Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

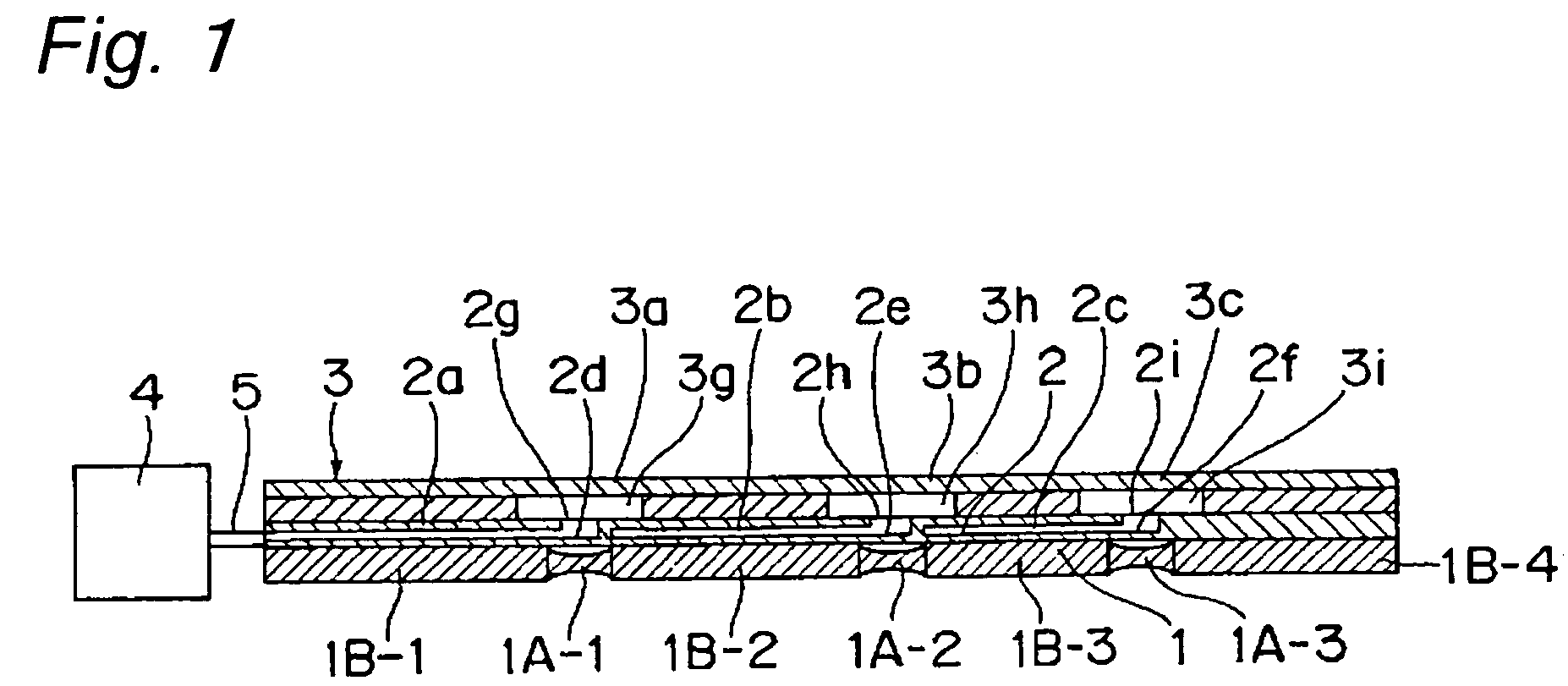

455 results about "Pneumatic tube" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Pneumatic tubes (or capsule pipelines; also known as pneumatic tube transport or PTT) are systems that propel cylindrical containers through networks of tubes by compressed air or by partial vacuum. They are used for transporting solid objects, as opposed to conventional pipelines, which transport fluids. Pneumatic tube networks gained acceptance in the late 19th and early 20th centuries for ...

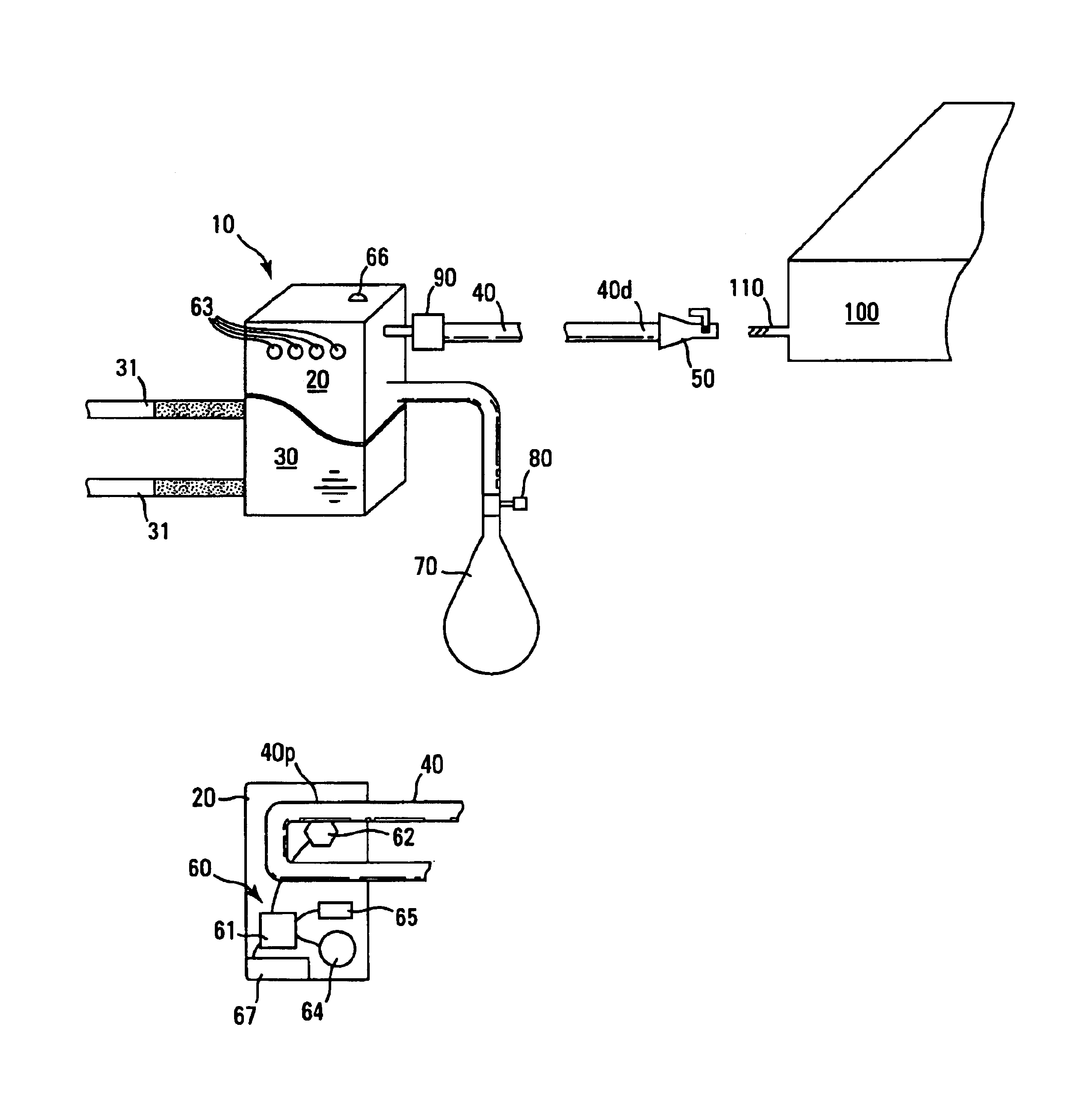

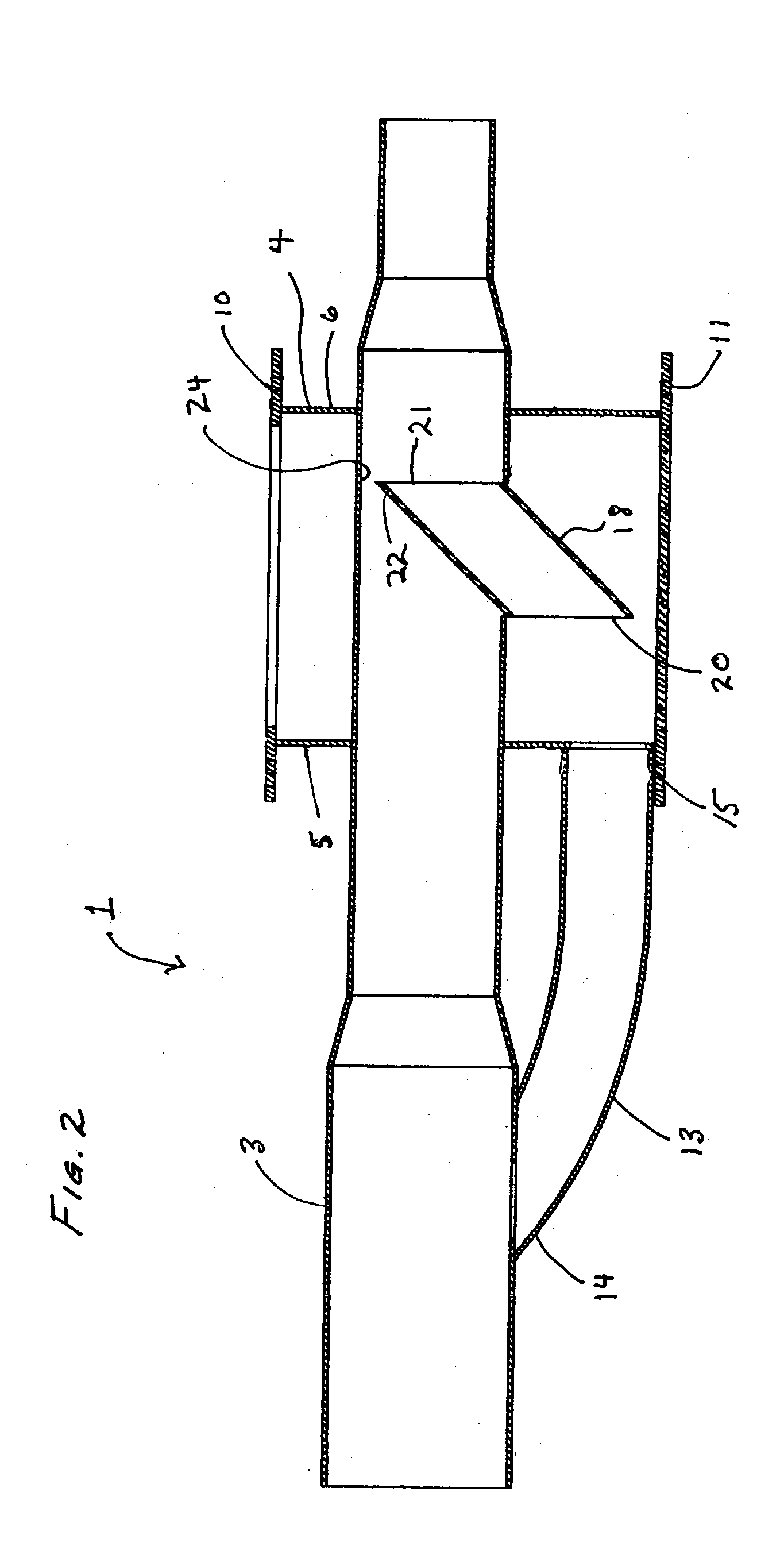

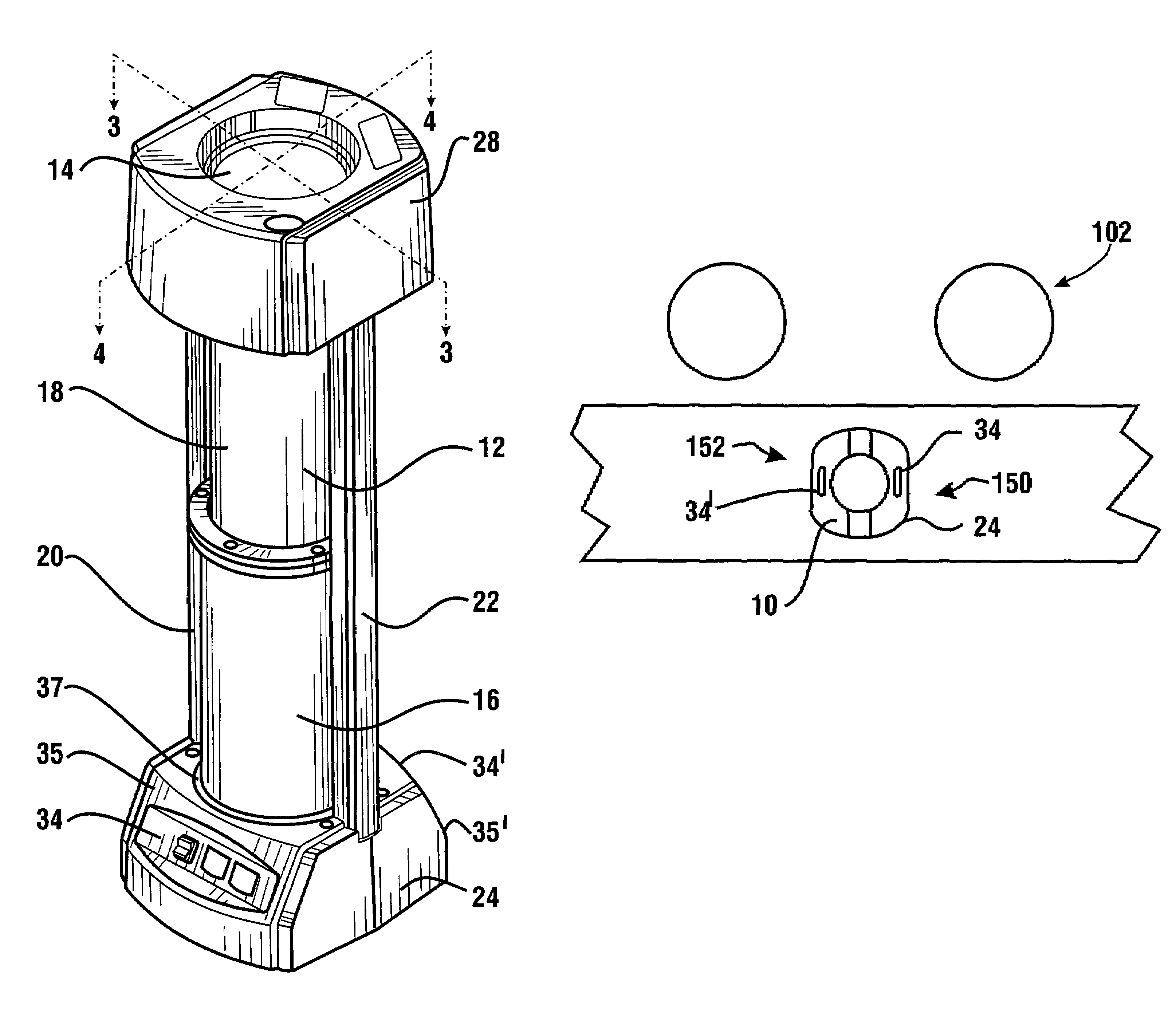

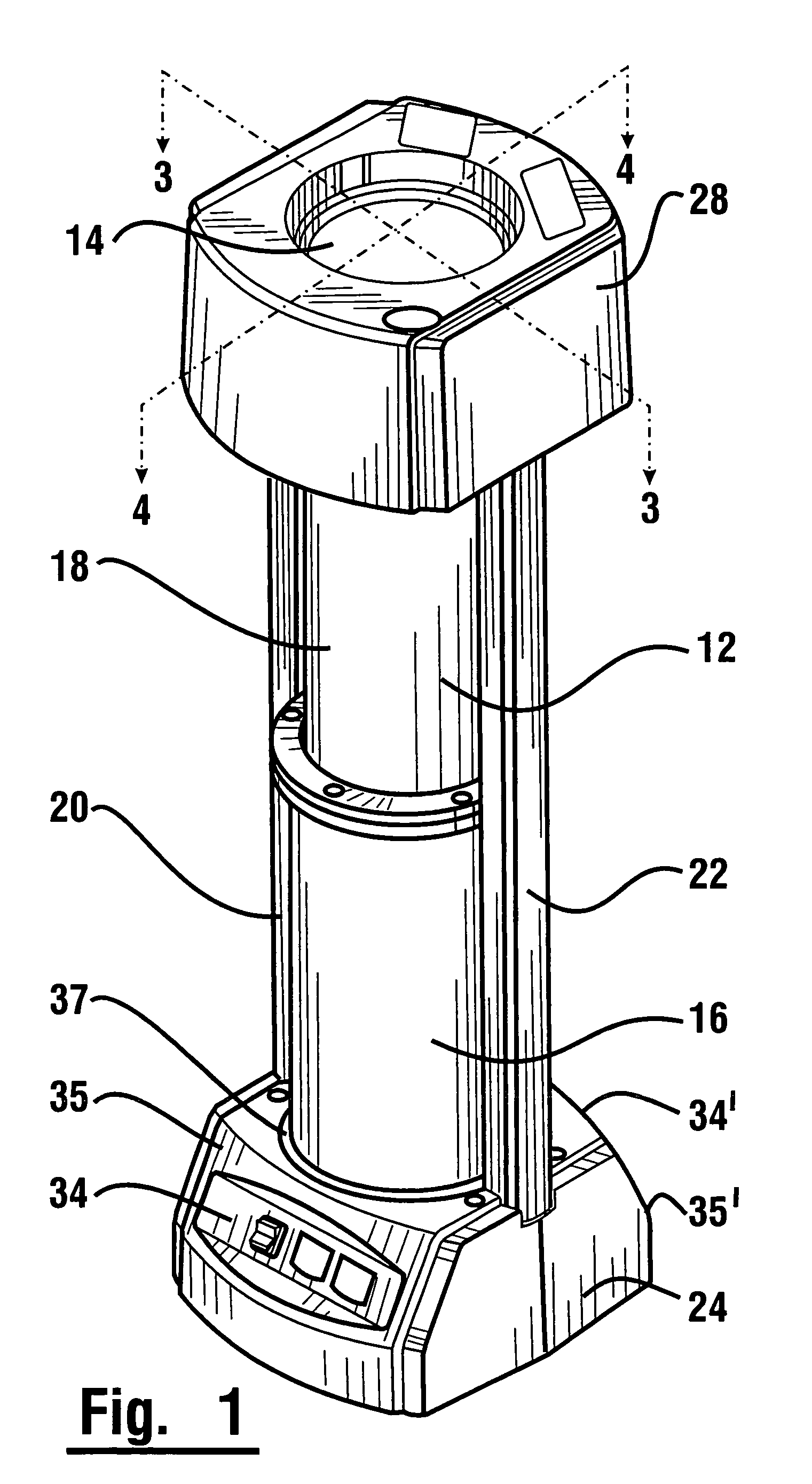

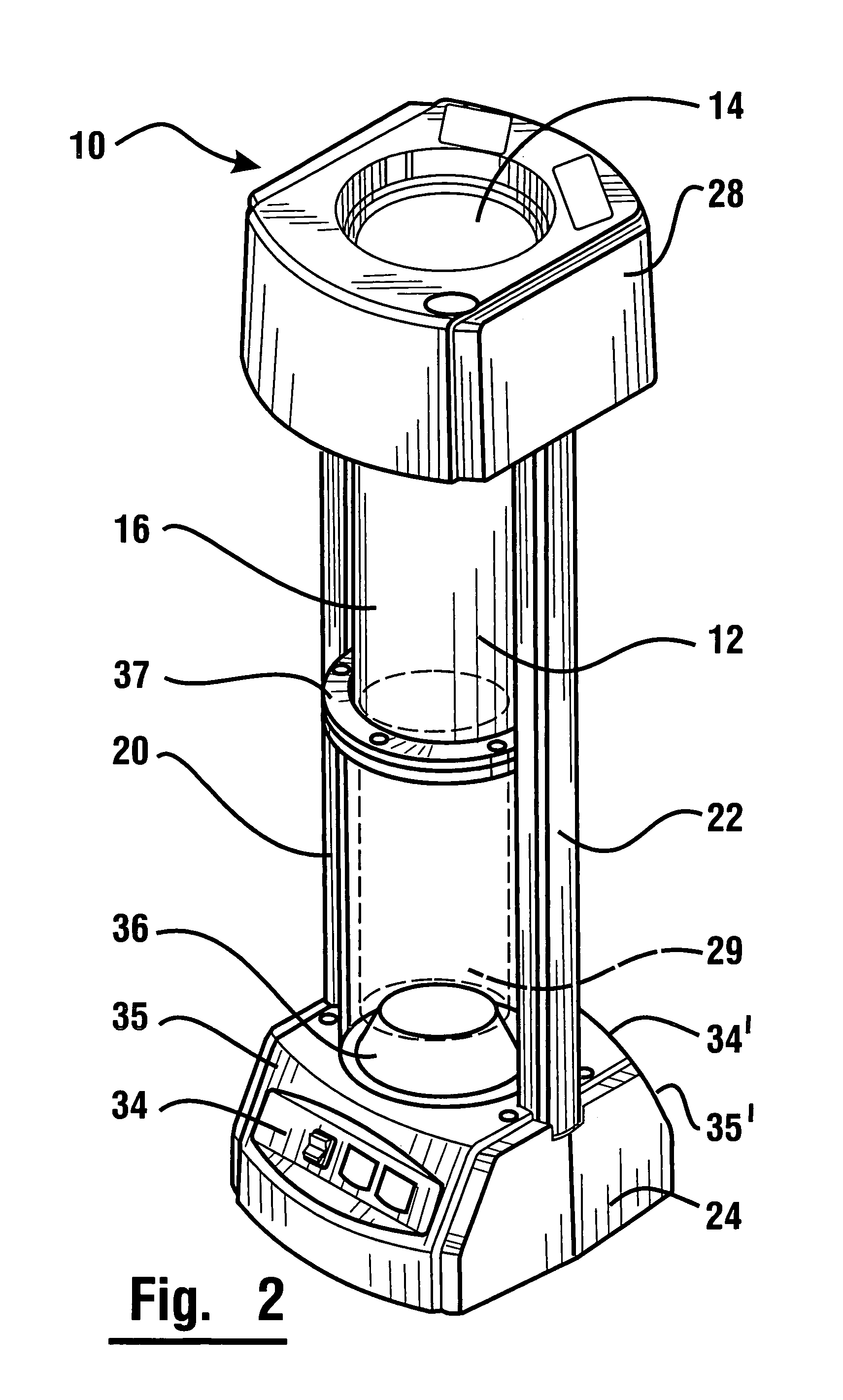

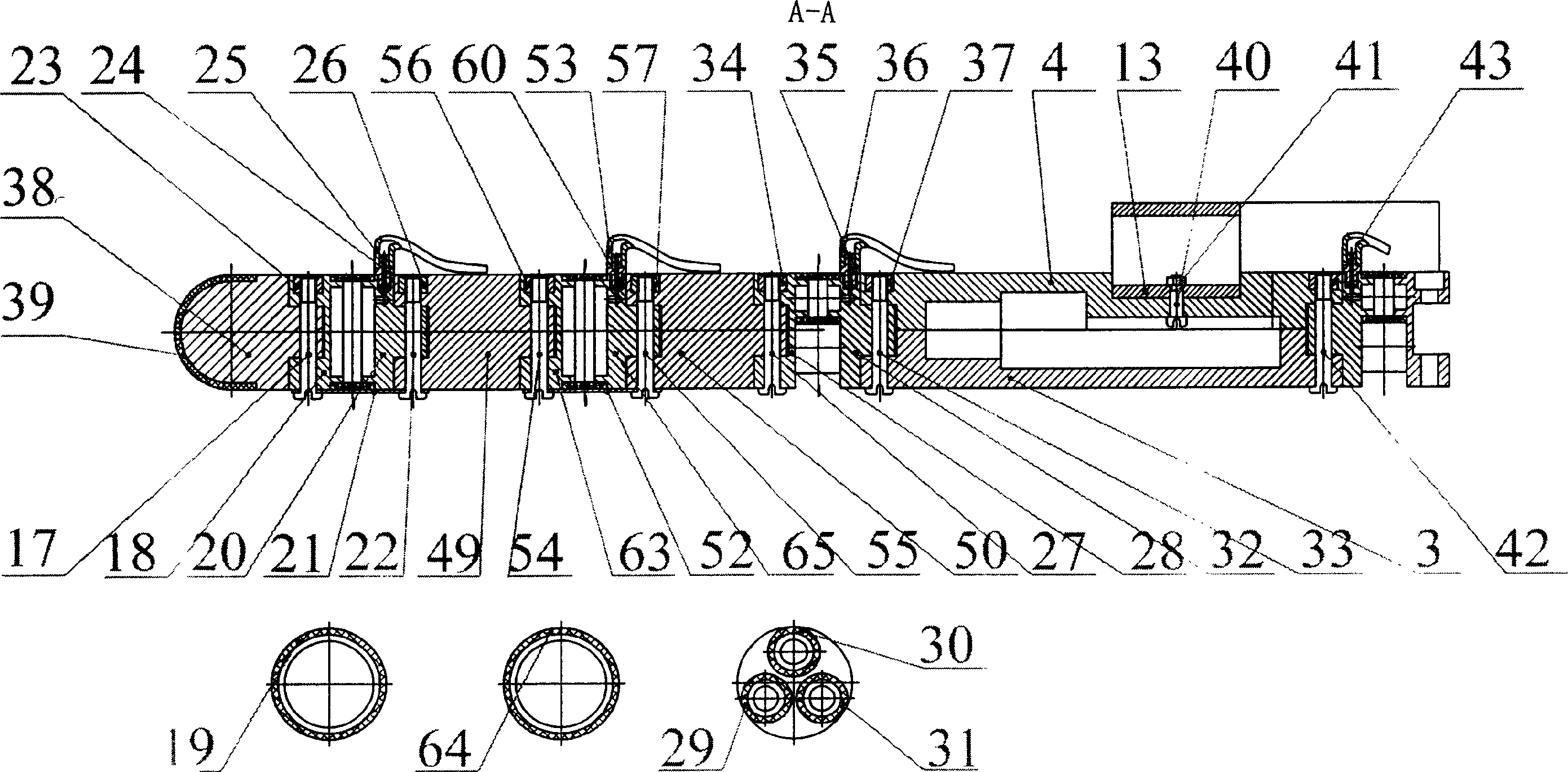

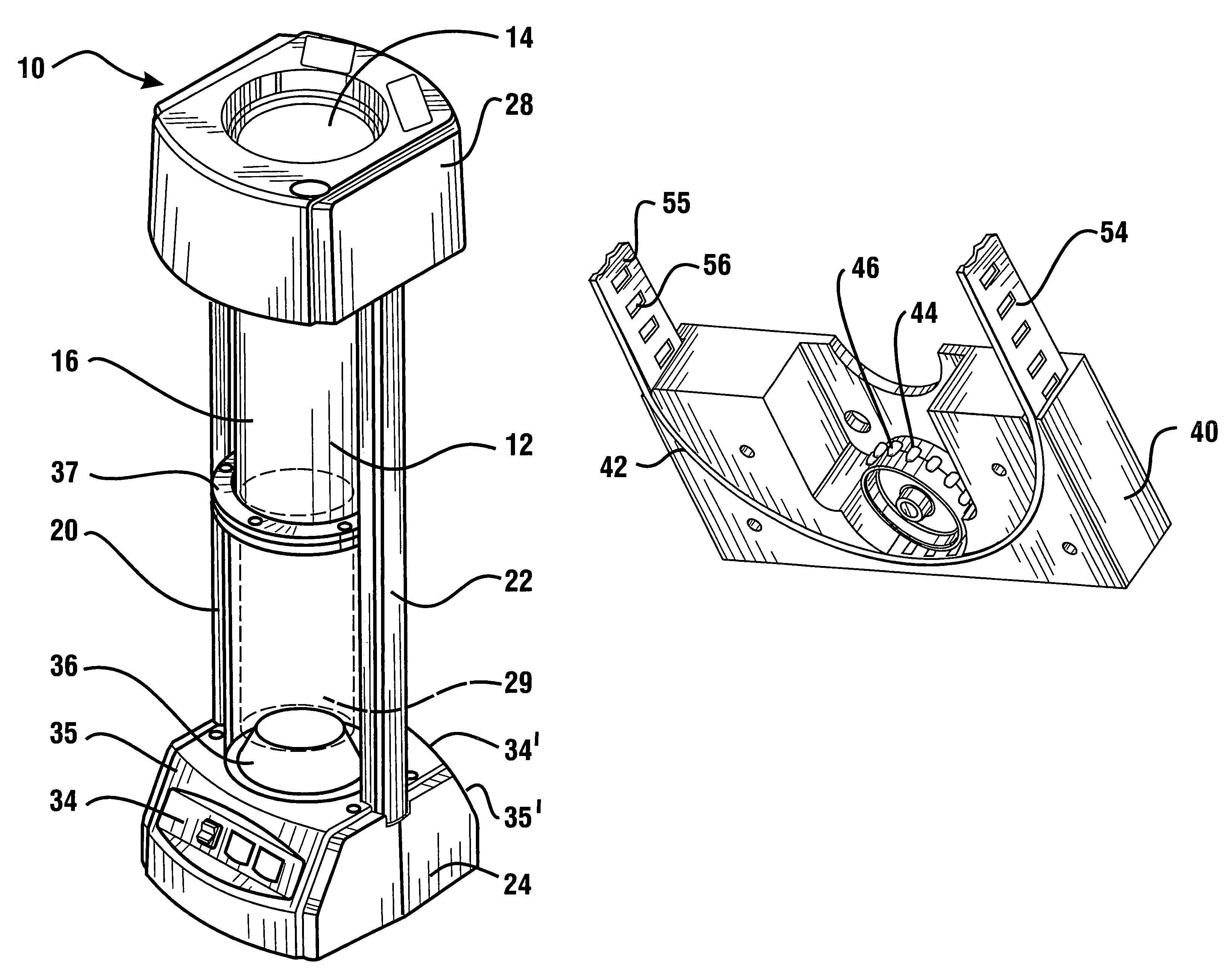

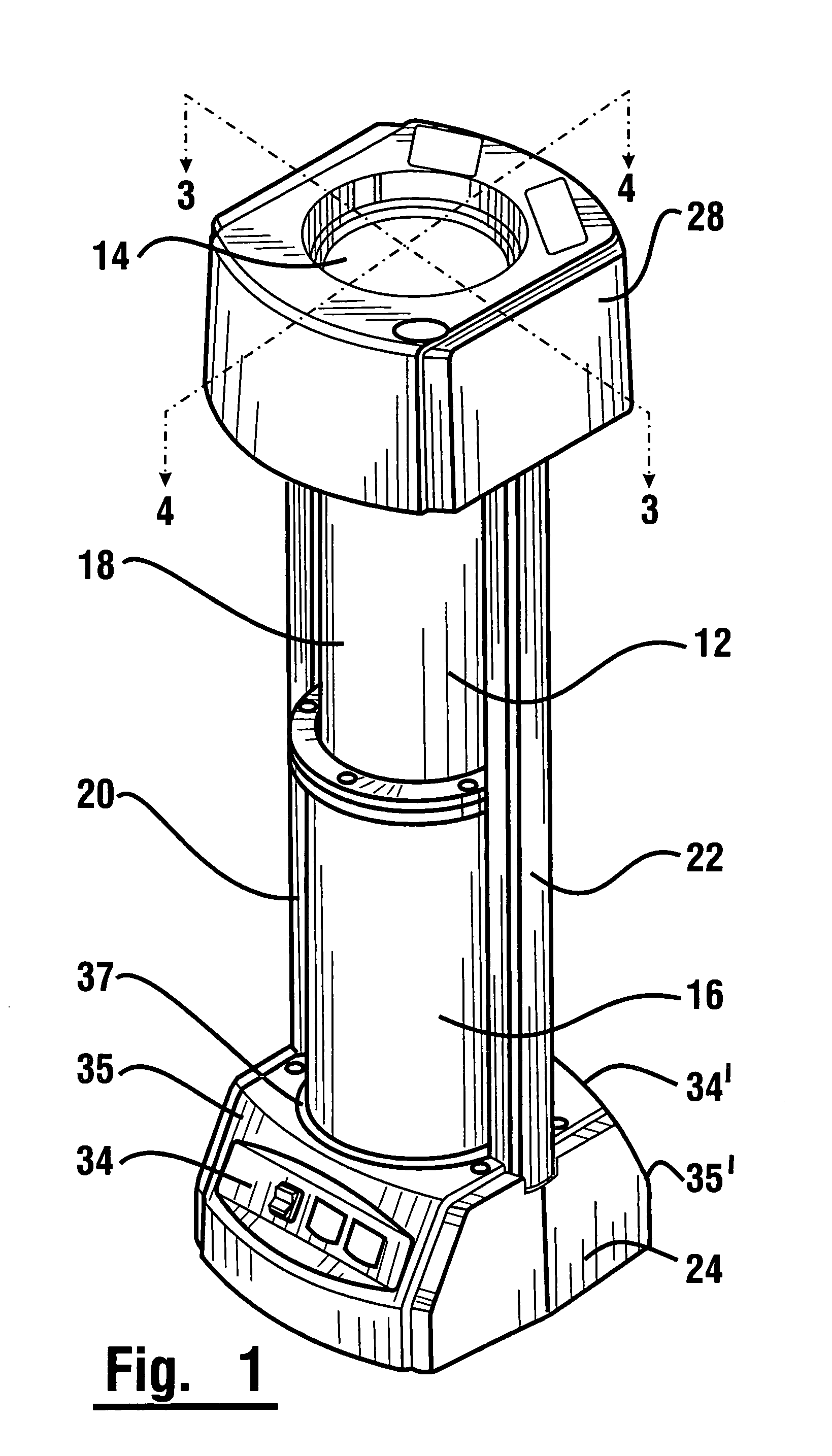

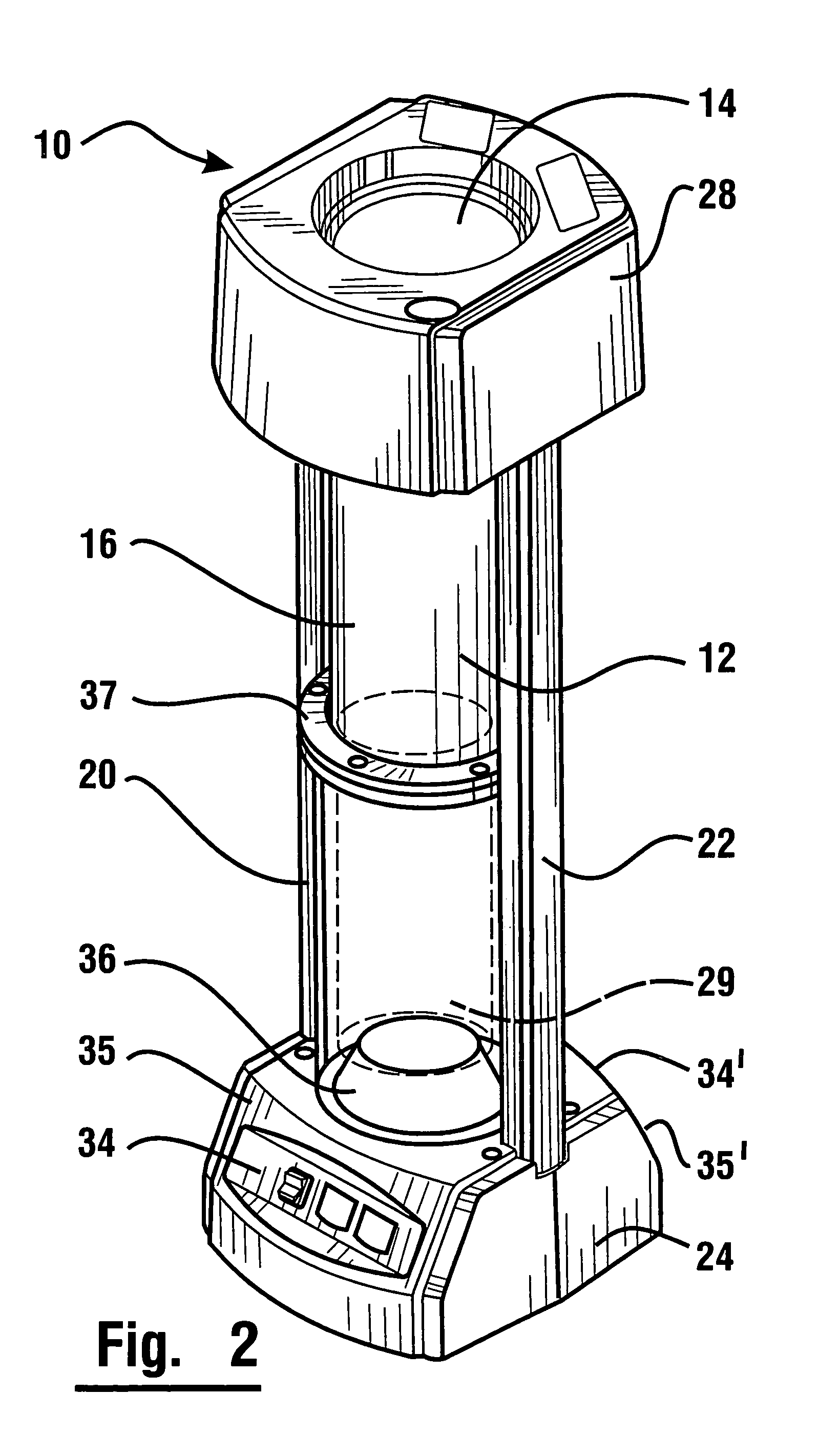

Inflation level monitoring system for inflatable cushions

InactiveUS6848135B1Efficiently attachedStuffed mattressesSpring mattressesMonitoring systemPressure sense

A monitoring system for monitoring inflation pressure within an inflatable cushion. The monitoring system includes a housing, a pneumatic tube, a locking adaptor and a sensing and signaling system. The pneumatic tube extends through the housing with the locking adaptor attached to the distal end of the pneumatic tube. The locking adaptor is effective for releasably and sealingly attaching the pneumatic tube to a stem valve on an inflatable cushion. The sensing and signaling is retained within the housing and includes at least a pressure sensor in pneumatic communication with the pneumatic tube proximate a proximal end of the pneumatic tube, and a means in communication with the pressure sensor for generating a perceptible signal when the pressure sensed by the pressure sensor falls below a predetermined threshold value.

