A bi-component adhesive and its preparation method thereof

An adhesive and two-component technology, applied in the direction of non-polymer adhesive additives, adhesive types, adhesives, etc., can solve problems such as seal failure, high brittleness, and irritating odor, and achieve improved adhesion Strength, increase service life, and promote the effect of Brownian motion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

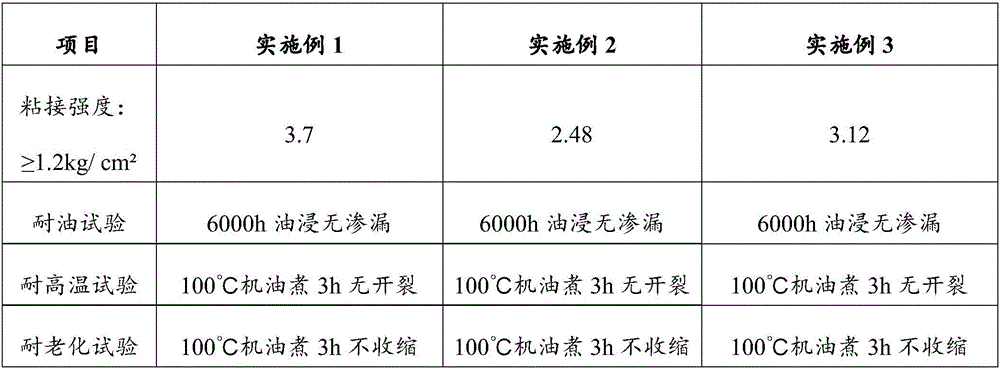

Examples

Embodiment 1

[0032] A two-component adhesive, the adhesive comprises component A and component B, wherein,

[0033] Component A contains the following components by weight: 30 parts of polyamide resin, 4 parts of benzyl alcohol, 100 parts of calcite powder, 3 parts of coupling agent KH-550; Component B contains the following components by weight : 85 parts of epoxy resin, 6 parts of benzyl alcohol, 22 parts of aluminum hydroxide, 2 parts of accelerator Z612;

[0034] Component A and component B are stored separately, and when used, the weight ratio of component A:component B=2:1 is formulated for use.

[0035] The preparation method of this adhesive comprises the steps:

[0036] a. Preparation of component A: Weigh the polyamide resin and benzyl alcohol of the prescribed amount and mix them evenly, heat to 50°C, add the calcite powder of the prescribed amount and stir for 60 minutes; then add the coupling agent of the prescribed amount and continue stirring for 13 minutes ;

[0037] b. ...

Embodiment 2

[0041] A two-component adhesive, the adhesive comprises component A and component B, wherein,

[0042] Component A contains the following components by weight: 35 parts of polyamide resin, 6 parts of benzyl alcohol, 130 parts of calcite powder, 5 parts of coupling agent KH-570; Component B contains the following components by weight : 100 parts of epoxy resin, 7 parts of benzyl alcohol, 27 parts of aluminum hydroxide, 4.2 parts of accelerator K-54;

[0043] Component A and component B are stored separately, and when used, the weight ratio of component A:component B=3:1 is formulated for use.

[0044] The preparation method of this adhesive comprises the steps:

[0045] a. Preparation of component A: Weigh the polyamide resin and benzyl alcohol of the prescribed amount and mix them evenly, heat to 40°C, add the calcite powder of the prescribed amount and stir for 30 minutes; then add the coupling agent of the prescribed amount and continue to stir for 15 minutes ;

[0046] b...

Embodiment 3

[0050] A two-component adhesive, the adhesive comprises component A and component B, wherein,

[0051] Component A contains the following components by weight: 33 parts of polyamide resin, 5 parts of benzyl alcohol, 125 parts of calcite powder, 4 parts of coupling agent KBM-903; Component B contains the following components by weight : 95 parts of epoxy resin, 6 parts of benzyl alcohol, 25 parts of aluminum hydroxide, 3.5 parts of accelerator Z612;

[0052] Component A and component B are stored separately, and when used, the weight ratio of component A: component B = 4:1 is formulated for use.

[0053] The preparation method of this adhesive comprises the steps:

[0054] a. Preparation of component A: Weigh the polyamide resin and benzyl alcohol of the prescribed amount and mix them evenly, heat to 60°C, add the calcite powder of the prescribed amount and stir for 90 minutes; then add the coupling agent of the prescribed amount and continue stirring for 10 minutes ;

[005...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com