Smelting method of boron carbide material

A smelting method and boron carbide technology, applied in chemical instruments and methods, carbon compounds, inorganic chemistry, etc., can solve problems such as poor uniformity of temperature field, difficulty in preparing fine powders, loss of boron volatilization, etc., and improve temperature uniformity. , the effect of increasing the heating speed and increasing the cohesion force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

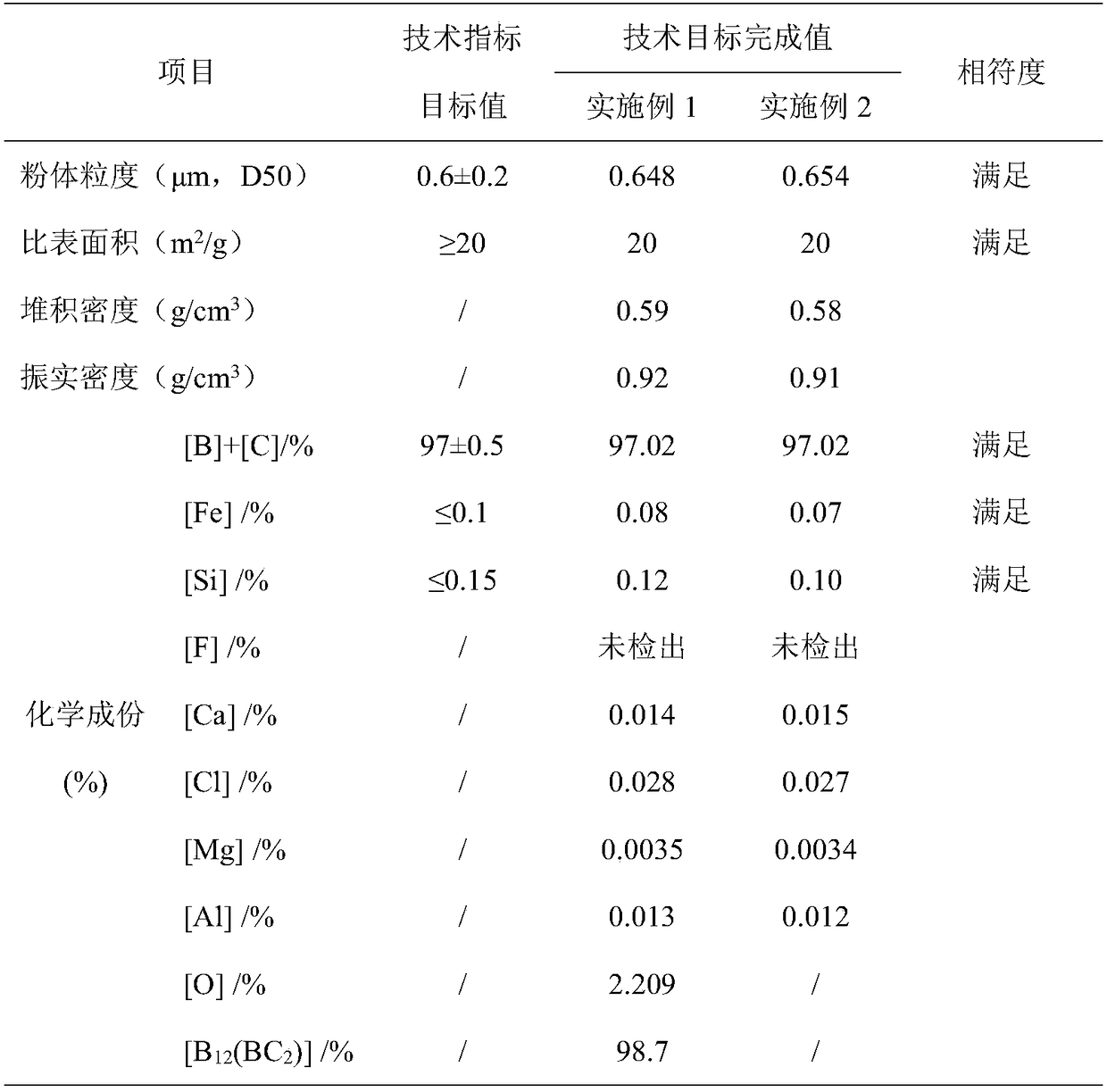

Embodiment 1

[0042] Embodiment 1 concrete operation steps are as follows:

