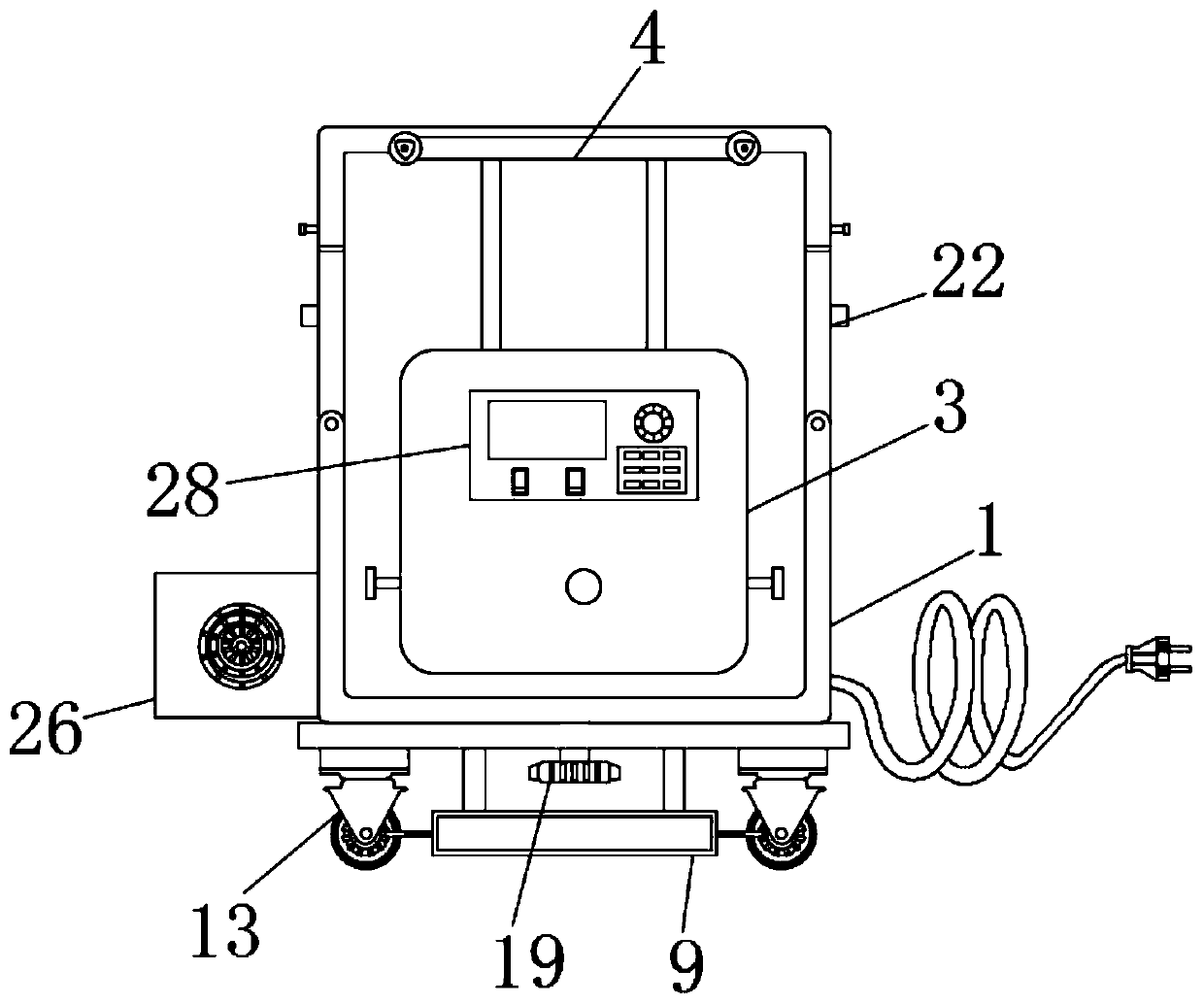

Hard capsule sealing device

InactiveCN106901988AShort duration of actionTightly boundCapsule deliveryHard CapsuleContact position

---- The invention belongs to the field of hard capsule sealing equipment, and in particular relates to a hard capsule sealing device, which includes a motor, a feeding funnel, and a longitudinal passage connected to the feeding funnel. The longitudinal passage is provided with several capsule passages through which individual capsules pass. The bottom end of the capsule passage is There is an upper transmission device and a lower transmission device. The upper transmission device and the lower transmission device are synchronously driven to drive the capsule to the right. There is a heating strip between the upper transmission device and the lower transmission device. The capsule body and capsule cap are connected. There is a sugar-coated layer; the end of the upper transmission device and the lower transmission device is provided with a collection device. By setting the sugar-coated layer at the junction of the capsule body and the capsule cap, the sugar-coated layer is heated under the condition of contact with the heating bar to speed up the Browning process. The movement makes the sugar molecules and the capsule shell more tightly combined, and the sealing effect is better. Because the heating strip has a short action time, and the contact position between the capsule body and the capsule cap is double-layer gelatin, under the condition of temperature control, it will not cause excessive temperature. high.

