Luminescent colored bitumen emulsion and preparation method thereof

A technology of colored asphalt and emulsion, applied in building components, building insulation materials, buildings, etc., can solve the problems that the characteristics of colored pavement cannot be fully reflected, dull and dull, and achieve the effect of brilliant colors, advanced technology and excellent quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

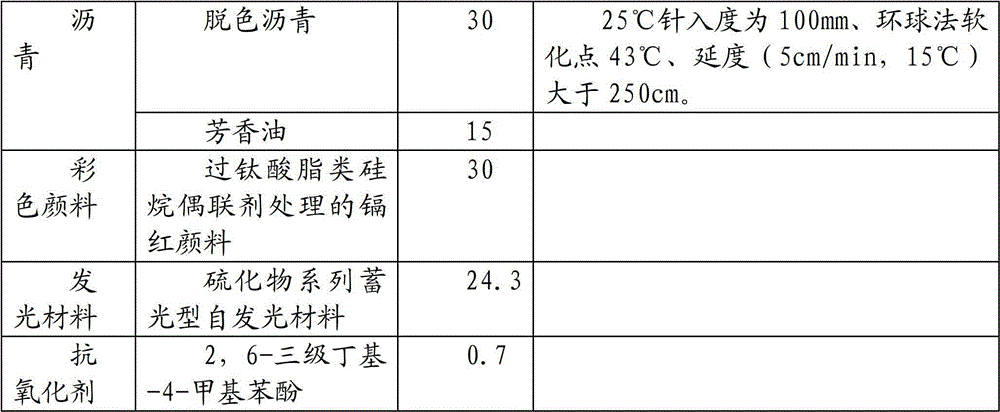

[0022] Luminous colored asphalt formula, based on the total amount of luminous colored asphalt:

[0023]

[0024] Weigh the color pigments, luminescent materials, and antioxidants according to the proportion and mix them evenly in a high-speed stirring device, and stir them evenly in the asphalt heated to a specified ratio of 130-160°C;

[0025] A formula of luminescent colored asphalt emulsion of the present invention, based on the total amount of luminous colored asphalt emulsion:

[0026]

[0027] Weigh the emulsifier and stabilizer according to the proportion, add them into the water at 45-65°C, and stir evenly.

[0028] Inject the prepared soap liquid and luminescent colored asphalt into the colloid mill, and after grinding, make the emulsion mode particle size less than 5 μm and the average particle size less than 7 μm.

Embodiment 2

[0030] Luminous colored asphalt formula, based on the total amount of luminous colored asphalt:

[0031]

[0032]

[0033] Weigh the color pigments, luminescent materials, and antioxidants according to the proportion and mix them evenly in a high-speed stirring device, and stir them evenly in the asphalt heated to a specified ratio of 130-160°C;

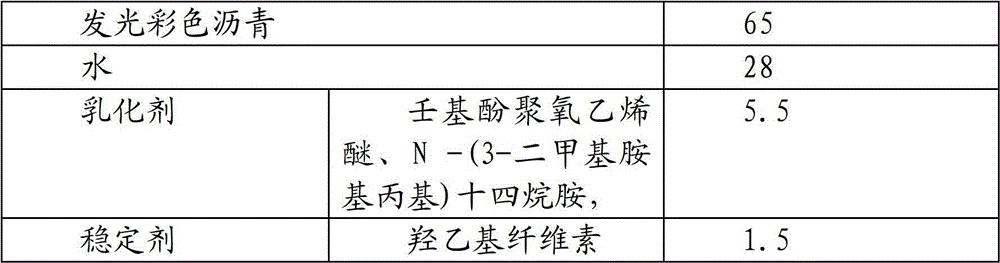

[0034] A formula of luminescent colored asphalt emulsion of the present invention, based on the total amount of luminous colored asphalt emulsion:

[0035]

[0036] Weigh the emulsifier and stabilizer according to the proportion, add them into the water at 45-65°C, and stir evenly.

[0037] Inject the prepared soap liquid and luminescent colored asphalt into the colloid mill, and after grinding, make the emulsion mode particle size less than 5 μm and the average particle size less than 7 μm.

Embodiment 3

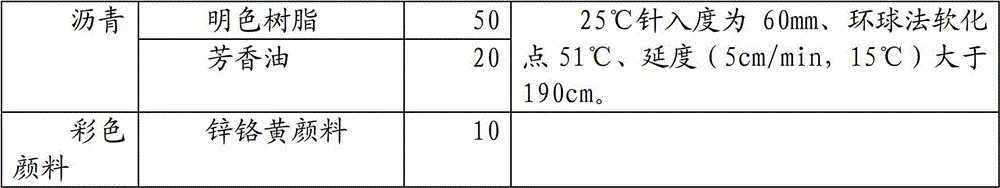

[0039] Luminous colored asphalt formula, based on the total amount of luminous colored asphalt:

[0040]

[0041] Weigh the color pigments, luminescent materials, and antioxidants according to the proportion and mix them evenly in a high-speed stirring device, and stir them evenly in the asphalt heated to a specified ratio of 130-160°C;

[0042] A formula of luminescent colored asphalt emulsion of the present invention, based on the total amount of luminous colored asphalt emulsion:

[0043]

[0044] Weigh the emulsifier and stabilizer according to the proportion, add them into the water at 45-65°C, and stir evenly.

[0045] Inject the prepared soap liquid and luminescent colored asphalt into the colloid mill, and after grinding, make the emulsion mode particle size less than 5 μm and the average particle size less than 7 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com