Owner:AQUILA OF WISCONSIN

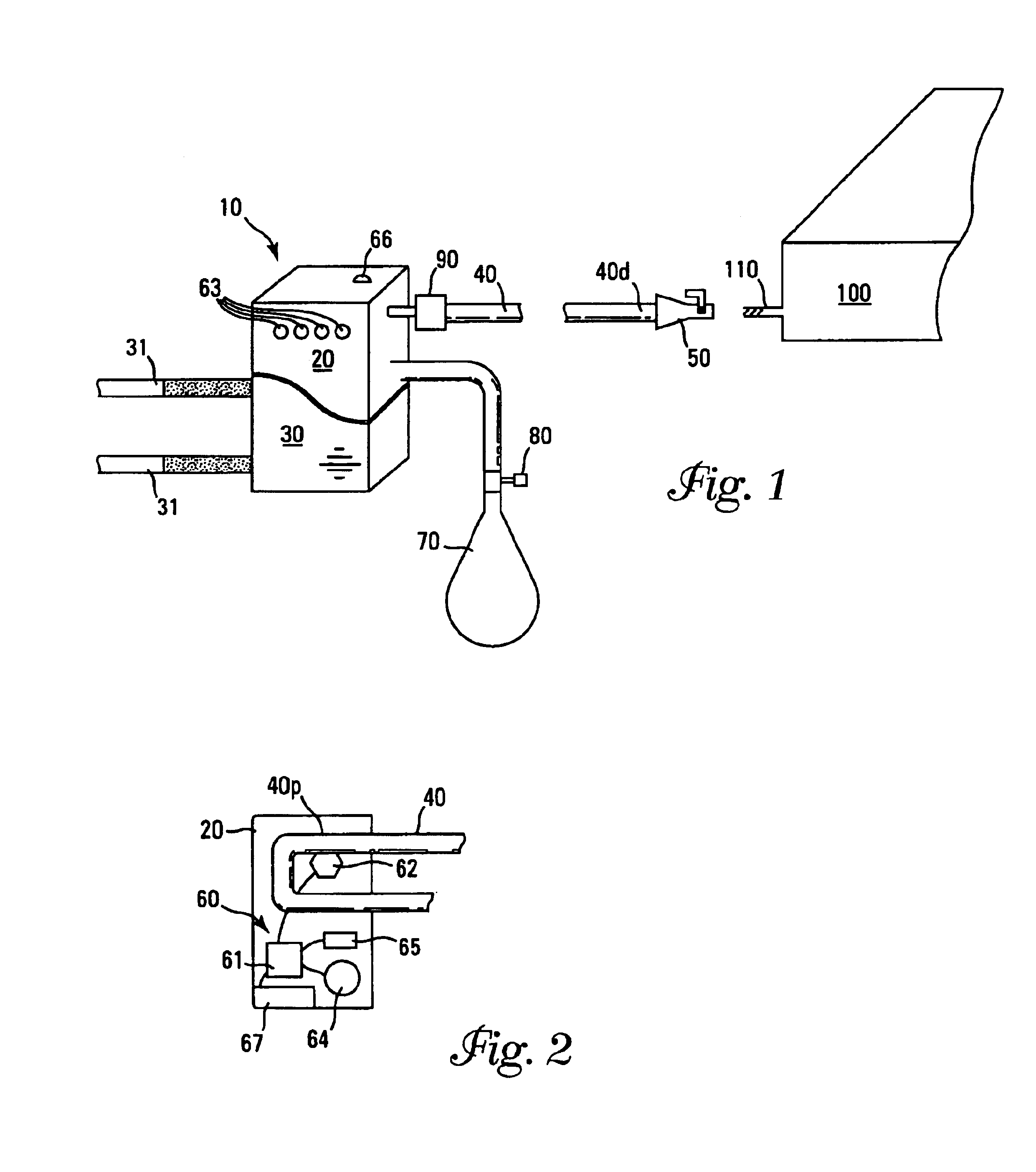

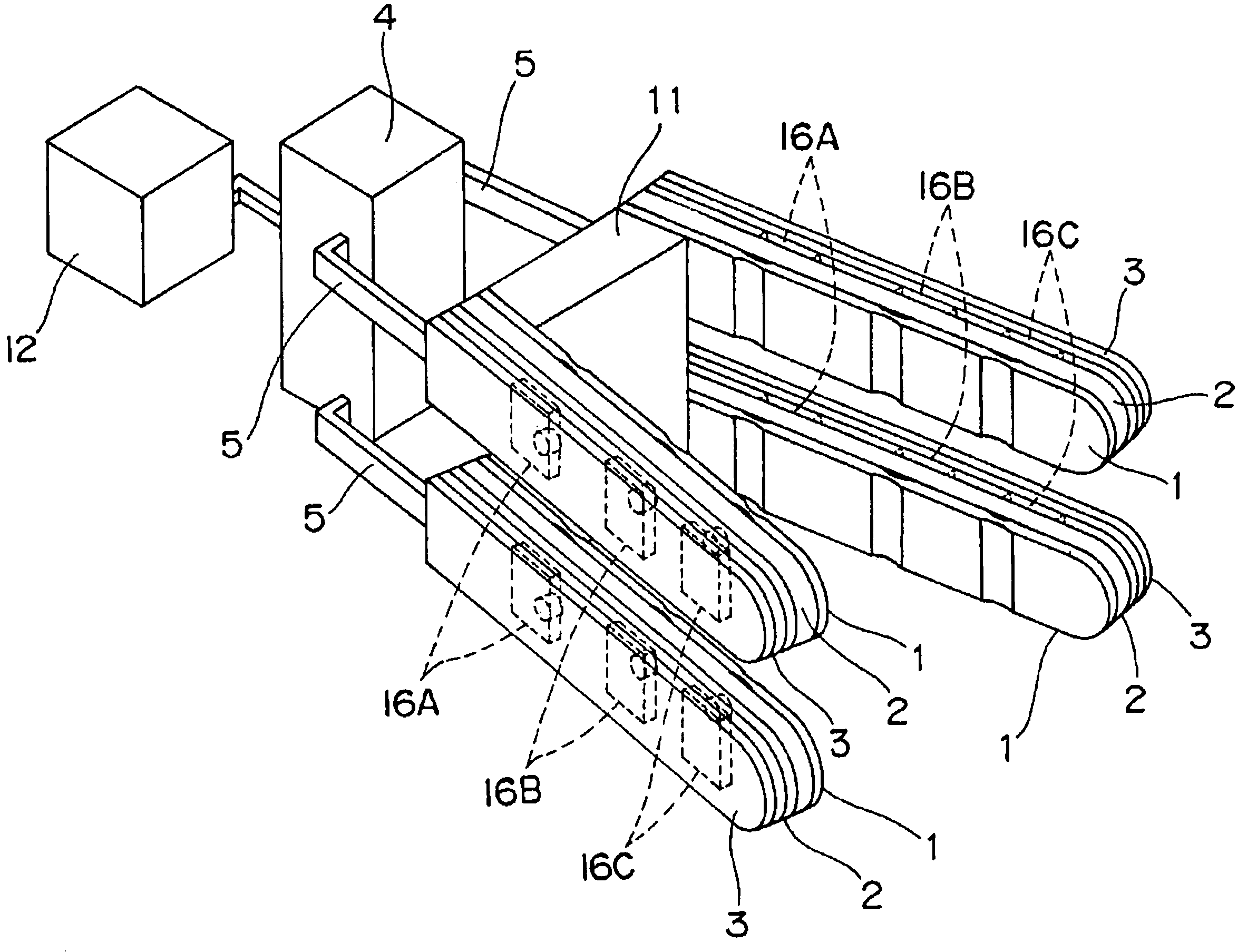

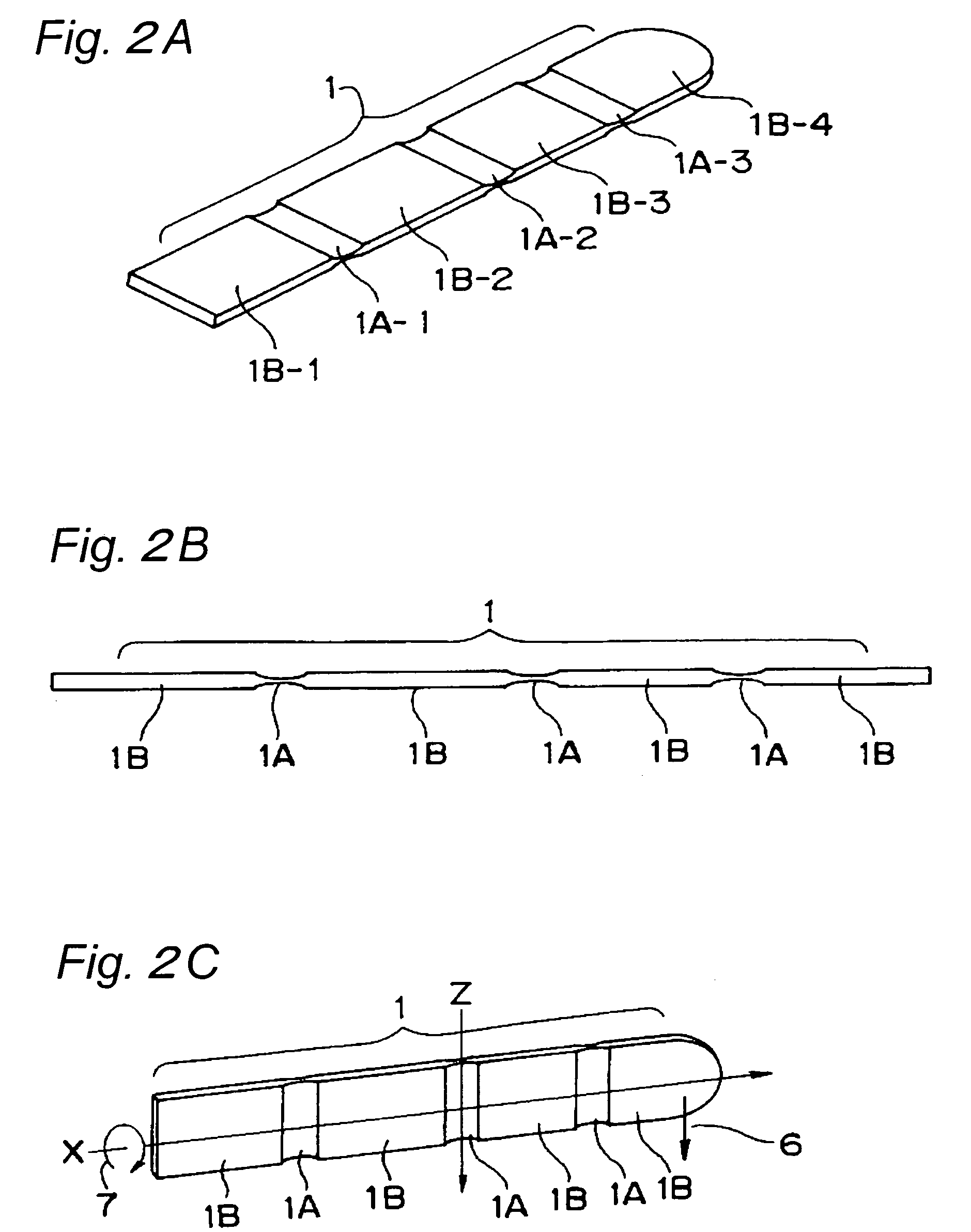

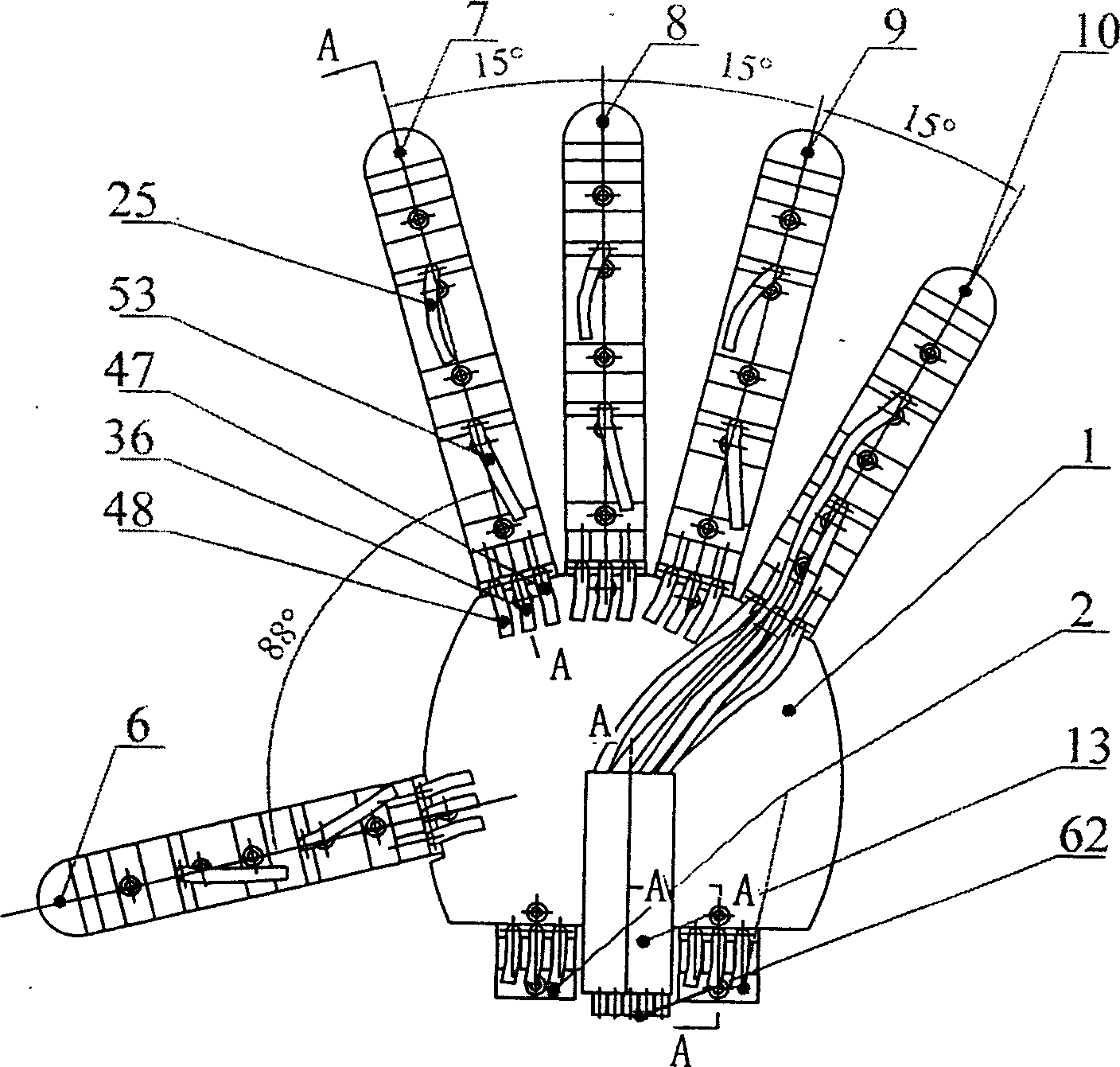

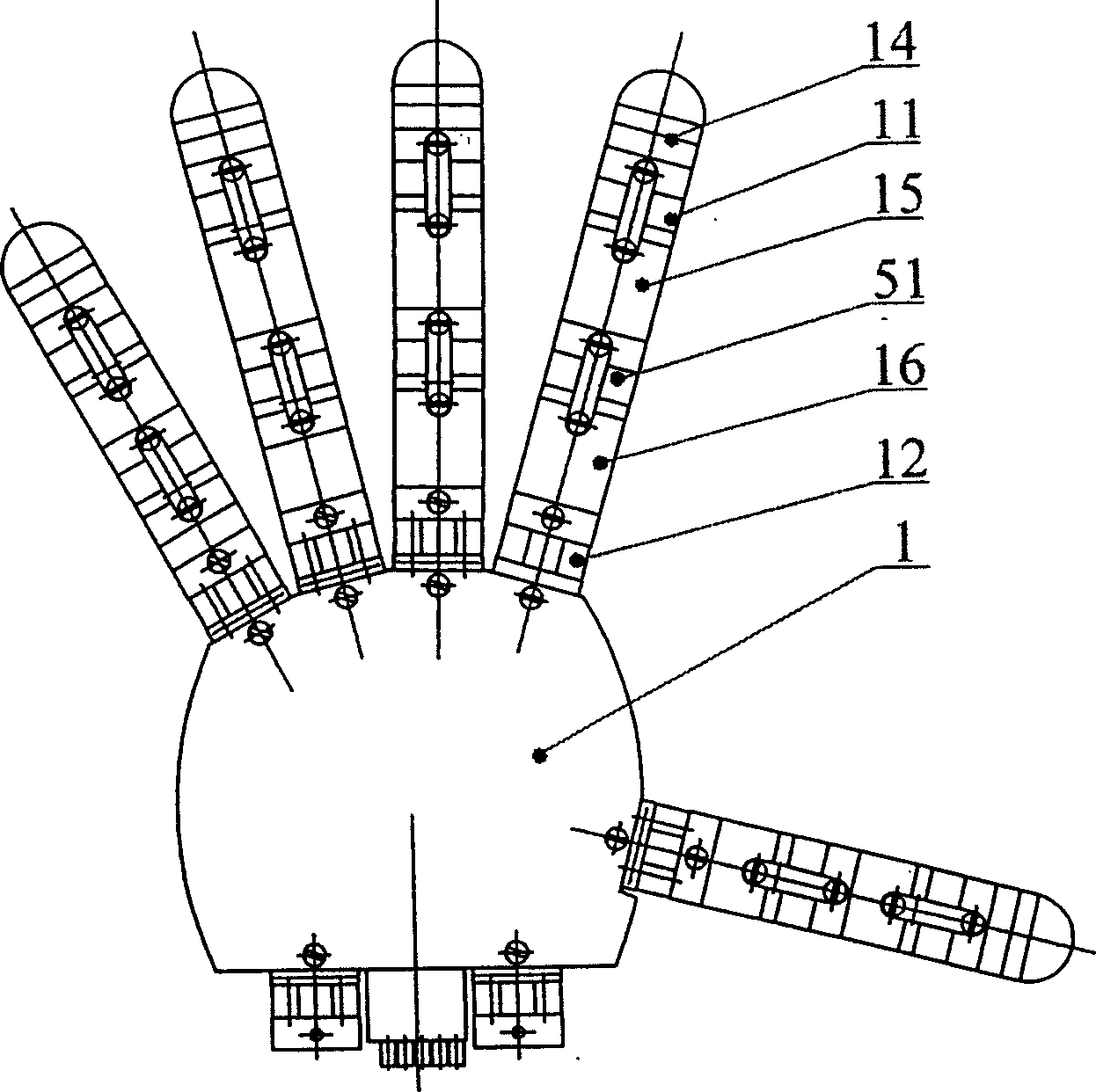

Laminated-type multi-joint portion drive mechanism and manufacturing method therefor, grasping hand and robot arm provided with the same

A laminated-type multi-joint portion drive mechanism includes a bone member having at least two elastic deformation portions, a laminated-type pneumatic tube member having at least twoline-tubes which are stacked on the bone member and which are connected to a pneumatic drive source, and a planar-type joint-portion deformation member which is stacked on the laminated-type pneumatic tube member and has pneumatic operation chambers which are placed at joint portions confronting the deformation portions, respectively, and which are connected to the tubes, wherein when pneumatic pressure is applied to one of the pneumatic operation chambers, the joint portion corresponding to the pneumatic operation chamber to which the pneumatic pressure is applied is deformable.

Owner:PANASONIC CORP

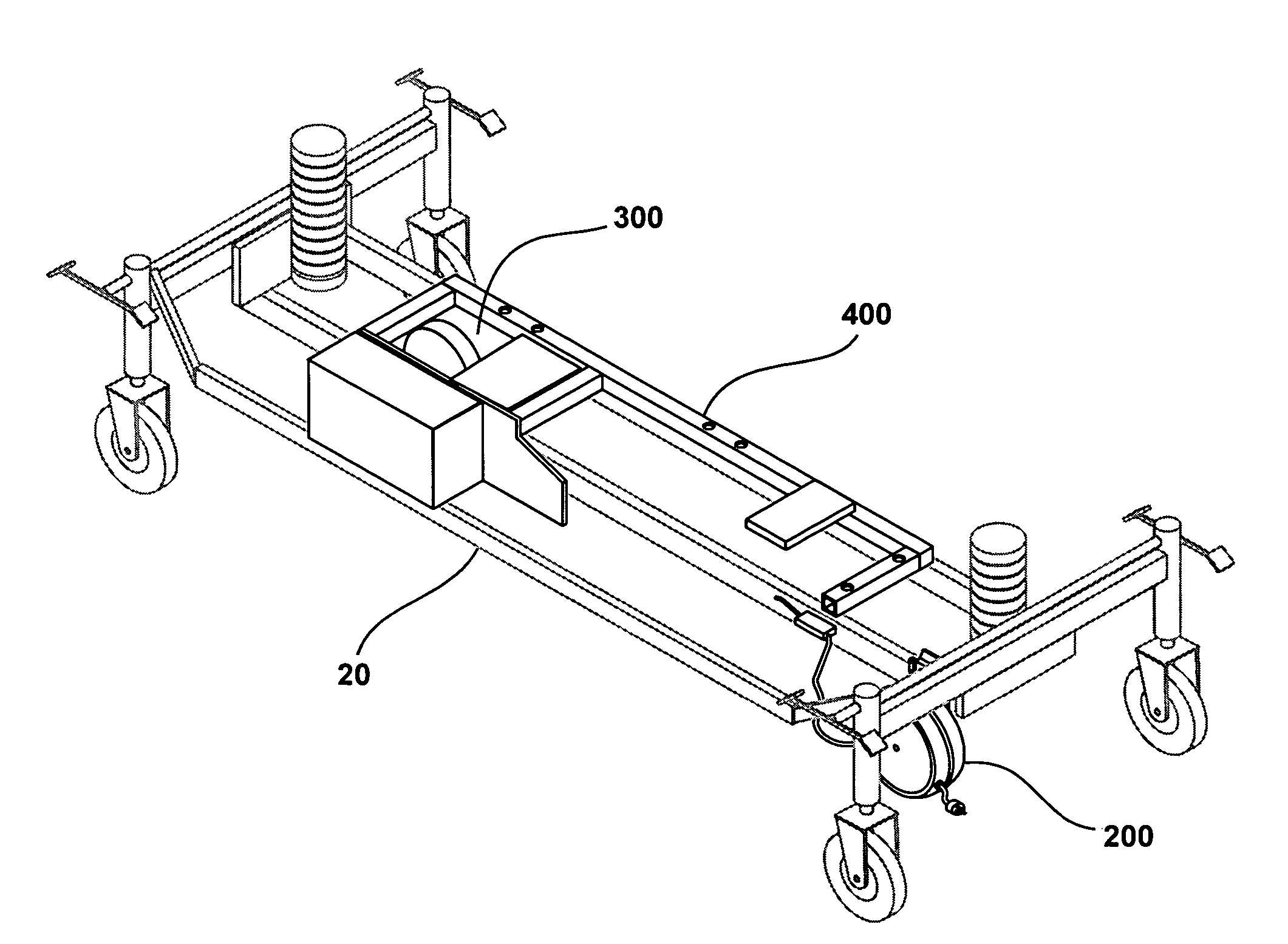

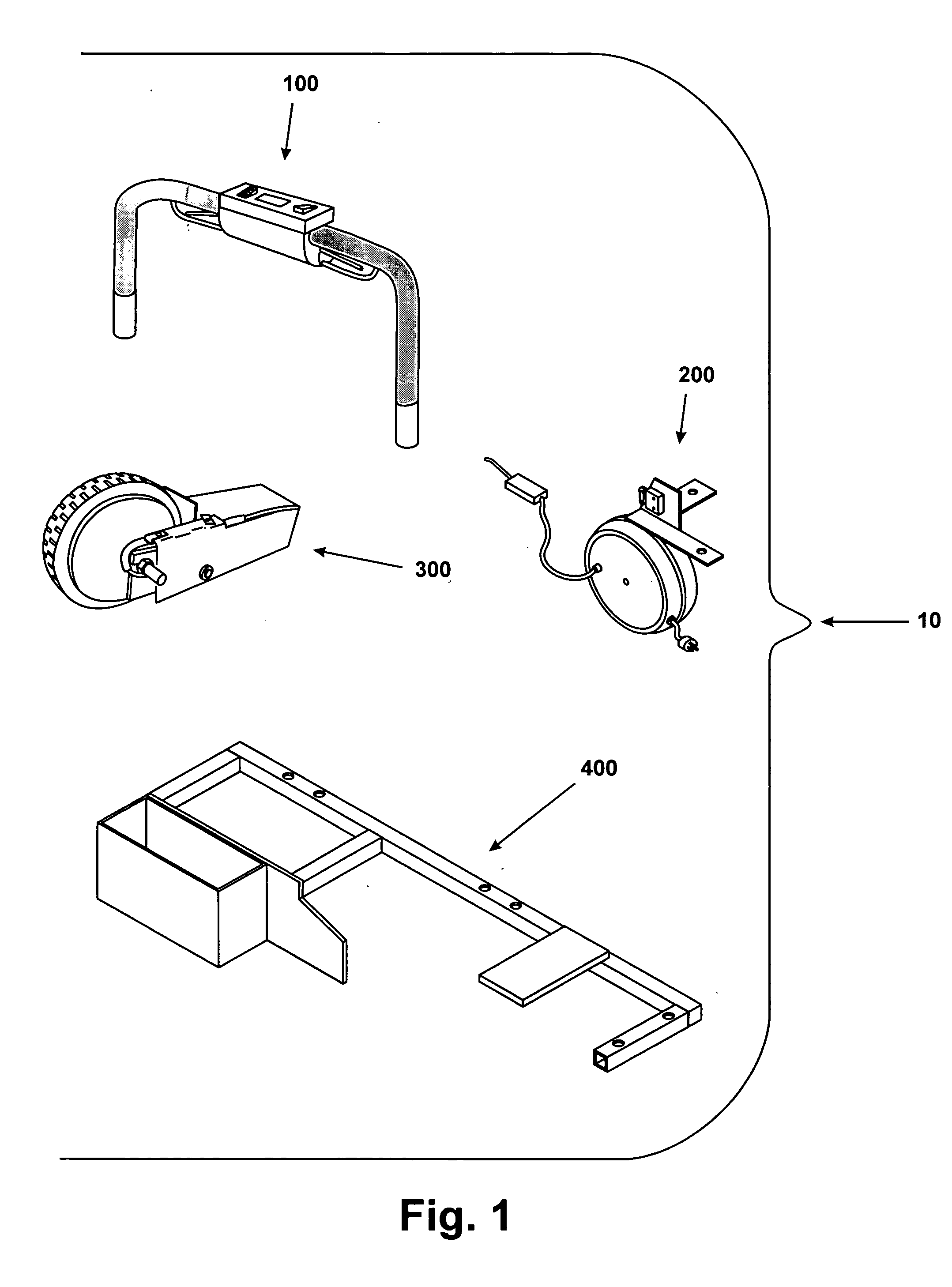

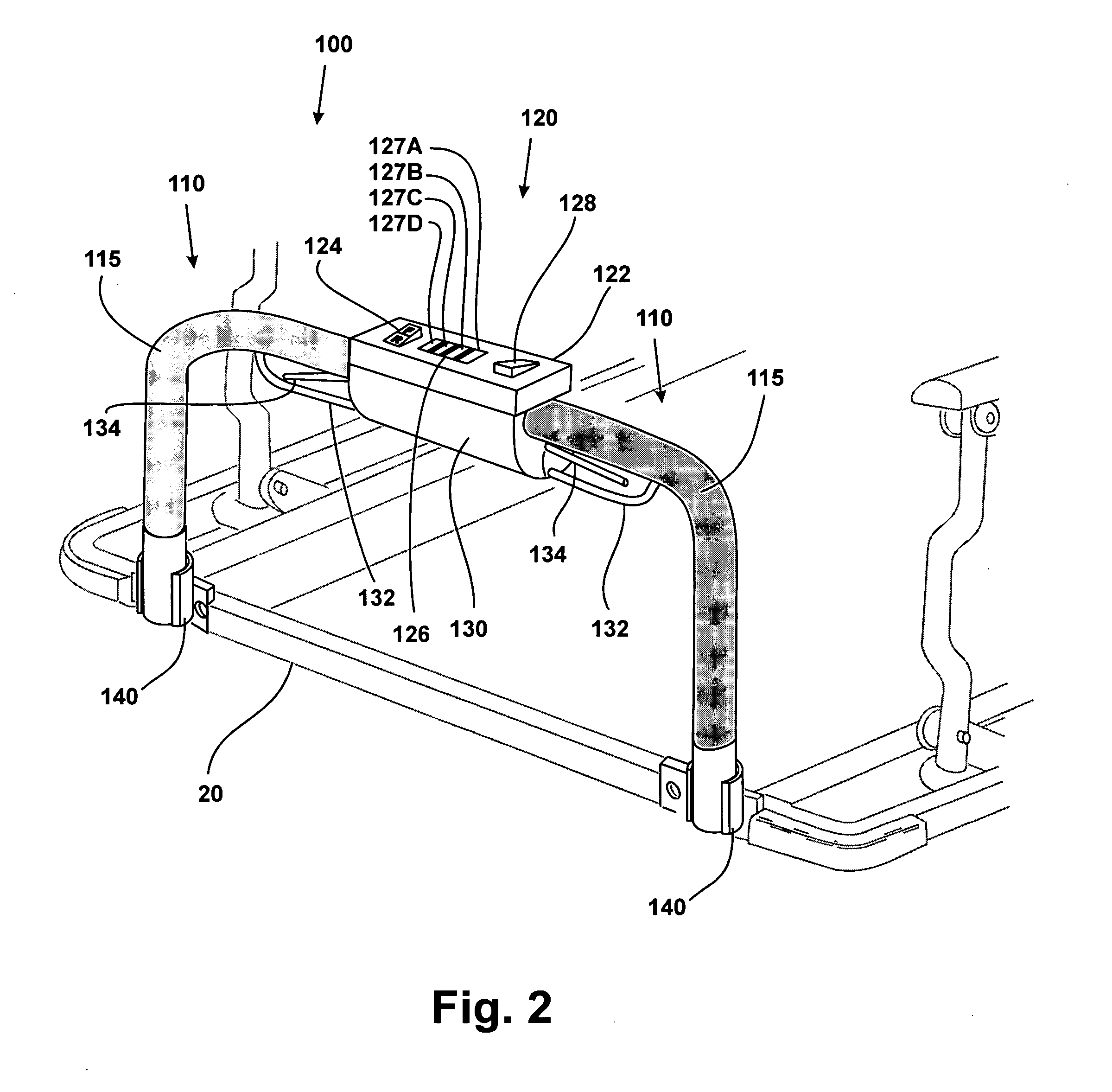

Self propelled gurney and related structure confidential and proprietary document

ActiveUS20050126835A1Easily and quickly mountMinimal effortStretcherElectric propulsion mountingBattery state of chargeBattery charge

The present invention comprises a series of modules, including a control / handle module, a cord reel / charger module, a drive module, and a chassis assembly, plus all needed electrical wiring harnesses and pneumatic tubing to connect them. Also included are means to mount the modules to any existing gurney and to each other without making permanent modifications to the gurney. The gurney is controlled by a handle assembly containing all necessary controls and indicators to allow the operator to select forward or reverse direction, increase or reduce speed of travel, observe the state of battery charge, and energize or deenergize power from the various modules. In addition, the handle may be swung down through 180 degrees to facilitate loading and unloading the gurney.