Owner:鸿昶龙(天津)科技有限公司

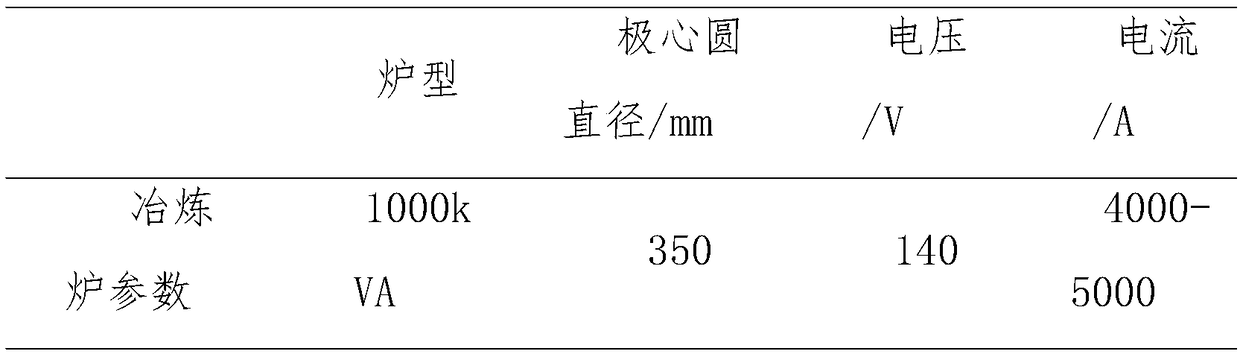

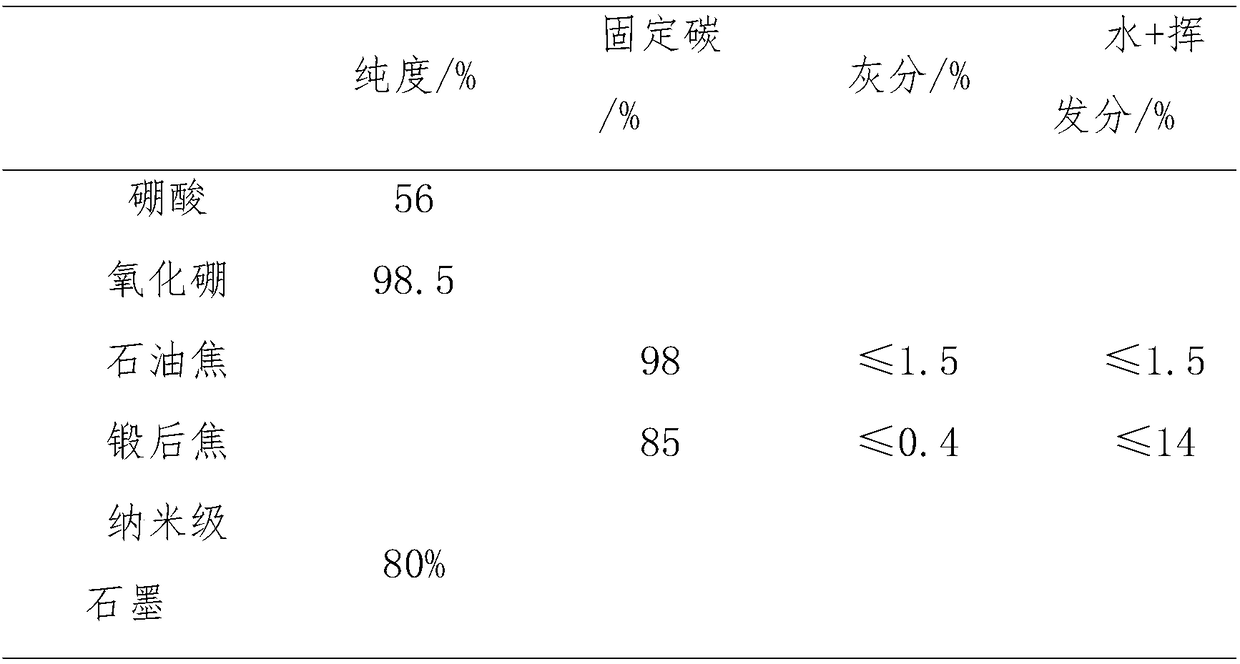

Smelting method of boron carbide material

The invention discloses a smelting method of a boron carbide material. Raw materials comprise a boron source material, a carbon source material and an additive material, wherein the additive materialis mainly used for adjusting the resistivity of a furnace charge and stabilizing the current. The smelting method has the advantages that: 1, the boron source and carbon source of the furnace charge are increased, the resistivity of the furnace charge is reduced, the furnace starting current can increase rapidly, the material heating speed is high, and the temperature is stable; 2, by virtue of the cooperation of pole core circle, voltage and current, the temperature uniformity of a crucible area in a furnace can be improved, and a stable environment can be provided for the growth of boron carbide crystals; 3, after the boron-carbon steam pressure increases, the Brownian movement is accelerated, and the polymerization of crystallized blocks can be improved; 4, the current supply amount isconstant, so that the reduction reaction in the furnace is consistent, and the compactness of the boron carbide crystallized blocks is consistent; and 5, by adjusting the raw materials, proportion, smelting parameters and operation parameters, the purity of the boron carbide crystallized blocks is improved, and the yield of the high-purity crystallized blocks is increased.

