Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

94results about How to "Reduce molding process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method and System for Processing Fixed Format Forms Online

InactiveUS20100251092A1Simple processEasy to integrateNatural language data processingSpecial data processing applicationsElectronic formForm processing

A form processing system for processing electronic forms (e-form) forms while preserving the e-form fixed format is provided. The form processing system includes three functional modes or subsystems: the design mode, the edit mode and the view mode. The system, in design mode, designs form templates, manages permission and sets up dynamic workflow parameters. In the view mode, the form is read-only. The form looks like a regular PDF document. This mode is used for exporting data to e-form, printing form and sharing form by multiple users.

Owner:SUN JUN SHI

Casting method of large water turbine blade

ActiveCN101716655AUnique process methodRigid enoughFoundry mouldsFoundry coresWater turbineMaterials science

The invention relates to a stereoscopic core assembly casting method of a water turbine blade, in particular to a casting method of a large water turbine blade. The casting method is characterized in that the casting method comprises the steps of designing process, making a core box, making a core bar, making a core, patching a sand core, assembling the cores, putting the cores into a sand box, paving a spure, sounding the sand core with silica sand, assembling the box, pressing the box, pouring, cutting a dead head, tempering, detecting a mold line, grinding and shotblasting. The casting method obviously shortens production cycle, reduces equipment capacity requirements for blade production, is simple in operation and easy to control and achieves blade mass production.

Owner:KOCEL EQUIP

Core-shell structure magnetic microsphere aluminum oxide and method for preparing the same

InactiveCN101112687AHigh sphericityMeet the use requirementsCatalyst carriersMetal/metal-oxides/metal-hydroxide catalystsMicrosphereProtection layer

The invention provides a core-shell structure magnetic micro-spherical alumina MeFe2O4-SiO2-Al2O3 and the preparation method. According to the positioning effect of the LDHs laminated metal element, the invention firstly prepares the Me-Fe2+-Fe3+-LDHs laminated precursor by introducing the Me2+, Fe2+ and Fe3+ into the hydrotalcite laminate, and the spinel ferrite MeFe2O4 is formed by high-temperature roasting; the Na2SiO3.9H2O or silicon ester hydrolysis is adopted to coat a SiO2 protection layer on the surface of the MeFe2O4, the organic alcohol aluminum hydrolysis method is adopted to coat the alumina layer for a plurality of times, and finally the magnetic micro-spherical alumina MeFe2O4-SiO2-Al2O3 is obtained. The method saves the forming process of the traditional preparation method, and adjusts the magnetic structure and pore structure of the samples by changing the thickness of the SiO2 protection layer and the adding quantity of the magnetic object MeFe2O4 for meeting the application requirement of the magnetic stable bed process.

Owner:BEIJING UNIV OF CHEM TECH

Barium titanate ceramic dielectric material

InactiveCN101348369AUniform particle size distributionGood dispersionFixed capacitor dielectricDispersityGranularity

The invention discloses a barium titanate ceramic dielectric material, consisting of a main crystal phase, a modified additive and a glass flux. In percentage by mol, the main crystal phase BaTiO3 accounts for 80 to 95 percent; the modified additive accounts for 0.7 to 19.5 percent; and the glass flux accounts for 1.21 to 9.1 percent. The invention has the advantages that the barium titanate ceramic dielectric material accords with X7R ceramic dielectric characteristics, and is good in environmental protection property, high in material dispersity and good in molding process; when the material is used for manufacturing MLCC products, and sintering temperature is low; and the barium titanate ceramic dielectric material is uniform in particle size distribution, uniform and compact in grain growth and free from or few in product detects.

Owner:GUANGDONG FENGHUA ADVANCED TECH HLDG

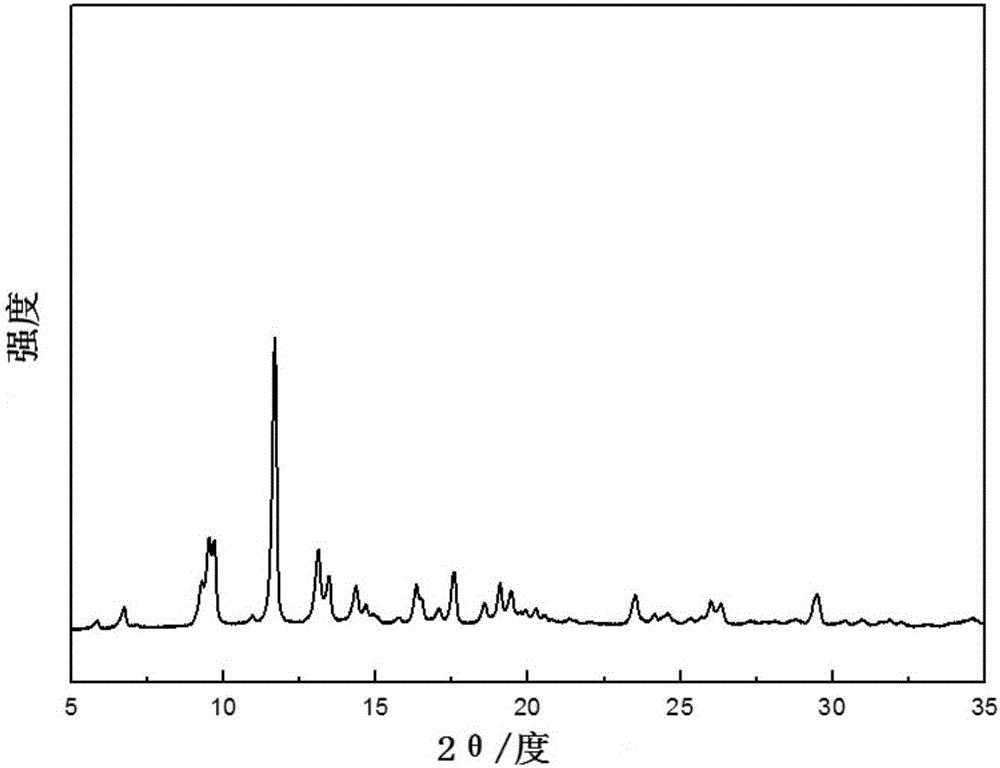

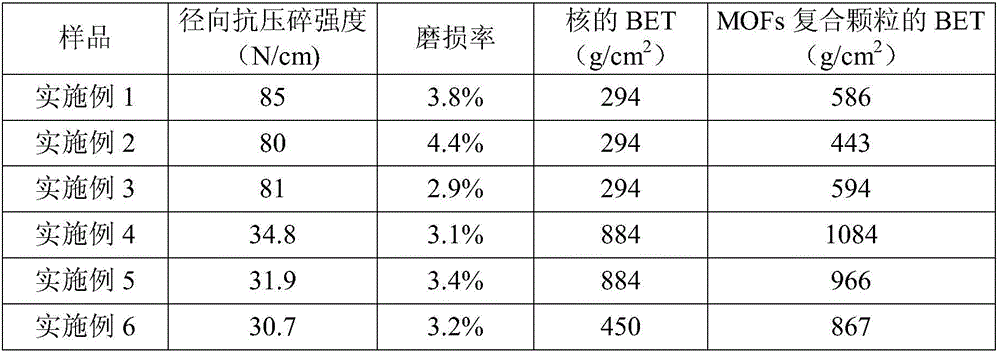

Core-shell type MOFs composite particles and preparation method and application thereof

InactiveCN106268554AHigh radial crush strengthReduce wear rateOther chemical processesDispersed particle separationNanotechnologyInterface bonding

The invention relates to core-shell type MOFs composite particles and a preparation method and application thereof. The preparation method of the core-shell type MOFs composite particles includes the following steps that a porous material and a molding promoter are mixed, wet granulating and calcining are carried out, and spherical cores are obtained; the cores are soaked with a binder solution, the cores are subjected to rolling pelleting in MOFs raw powder, and the core-shell type MOFs composite particles are obtained after drying. According to the core-shell type MOFs composite particles, compounding of core-shell materials is achieved in a mechanical bonding mode, the process is simple, the limitation that the varieties of core-shell materials are limited in a traditional in-situ chemical compounding mode is overcome, the application range is wide, interface bonding force is high, the yield is high, and industrial production is easy.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

