Preparation method of carboxylic carbon nano-tube /nylon 66 composite material

A technology of carboxylated carbon and composite materials, which is applied in the field of materials, can solve the problems of poor dry impact strength, high water absorption, and low notched impact strength, and achieve the effects of reducing clustering, good dispersion performance, and improved dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

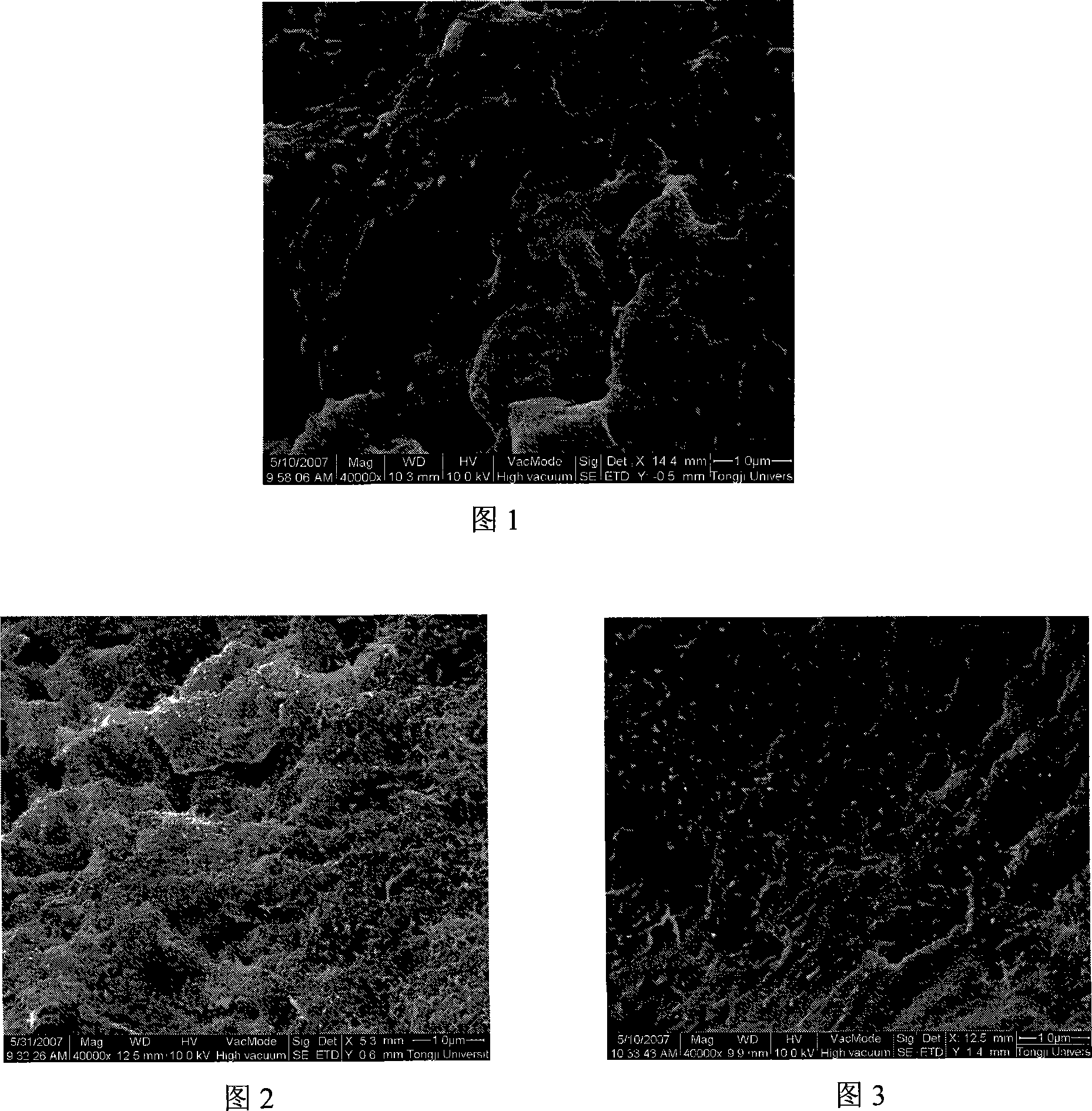

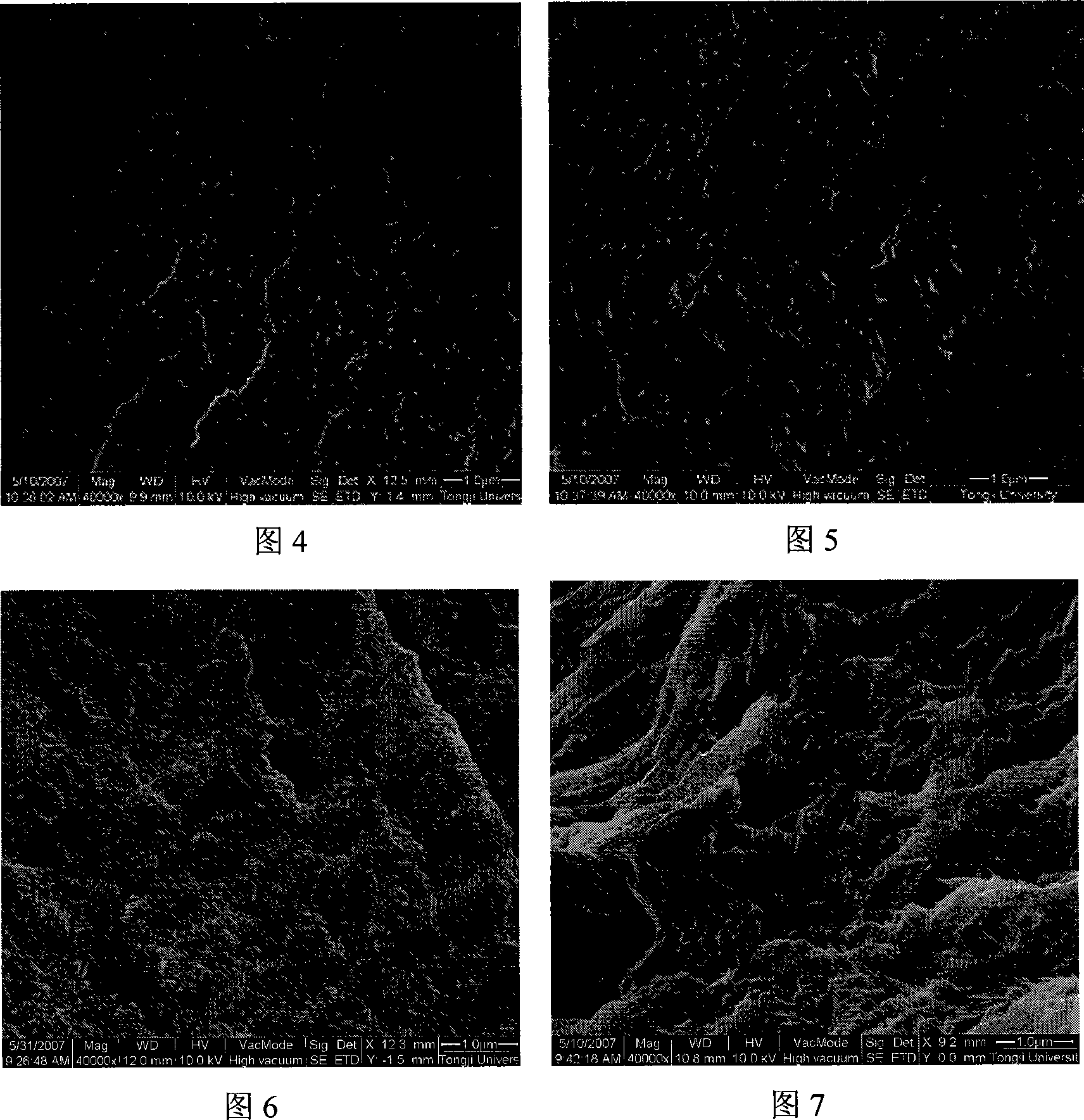

Image

Examples

Embodiment 1

[0034] Step 1: Preparation of carboxylated carbon nanotubes

[0035] 1 g of carbon nanotubes with a diameter of 1-50 nm and a length of 0.1-50 μm, 120 ml of concentrated sulfuric acid and 40 ml of concentrated nitric acid were mixed evenly, and ultrasonically oscillated at 50° C. for 4 hours. After the reaction is completed, use a large amount of deionized water to remove mixed acid and other by-products, filter with a microporous membrane (0.45 μm in diameter) until the filtrate is neutral, and dry to obtain acidified carbon nanotubes. Mix 1 g of acidified carbon nanotubes with 40 ml of concentrated sulfuric acid and 10 ml of hydrogen peroxide, and vibrate ultrasonically at 80° C. for 0.5 h. After the reaction is completed, use a large amount of deionized water to remove mixed acid and other by-products, filter with a microporous membrane (0.45 μm in diameter) until the filtrate is neutral, and dry to obtain carboxylated carbon nanotubes.

[0036] The second step: preparatio...

Embodiment 2

[0039] Step 1: Preparation of carboxylated carbon nanotubes

