Hard capsule sealing device

A sealing device and a technology for hard capsules, which are applied in the directions of capsule delivery, drug delivery, and pharmaceutical formulations, can solve problems such as poor sealing, and achieve the effects of high sealing efficiency, tight bonding and short action time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further explained below in conjunction with accompanying drawing.

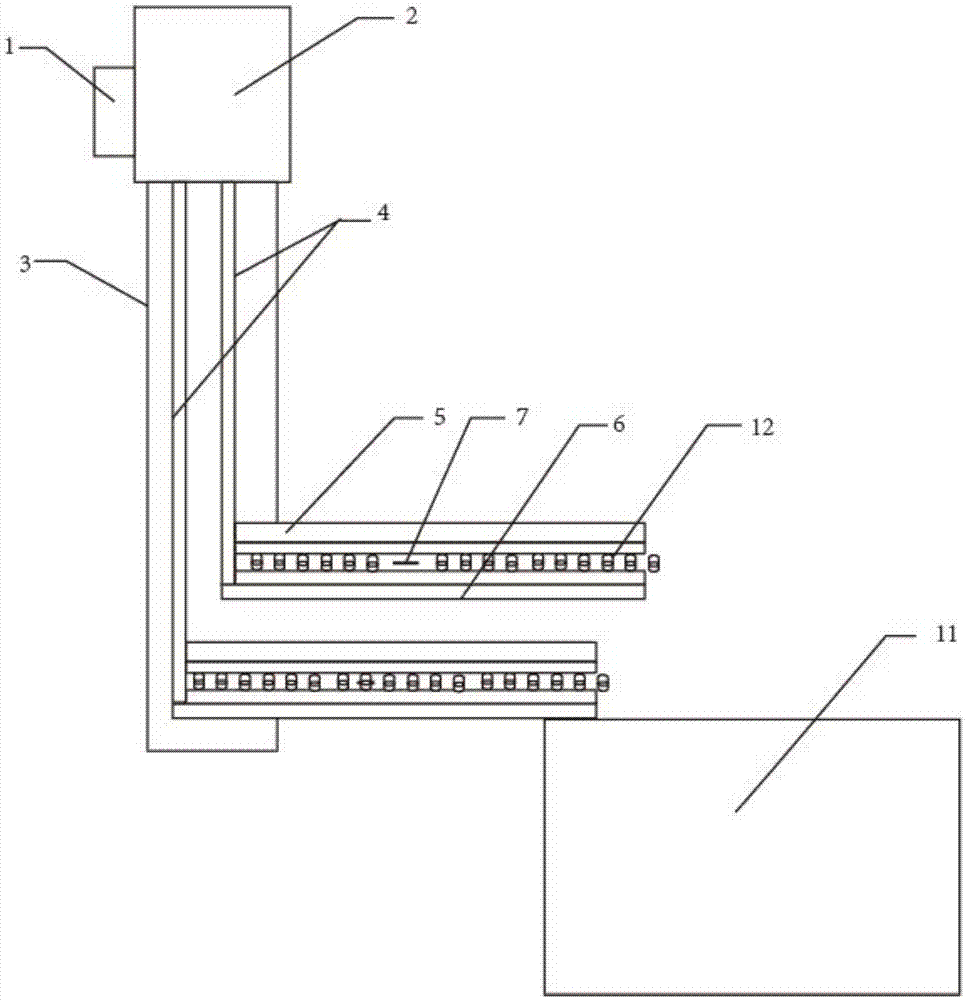

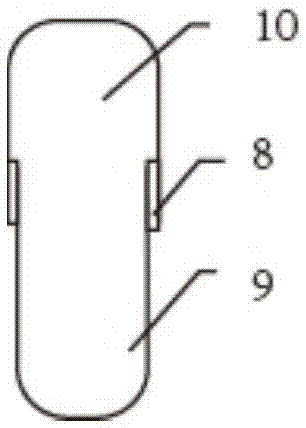

[0012] In the figure, 1. Motor, 2. Feeding funnel, 3. Longitudinal channel, 4. Capsule channel, 5. Upper transmission device, 6. Lower transmission device, 7. Heating bar, 8. Sugar coating layer, 9. Capsule body, 10 , capsule cap, 11, collection device, 12, capsule.

[0013] Such as Figure 1-2 As shown, a hard capsule sealing device provided by the present invention includes a motor 1, a feeding funnel 2, a longitudinal passage 3 connected to the feeding funnel 2, and the longitudinal passage 3 is provided with a capsule passage 4 through which several individual capsules 12 pass. The bottom end of the capsule channel 4 is provided with an upper transmission device 5 and a lower transmission device 6. The upper transmission device 5 and the lower transmission device 6 are synchronously driven to drive the capsule 12 and then transmitted to the right. Heating bar 7, the j...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com