Manganese slag supersulfate cement and preparation method thereof

A technology of supersulfate cement and sulfate, applied in the field of special cement, can solve the problems of low early strength, long setting time, shortening the setting time of supersulfate cement, etc., to prolong the acceleration period and deceleration period, save heap The effect of saving land and saving resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

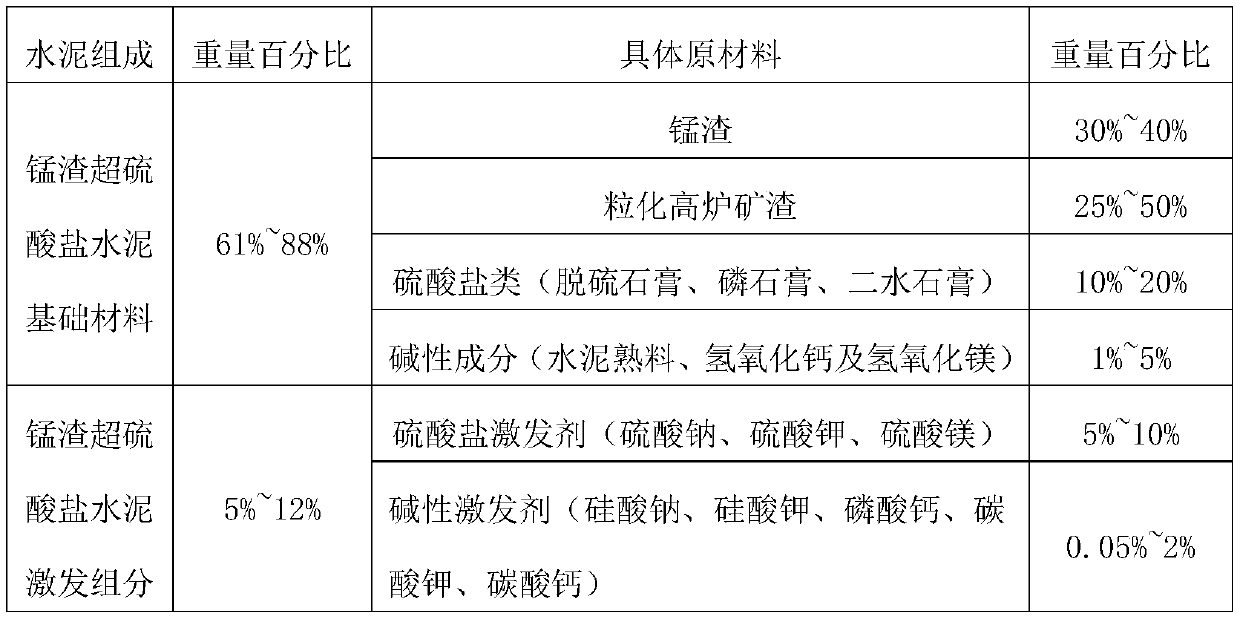

Method used

Image

Examples

Embodiment 1

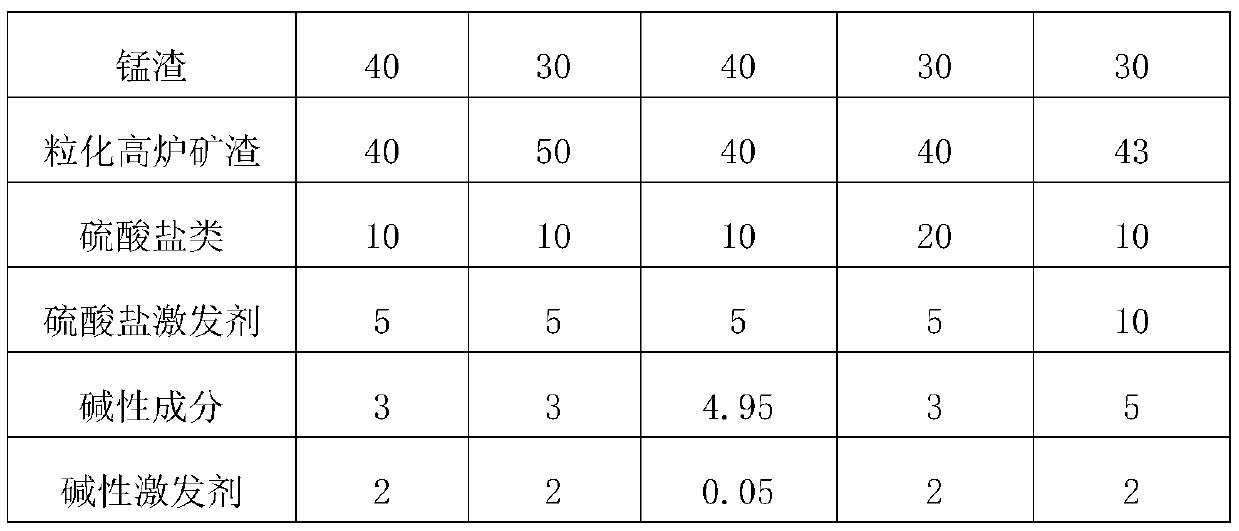

[0032] Grind manganese slag and granulated blast furnace slag to a specific surface area of 400m 2 / Kg~450m 2 / Kg, grind desulfurized gypsum, sodium sulfate, cement clinker, and calcium carbonate until the specific surface area is 450m 2 / Kg~500m 2 / Kg, then formula one according to Table 2 (wherein the manganese slag dosage is 40%, the granulated blast furnace slag dosage is 40%, the desulfurization gypsum dosage is 10%, the sodium sulfate dosage is 5%, the cement clinker dosage is 3%, the carbonic acid Calcium content is 2%) proportional metering and weighing, each raw material is fully mixed uniformly in the forced mixer, and the unloaded material is the prepared novel manganese slag super sulfate cement. The chemical composition analysis of the super sulfate cement is shown in Table 3. The test results of physical and mechanical properties of the corresponding cement are shown in Table 4. From the performance index of formula 1 in Table 4, it can be seen that the set...

Embodiment 2