Owner:GEROPHARM

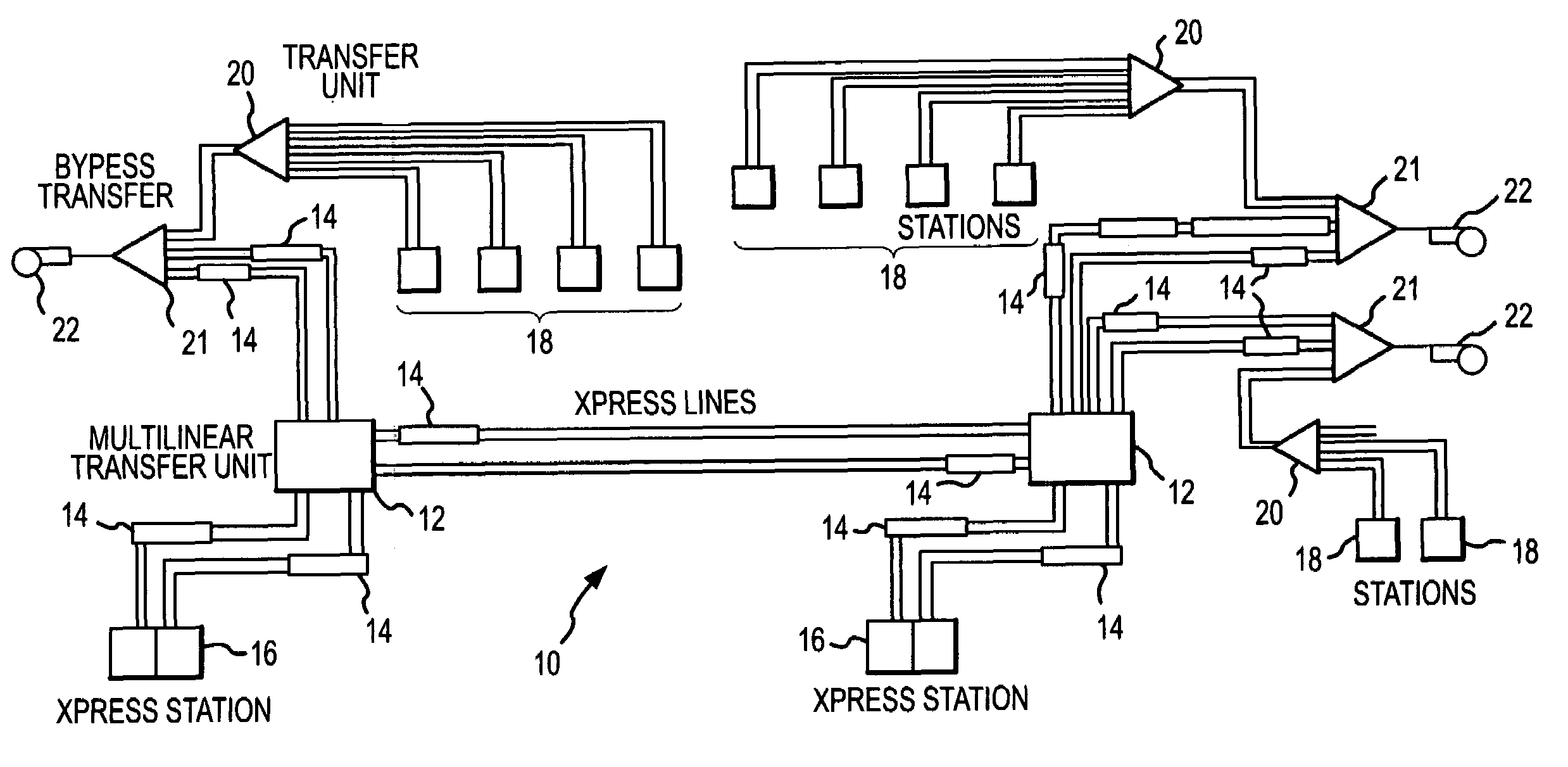

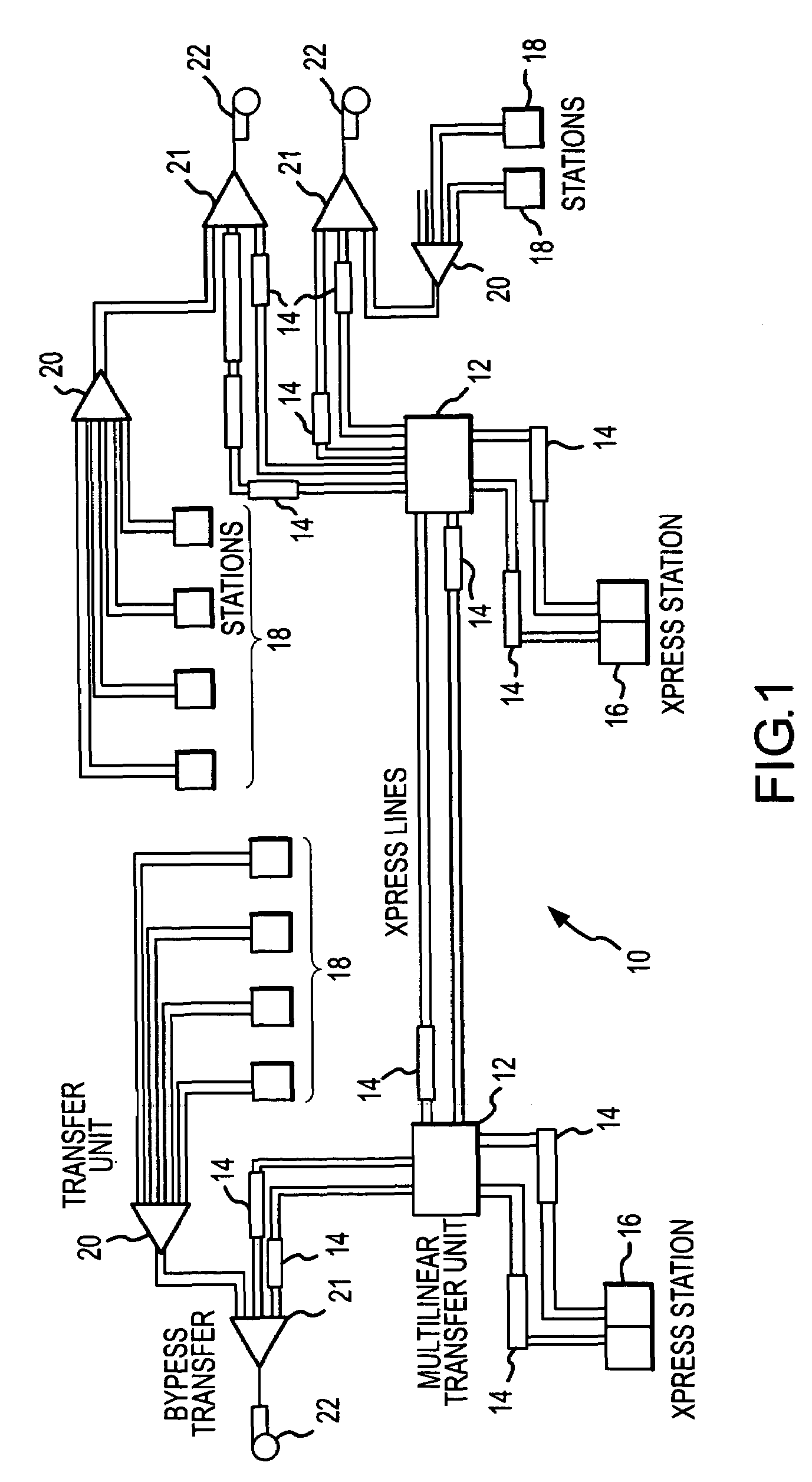

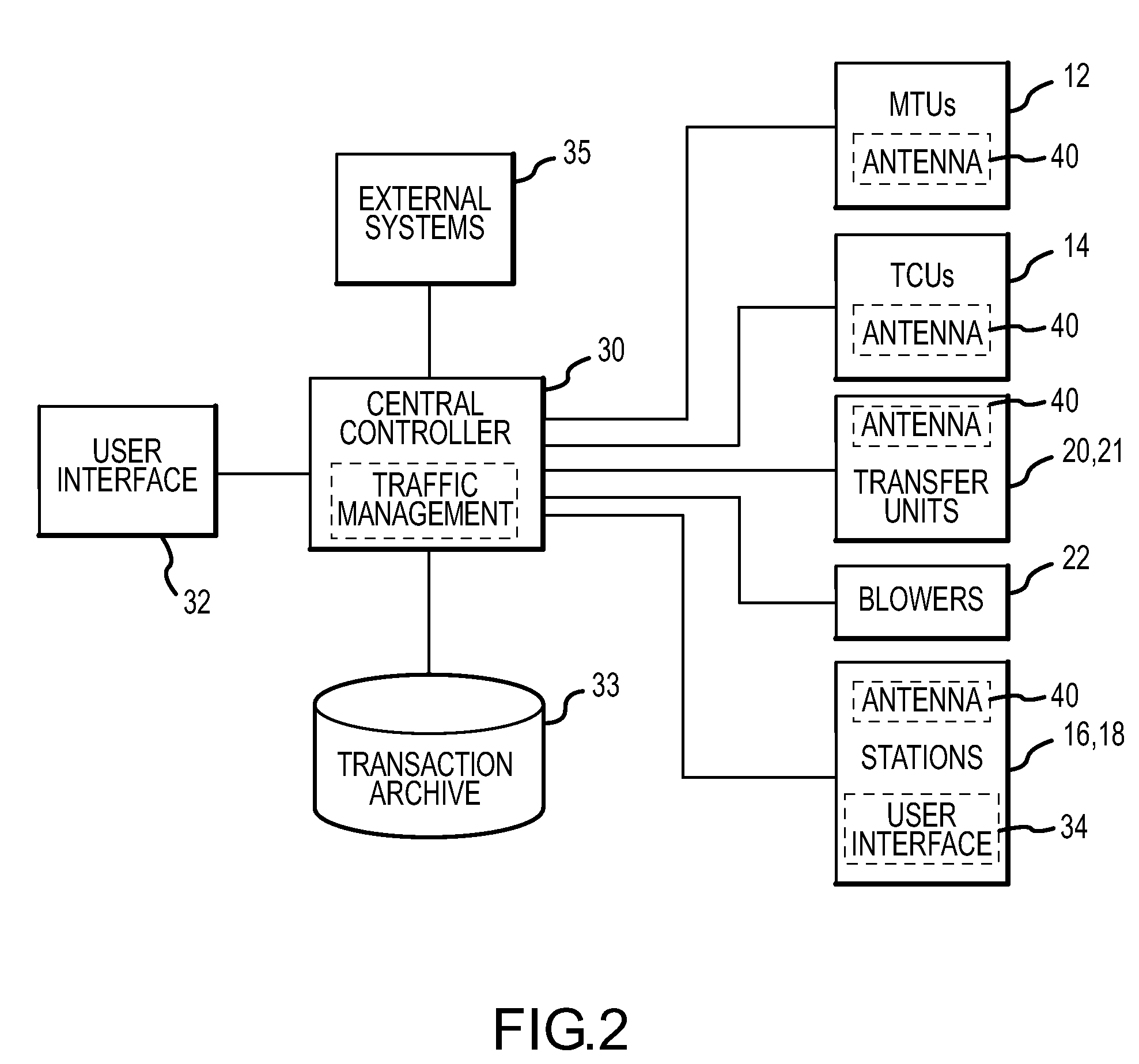

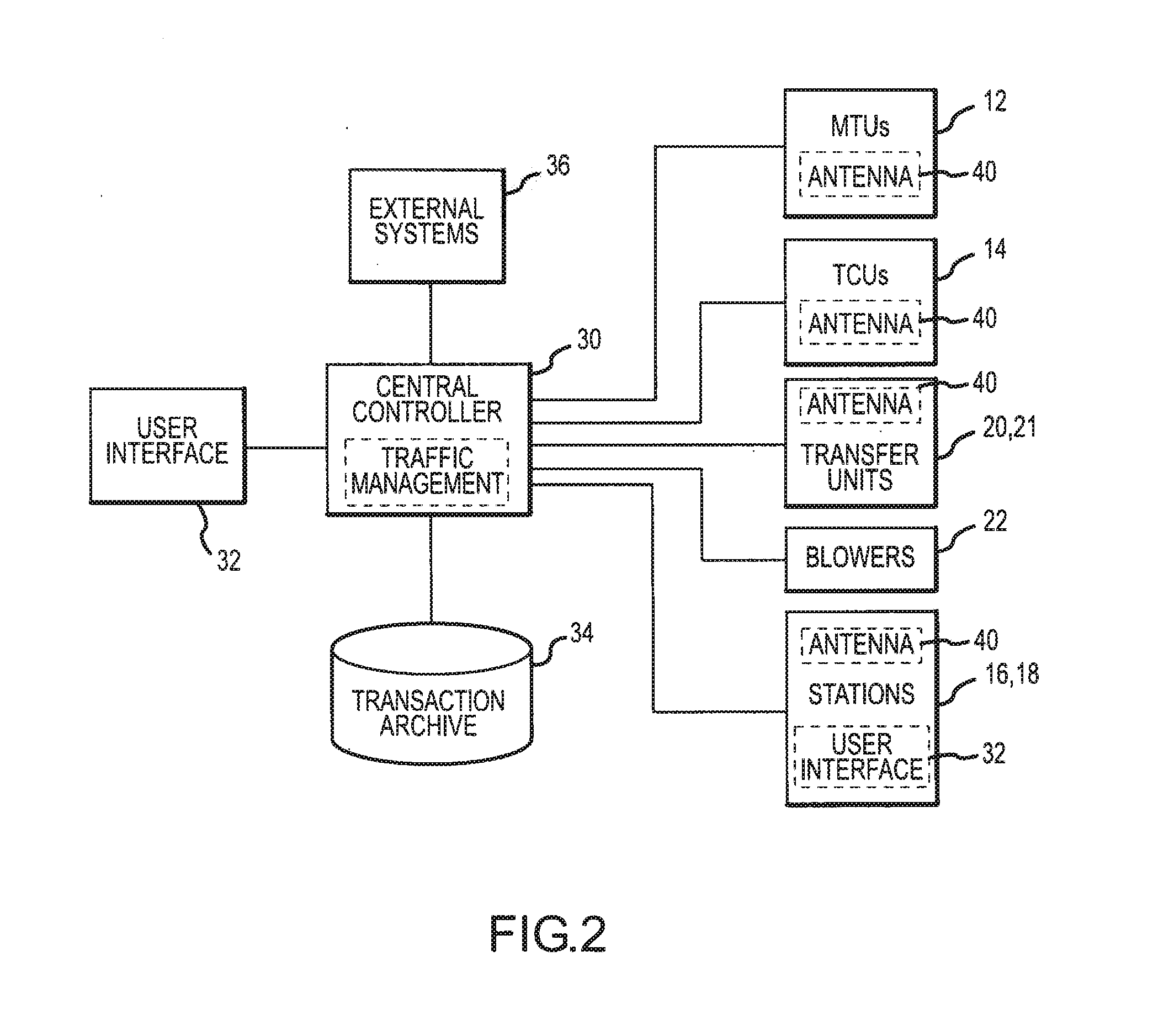

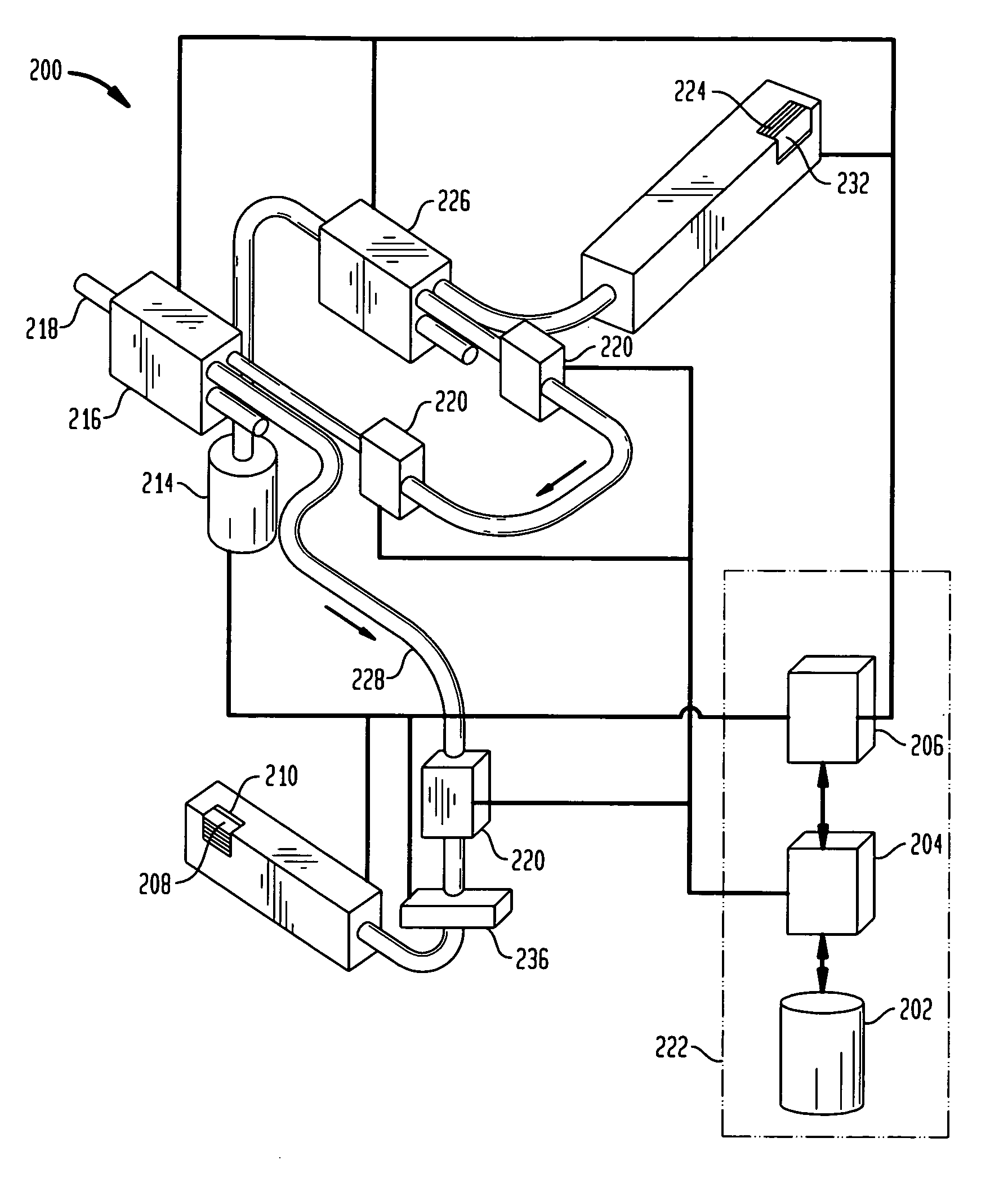

System and method for carrier identification in a pneumatic tube system

ActiveUS7243002B1Facilitate numberEasy to adjustConveyorsDigital data processing detailsCarrier signalIdentification device

A system and method provides for the identification and monitoring of carriers within a pneumatic carrier system. Each carrier which is to be employed within the system includes an identification device such as a radio frequency identification (RFID) chip which has stored thereon identification information for the carrier. Positioned throughout the system are communications devices such as antennas and readers which are employed to read and / or write identification information on the chip. When a carrier is put in the system, a destination location can be associated with the particular carrier ID. This associated information is then employed to, among many things, monitor and confirm identity of the carrier as it moves to its destination.

Owner:TRANSLOGIC

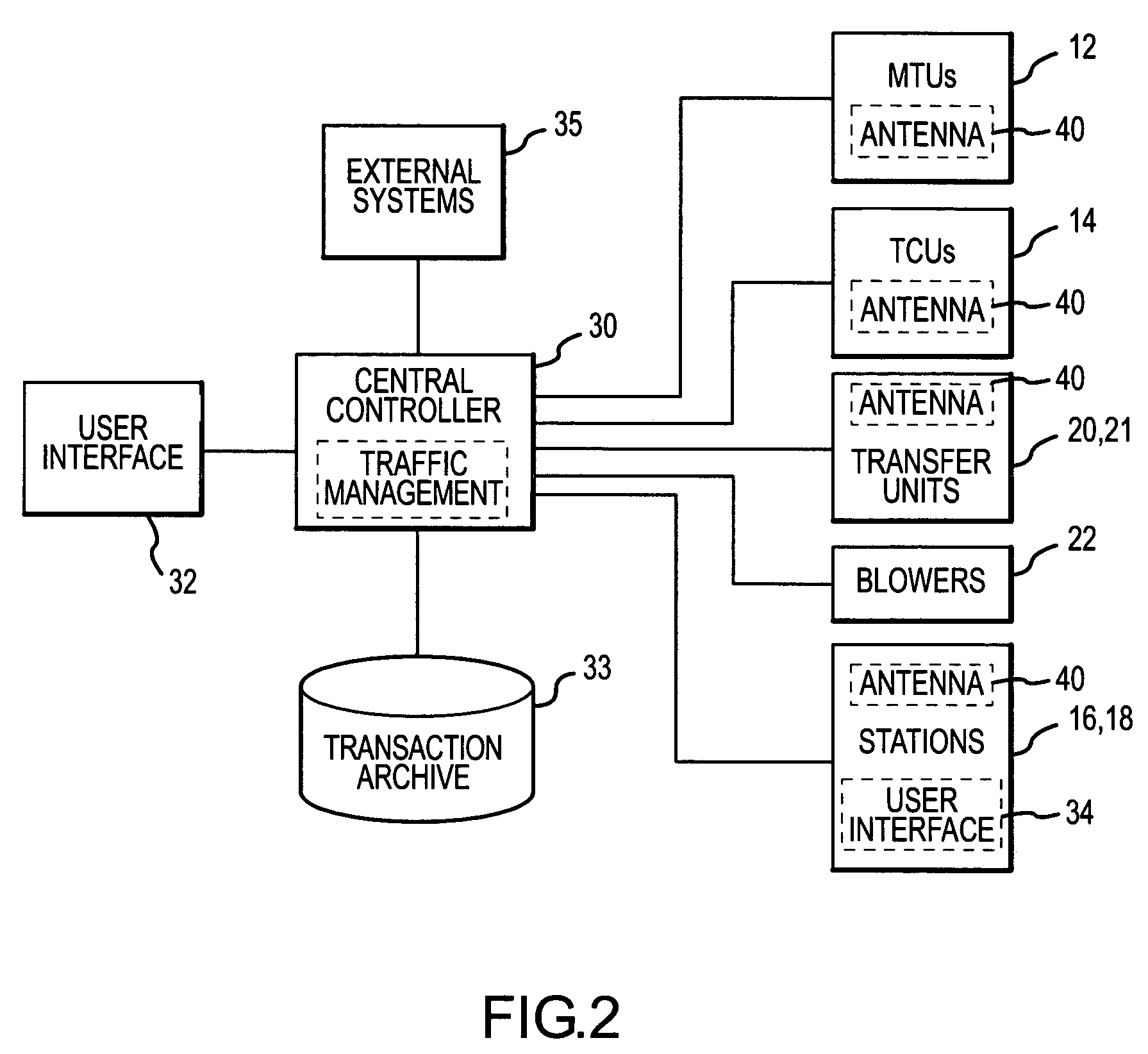

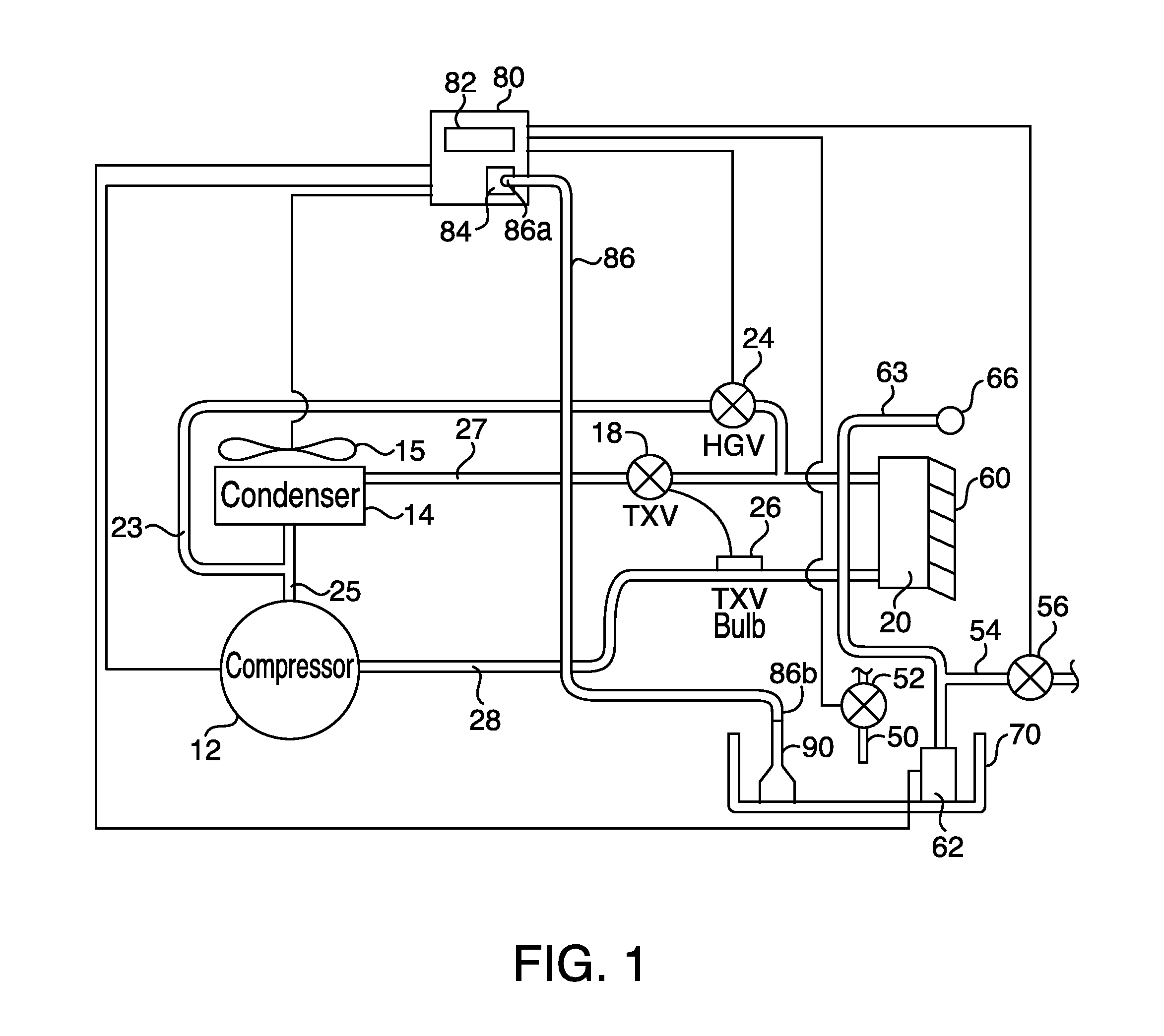

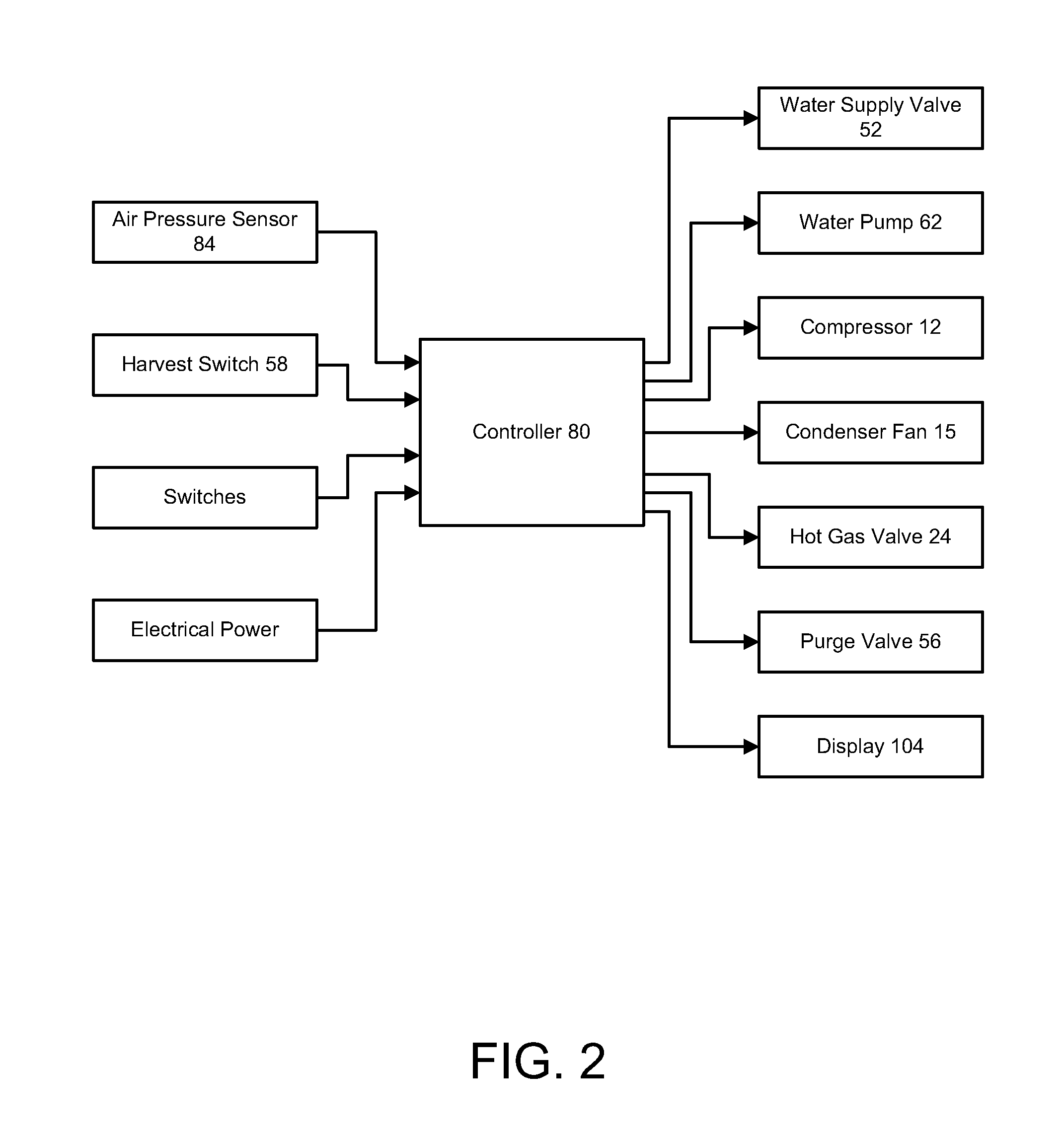

Apparatus and method for sensing ice thickness and detecting failure modes of an ice maker

An ice maker comprising a refrigeration system, a water system, and a control system. The control system includes an air fitting disposed in the sump of the water system, a pneumatic tube, and a controller comprising a processor and an air pressure sensor. The air fitting defines a chamber in which air may be trapped and includes openings through which water in the sump is in fluid communication with the air in the chamber. The pneumatic tube is in fluid communication with the air pressure sensor and the air fitting. The air pressure sensor is adapted to sense a pressure corresponding to a sump water level. The controller is adapted to control the operation of the refrigeration system and the operation of the water system based upon the sump water level and to detect one or more failure modes of the water system based upon the sump water level.

Owner:TRUE MFG CO INC

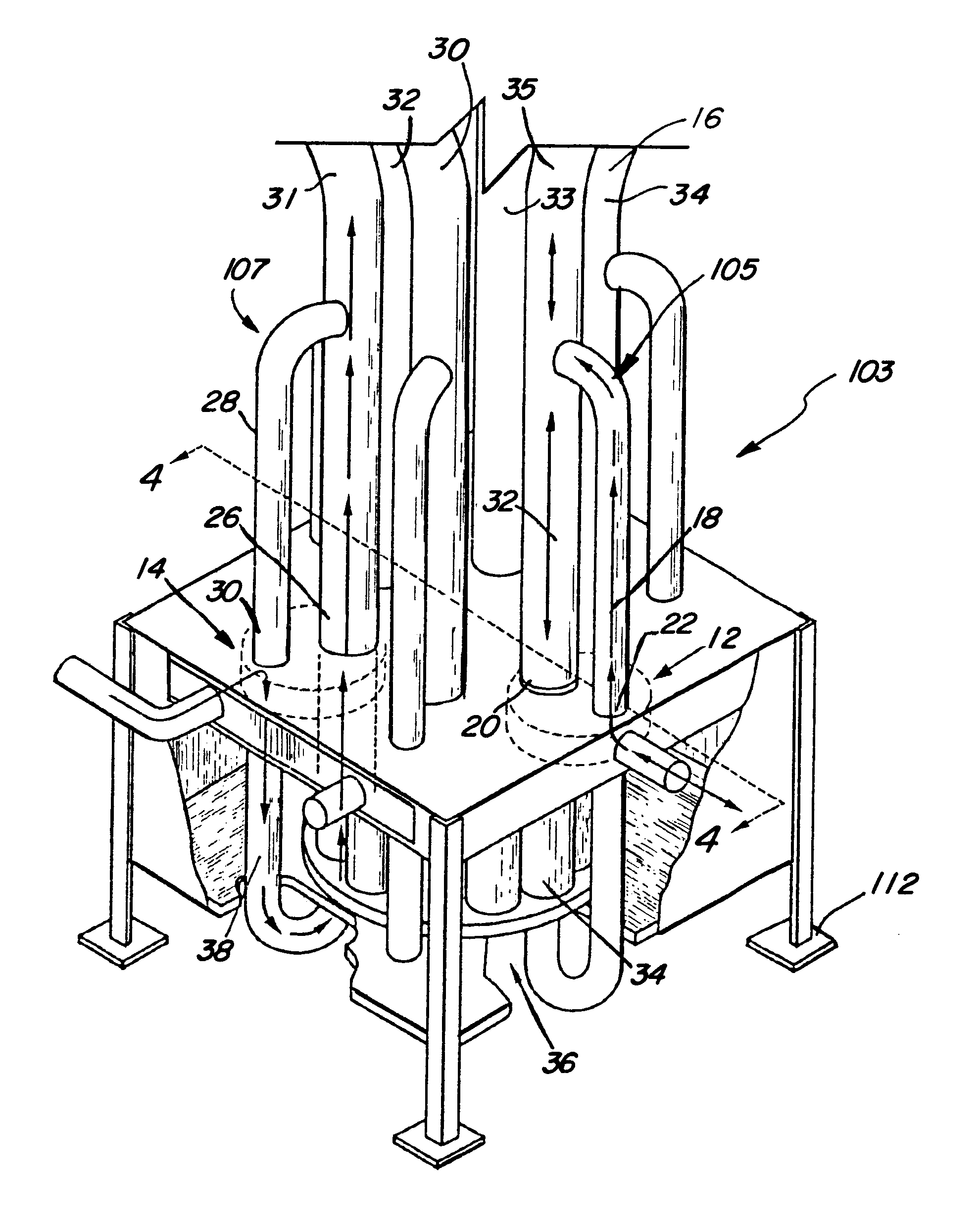

Pneumatic tube distribution system and method

A pneumatic system for transporting a carrier includes a first transport tube coupled to a first transport station and a second transport tube coupled to a second transport station. A distributor coupled to the first transport tube and the second transport tube includes a carousel having at least one storage chamber. The carousel is rotatable about an axis to align the storage chamber with the first transport tube and the second transport tube. A source of airflow coupled to the distributor facilitates movement of the carrier through the first transport tube and into the storage chamber of the carousel, and facilitates movement of the carrier from the storage chamber of the carousel into the second transport tube. An associated method for transporting the carrier includes the step of moving the carrier from the first transport tube in a first direction into the storage chamber of the distributor. The distributor is then rotated with a carrier in the storage chamber, and the carrier is moved from the storage chamber in a second direction opposite to the first direction and into the second transport tube.

Owner:ADVANCED PNEUMATIC TUBES

System and method for carrier identification in a pneumatic tube system

ActiveUS7328084B1Facilitate numberEasy to adjustConveyorsDigital data processing detailsRelevant informationIdentification device

Owner:TRANSLOGIC

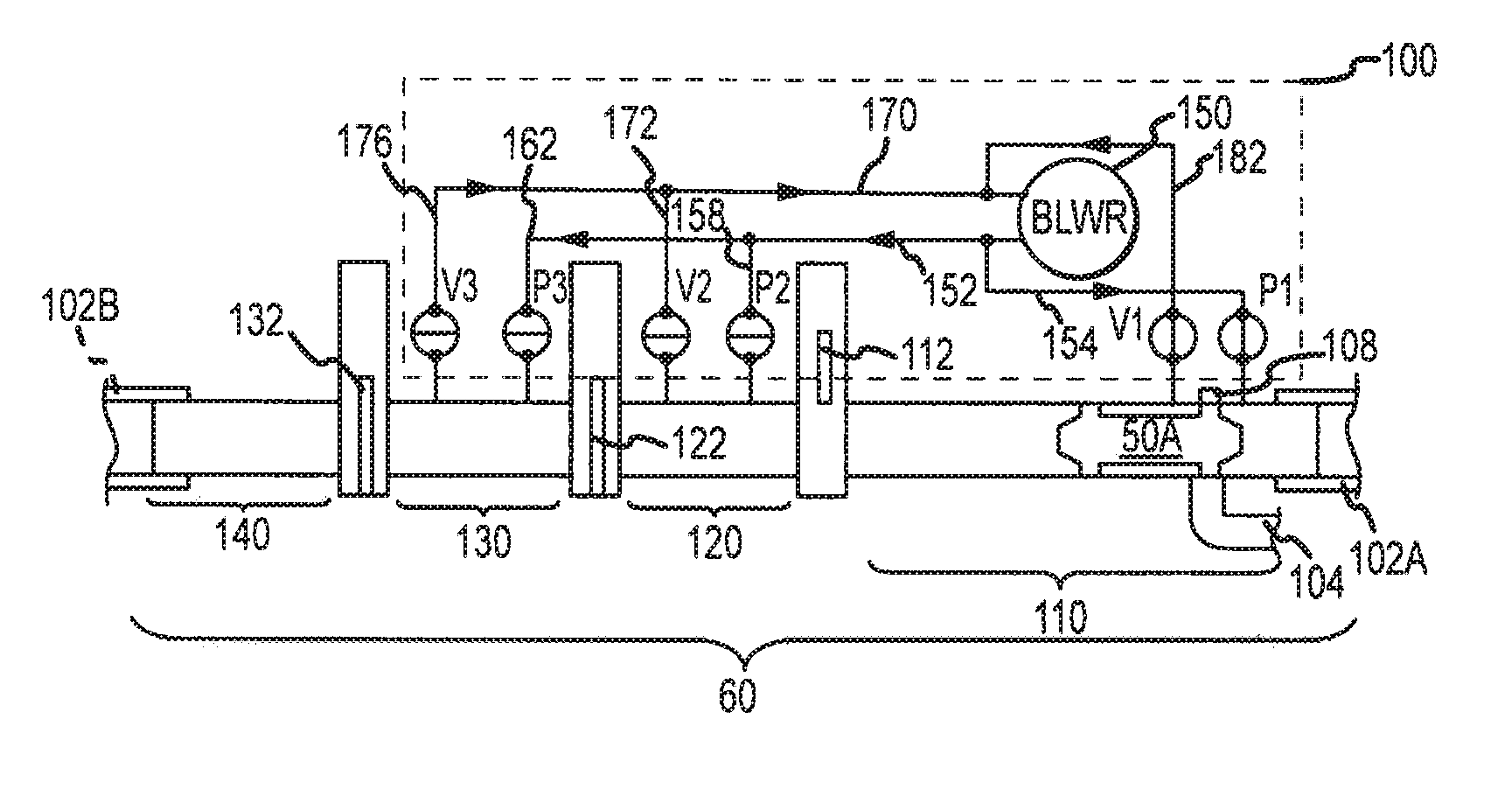

Air powered storage device for pneumatic transport system

An air powered storage device is provided that is operative to temporarily store pneumatic carriers within a pneumatic carrier system. Generally, the device includes a pneumatic tube that is sized to permit the passage of pneumatic carriers. A gate member is selectively positionable into and out of an internal bore of the pneumatic tube to impede movement of pneumatic carriers there through. The device further includes a blower having a first fluid inlet disposed on a first side of the gate member and a fluid outlet disposed on a second side of the gate member. The fluid inlet and outlet are fluidly interconnected to the internal bore of the pneumatic tube such that the blower is selectively operable to generate a fluid flow through the internal bore between the fluid outlet and the fluid inlet. Such fluid flow may be utilized to reinitiate movement of a stopped carrier.

