Device and method for promoting fine particle matters to be removed in coal-burning wet flue gas desulfuration process

A wet flue gas desulfurization and fine particle technology, applied in separation methods, chemical instruments and methods, dispersed particle separation, etc., can solve the problem of difficult to capture fine particles, and achieve efficient removal, reduced steam consumption, The effect of removing coal fly ash

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

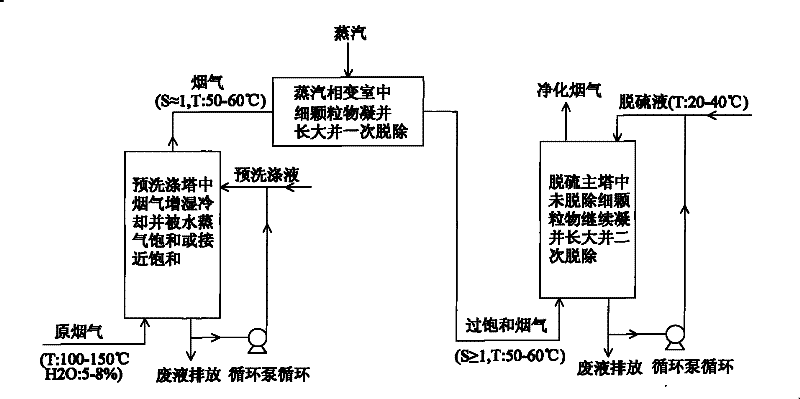

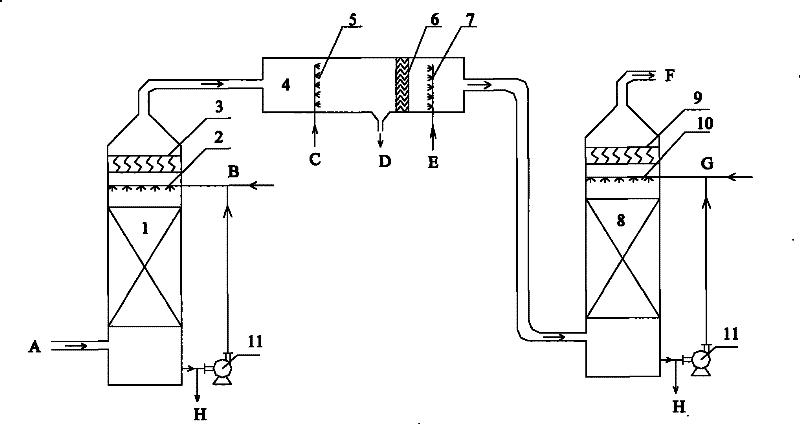

[0019] According to the present invention, a method for promoting the removal of fine particles in a coal-fired wet flue gas desulfurization process is as follows: figure 1 , figure 2Shown: the high-temperature coal-fired flue gas enters the pre-washing tower 1, and after contacting with the washing liquid, the flue gas temperature drops from 100-150°C to 50-65°C, is saturated or nearly saturated by water vapor, and removes coarse particles in the flue gas , and then the mist is removed by the pre-washing tower demister 3 and enters the steam phase change chamber 4, and an appropriate amount of saturated steam at normal pressure is injected through the steam nozzle 5 to make the flue gas reach a supersaturated state, and the supersaturated water vapor takes fine particles as condensation nuclei Nucleation condensation occurs on the surface of fine particles, and at the same time, diffusion swimming and thermophoresis are produced, which increases the particle size and quality...

Embodiment 2

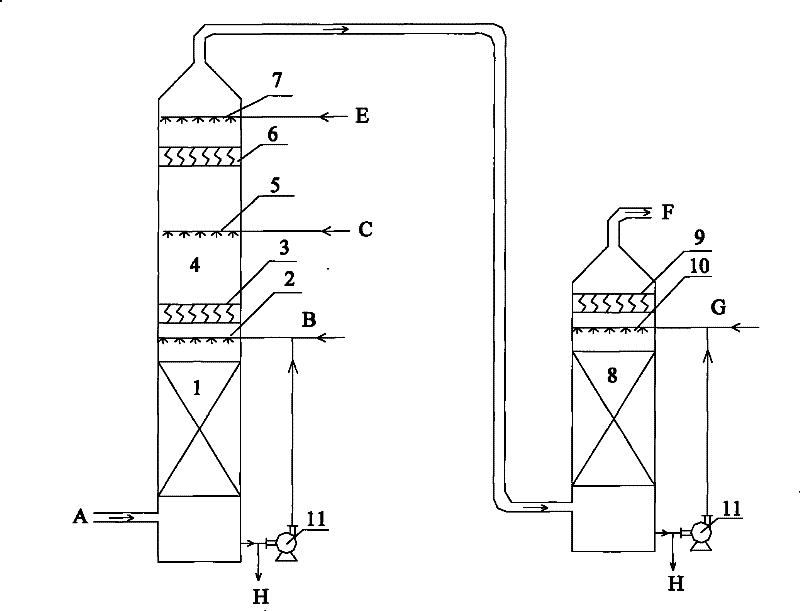

[0022] Such as image 3 As shown, the difference from Example 1 is that a steam phase change chamber is not specially set between the flue gas outlet of the pre-scrubber and the flue gas inlet of the desulfurization main tower, but the height of the pre-scrubber 1 is appropriately increased to demist the pre-scrubber The space above the device 3 is used as a steam phase change chamber 4, and an appropriate amount of steam is injected. A high-efficiency demister and a demister flushing water nozzle 7 are installed at the outlet of the flue gas at the top of the tower. The flue gas enters the desulfurization after pre-washing and removal of some fine particles. Main tower, all the other are with embodiment 1.

Embodiment 3

[0024] A method for promoting the removal of fine particles in a coal-fired wet flue gas desulfurization process, the steps are: remove fine particles once: after the coal-fired flue gas is pre-washed and dust-removed, it is saturated or nearly saturated with water vapor, and water mist is removed After entering the steam phase change chamber, the residence time of the flue gas in the steam phase change chamber is ≥50-200 milliseconds, injecting saturated steam at normal pressure to establish the supersaturated water vapor environment required for the condensation and growth of fine particles, and the condensation and growth The fine particles are partially removed by the high-efficiency demister placed at the flue gas outlet of the steam phase change chamber, and the removal rate of the primary concentration is 50-60%; the secondary removal of fine particles: the supersaturated flue gas is removed by the steam phase change chamber After removing part of the fine particles, it ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com