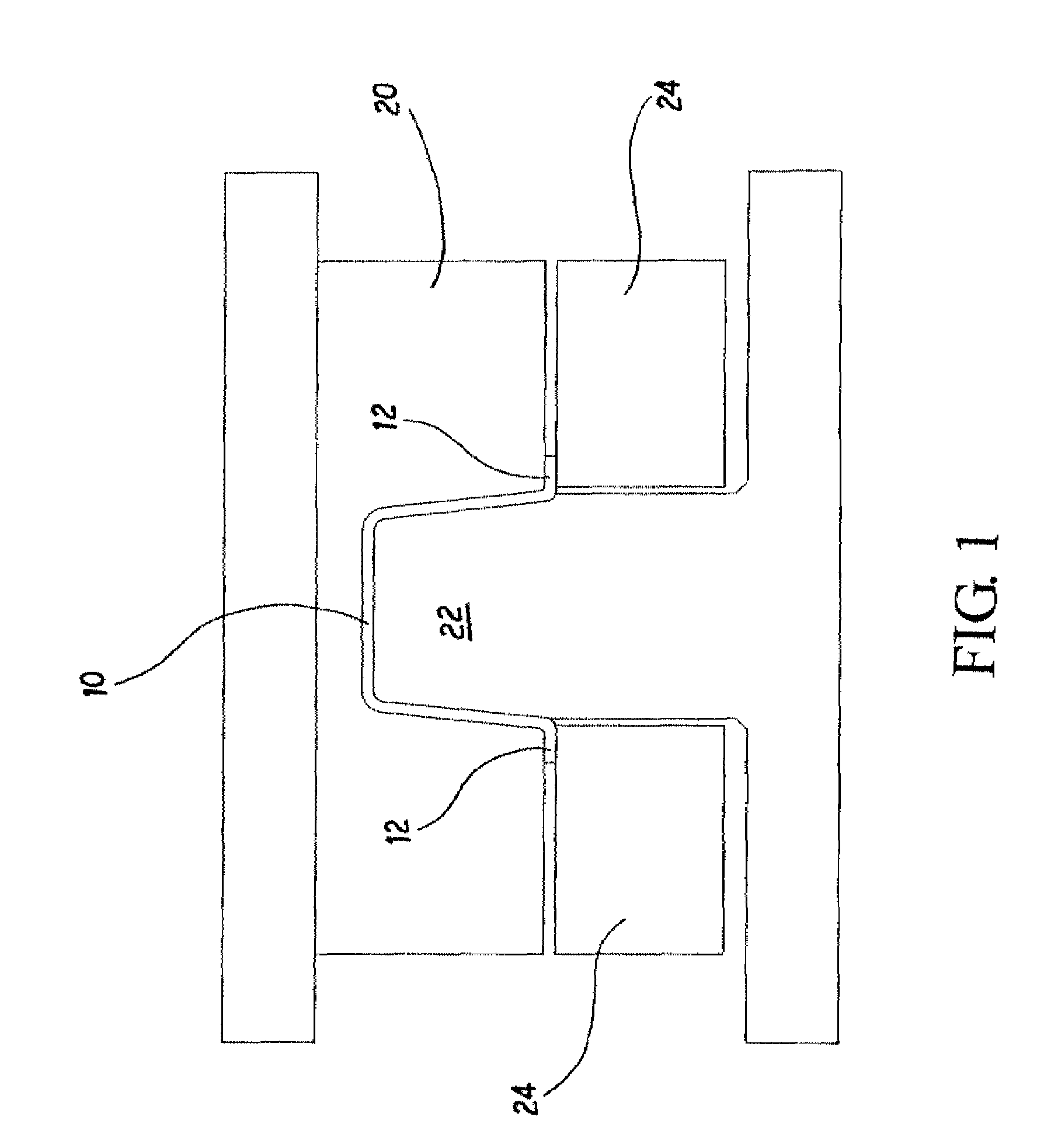

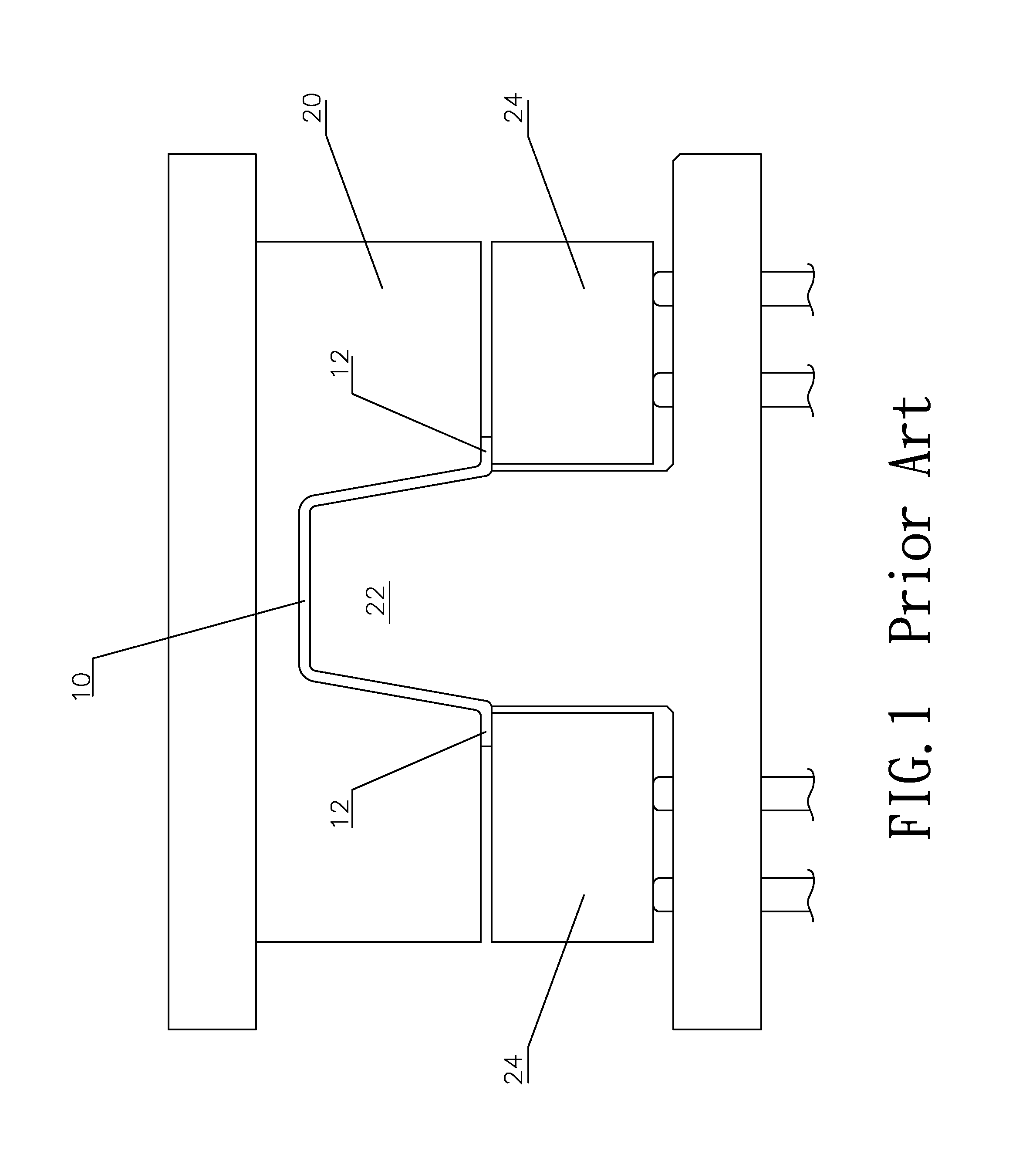

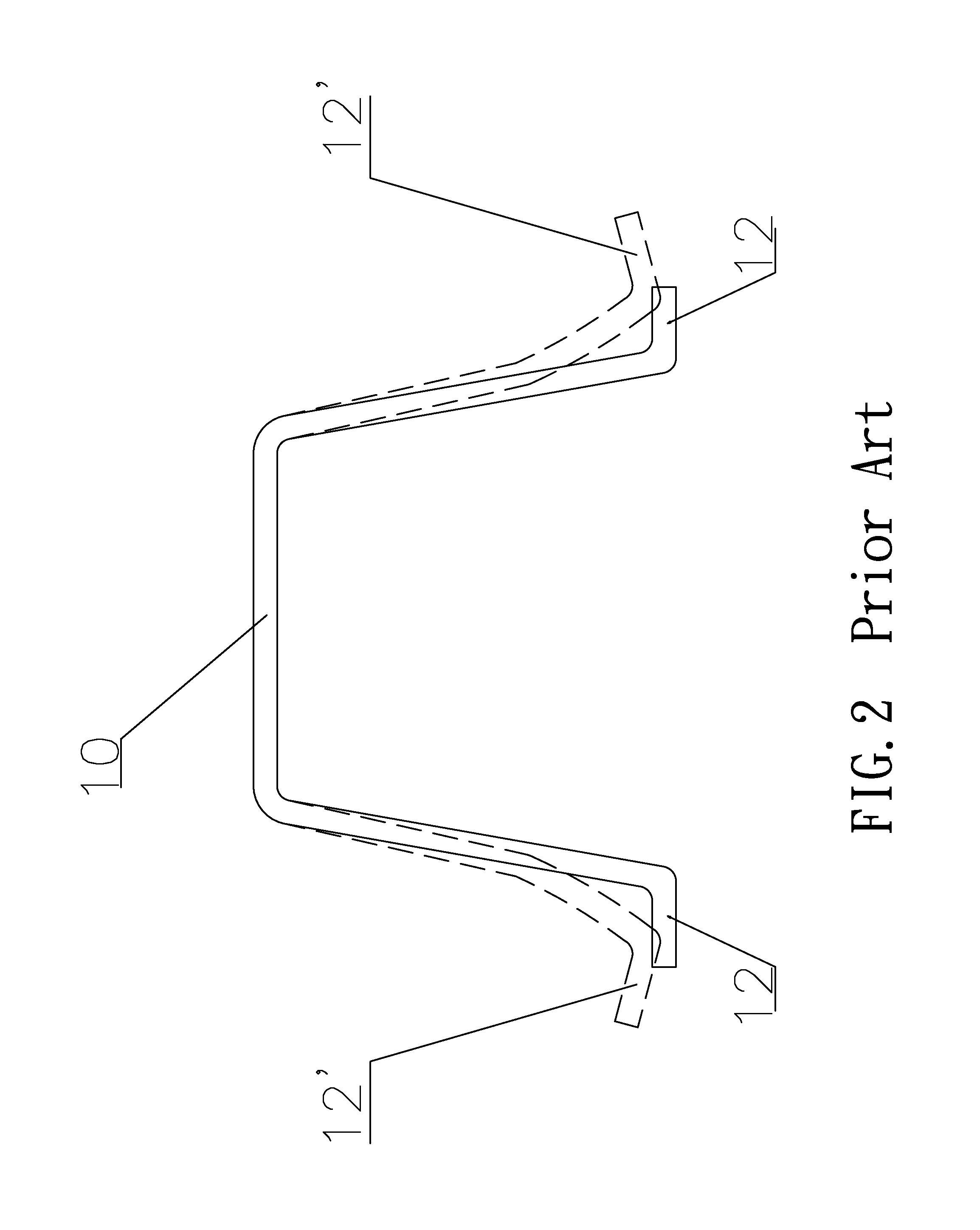

Method for forming high tensile strength metal sheet

A method for forming a high tensile strength metal sheet (HTSMS), which is performed in a power press machine composed of a die, a punch and a blank holder, is disclosed. The HTSMS is placed between the die and punch with blank holder. A step portion appears at both an outer side of the punch and a pressing portion of the blank holder. The step portion is corresponding to a predetermined bent portion of the HTSMS. A step will be formed at an edge of the HTSMS by progressively pressing of the step portion to avoid recoil of the HTSMS after forming process.