Owner:通辽中硼新材料科技有限公司

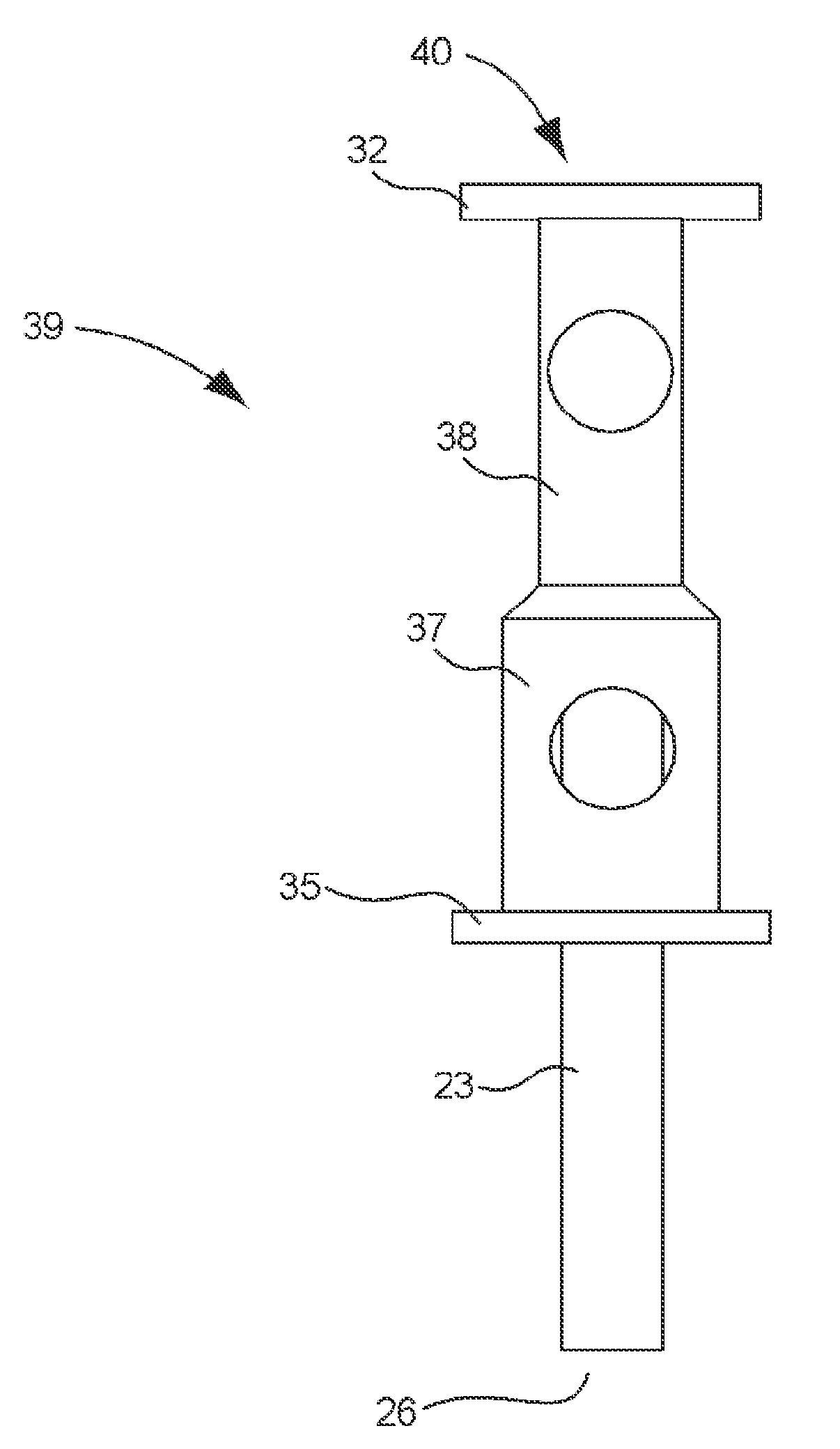

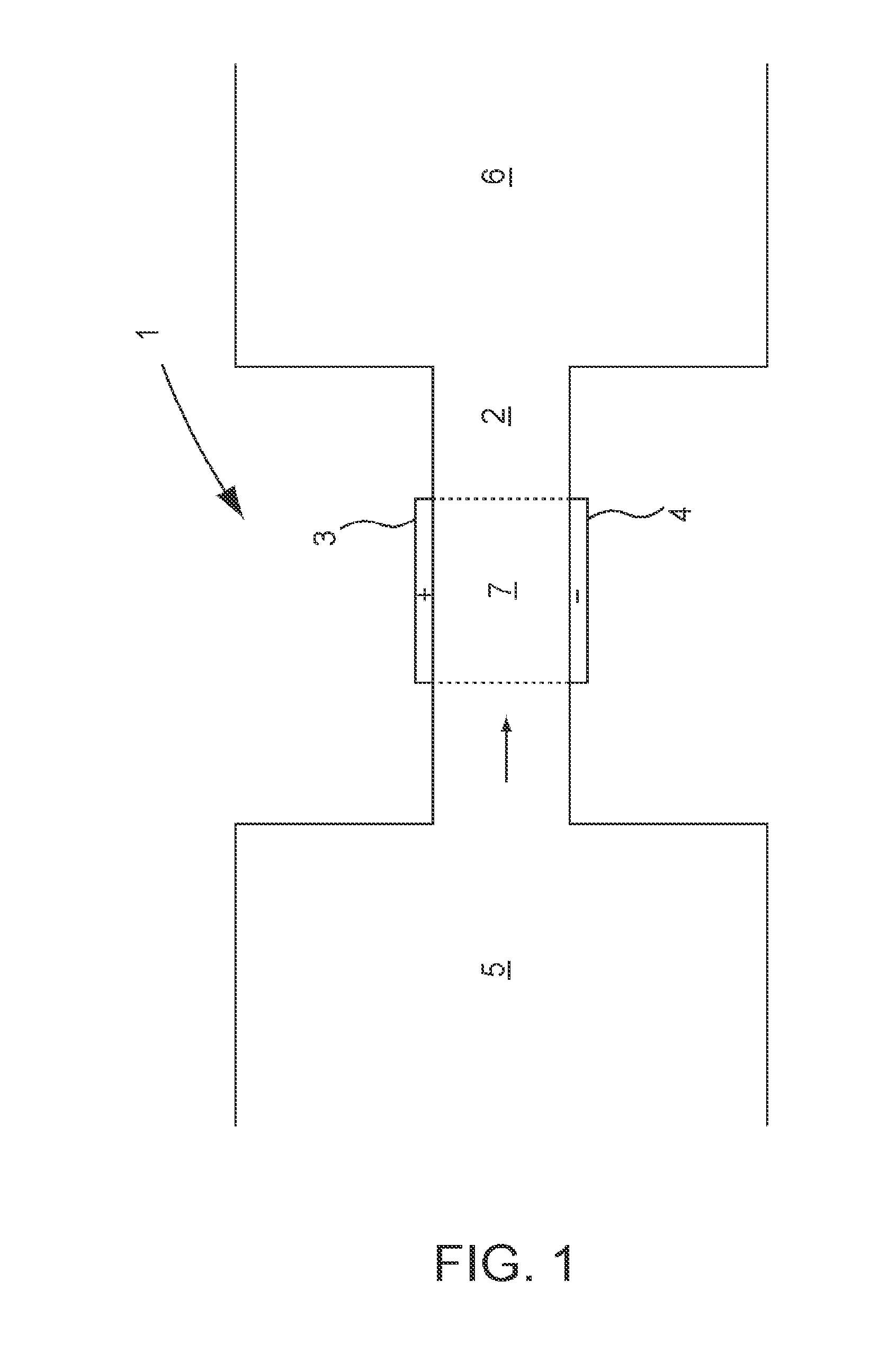

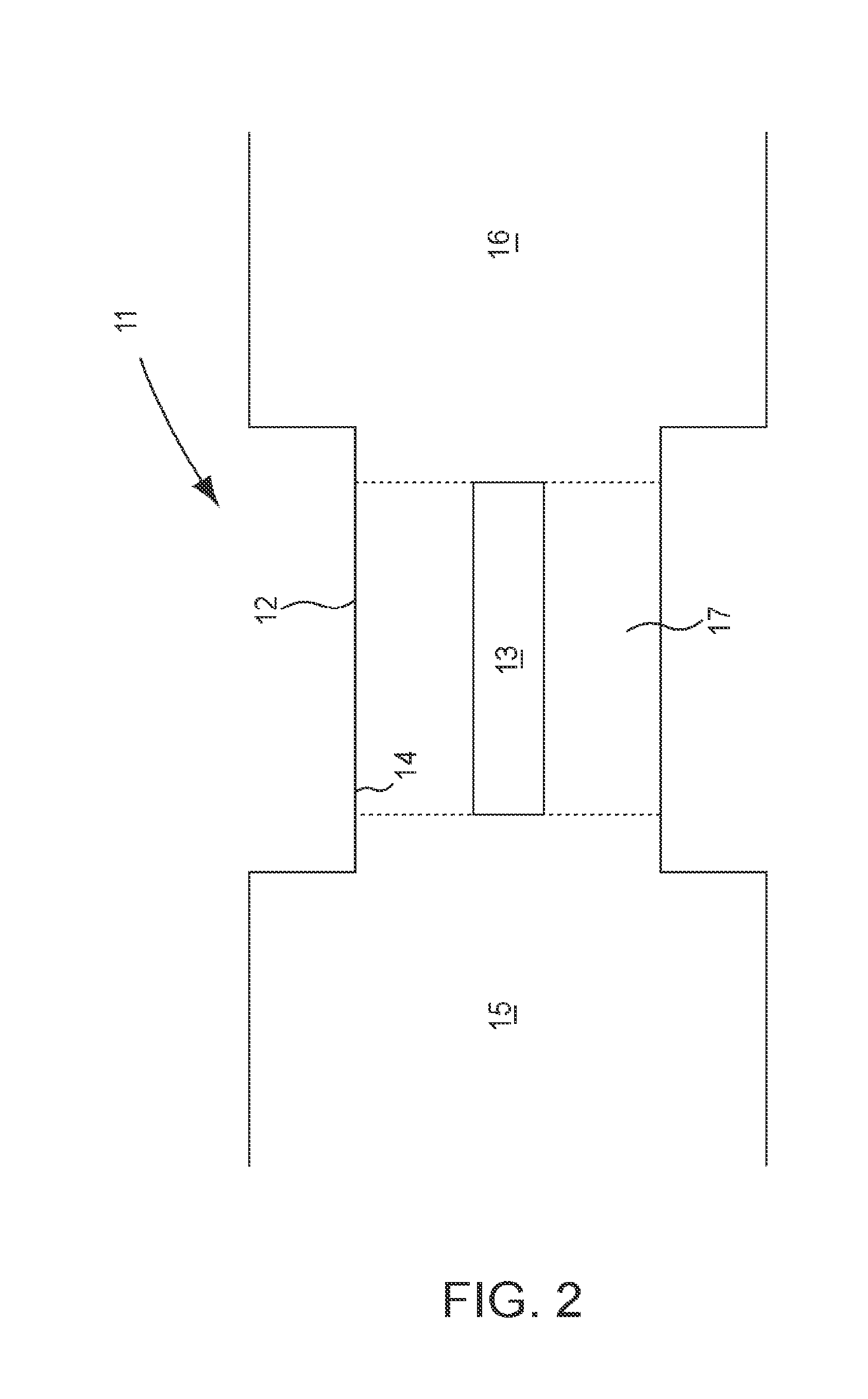

Fluid conditioning system and process of conditioning fluid

InactiveUS7740764B1Reduce amount of energyTemperature be not raiseWater/sewage treatment by magnetic/electric fieldsNature of treatment waterPre conditioningPre-condition

