Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

168 results about "Interfacial binding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Phosphate flame-retardant PC/ABS (polycarbonate/acrylonitrile-butadiene-styrene) alloy and preparation method thereof

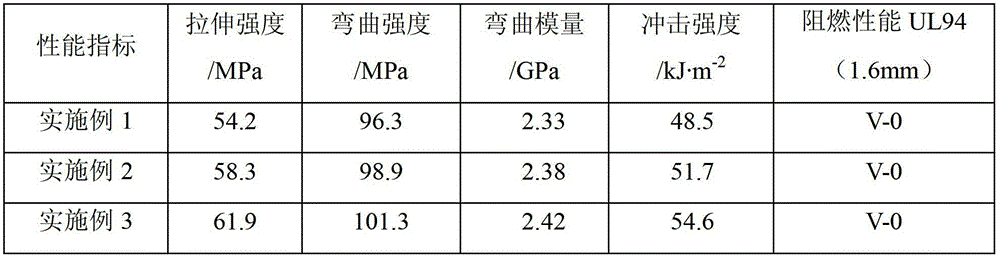

The invention belongs to the technical field of high-polymer alloy materials, and relates to a phosphate flame-retardant PC / ABS (polycarbonate / acrylonitrile-butadiene-styrene) alloy and a preparation method thereof. The alloy material is prepared from the following components in parts by weight: 55-75 parts of PC resin, 25-45 parts of ABS resin, 2-10 parts of compatilizer, 2-10 parts of toughening agent, 10-20 parts of flame retardant, 2-10 parts of inorganic filler, 0.1-0.5 part of antioxidant, 0.2-1.0 part of lubricant and 0.2-1.0 part of anti-dripping agent. The compatilizer, toughening agent and inorganic filler are utilized to enhance the interfacial binding force between the PC resin and ABS resin and the mechanical properties of the PC / ABS alloy. Besides, the nano silicon dioxide and other inorganic fillers added into the PC / ABS alloy can effectively perform the synergic flame-retardant function; and the anti-dripping agent in the formula can effectively inhibit the melt from dripping in the alloy material combustion process, thereby enhancing the flame retardancy of the material.

Owner:SHANGHAI GENIUS ADVANCED MATERIAL (GRP) CO LTD

Mo/Ag laminated metal matrix composite for solar cell interconnected sheet and preparation process thereof

InactiveCN102169912AElectric discharge tubesFinal product manufactureGround testingBiological activation

The invention relates to a Mo / Ag laminated metal matrix composite for solar cell interconnected sheets and a preparation process thereof. By employing a vacuum metal plasma implantation technology, the invention comprises the steps of implanting metallic elements according to certain energy and dosage into molybdenum foil interconnected sheet materials processed by burnishing, degreasing and acidpickling activation; plating silver on the surface of molybdenum foils by a non-cyanide electroplating method; and conducting high temperature annealing under the protection of argon so that the metallic element of silver diffuses and penetrates into the molybdenum foils to form a metallurgical binding with Mo / Ag interfaces and finally to obtain the Mo / Ag laminated metal matrix composite having high interfacial binding strength and high welding strength. The welding (interfacial) strength of the composite reaches 460gf by single-point resistance spot welding. According to the invention, the Mo / Ag laminated metal matrix composite is prepared without adding an intermediate metal layer and cyanide electroplated silver. The ground testing is conducted and the performance requirement is achieved.

Owner:TIANJIN UNIV

Plant fiber starch fully-biodegradable material and preparation method thereof

The invention discloses a plant fiber starch fully-biodegradable material and a preparation method thereof. The material is a product prepared by melting, blending and extruding thermoplastic corn starch, 50 to 60 mesh needlebush fibers, polylactic acid, inorganic stuffing, a crosslinking agent and a solubilizer in a twin-screw extruder. The thermoplastic corn starch is a product prepared by extruding the corn starch and the solubilizer which are blended according to a ratio of 40 to 70: 2 to 5 in a single screw extruder. In the invention, dioctyl maleate (MOD) is grafted onto the polylactic acid to perform a hydroxylation reaction of MOD-functionalized polylactic acid and thermoplastic starch, so that PLA and TPS interfaces are soluble mutually and the binding force of the interfaces is improved. The product has high water resistance and high mechanical properties. Compared with the conventional thermoplastic corn starch composition packing material, the stretching strength of the material of the invention is improved by 30 to 60 percent, the rigidity is increased by 15 to 35 percent, the water absorption is reduced by 13 to 40 percent, and the material is nontoxic and low in cost.

Owner:HUNAN UNIV OF TECH

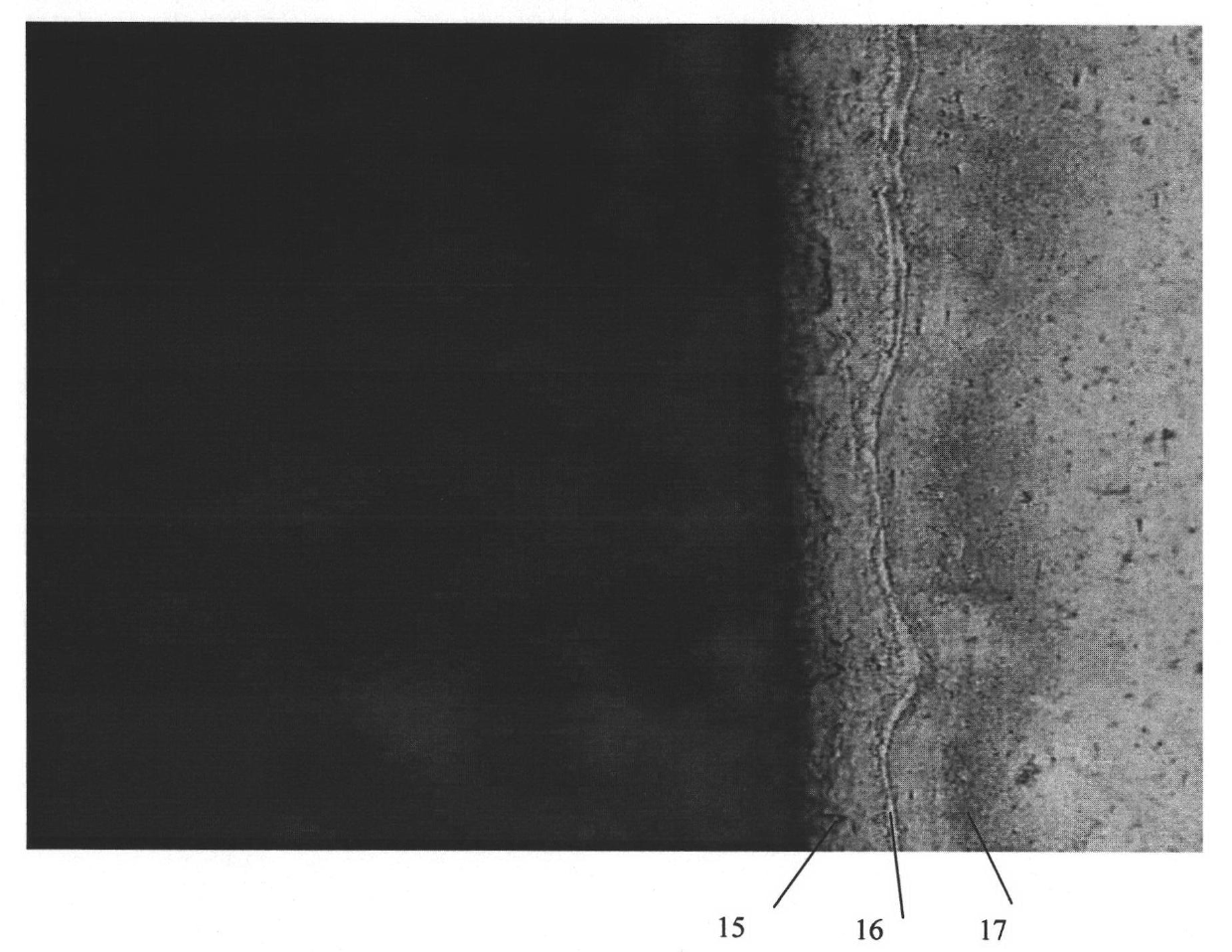

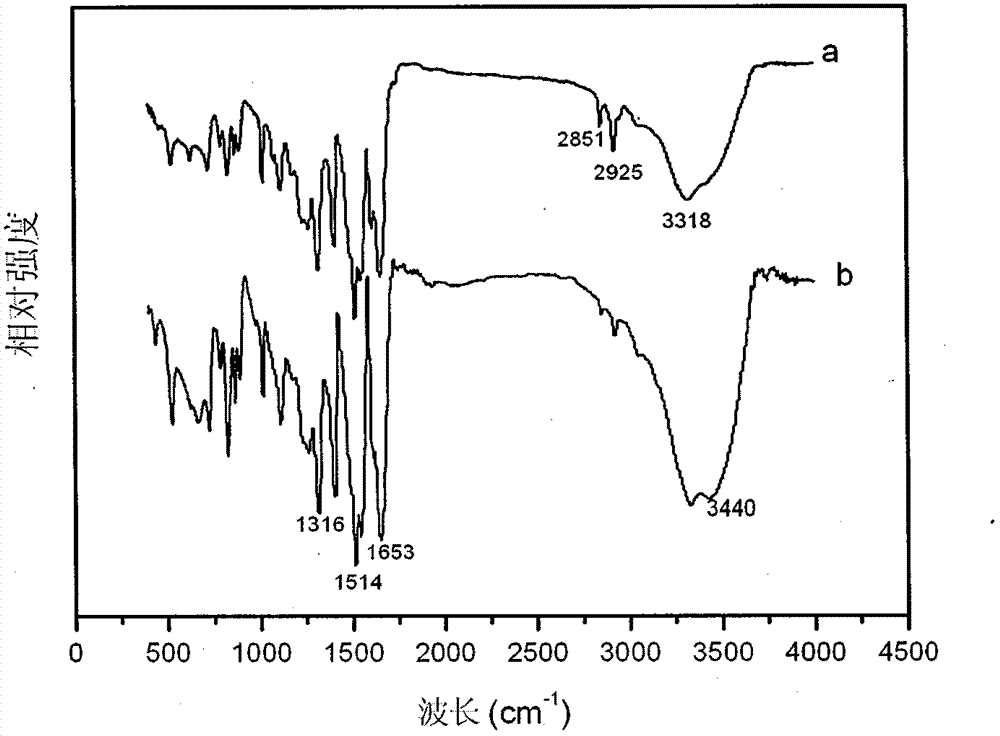

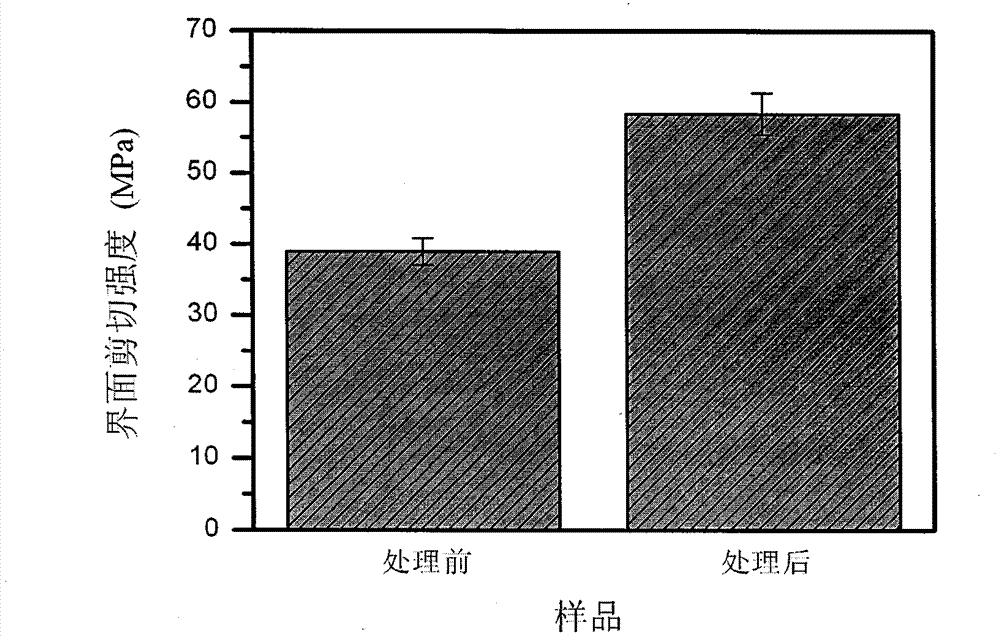

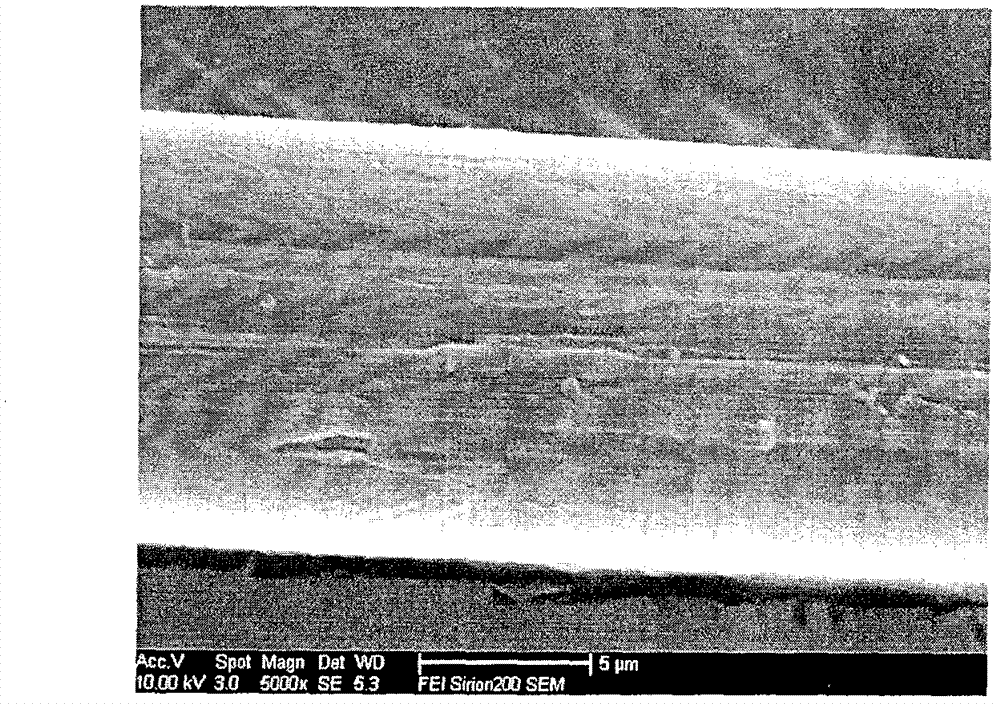

Method for improving surface activity of aramid fiber

InactiveCN103031708AImprove surface activityImprove interfacial bond strengthFibre typesFiber-reinforced compositeBiological activation

The invention discloses a method for improving the surface activity of aramid fiber. The method comprises the following steps of: (1) immersing the aramid fiber in acetone, heating and boiling for 1 hour, further immersing into anhydrous ethanol, and heating and boiling for 1 hour; and then placing into deionized water for washing, and drying for 2 hours after the treatment; and (2) performing surface activation treatment on the aramid fiber: (a) preparing a hydrogen peroxide solution with the concentration of 20%-60%; (b) cutting the aramid fiber after pretreatment into samples of 20cm, and placing into the hydrogen peroxide solution for performing treatment at the temperature of 0 DEG C-80 DEG C for 30min-90min; (c) washing with the deionized water till the pH value of a washing solution is 7; and (d) drying after washing to obtain the aramid fiber with surface modification. The treatment method disclosed by the invention is simple, the interfacial binding strength of an aramid fiber-reinforced composite material can be greatly improved, the mechanical strength of the aramid fiber can be also kept unchanged, the equipment is simple, the operation is convenient, and the industrial continuous treatment is convenient to realize.