Owner:TRANSLOGIC

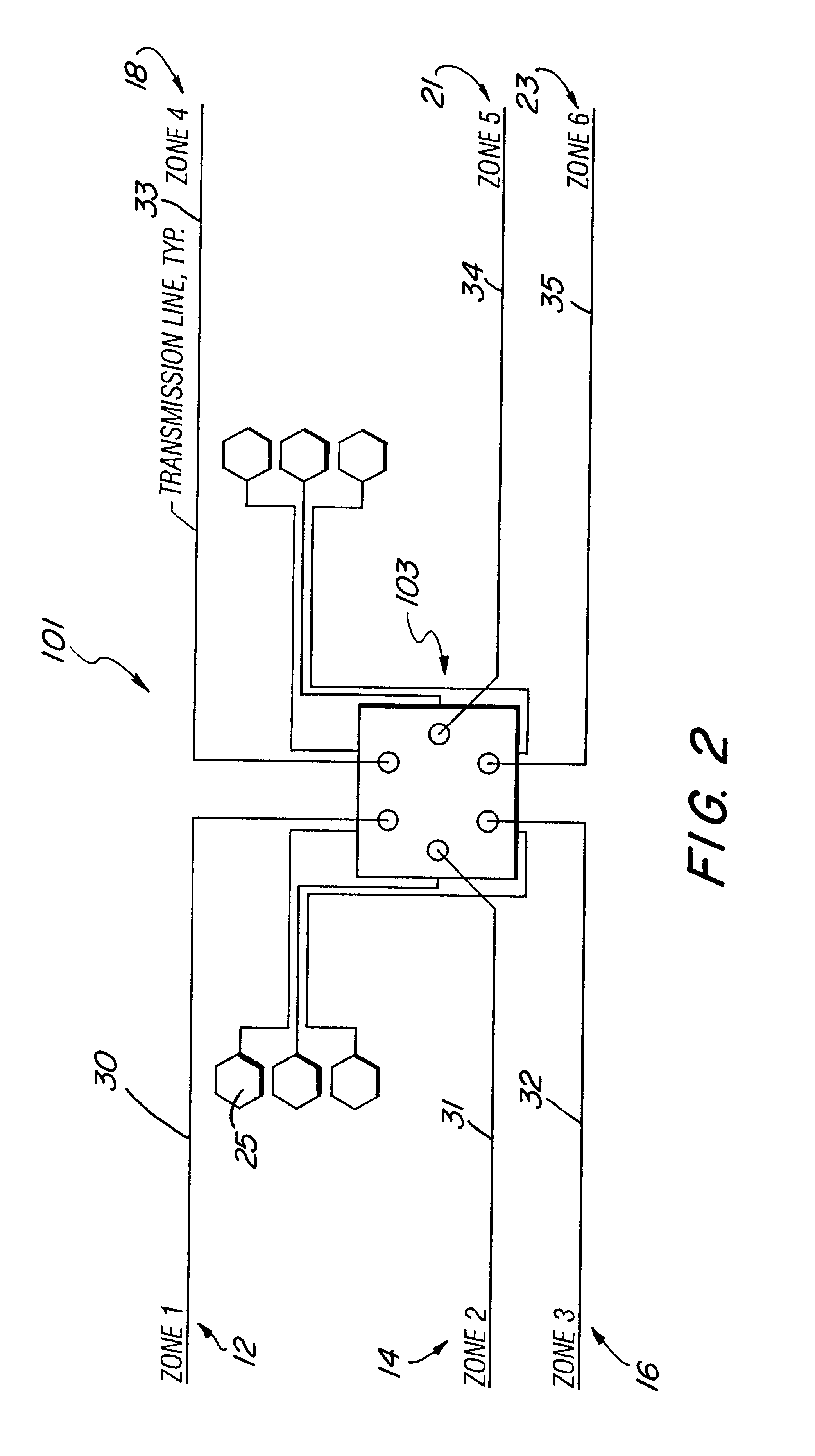

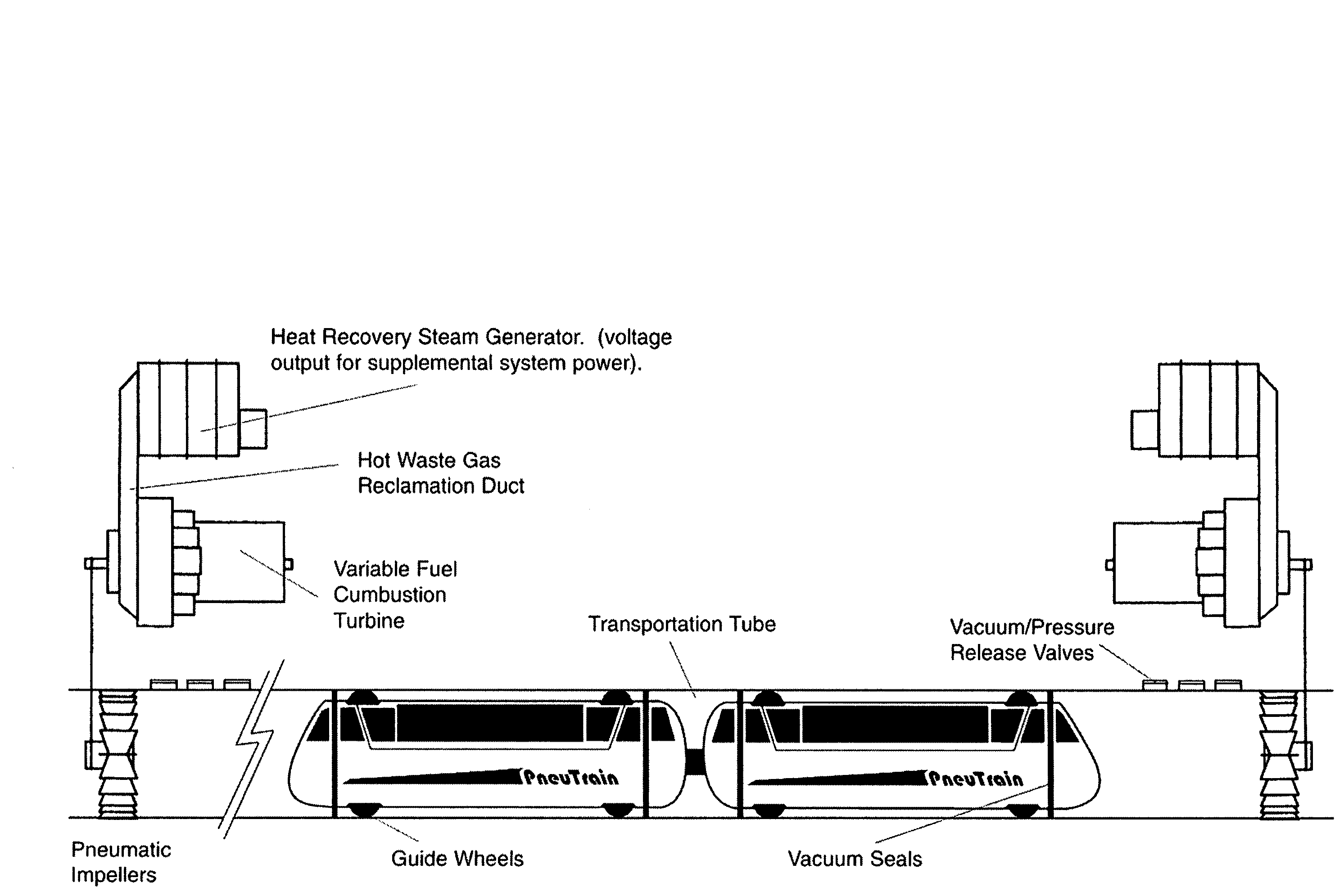

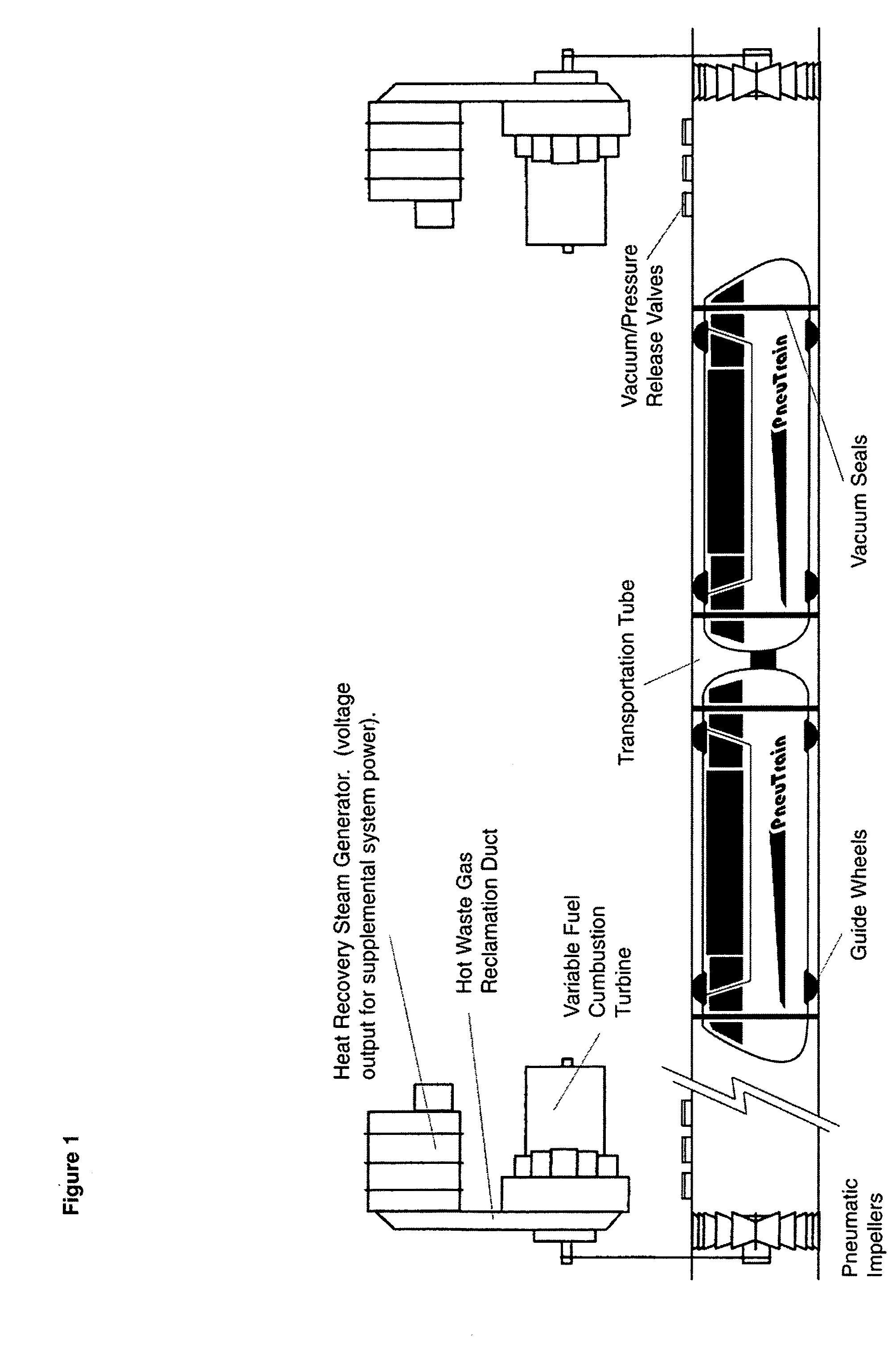

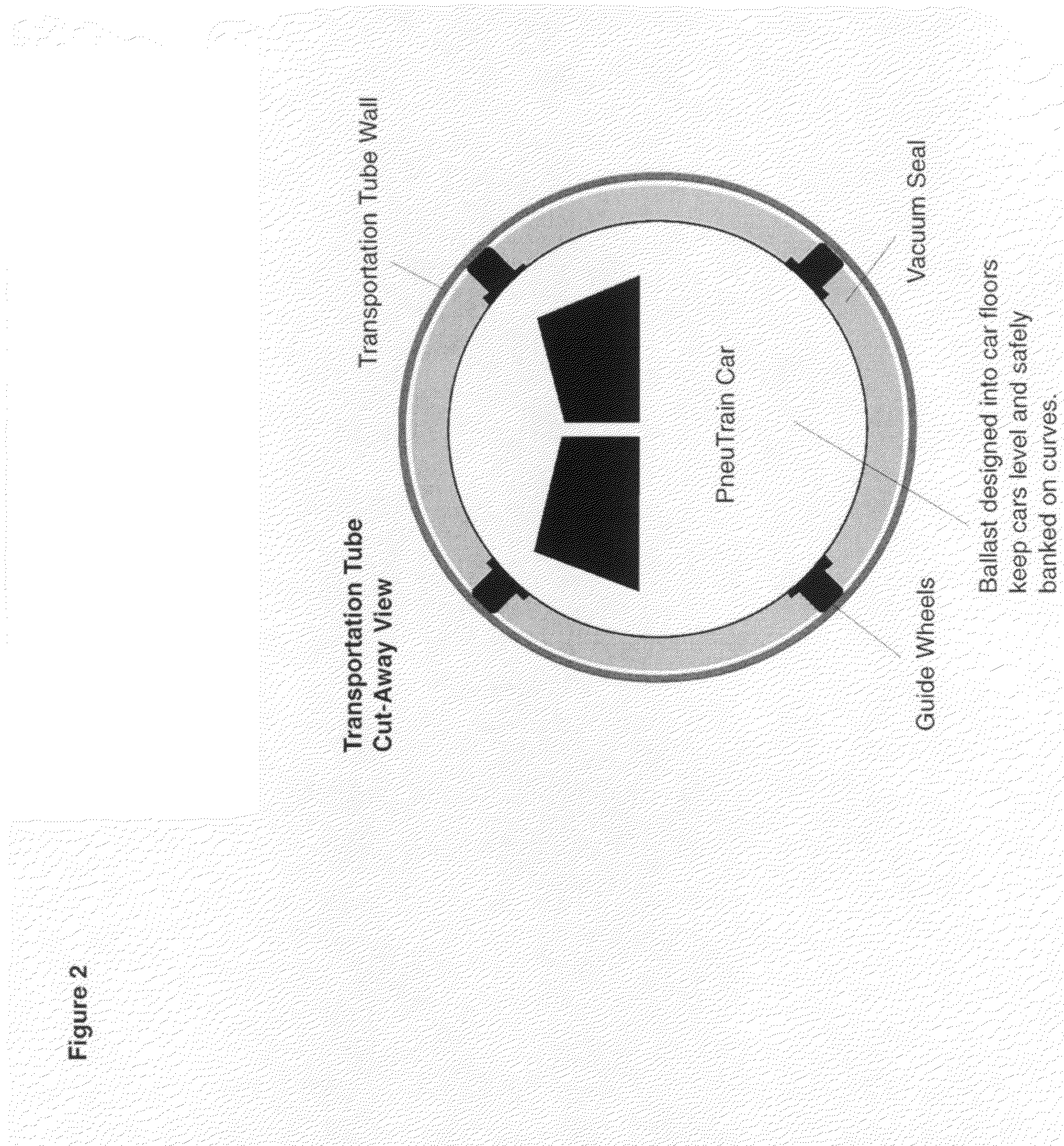

Pneutrain pneumatic mass transportation system

This invention is a pneumatic mass transportation system on the cutting edge of technology employing a combined cycle turbine power system with digital controls to effect acceleration, deceleration and train propulsion. The combustion turbines can be adapted to use alternative fuels including bio fuels as they are developed. The heat recover steam generator will recycle the hot exhaust gasses from the turbines to generate electricity to be used by the system. The multi-car train is propelled by differential air pressure forward and aft of the vehicle in the pneumatic tube. Air propulsion is achieved by large in-tube impellers driven by the turbines. A digital control system will operate the pitch of the impeller blades and the vacuum / pressure release valves in the tubes to produce full movement control of the trains.