A process of conditioning a fluid includes passing the fluid through a magnetic field. A fluid conditioning system includes a conduit adapted to allow fluid to pass from a pre-conditioned volume to a post-conditioned volume, and a magnet assembly including at least one magnet disposed such that magnetic field produced by the at least one magnet penetrates the conduit. The conduit is formed from a material that allows the magnetic field produced by the at least one magnet to have a magnetic effect on molecules of the fluid as the fluid passes through the conduit.

Owner:MANNING JAMES

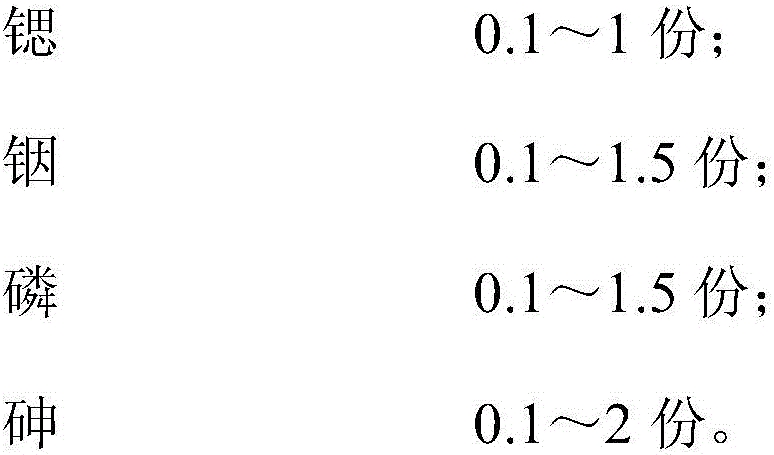

A bi-component adhesive and its preparation method thereof

ActiveCN106281172APerformance and environmental protectionAging resistantNon-macromolecular adhesive additivesEpoxy resin adhesivesEpoxyAging resistance

This invention discloses a bi-component adhesive and its preparation method thereof, which belongs to the field of adhesive technology. The adhesive contains a component A and a component B. The Component A therein contains components calculated in parts by weight as follows: 30-35 parts of amilan; 4-5.5 parts of benzyl alcohol; 100-132 parts of calcite in powder; 3-5.5 parts of coupling reagent. The Component B contains components calculated in parts by weight as follows: 80-100 parts of epoxy resin; 6-8.5 parts of benzyl alcohol; 18-29 parts of aluminum hydroxide and 4.4 parts of accelerant. The Component A and Component B are restored separately. When used, the ration of preparing Component A and Component B is 1-8:1. By screening adhesive components according to the component ratio, the preparation method effectively enhances the adhesive strength and endows the adhesive with the advantages of oil resistance, high temperature resistance and aging resistance which has effectively increased the service life of a filter. The technology of its preparation method is quite simple and the operation is quite convenient. The bi-component adhesive and the preparation method thereof are also clean and environmentally friendly.

Owner:珠海圣菲玛滤清器有限公司

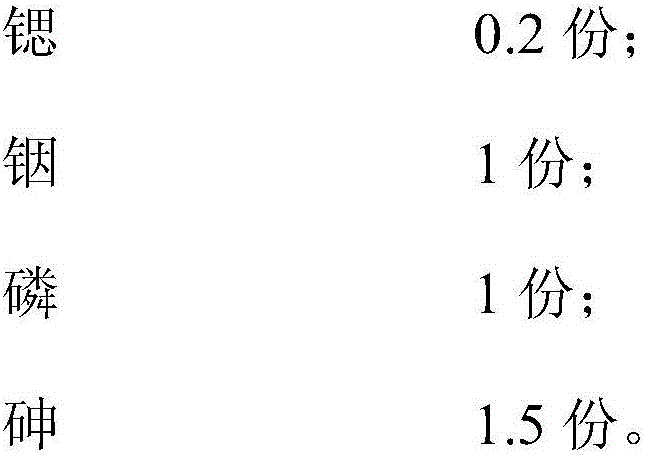

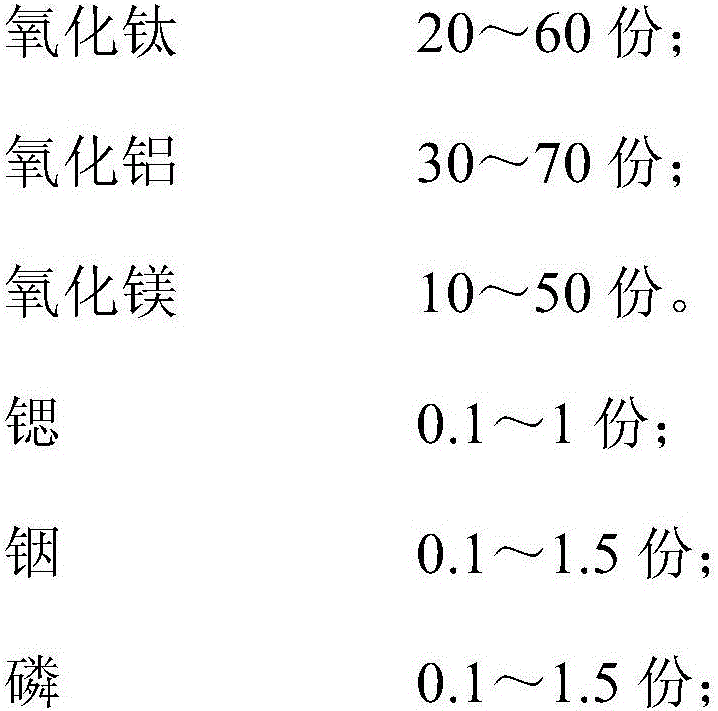

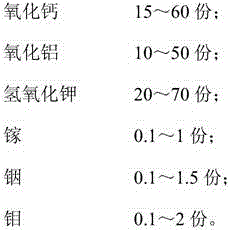

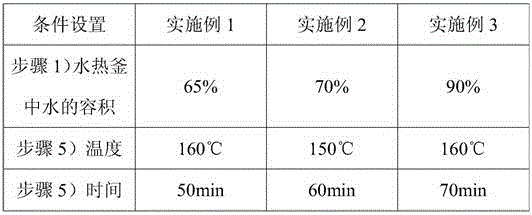

Carbon dioxide adsorbent, carbon dioxide adsorption device and manufacturing method of carbon dioxide adsorption device