Owner:SHANDONG UNIV OF TECH

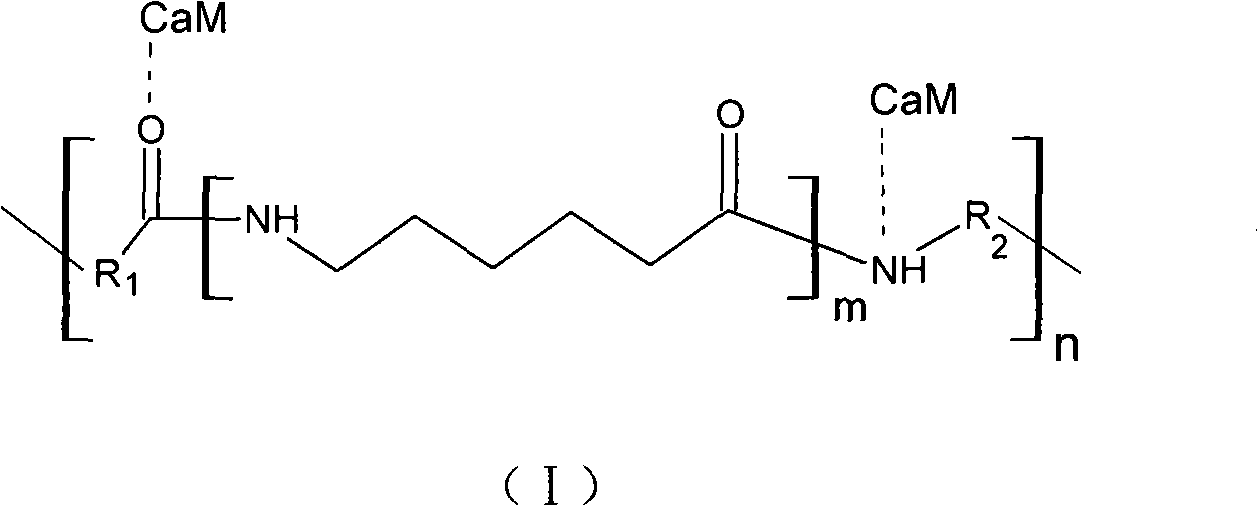

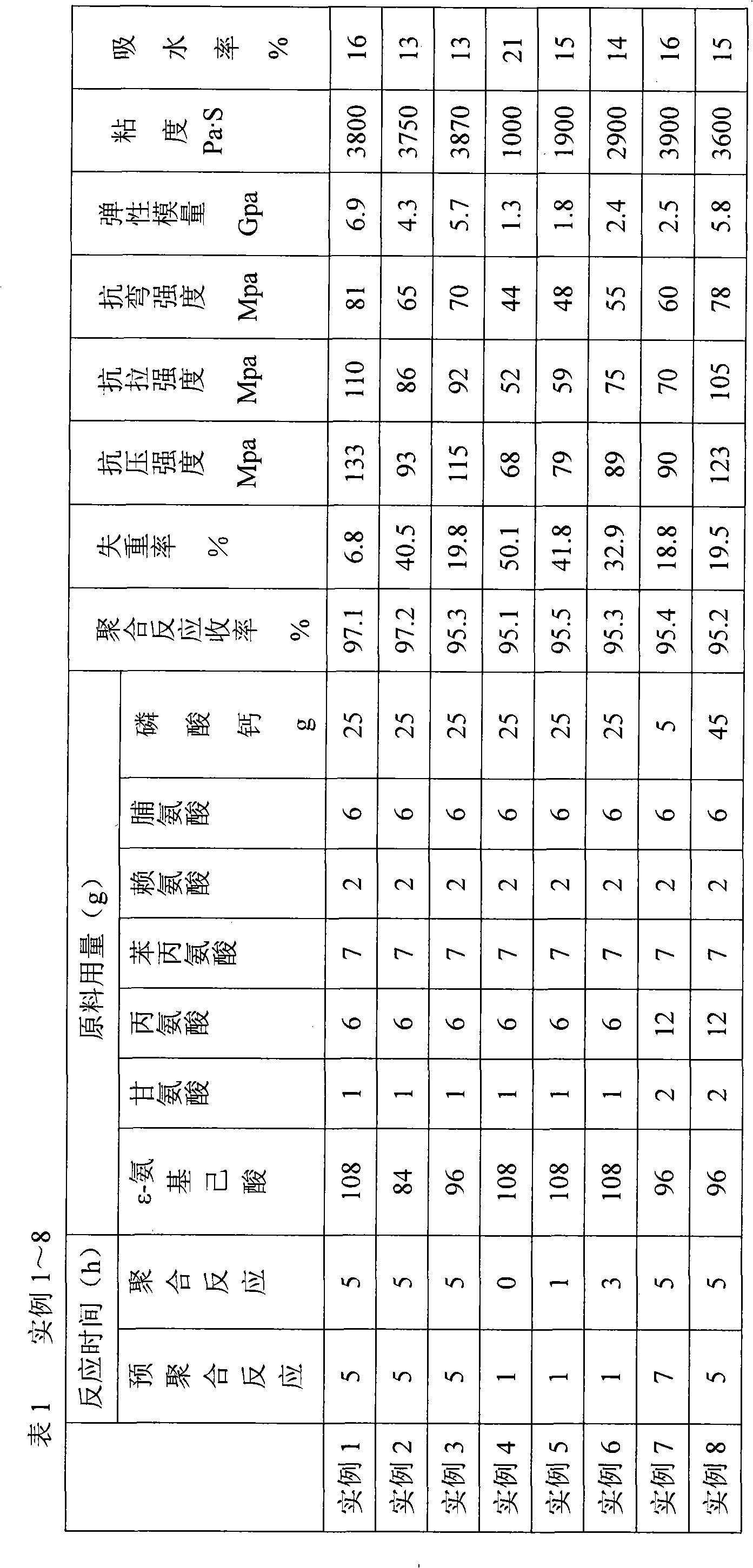

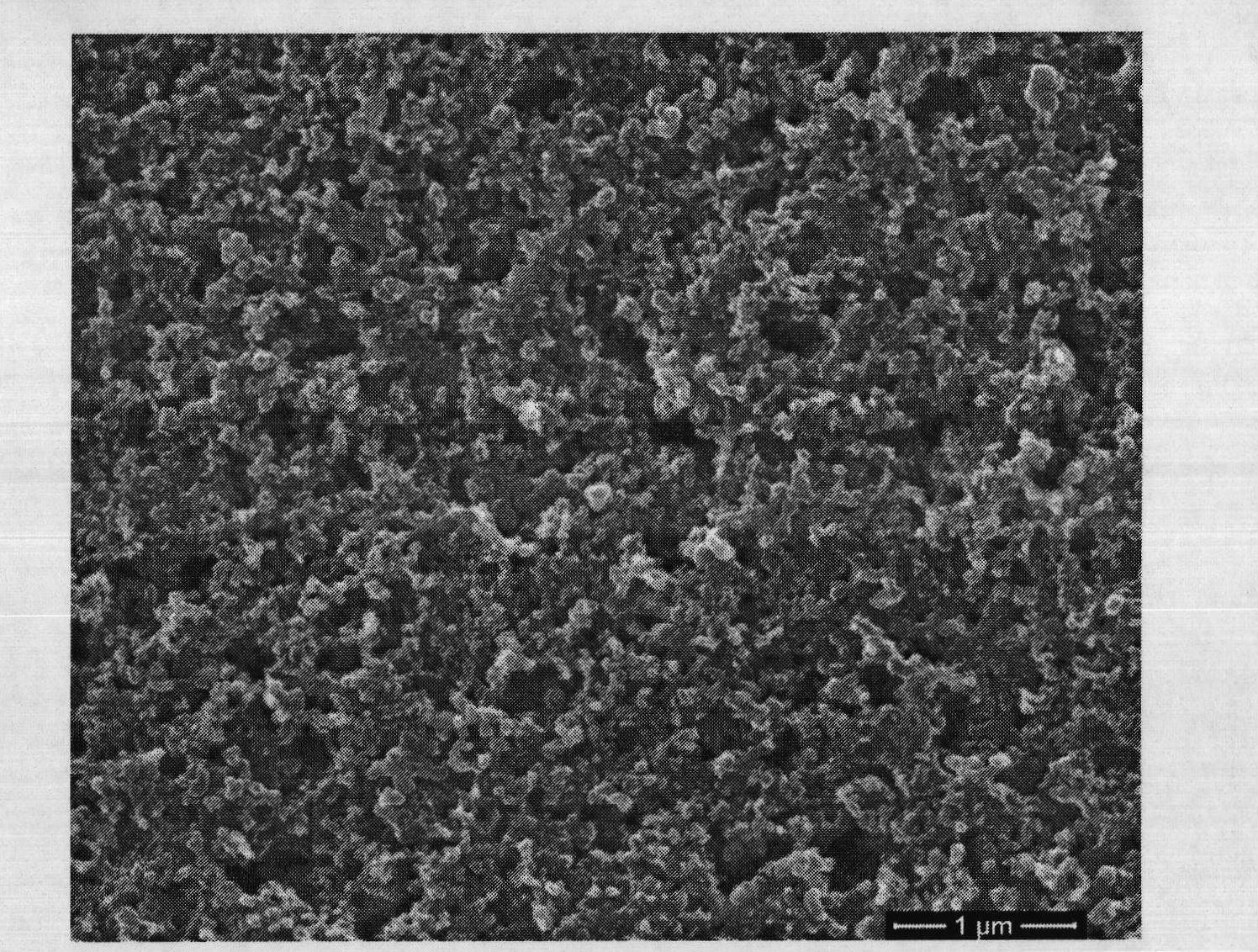

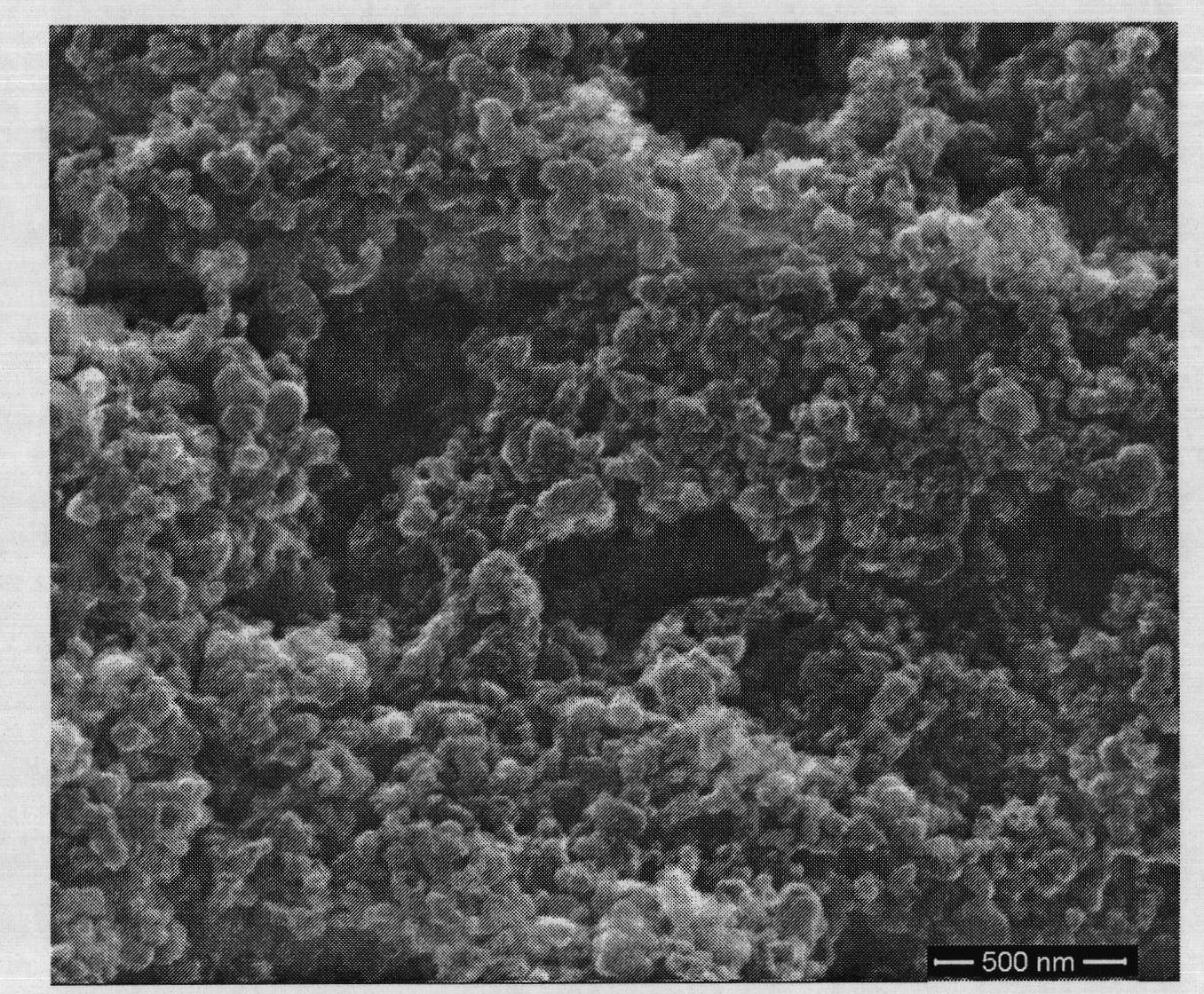

Composite polymer bone-renovation material containing ceramic component and preparation method thereof

InactiveCN101342384AImprove securityImprove hydrophilicityProsthesisAdditive ingredientBiocompatibility Testing

The present invention relates to a bone-repairing composite polymer material containing a ceramic ingredient and a preparation method thereof. The bone-repairing composite polymer material is composed of the calcium phosphate ceramic ingredient and a polybasic amino acid polymer ingredient, wherein, the mass ratio of the calcium phosphate ceramic ingredient is between 5 percent and 30 percent, and the rest is the polybasic amino acid polymer ingredient. Epsilon-aminocaproic acid is polymerized with at least two other types of amine acids to form the polybasic amino acid polymer ingredient, wherein, the mole ratio of the epsilon-aminocaproic acid in the polybasic amino acid polymer ingredient is between 50 percent and 90 percent, and the rest is the other amine acids including aminoacetic acid, lactamic acid, phenylalanine, lysine and proline. Under the protection of a inert gas, the materials, the amine acids and the calcium phosphate, are sufficiently and uniformly dispersed into water and then heated, so that various forms of waters can be removed from the materials, and finally, the materials are polymerized in two steps, respectively under a temperature between 200 DEG C and 220 DEG C and a temperature between 230 DEG C and 250 DEG C. The bone-repairing composite polymer material, which has excellent mechanical property, bioactivity, biocompatibility and controllable degradation property, can be perfectly combined with the interface of the bone tissue, and moreover, the degradation product is non-toxic and non-irritant.

Owner:SICHUAN GUONA TECH

Carbon/aluminum composite cathode foil for solid aluminum electrolytic capacitor and preparation method thereof

InactiveCN101923961AImprove bindingExtended service lifeSolid electrolytic capacitorsCapacitanceElectrolysis

The invention relates to a carbon / aluminum composite cathode foil for a solid aluminum electrolytic capacitor and a preparation method thereof. The technical scheme is as follows: carrying out proportioning according to that the weight ratio of conductive carbon black: dispersant: organic binder: solvent is 1: (0.0001-0.05): (0.01-1): (10-1000), firstly mixing the conductive carbon black, the dispersant and the organic binder, further adding the solvent, uniformly stirring and mixing, and preparing into slurry; uniformly coating the prepared slurry on the surface of an aluminum foil after pretreatment, then placing the aluminum foil coated with the slurry into a vacuum furnace, keeping the temperature for 1-40h under the conditions that the vacuum degree is 10-4-10-1Pa and the temperature is 300-660 DEG C, naturally cooling to room temperature in the vacuum furnace, and directly preparing the carbon / aluminum composite foil for the solid aluminum electrolytic capacitor or preparing the carbon / aluminum composite foil for the solid aluminum electrolytic capacitor after activation treatment. The process is simple and the preparation process is safe and environment-friendly; and the prepared product has the characteristics of high specific capacitance, good stability, high carbon / aluminum interfacial binding force and long service life.

Owner:WUHAN UNIV OF SCI & TECH

Metal-based self-lubricating composite material and preparation method thereof

InactiveCN101871058AImprove mechanical propertiesGood friction propertiesWear resistantSpherical shaped

The invention discloses a metal-based self-lubricating composite material, comprising the following components by weight percent: 4-10 percent of copper-plated graphite powder and 90-96 percent of bronze powder, wherein the proportion of copper and graphite in the copper-plated graphite powder is 30-50 percent of copper and 50-70 percent of graphite. A preparation method of the metal-based self-lubricating composite material comprises the steps that: a layer of spherical bronze powder is pre-sintered on a steel matrix, mixing the copper-plated graphite powder and the bronze powder according to the proportion, the mixture is stirred and then is uniformly coated on the surface of the matrix, hydrogen is taken as protective atmosphere, pre-sintering and forming are carried out, then re-sintering is carried out after rolling treatment, and the temperature schedule for the pre-sintering and re-sintering is as follows: the temperature is kept for 0.5-1 hour at the temperature of 700-850 DEG C. The high-strength and wear-resistant metal-based self-lubricating composite material has even distribution, good interface bonding, and the whole material integrates the good mechanical performance and wear resistance. Simultaneously, the use of the composite material can save a great amount of non-ferrous metal material, reduce the cost; and in addition, the composite material does not contain lead, is green and environment-friendly and can be used for manufacturing self-lubricating sliding bearings and chute boards.