Owner:FLYNN PATRICK JOSEPH

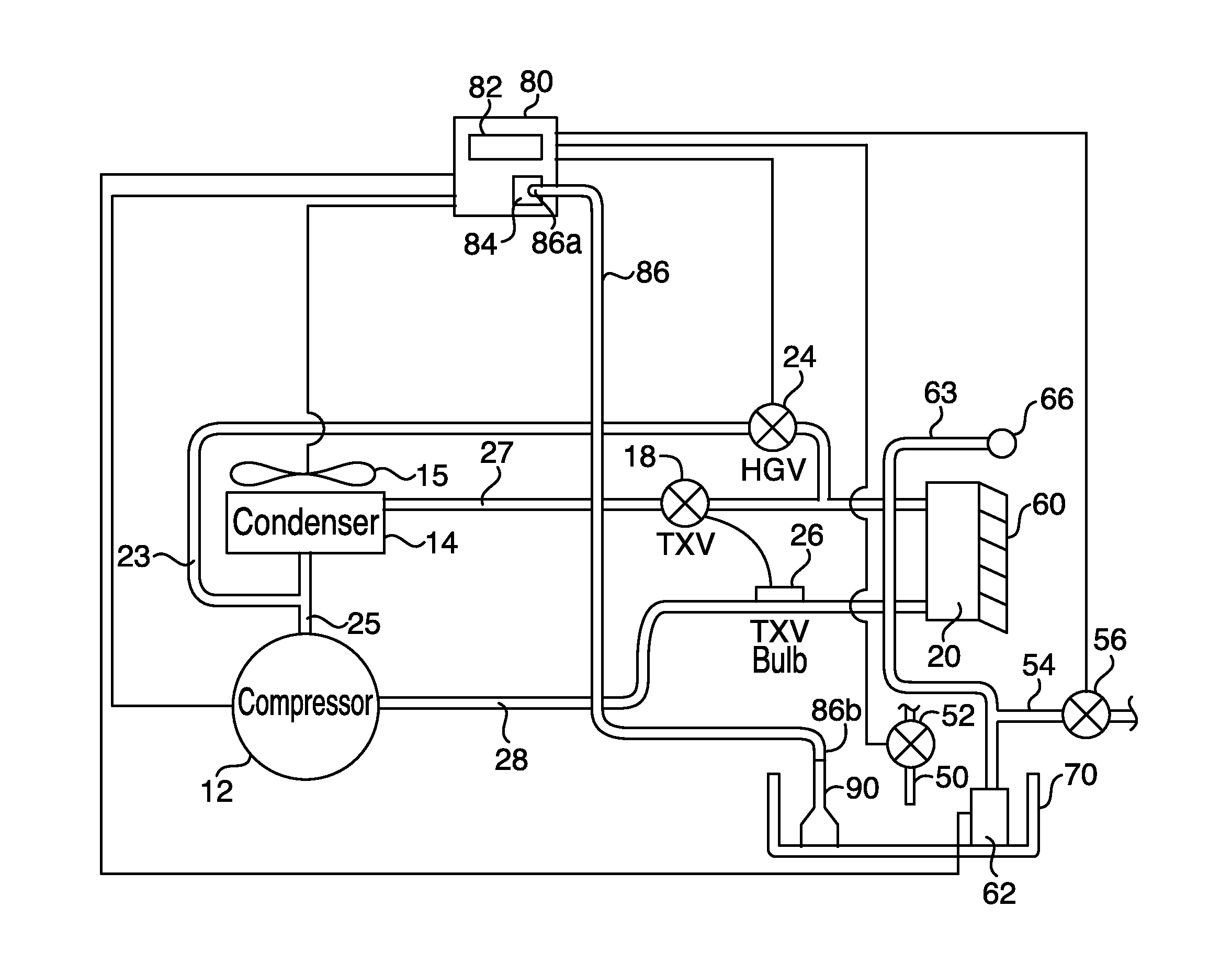

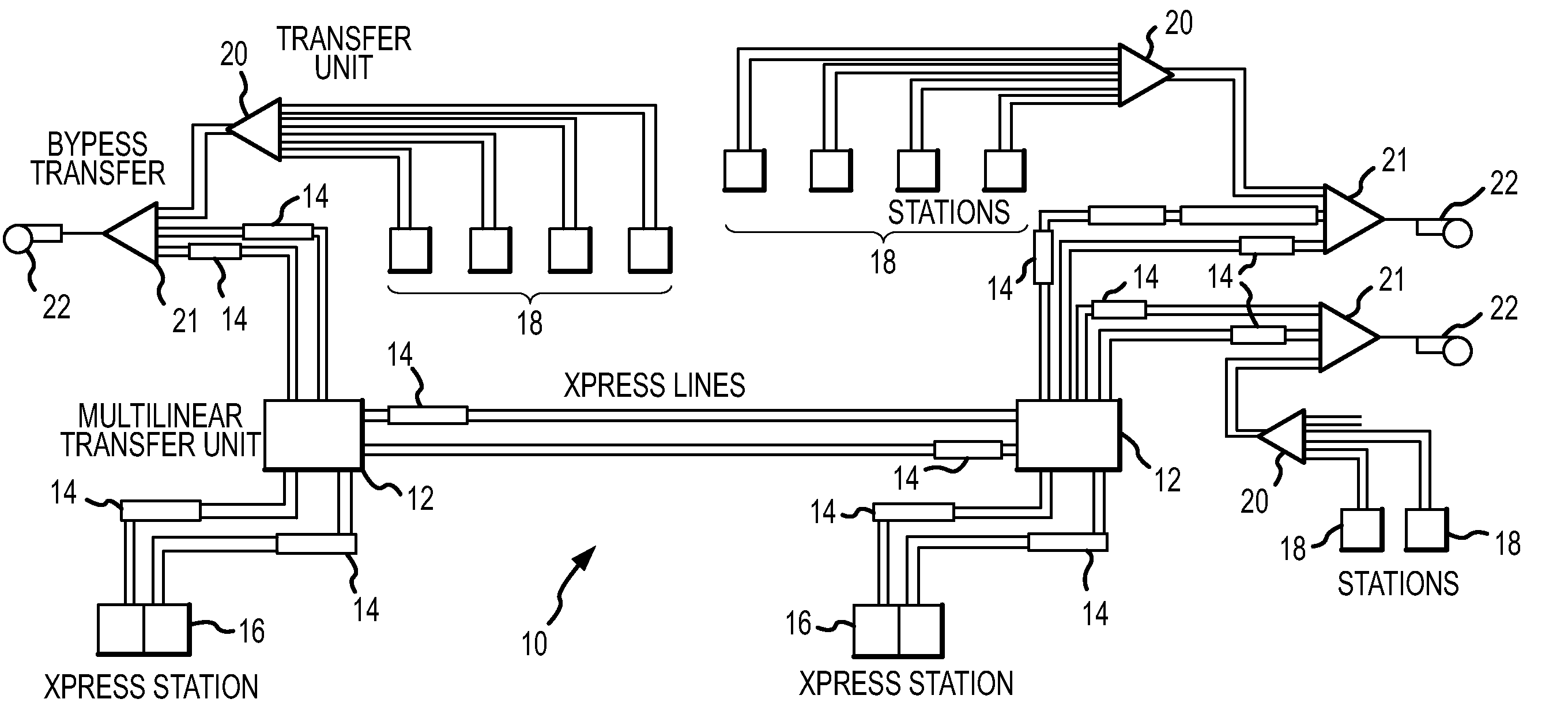

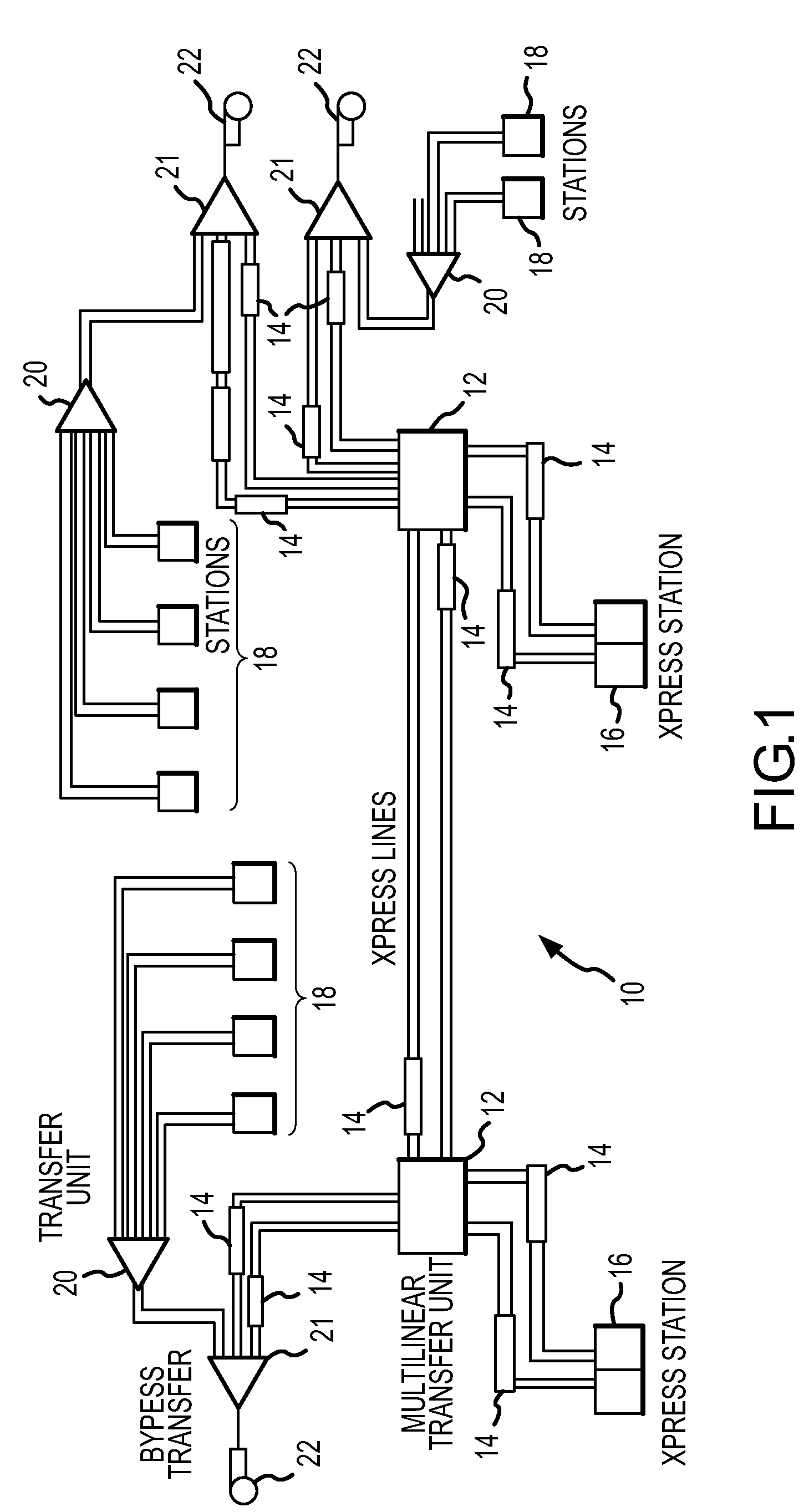

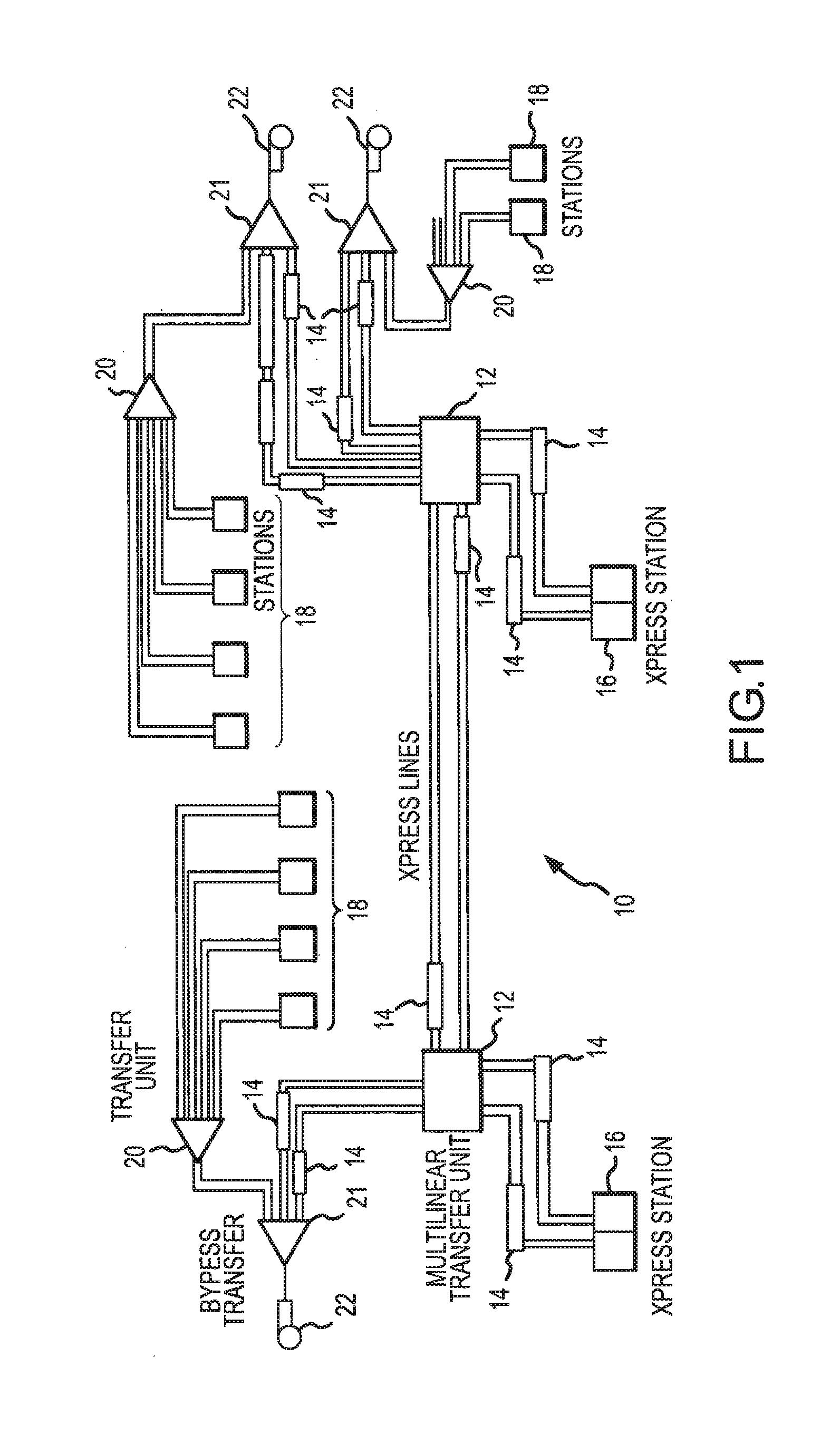

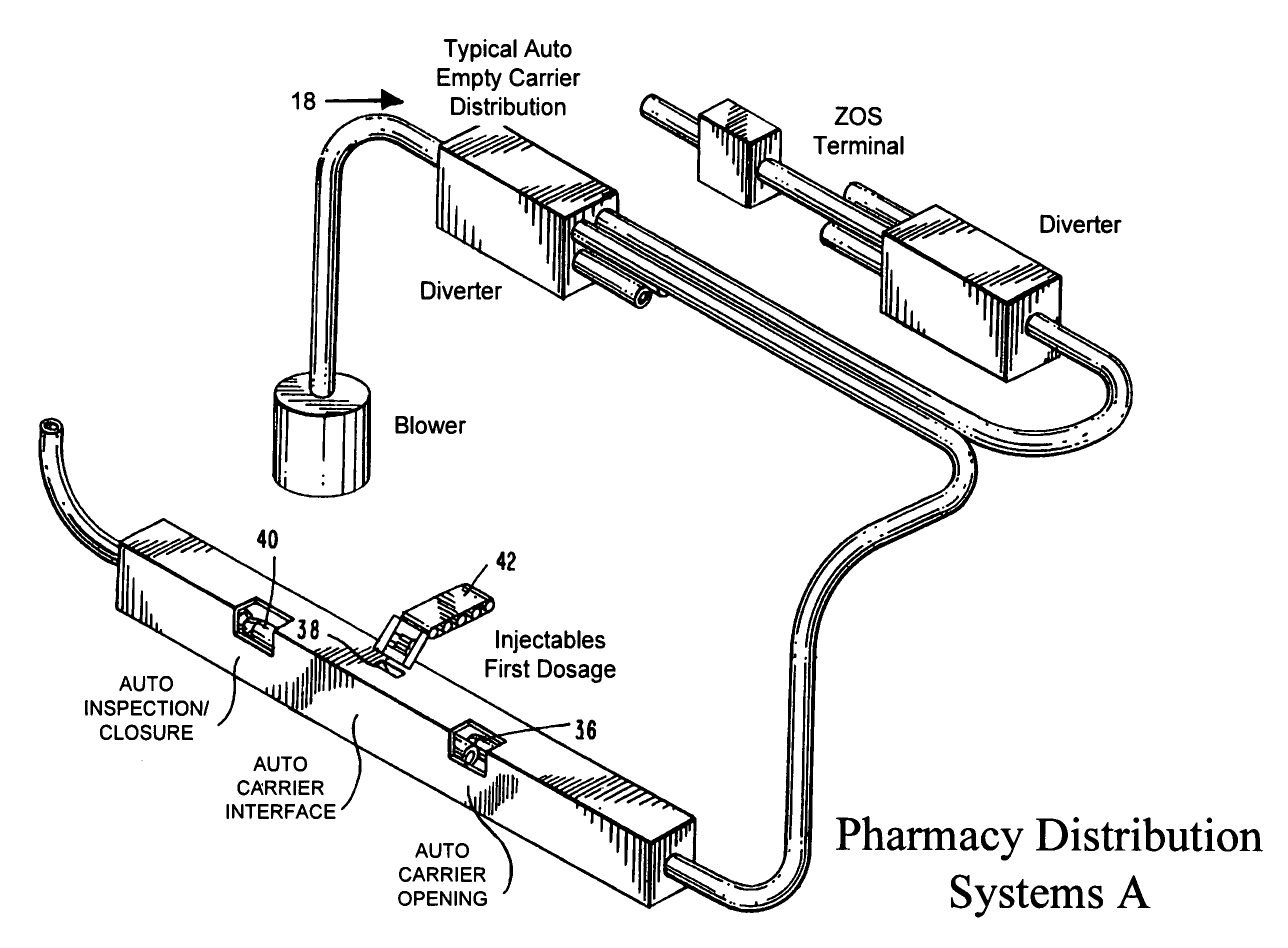

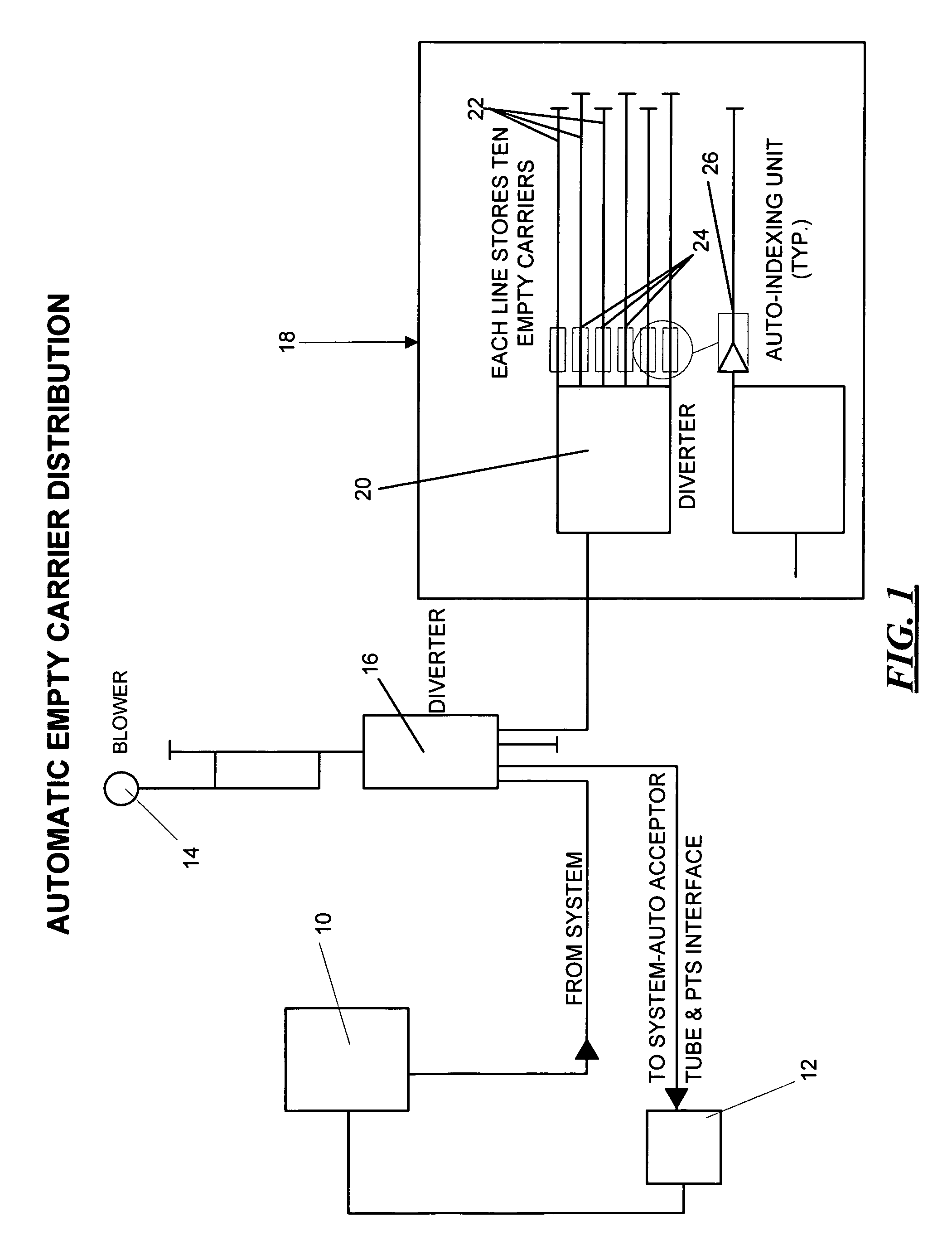

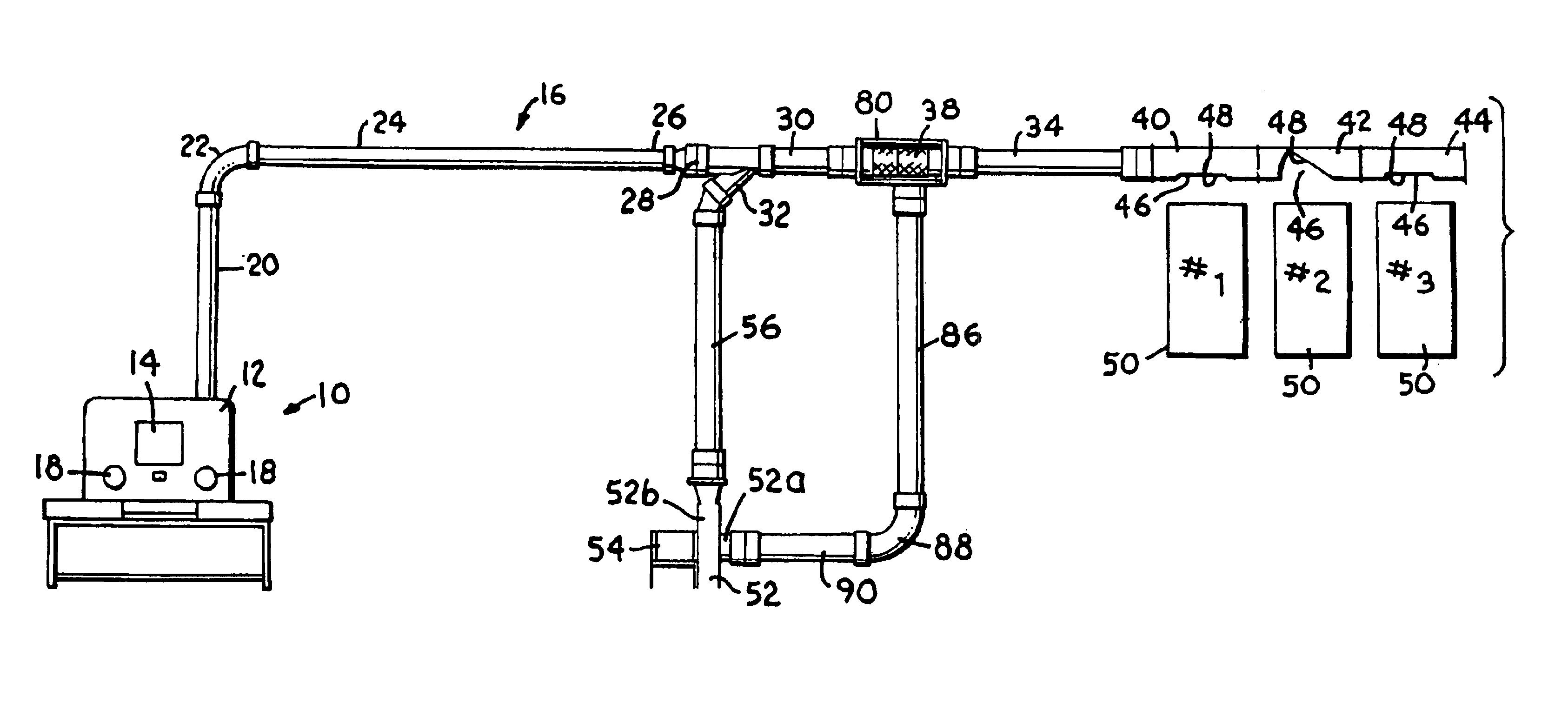

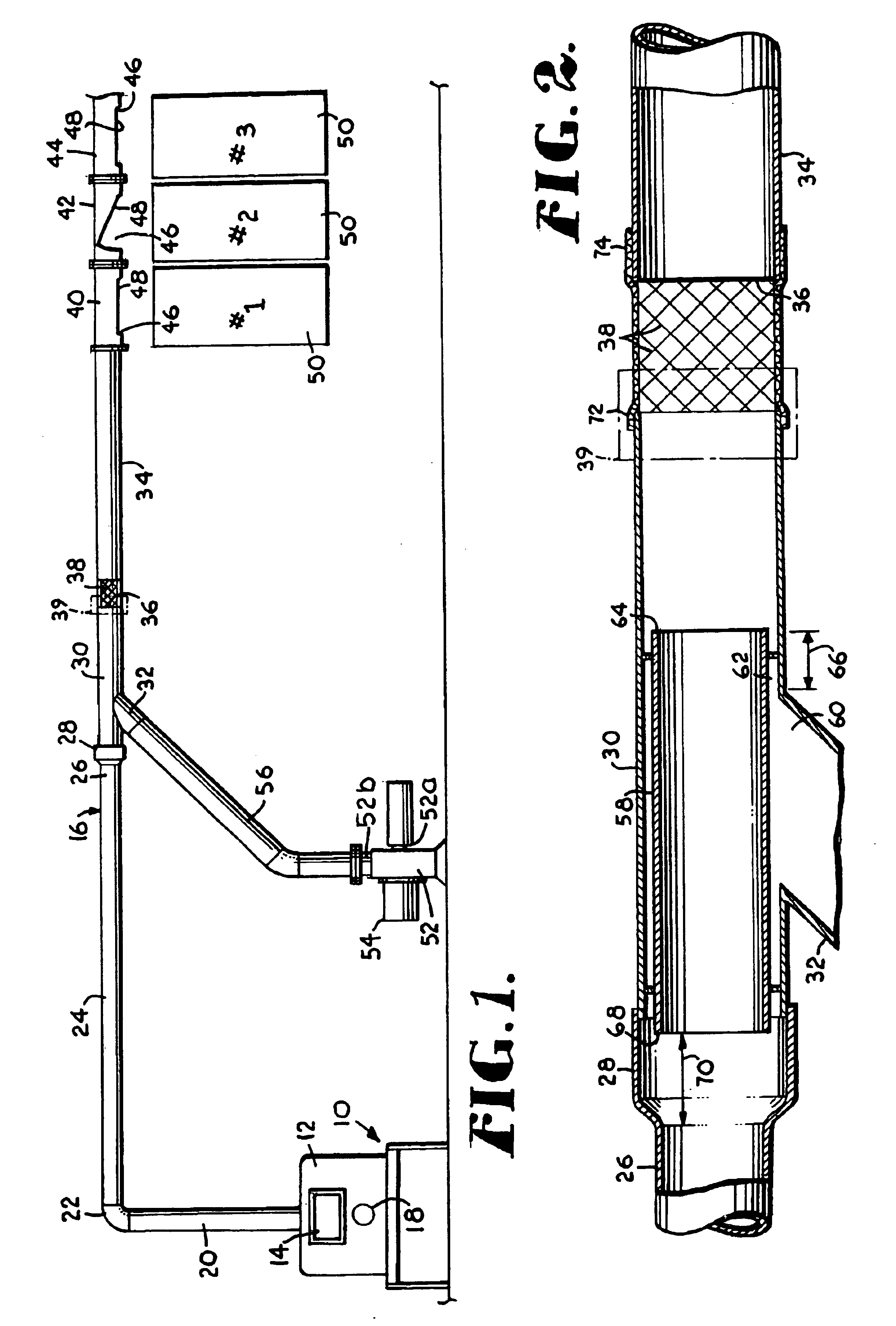

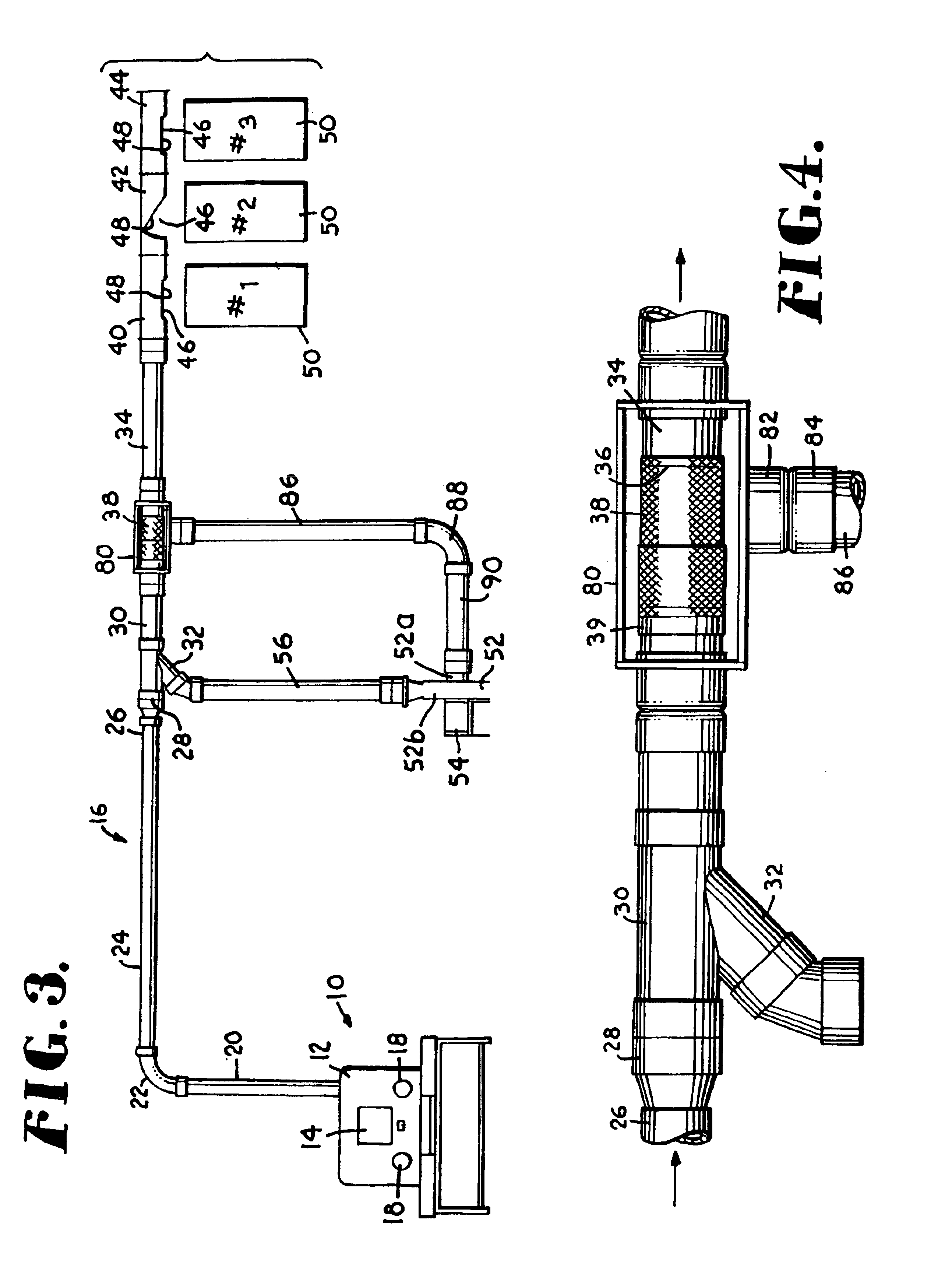

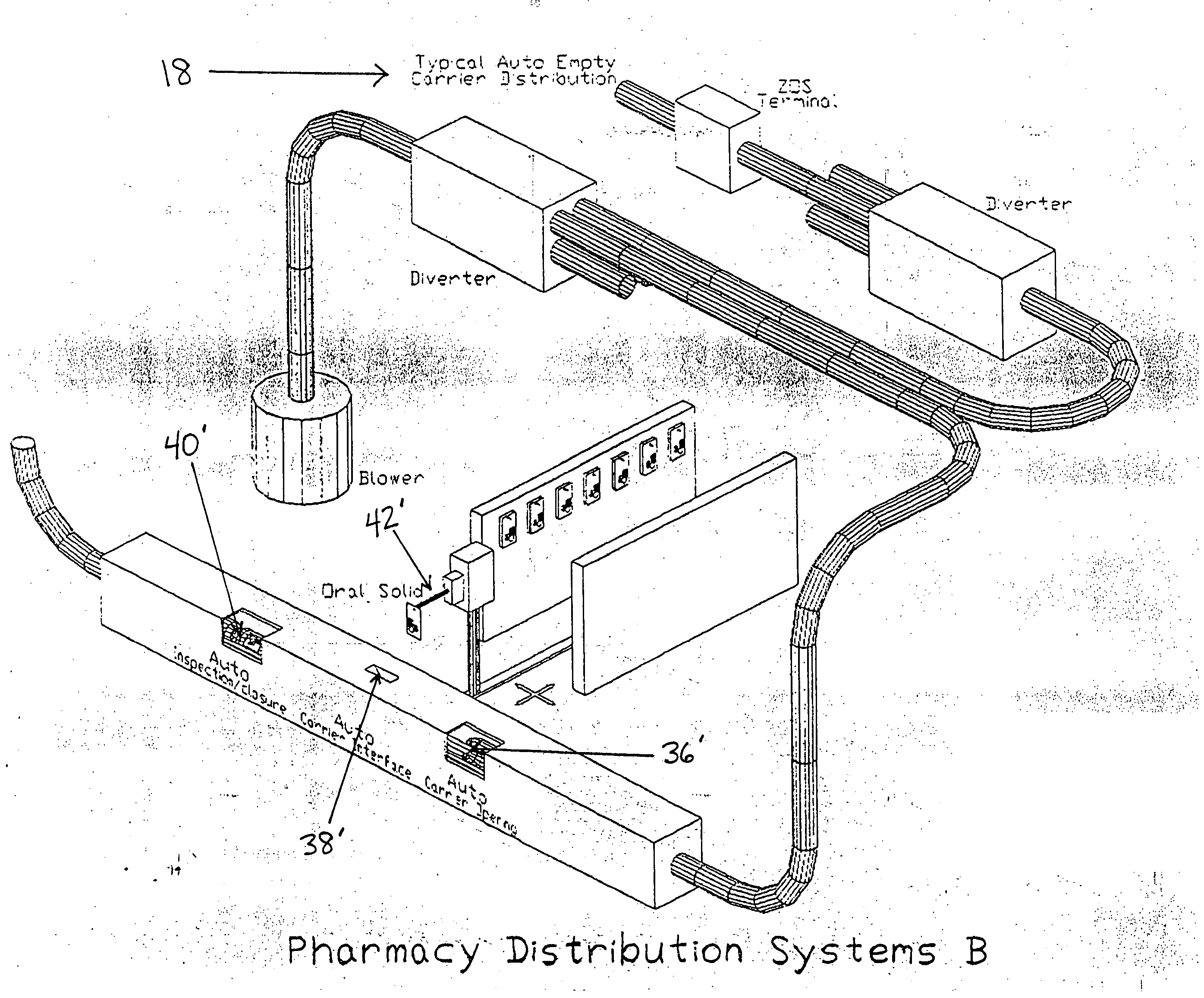

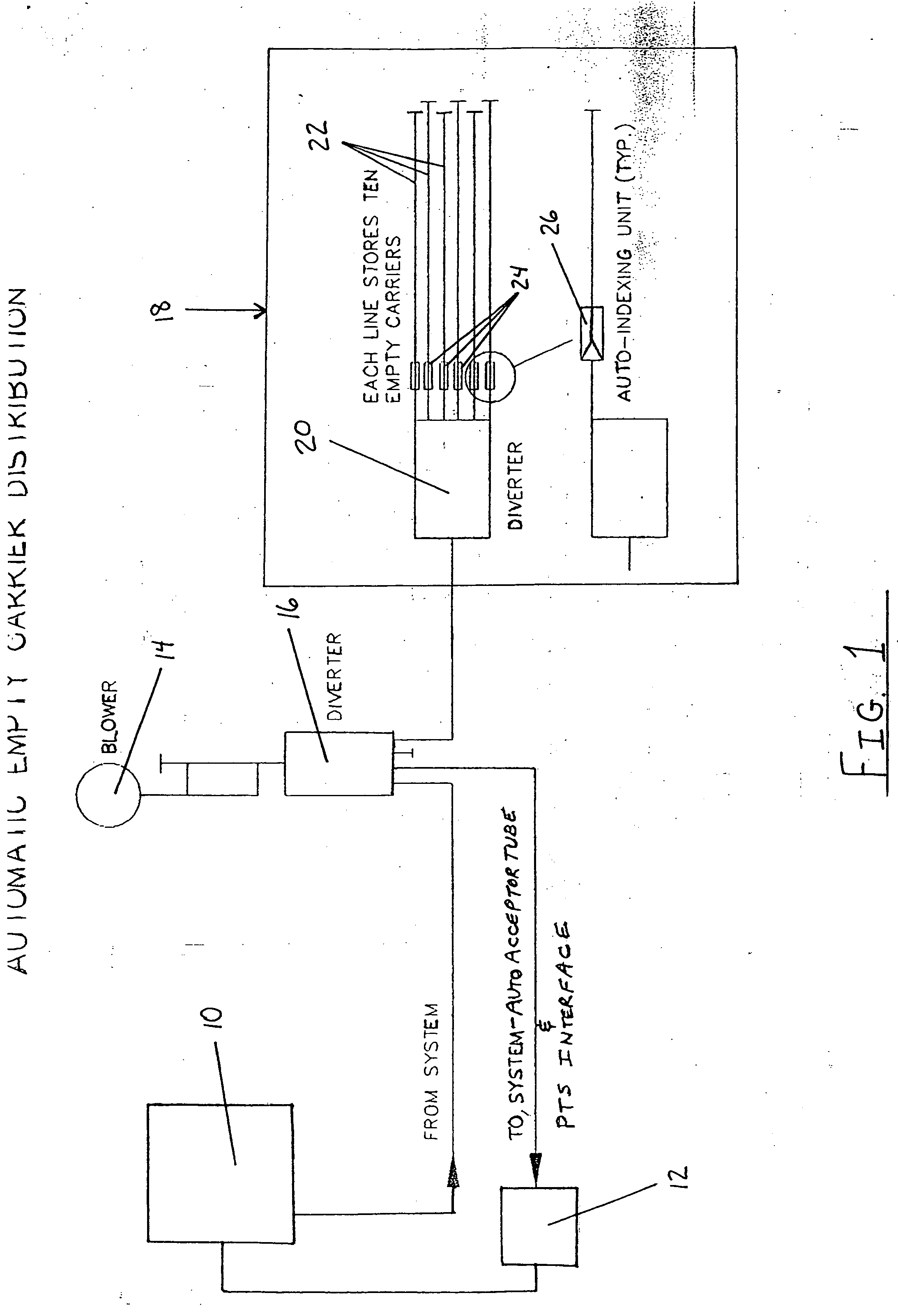

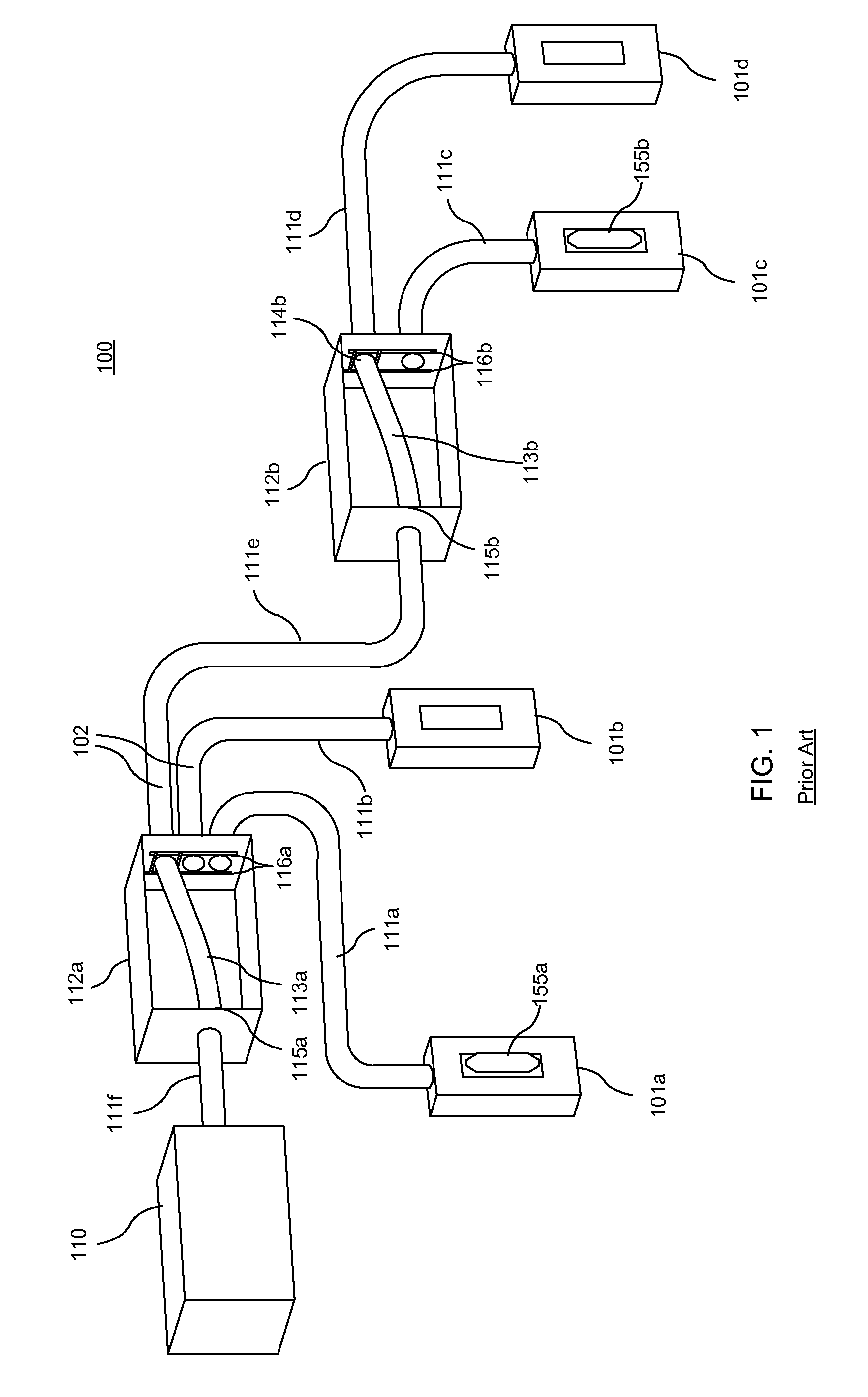

Automatic empty carrier storage, retrieval and distribution system

InactiveUS7751930B2Quick and reliableEasy to operateAcutation objectsConveyorsPrimary stationMarket place

The present invention relates to pneumatic tube systems generally. More specifically, it relates to an automated system for the storage and distribution of empty carriers for a pneumatic tube system. The system comprises an easy to use one-touch process and includes the following apparatus: storage cabinets and pneumatic tube system comprising a blower, controller, retrieval cabinets, and main station.According to the invention there is provided an automated storage and distribution system comprising a pneumatic tube system, a first diverter with blower, and a storage cabinet with a second diverter. The system comprises several methods which are currently in the market place, and is useful in many places, such as hospitals, where the automated processing of pharmaceutical products via robot devices is used. Such a system is disclosed in co-pending application Parenteral Products Automation System (PPAS), application Ser. No. 08 / 513,569.

Owner:PEVCO SYST INT

Gas drive fluid lifting system

A passive collection and pneumatic lifting system located in a well comprising a pneumatic tube, a fluid tube mounted within the pneumatic tube creating an annulus and a jet barrel chamber formed between the pneumatic tube and fluid tube in fluid communication at the zone to be recovered. A valve in the jet barrel in communication with the jet barrel and the zone to be recovered for allowing passive flow of product to be recovered into the jet barrel for collection therein and for closing upon the introduction of pneumatic fluid pressure by a pneumatic pressure generator to generate pneumatic fluid pressure sufficient to drive the product collected in the jet barrel up hole for recovery. A seal is located below the valve for sealing the product zone in the well from flow except through the valve.

Owner:JET ELEVATORING SYST

Venturi system using closed loop air return for conveying flexible fabrics

InactiveUS6942133B2Avoid disadvantagesReduces equipment cost and labor cost and space requirementLiquid/gas/vapor article treatmentBulk conveyorsAcute angleNoise level

Owner:AUTOMATION DYNAMICS

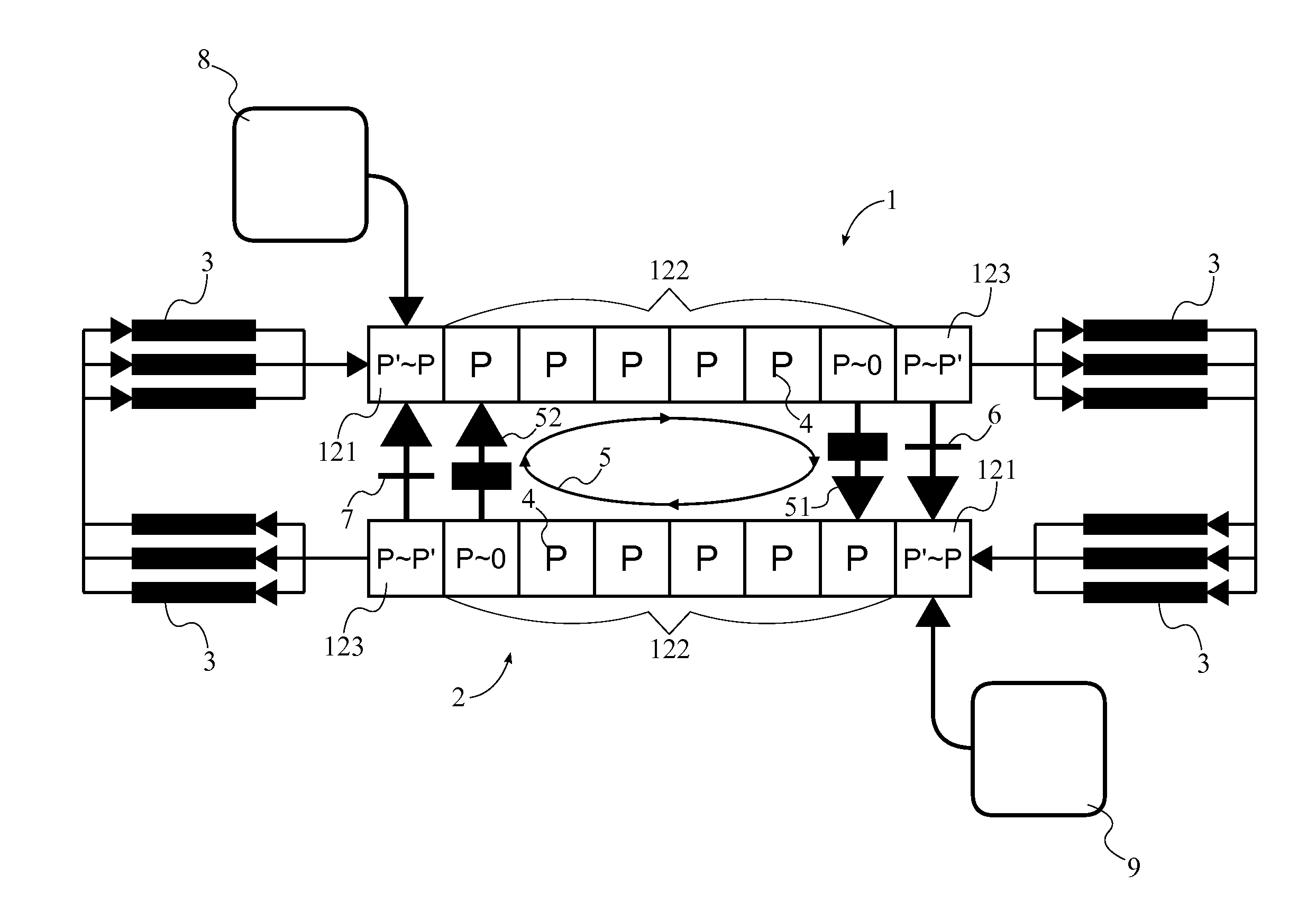

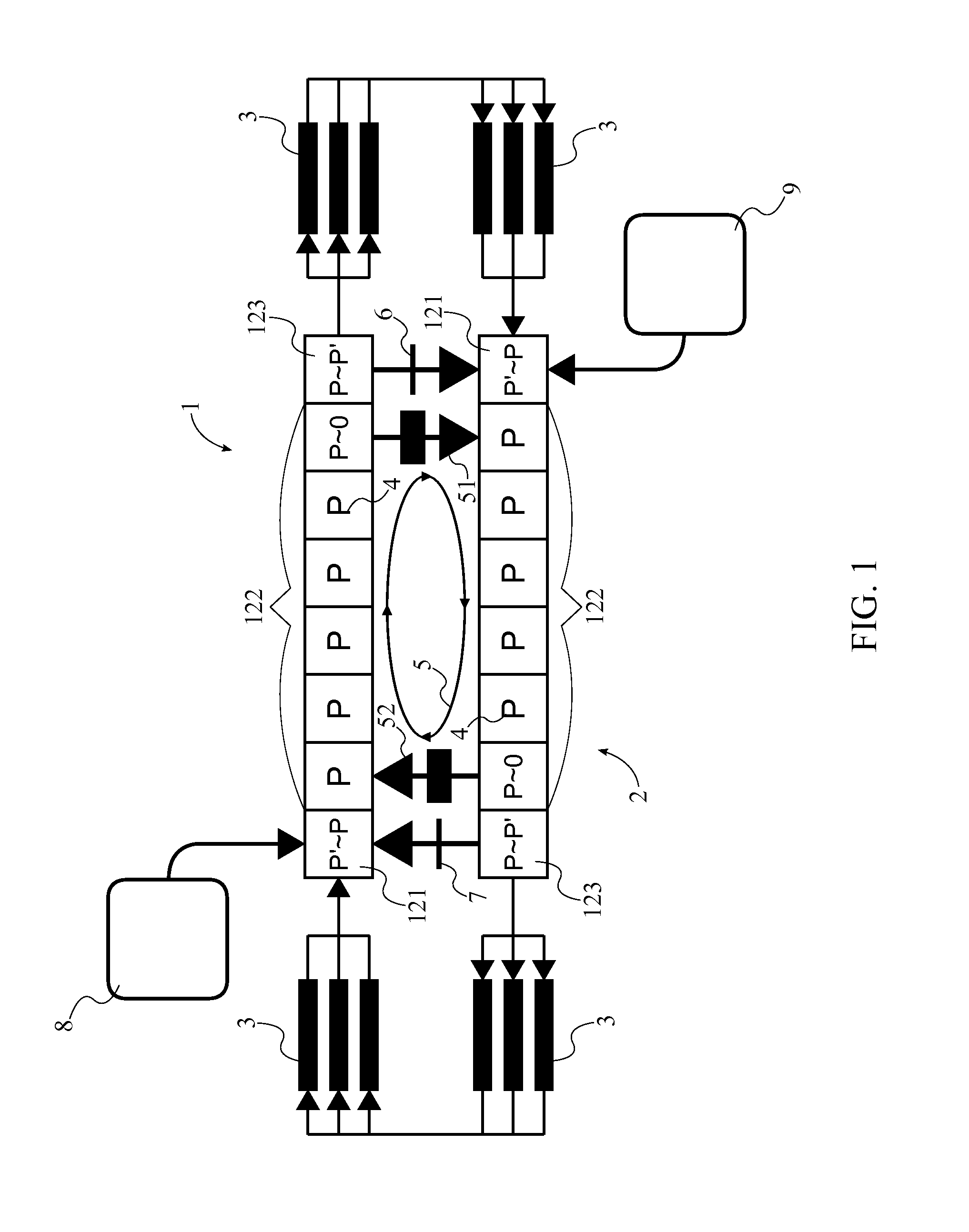

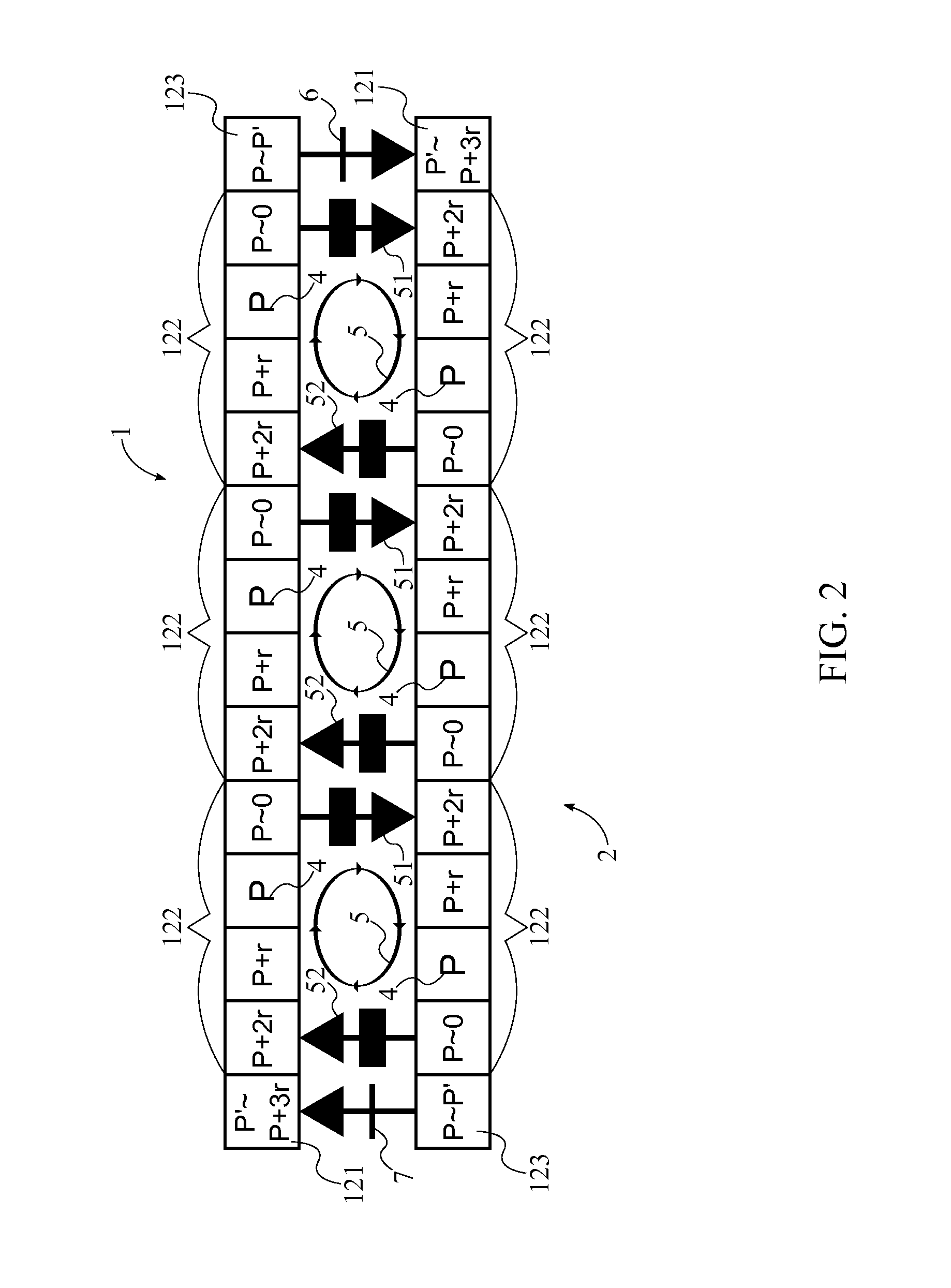

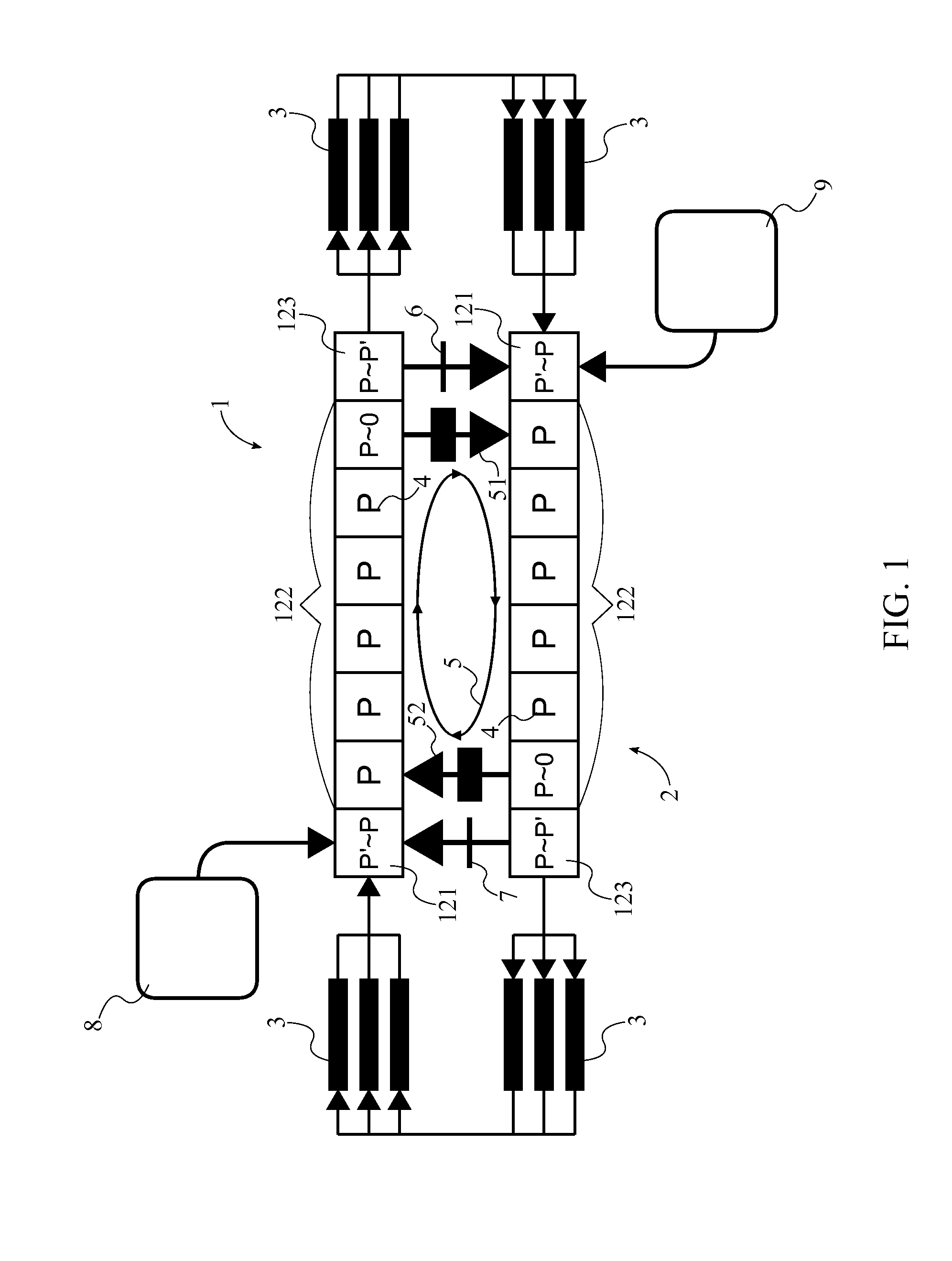

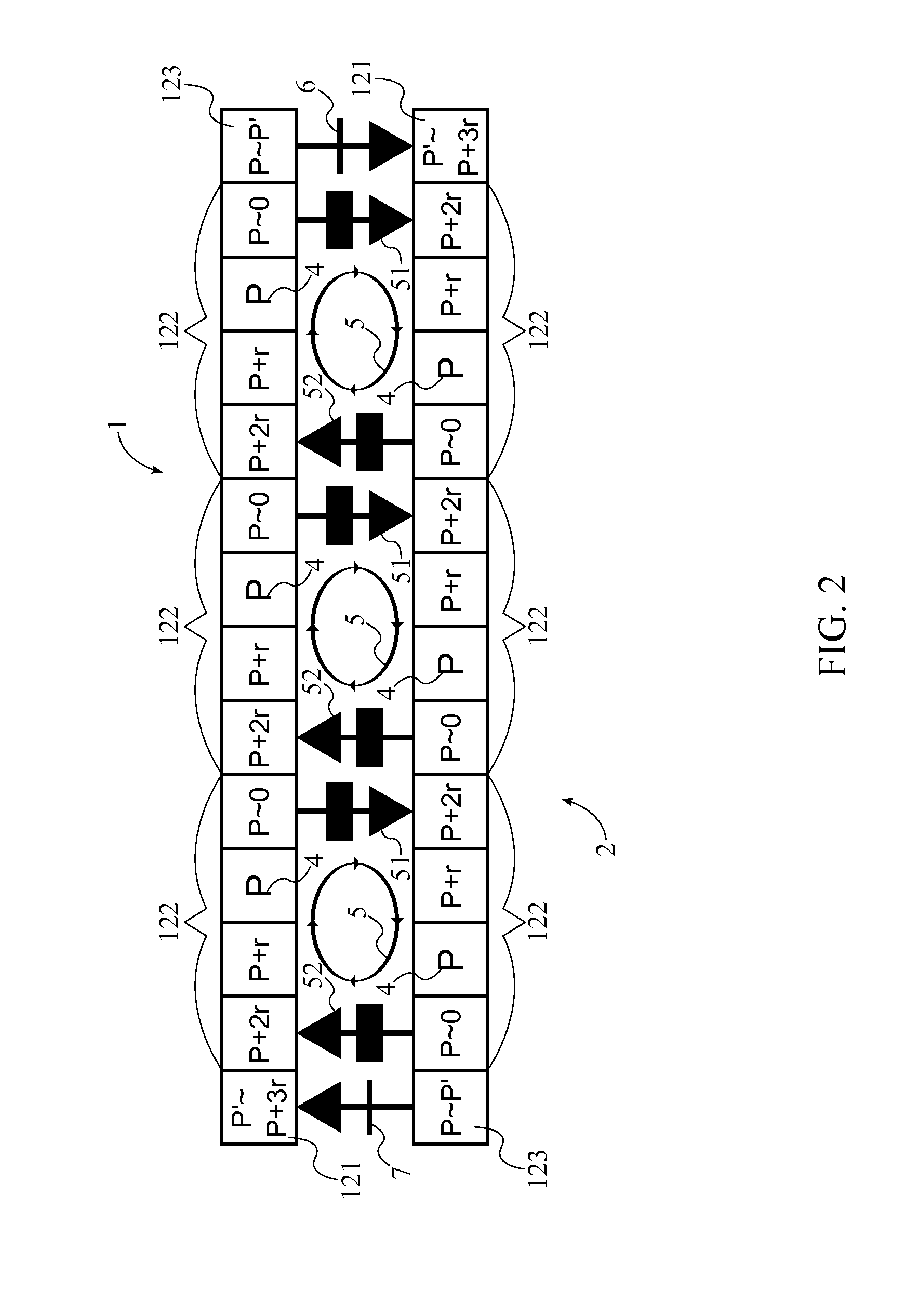

Circulated pneumatic tube transit system

A circulated pneumatic tube transit system is used to transport passengers / cargo along a pair of pneumatic tubes, which are positioned along each other. Capsules are movably suspended within the tubes by either a maglev system or wheels. The capsules travel in opposite directions in each tube so that the system provides back and forth transportation between two destinations. A fluid loop mechanism cycles a volume of air through the tubes as a means to propel the capsules through each tube. A series of fluid loop mechanism can be air multipliers as the volume of air cycles through the tubes. Two one-directional valves are located at opposite ends of the tubes and are used to transfer the kinetic energy for an arriving capsule within one tube into kinetic energy for a departing capsule within the other tube.

Owner:ZHOU BO

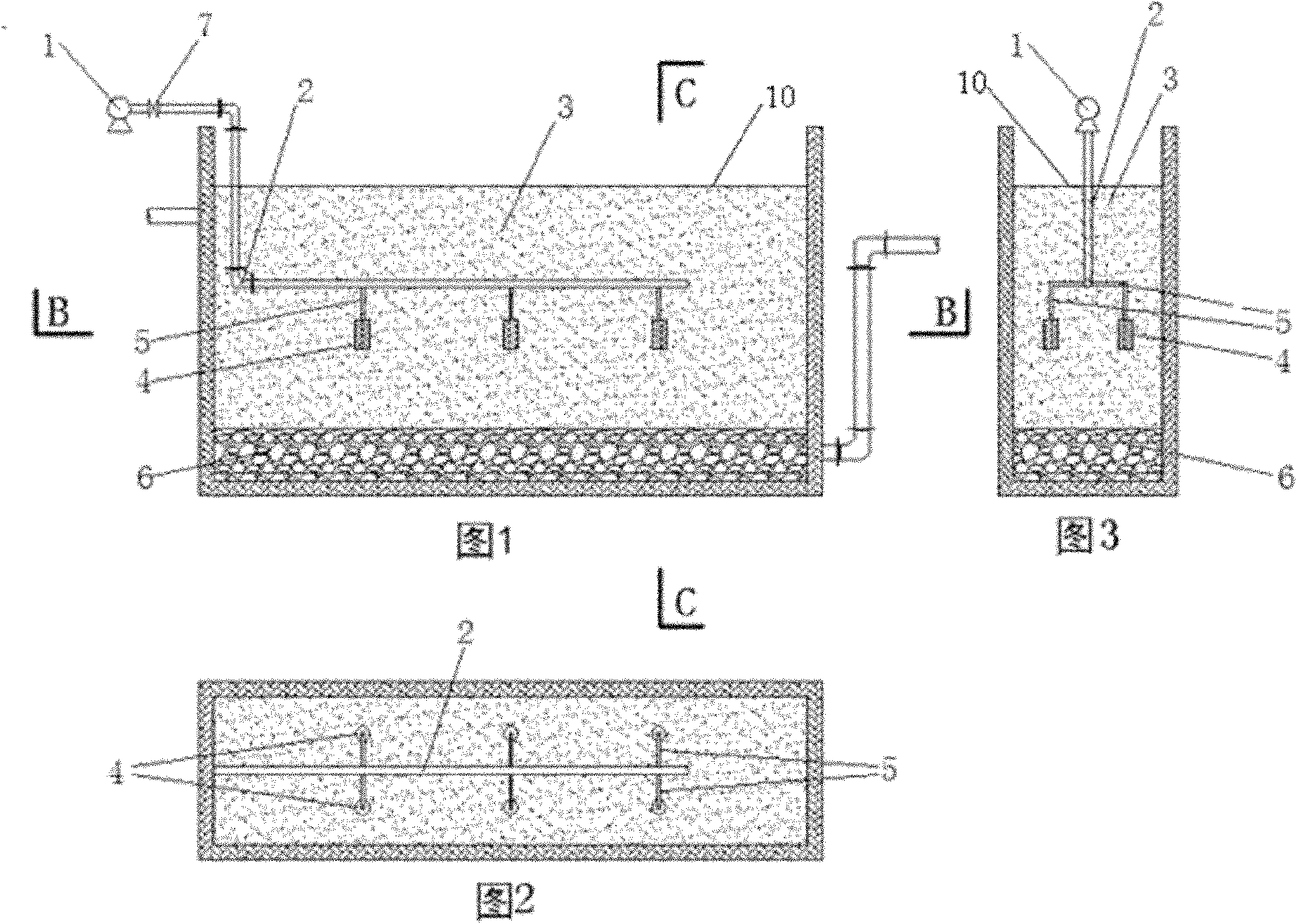

Anti-plugging method and device of constructed wetland

InactiveCN102126791AImprove operational efficiencyInhibit massive proliferationTreatment with aerobic and anaerobic processesSustainable biological treatmentConstructed wetlandEnvironmental engineering

The invention discloses an anti-plugging device of a constructed wetland. The anti-plugging device is characterized by comprising a water collection area substrate and a wetland substrate which are distributed in a vertical current constructed wetland from down to up, wherein wetland plants are grown on the wetland substrate; a pneumatic tube is installed in the wetland substrate; the horizontal section of the wetland substrate faces downwardly and provided with an aeration branch pipe in parallel; the end head of the aeration branch pipe is provided with an aeration head, and the aeration head is located in the middle of the wetland in a vertical direction; one end of the pneumatic tube extending out of the wetland substrate is connected with a gas pump and provided with a valve; and the water collection area substrate is made of gravel, and the wetland substrate is made of coarse sand. The air passes through the pneumatic tube by the gas pump and then is output from the aeration branch pipe and the aeration head, so that the convention current is formed between the air and downlink flooding water so as to impact substrate particles, thereby improving effective porosity, inhibiting blockage and ensuring aerobic environment required by activity of wetland microorganisms.