Owner:WUU SHIANG INDAL

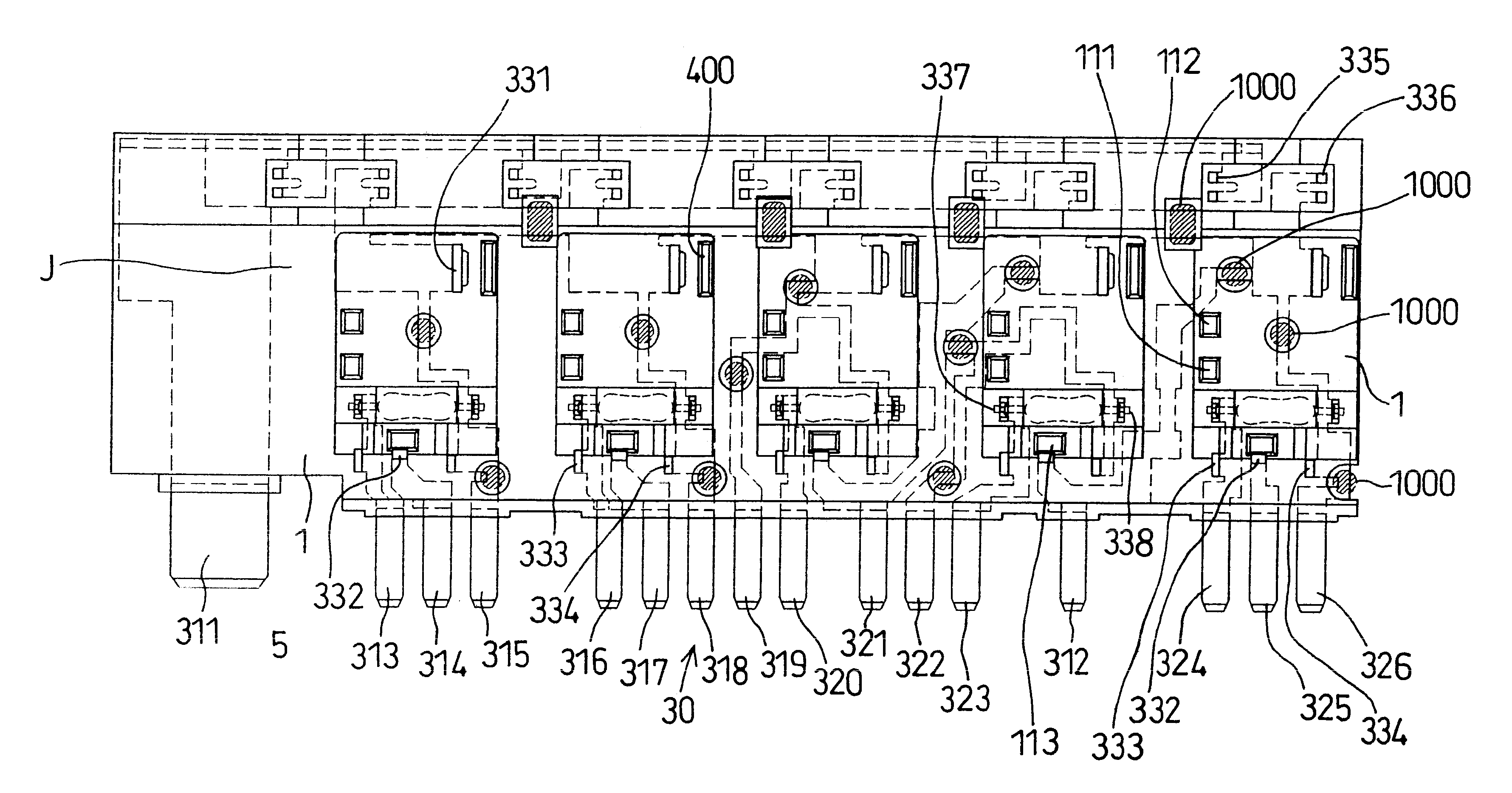

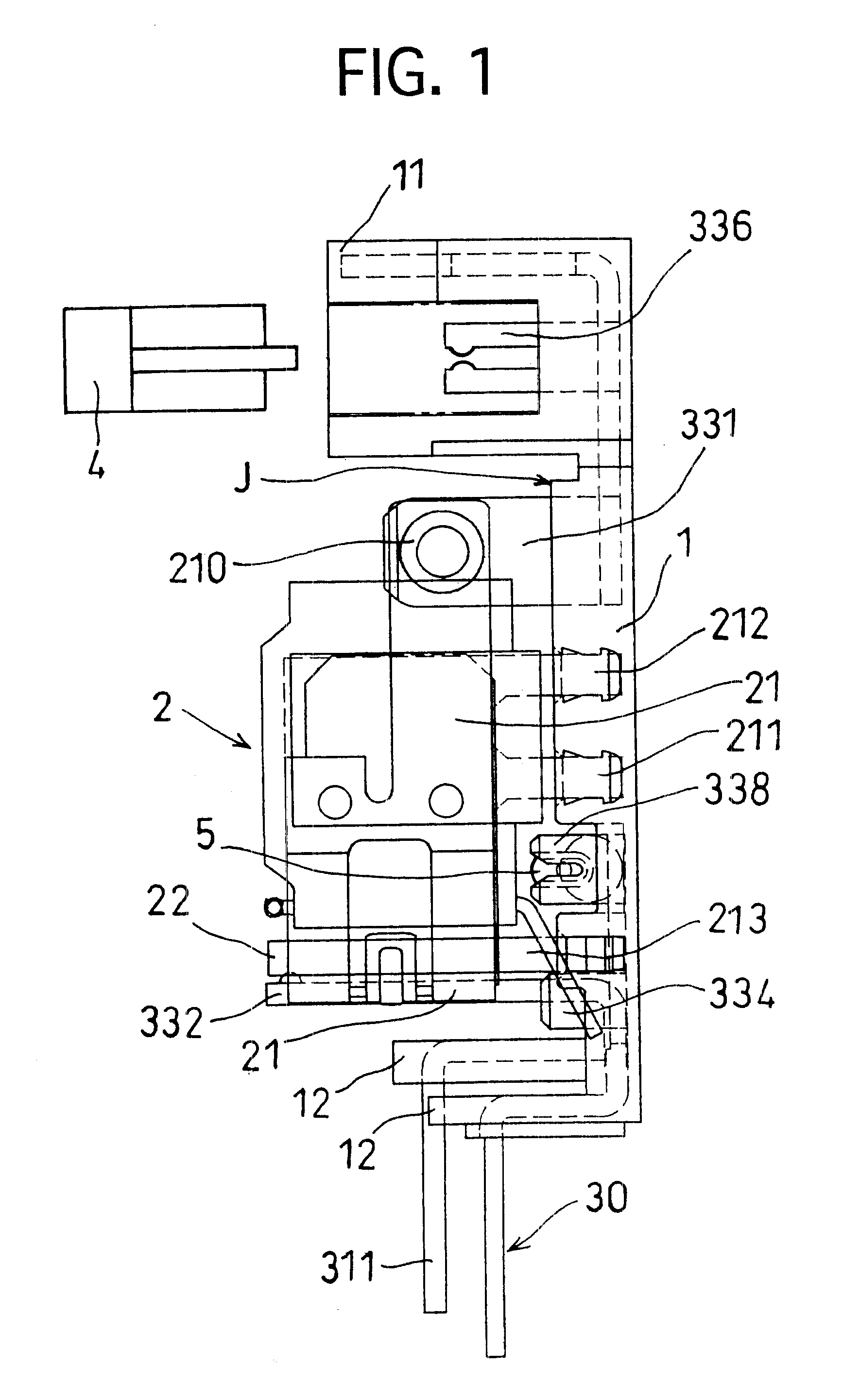

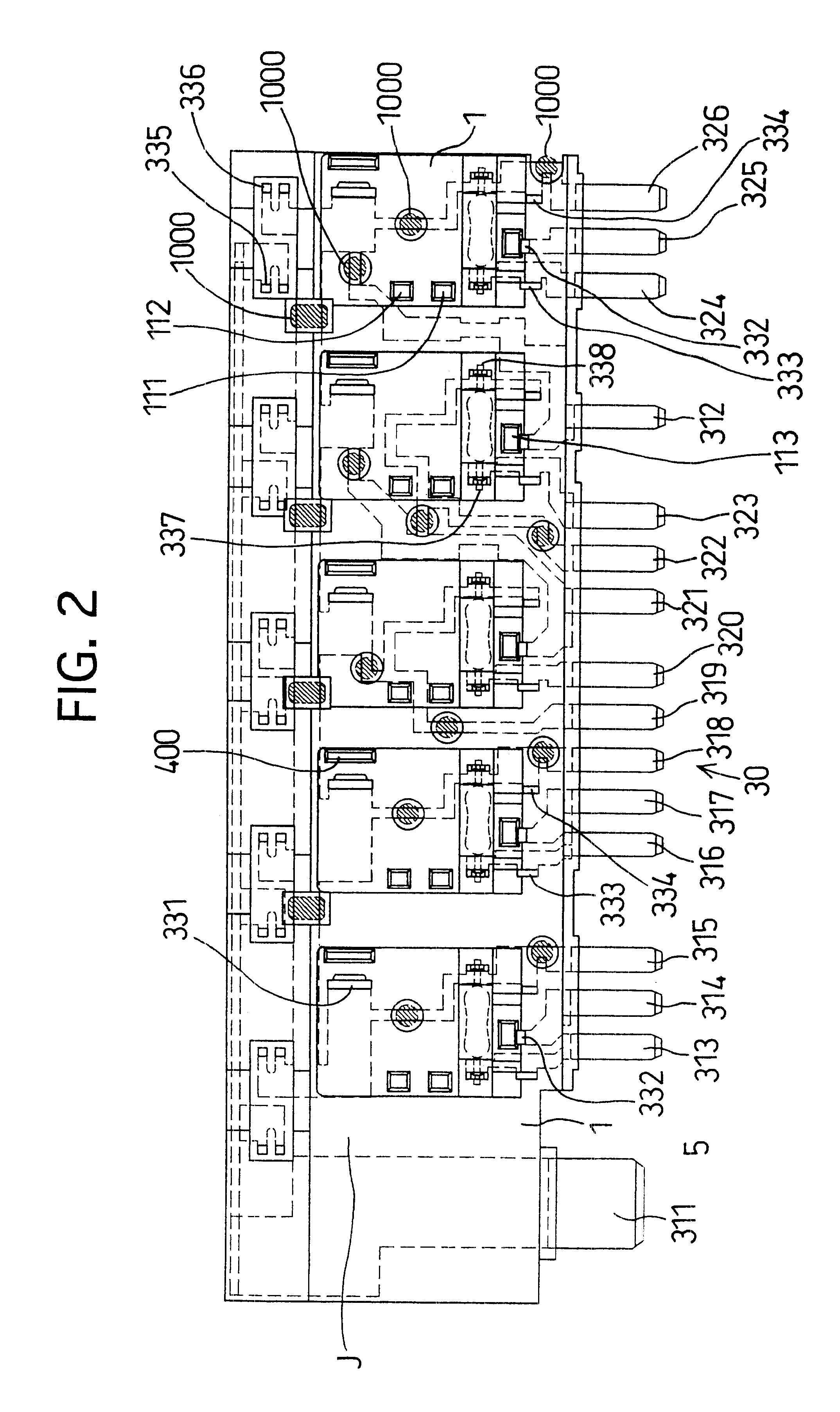

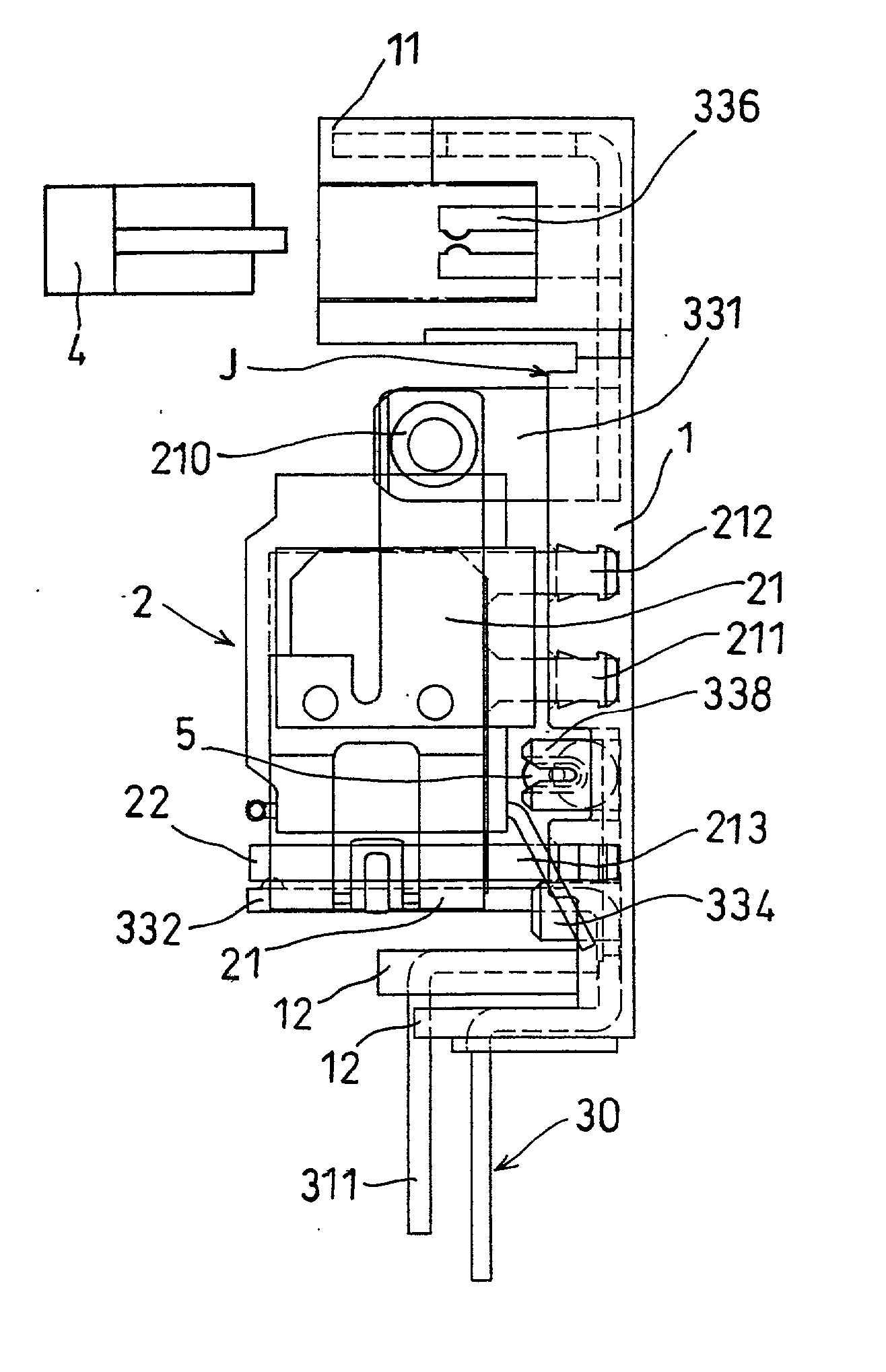

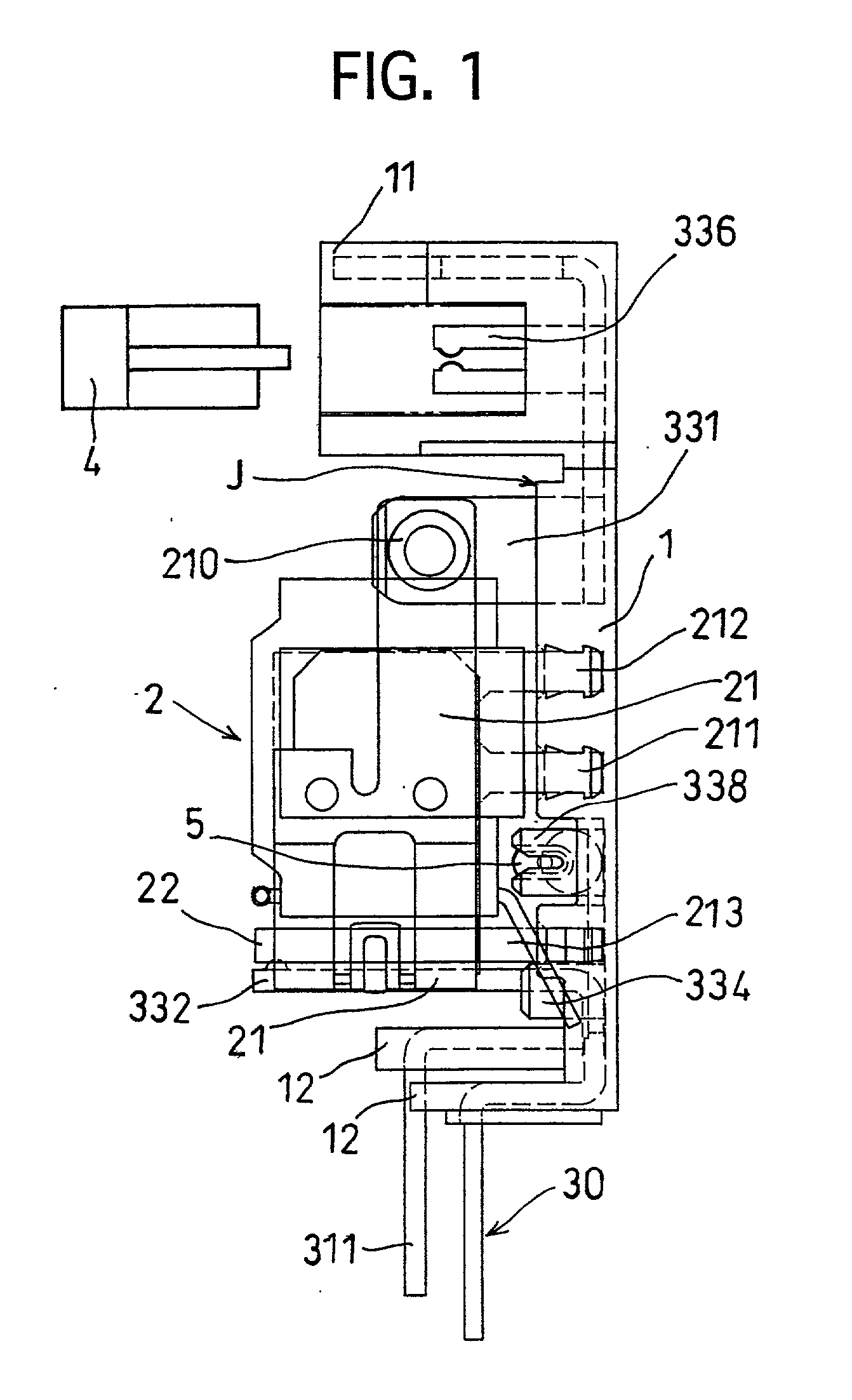

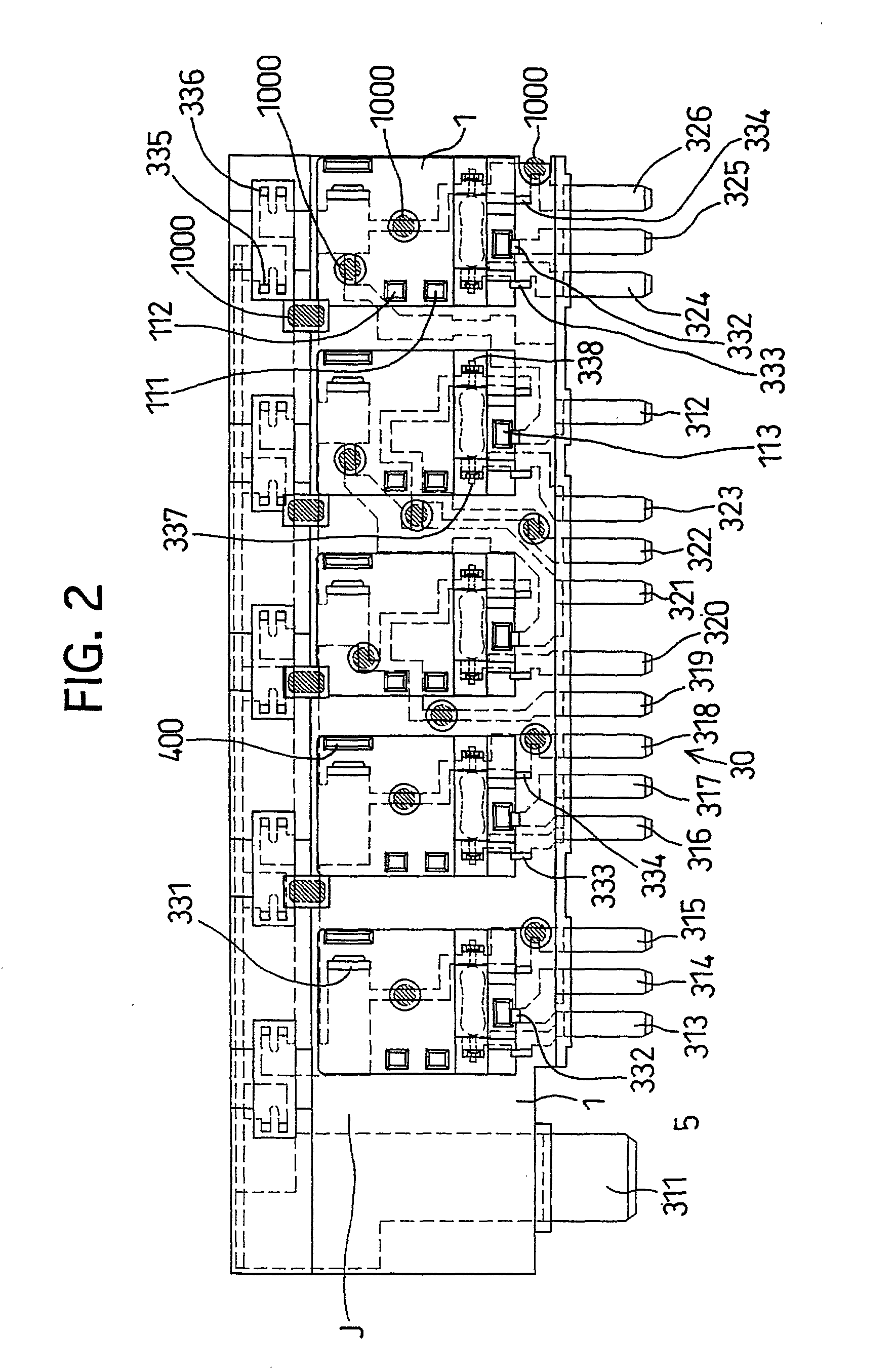

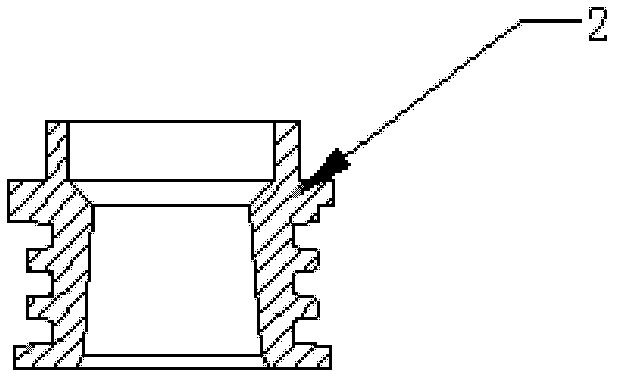

Relay device

InactiveUS6686821B2Reduce molding processReduce the number of partsElectric switchesRelay detailsCommon baseElectricity

A relay device capable of reducing the manufacturing costs thereof by decreasing the number of parts and the number of electrical connections between these parts, and making the manufacturing process simple. The relay device has a plurality of electromagnetic relays and uses a common base plate with which stems of the electromagnetic relays are formed integrally, and on which a wiring member is formed by resin molding. The wiring member on the common base plate is projected from the molded resin to define a fixed contact member of each electromagnetic relay. Each relay unit assembly of each electromagnetic relay except for the fixed contact member thereof is secured to the common base plate such that a movable iron piece is driven in parallel with a surface of the common base plate. The construction of the resultant relay device is compact, the relay properties are readily adjusted, and the number of parts can be reduced.