Owner:DALIAN HONGRUN COMPOSITE BEARING

Vacuum stirring composite granule reinforcing aluminium-based composite material and preparation technique thereof

The invention relates to a composite material of vacuum churning composite granule enhanced aluminum matrix and a preparation technique, which comprises: Si 0-15Wt%, Mg 0-1.5Wt%, Cu 0-2.0Wt%, Mn 0-1.0Wt%, Cr 0-0.4Wt%, Ti 0-0.2Wt%, SiC 0.1-20% (volume proportion). Firstly base alloy is smelted, slag is removed, and refined, churned slowly in vacuum to complete degassing procedure for base melt, the pre-treated enhanced granule is continuously added into the aluminum base melt, mechanical churning to roll the granule into the melt, after the granule is completely rolled in the melt, strong churning and slow churning in reverse direction are conducted so as to disperse the granule evenly in the base; the temperature raises, modifier and refiner are added; the vacuum is dismounted, and placed in static, the floating slag is removed above the melt, and cast. The composition between the granule and the base is realized via vacuum mechanical churning, the joining interface is good, the enhanced granule is evenly dispersed in the base, the prepared composite material has low porosity rate, which is easy to realize industrial mass production.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND +1

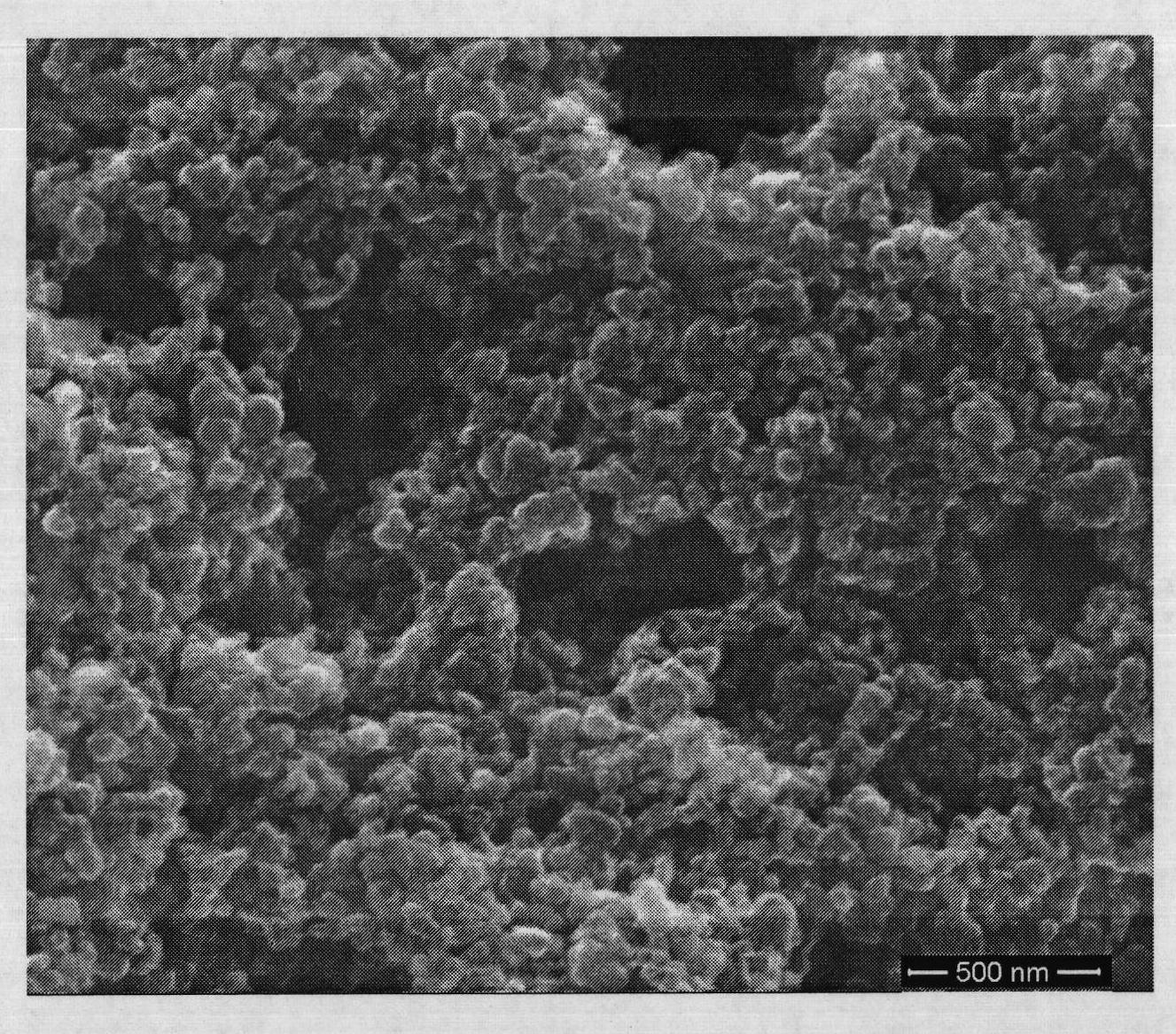

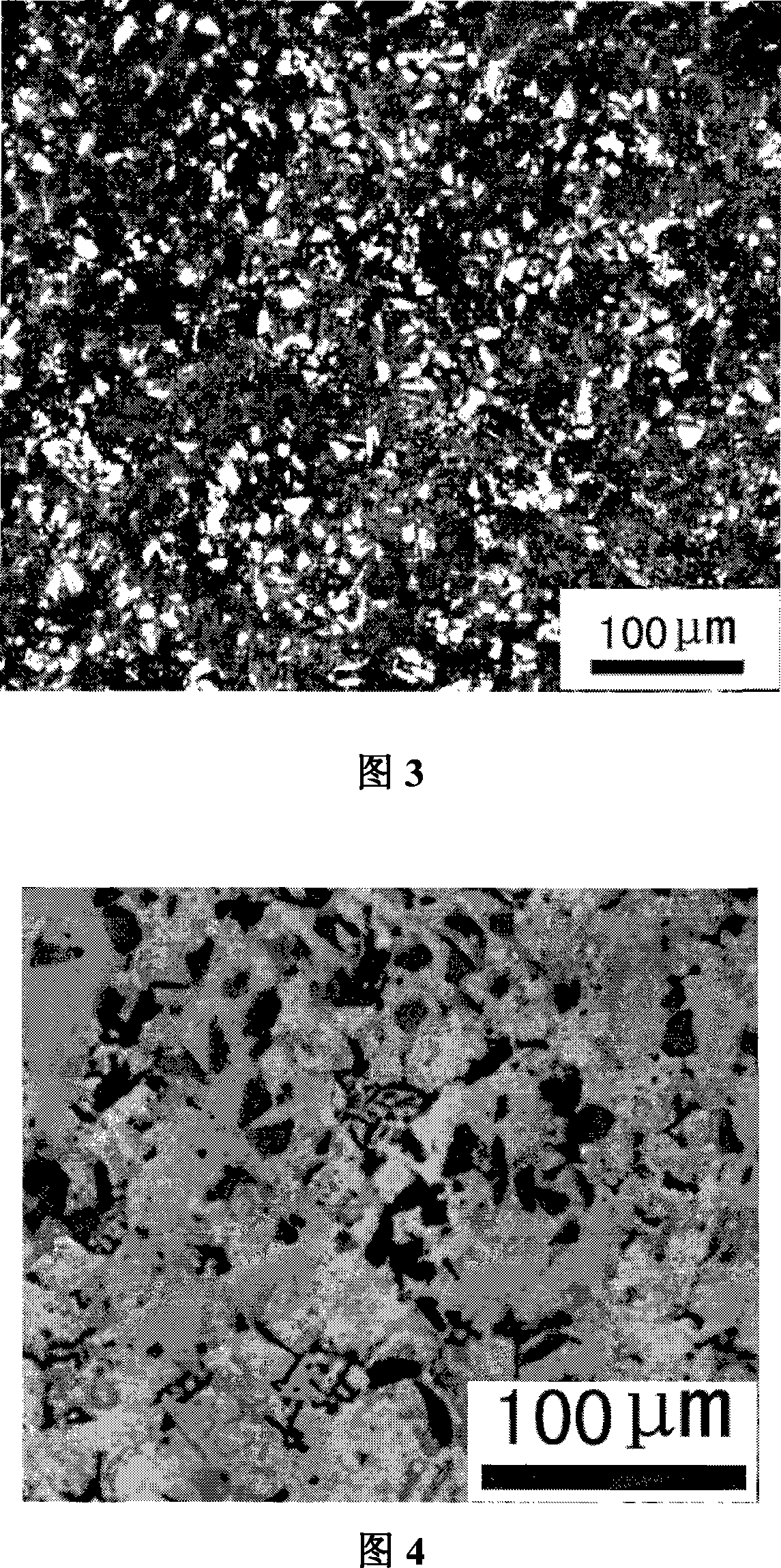

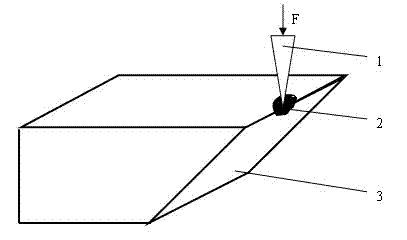

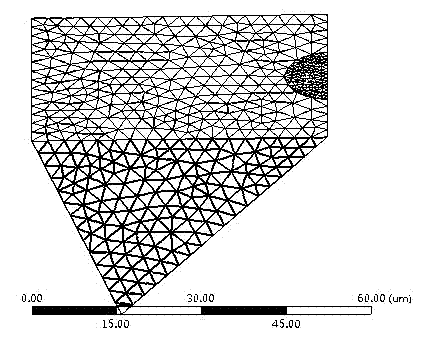

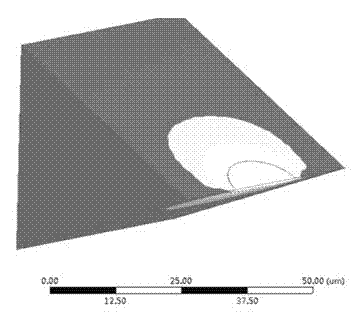

Detection method for interface bonding strength of particle reinforced metal matrix composite material

InactiveCN102494997AAdaptableEasy to operateUsing mechanical meansMaterial analysisBurnishing (metal)Scanning electron microscope

The invention relates to a detection method for interface bonding strength of a particle reinforced metal matrix composite material. The method is characterized in that a mechanical processing method is firstly adopted to process a particle reinforced metal matrix composite material sample into a cuboid, wherein the cuboid is conveniently observed by a scanning electron microscope; a piece of the cuboid is cut along the shortest edge of the cuboid, and it is ensured that the two adjacent surfaces on the edge form an angle of 45 DEG after cutting; treatments of burnishing and polishing are performed on the two adjacent surfaces; under the scanning electron microscope, a loading head with a conductive adhesive performs stripping on the particles positioned on the 45 DEG edge of the sample in a vertical loading way, wherein the sample is fixed on an object stage during the stripping process; the stripped particles are adhered to the conductive adhesive to observe the morphology of the particles; concurrently the exact loading positions of the loading head on the particles are determined; the particle-matrix interface bonding strength is derived according to the stress simulation result of the loading process. The method of the present invention has strong adaptability, and can be used for interface bonding strength measurements of a plurality of composite materials, and the operation of the method is simple and convenient.

Owner:JIANGSU UNIV

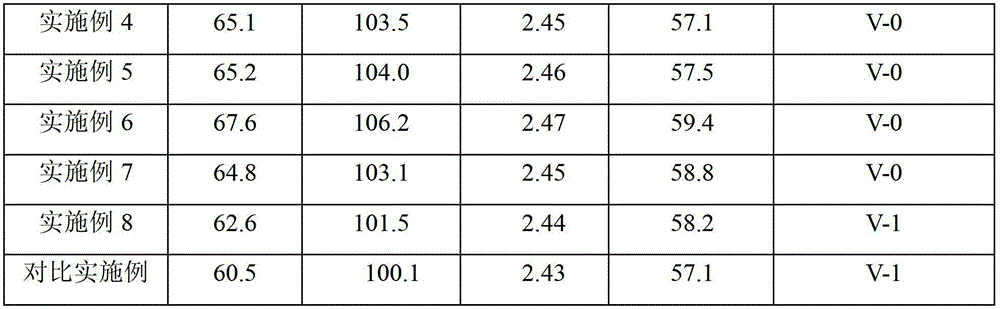

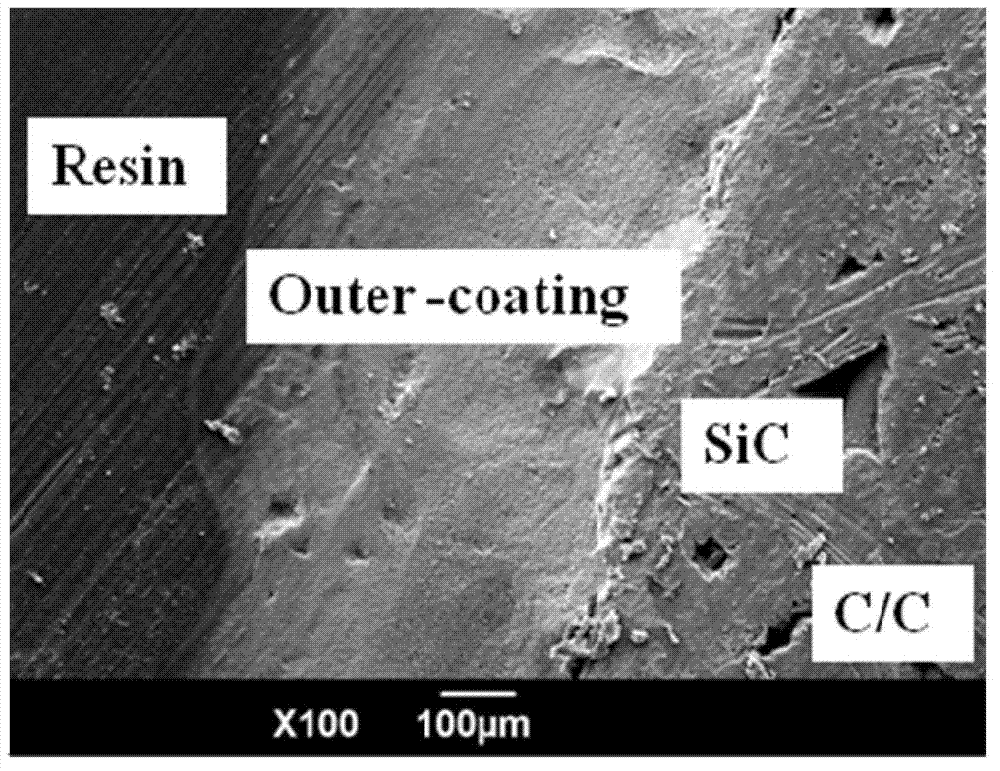

Method for preparing carbon/carbon composite MoSi2-ZrSiO4-SiC gradient complex outer coating

The invention discloses a method for preparing a carbon / carbon composite MoSi2-ZrSiO4-SiC gradient complex outer coating. The MoSi2-ZrSiO4-SiC gradient complex outer coating is prepared with a cathode rotating microwave hydrothermal pulsed arc discharge deposition method; microwave presents self-heating and high efficiency in a reaction system, and generated partial high temperature and high pressure can effectively reduce the reaction activation energy of MoSi2, ZrSiO4 and SiC suspended particles, so that reaction of the suspended particles is more complete and sufficient in a pulsed arc discharge depotition process, and the coating with a dense structure is obtained. In addition, as a cathode rotates at a high speed, the defect that a coating with a dense and uniform structure can only be obtained through coating repeatedly with the traditional hydrothermal method is avoided, and the dense MoSi2-ZrSiO4-SiC gradient complex outer coating with microscopic cracks and different thicknesses can be obtained under controllable conditions. According to the MoSi2-ZrSiO4-SiC gradient complex outer coating prepared with the method, nano silicon carbide is diffused in the coating in a gradient manner, so that the defect is filled, the coating is densified, and the interfacial binding force is good.

