Polymer modified emulsified asphalt composition and preparation method thereof

A technology of emulsified asphalt and composition, which is applied in the field of cationic emulsified petroleum asphalt building waterproof material composition and its preparation, can solve the problems of operator influence, long drying process, external force damage, etc., achieve high elongation at break, improve Anti-corrosion and permeability-enhancing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

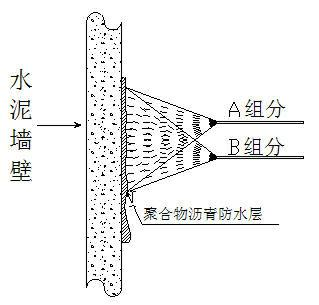

Image

Examples

specific Embodiment approach 1

[0033] Implement the preparation method of the polymer modified emulsified asphalt composition of the present invention, its composition and mass content parts are as follows:

[0034] Component A: 46 parts of emulsified petroleum asphalt, 22 parts of neoprene latex, 9 parts of styrene-butadiene latex, 4 parts of acrylate latex, 6 parts of epoxy resin emulsion, 5 parts of dioctyl phthalate, tetradecyl di 0.5 parts of methyl ammonium chloride emulsifier, 0.5 parts of BYK-8821 defoamer, 7.0 parts of deionized water; the emulsifier tetradecyl dimethyl ammonium chloride in the above materials was stirred and dissolved in After deionized water, then add the plasticizer dioctyl phthalate to stir and emulsify, and then stir and mix with other components at room temperature to obtain component A of the polymer asphalt emulsion.

[0035] Component B: 20 parts of industrial ethanol, 6 parts of industrial ethylene glycol, 5 parts of sodium hydroxide, 7 parts of water-based epoxy resin ...

specific Embodiment approach 2

[0037] Implement the preparation method of the polymer modified emulsified asphalt composition of the present invention, its composition and mass content parts are as follows:

[0038] Component A: 50 parts of emulsified petroleum asphalt, 20 parts of neoprene latex, 5 parts of styrene-butadiene latex, 3 parts of acrylic latex, 4 parts of epoxy resin emulsion, 4 parts of dioctyl phthalate, cetyl di 0.3 parts of methyl benzyl ammonium chloride emulsifier, 0.4 parts of BYK-8821 defoamer, 13.3 parts of deionized water; After stirring and dissolving in deionized water, then adding the plasticizer dioctyl phthalate to stir and emulsify, and then stirring and mixing with other components at room temperature to obtain component A of the polymer asphalt emulsion.

[0039] Component B: 30 parts of industrial ethanol, 4 parts of industrial ethylene glycol, 4 parts of sodium hydroxide, 5 parts of water-based epoxy resin curing agent, 57 parts of industrial water; dissolve the sodium hydr...

specific Embodiment approach 3

[0041] Implement the preparation method of the polymer modified emulsified asphalt composition of the present invention, its composition and mass content parts are as follows:

[0042] Component A: 56 parts of emulsified petroleum asphalt, 17 parts of neoprene latex, 4 parts of styrene-butadiene latex, 1 part of acrylic latex, 3 parts of epoxy resin emulsion, 3 parts of dioctyl phthalate, 3 parts of octadecyl tri 0.2 parts of methyl ammonium chloride emulsifier, 0.3 parts of BYK-8821 defoamer, 15.5 parts of deionized water; the emulsifier octadecyl trimethyl ammonium chloride in the above materials was stirred and dissolved in After deionized water, then add the plasticizer dioctyl phthalate to stir and emulsify, and then stir and mix with other components at room temperature to obtain component A of the polymer asphalt emulsion.

[0043] Component B: 35 parts of industrial ethanol, 2 parts of industrial ethylene glycol, 3 parts of sodium hydroxide, 4 parts of water-based epox...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tear strength | aaaaa | aaaaa |

| Bond strength | aaaaa | aaaaa |

| Elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com