Composite polymer modified asphalt and preparing method of composite polymer modified asphalt

A technology of composite polymer and modified asphalt, applied in building structures, building components, building insulation materials, etc., can solve the problems of poor high temperature resistance, poor high temperature storage stability, difficult practical application, etc., to improve high temperature resistance. and high temperature storage stability, good anti-aging performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

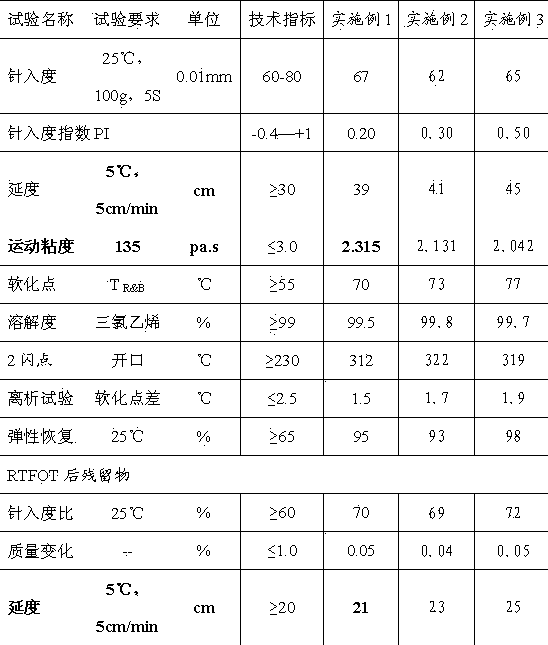

Examples

Embodiment 1

[0030] A composite polymer modified asphalt, the composite polymer modified emulsified asphalt contains the following raw materials in proportion by weight: 4 parts of SBS, 1 part of SBR, 1 part of EVA, 0.8 parts of LDPE, 9 parts of rubber oil, base asphalt 88 parts, 2 parts of anti-crack fiber, 3 parts of diatomaceous earth, the particle size is 130nm nano TiO 2 1.2 parts of anti-aging agent, 1.5 parts of polyester fiber stabilizer, the anti-cracking fiber is a mixture of basalt fiber, carbon fiber and asbestos fiber, and the weight ratio of the basalt fiber, carbon fiber and asbestos fiber is 1:2.5: 0.5.

[0031] Its preparation method specifically comprises the following steps:

[0032] (1) Weigh each raw material according to the weight ratio;

[0033] (2) Add SBS, SBR, EVA, LDPE and rubber oil into the modified mixing tank at a speed of 800r / min, and stir for 5-10 min;

[0034] (3) Then add base asphalt, while stirring, add anti-crack fiber, diatomaceous earth, and nan...

Embodiment 2

[0037] A composite polymer modified asphalt, the composite polymer modified emulsified asphalt contains the following raw materials in proportion by weight: 5 parts of SBS, 1.5 parts of SBR, 1.5 parts of EVA, 1.5 parts of LDPE, 10 parts of rubber oil, base asphalt 95 parts, 3 parts of anti-crack fiber, 5 parts of kaolin, particle size of 50nm nano-SiO 2 2 parts of anti-aging agent, 2 parts of lignin fiber stabilizer, the anti-cracking fiber is a mixture of basalt fiber, carbon fiber and asbestos fiber, and the weight ratio of the basalt fiber, carbon fiber and asbestos fiber is 1:3: 0.8.

[0038] Its preparation method specifically comprises the following steps:

[0039] (1) Weigh each raw material according to the weight ratio;

[0040] (2) Add SBS, SBR, EVA, LDPE and rubber oil into the modified mixing tank at a speed of 900r / min, and stir for 5-10 min;

[0041] (3) Then add base asphalt, while stirring, add anti-crack fiber, kaolin, and nano-SiO with a particle size of 5...

Embodiment 3

[0044] A composite polymer modified asphalt, the composite polymer modified emulsified asphalt contains the following raw materials in proportion by weight: 3 parts of SBS, 0.5 part of SBR, 0.5 part of EVA, 0.5 part of LDPE, 7 parts of rubber oil, base asphalt 80 parts, 1 part of anti-crack fiber, 2 parts of montmorillonite, the particle size is 200nm nanometer Fe 2 o 3 0.7 parts of anti-aging agent, 1 part of lignin fiber stabilizer, the anti-cracking fiber is a mixture of basalt fiber, carbon fiber and asbestos fiber, and the weight ratio of the basalt fiber, carbon fiber and asbestos fiber is 1:2: 0.3.

[0045] Its preparation method specifically comprises the following steps:

[0046] (1) Weigh each raw material according to the weight ratio;

[0047] (2) Add SBS, SBR, EVA, LDPE and rubber oil into the modified mixing tank at a speed of 1000r / min, and stir for 5-10 min;

[0048] (3) Then add base asphalt, while stirring, add anti-crack fiber, montmorillonite, and nano-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com