Owner:HOHAI UNIV

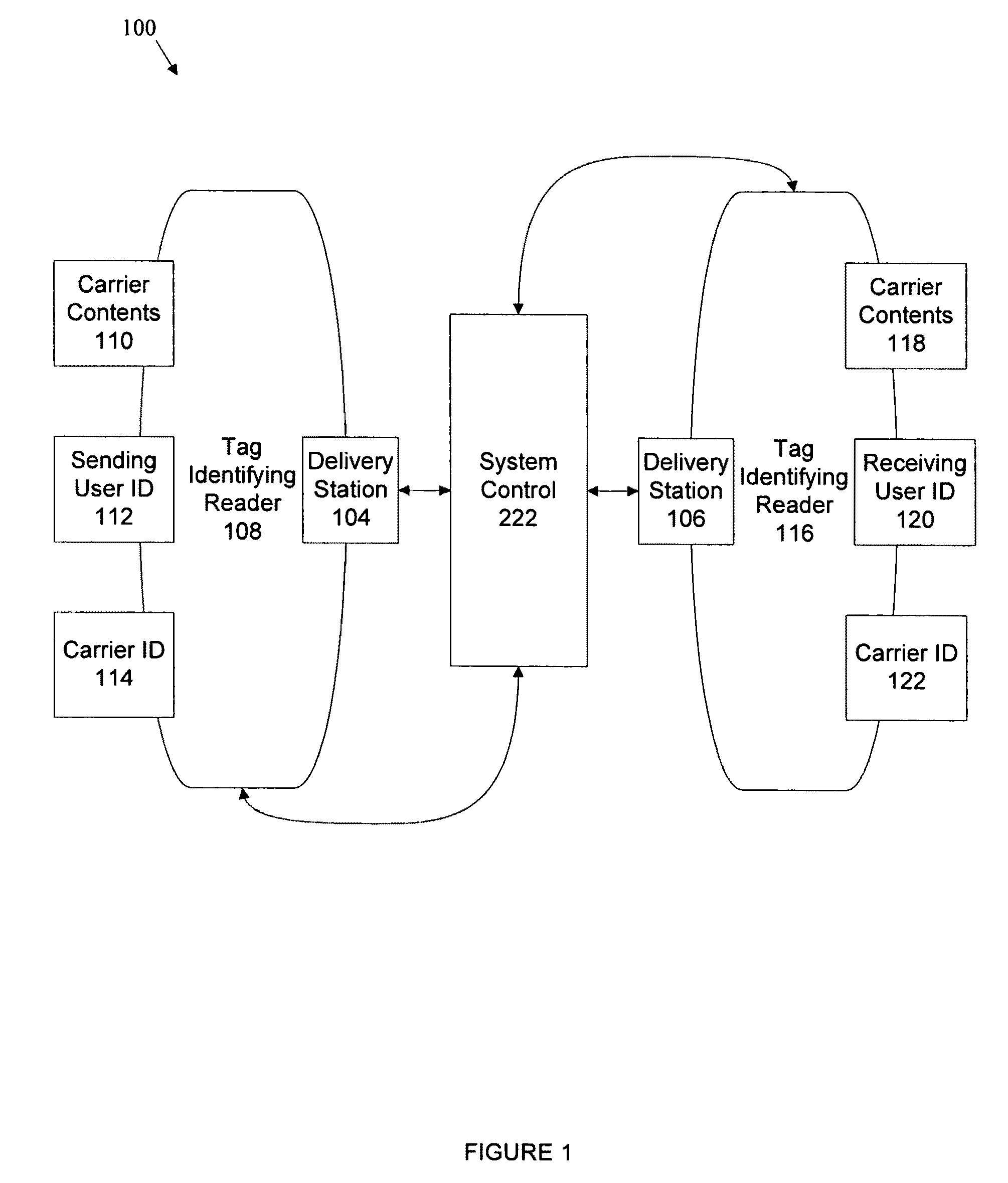

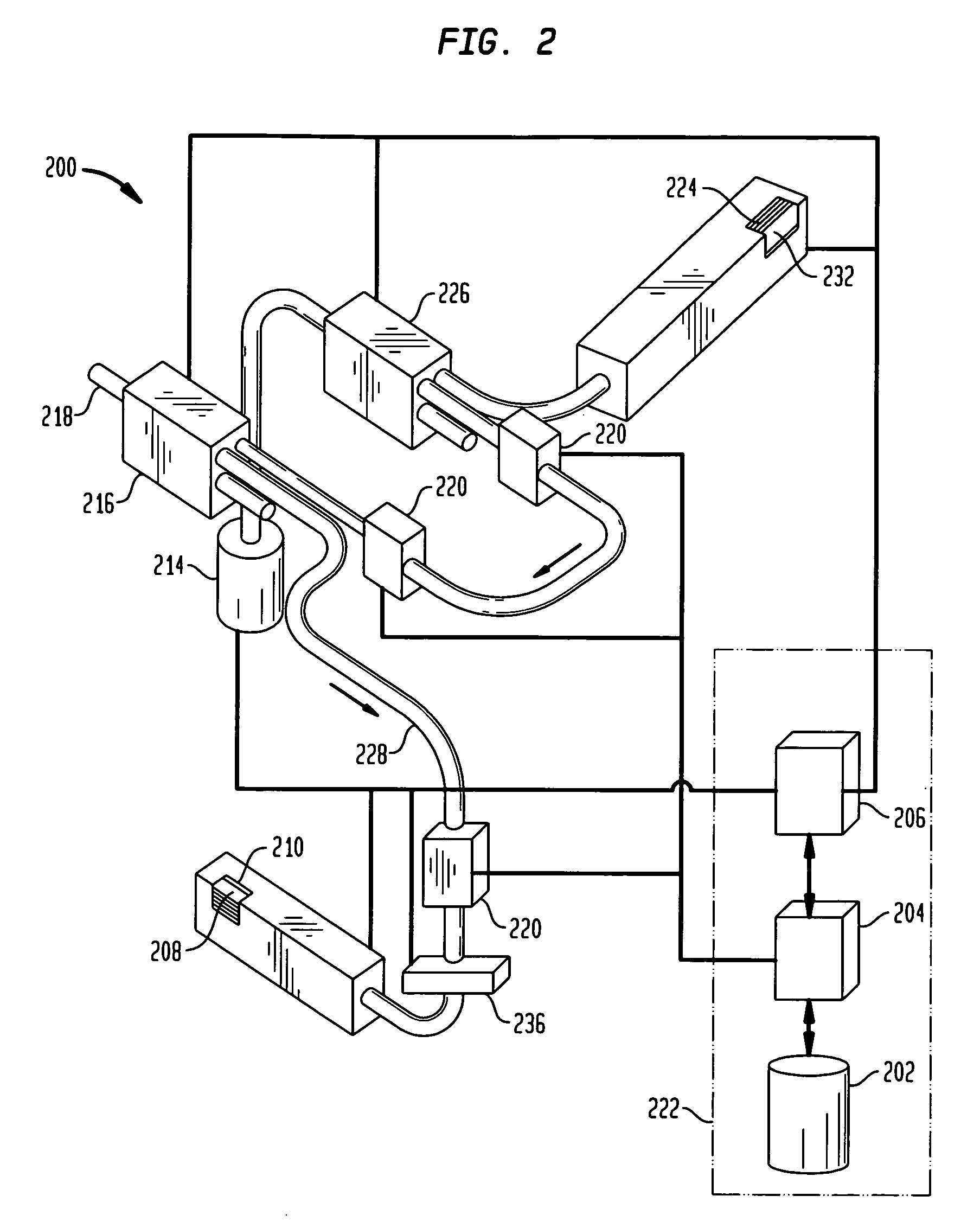

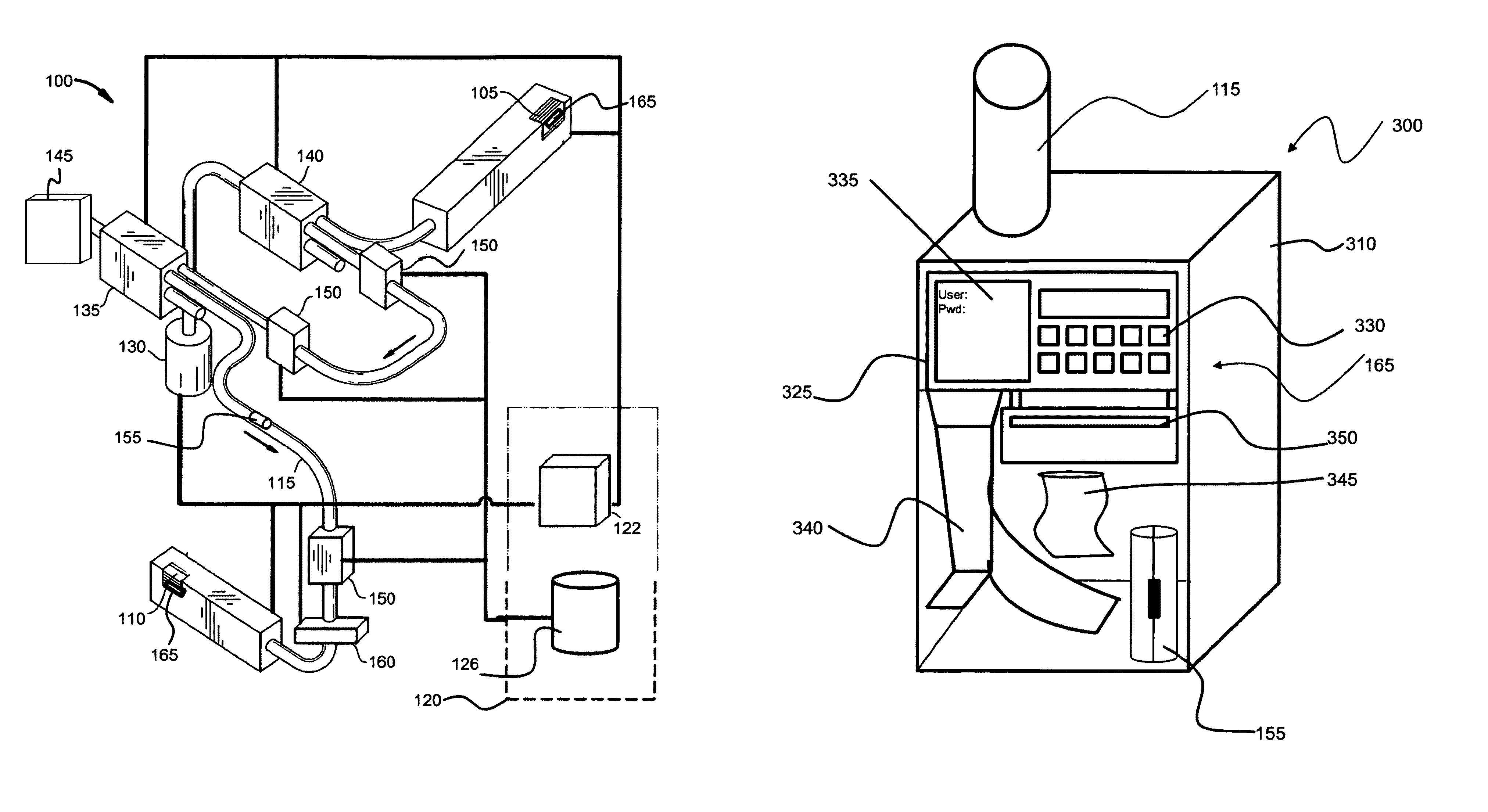

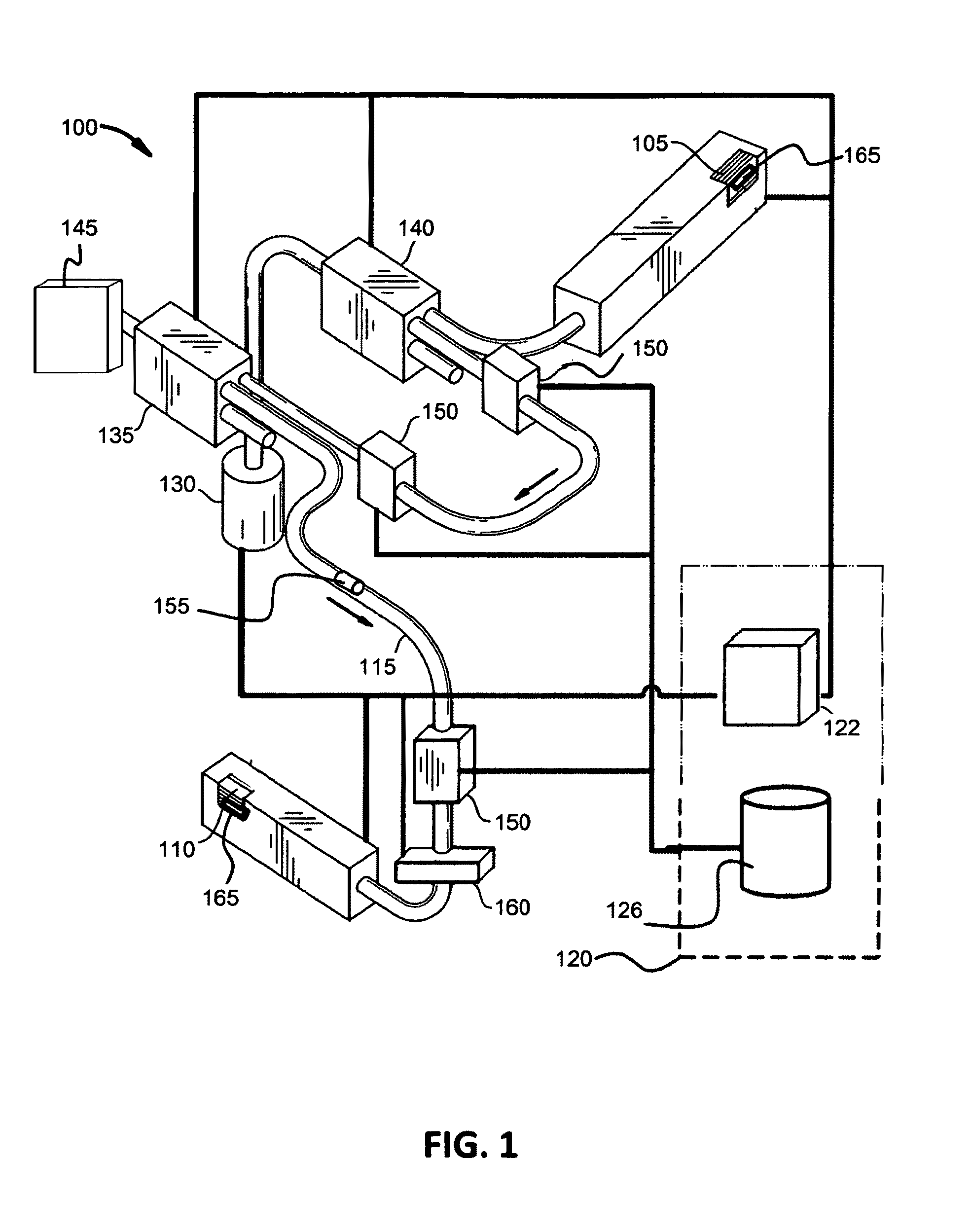

Pneumatic tube carrier tracking system

ActiveUS8116906B2Data processing applicationsDigital data processing detailsCarrier signalComputer module

A system and method provides for a pneumatic tube carrier tracking system having a system control module that captures and presents tracking information associated with sending and receiving carriers. The pneumatic tube carrier tracking system comprises sending and receiving stations connected by pneumatic tubing, and which are configured to securely send carriers, with receiving users optionally being restricted from unauthorized access of carriers. The sending and receiving stations have identifying tag readers configured to scan identifier tags to read carrier delivery, carrier receipt and receiving user information. Destination and intended recipient information are entered at the sending station when sending a carrier and are transmitted to a system control module, which routably delivers and secures the carriers in response the destination and intended recipient information.

Owner:PEVCO SYST INT

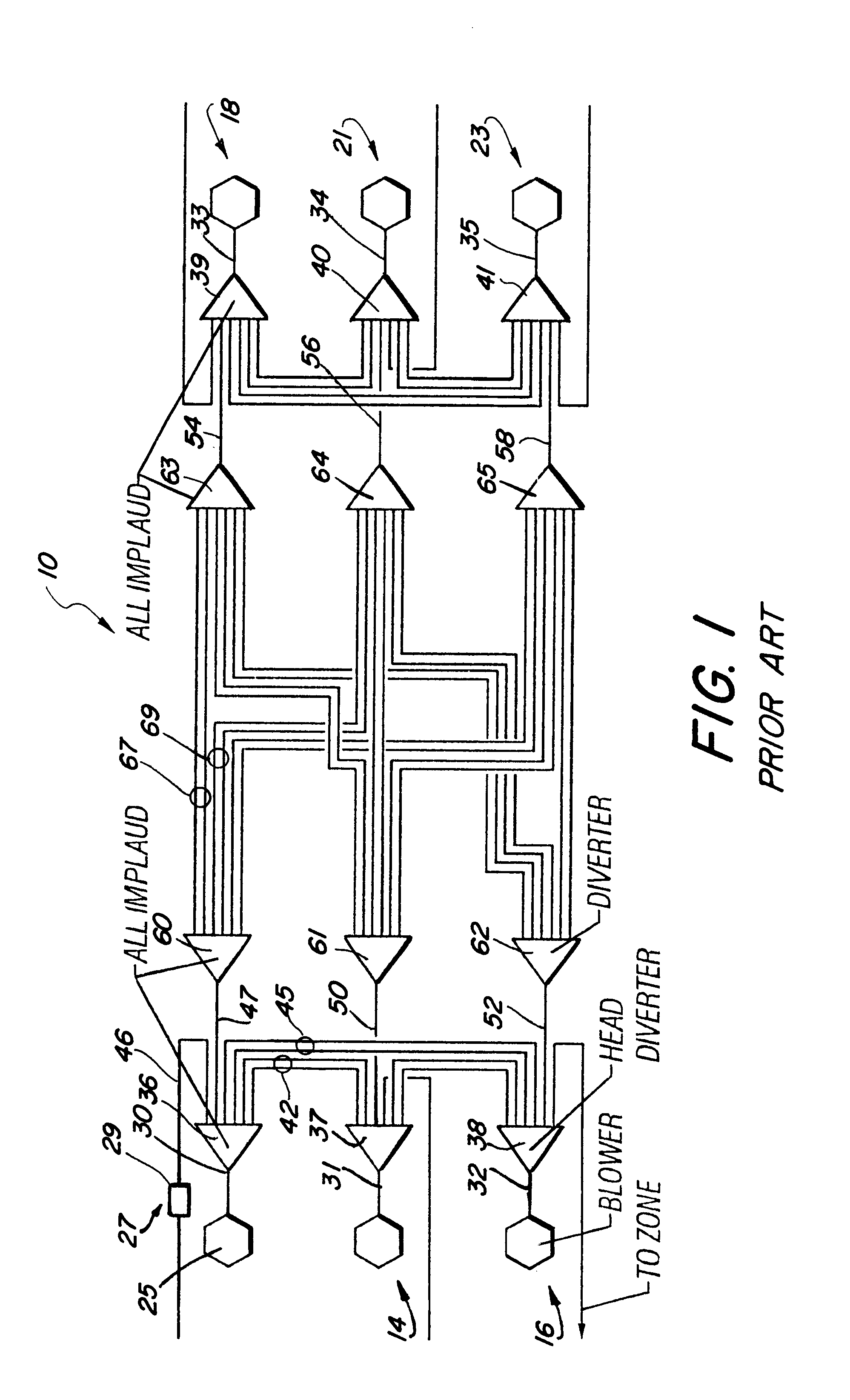

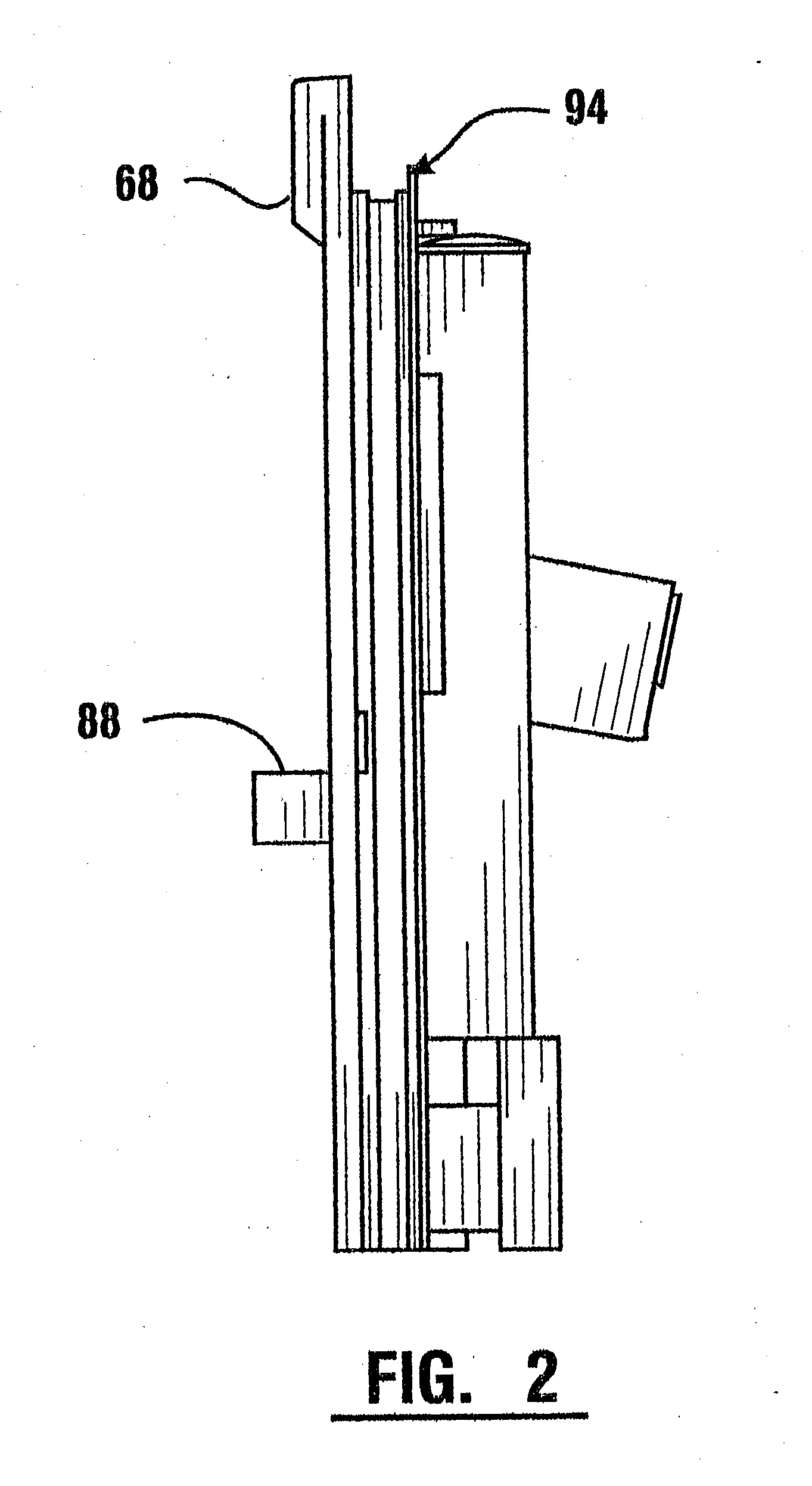

Automatic empty carrier storage, retrieval and distribution system

InactiveUS20050273196A1Easy to useQuick and reliableConveyorsDigital data processing detailsPrimary stationMarket place

The present invention relates to pneumatic tube systems generally. More specifically, it relates to an automated system for the storage and distribution of empty carriers for a pneumatic tube system. The system comprises an easy to use one-touch process and includes the following apparatus: storage cabinets and pneumatic tube system comprising a blower, controller, retrieval cabinets, and main station. According to the invention there is provided an automated storage and distribution system comprising a pneumatic tube system; a first diverter with blower, and a storage cabinet with a second diverter. The system comprises several methods which are currently in the market place, and is useful in many places, such as hospitals, where the automated processing of pharmaceutical products via robot devices is used. Such a system is disclosed in co-pending application Parenteral Products Automation System (PPAS), application Ser. No. 08 / 513,569.

Owner:PEVCO SYST INT

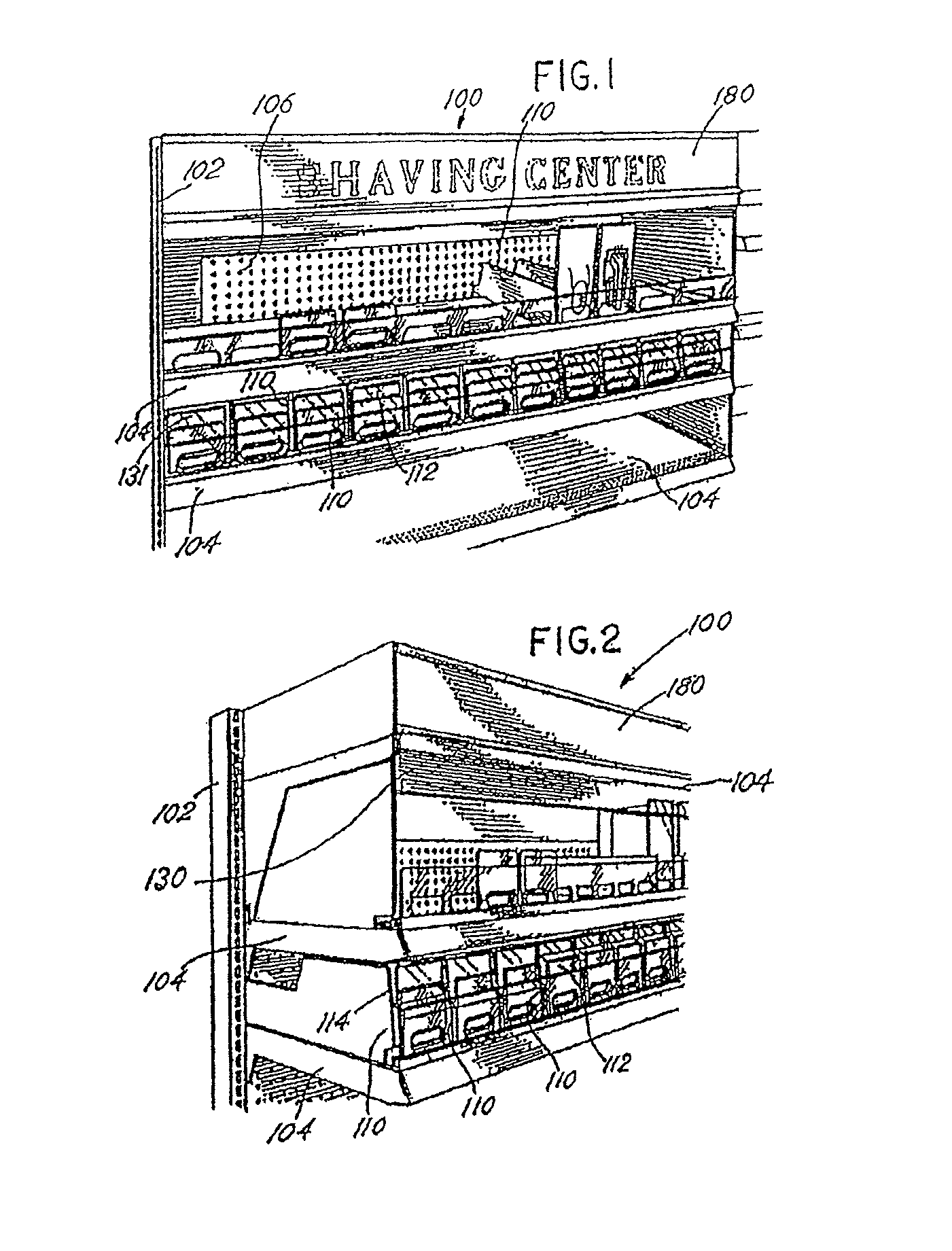

Transaction system

InactiveUS20030179290A1Minimize unproductive timeGood serviceComplete banking machinesColor television detailsService provisionDisplay device

A system for carrying out transactions includes customer stations (118) and ATM stations (120) and a service provider station (114). The service provider station and customer stations are operated in a building (116) or other facility in which a service provider operates the service provider station in a secure room. Audio and video communications are established between the service provider and customers at the customer stations and ATM stations. Items can be exchanged between customer station customers and the service provider through carriers (26) transmitted through a pneumatic tube system (22). A video material presentation device (50) provides promotional or other video material which may be presented on displays at the customer stations. The video material may be presented to customers when the customer terminal is not in communication with the service provider terminal.

Owner:DIEBOLD NIXDORF

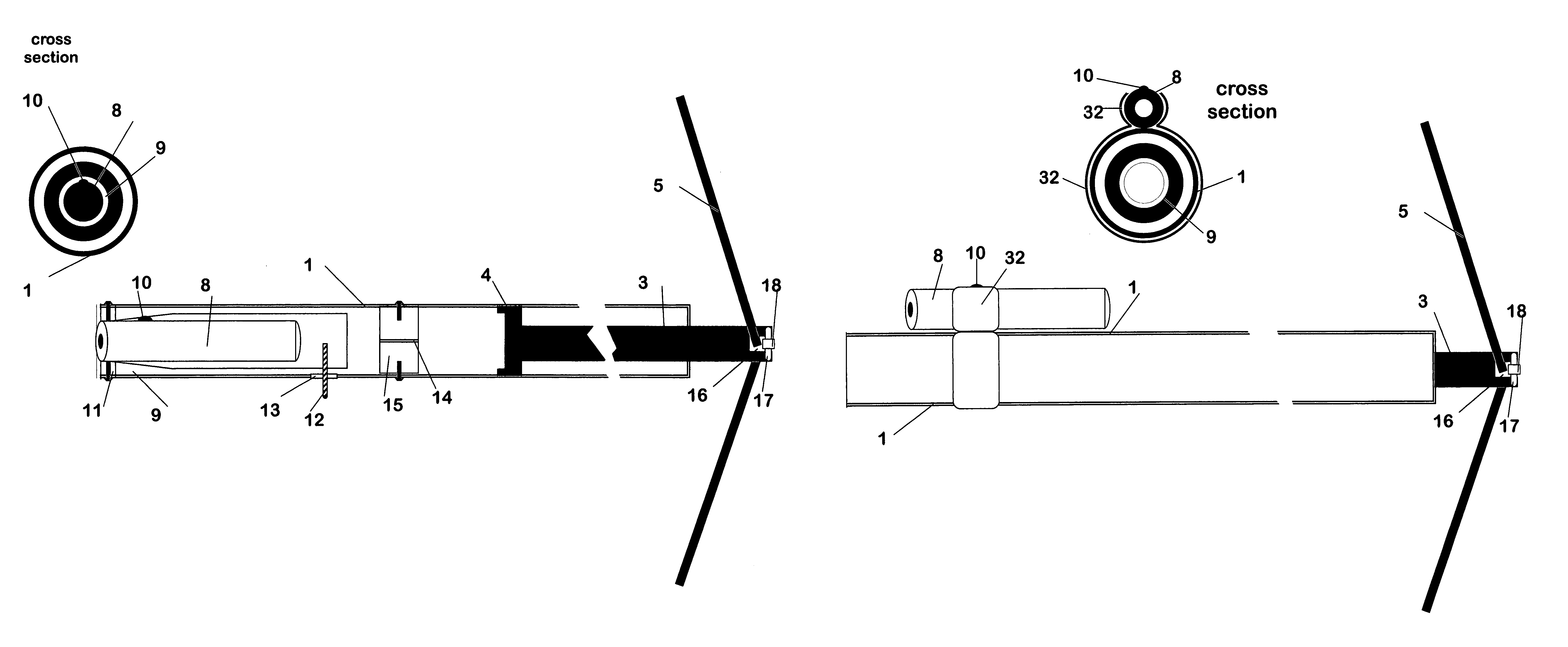

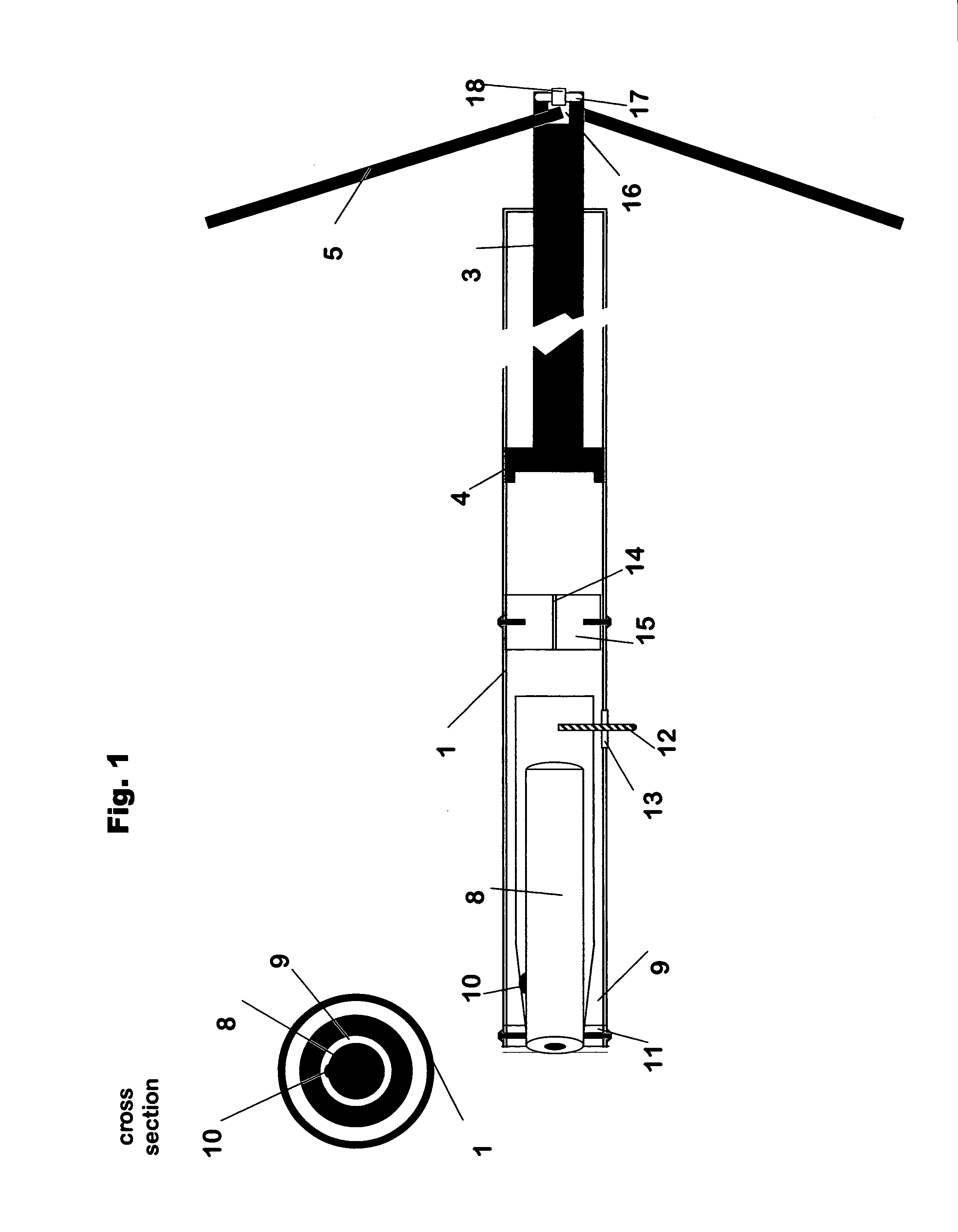

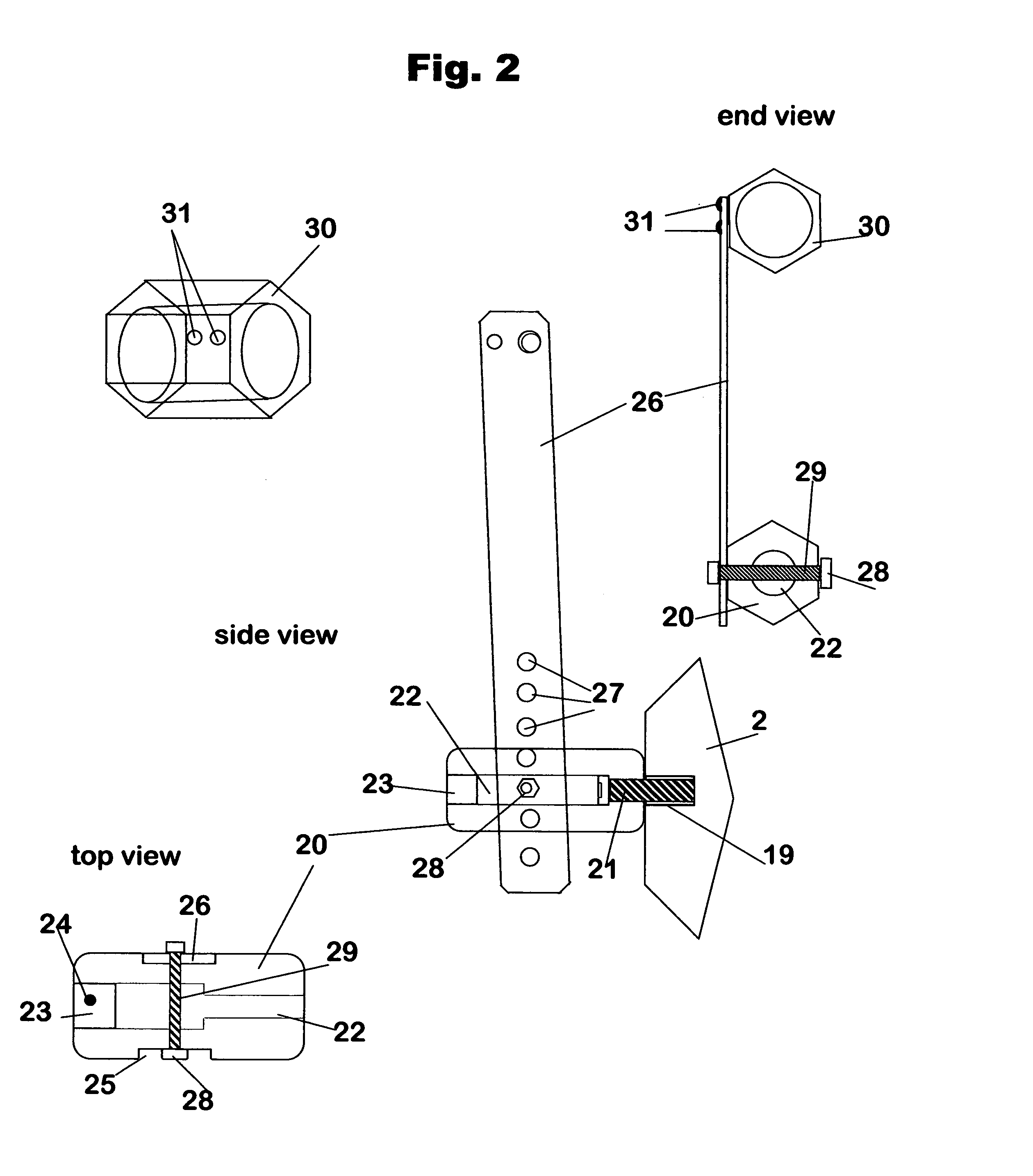

Laser-equipped pneumatic training aid for safe drawing of the bowstring

InactiveUS7216643B2Quickly and safely attachedEasy to separateBows/crossbowsSighting devicesAerodynamic dragLaser light

A pneumatic tube that is secured to the bow and bowstring with an arrow and piston inside for safe drawing and firing of an archery bow. When the archer looses the string and it drives the arrow forward, the piston creates pneumatic air resistance like a hand operated bicycle pump. This resistance is sufficient to prevent damage to the bow and / or its components from loosing the string without an actual arrow on the string. Normal loosing the string without an arrow on it is called “dry-firing” and would damage the bow and / or its components. This tube is attached to a bracket that is affixed to a mounting block that can be fastened to the front of the bow at the standard stabilizer mounting hole. There is also a laser mounted in the end of the tube, which can be turned on by the archer and projects a laser light on the target. This light is automatically turned off as the bow is fired, thus showing the archer exactly where an actual arrow would have hit. This device can be used without removing or disabling the arrow rest and is used in practice and to identify and then rectify any release flaws and other shooting maladies.

