Core-shell type MOFs composite particles and preparation method and application thereof

A composite particle and core-shell technology, applied in the direction of microsphere preparation, separation methods, chemical instruments and methods, etc., can solve the problems of complicated steps, achieve the effects of wide application range, overcome limitations, and low wear rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

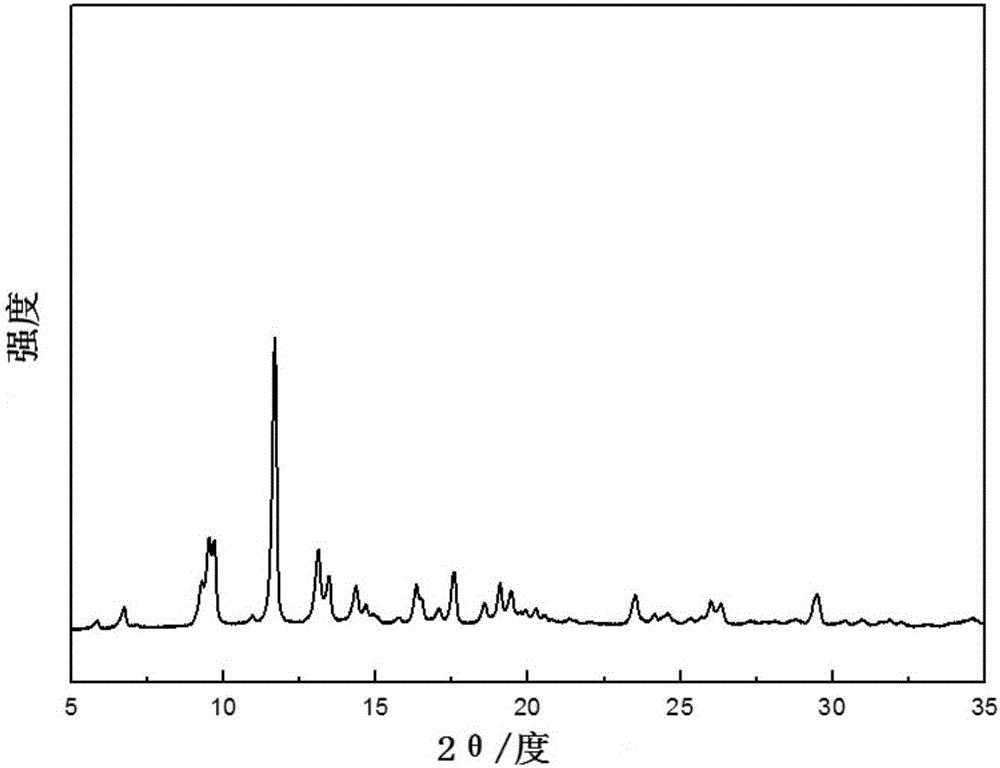

Image

Examples

Embodiment 1

[0026] This embodiment provides a method for preparing core-shell type MOFs composite particles, which includes the following steps:

[0027] Put 100g of alumina powder into a ceramic crucible and mix, drop into it 200ml of dilute nitric acid solution with a mass percentage concentration of 15wt%, stir evenly with a glass rod to obtain a wet dough, and put the wet dough into a extrusion molding machine Extrude the strip, then put the strip-shaped product into the traditional Chinese medicine pellet machine to granulate and shape, and obtain spherical particles with a diameter of 2mm; put the spherical particles into a muffle furnace after shaping, at a rate of 2-6°C / min The temperature was raised to 120°C, and then calcined at a high temperature of 120°C for 5 hours to obtain spherical cores.

[0028] Soak the above-mentioned cores evenly in a dextrin solution with a concentration of 10% by mass, put them into the drum of a traditional Chinese medicine pill making machine that...

Embodiment 2

[0033] This embodiment provides a method for preparing core-shell type MOFs composite particles, which includes the following steps:

[0034] The core was prepared as described in Example 1.

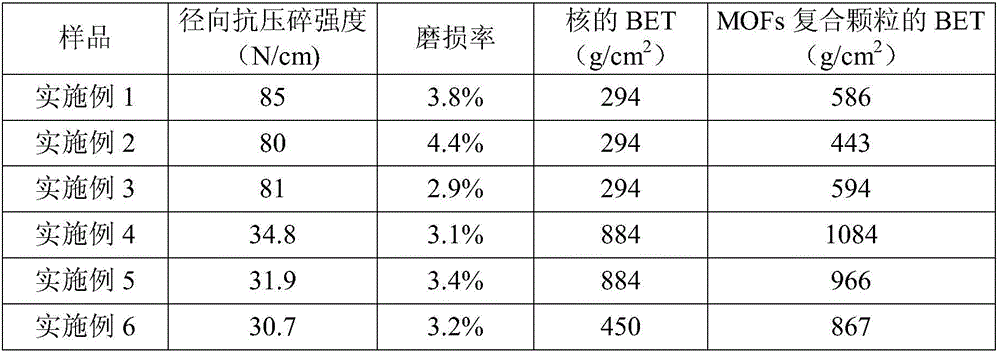

[0035] Soak the above-mentioned core in a starch solution with a mass percentage concentration of 10% evenly, put it into the drum of the traditional Chinese medicine pill making machine that has been added with HKUST-1, and roll at a speed of 90r / min for 30min, then repeat the steps of soaking and rolling, A shell with a thickness of 0.6mm is formed on the surface of the core, and then the obtained particles are put into a vacuum drying oven and vacuum-dried at 180°C for 12 hours to prepare core-shell MOFs composite particles. The radial crushing strength, The results of wear resistance and BET specific surface area are shown in Table 1.

[0036] The core-shell MOFs composite particles can be directly applied to industrial fields such as gas adsorption separation, gas storage, drug susta...

Embodiment 3

[0038] This embodiment provides a method for preparing core-shell type MOFs composite particles, which includes the following steps:

[0039] The core was prepared as described in Example 1.

[0040] Soak the above-mentioned core in the mixed solution of starch and dextrin with a mass percentage concentration of 20% evenly, put it into the drum of the traditional Chinese medicine pill making machine that has been added with HKUST-1, roll it at a speed of 90r / min for 30min, and repeat the soaking and rolling steps to form a shell with a thickness of 0.6 mm on the surface of the core, and then put the obtained particles into a vacuum drying oven and vacuum-dry them at 180 ° C for 12 hours to prepare core-shell MOFs composite particles. The results of crush strength, wear resistance and BET specific surface area are shown in Table 1.

[0041] The core-shell MOFs composite particles can be directly applied to industrial fields such as gas adsorption separation, gas storage, drug ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com