Preparation of carbon nanotube material embedded with quantum-dot modified metal organic framework

A metal-organic framework, quantum dot material technology, applied in electrical components, battery electrodes, circuits, etc., can solve problems such as poor electrical conductivity of metal-organic frameworks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

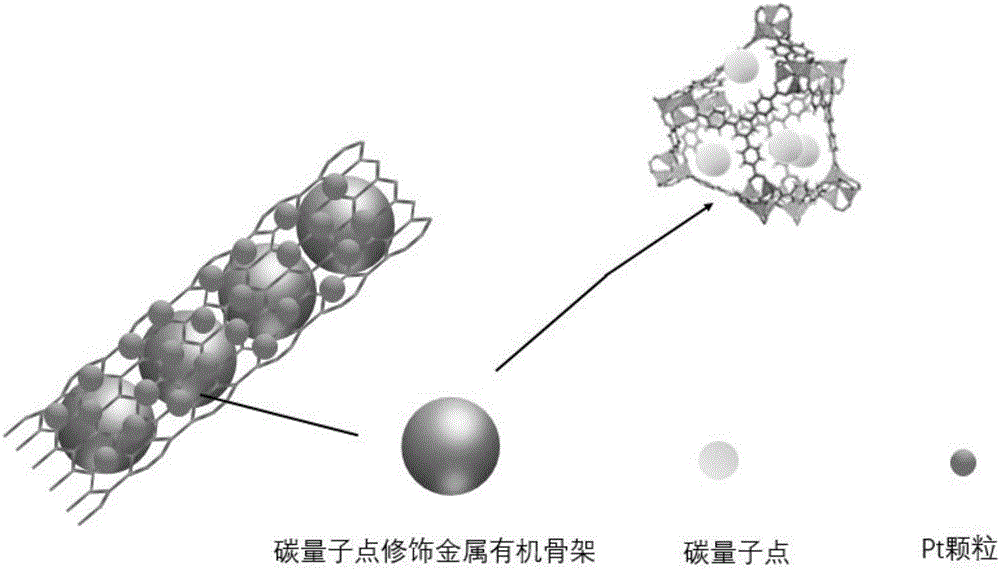

[0068] A schematic diagram of a carbon quantum dot-modified metal-organic framework embedded in a carbon nanotube material, see figure 1 , the detailed preparation steps are as follows: first, zinc nitrate (Zn(NO 3 ) 2 ·6H 2 O) 0.20g and terephthalic acid 0.04g were placed in a 50ml wide-mouth bottle, 15mL N,N-diethylformamide (DEF) was added, and ultrasonic treatment was performed for 30min to completely dissolve the solid and turn into a clear solution. Then, 20 mg of carbon quantum dots (CQD) were added under stirring conditions, transferred to a screw bottle and sealed, and transferred to a constant temperature drying oven at 100° C. for 48 h. The product was moved to a glove box, filtered at room temperature, rinsed with 15 mL of DEF, and dried naturally to obtain CQD / UMCM-1 with a certain crystal structure. Then the obtained 3.0g CQD / UMCM-1 sample was mixed with 3.0g melamine powder, and heated at 5°C min under the protection of nitrogen flow. -1 The temperature was ...

Embodiment 2

[0071] A schematic diagram of a carbon quantum dot-modified metal-organic framework embedded in a carbon nanotube material, see figure 1 , the detailed preparation steps are as follows: first, zinc nitrate (Zn(NO 3 ) 2 ·6H 2 (O) 0.30g and terephthalic acid 0.06g were put into a 50ml wide-mouth bottle, 20mL N,N-diethylformamide (DEF) was added, and ultrasonic treatment was performed for 40min to completely dissolve the solid and turn into a clear solution. Then, 30 mg of carbon quantum dots (CQD) were added under stirring conditions, transferred to a screw bottle to seal, and transferred to a constant temperature drying oven to react at a temperature of 120°C for 48 hours. The product was moved to a glove box, filtered at room temperature, then rinsed with 20 mL of DEF, and dried naturally to obtain CQD / UMCM-1 with a certain crystal structure. Then the obtained 5.0g CQD / UMCM-1 sample was mixed with 5.0g melamine powder, and heated at 8°C min under the protection of nitrogen ...

Embodiment 3

[0073] A schematic diagram of a carbon quantum dot-modified metal-organic framework embedded in a carbon nanotube material, see figure 1 , the detailed preparation steps are as follows: first, zinc nitrate (Zn(NO 3 ) 2 ·6H 2 O) 0.60 g and terephthalic acid 0.08 g were placed in a 50 ml wide-mouth bottle, 25 mL of N,N-diethylformamide (DEF) was added, and ultrasonic treatment was performed for 45 min to completely dissolve the solid and turn into a clear solution. Then, 40 mg of carbon quantum dots (CQD) were added under stirring conditions, transferred to a screw bottle and sealed, and transferred to a constant temperature drying oven at 150° C. for 48 hours. The product was moved to a glove box, filtered at room temperature, then rinsed with 25 mL of DEF, and dried naturally to obtain CQD / UMCM-1 with a certain crystal structure. Then the obtained 8.0g CQD / UMCM-1 sample was mixed with 8.0g melamine powder, and heated at 10°C min under the protection of nitrogen flow. -1The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com