Owner:PELLERITE BERNARD M

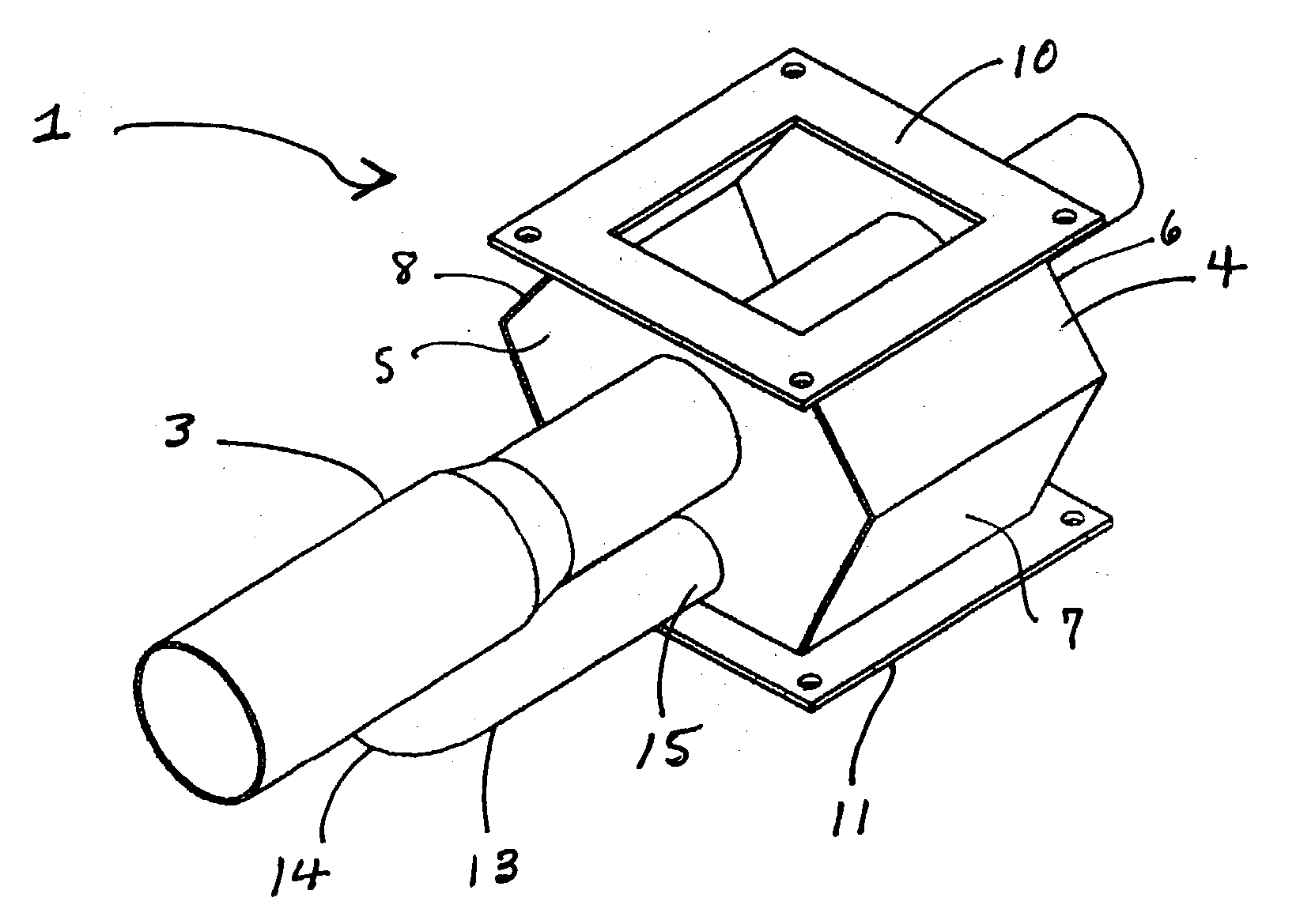

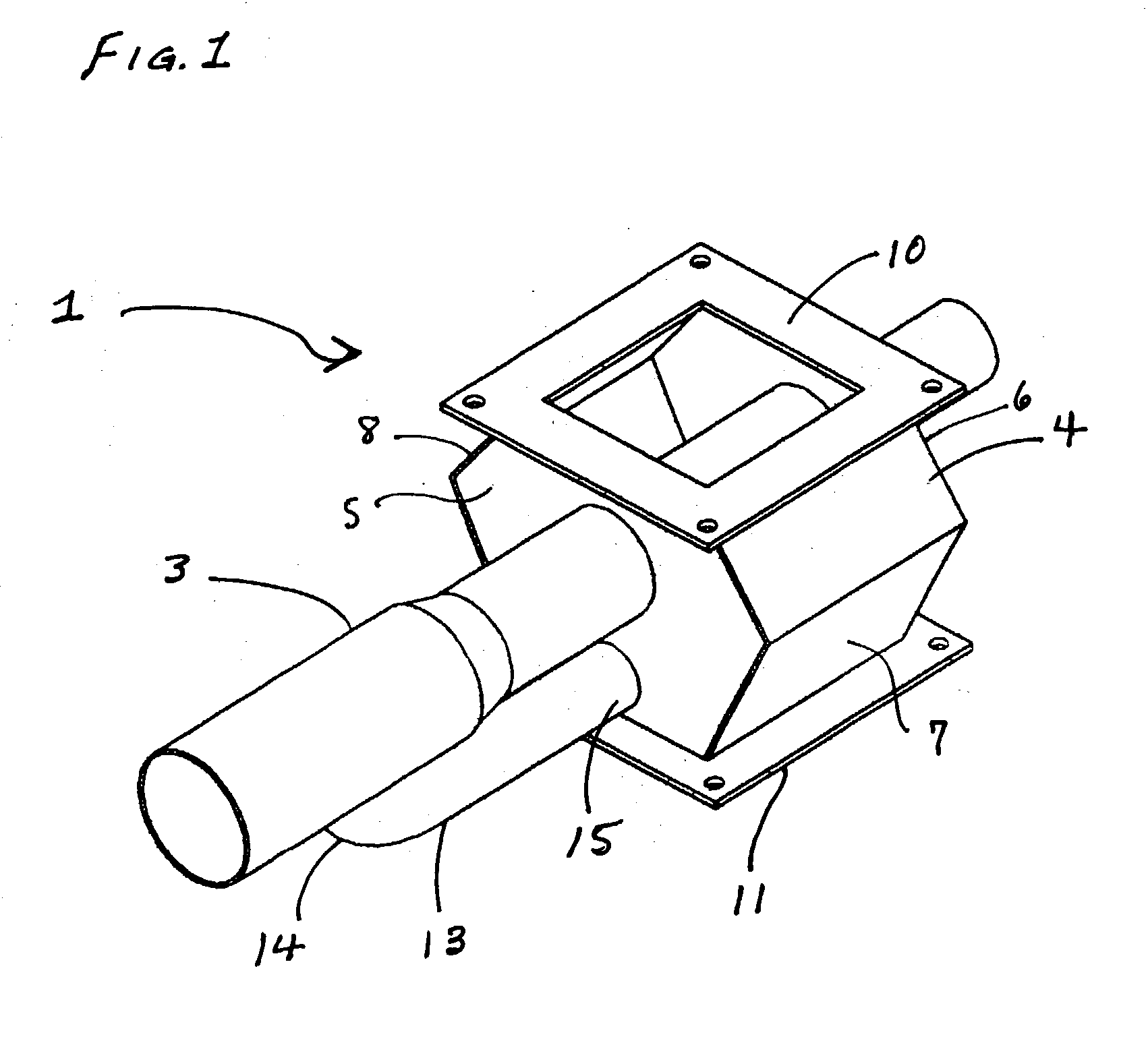

Seed eductor assembly

InactiveUS20040163578A1Reduce and eliminate clogPotato plantersFurrow making/coveringLine tubingEngineering

An eductor assembly is adapted for seed delivery and is designed to reduce or eliminate clogs. The eductor uses a compartment comprising a feed section into which falls seed from a primary storage hopper. A primary pneumatic tube runs through the compartment and continues on to delivery sites such as secondary hoppers which feed the seed to singulators. A secondary pneumatic tube branches from the primary tube and opens into the compartment generally below the primary tube, pressurizing the compartment and creating turbulence sufficient to prevent seed from packing. An eductor tube is mounted within the compartment and has an open, lower end that extends from adjacent the termination of the secondary pneumatic tube so that seed accumulating in the compartment is drawn through the eductor. The eductor tube at its upper end extends into the primary pneumatic tube and has an outlet end positioned so as to form a constriction in the first pneumatic line to create a venturi to draw seed through the eductor tube. Any clogs that occur at the constriction in the primary pneumatic tube are relieved by a concurrent increase in air pressure and flow rate through the secondary pneumatic tube to urge seed through the eductor and break the clog. Additionally, the turbulent mixing of the seed in the eductor compartment inhibits packing, bridging and clogging of the seed.

Owner:CRUSTBUSTERSPEED KING

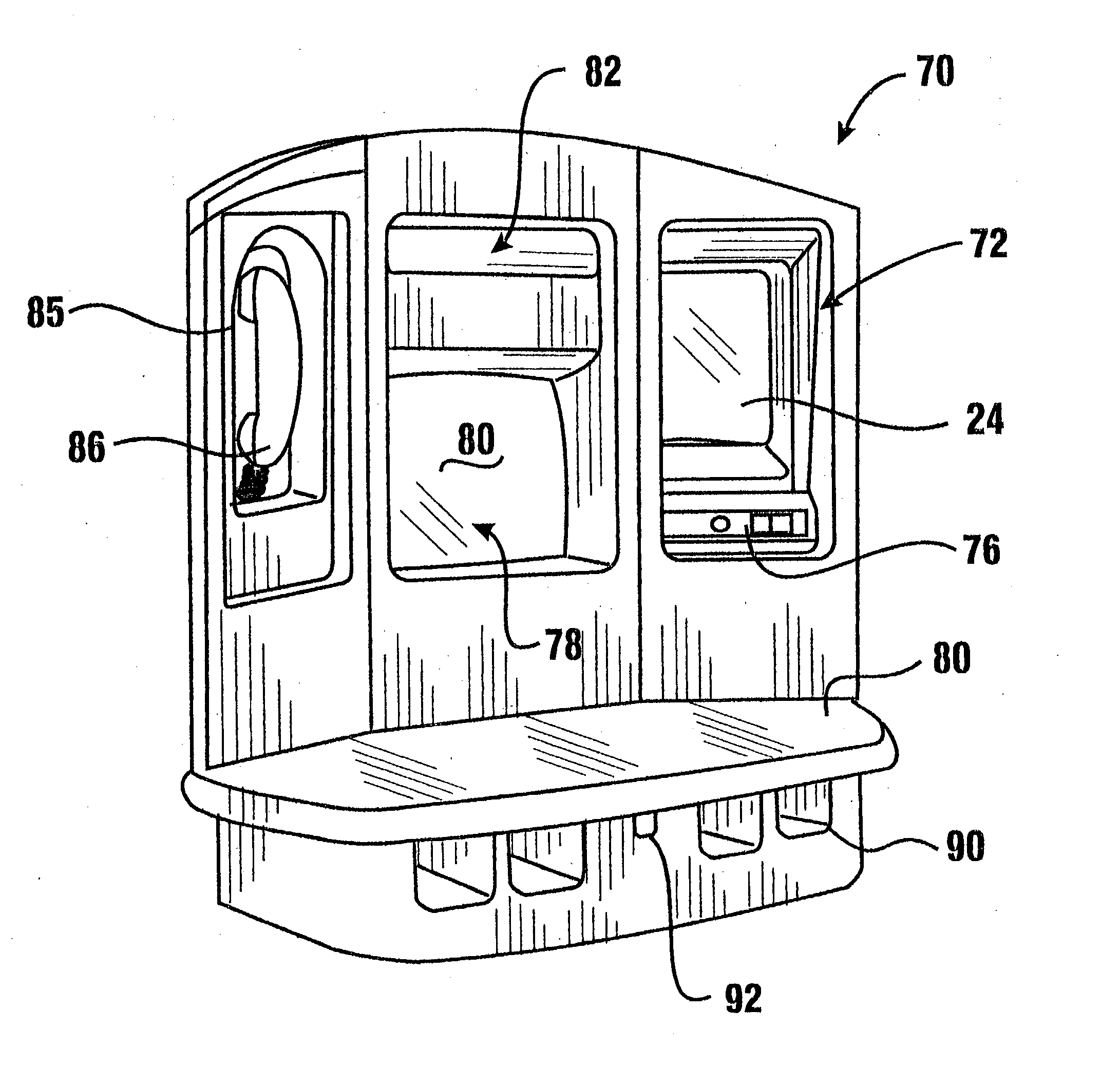

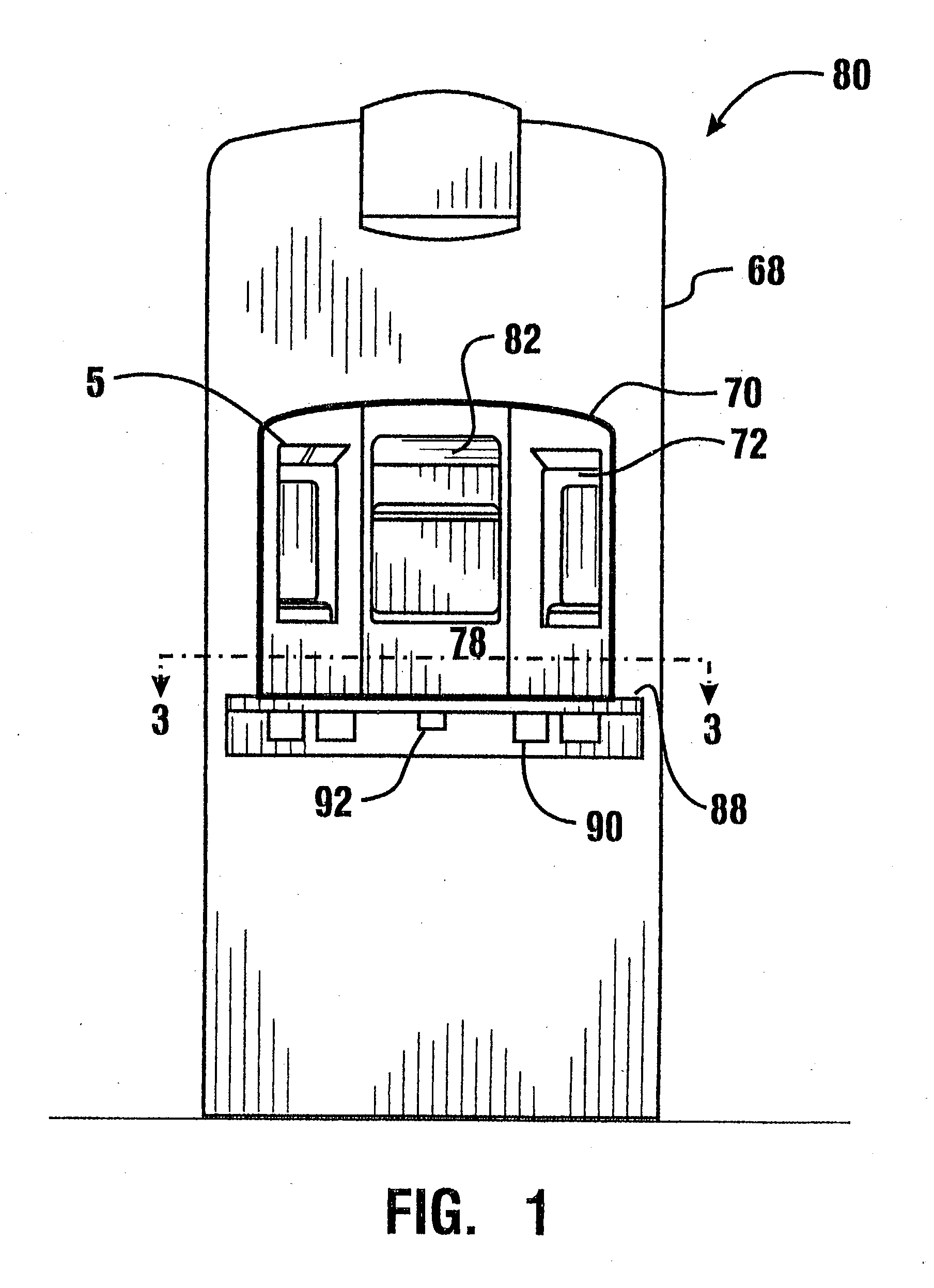

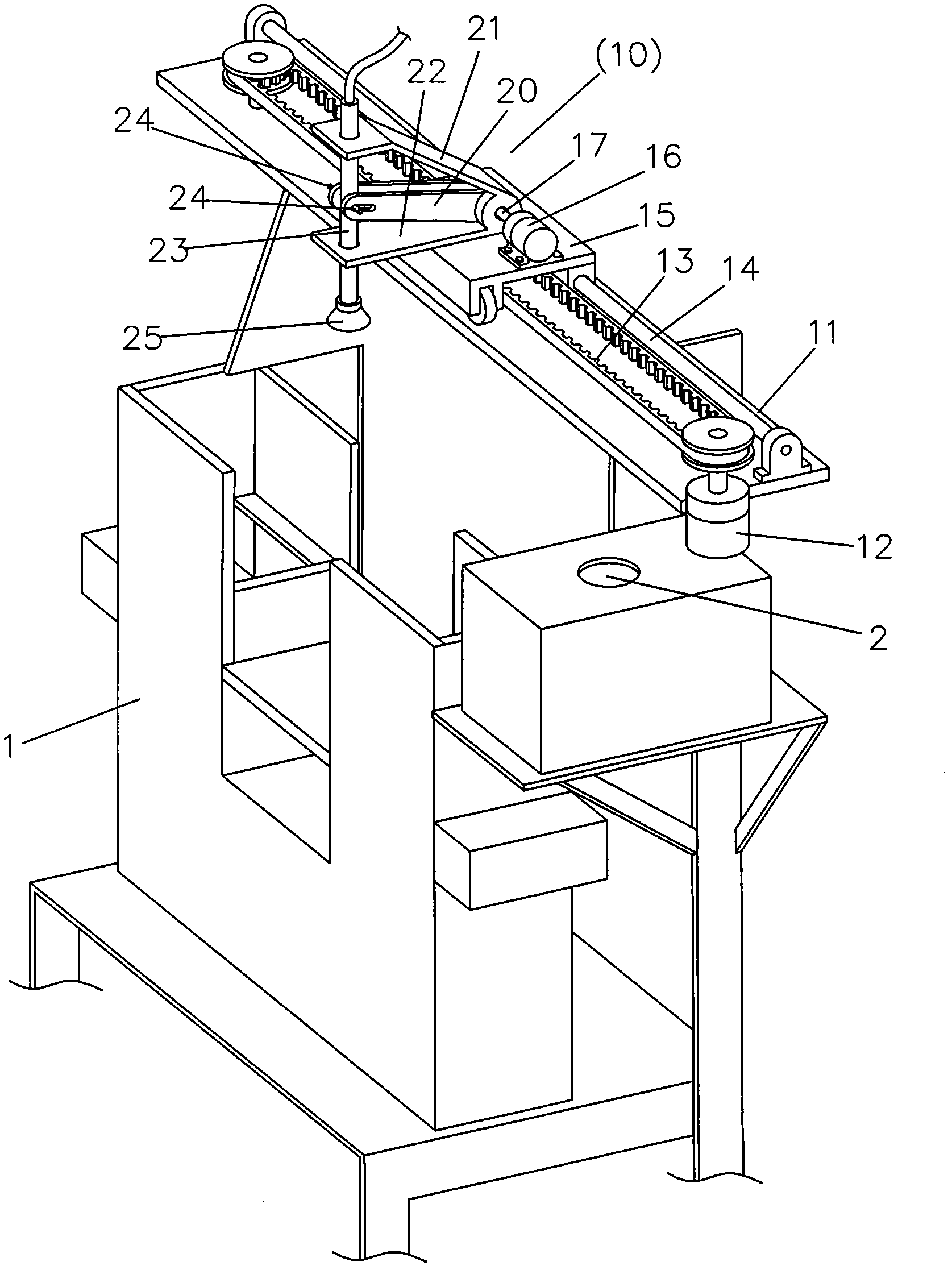

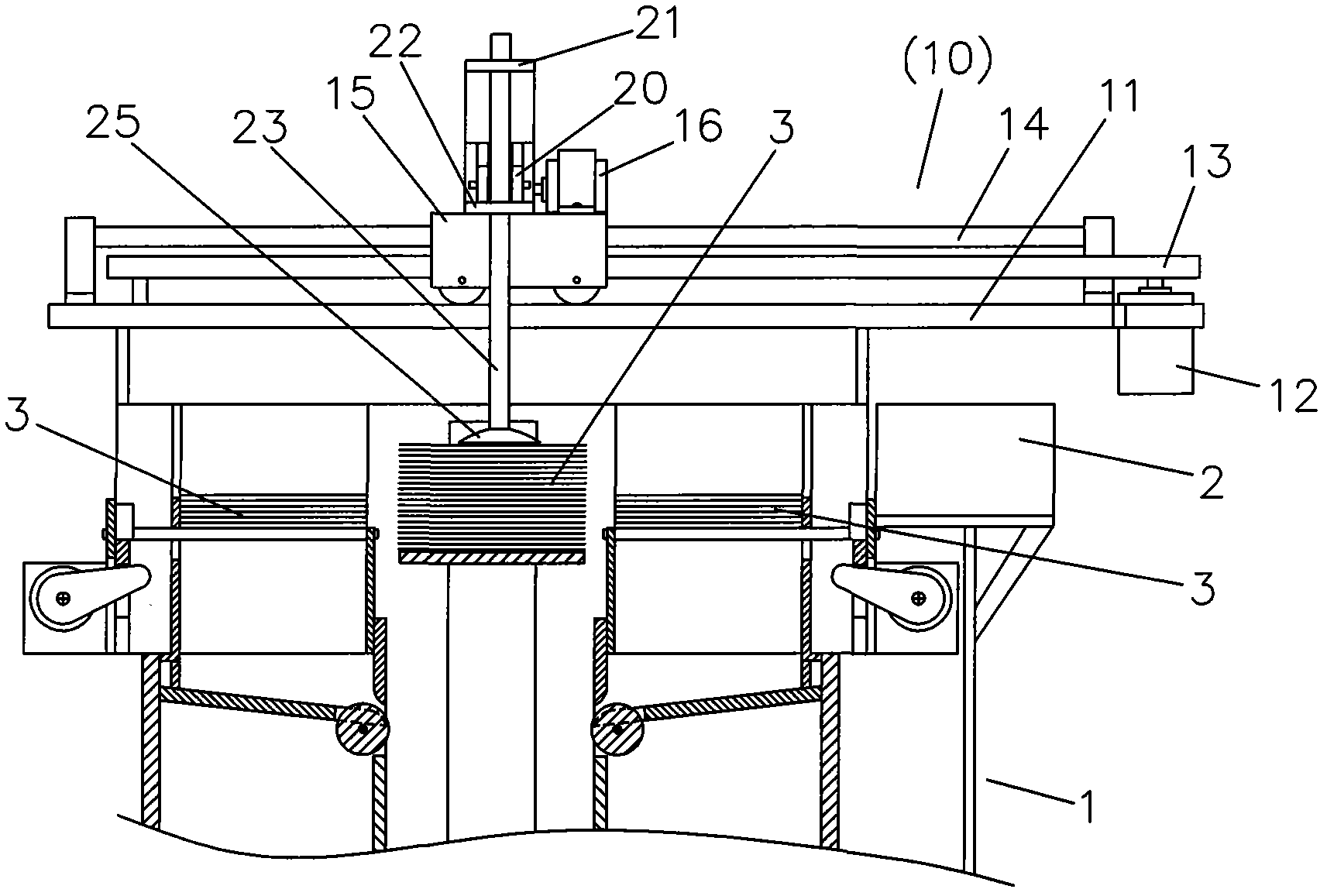

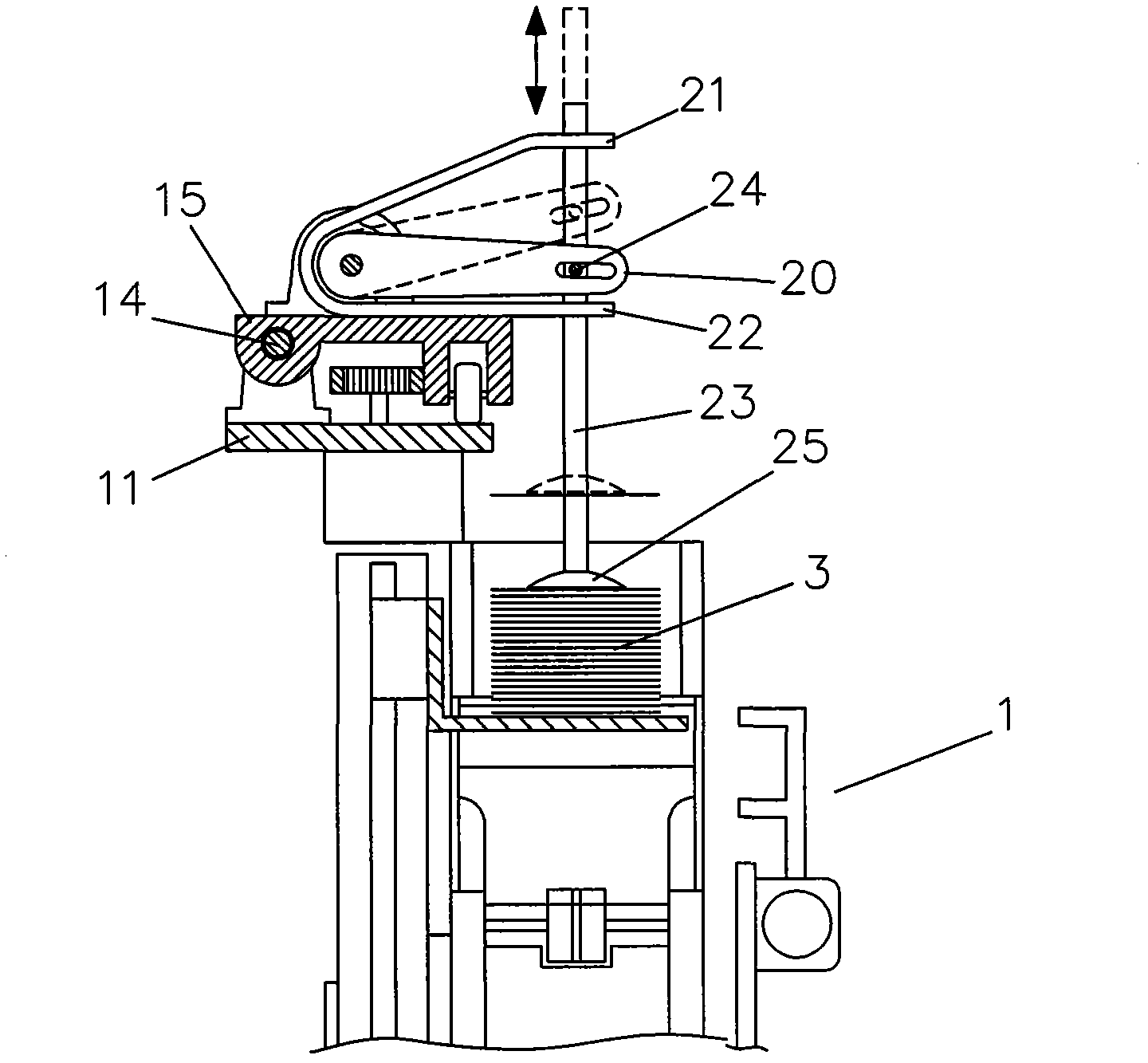

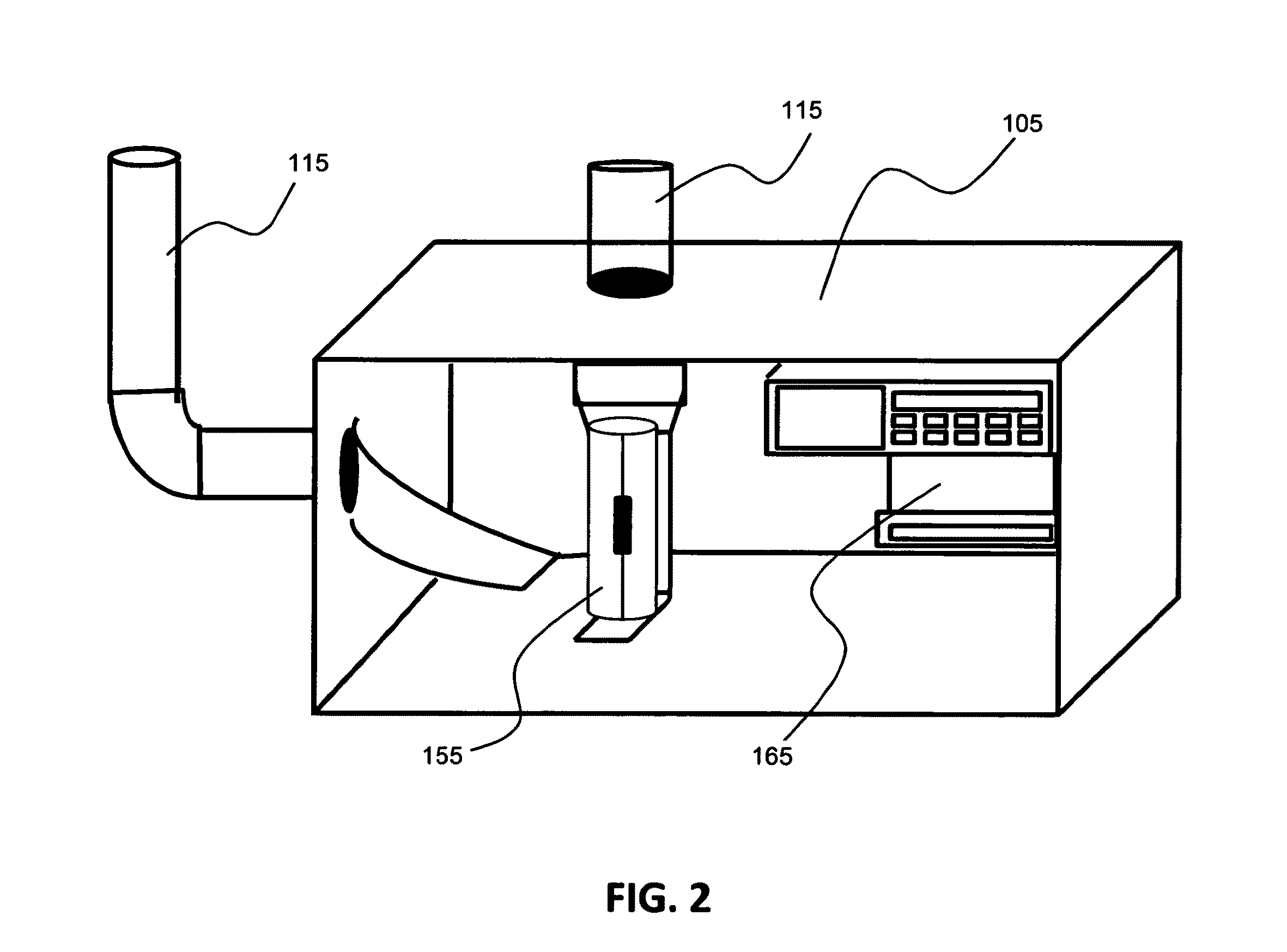

Pneumatic tube system terminal and method

A pneumatic transport system including a user terminal at a service provider station having a movable member operably connected with a flexible drive member. The drive member moves within at least one side rail to vertically displace the movable member to permit access to a carrier at the user terminal. The user terminal includes control mechanisms on opposite sides of a base to enable two users to operate and access the carrier at the user terminal.

Owner:DIEBOLD NIXDORF

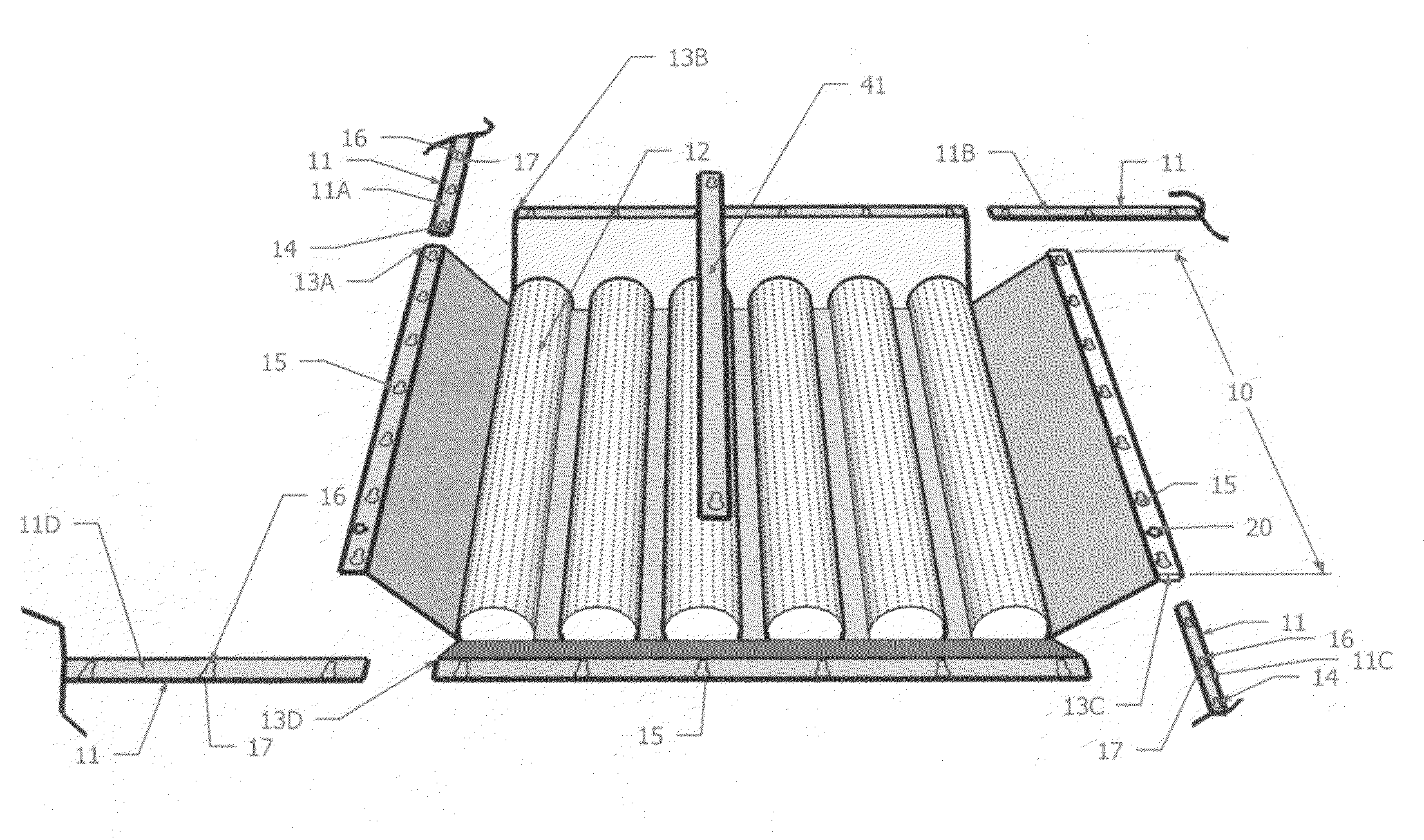

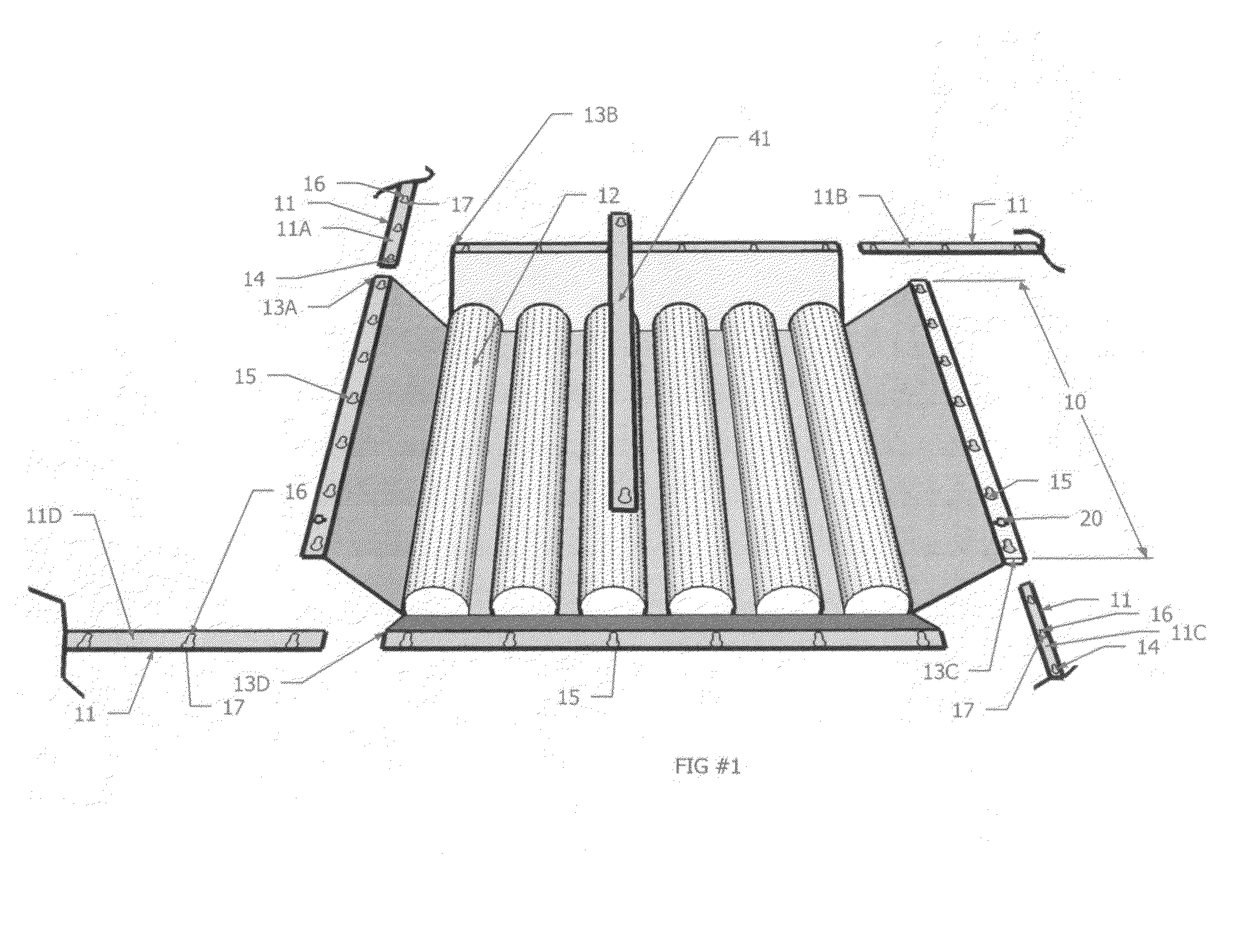

Pneumatic hurricane shutters

InactiveUS7464506B2Prevent removalIncrease elasticityHuman health protectionHurricane shuttersHurricane shutterWindow shutter

Pneumatic hurricane shutters are designed to temporarily cover a window or door in a building or other structure. The shutters have a lightweight rigid frame for surrounding the openings and mounting on fasteners attached to the building. Elongated pneumatic tubes are connected to frame rails and span the space between the rails to protect the opening. The frames can be locked in place to prevent inadvertent removal once in place. The frames and deflated tubes can be stored until the approach of a storm at which time the frames may be attached to the building and the tubes inflated to protect the openings.

