A pre-diffusion bonded powder for powder metallurgy, its manufacturing method, and a method of using the powder to manufacture oil-impregnated bearings

A powder metallurgy and pre-diffusion technology, which is applied in the field of powder metallurgy pre-diffusion combined with powder and its manufacturing, can solve the problem of not being able to meet the further development of the industry, and achieve the effect of small size change and accurate size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A pre-diffusion bonded powder for powder metallurgy, comprising the following raw materials by weight percentage: Cu18-20%, Sn3-5%, Mo0.5-1%, Ni1.5-2%, C1.5-2 %, the balance is Fe.

[0026] Particularly preferably, it contains the following raw materials by weight percentage: 19.2% Cu, 3.8% Sn, 0.78% Mo, 1.7% Ni, 1.8% Cl, and the balance is Fe.

[0027] Particularly preferably, Cu, Sn, Mo, Ni, C and Fe are all in the form of powder, and the particle size is not more than 10 μm.

[0028] Particularly preferably, it also includes 0.5-1% binder to prevent the segregation of the pre-diffusion bonded powder during transportation or processing, and can also improve chemical and physical stability, and can keep the particles bonded for a long time without hardening, And it can be easily burned during the sintering operation.

[0029] Particularly preferably, the binder is polyglycerol, polyglycerol is a polyhydric alcohol in which the hydroxyl groups between two or more glyc...

Embodiment 2

[0031] A method for manufacturing pre-diffusion bonded powder for powder metallurgy, comprising the following steps:

[0032] Step 1, mix the Ni, Mo and Fe of formula quantity evenly, in the non-oxidizing atmosphere of 900-980 ℃ or vacuum (vacuum degree is less than 10 -3 MPa) to heat the mixed powder for 30-50min to realize the pre-diffusion combination of alloy elements Ni, Mo and Fe matrix to form a weakly sintered cake; through the pre-diffusion alloying process, the alloy phase is evenly distributed in fine particles in the material , which plays the role of alloy strengthening and dispersion strengthening, so that the material has higher strength properties. At the same time, due to the spheroidization of pores, the source of cracks in the sintered body is reduced, and the strength of the sintered body is correspondingly improved; the diffusion temperature is low, and the sintering When the neck grows, the particle structure becomes irregular, the bulk density decreases,...

Embodiment 3

[0037] 7. A method for manufacturing oil-impregnated bearings using pre-diffusion bonded powders for powder metallurgy, comprising the following steps:

[0038] Step 1. When the mold is pressed, the pre-diffusion bonded powder is filled in one time, and is pressed into the mold with a pressure of 490-510MPa;

[0039] Step 2. During sintering, adopt the sintering method of gradually increasing the temperature in different zones, which are divided into five zones, the maximum temperature does not exceed 1085°C, the sintering time is 55-65min, the cooling method is natural cooling by water circulation, and the entire cooling process takes about 10 hours;

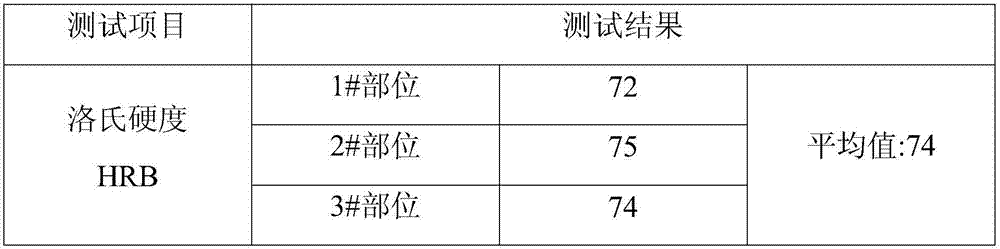

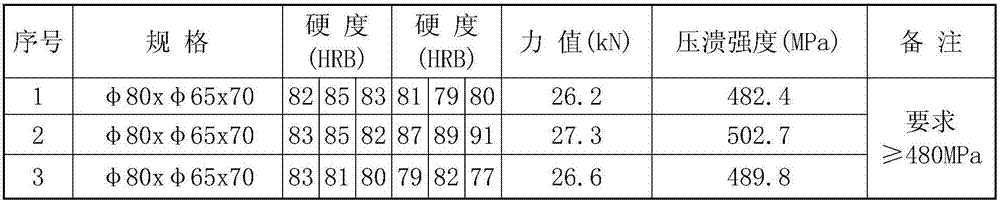

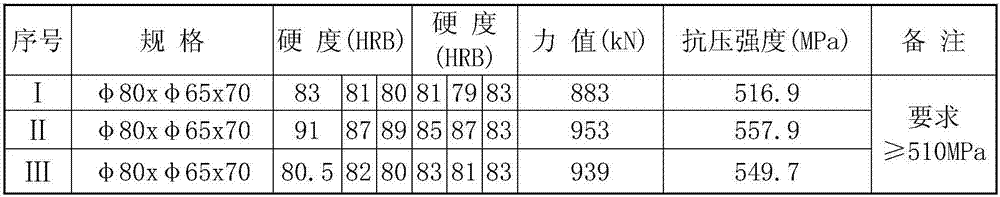

[0040] Step 3, heat treatment, the overall C penetration heat treatment is adopted, and the hardness is controlled above HRB70; after the overall C penetration heat treatment, the radial crushing strength of the oil-impregnated bearing is ≥ 480 MPa, and the axial compressive strength is ≥ 510 MPa

[0041] Step 4, cutting proces...

PUM

| Property | Measurement | Unit |

|---|---|---|

| crushing strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com