Fluorine elastomer containing high fluorine content and preparation process thereof

A fluoroelastomer, content technology, used in the chemical field, can solve problems such as poor oil resistance and solvent resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

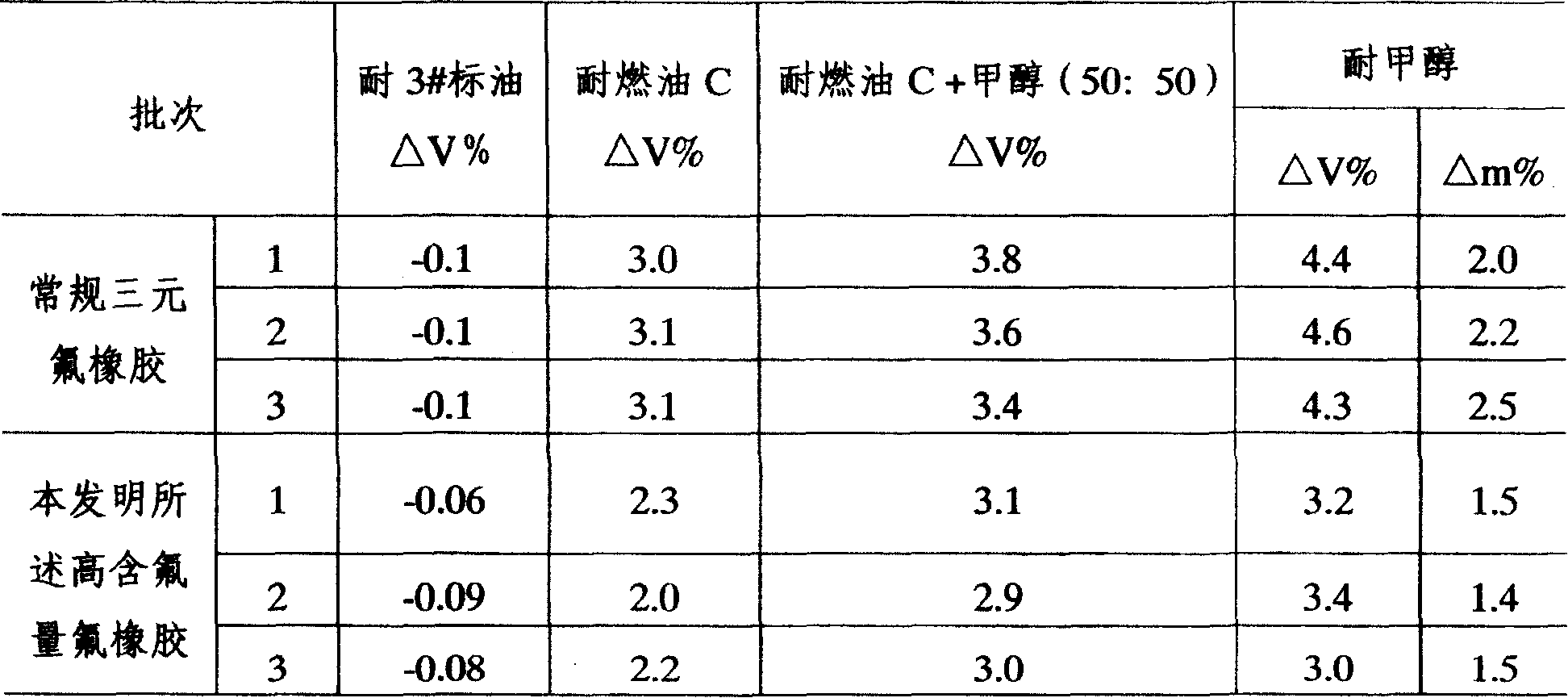

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Add water medium and sodium perfluorooctanoate to the reactor, so that there is enough vapor space to accept gaseous mixed monomers in the reactor, the concentration of sodium perfluorooctanoate in the water medium is to add 0.001 parts by weight of sodium perfluorooctanoate in every 100 parts by weight of water medium, In the vapor space of the reactor, add 30% 1,1-difluoroethylene, 40% perfluoropropylene and 30% tetrafluoroethylene mixed monomer in molar percentage, mix to form emulsion, every 100 parts by weight of water Add 50 parts by weight of mixed monomers to the medium. Add potassium persulfate and sodium tetraborate, and polymerize at 20°C, 5MPa, and pH4 for 2 hours. The amount of potassium persulfate is 0.001 parts by weight of potassium persulfate per 100 parts by weight of water medium. Add it to the reactor in the form of a 7% aqueous solution. During the polymerization process, add carbon tetrachloride to the reactor at one time, add 0.1 parts by weight ...

Embodiment 2

[0031] Add water medium and perfluorooctanoic acid ammonium in the reactor, make the steam space that is enough to accept gaseous mixed monomer in the reactor, the concentration of perfluorooctanoic acid ammonium in the aqueous medium is to add 3 parts by weight of perfluorooctanoic acid ammonium in every 100 parts by weight of aqueous medium, In the vapor space of the reactor, add 60% 1,1-difluoroethylene, 20% perfluoropropylene and 20% tetrafluoroethylene mixed monomers in molar percentage, mix to form emulsion, every 100 parts by weight of water Add 150 parts by weight of mixed monomers to the medium. Add diisopropyl peroxydicarbonate and dipotassium hydrogen phosphate, and polymerize at 100° C. under 0.7 MPapH5 for 20 hours. The amount of diisopropyl peroxydicarbonate is 5 weight parts per 100 parts by weight of water medium Parts of diisopropyl peroxydicarbonate, diisopropyl peroxydicarbonate is added to the reactor in the form of a 0.1% aqueous solution by weight percent...

Embodiment 3

[0033] Add water medium and perfluorooctanoic acid ammonium in the reactor, make enough to leave the steam space that accepts gaseous mixed monomer in the reactor, the concentration of perfluorooctanoic acid ammonium in the aqueous medium is to add 0.05 weight part of perfluorooctanoic acid ammonium in every 100 weight parts of water medium, In the vapor space of the reactor, add 40% 1,1-difluoroethylene, 30% perfluoropropylene and 30% tetrafluoroethylene mixed monomers in molar percentage, mix to form emulsion, every 100 parts by weight of water Add 100 parts by weight of mixed monomers to the medium. Add diisopropyl peroxydicarbonate and dipotassium hydrogen phosphate, and polymerize for 11 hours under 3MPa pH6 at 60°C. The amount of diisopropyl peroxydicarbonate is 0.05 wt. Parts of diisopropyl peroxydicarbonate, diisopropyl peroxydicarbonate is added to the reactor in the form of a 3% aqueous solution by weight percentage. During the polymerization process, add diethyl ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com