[0040] Mix 1 g of carbon nanotubes with a diameter of 1-50 nm and a length of 0.1-50 μm, 120 ml of concentrated sulfuric acid and 40 ml of concentrated hydrochloric acid, and ultrasonically shake at 50° C. for 4 hours. After the reaction is completed, use a large amount of deionized water to remove mixed acid and other by-products, filter with a microporous membrane (0.45 μm in diameter) until the filtrate is neutral, and dry to obtain acidified carbon nanotubes. Mix 1 g of acidified carbon nanotubes with 40 ml of concentrated sulfuric acid and 10 ml of hydrogen peroxide, and vibrate ultrasonically at 70° C. for 1 h. After the reaction is completed, use a large amount of deionized water to remove mixed acid and other by-products, filter with a microporous membrane (0.45 μm in diameter) until the filtrate is neutral, and dry to obtain carboxylated carbon nanotubes.

[0041] The second step: preparation of carboxylat...

Embodiment 3

[0044] Step 1: Preparation of carboxylated carbon nanotubes

[0045] 1 g of carbon nanotubes with a diameter of 1-50 nm and a length of 0.1-50 μm, 120 ml of concentrated sulfuric acid and 40 ml of concentrated nitric acid were mixed evenly, and ultrasonically oscillated at 50° C. for 4 hours. After the reaction is completed, use a large amount of deionized water to remove mixed acid and other by-products, filter with a microporous membrane (0.45 μm in diameter) until the filtrate is neutral, and dry to obtain acidified carbon nanotubes. Mix 1 g of acidified carbon nanotubes with 40 ml of dilute sulfuric acid and 10 ml of hydrogen peroxide, and vibrate ultrasonically at 70° C. for 0.5 h. After the reaction is completed, use a large amount of deionized water to remove mixed acid and other by-products, filter with a microporous membrane (0.45 μm in diameter) until the filtrate is neutral, and dry to obtain carboxylated carbon nanotubes.

[0046]The second step: preparation of ca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com