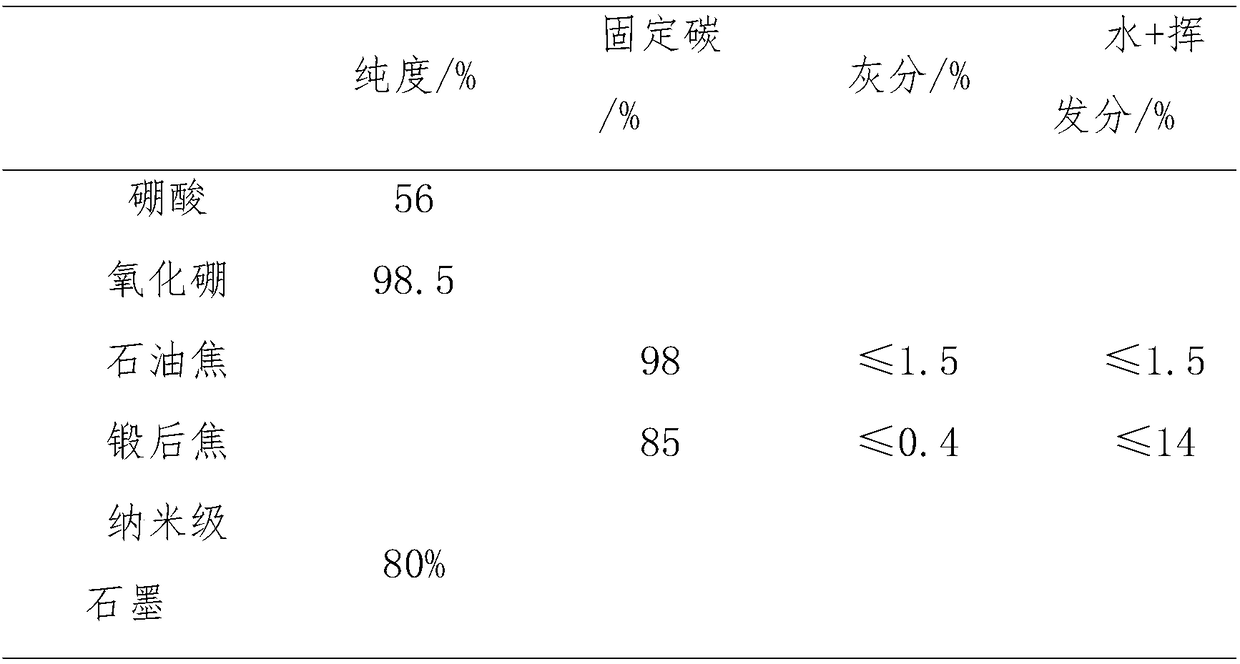

[0043] (1) Select boron source material boric acid or boron oxide with high boron content to reduce boron volatilization loss in the smelting process; select nano-scale graphite with high purity, fine particle size, good conductivity, and a mixture of massive recycled materials, nano-scale The weight ratio of graphite and lumpy returned charge is 10:1-3, which increases electrical conductivity and improves reactivity;

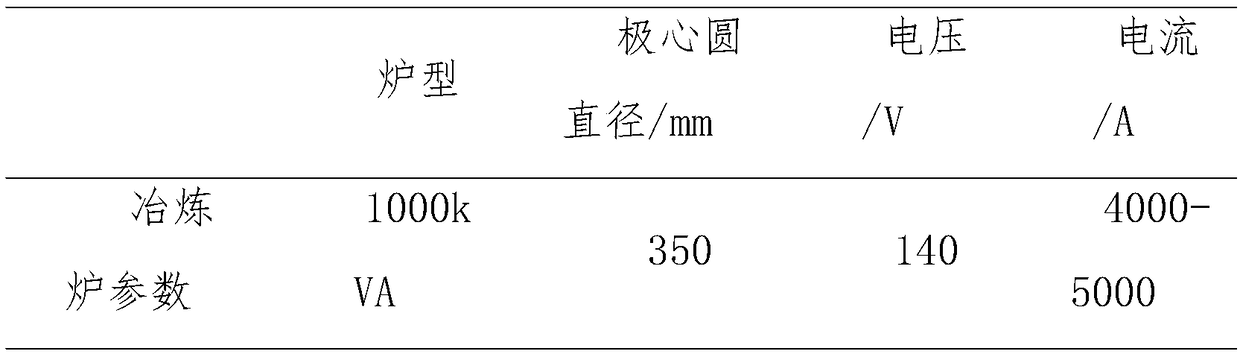

[0044] (2) Optimizing the mixing process technology, using a rotor mixer, adopting the method of first inputting a large proportion of the boron source material boric acid or boron oxide in the formula into the mixer, and then inputting carbon source materials with poor conductivity such as petroleum coke, wrought iron, etc. After the coke, the two-phase materials are evenly mixed, and then the mixture of nano-scale graphite with good conductivity and fine particle size and block return charge is ad...

Embodiment 2

[0053] The difference between embodiment 2 and embodiment 1 is: 1) choose the boron source material boric acid or boron oxide with high boron content, reduce the boron volatilization loss in the smelting process; choose nanoscale graphite with high purity, fine particle size and good conductivity , A mixture of massive recycled materials, the weight ratio of nano-scale graphite and massive recycled materials is 10:3, which increases electrical conductivity and improves reactivity;

[0054] (2) Optimizing the mixing process technology, using a rotor mixer, adopting the method of first inputting a large proportion of the boron source material boron oxide in the formula into the mixer, and then inputting carbon source materials such as charcoal, straw, and sawdust with poor conductivity, After the two-phase materials are uniformly mixed, the mixture of nano-scale graphite with good conductivity and fine particle size and massive recycled materials is added again, so that the mixtu...

Embodiment 3

[0057] The difference between embodiment 3 and embodiment 1 is:

[0058] 1) Select boron source materials with high boron content, boric acid or boron oxide, to reduce boron volatilization loss during the smelting process; select nano-scale graphite with high purity, fine particle size, and good electrical conductivity, a mixture of massive recycled materials, nano-scale graphite , The weight ratio of lumpy returned charge is 10:2, which increases the electrical conductivity and improves the reactivity;

[0059](2) Optimizing the mixing process technology, adopting the rotor mixer, adopting the method of first inputting the boron source material boron oxide with a large proportion in the formula into the mixer, and secondly inputting the carbon source materials with poor conductivity, petroleum coke and charcoal, so that After the two-phase materials are uniformly mixed, the mixture of nano-scale graphite with good conductivity and fine particle size and massive recycled mater...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com