ActiveCN106179179AImprove adsorption efficiencyEnhanced surface potential energyNitrous oxide captureProductsSorbentMagnesium salt

The invention discloses a carbon dioxide adsorbent, a carbon dioxide adsorption device and a manufacturing method of the carbon dioxide adsorption device. The carbon dioxide adsorbent is prepared from 20-60 parts by weight of titanium oxide, 30-70 parts by weight of aluminium oxide and 10-50 parts by weight of magnesium oxide, adsorbs carbon dioxide in laughing gas efficiently and purifies the laughing gas. The manufacturing method of the carbon dioxide adsorption device comprises the following steps: 1) adding deionized water to a hydrothermal kettle; 2) adding titanium salt, aluminium salt and magnesium salt to the hydrothermal kettle; 3) preparing a salt solution from a modifier and adding the salt solution to the hydrothermal kettle; 4) placing a blank filling layer into the hydrothermal kettle and performing hydrothermal treatment; 5) taking out the filling layer to obtain an adsorbent filling layer; 6) installing the adsorbent filling layer on a filtering channel of the carbon dioxide adsorption device. With adoption of the manufacturing method, nanoscale carbon dioxide adsorbent is uniformly attached to the filling layer, so that the adsorbent filling layer has efficient carbon dioxide adsorption performance.

Owner:SUZHOU JINHONG GAS CO LTD

High-temperature-resistant conductive copper alloy protective agent, preparation method and copper alloy passivation method

ActiveCN113106460AReduce exposureImprove high temperature resistanceMetallic material coating processesDiethylene glycol diethyl etherPassivation

The invention relates to the technical field of copper alloy protective agents, and particularly discloses a high-temperature-resistant conductive copper alloy protective agent, a preparation method and a copper alloy passivation method. The copper alloy protective agent is prepared from the following raw materials in percentage by weight: 4-6% of diethylene glycol diethyl ether, 30-55% of an emulsifying dispersant, 0.5-1.5% of a wetting agent, 0.3-2% of a chelating agent, 1.5-2.5% of 2-mercaptobenzothiazole, 2.5-3.5% of 2-heptadecyl imidazole, 7.5-12.5% of 2-sulfydryl-5-methylbenzimidazole and the balance deionized water. According to the copper alloy protective agent, through the synergistic effect of the raw materials, the high temperature resistance and the salt fog resistance of a passivated copper alloy are effectively improved, the service life of the passivated copper alloy is prolonged, the stability of the passivated copper alloy is improved, the using effect of the copper alloy protective agent is also improved, and the market requirements are met.

Owner:深圳市钝化技术有限公司

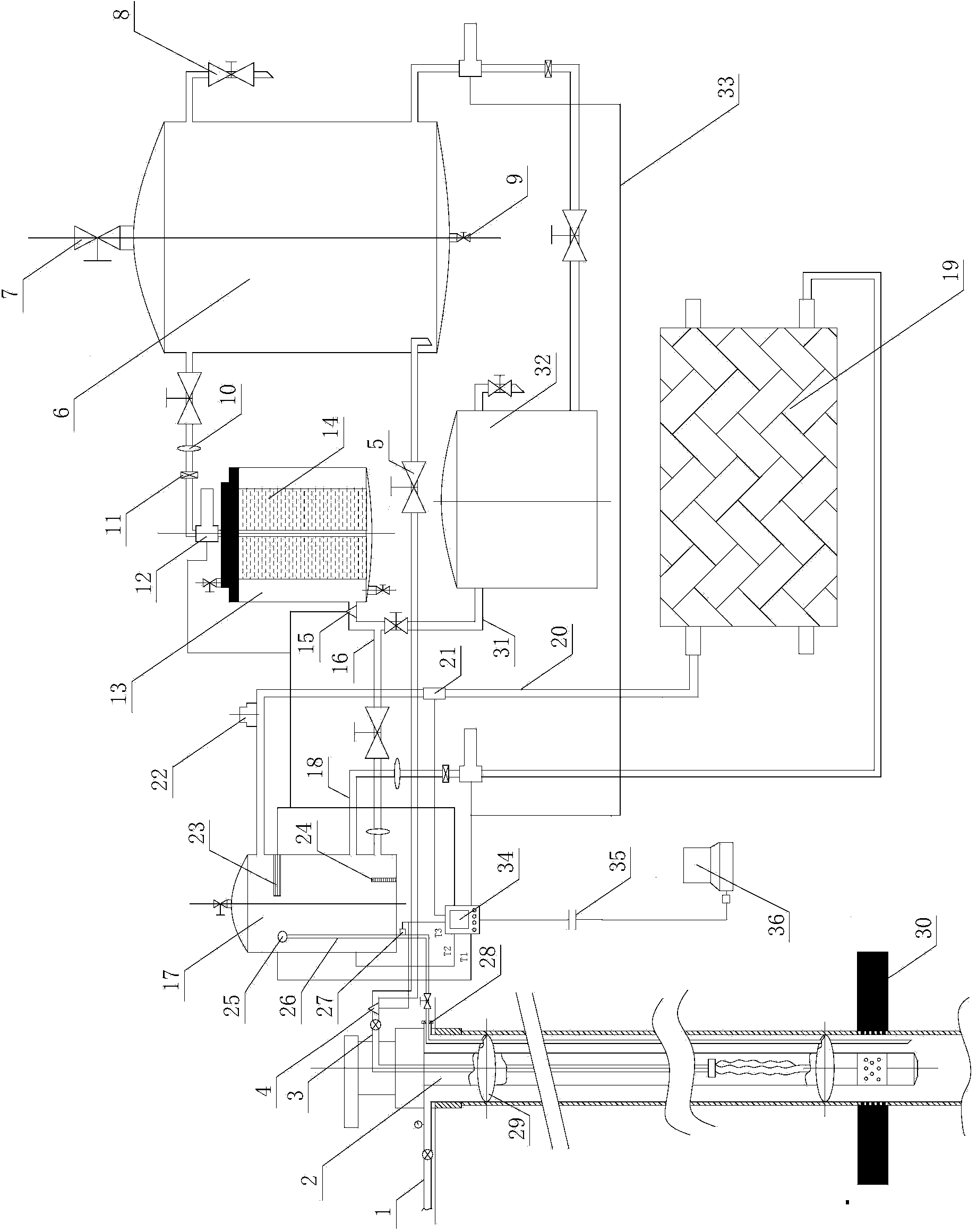

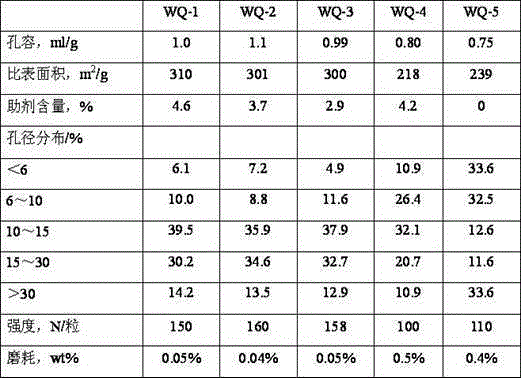

Preparation method of aluminum oxide carrier

ActiveCN106669852AImprove performanceImprove desulfurizationCatalyst carriersEnergy based chemical/physical/physico-chemical processesAluminateIonic liquid