Owner:ATKINSON ALLEN J

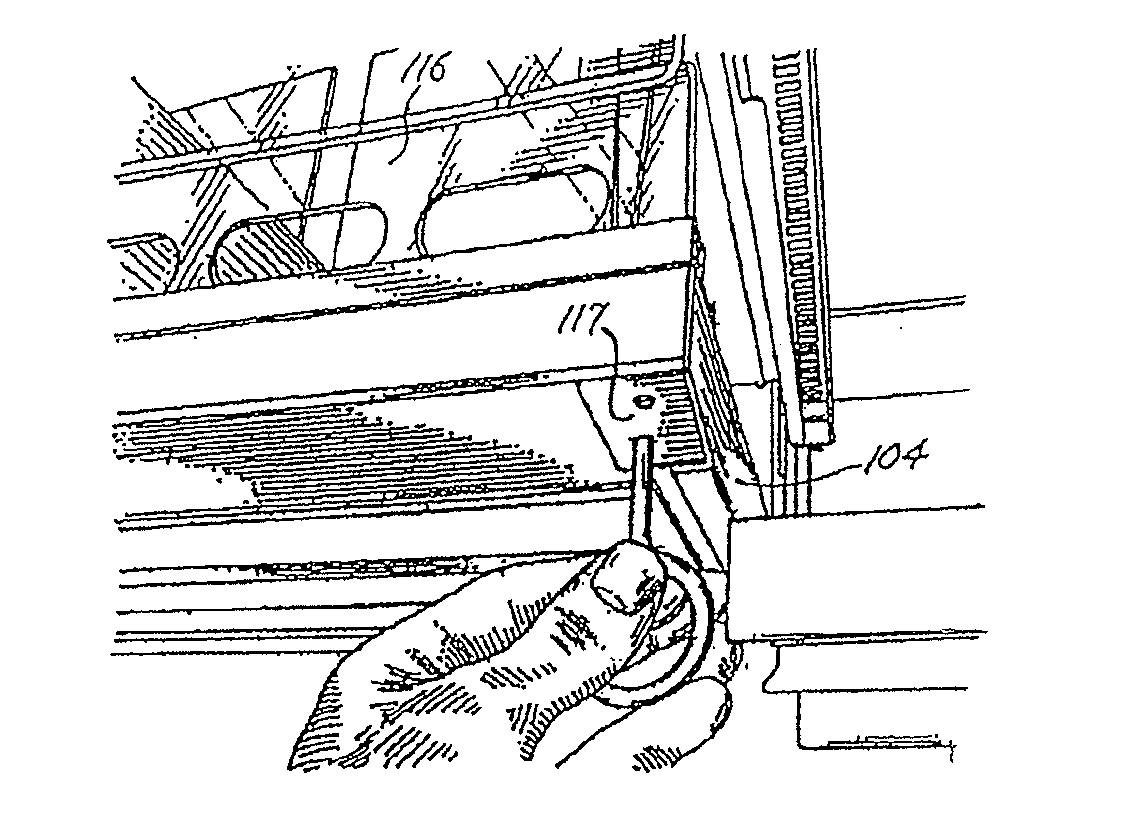

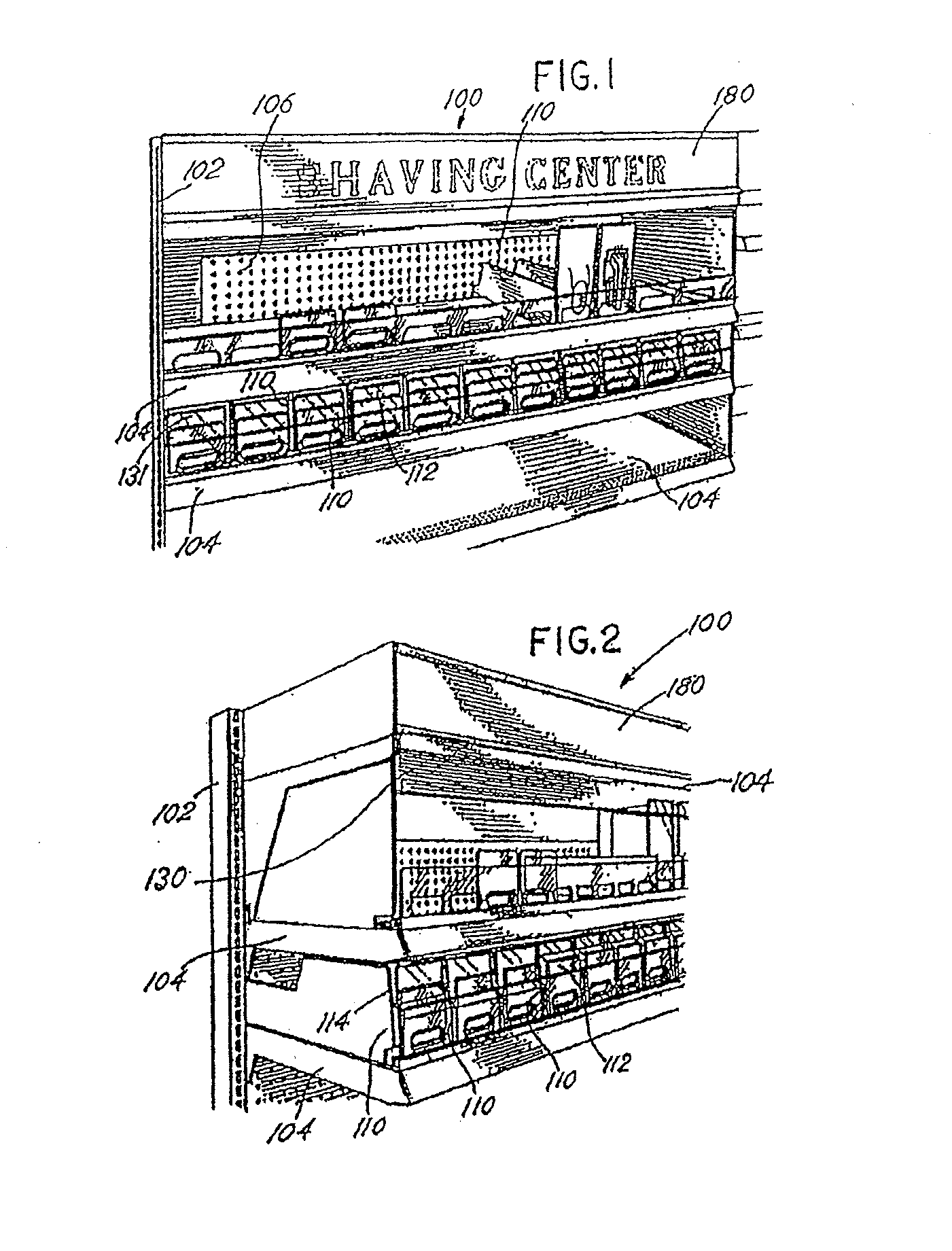

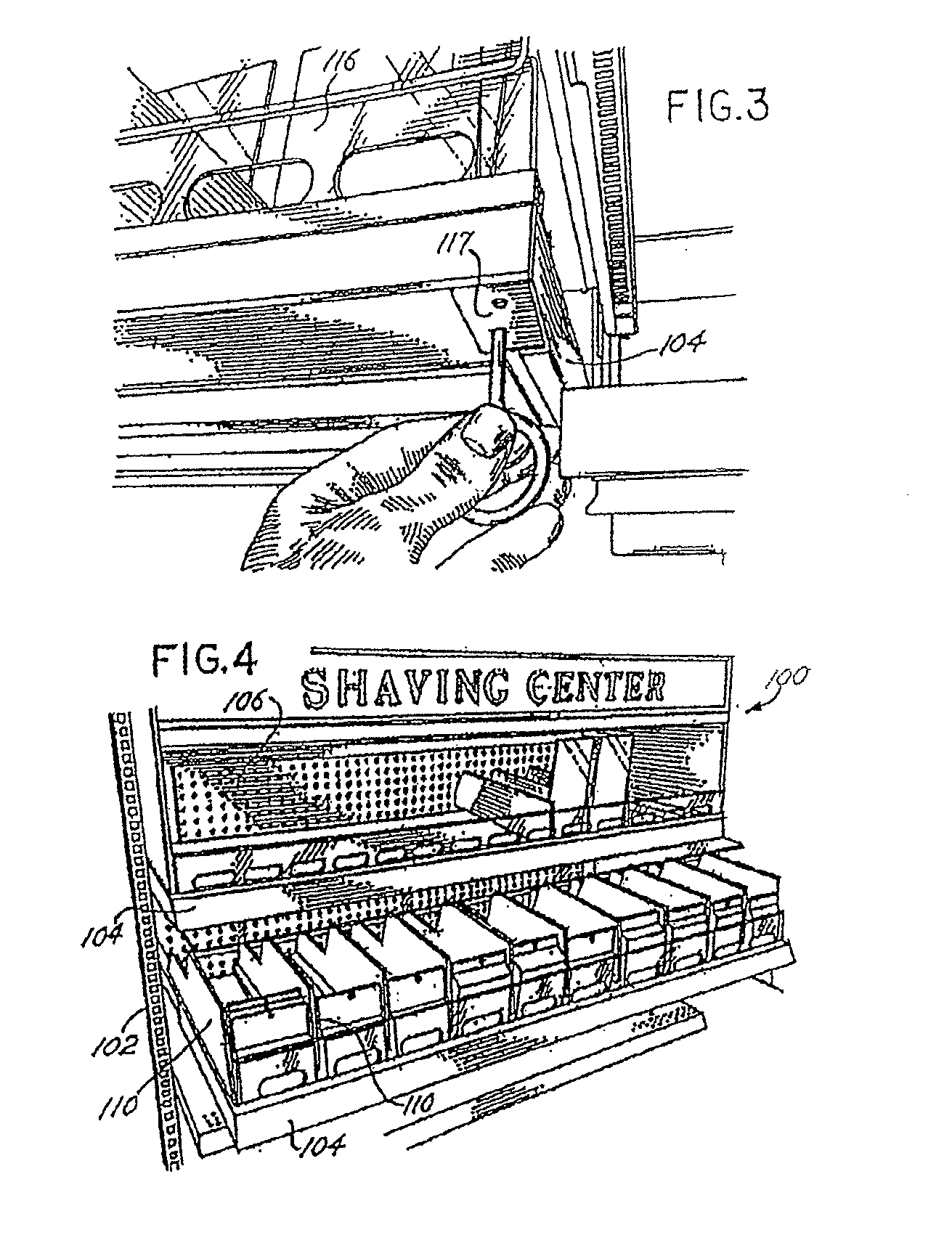

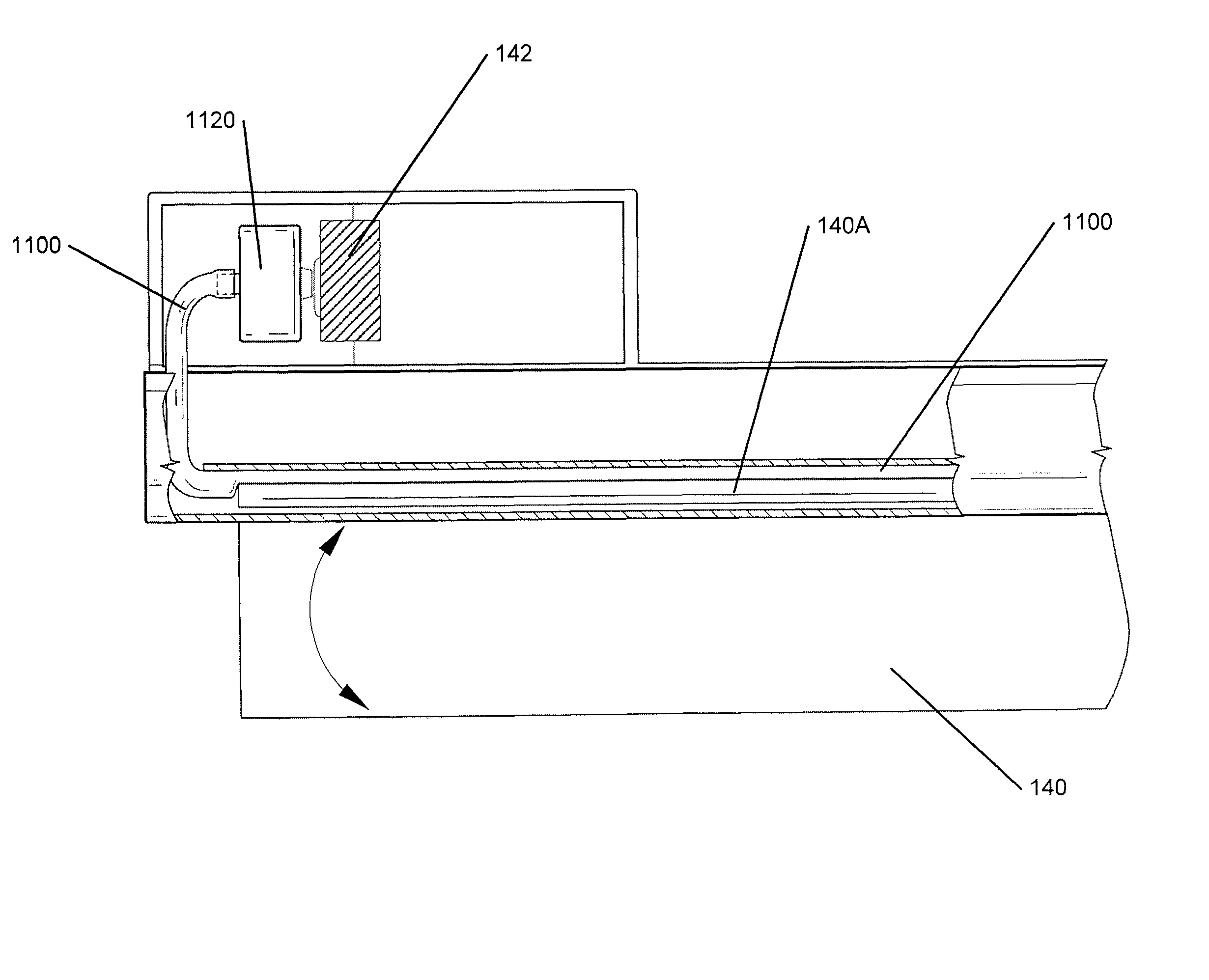

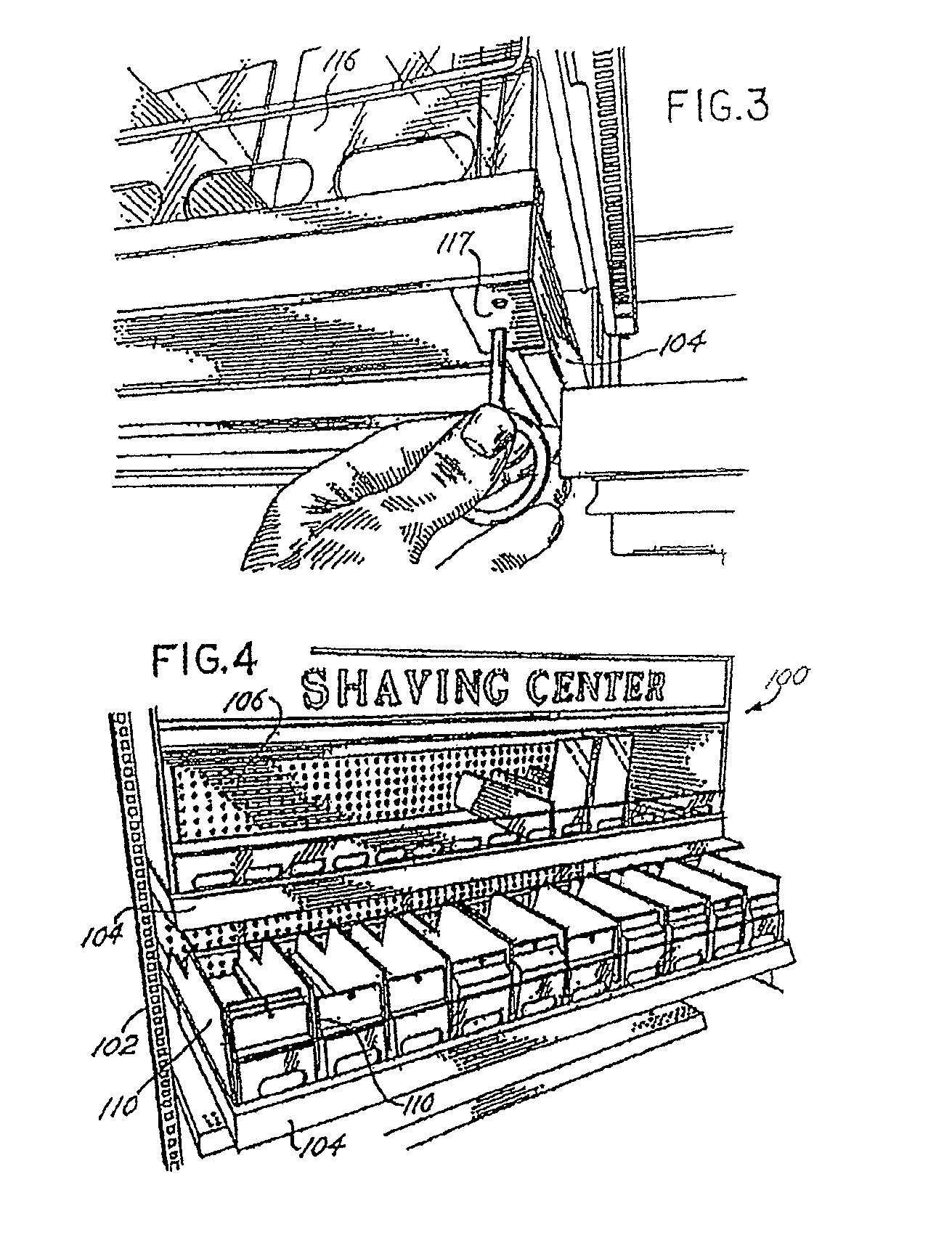

Product Securement and Management System

A system for detecting the potential theft of product from a display shelf may comprise: at least one shelf for containing product, a barrier, and an alert device. The barrier may be movable between a closed position and an open position. The alert device may be operatively connected to the barrier by an air switch and a pressurized pneumatic tube connected to the air switch and located adjacent to the first end of the barrier, wherein the alert device detects movement of the barrier and provides an alert indicative of a potential theft of product from the shelf When the barrier moves from the closed position to the open position, the barrier may engage the pneumatic tubing, thereby compressing the pneumatic tubing, activating the air switch, and sending a signal to the alert device.

Owner:RTC IND

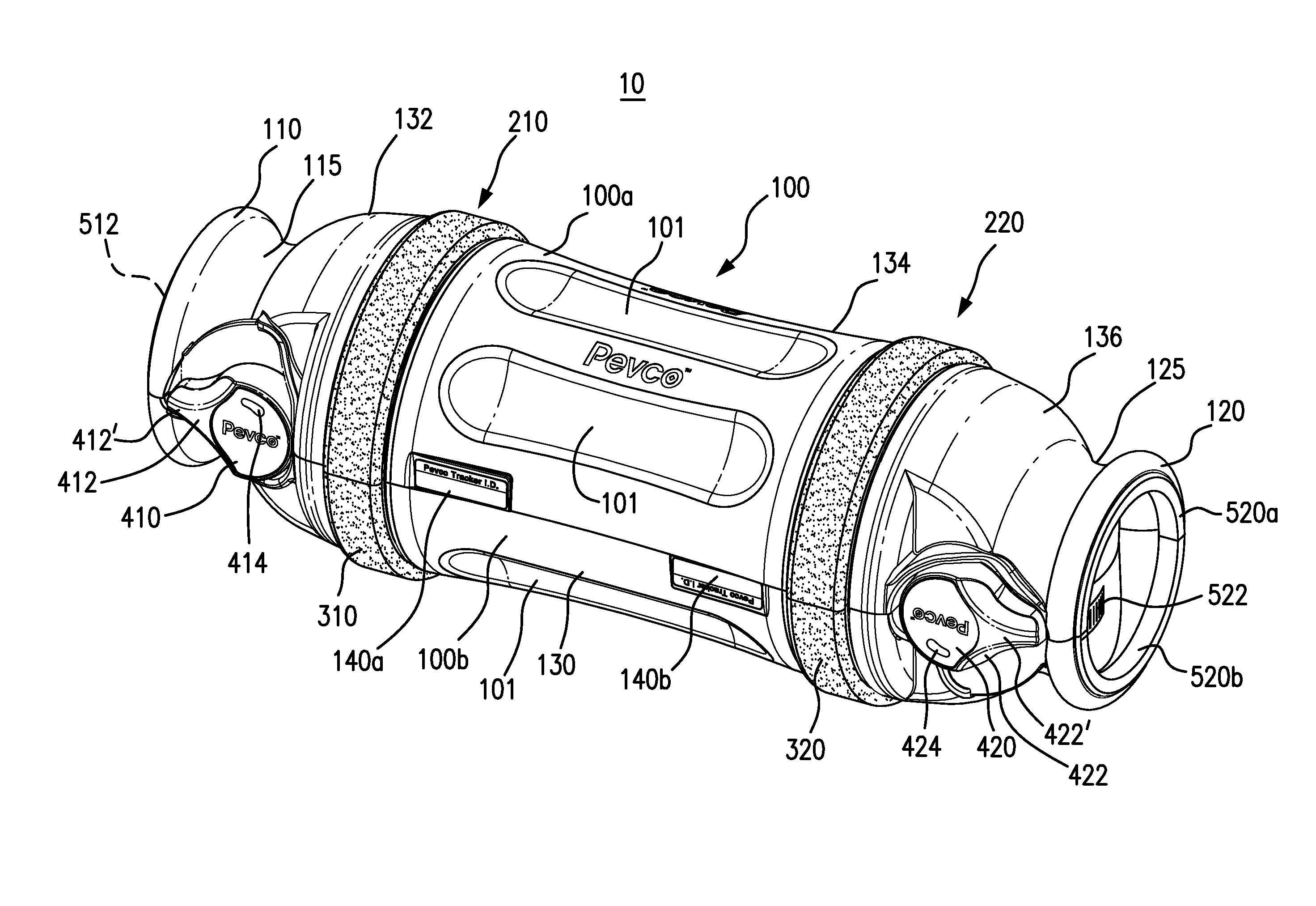

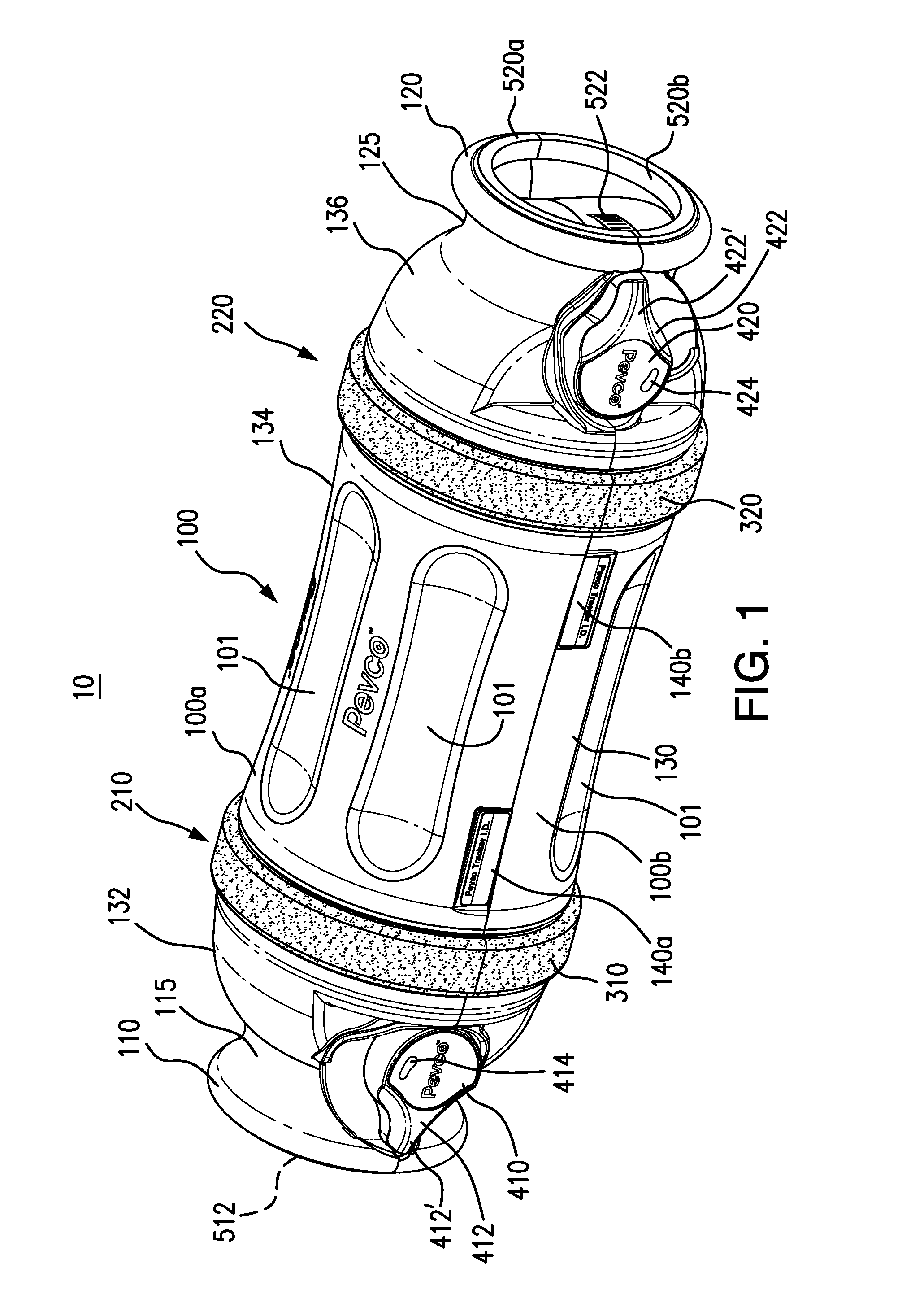

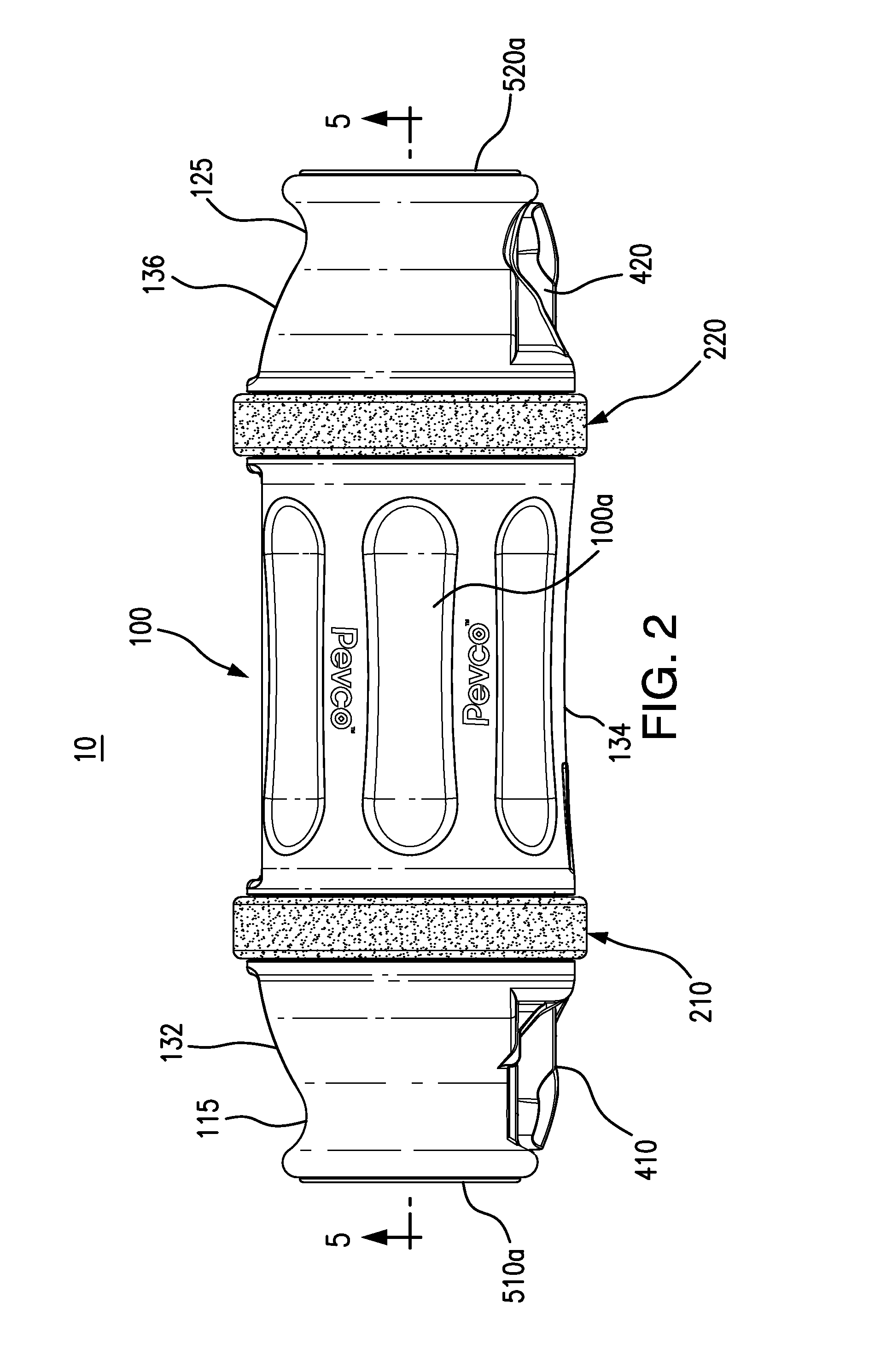

Carrier apparatus for pneumatic tube delivery system

A carrier apparatus is provided for transport through a pneumatic tube delivery system. The carrier apparatus comprises a housing contoured with forward and aft portions and an axially extended body portion disposed therebetween. The housing includes at least first and second separable sections enclosing a carrying compartment. At least a pair of retaining assemblies are detachably coupled to the housing, with each retaining assembly encircling the housing's body portion to couple the first and second housing sections for angular displacement one relative to the other between open and closed configurations. Each of the retaining assemblies includes a glide band portion disposed to protrude radially from the housing in the closed configuration for slidably engaging an inner wall surface of a pneumatic delivery tube. At least one latch assembly is coupled to releasably lock the housing sections in the closed configuration.

Owner:PEVCO SYST INT

Circulated Pneumatic Tube Transit System

A circulated pneumatic tube transit system is used to transport passengers / cargo along a pair of pneumatic tubes, which are positioned along each other. Capsules are movably suspended within the tubes by either a maglev system or wheels. The capsules travel in opposite directions in each tube so that the system provides back and forth transportation between two destinations. A fluid loop mechanism cycles a volume of air through the tubes as a means to propel the capsules through each tube. A series of fluid loop mechanism can be air multipliers as the volume of air cycles through the tubes. Two one-directional valves are located at opposite ends of the tubes and are used to transfer the kinetic energy for an arriving capsule within one tube into kinetic energy for a departing capsule within the other tube.

Owner:ZHOU BO

Device for dealing and displaying playing cards

InactiveCN102580306AReach pattern pointsEliminate doubts about cheatingCard gamesEngineeringPneumatic tube

The invention relates to a device for dealing and displaying playing cards. The device is capable of dealing playing cards in a fully-automatic way and saving labor force, and is high in credibility in playing card games. The device is mainly characterized in that a machine table with a shuffle machine unit and an identifier unit is provided with a playing card taking unit, the playing card taking unit is so configured that a fixed seat is provided with a motor, a belt and a sliding seat, and the sliding seat is further provided with a motor, an inner swing arm, integrated upper and lower swing arms, a pneumatic tube and a sucking disc. The device of the invention can take out playing cards automatically, identify patterns and values of the playing cards and display the playing cards, thereby achieving the effects of dealing playing cards without any manual work, simulating manual playing cards display and avoiding cheating doubts as the playing cards are not in contact with human hands.

Owner:BINGOTIMES DIGITAL TECH

Robot pneumatic shillful hand

InactiveCN1651200ASimplify mechanical designCompact structureJointsGripping headsManufacturing cost reductionIndex finger

Owner:ZHEJIANG SCI-TECH UNIV

Product securement and management system

ActiveUS8235222B2Limit takingMinimize impactShow cabinetsBurglar alarm by openingEngineeringPneumatic tube

A system for detecting the potential theft of product from a display shelf may comprise: at least one shelf for containing product, a barrier, and an alert device. The barrier may be movable between a closed position and an open position. The alert device may be operatively connected to the barrier by an air switch and a pressurized pneumatic tube connected to the air switch and located adjacent to the first end of the barrier, wherein the alert device detects movement of the barrier and provides an alert indicative of a potential theft of product from the shelf. When the barrier moves from the closed position to the open position, the barrier may engage the pneumatic tubing, thereby compressing the pneumatic tubing, activating the air switch, and sending a signal to the alert device.

Owner:RTC IND

Pneumatic tube system terminal and method

A pneumatic transport system including a user terminal at a service provider station having a movable member operably connected with a flexible drive member. The drive member moves within at least one side rail to vertically displace the movable member to permit access to a carrier at the user terminal. The user terminal includes control mechanisms on opposite sides of a base to enable two users to operate and access the carrier at the user terminal.

Owner:DIEBOLD NIXDORF

Method and system for sealing products in a pneumatic tube carrier

InactiveUS8029212B2Guaranteed safe sealAvoid cross contaminationDigital data processing detailsControl devices for conveyorsInterior spacePneumatic tube

A pneumatic tube system, including at least one system control module for controlling delivery of a pneumatic carrier through pneumatic tubing. The system includes at least one pneumatic tube station having a sealer, the sealer includes a heating pad and a sealing strip, where the sealer automatically grips the open end within the heating pad and the sealing strip upon insertion of the bag into the system. In one example, the sealer creates a vacuum to extract air from an interior space of the bag. The sealer applies heat to the open end to seal the bag. The system includes at least one pneumatic tube station configured for sending at least one carrier, the at least one sending pneumatic tube station being in signal communication with the at least one system control module, where the at least one carrier is sent through the system by pneumatic tubing.

Owner:PEVCO SYST INT

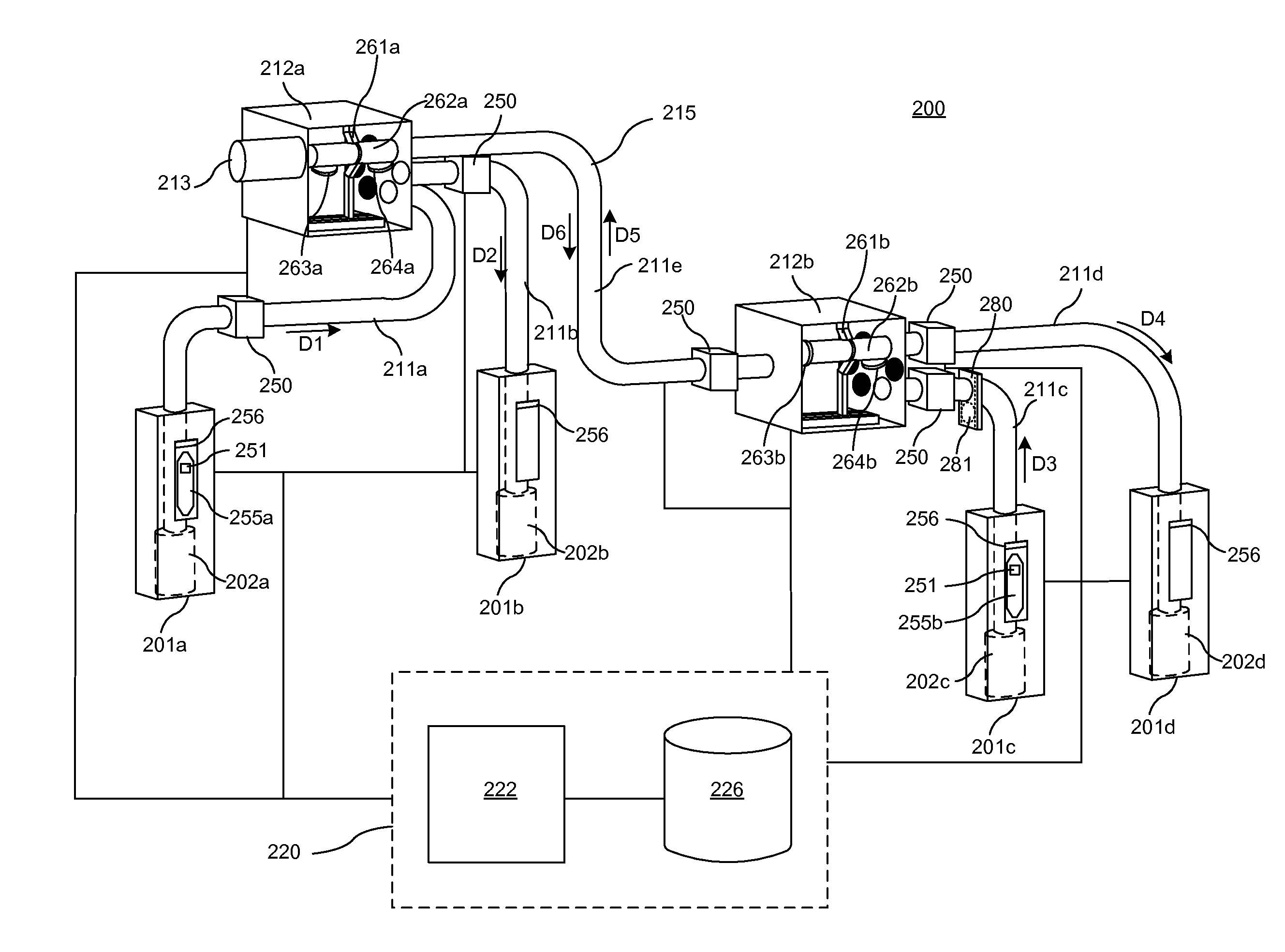

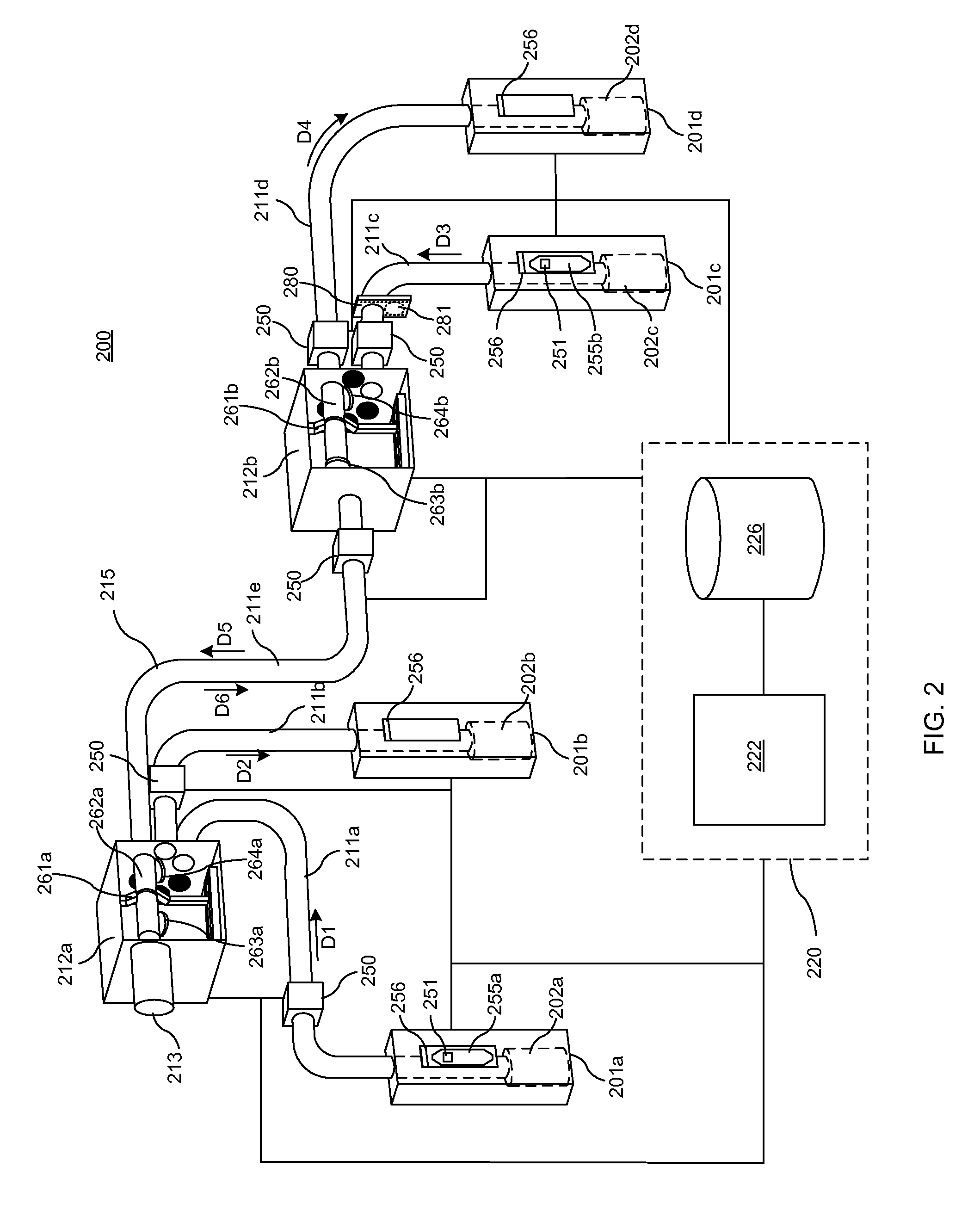

Pneumatic tube carrier system and method

ActiveUS20150298919A1Promote faster travel timeIncrease the number ofBulk conveyorsRobotic armCarrier system

A pneumatic tube delivery system and method for simultaneously transporting pneumatic carriers across a plurality of sending and receiving stations connected via pneumatic tubing and diverters. The plurality of sending and receiving stations each comprises a pneumatic device to coordinate and direct the transportation of carriers through vacuum or pressure throughout the pneumatic tube system. One or more diverters in the pneumatic tube system may also comprise a pneumatic device for transporting carriers between two diverters. Each pneumatic device is only responsible for transporting a carrier though a single pneumatic tube sector within the system, enabling the pneumatic tube sectors to operate independently from one another. Accordingly, two or more carriers can be simultaneously transported within the pneumatic tube system. The diverter of the present invention for diverting carriers between pneumatic tube sectors may comprise at least one robotic arm connected to a movable tube for retaining the carrier and shifting the carrier within the diverter.

Owner:LE NGOC MINH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com