Owner:SHAANXI UNIV OF SCI & TECH

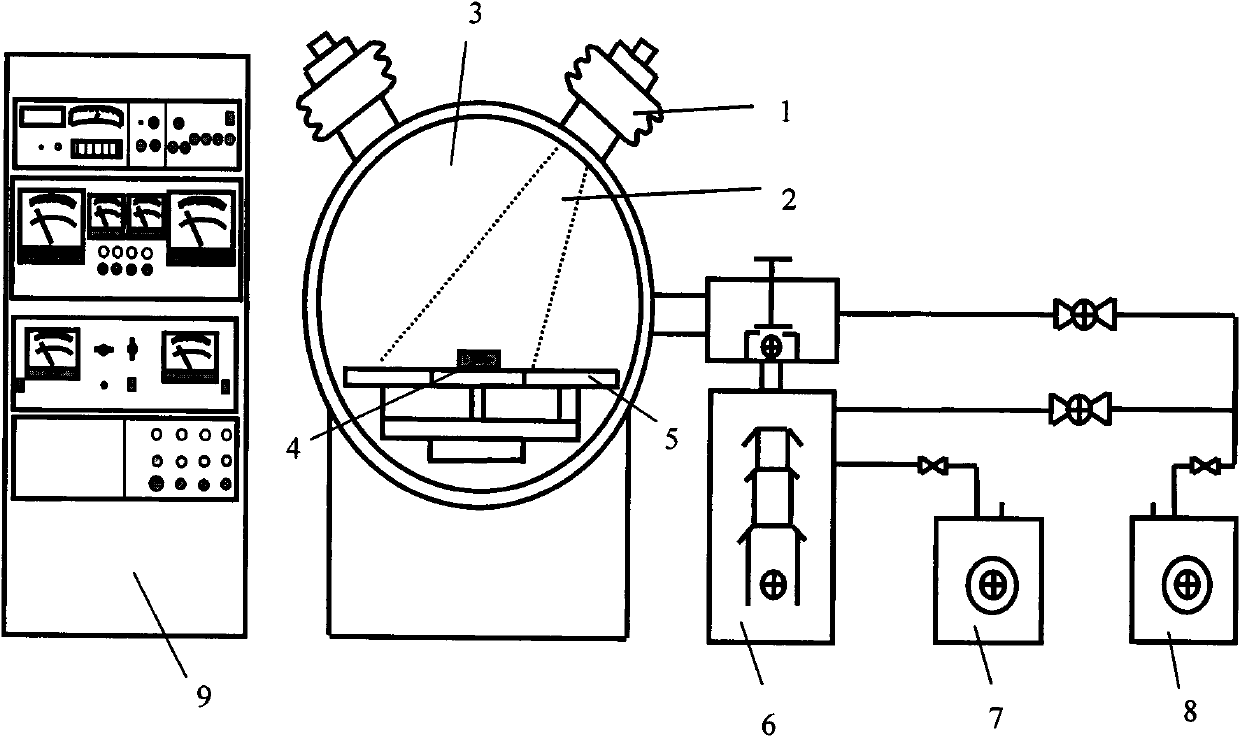

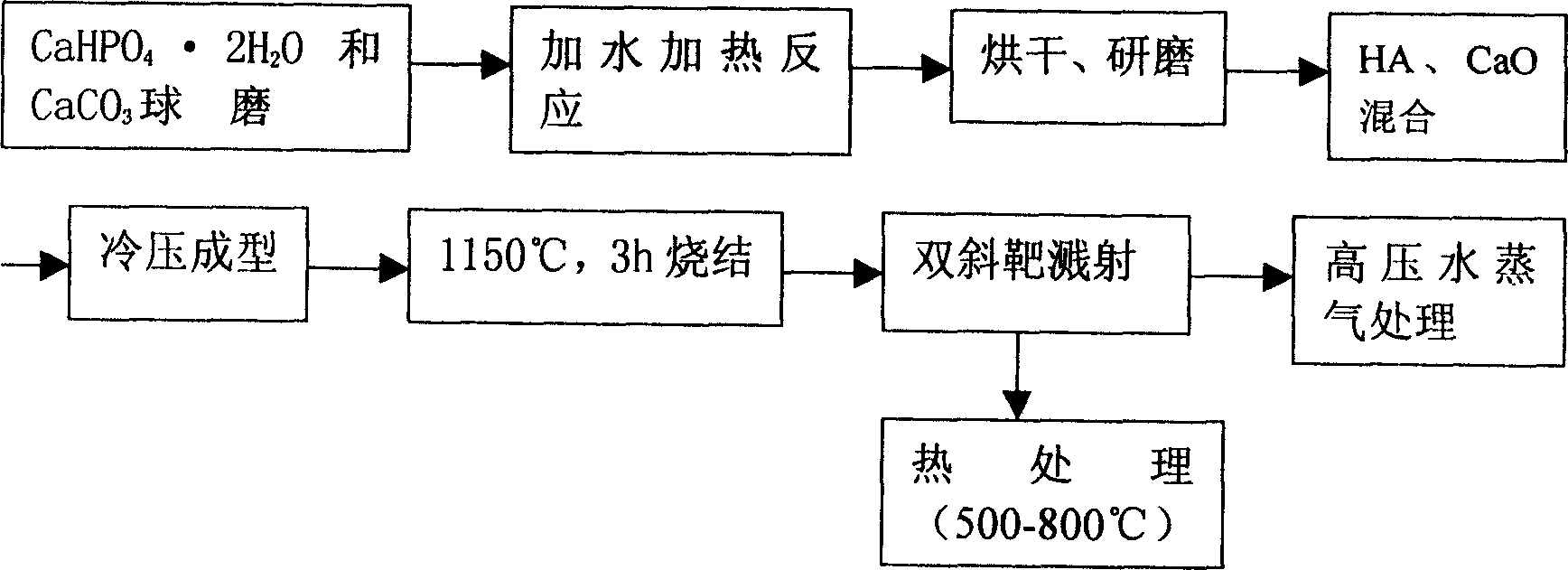

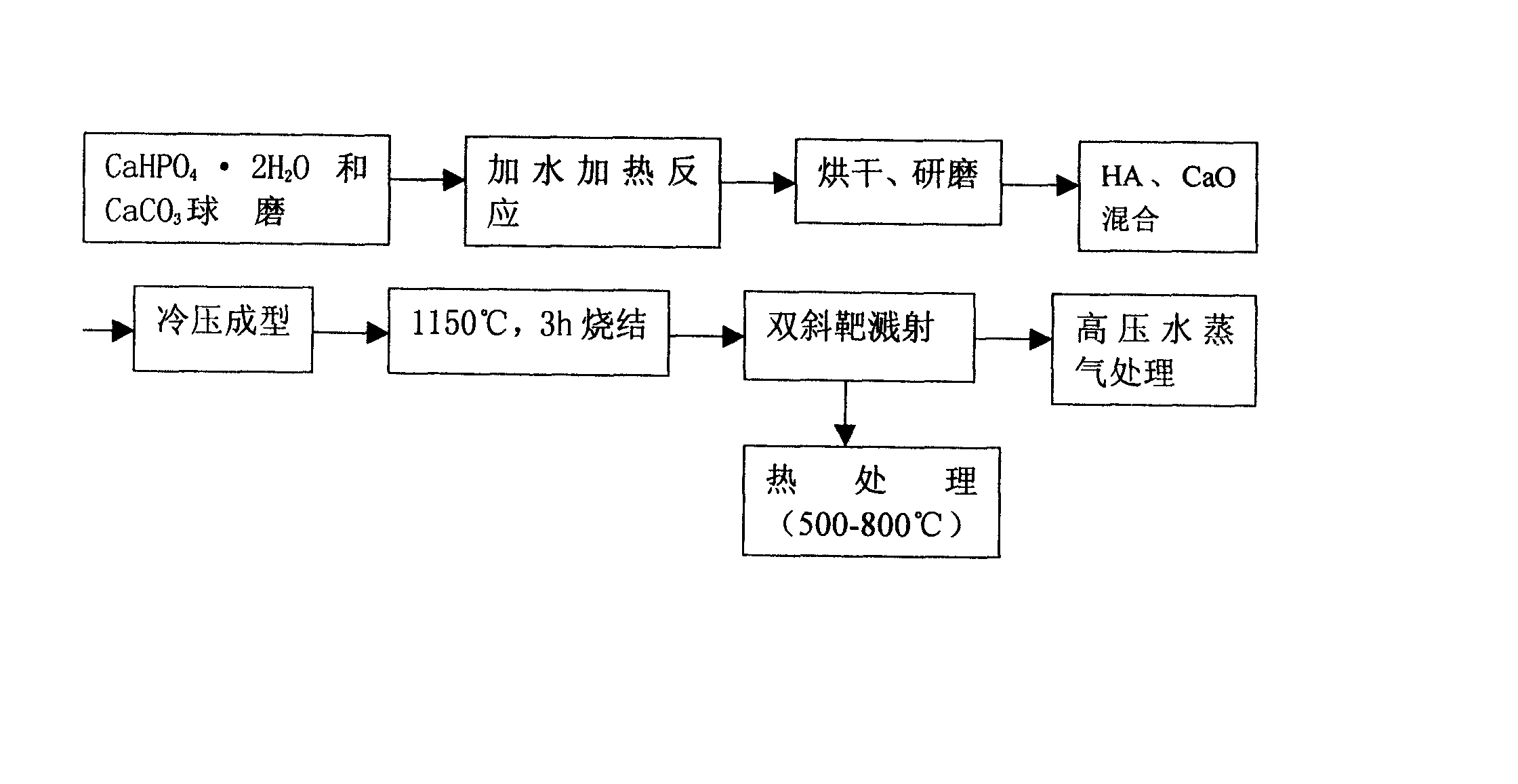

Method and product of sputtering and depositing bioactive gradient hydroxyapatite/Ti layer on Ti alloy surface

InactiveCN1487117AImprove stabilityWeakening interface mutationVacuum evaporation coatingSputtering coatingTitaniumBiological activation

The method of sputtering and depositing bioactive gradient hydroxyapatite / Ti layer on Ti alloy surface includes the following steps: mixing and ball milling material powder; hydrothermal reaction; stoving and grinding; mixing target material; cold pressing at 200-300 MPa to form; sintering; double-inclined target sputtering; and heat treatment of the sputtered film. The product has multilayer structure of Ti alloy matrix, compact transition TiO2 layer I with dispersed hydroxyapatite, TiO2 reinforced transition hydroxyapatite layer II, and porous hydroxyapatite layer. The present invention realizes the double gradient of both component and structure, and raises the interface binding strength effectively. The present invention has simple film preparing process and homogeneous film thickness, is suitable for surface activation of implant with complicated shape, and can prepare hard tissue for clinical need, especially as bearing bone repairing and substituting material.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY

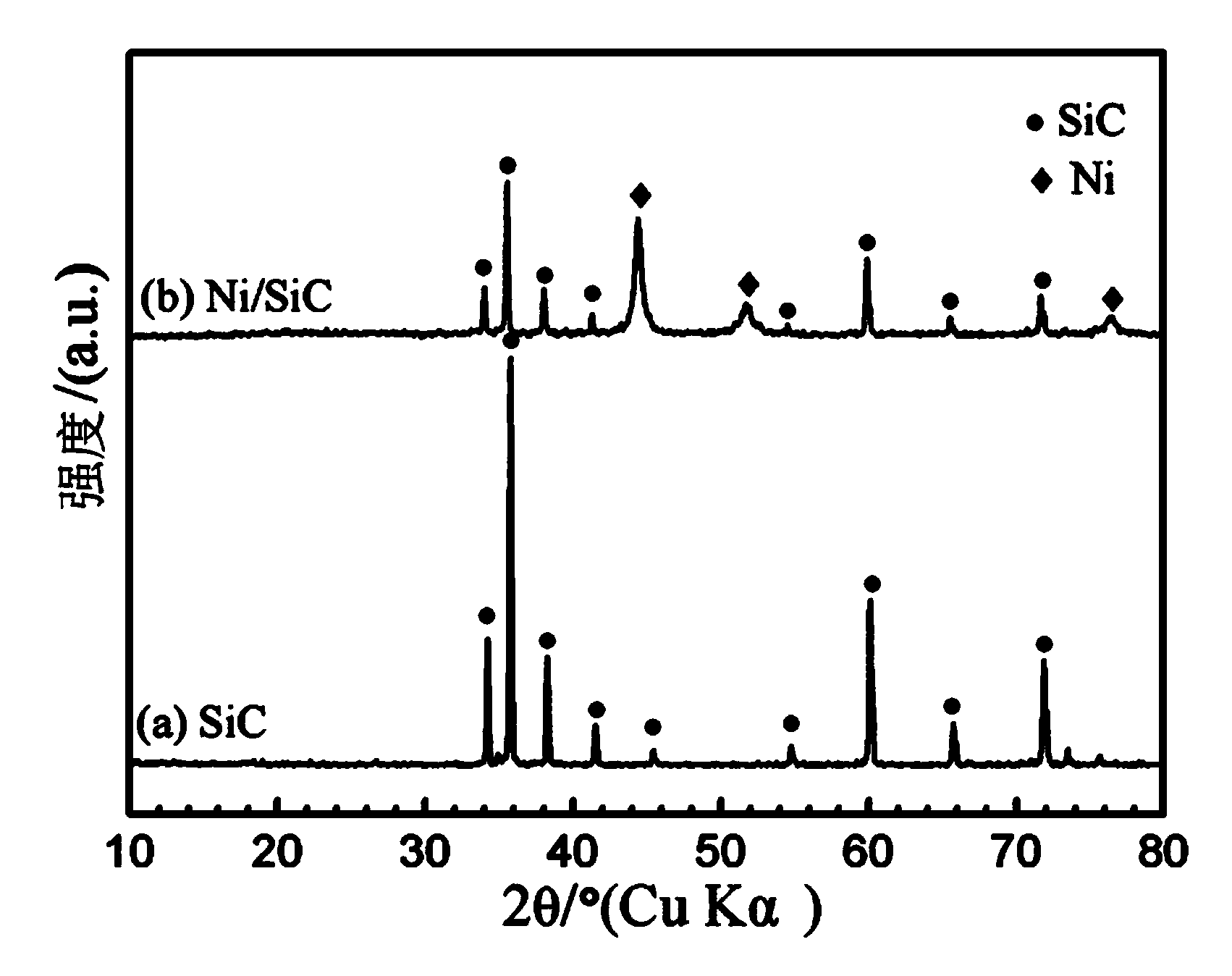

Ni coated SiC compound powder enhanced iron-based composite material, and preparation method thereof

ActiveCN104313459AEnhanced interface bindingImprove mechanical propertiesTransportation and packagingMetal-working apparatusFerrosiliconInterfacial binding

The invention discloses a Ni coated SiC compound powder enhanced iron-based composite material, and a preparation method thereof. The composite material comprises, by weight, 2%-18% of Ni coated SiC compound powder and 82-98% of iron. According to the Ni coated SiC compound powder enhanced iron-based composite material, Ni coats silicon carbide particle surfaces to be used as a transition layer; the Ni transition layer has relatively good interface affinity with the SiC particles, and improves interface adhesion between a silicon carbide particle reinforced phase and an iron substrate and dispersion uniformity; the Ni transition layer can prevent direct surface contact when a plurality of SiC particles aggregate; and a Ni-Fe alloy phase formed by the Ni transition layer and the substrate Fe can prevent or delay mutual diffusion of reactant atoms in a SiC / Fe interface solid phase reaction, thereby effectively inhibiting formation of hard and crisp ferrosilicon compounds, so that the composite material gains good comprehensive mechanical properties, use performances and performance stability.

Owner:ZHENGZHOU UNIV

Core-shell type MOFs composite particles and preparation method and application thereof

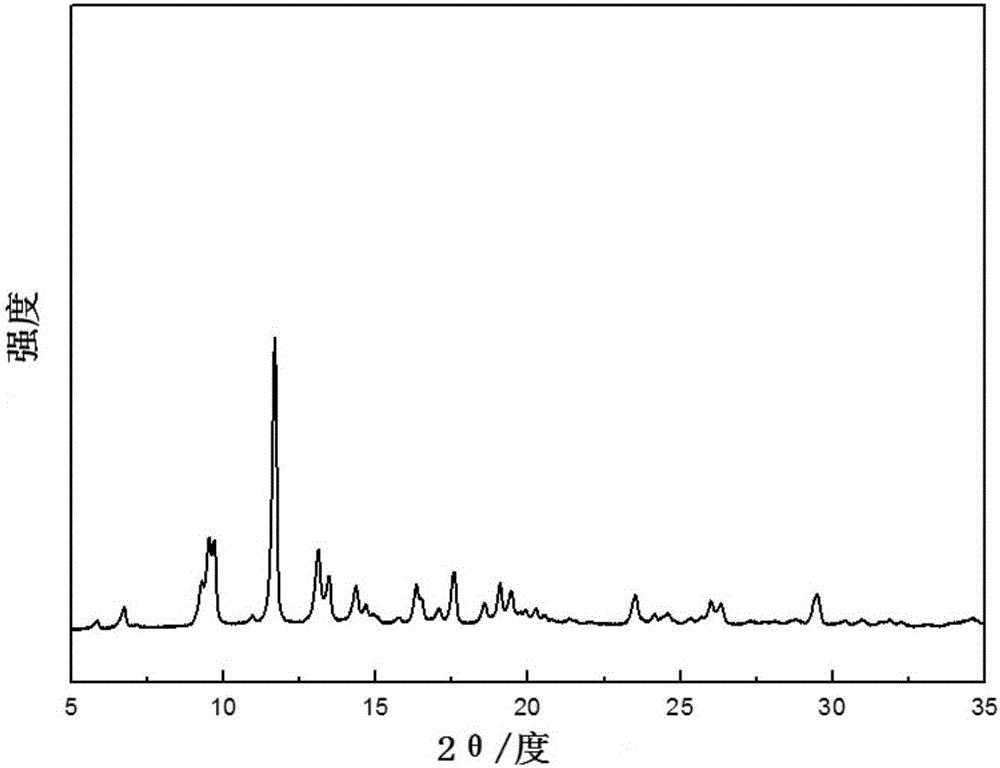

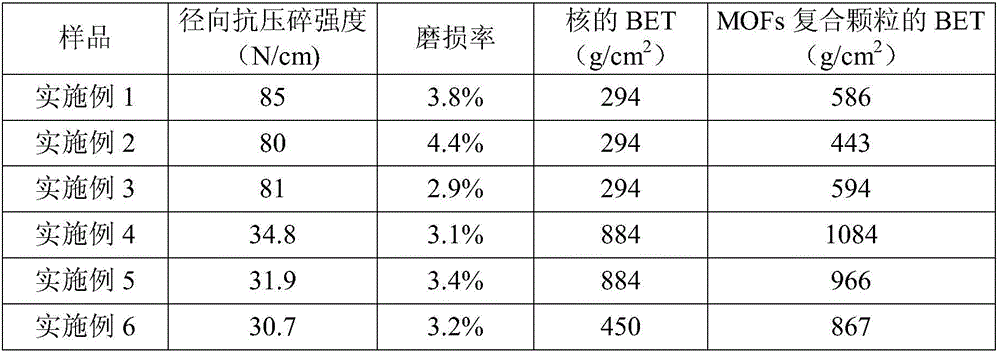

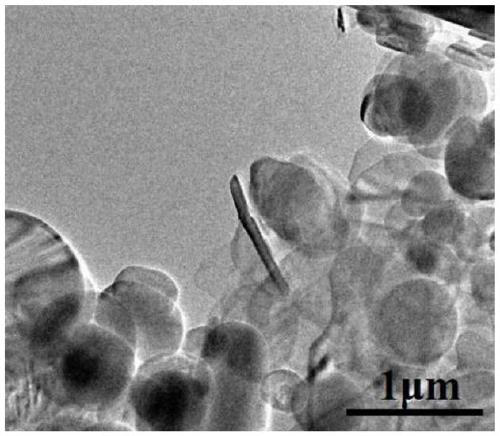

InactiveCN106268554AHigh radial crush strengthReduce wear rateOther chemical processesDispersed particle separationNanotechnologyInterface bonding

The invention relates to core-shell type MOFs composite particles and a preparation method and application thereof. The preparation method of the core-shell type MOFs composite particles includes the following steps that a porous material and a molding promoter are mixed, wet granulating and calcining are carried out, and spherical cores are obtained; the cores are soaked with a binder solution, the cores are subjected to rolling pelleting in MOFs raw powder, and the core-shell type MOFs composite particles are obtained after drying. According to the core-shell type MOFs composite particles, compounding of core-shell materials is achieved in a mechanical bonding mode, the process is simple, the limitation that the varieties of core-shell materials are limited in a traditional in-situ chemical compounding mode is overcome, the application range is wide, interface bonding force is high, the yield is high, and industrial production is easy.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Dopamine modified hexagonal boron nitride/para-aramid nanofiber composite material and preparation method thereof

InactiveCN110229518AImprove insulation performanceImprove thermal conductivityHeat-exchange elementsVacuum assistedFiltration

The invention relates to a dopamine modified hexagonal boron nitride / para-aramid nanofiber composite material and a preparation method thereof. The method includes: step 1, mixing a dopamine modifiedhexagonal boron nitride dispersion solution and a para-aramid nanofiber dispersion solution, and then performing ultrasonic treatment to obtain a mixed system A, wherein the mass of the dopamine modified hexagonal boron nitride accounts for 10%-40% of the total mass of the para-aramid nanofiber; and step 2, conducting vacuum-assisted filtration and hot press drying on the mixed system A to obtainthe dopamine modified hexagonal boron nitride / para-aramid nanofiber composite material. The method ensures the formation of certain microstructure in the composite material, and then enhances the insulation properties of the composite material, and improves the interfacial binding capacity of the dopamine modified hexagonal boron nitride and para-aramid nanofiber, strengthens the stress transfer between the two materials while guaranteeing good heat conduction, strengthens the mechanical strength of the composite material, and acquires the composite material with excellent insulating performance and heat-conducting properties.