The invention discloses a preparation method of an aluminum oxide carrier. The method comprises the following steps: (1) bottom water is added into a pressure zone and a reaction zone of a reactor, ionic liquid I is added, and gelling temperature is adjusted; (2) an aqueous solution of alkaline aluminate is added into the reactor, at the same time CO2 enters the reaction zone from the lower part of the reaction zone, CO2 and the aqueous solution of alkaline aluminate are neutralized for carrying out a sol forming reaction, when water in the pressure zone enters the reaction zone through a semi-permeable membrane, the sol concentration is kept in a concentration range, and the reaction is continuously carried out; (3) after the reaction ends, ultrasonic vibration at the bottom is started, and after aging, washing and drying are carried out, pseudo-boehmite is obtained. (4) mixing and kneading, moulding, drying and calcination of the pseudo-boehmite prepared in the step (3), an adhesive and ionic liquid II are carried out, and the aluminum oxide carrier is obtained. The aluminum oxide carrier has the advantages of high specific surface area, large aperture and pore volume, high lateral compressive strength, and low abrasion; and the product is adapted to be the carrier of boiling bed wax oil, residual oil hydrogenation catalysts.

Owner:CHINA PETROLEUM & CHEM CORP +1

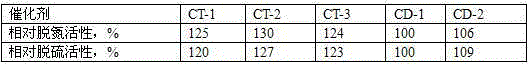

Nitrogen dioxide adsorbent, nitrogen dioxide absorbing device and manufacturing method of nitrogen dioxide absorbing device

ActiveCN106345393AImprove adsorption efficiencyEnhanced surface potential energyNitrous oxide captureGas treatmentSorbentPotassium hydroxide

The invention discloses nitrogen dioxide adsorbent, a nitrogen dioxide absorbing device and a manufacturing method of the nitrogen dioxide absorbing device. The nitrogen dioxide adsorbent comprises, by weight, 15-60 parts of calcium oxide, 10-50 parts of aluminum oxide and 20-70 parts of potassium hydroxide and is capable of purifying nitrous oxide by efficiently absorbing nitrogen dioxide in the nitrous oxide. The manufacturing method of the nitrogen dioxide absorbing device includes the steps of 1) adding deionized water in a hydrothermal kettle; 2) adding calcium salt, aluminum salt and sylvite in the hydrothermal kettle; 3) preparing a modifying agent into a saline solution, and adding the saline solution in the hydrothermal kettle; 4) adding a blank filler layer into the hydrothermal kettle for hydrothermal treatment; 5) taking out the filler layer to obtain an adsorbent filler layer; and 6) mounting the adsorbent filler layer in a filtering passageway of the nitrogen dioxide absorbing device. The manufacturing method has the advantages that the nano-size nitrogen dioxide adsorbent evenly attaches to the filler layer, and accordingly the adsorbent filler layer is high in nitrogen dioxide absorbing efficiency.

Owner:SUZHOU JINHONG GAS CO LTD

Fluid conditioning system and process of conditioning fluid

InactiveUS8268178B1Weaken energyReduce the temperatureWater/sewage treatment by magnetic/electric fieldsNature of treatment waterMagnetic effectEngineering

A process of conditioning a fluid includes passing the fluid through a magnetic field. A fluid conditioning system includes a conduit through which fluid passes, and a magnet assembly including at least one magnet disposed such that the produced magnetic field penetrates the conduit. The conduit is formed from a material that allows the magnetic field to have a magnetic effect on molecules of the fluid as it passes through the conduit. The conduit has a cross-sectional area designed to maintain a flow rate of the fluid through the conditioning volume within a pre-determined range. The magnetic field produced by the magnet has a field strength within the conduit, and the predetermined range is predetermined as a factor in combination with the field strength to precipitate an ion from the fluid in the conditioning volume.

Owner:MANNING JAMES

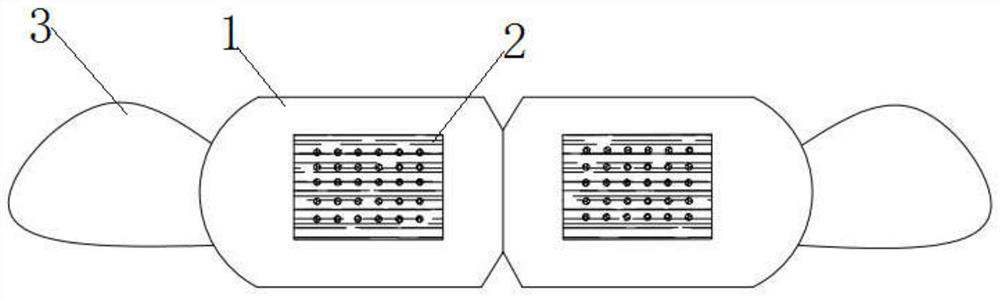

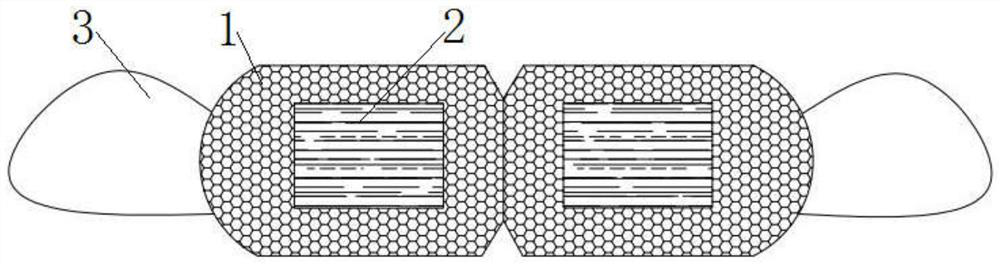

Steam eyeshade

PendingCN113616419AReduce volatile lossExtended storage timeEye-masksBathing devicesPersonal careChemical reaction

The embodiment of the invention discloses a steam eyeshade, which belongs to the technical field of personal care and comprises an eyeshade body and a heating body arranged between the inner layer and the outer layer of the eyeshade body. The eyeshade further comprises ear hooks which are arranged on the two sides of the eyeshade body. The eyeshade also comprises essential oil microcapsules and the essential oil microcapsules are arranged between the heating body and the inner layer of the eyeshade body, or a finishing agent containing the essential oil microcapsules is uniformly distributed on the eyeshade body. Under the action of heat generated during chemical reaction of the heating body, the wall material of the essential oil microcapsule is broken, and volatile oil contained in the essential oil microcapsule is released and enters eyes through skin, so that eye fatigue can be effectively relieved, and the essential oil microcapsule has a very good improvement effect on dark circles, dry eyes and eye astringency and has very obvious effects of soothing the nerves and tranquilizing the mind. After the essential oil is microencapsulated, the volatilization loss of the essential oil can be effectively reduced through the sealing effect of the wall material, and the storage time and the use stability of the essential oil are improved.

