New/old cement concrete interfacial binding agent and construction method for interfacial binding by using same

A technology of cement concrete and interface adhesive, which is applied in the direction of buildings, roads, bridges, etc. It can solve the problems of environmental hazards, poor bonding effect of cement-based adhesives, polluted air and ground water, etc., and achieve improved bond strength , Improve maintenance quality and service life, and facilitate construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

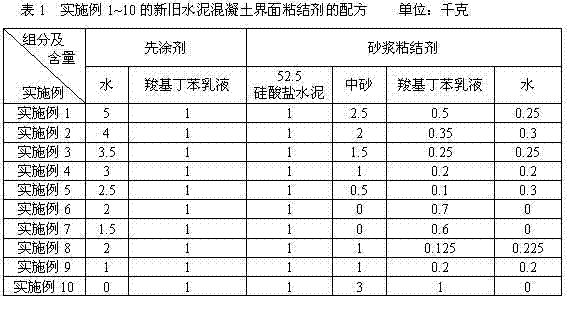

[0025] The old and new cement concrete interface binder of the present embodiment is divided into two parts, the pre-coating agent and the mortar binder; the respective components and parts by weight of the first coating agent and the mortar binder are as shown in the corresponding items in Table 1 . The pre-coating agent and the mortar adhesive are prepared by conventional mixing and stirring, and the pre-coating agent and the mortar adhesive can be prepared on site.

[0026] The construction method of using the above-mentioned old and new cement concrete interface binder to bond the old and new cement concrete interface of the present embodiment includes the following steps:

[0027] 1) First clean up the dirt on the surface of the old cement concrete and the place to be shed, and then evenly apply the first coating agent on the surface of the old cement concrete twice (it can also be sprayed, the effect is basically the same) to form a first coating;

[0028] 2) After the...

Embodiment 2

[0031] The old and new cement concrete interface binder of the present embodiment is divided into two parts, the pre-coating agent and the mortar binder; the respective components and parts by weight of the first coating agent and the mortar binder are as shown in the corresponding items in Table 1 . The pre-coating agent and the mortar adhesive are prepared by conventional mixing and stirring, and the pre-coating agent and the mortar adhesive can be prepared on site.

[0032] The difference between the construction method of this embodiment and the embodiment 1 is that the thickness of the mortar bonding layer is controlled to be about 1mm.

Embodiment 3

[0034] The old and new cement concrete interface binder of the present embodiment is divided into two parts, the pre-coating agent and the mortar binder; the respective components and parts by weight of the first coating agent and the mortar binder are as shown in the corresponding items in Table 1 . The pre-coating agent and the mortar adhesive are prepared by conventional mixing and stirring, and the pre-coating agent and the mortar adhesive can be prepared on site.

[0035] The difference between the construction method of this embodiment and the embodiment 1 is that the thickness of the mortar bonding layer is controlled at about 2mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com