Owner:SHAANXI UNIV OF SCI & TECH

New-old concrete combining construction method at local repair section

The invention relates to a new-old concrete combining construction method at a local repair section. The construction method comprises the following steps of: (1) old concrete grooving: sawing joints on the old concrete on one side of a combination surface by a joint saw and uniformly arranging grooves at equal intervals; (2) groove cleaning: cleaning away the concrete within a grooving range in the step (1) by using impacting equipment and manually chiseling away edge-corner areas to form flat groove bottoms; (3) combination surface scabbling: scabbling the cutting surface of the middle and old concrete in the step (1); (4) interfacial agent spraying: spraying an interfacial binding agent on the combination surface of the new-old concrete; (5) steel bar laying: laying steel bars or steel bar supports in the grooves arranged in the step (1); and (6) new concrete pouring: pouring the new concrete inside the erected steel bar supports and the grooves. The new-old concrete combining construction method provided by the invention is simple in construction method and flexible in technological operation, can enable the new and old concrete at the local repair section to be closely combined, is durable and stable, and is widely applicable to new-old concrete engineering practice at the local repair section.

Owner:SHANXI PROVINCIAL RES INST OF COMM +1

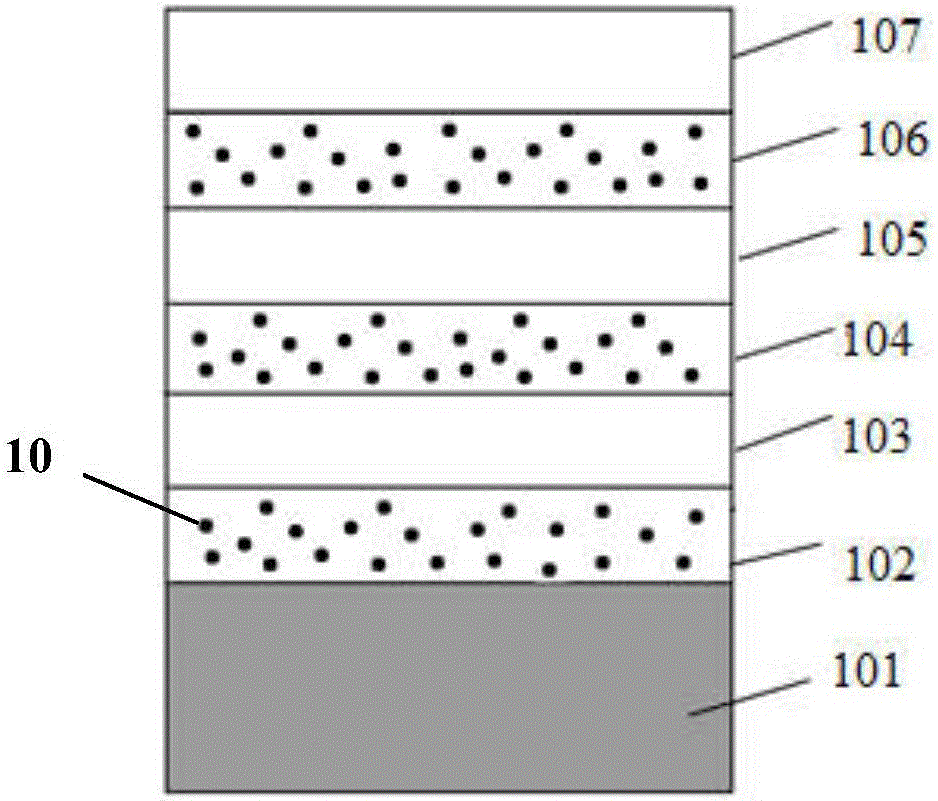

Tool provided with diamond/silicon carbide composite coating and preparation method thereof

ActiveCN106835064AEliminationHigh bonding strengthChemical vapor deposition coatingShear stressInterfacial binding

The invention provides a tool provided with a diamond / silicon carbide composite coating. The tool provided with the diamond / silicon carbide composite coating comprises a base body, and a multi-layer coating structure, wherein the multi-layer coating structure is arranged on the base body. The multi-layer coating structure comprises the silicon carbide / diamond composite coating and a diamond coating. The silicon carbide / diamond composite coating and the diamond coating are sequentially and alternately arranged upwards from the surface of the base body to form the multi-layer coating structure; and the diamond coating is arranged on the top layer of the multi-layer coating structure. Each layer of the multi-layer coating structure can achieve continuous growth of the diamond phase, and accordingly the interface bonding strength between the layers is strengthened, the internal stress of the coatings can be reduced effectively, the adhesion between a thin film and the base body can be strengthened, and particularly the multi-layer coating structure is beneficial for resisting the strong shear stress generated in the cutting process of the tool. In addition, the overall fracture toughness in the thickness direction of the coatings can be strengthened. The invention also provides a production method of the tool provided with the diamond coating.

Owner:SHENZHEN INST OF ADVANCED TECH CHINESE ACAD OF SCI

Method for preparing diffusion couple by using powder

InactiveCN101255060ALow cost manufacturingTightly boundCeramic shaping apparatusDiffusionChemical reaction

The invention relates to a method for producing diffusion couple with powders including the following steps: (1) powder material A is filled in a metal casing which do not diffuse or react with the contacted powder and then is pressed to form a compact; (2) the compact is punched by a die with a diameter which is 4-6 mm smaller than the inner diameter of the metal casing; (3) another powder material B is filled in the holes and then treated by compaction, sintering at a certain temperature, air-cooling to get a diffusion couple. The ring canning diffusion couple produced by compacting powder in the invention utilizes the high shrinkage of the outer powder in the sintering process to provide a interfacial binding force to the powder material of each layer in the jacket, thereby guaranteeing a full integration of the powder in each layer and providing a possibility to the preparation and the interface study of the layered composite powder materials.

Owner:CHONGQING UNIV

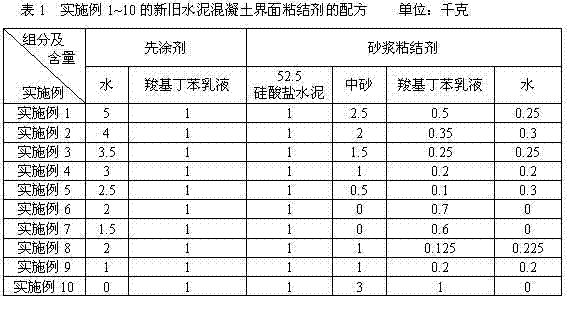

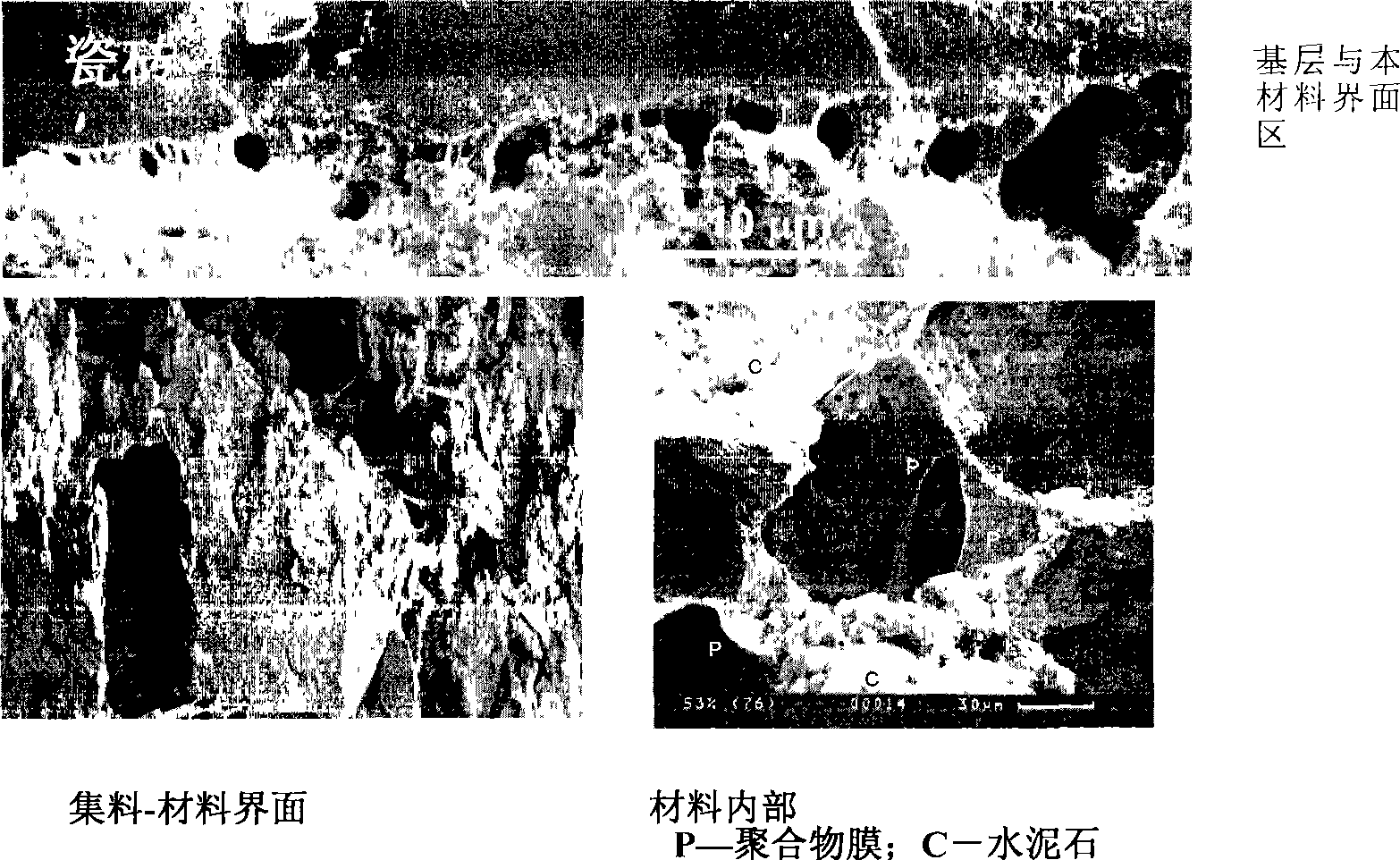

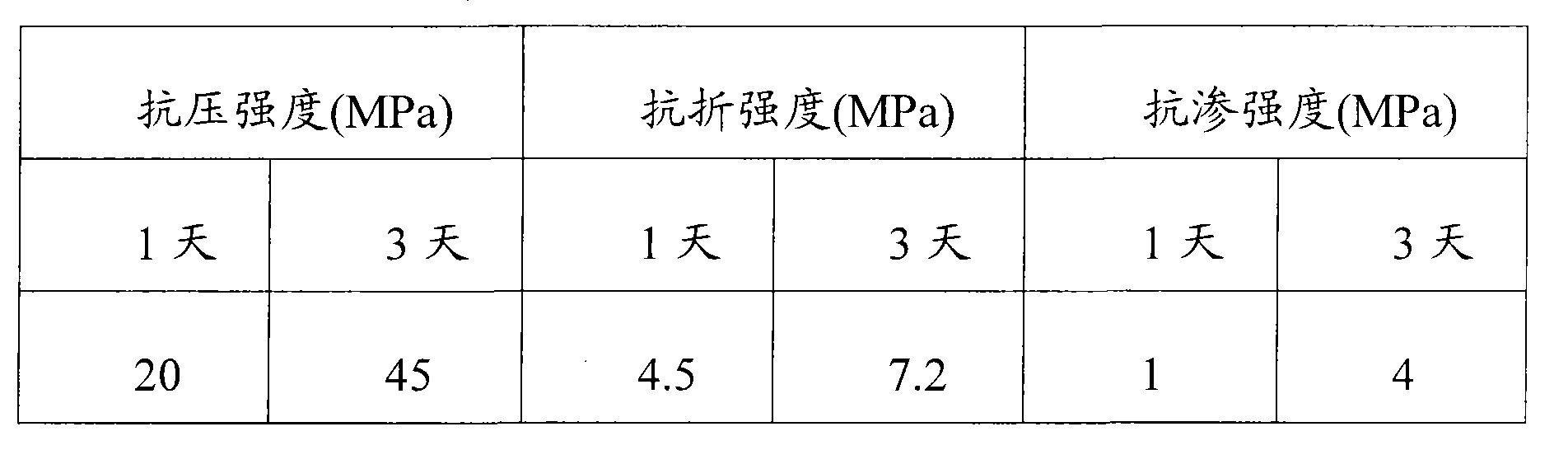

New/old cement concrete interfacial binding agent and construction method for interfacial binding by using same

InactiveCN102643058AImprove adhesionHigh bonding strengthCovering/liningsBridge erection/assemblyCoated surfaceInterfacial binding

The invention discloses a new / old cement concrete interfacial binding agent and a construction method for interfacial binding by using the same. The new / old cement concrete interfacial binding agent is divided into a pre-coating agent and a mortar binding agent, wherein the pre-coating agent is prepared from 1 part by weight of carboxybutylbenzene emulsion and 0-5 parts by weight of water; and the mortar binding agent is prepared from 1 part by weight of cement, 0.1-1 part by weight of carboxybutylbenzene emulsion, 0-3 parts by weight of sand and 0-0.3 part by weight of water. The construction method for interfacial binding by using the interfacial binding agent comprises the following steps: brushing or spraying the pre-coating agent on the surface of old cement concrete to form a pre-coating; after the surface of the pre-coating becomes dry, brushing the mortar binding agent on the surface of the pre-coating to form a mortar binding layer; and after the surface of the mortar bindinglayer becomes dry and before the cement in the mortar binding layer initially sets, casting new cement concrete which is bound with the old cement concrete. The invention obviously enhances the binding strength between new cement concrete and old cement concrete, is innoxious and harmless, and is convenient for use and construction.

Owner:CHINA MERCHANTS CHONGQING COMM RES & DESIGN INST

Polyether-ether-ketone composite material containing fluorine phosphorus lime, preparation method and usage thereof

InactiveCN101899193AEnsure initial fixationGood biocompatibilityProsthesisBinding forceDrug biological activity

The present invention provides a polyether-ether-ketone composite material with fluorine phosphorus lime, a preparation method and usage thereof. The preparation method of the composite material comprises the following steps of: melting and blending the raw material fluorine phosphorus lime and the polyether ether ketone, and then cooling, wherein the dosage of the fluorine phosphorus lime takes 10-50wt% of the total weight of the raw material, and the dosage of the polyether ether ketone takes 50-90% of the total weight of the raw material. The composite material is featured by good mechanical compatibility, reducing stress resistance, greatly increasing binding force between interfaces, reducing shearing stress, reducing tender movement and vertical displacement, and guaranteeing initial fixing of the composite material. Besides, the composite material has the advantages of good biological compatibility and biological activity, capable of promoting bone tissue growth, realizing biological fixing and being used as substitute of metal or ceramic bone substitute material.

Owner:EAST CHINA UNIV OF SCI & TECH

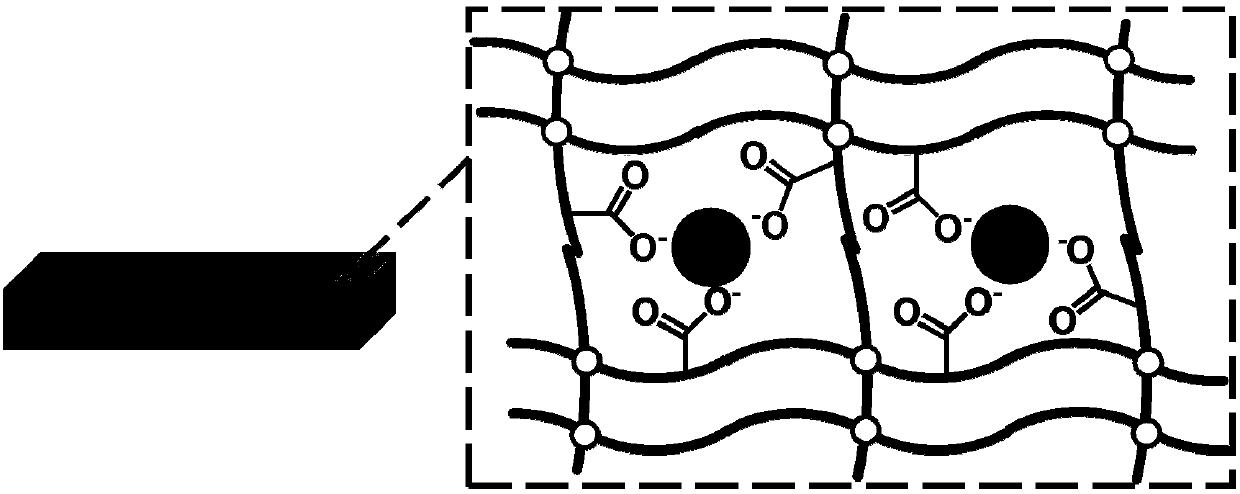

Bilayer hydrogel for promoting interfacial bonding through non-covalent action and preparation method thereof

The invention discloses bilayer hydrogel for promoting interfacial bonding through non-covalent action and a preparation method thereof. Two hydrogel sheets containing the same or different materialsform bilayer hydrogel with excellent interface bonding strength through a coordination bond of Fe<3+> and COO<-> in the hydrogel. The bilayer hydrogel assembly has excellent interface bonding strengththrough bonding of two layers under coordination bonds. The preparation method is free of complex and uncontrollable traditional processes for preparing bilayer hydrogel. The bilayer hydrogel has a good application prospect.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Completely biodegradable composite material and preparation method thereof

The invention provides a completely biodegradable composite material and a preparation method thereof and relates to the technical field of biodegradation. The completely biodegradable composite material is prepared by the following steps of: mixing 35-88% of polylactic acid, 10-50% of starch, 1-10% of compatibilizer and 1-5% of reaction type plasticizer; extruding the mixture through a double-screw extruder; cooling, pelleting and drying. An interfacial compatibilizer can be used for greatly improving the interfacial binding force between the polylactic acid and the starch, and the reaction type plasticizer can be used for improving the tensile strength and increasing the breaking elongation rate of the composite material. The prepared composite material has the advantages of excellent mechanical performances, biological compatibility and low price and can be completely biodegradable; moreover, the composite material can be widely applied to the preparation in fields such as agriculture, hygiene, engineering materials, packaging materials, tableware and the like, has market application potential, and belongs to a novel material characterized in high environment friendliness.