Owner:ANDEN CORP

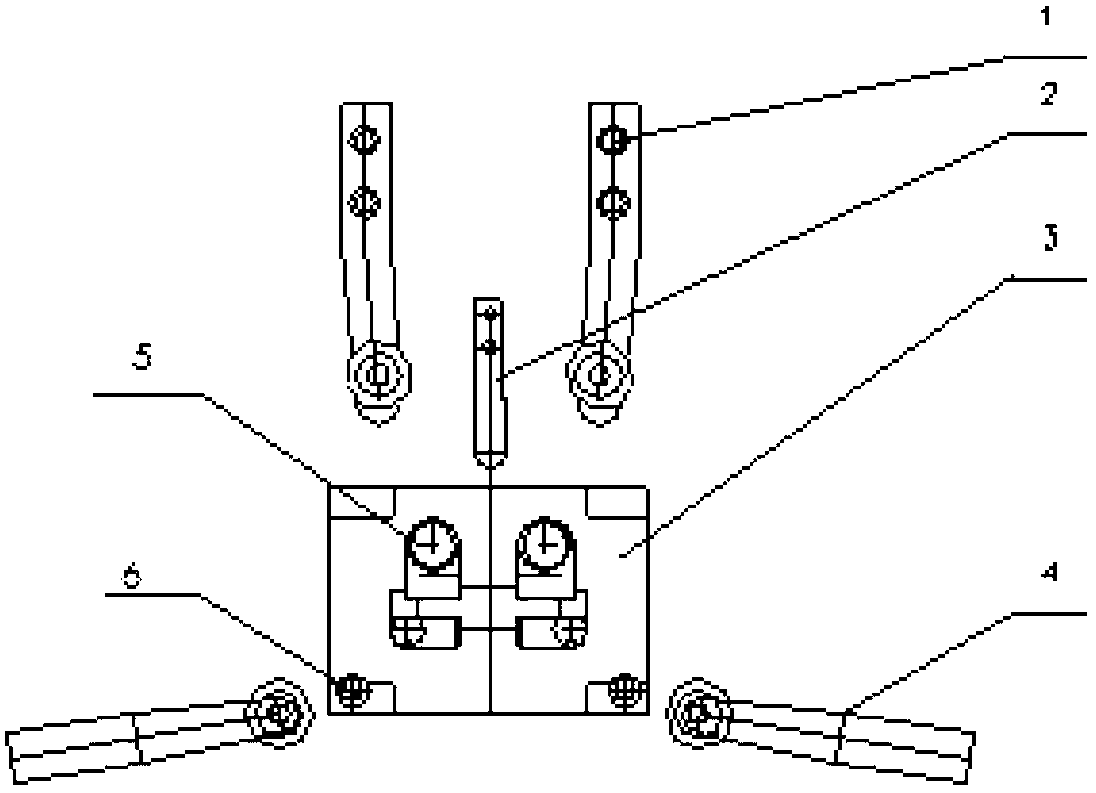

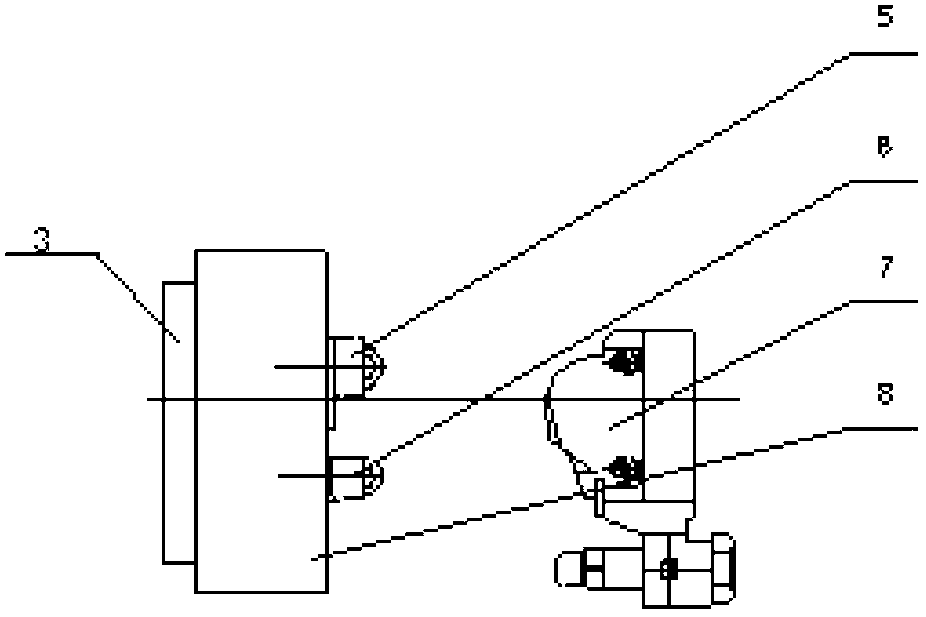

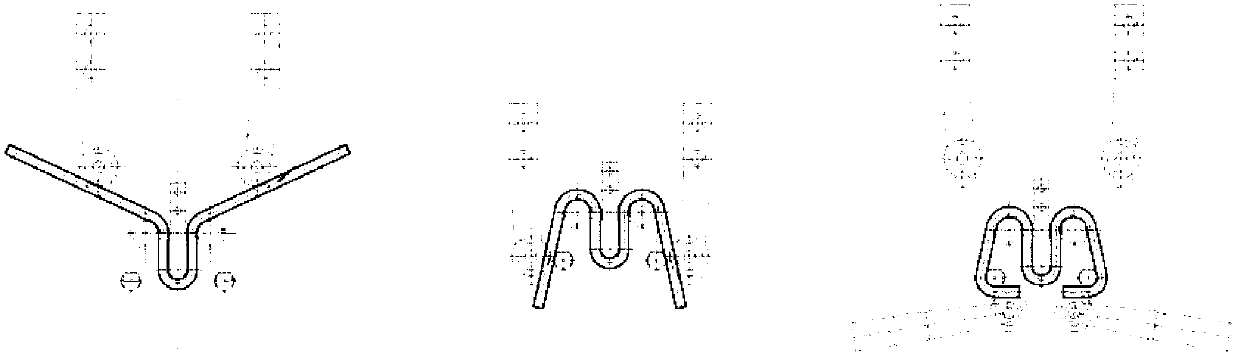

