Fluorine-containing hydrated alumina forming composition and preparation method thereof

A technology of hydrated alumina and moldings, applied in chemical instruments and methods, chemical/physical processes, catalyst carriers, etc., can solve the problems of inability to use adsorbents or carriers, and achieve low water absorption and high radial crushing strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

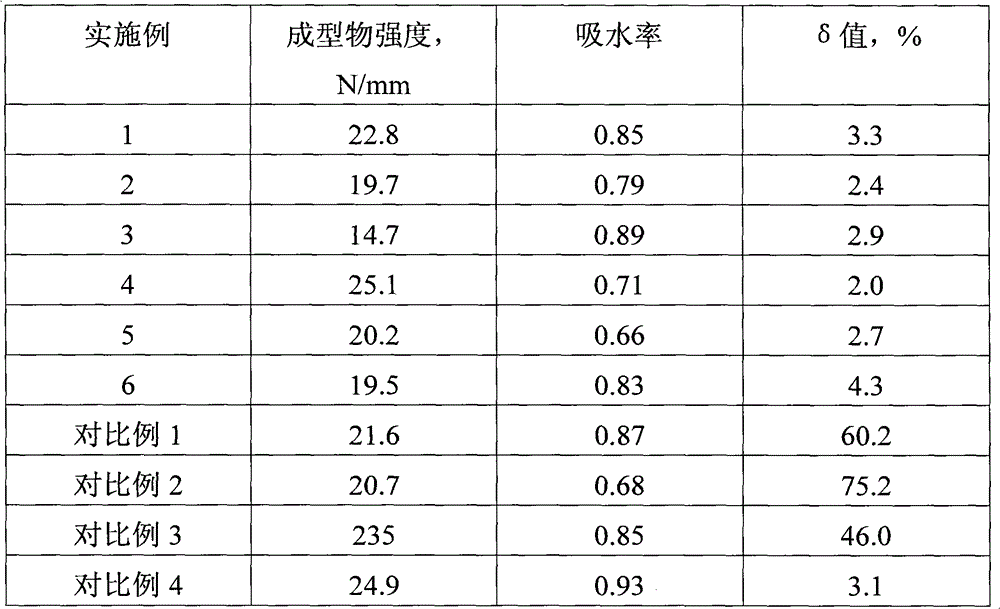

[0039] Get the pseudo-boehmite powder 100g produced by Catalyst Changling Branch Company, add 4.0g methylcellulose, 3.0g squash powder, 4.5g NH 4 F and 95mL deionized water, fully stirred and mixed evenly, after kneading evenly by an extruder, extruded to obtain a wet strip of formed product of hydrated alumina. The wet strips were dried in an oven at 150°C for 12 hours. The radial crushing strength, water absorption rate and δ value of the molded carrier after drying were measured, and the results are listed in Table 1.

Embodiment 2

[0041] Get 50g of pseudo-boehmite powder produced by Catalyst Changling Branch Company, 50g of self-made amorphous aluminum hydroxide powder, add 2.0g methylcellulose, 3.0g hydroxyethylmethylcellulose, 8.5g NH 4 F and 95mL deionized water, fully stirred and mixed evenly, after kneading evenly by extruder, extruded to obtain the wet molding of aluminum hydroxide. Place the wet aluminum hydroxide molding in an oven at 220°C to dry for 6 hours. The radial crushing strength, water absorption rate and δ value of the molded carrier after drying were measured, and the results are listed in Table 1.

Embodiment 3

[0043] Get 60g of pseudo-boehmite powder produced by Catalyst Changling Branch, 40g of aluminum hydroxide trihydrate, add 1.0g of methylcellulose, 2.0g of hydroxypropylmethylcellulose, 3.0g of turnip powder, 40.0% HF solution 5mL and 95mL of deionized water, fully stirred and mixed evenly, after kneading evenly by extruder, extruded to obtain the wet molding of aluminum hydroxide. Place the wet aluminum hydroxide molding in an oven at 80°C for 12 hours to dry. The radial crushing strength, water absorption rate and δ value of the molded carrier after drying were measured, and the results are listed in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Radial crushing strength | aaaaa | aaaaa |

| Radial crushing strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com