Owner:YANGZHOU UNIV

Non-toxic, environmental friendly, anti-corrosive, water proof, anti-seepage and wearable reinforcement material and preparation method thereof

ActiveCN101456717AImprove physical and mechanical propertiesGood effectSolid waste managementSodium BentoniteWear resistant

The invention relates to a nontoxic, environment-friendly, anticorrosive, imperious, waterproof, wear-resistant reinforcing material applicable to underground building engineering and a preparation method thereof. The reinforcing material comprises the following compositions: 5 to 10 weight portions of cation rubber powder, 5 to 8 weight portions of modified complex calcium, 15 to 30 weight portions of nanometer active SiO2 white carbon black, 1 to 5 weight portions of organic silicon modified nanometer bentonite, 0.1 to 3 weight portions of organic silicon reinforced compacting agent, 100 to300 weight portions of ground sulphoaluminate cement, 0.3 to 1.2 weight portions of dispersant, and 150 to 500 weight portions of quartz sand. The reinforcing material has good interfacial binding force, infiltration capacity and ultrastrong stability, and is a material with special use for the water resistance, impermeability, reinforcement and corrosion resistance of underground structures.

Owner:湖南腾达岩土工程技术有限公司

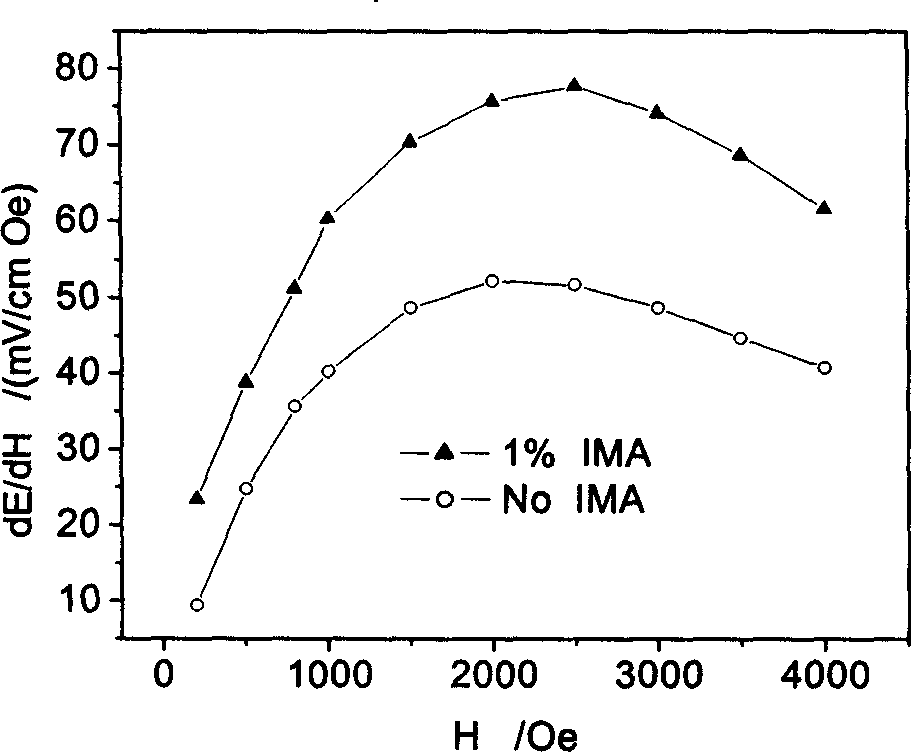

Interface modifier of organic polymer and iron inorganic composite materials and its preparation

The modifier for the interface between organic polymer and ferric inorganic composite material has nanometer inorganic particle in the composite material as inorganophilic phase and polymer in the composite material as the compounding mother grain for the organic phase. The interface modifier may be used in composite piezoelectric ceramic-polymer material and in composite piezoelectric ceramic-polymer-RE alloy material. The interface modifier is prepared through either in-situ compounding process or ultrasonic dispersing process, the former includes adding acetate into polymer solution, adding acetylacetone or glacial acetic acid after heating, adding titanate to react, distillation the solution or depositing in solvent to obtain sol, drying and grinding; the latter includes sintering prepared inorganic nanometer particles, ultrasonic dispersing in polymer solution, filming, drying and grinding. The interface modifier is used to improve interface binding and raise performance.

Owner:WUHAN UNIV OF TECH

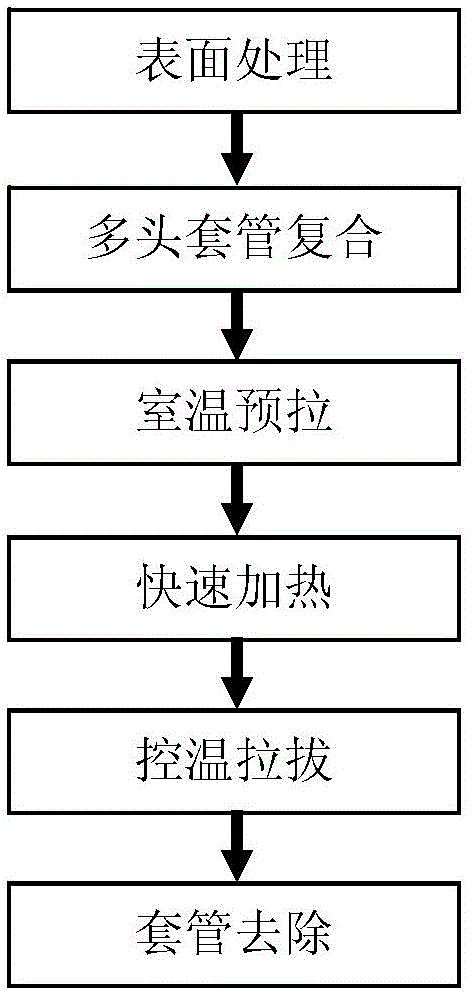

Preparation method of metal layered composite material by multi-head sleeve drawing composition

ActiveCN104148438AHigh composite interface bonding strengthQuality improvementManufactured materialUltimate tensile strength

The invention discloses a preparation method of a metal layered composite material by multi-head sleeve drawing composition and belongs to the technical field of preparation of the metal layered composite materials. The preparation method is characterized in that by combination of sheathing two or more than two special metal wires on a metal sleeve, one-pass drawing pre-composition under room temperature, fast heating, single-pass or multi-pass temperature-control drawing metallurgical composition and removal of a metal sleeve layer on the surface, the high-quality special metal layered composite material with all metal components and parallel and non-coincided axis lines can be prepared. The preparation method disclosed by the invention has the advantages that short-process and high-efficiency preparation of the special metal layered composite material is realized, a composite interface with the composite material is high in bonding strength, a diffusion layer is thin, the specification of a product is flexible, the freedom of combination of the materials is large, and the quality and the performance of the product are excellent and the like, the preparation method is especially suitable for preparing a special metal layered composite material with the composite interface and easy generation of intermetallic compounds and a special metal layered composite material with difficulty in processing, and meets the urgent need of all the industries for the special metal layered composite material.

Owner:UNIV OF SCI & TECH BEIJING

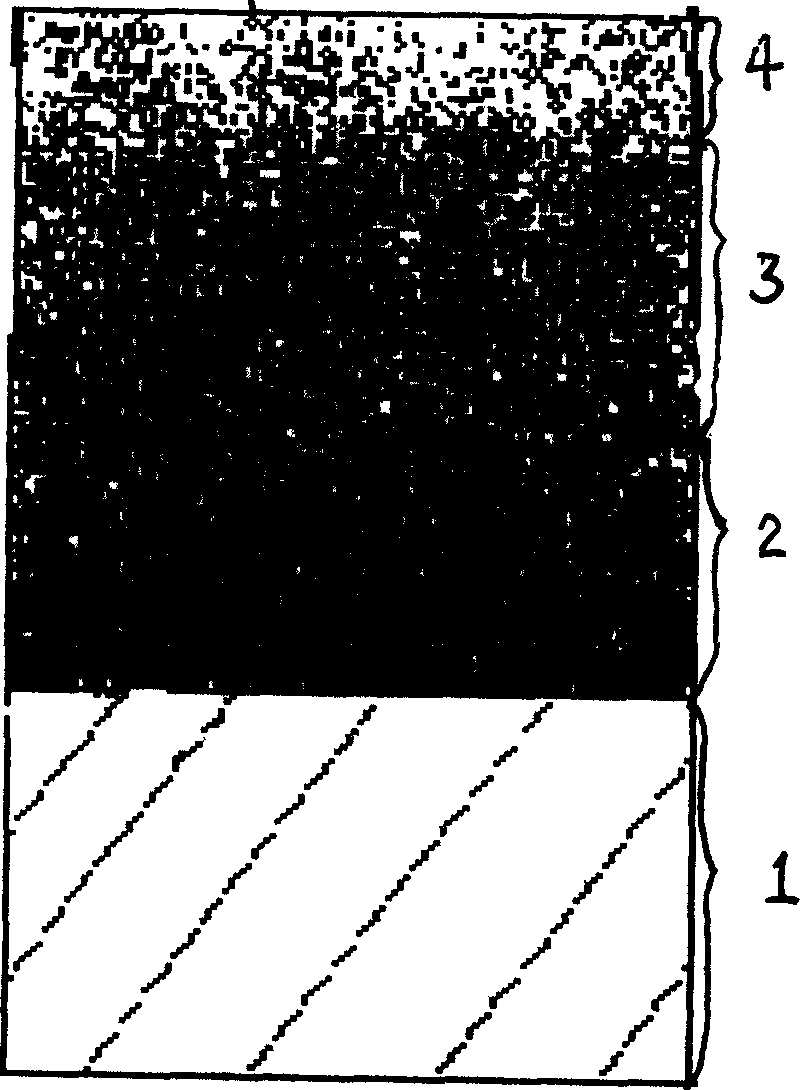

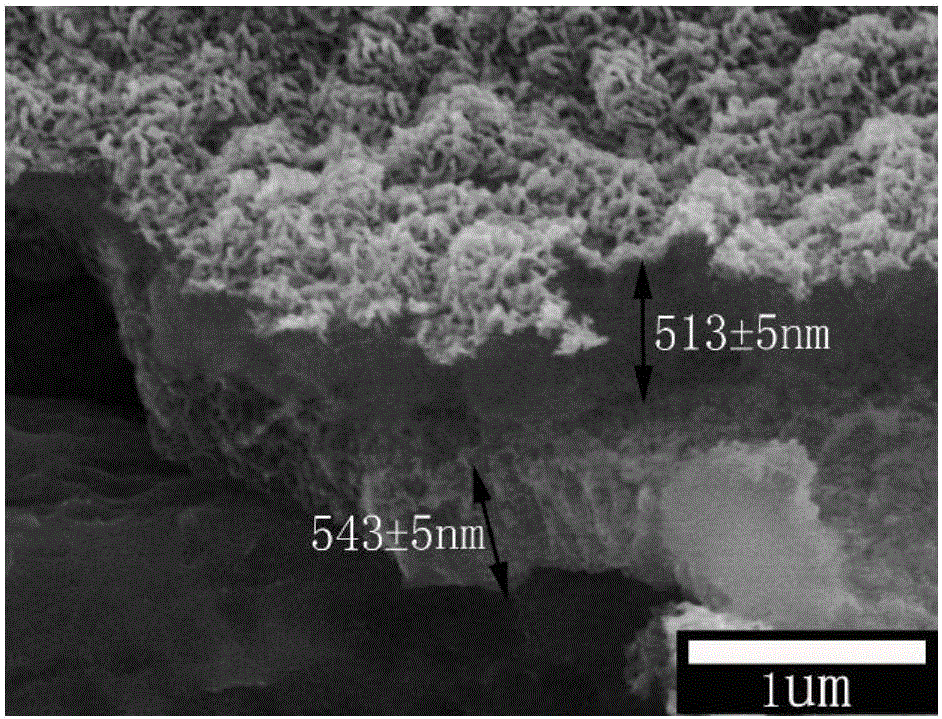

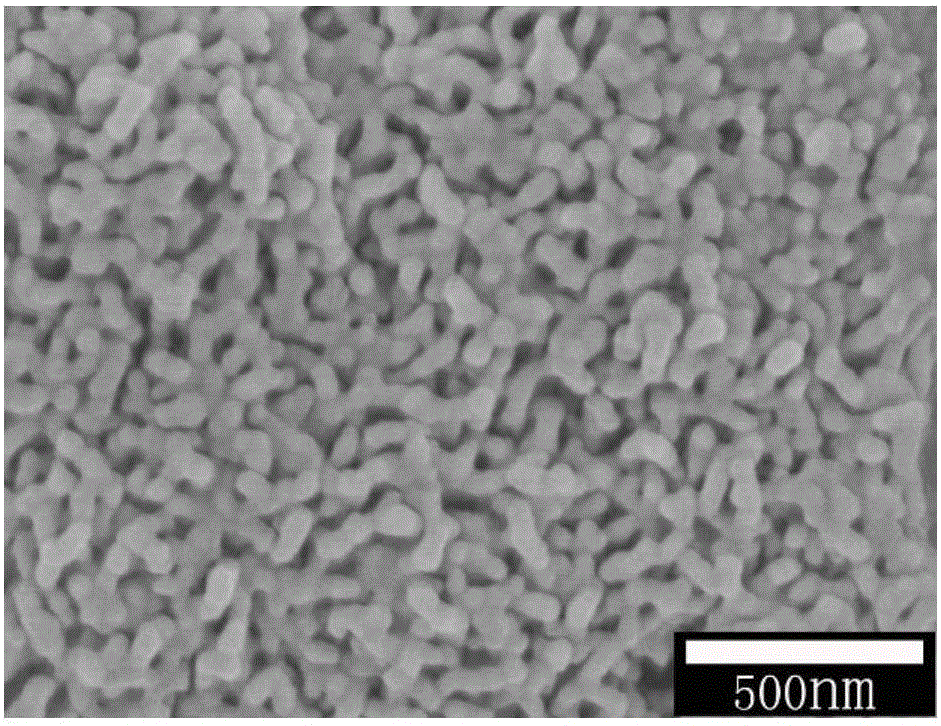

Titanium dioxide nanotube/hydroxyapatite composite coating used for medical porous titanium and preparation method of titanium dioxide nanotube/hydroxyapatite composite coating

InactiveCN105963780AImprove adsorption capacityLarge specific surface areaTissue regenerationCoatingsApatiteDrug biological activity

The invention relates to a titanium dioxide nanotube / hydroxyapatite composite coating used for medical porous titanium and a preparation method of the titanium dioxide nanotube / hydroxyapatite composite coating, belonging to the technical field of the improvement for medical titanium materials. According to the titanium dioxide nanotube / hydroxyapatite composite coating used for medical porous titanium, porous titanium is taken as a substrate, a composite coating is distributed on the inner surfaces and the outer surfaces of hole structures of porous titanium, and specifically, the composite coating is composed of a titanium dioxide nanotube and hydroxyapatite deposited on the titanium dioxide nanotube. The titanium dioxide nanotube / hydroxyapatite composite coating used for medical porous titanium is uniform and compact, and has strong interface bonding strength, as well as good biological activity and good compatibility. The invention further provides the preparation method of the composite coating which is characterized in that a preparation process is simple, the period is short, and the operability is strong.