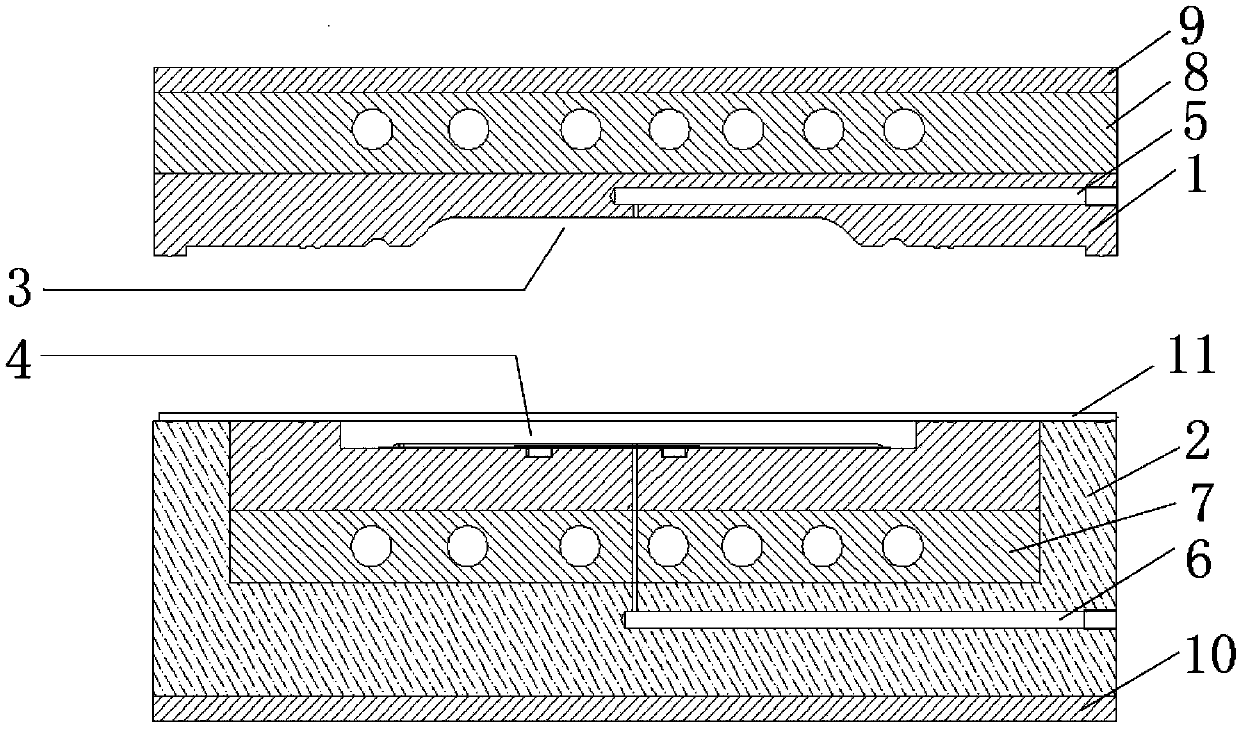

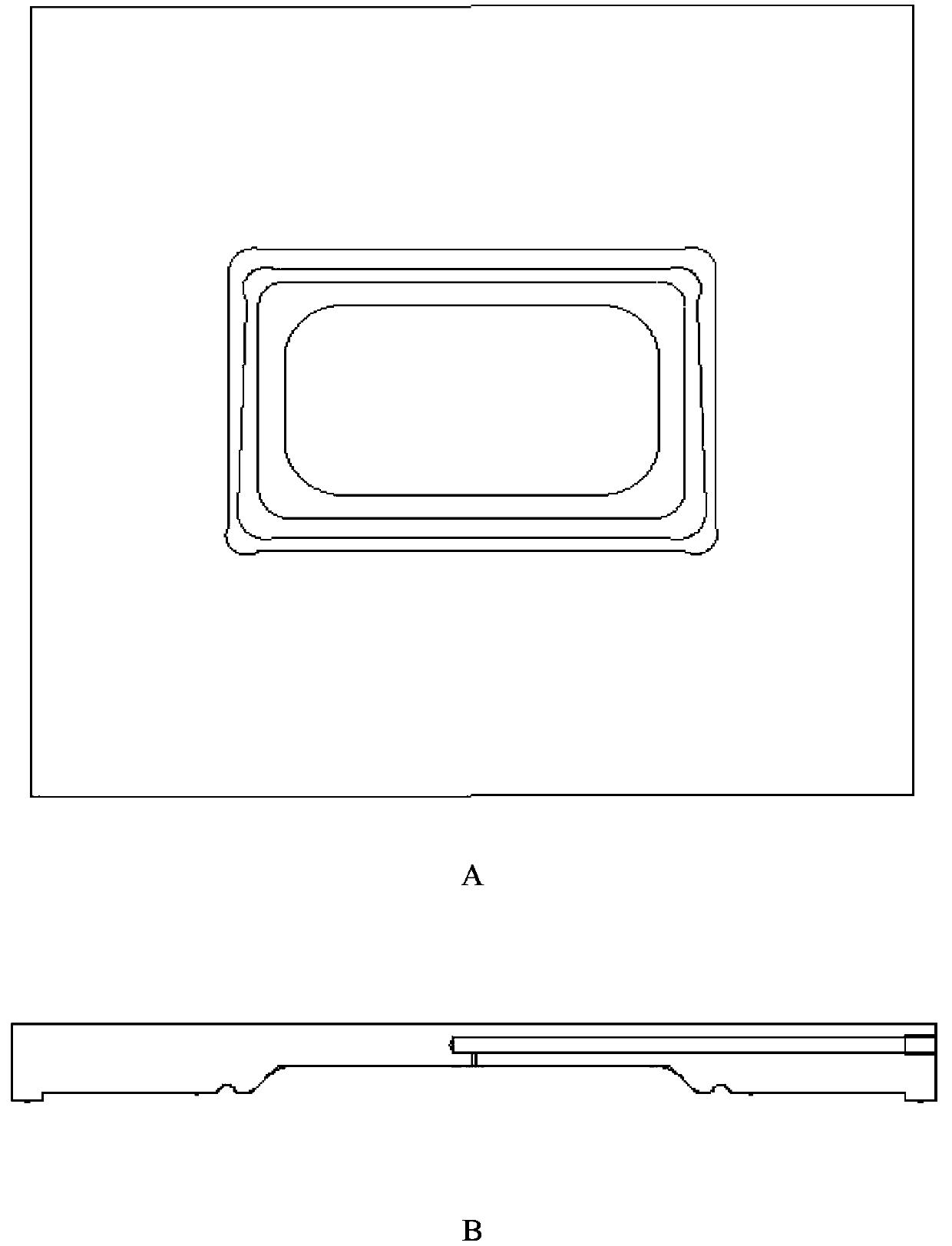

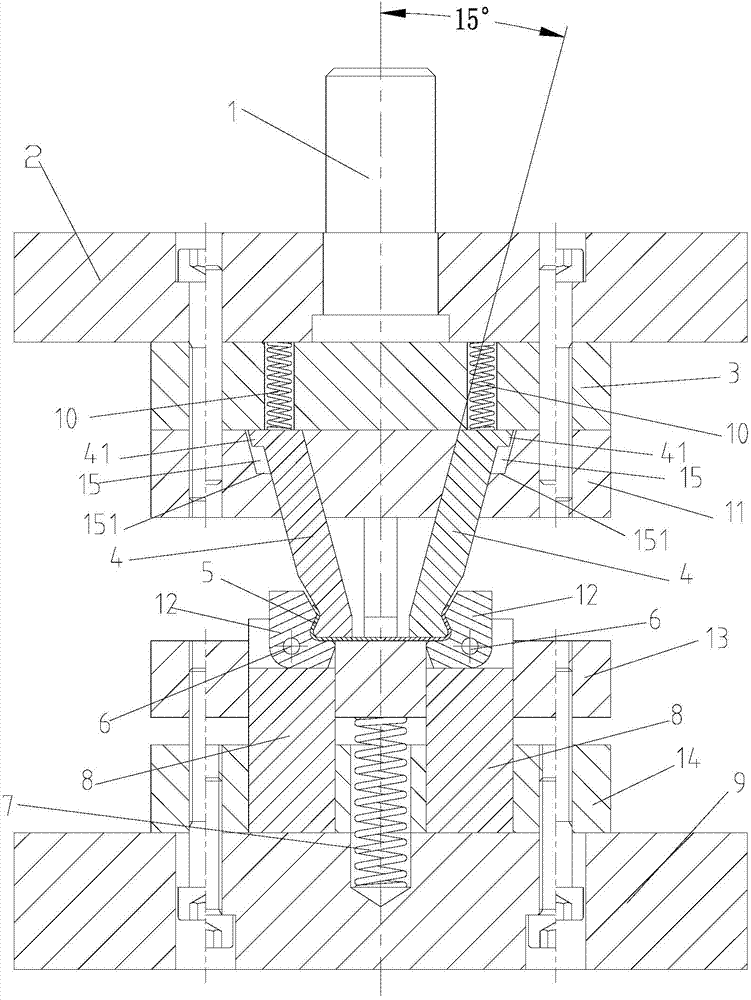

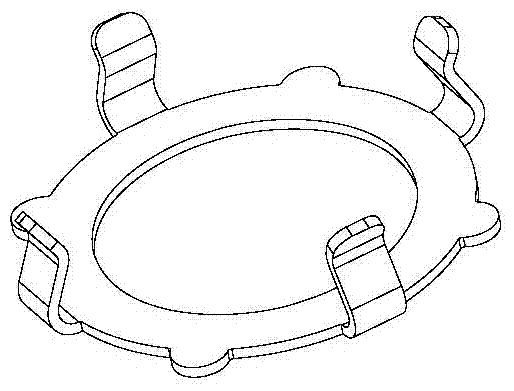