Owner:TIANJIN FUQIN SCI & TECH

Antibacterial microcapsule capable of controllably releasing cinnamyl aldehyde and preparation method thereof

ActiveCN114522635AEfficient embeddingImprove solubilityAntibacterial agentsBiocideColiform bacilliAlcohol ethyl

The invention discloses an antibacterial microcapsule capable of controllably releasing cinnamyl aldehyde and a preparation method of the antibacterial microcapsule. The preparation method comprises the following steps: dispersing starch in an ethanol aqueous solution 1, and dropwise adding a NaOH solution; stirring, dropwise adding an ethanol water solution 2, and centrifuging; washing and dispersing by using an ethanol water solution 3, neutralizing and centrifuging by using an ethanol hydrochloric acid solution, washing once by using an ethanol water solution 4 and absolute ethyl alcohol respectively, drying, crushing and sieving to obtain hollow V-shaped starch; the preparation method comprises the following steps: dispersing cinnamyl aldehyde in absolute ethyl alcohol containing cinnamyl aldehyde, and then adding deionized water until the mass concentration of the ethyl alcohol is 40-60%; and sealing and stirring, cooling to room temperature, centrifuging, washing and drying to obtain the antibacterial microcapsule. The prepared microcapsule can efficiently package cinnamyl aldehyde (62.38 mg / g), has an excellent controlled release effect (continuous release for 3 weeks at normal temperature) on cinnamyl aldehyde, and can remarkably inhibit growth of staphylococcus aureus and escherichia coli (the diameter of an inhibition zone reaches 12 mm).

Owner:SOUTH CHINA UNIV OF TECH +1

Carbon dioxide adsorbent, carbon dioxide adsorption device and manufacturing method thereof

ActiveCN106179179BImprove adsorption efficiencyEnhanced surface potential energyNitrous oxide captureProductsMagnesium saltSorbent

The invention discloses a carbon dioxide adsorbent, a carbon dioxide adsorption device and a manufacturing method of the carbon dioxide adsorption device. The carbon dioxide adsorbent is prepared from 20-60 parts by weight of titanium oxide, 30-70 parts by weight of aluminium oxide and 10-50 parts by weight of magnesium oxide, adsorbs carbon dioxide in laughing gas efficiently and purifies the laughing gas. The manufacturing method of the carbon dioxide adsorption device comprises the following steps: 1) adding deionized water to a hydrothermal kettle; 2) adding titanium salt, aluminium salt and magnesium salt to the hydrothermal kettle; 3) preparing a salt solution from a modifier and adding the salt solution to the hydrothermal kettle; 4) placing a blank filling layer into the hydrothermal kettle and performing hydrothermal treatment; 5) taking out the filling layer to obtain an adsorbent filling layer; 6) installing the adsorbent filling layer on a filtering channel of the carbon dioxide adsorption device. With adoption of the manufacturing method, nanoscale carbon dioxide adsorbent is uniformly attached to the filling layer, so that the adsorbent filling layer has efficient carbon dioxide adsorption performance.