Owner:TAIYUAN UNIV OF TECH

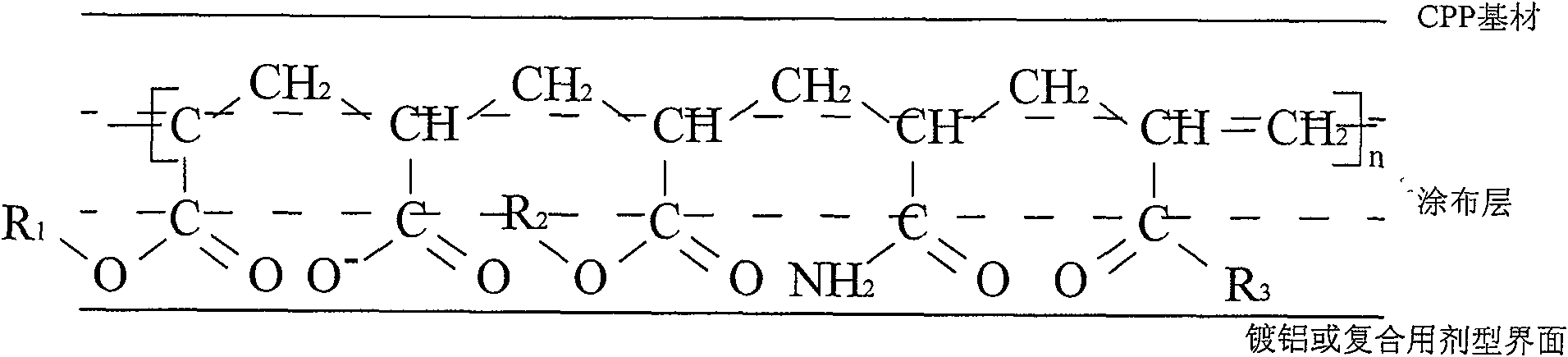

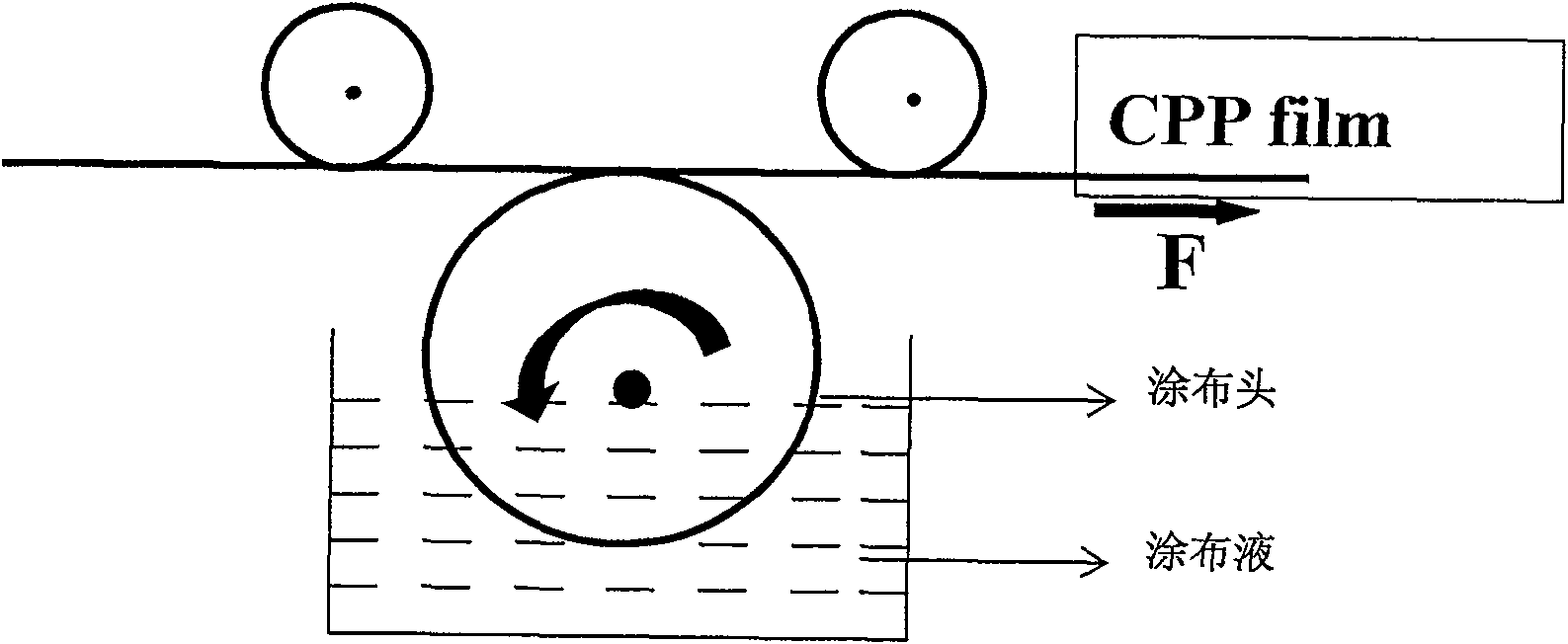

CPP film with high interfacial bonding strength

InactiveCN101618621ASolve low surface tensionSolve the problems that hinder the development of the industry, such as the obvious degradation effectFlexible coversWrappersFunctional monomerMicroemulsion

The invention discloses a CPP film with high interfacial bonding strength, which is prepared by a surface coating method. The CPP film comprises a CPP base material layer and a coating layer, and the coating layer is polymer microemulsion. A preparation process of the polymer microemulsion comprises the following steps: adding 1-3 percent of emulsifying agent and 97-99 percent of water into a reaction kettle provided with a temperature controller, an N2 ingress pipe, a stirrer and a condensation pipe and carrying out dispersion at 45-65 DEG C; keeping constant temperature for 0.5-1.5 hours after the dispersion; dropping a mixed solution containing 0.5-1 percent of the emulsifying agent and 0.2-3 percent of crosslinking functional monomers into the reaction kettle and the pH being maintained between 3 and 9; after keeping the constant temperature for 1-2 hours, adding an aqueous initiating agent into the reaction kettle and raising the temperature to 75-95 DEG C; and after reacting for 4-6 hours, obtaining the polymer microemulsion. The CPP film can adopt the self-synthesized polymer microemulsion as coating liquid which ensures that the surface tension of the coated CPP film can be adjusted, and after the CPP film is plated with aluminum, the interlaminar strength of the CPP film reaches more than 1.5N / 15mm. The CPP film completely meets the requirement on the compound interlaminar strength of gas packaging, and the bag breaking rate of the coated CPP film reaches a standard being lower than 0.1 percent of an industry requirement.

Owner:成都富林达新材料有限公司

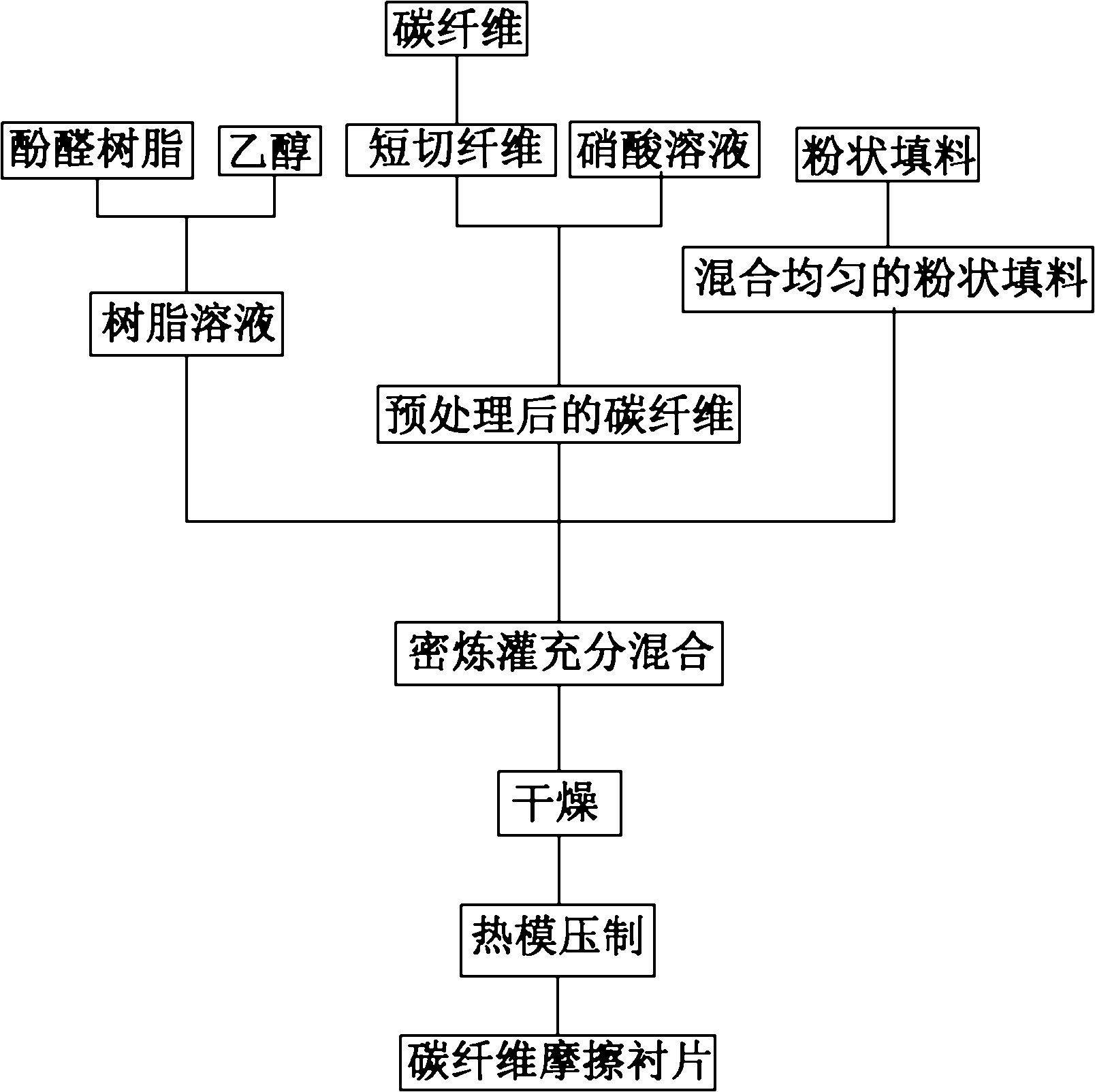

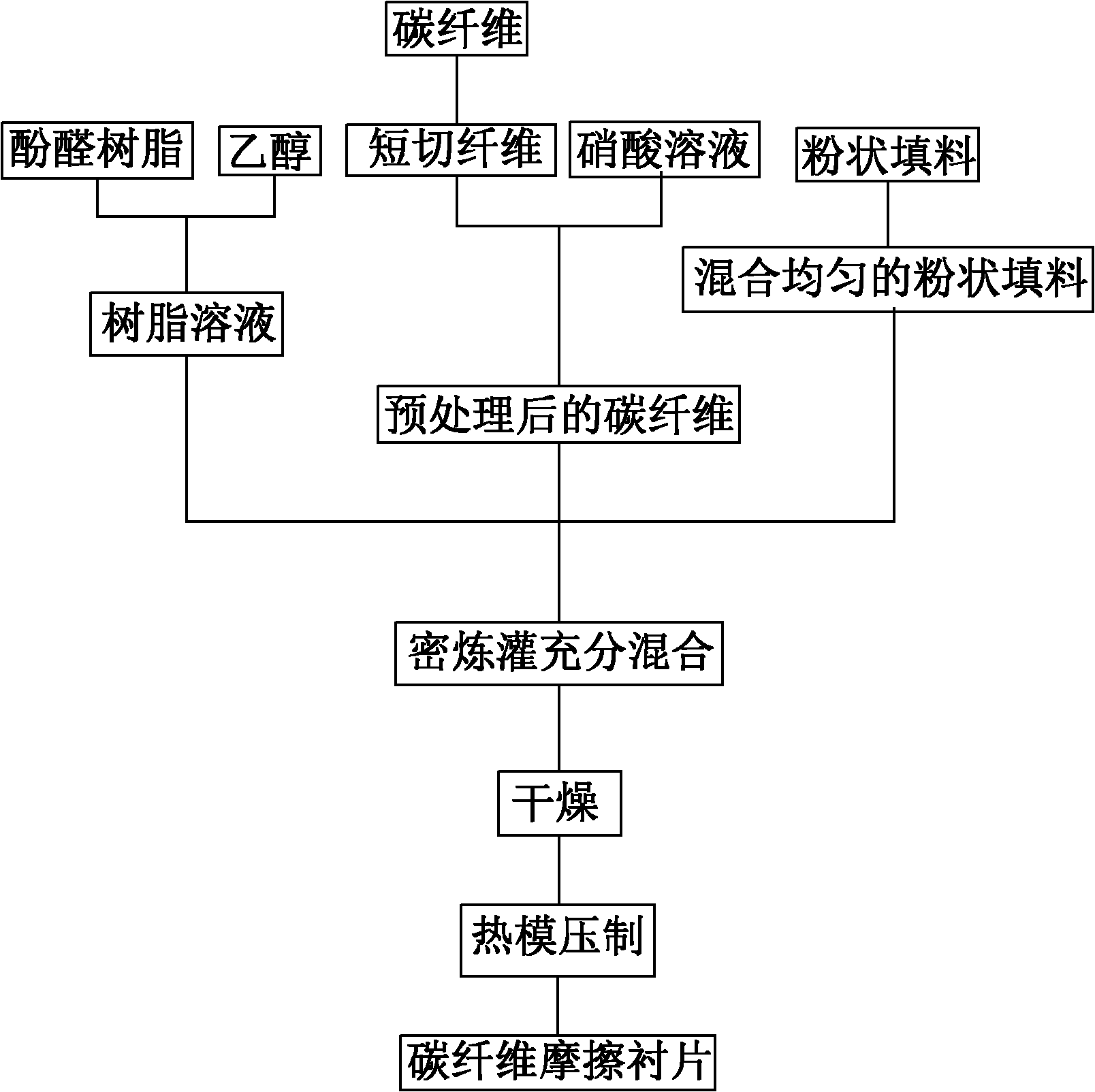

Method for preparing carbon fiber brake lining

InactiveCN102010564ALow densityImprove braking effectOther chemical processesFriction liningFiberCarbon fibers

The invention provides a method for preparing a carbon fiber brake lining, which belongs to the technical field of materials and solves the problems of poor interfacial binding force between a carbon fiber surface and a base body, and unreasonable material ratio of each part of the carbon fiber brake lining prepared by the conventional method for preparing the carbon fiber brake lining. The method for preparing the carbon fiber brake lining comprises the following steps of: A, pretreating carbon fibers; B, preparing resin solution; C, mixing powdery fillers; and D, forming. By the method for preparing the carbon fiber brake lining, the carbon fiber brake lining has low density, high braking ability, high environmental tolerance, low braking noise, high abrasion resistance, unchanged or slightly increased friction coefficient along with temperature rise, and high braking stability.

Owner:ZHEJIANG GEELY AUTOMOBILE RES INST CO LTD +1

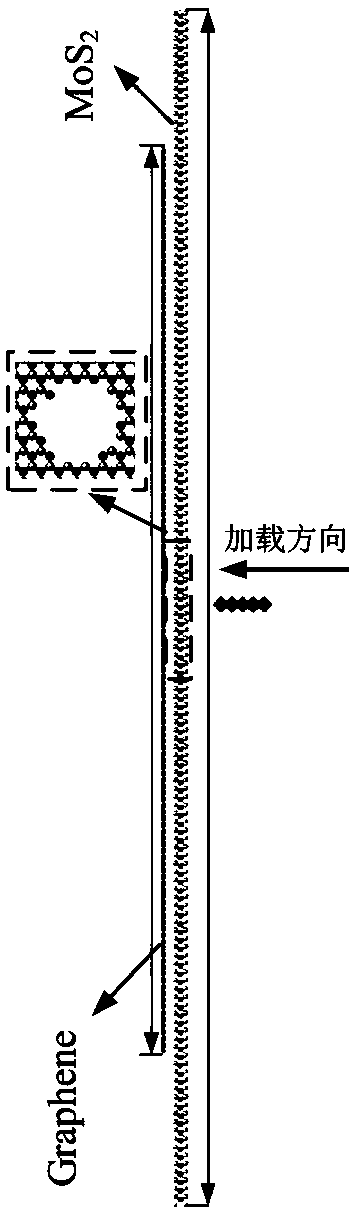

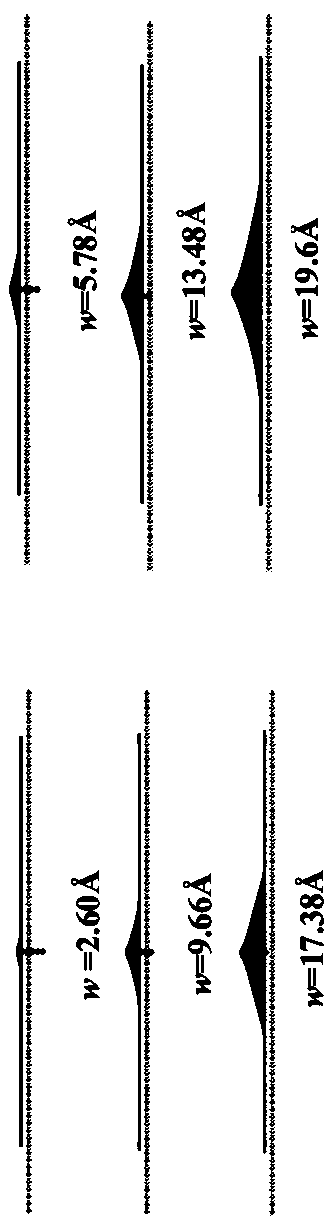

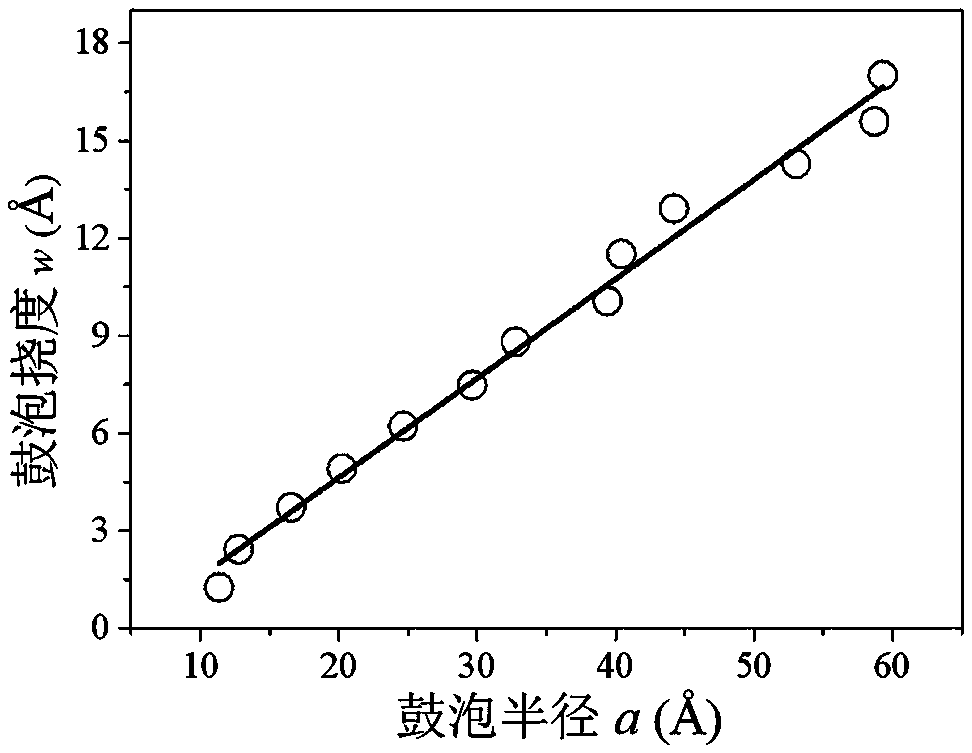

Method for measuring interface bonding energy of heterojunction material based on molecular dynamics

ActiveCN111414693AMature manufacturing technologyThe preparation technology is matureDesign optimisation/simulationHeterojunctionBinding energy

The invention discloses a method for measuring interface bonding energy of a heterojunction material based on molecular dynamics. The method comprises the following steps: 1) establishing a heterojunction material bubbling method model based on molecular dynamics simulation software Materials Studio; 2) performing molecular dynamics analogue simulation on the heterojunction bubbling model by usingmolecular dynamics simulation software Lamps; 3) observing the heterojunction interface from bubbling to debonding under the action of the probe so as to observe the occurrence mechanism of the bubbling process, and measuring the bubbling radius and the bubbling deflection in the bubbling process; 4) analyzing the mutual relationship among the bubbling radius, the bubbling deflection and the loading force to obtain the interface characteristics of the bubbling process, the bubbling radius and the bubbling deflection being in a linear relationship in the stable tearing stage, and the bubblingdeflection and the loading force being also in a linear relationship; and 5) calculating the interface energy W of the heterojunction material through related theories based on the obtained related data.