[0034] Grind manganese slag and granulated blast furnace slag to a specific surface area of 400m 2 / Kg~450m 2 / Kg, grind phosphogypsum, potassium sulfate, cement clinker, and potassium carbonate until the specific surface area is 450m 2 / Kg~500m 2 / Kg, then formula two according to Table 2 (wherein the manganese slag dosage is 30%, the granulated blast furnace slag dosage is 50%, the phosphogypsum dosage is 10%, the potassium sulfate dosage is 5%, the cement clinker dosage 3%, and the potassium carbonate dosage is 2%), and each raw material is fully ground in a cement mill to prepare manganese slag super sulfate cement. The chemical composition analysis of the super sulfate cement is shown in Table 3. The test results of physical and mechanical properties of the corresponding cement are shown in Table 4. It can be seen from the performance index of formula 2 in Table 4 that the setting time of the manganese slag super sulfate cement is normal, and the flexural and compres...

Embodiment 3

[0036] Grind manganese slag and granulated blast furnace slag to a specific surface area of 400m 2 / Kg~450m 2 / Kg, grind dihydrate gypsum, magnesium sulfate, calcium hydroxide, and potassium carbonate until the specific surface area is 450m 2 / Kg~500m 2 / Kg, formula three according to Table 2 (wherein the manganese slag dosage is 40%, the granulated blast furnace slag dosage is 40%, the dihydrate gypsum dosage is 10%, the magnesium sulfate dosage is 5%, the calcium hydroxide dosage is 4.95%, the carbonic acid Potassium dosage is 0.05%) proportional metering and weighing, and each raw material is prepared in the fully grinding in the cement mill that the specific surface area is 475m 2 / Kg manganese slag super sulfate cement. The chemical composition analysis of the super sulfate cement is shown in Table 3. The test results of physical and mechanical properties of the corresponding cement are shown in Table 4.4. It can be seen from the performance index of formula 3 in T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com