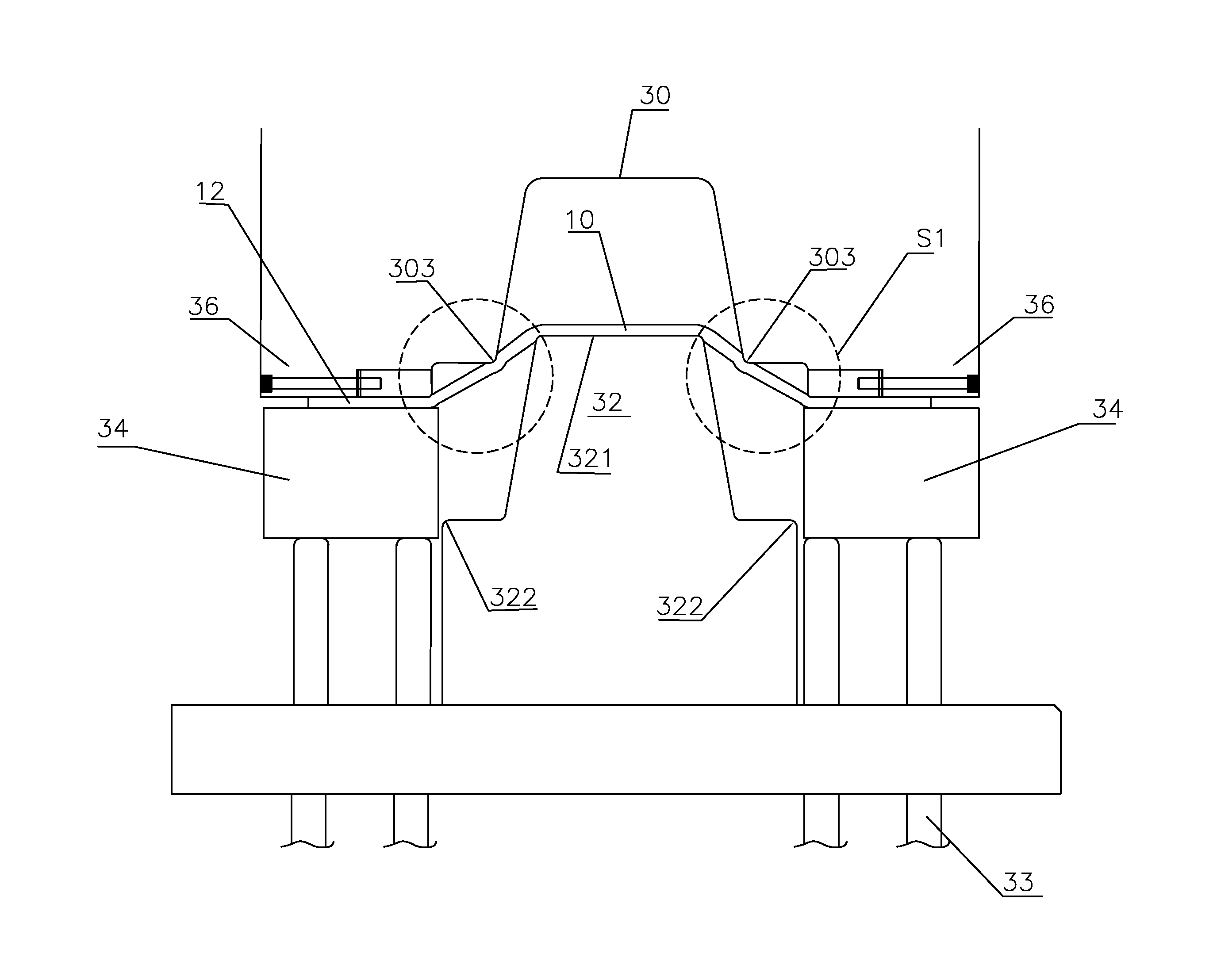

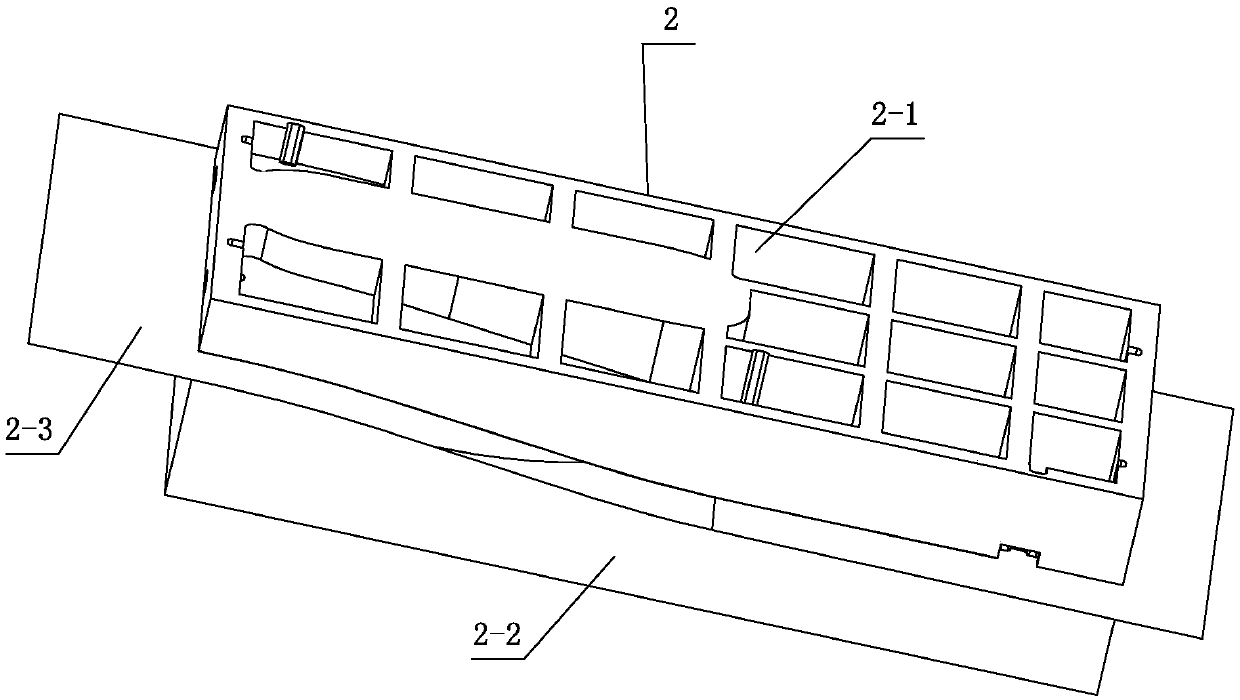

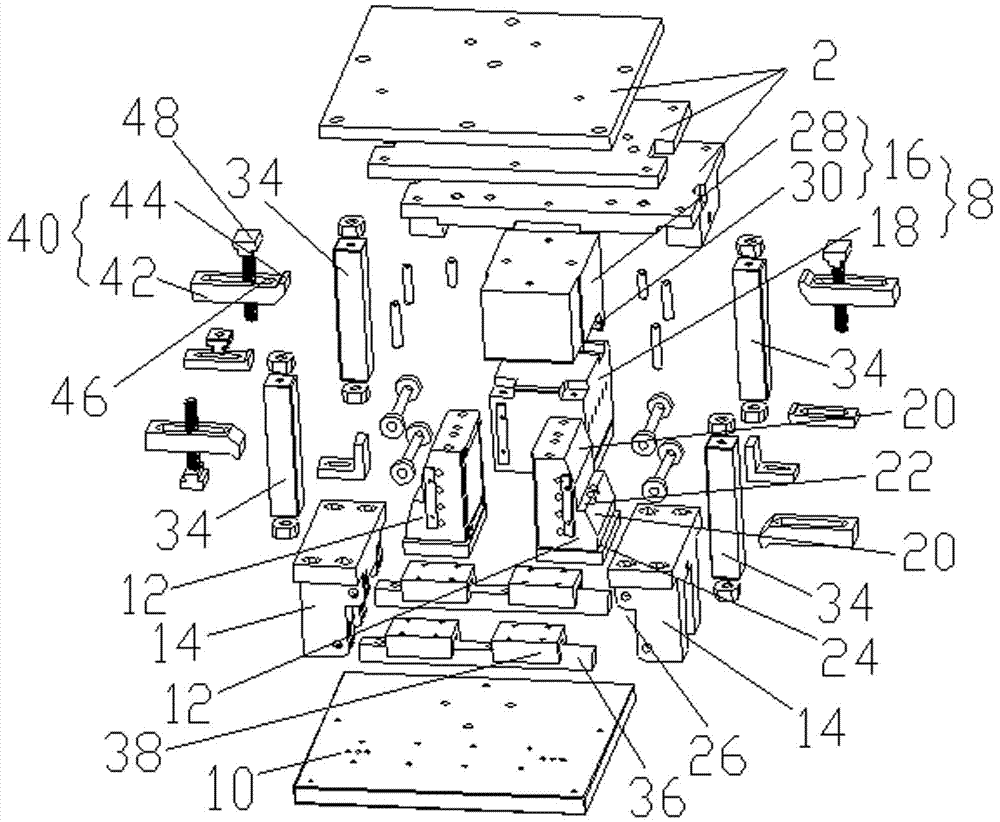

