Color polymer modified emulsion asphalt-base waterproof paint and preparation method thereof

A technology of high polymer modification and waterproof coatings, which is applied in asphalt coatings, chloroprene homopolymer coatings, coatings, etc. It can solve the problems of material elongation reduction and improve high temperature performance and low temperature performance, color Brilliant, life-prolonging effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

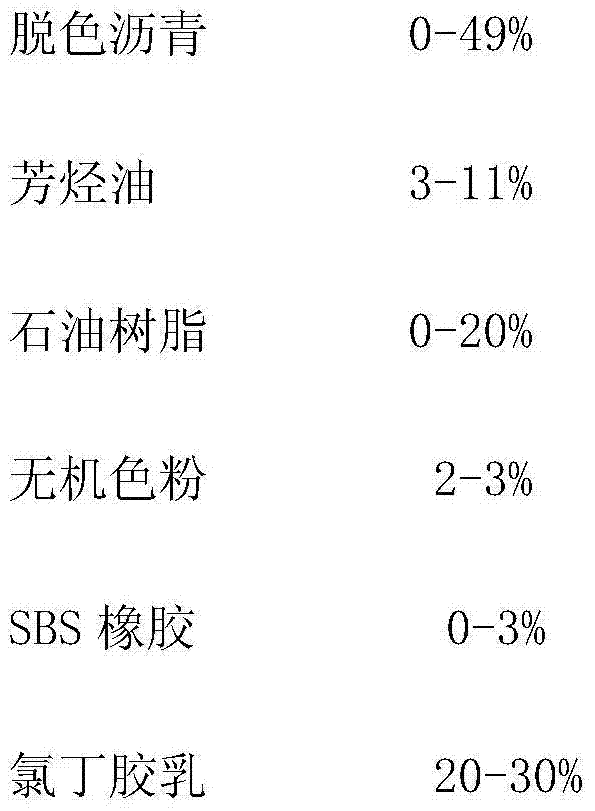

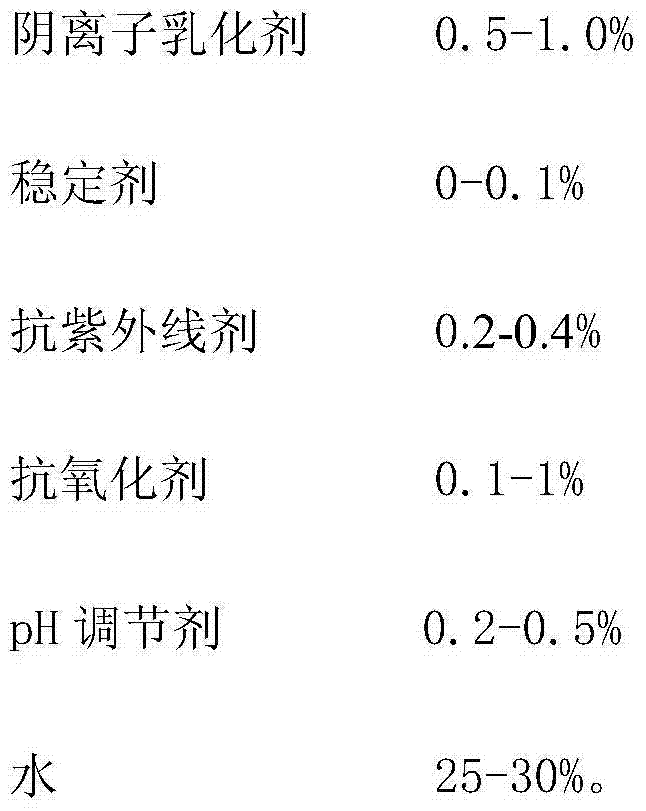

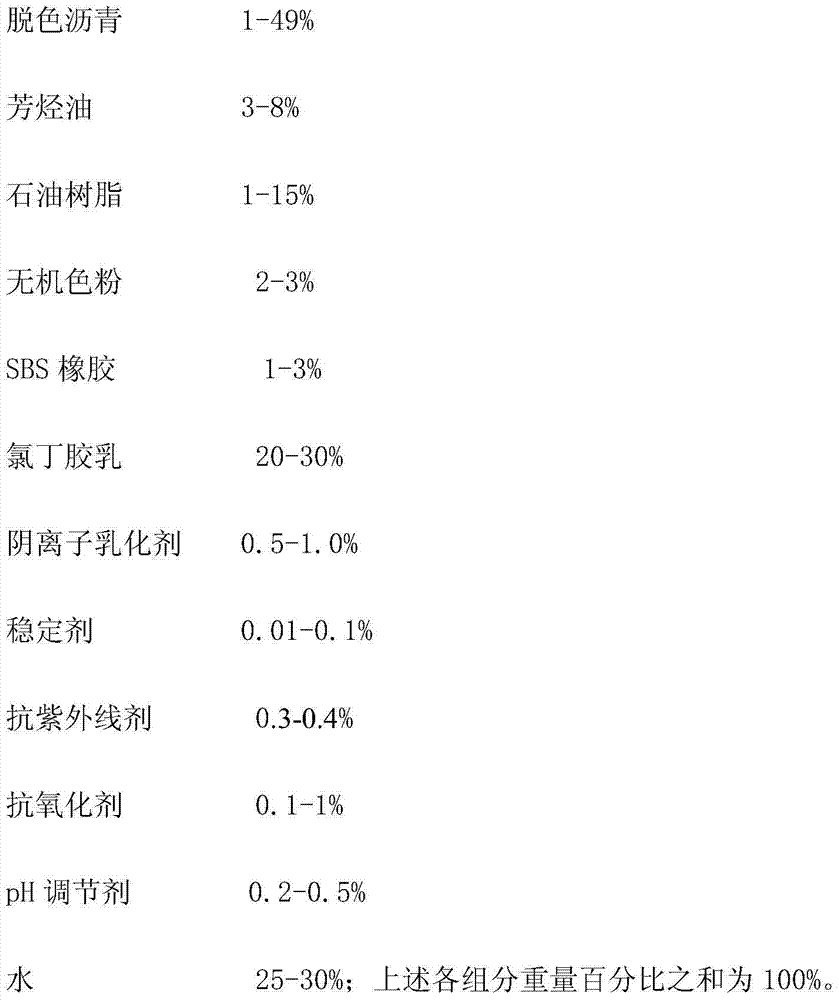

Method used

Image

Examples

Embodiment 1

[0035] Component A: First, add 3% of the imported Shell bright-colored asphalt (Shell decolorized asphalt) to aromatic oil, 10% of C9 petroleum resin, heat and stir at 150-160°C, put 3% iron oxide red into the asphalt, and stir evenly. Made into colored asphalt for later use. Pump the prepared colored asphalt into the asphalt tank through a special asphalt pump and heat it to 160°C~180°C, put in 2% SBS rubber, stir at 100r / min for 2 hours, and then grind it through a colloid mill to prepare the polymer modified asphalt material Stir for 2 hours to soak, set aside. Pump hot water at 60°C into the soap tank, add anionic emulsifier (tal oil or sulfonated tall oil soap or sulfosuccinic acid) 1% and AEO-9 stabilizer 0.05%, and adjust the pH with NaOH Value to 11 to make soap. The prepared polymer modified colored asphalt and soap solution are simultaneously passed through a high-speed shearing machine to make a modified emulsified asphalt emulsion with a mass concentration of abo...

Embodiment 2

[0038] Component A: First, heat and stir 11% aromatic oil, 10% C5 petroleum resin, and 10% C9 petroleum resin at 150-160°C, add 3% chrome green into it, stir well, and set aside. Pump hot water at 60°C into the soap tank, add anionic emulsifier (sodium abietate or sulfonated rosin) 1% and AEO-9 stabilizer 0.05%, and adjust the pH value to 11 with NaOH to make soap . The prepared polymer modified colored asphalt and soap solution are simultaneously passed through a high-speed shearing machine to make a modified emulsified asphalt emulsion with a mass concentration of about 60%. Add 30% neoprene latex to the emulsion, and then add 0.4% The anti-ultraviolet agent UV477 and 1% antioxidant 55 should be stirred slowly to disperse evenly during the feeding process. After the feeding is completed, keep stirring for 30 minutes, then stop stirring, add a small amount of defoamer and stand still for 30 minutes After defoaming treatment, the finished product is packed into barrels.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com