Composite heat dissipation device adopting composite phase change materials and micro-channel liquid cooling

A technology of composite phase change material and heat dissipation device, applied in the field of heat dissipation device, can solve the problems of unsatisfactory heat dissipation effect, poor heat dissipation effect, affecting the service life of LED, etc., and achieves the effects of compact structure, improved lubrication conditions, and improved heat dissipation effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

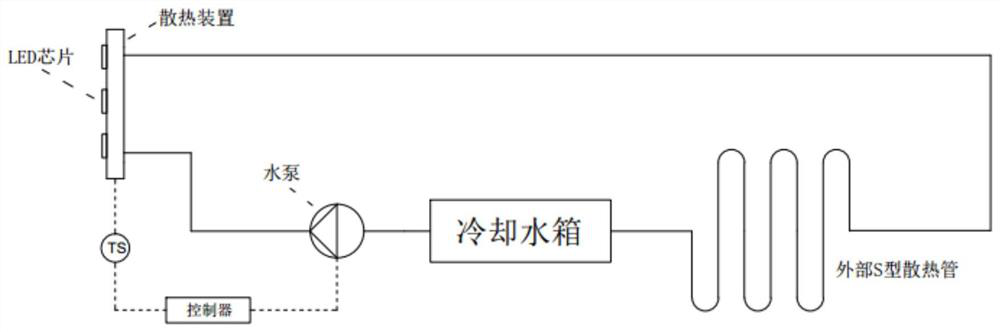

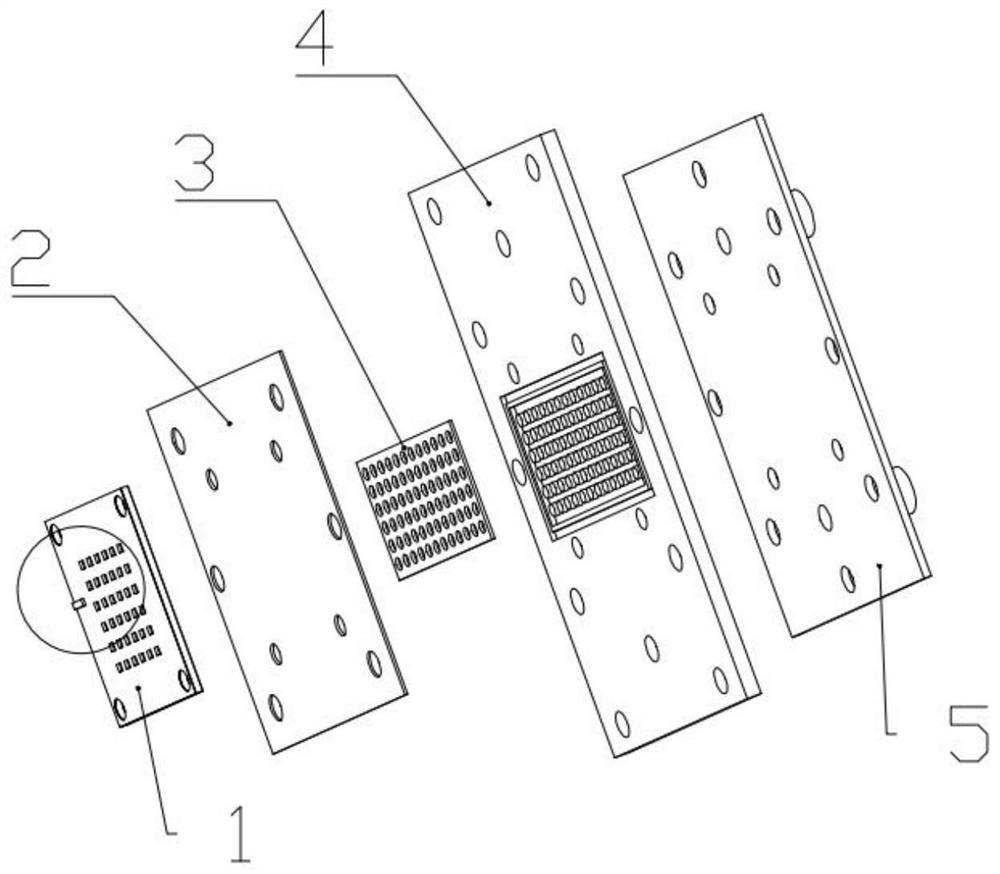

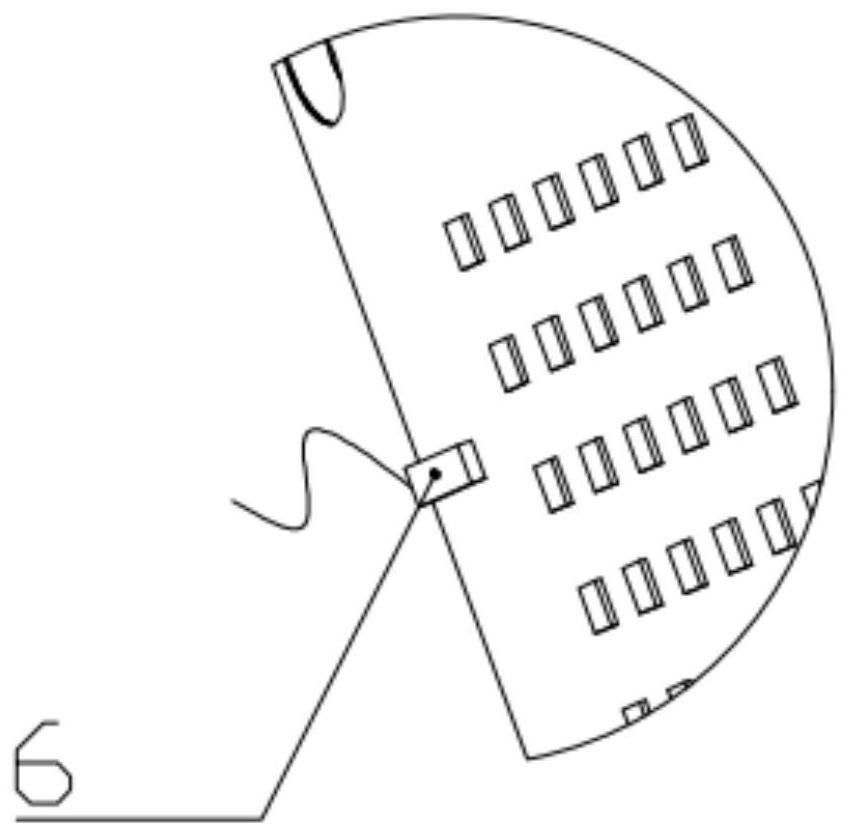

[0040] A composite heat dissipation device using composite phase change material and microchannel liquid cooling, including LED light source module 1, phase change zone cover plate 2, paraffin-graphene composite phase change material 3, radiator 4, and liquid cooling zone cover plate 5 , Temperature sensor 6, controller, water pump, cooling water tank, external S-shaped cooling pipe. The heat generated by the LED light source module 1 is transferred to the microchannel liquid cooling area through the paraffin-graphene latent heat release area 41, and the graphene cooling liquid flows into the radiator 4, flows in from the liquid injection port 51, and flows out from the liquid outlet 52, completing a round Heat dissipation.

[0041] Among them, the length and width of the central main flow channel are 38mm*5mm; the widest part of the spoiler column is 1mm, the length is 20mm, and the overall shape is arc-shaped; the length and width of the first-stage flow channel are 28mm*2mm...

Embodiment 2

[0046] On the basis of Embodiment 1, the speed of the water pump can be adjusted in real time through the temperature sensor 6 and the controller, which can reduce power loss, achieve optimal heat dissipation, save costs to the greatest extent, and prolong the service life of the entire system. At the same time, the structures of the paraffin latent heat release zone 41 and the microchannel liquid cooling zone can be optimized according to the requirements of different LED heat source densities, such as adjusting the density distribution of foamed aluminum, the mass fraction of graphene, and the paraffin-graphene latent heat release The volume size of the area, the width distribution of the microchannel, etc., to achieve the best heat dissipation effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com