Phase-change dust-removing and mist-removing paralleling device of high-efficiency pneumatic pipe bundle and application

A defogging device and phase change technology, which are applied in the fields of combination devices, dispersed particle separation, chemical instruments and methods, etc., can solve the problems of undiscovered patent publications, etc., and achieve the improvement of defogging and dust removal effect, centrifugal effect, and processing capacity. improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Hereinafter, the present invention will be further described in detail by taking the embodiment of the accompanying drawings as an example. The following embodiments are only descriptive, not restrictive, and cannot limit the protection scope of the present invention.

[0039] Structures not described in detail in the present invention can be understood as conventional structures in the art.

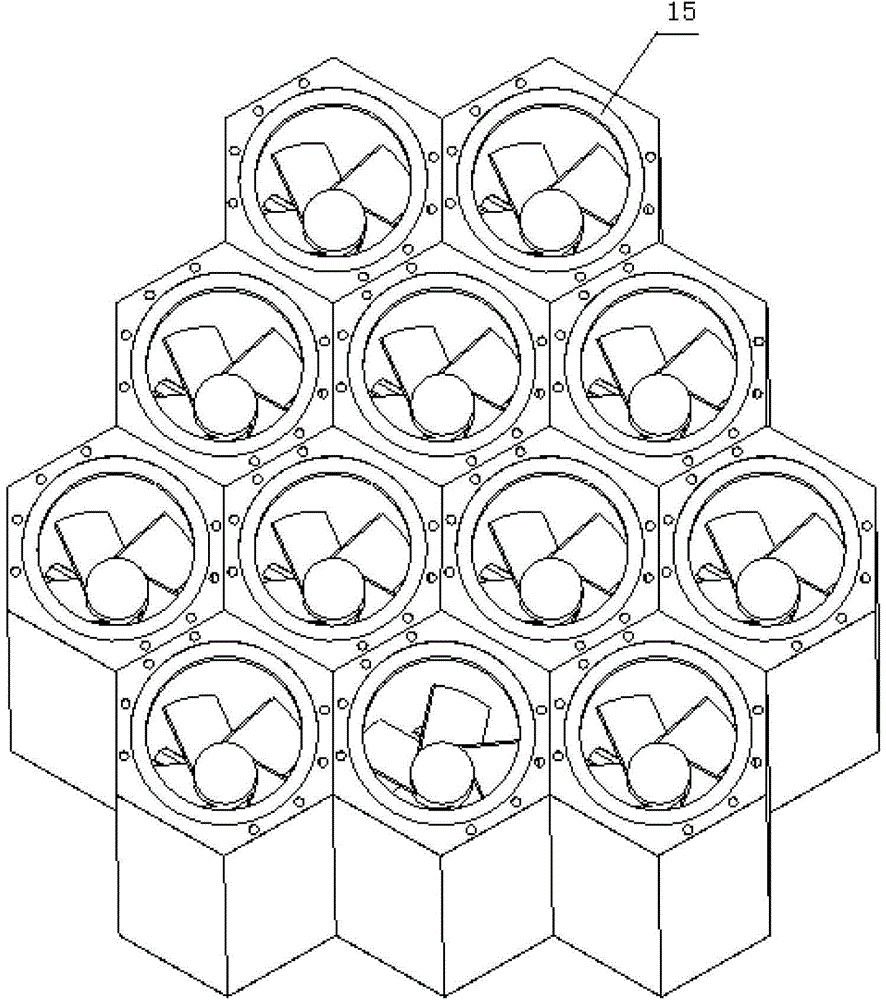

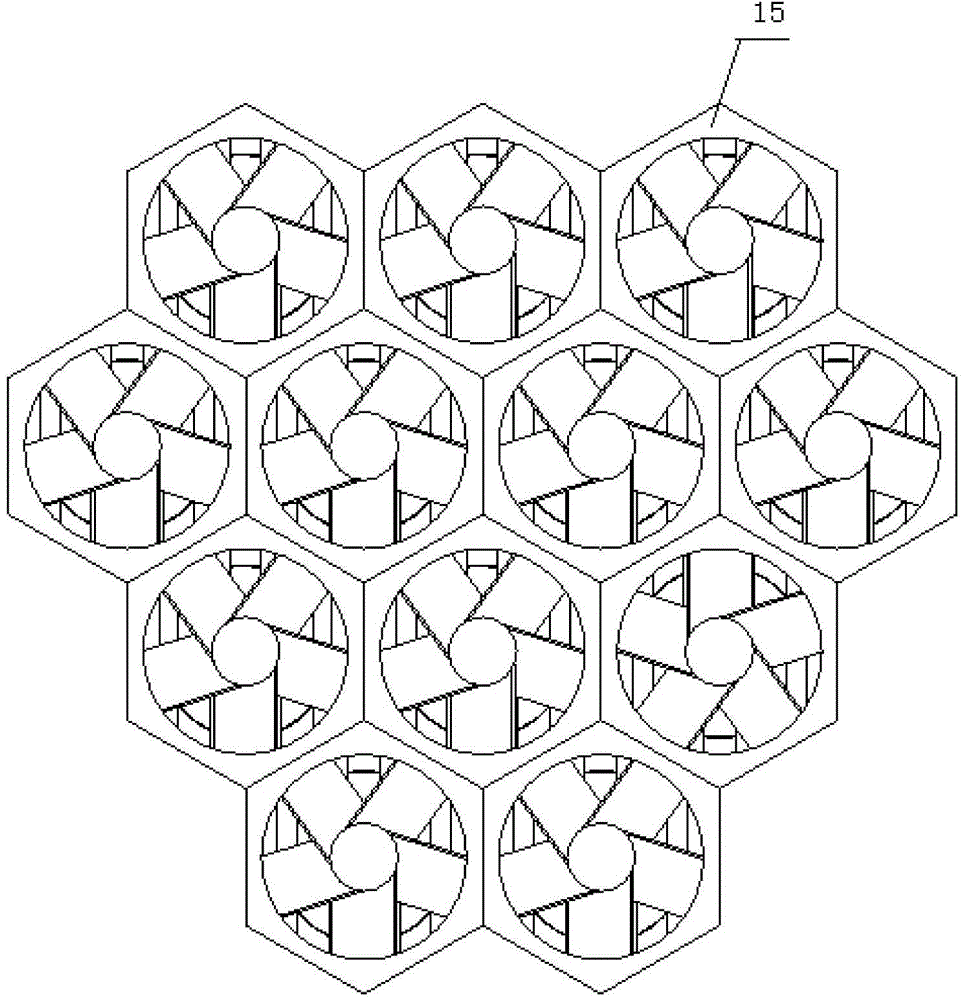

[0040] A high-efficiency pneumatic tube bundle phase change dedusting and demisting parallel device, such as figure 1 and figure 2 As shown, the device includes a plurality of high-efficiency pneumatic tube bundle phase-change dust and mist removal devices 15 connected in parallel. In this embodiment, two adjacent high-efficiency pneumatic tube bundle phase-change dedusting and mist removal devices are closely connected together by bonding, welding or holes to prevent short circuit of flue gas. The inner wall of the waste gas treatment device is sealed with a sealing plate (not...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com