Carbon dioxide adsorbent, carbon dioxide adsorption device and manufacturing method of carbon dioxide adsorption device

A carbon dioxide and adsorption device technology, which is applied in the field of gas filtration and purification, can solve the problems of non-use, etc., and achieve the effects of uniform pore size distribution, good adsorption performance, and good thermal stability

Active Publication Date: 2016-12-07

SUZHOU JINHONG GAS CO LTD

View PDF3 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

At present, mainstream LCD panel factories are researching higher-level display technologies, and the two major technologies of LTPS and Oxide have begun mass production in foreign mainstream factories. At present, China is still in the stage of research and development or trial production. These two technologies, Both require a large amount of high-purity laughing gas, but the original LCD panel technology hardly uses it, so it promotes the explosion of laughing gas applications

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1~3

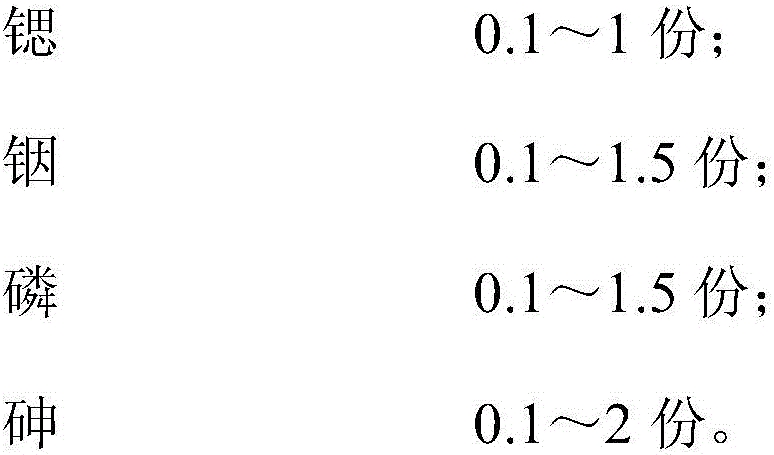

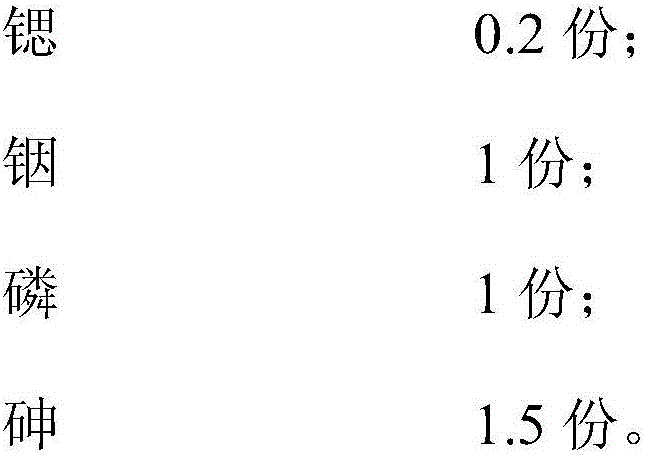

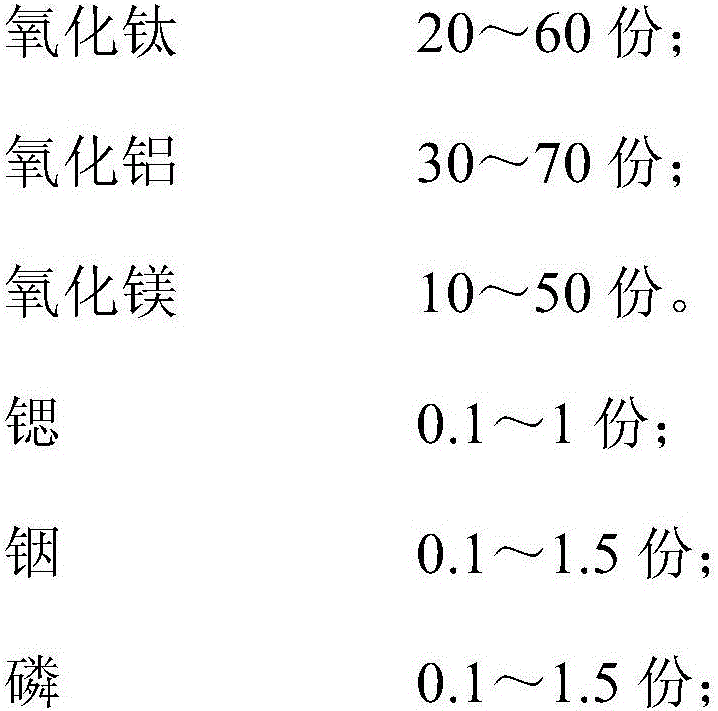

[0050] Embodiment 1~3 prepares raw material by table 1:

[0051] The raw material weight part of table 1 embodiment 1~3

[0052]

[0053]

[0054] And according to the parameter adjustment manufacturing method shown in table 2, carry out the manufacture of carbon dioxide adsorption device:

[0055] The manufacturing conditions of table 2 embodiment 1~3

[0056]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses a carbon dioxide adsorbent, a carbon dioxide adsorption device and a manufacturing method of the carbon dioxide adsorption device. The carbon dioxide adsorbent is prepared from 20-60 parts by weight of titanium oxide, 30-70 parts by weight of aluminium oxide and 10-50 parts by weight of magnesium oxide, adsorbs carbon dioxide in laughing gas efficiently and purifies the laughing gas. The manufacturing method of the carbon dioxide adsorption device comprises the following steps: 1) adding deionized water to a hydrothermal kettle; 2) adding titanium salt, aluminium salt and magnesium salt to the hydrothermal kettle; 3) preparing a salt solution from a modifier and adding the salt solution to the hydrothermal kettle; 4) placing a blank filling layer into the hydrothermal kettle and performing hydrothermal treatment; 5) taking out the filling layer to obtain an adsorbent filling layer; 6) installing the adsorbent filling layer on a filtering channel of the carbon dioxide adsorption device. With adoption of the manufacturing method, nanoscale carbon dioxide adsorbent is uniformly attached to the filling layer, so that the adsorbent filling layer has efficient carbon dioxide adsorption performance.

Description

technical field [0001] The invention relates to a carbon dioxide adsorbent, a carbon dioxide adsorption device and a manufacturing method thereof, and belongs to the technical field of gas filtration and purification. Background technique [0002] In China's laughing gas application market, the largest customer group is the LCD panel industry, which needs 5N high-purity laughing gas. At present, mainstream LCD panel factories are researching higher-level display technologies, and the two major technologies of LTPS and Oxide have begun mass production in foreign mainstream factories. At present, China is still in the stage of research and development or trial production. These two technologies, Both require the use of high-purity laughing gas in large quantities, but the original LCD panel technology hardly uses it, so it promotes the explosion of laughing gas applications. [0003] Applications in other Asia-Pacific regions are mainly in South Korea, Taiwan and Japan. Sout...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B01J20/08B01D53/04C01B21/22

CPCB01D53/04B01D2257/504B01D2259/401B01J20/0211B01J20/0248B01J20/0259B01J20/04B01J20/041B01J20/08C01B21/22C01B2210/0015Y02C20/10Y02C20/40Y02P20/151

Inventor 金向华孙猛陈琦峰

Owner SUZHOU JINHONG GAS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com