Owner:SUZHOU JINHONG GAS CO LTD

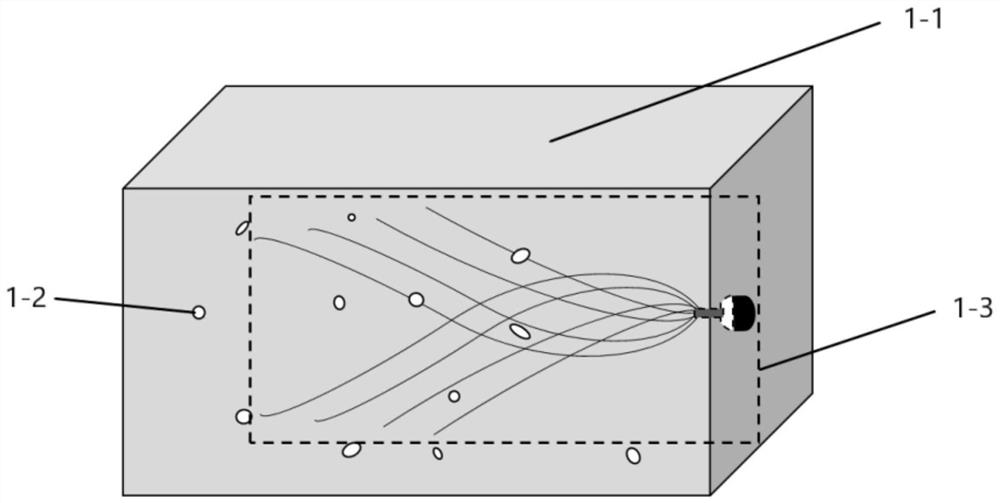

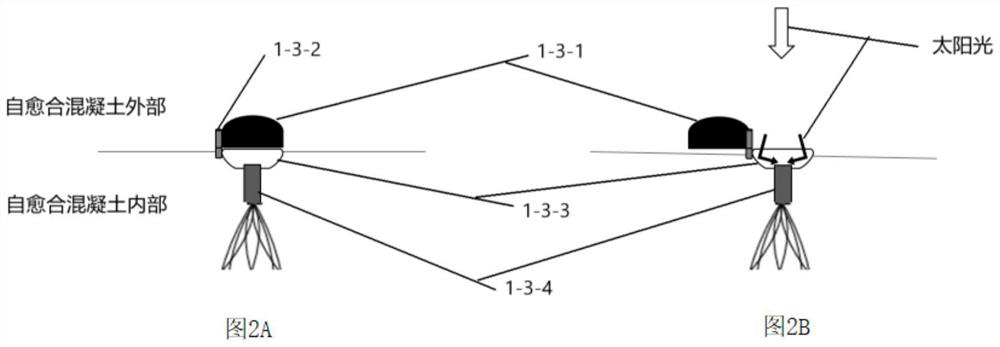

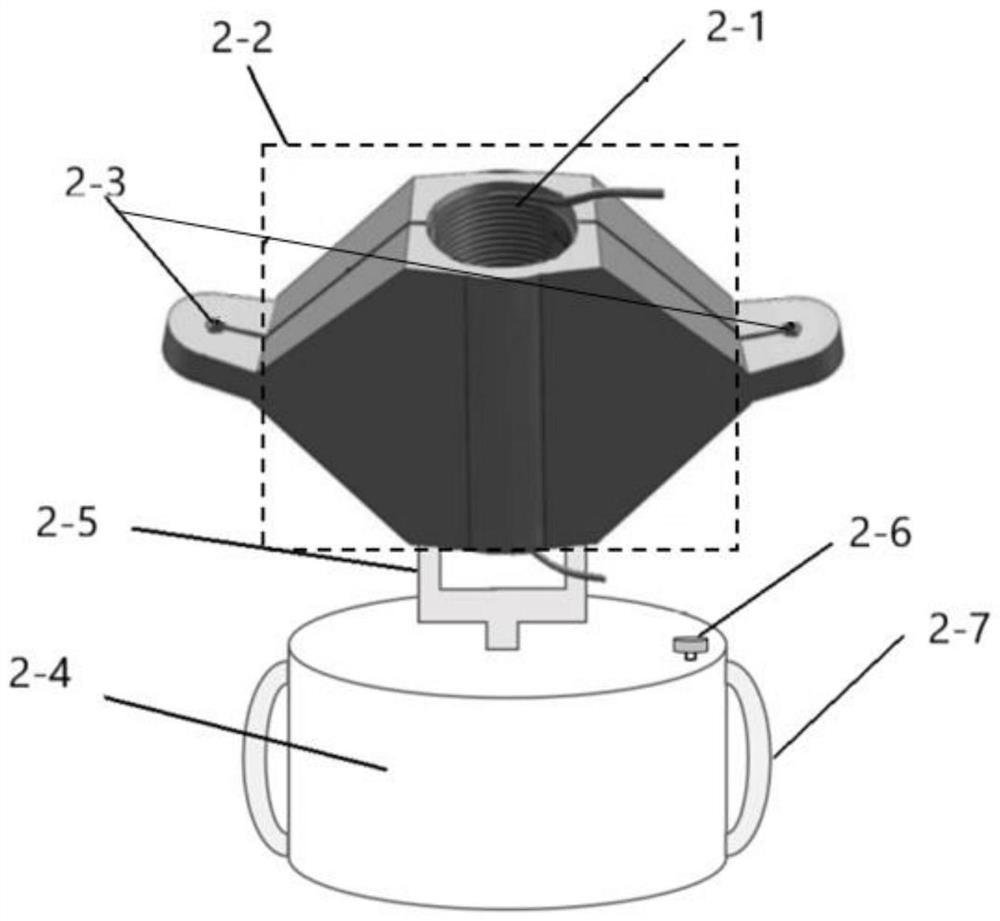

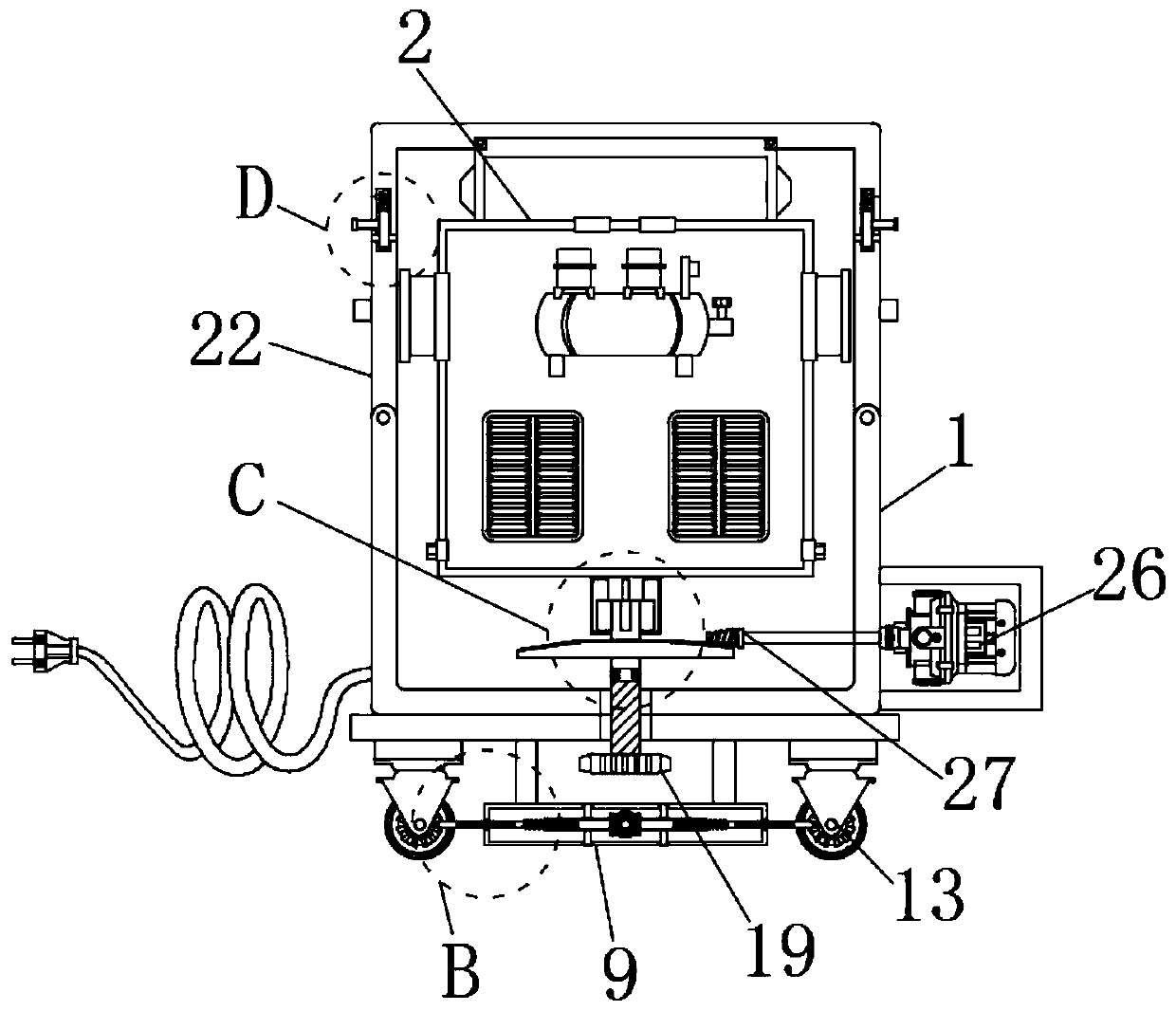

Photomagnetic coupling type self-healing concrete as well as preparation method and device thereof

ActiveCN114873956AAchieve self-healingAchieve regenerationSolid waste managementCeramic shaping apparatusLight guideArchitectural engineering

The invention discloses optomagnetic coupling type self-healing concrete and a preparation method and device thereof, and belongs to the technical field of functional building materials.The optomagnetic coupling type self-healing concrete comprises a concrete base part, magnetic microcapsules and a light guide device, and the magnetic microcapsules are distributed in the concrete base part; the light guide device is fixed to the concrete base part in a pouring mode. The magnetic microcapsules and the light guide device are added to form the self-healing concrete, and the repair efficiency of internal damage of the concrete and the self-healing capacity of the concrete are greatly improved through coordinated response of a photo-thermal field and a magnetic field and Brownian movement.

Owner:HOHAI UNIV

Negative ion air device

ActiveCN111536617AReduce the actual application effectGood application effectMechanical apparatusLighting and heating apparatusAir purifiersElectric machine

The invention discloses a negative ion air device. The negative ion air device comprises a protective outer shell, a negative ion air device body, a motor and a control panel, the negative ion air device body is arranged in the inner part of the protective outer shell, a second inserting rod is arranged in the inner part of a fixing groove, the motor is installed at the bottom end of the right side of the protective outer shell, the output end of the motor penetrates through the protective outer shell and extends to the inner part of the protective outer shell to be welded and fixed to a toothed bar, and the toothed bar is meshed with the control panel. According to the negative ion air device, a user can conveniently move a negative ion air purifier to all rooms so that air purification can be carried out, damage caused by falling of the negative ion air purifier in the carrying process is avoided, so that the user can increase the swimming speed of negative ions in air, rapidly purifying a fixed-point area can be carried out, diversification of functions of the device is achieved, the purification efficiency of the device is improved, and the practicability of the device is further improved.

Owner:SHENZHEN GUANGDA IND CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com