Owner:CHINA UNIV OF MINING & TECH

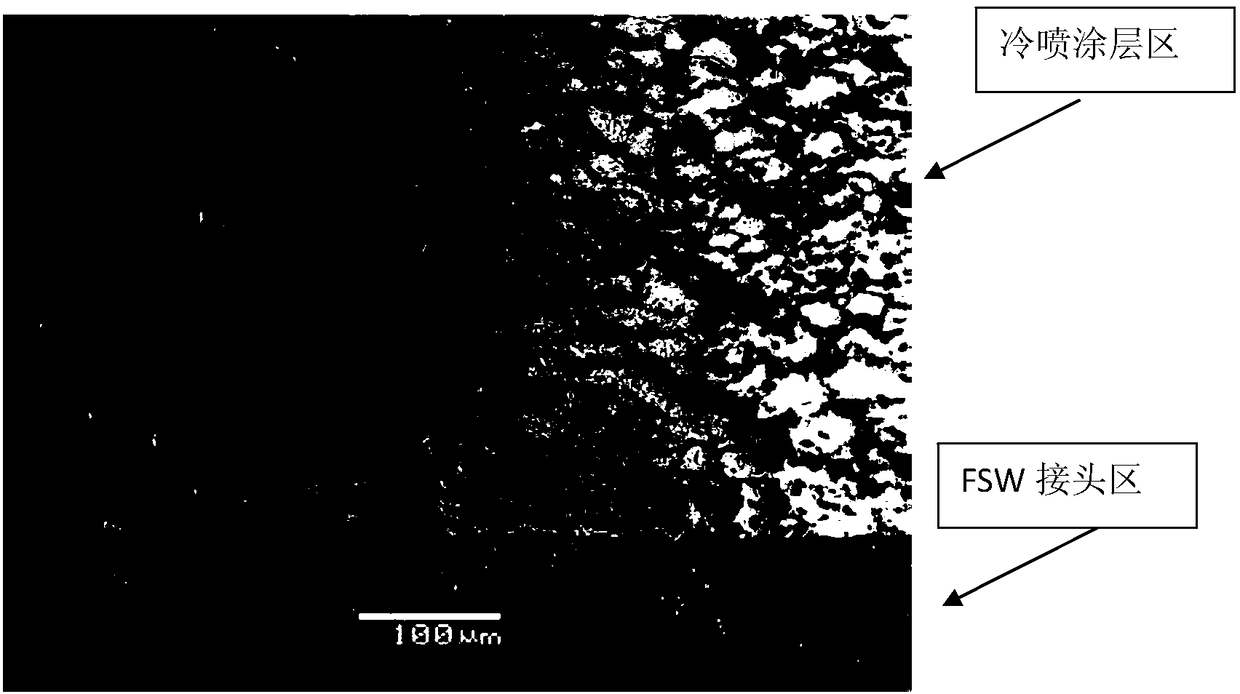

Method for improving corrosion performance of surface of light alloy friction-stir welding joint

InactiveCN108500444AImprove stress corrosion resistanceImprove bindingNon-electric welding apparatusTitanium alloyBinding force

The invention discloses a method for improving the corrosion performance of the surface of a light alloy (including an aluminum alloy, a magnesium alloy and a titanium alloy) friction-stir welding joint. The method mainly comprises the steps that the surface of the joint being subjected to friction-stir welding is subjected to sand blasting treatment and cold spraying treatment, and then the coldspraying surface is subjected to further treatment through a heat treatment method; and on the one hand, residual stress caused by welding is eliminated, on the other hand, element diffusion occurs ata coating / joint interface, a transition layer is formed, interfacial binding force of a cold spraying coating is improved, and finally, a layer of dense protective layer is formed on the surface of the joint. The method for improving the corrosion performance of the surface of the light alloy friction-stir welding joint is easy to operate, convenient to use, reliable in performance, economical and practical, the corrosion performance of the surface of the friction-stir welding joint can be remarkably improved, and great significance to practical application of friction-stir welding is achieved.

Owner:BEIJING INSTITUTE OF PETROCHEMICAL TECHNOLOGY

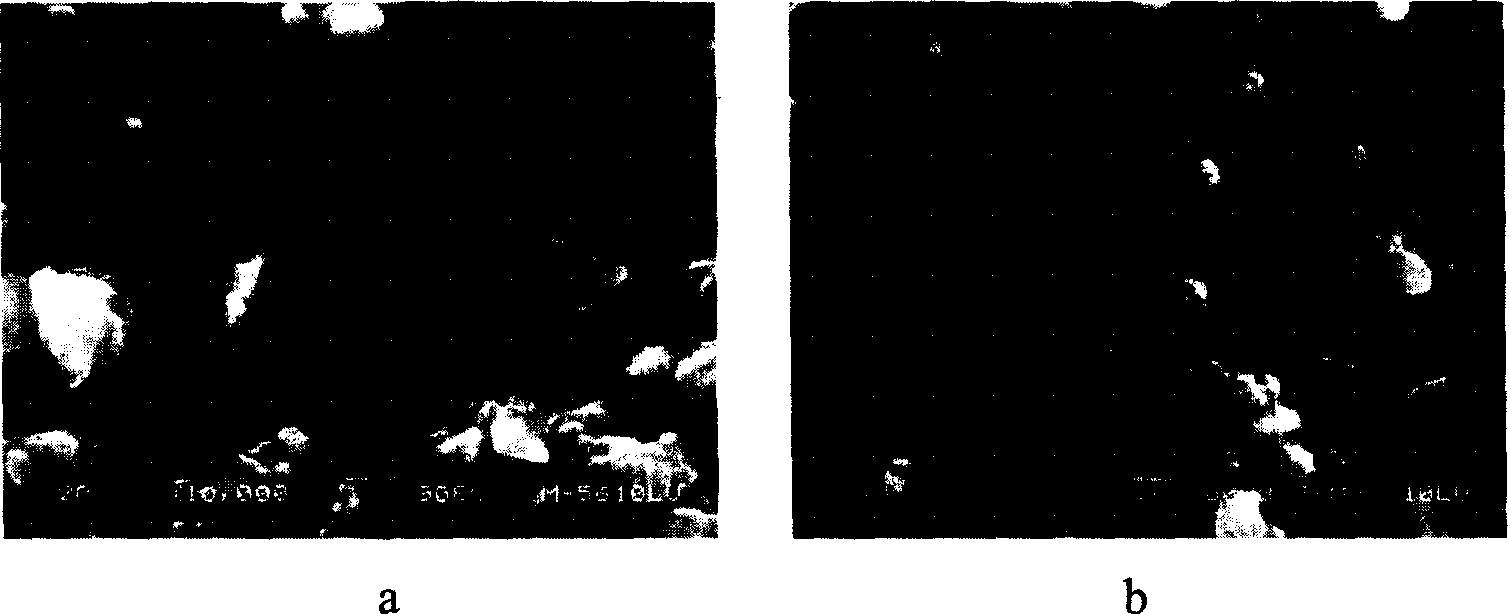

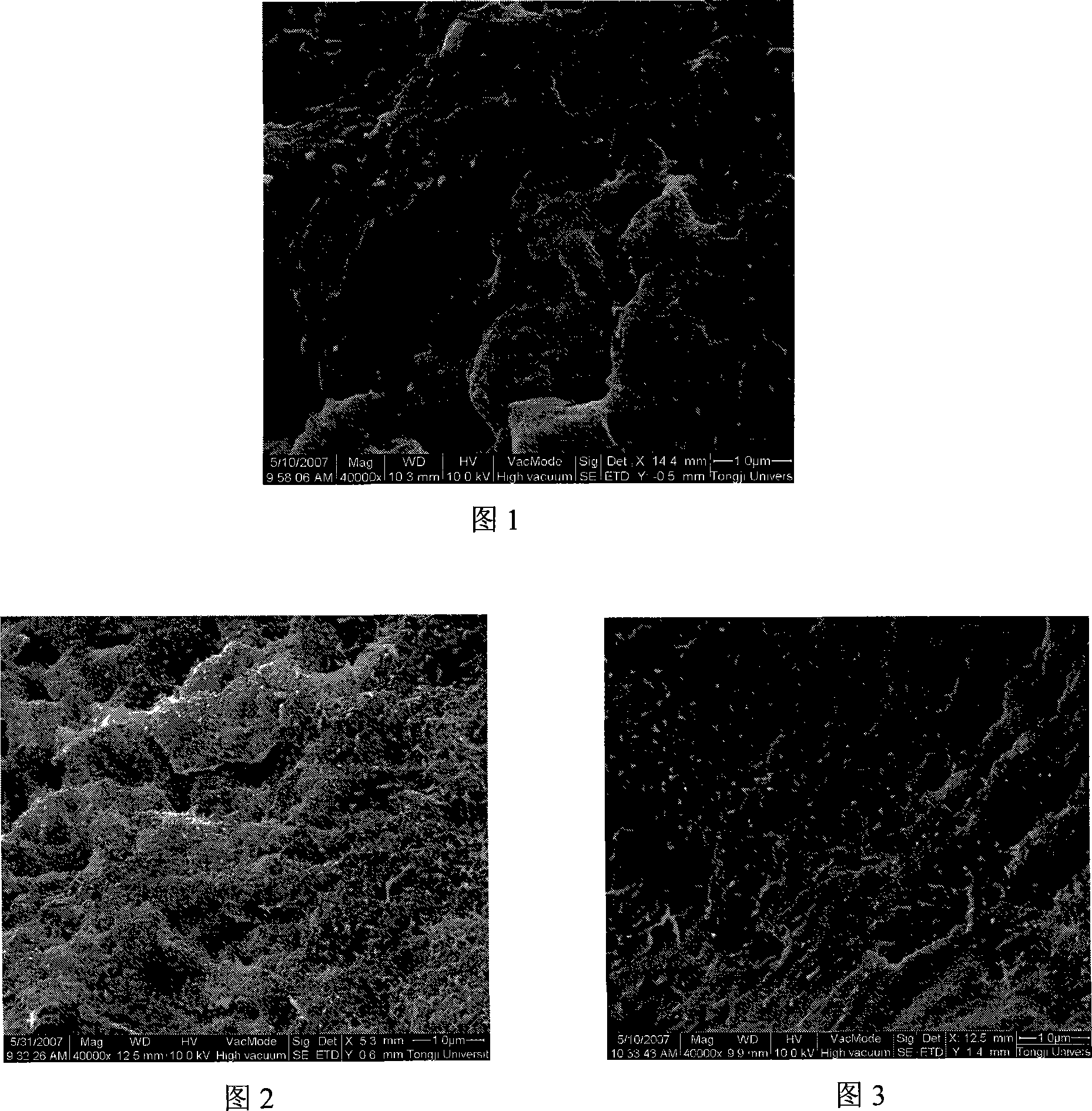

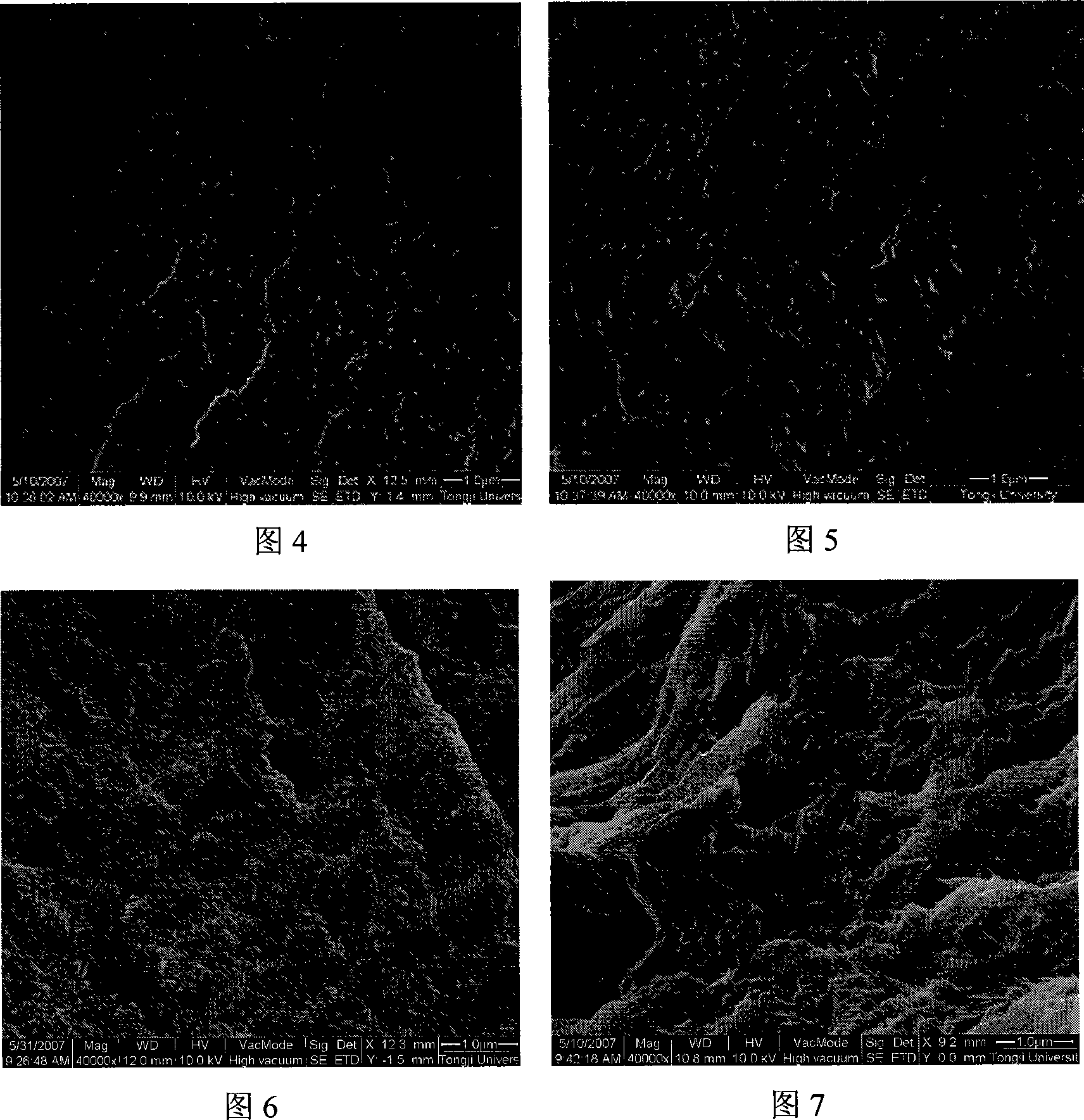

Preparation method of carboxylic carbon nano-tube /nylon 66 composite material

The invention pertains to the field of material technology, in particular to a preparation method for a carboxylic carbon nanotube / nylon 66 composite material.The particular preparation procedure is as follows: preparing a carbon nanotube with carboxyl by acidulating the carbon nanotube; Preparing the carboxylic carbon nanotube / nylon 66 composite material by polymerizing the carboxylic carbon nanotube and the raw material (such as polybasic acid and polybasic amine) which is used for preparing the nylon 66 through in situ polymerization. The polycondensation of carboxy group on the carbon nanotube improves the dispersity and interfacial binding force of the carbon nanotube in nylon matrix, and carboxylic carbon nanotube / nylon composite material with excellent dispersive property is obtained.

Owner:TONGJI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com