Preparation method of modified epoxy resin

An epoxy resin and modification technology, which is applied in the field of preparation of modified epoxy resin, can solve the problems of parameter drift, shrinkage reduction, and performance deterioration of electronic components, etc., and achieve good expansion and reduce volume shrinkage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

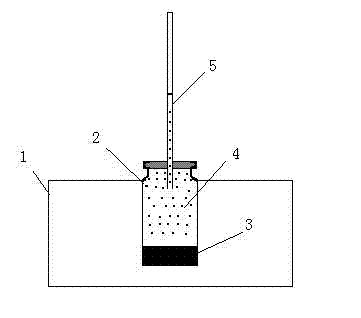

[0017] The present invention will be described in detail below with reference to the accompanying drawings.

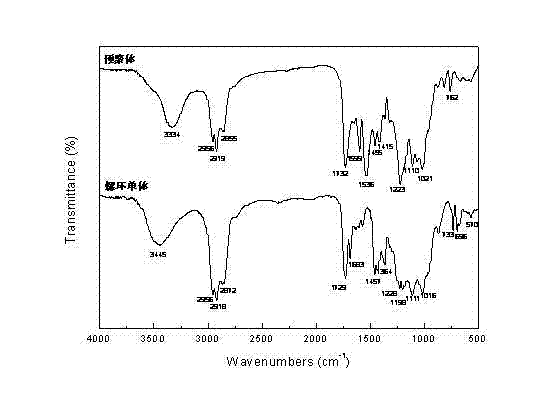

[0018] The present invention first synthesizes the spiro ring orthocarbonate prepolymer:

[0019] ⑴ Weigh M and TDI according to the molar ratio of M (spiro ring monomer): TDI (toluene-2,4-diisocyanate) in the ratio of 2:1, 3:2, 4:3, and put M into a three-necked bottle , add chloroform to dissolve it (according to the monomer mass: chloroform mass ratio is 1:10), control the oil bath temperature to 35°C, and electromagnetically stir.

[0020] (2) Dissolve TDI with 10 ml of chloroform, add the mixture into the constant pressure dropping funnel, install the funnel on the three-necked bottle, and install anhydrous CaCl above the dropping funnel 2 drying tube.

[0021] (3) Add the mixed solution in the funnel dropwise into the reaction bottle, react for 24 hours, then pour the obtained substance into a watch glass, let it cool naturally, the solvent evaporates naturally...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com