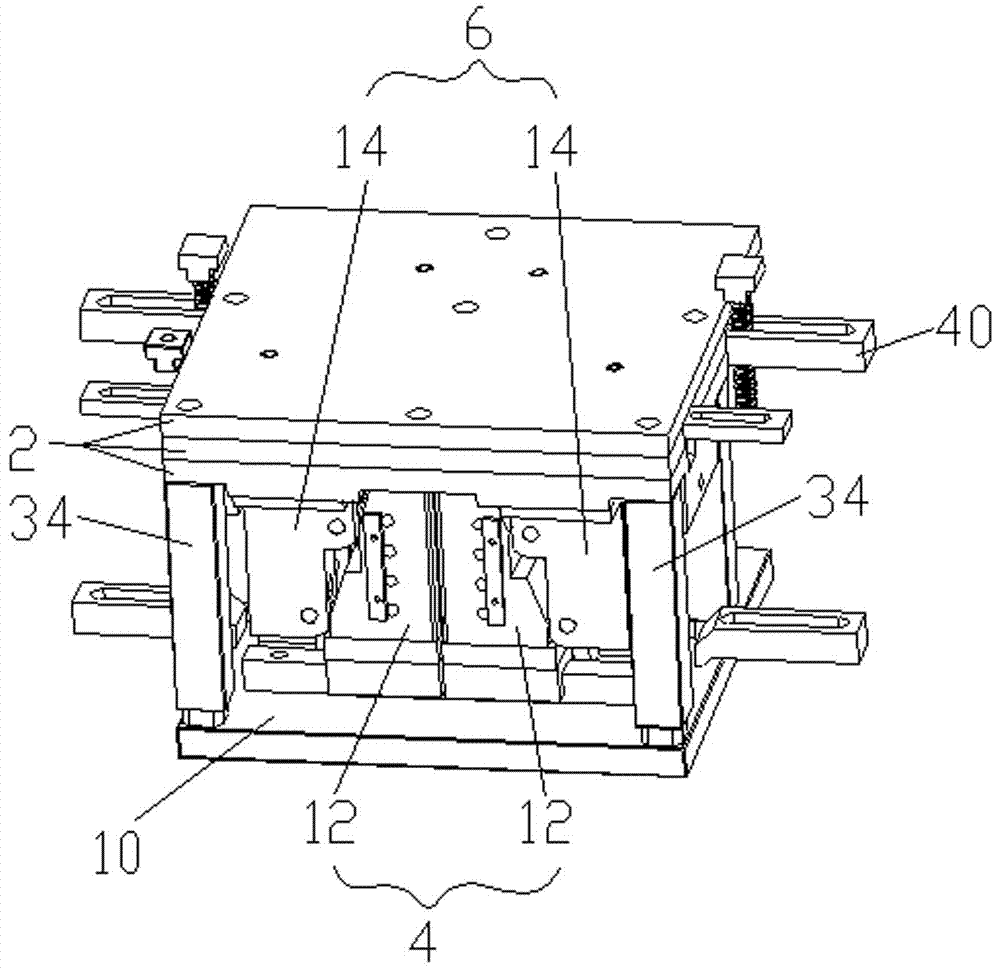

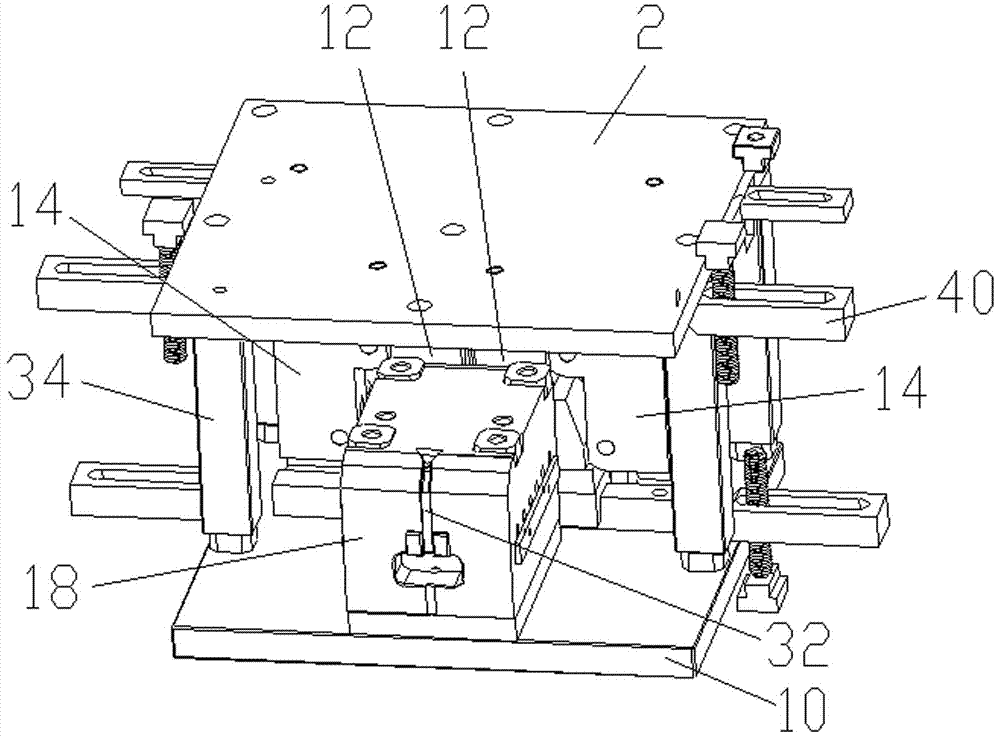

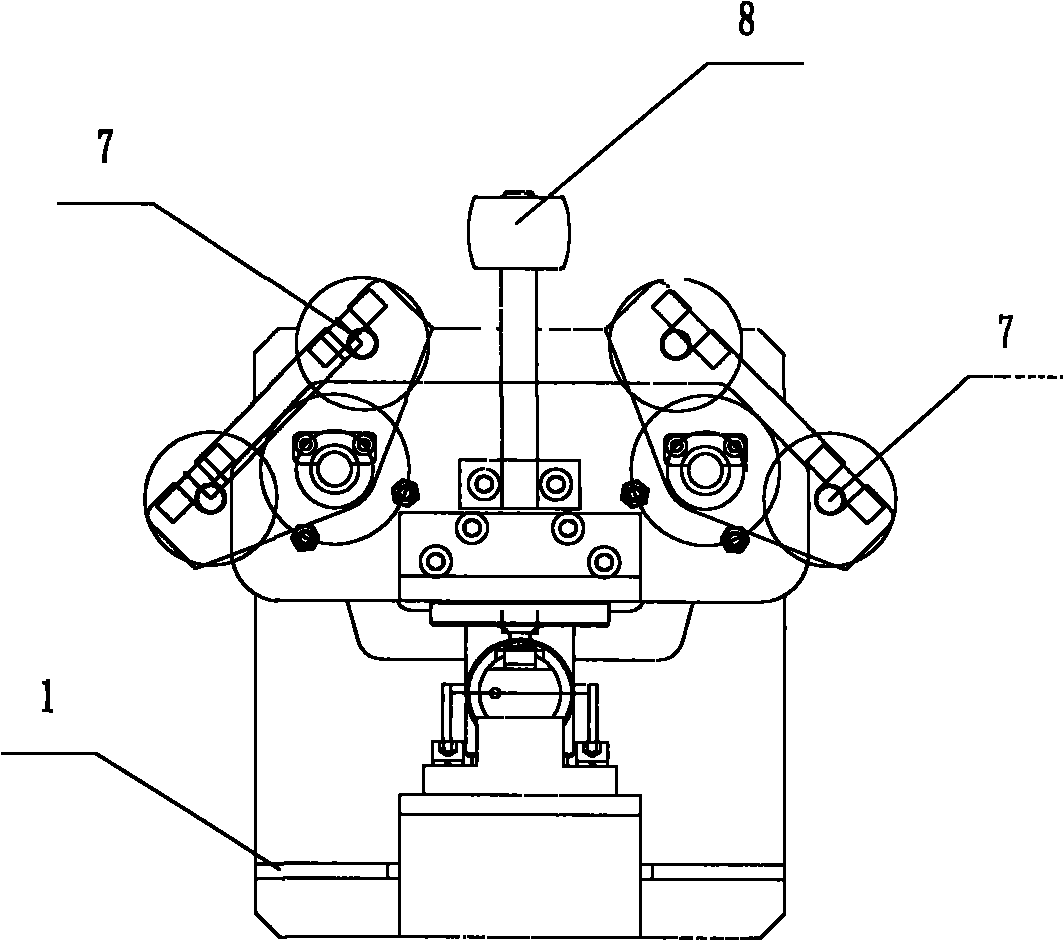

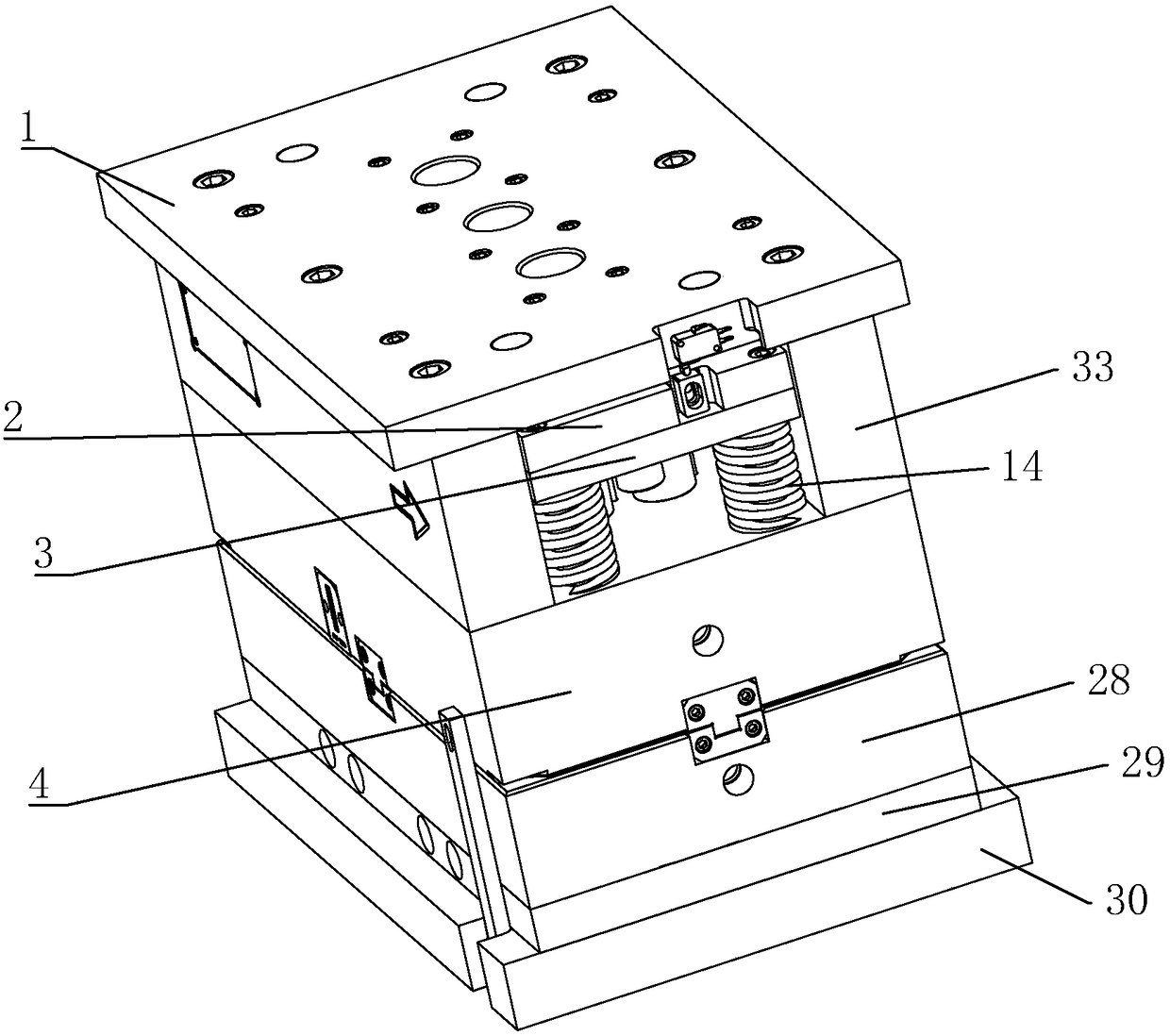

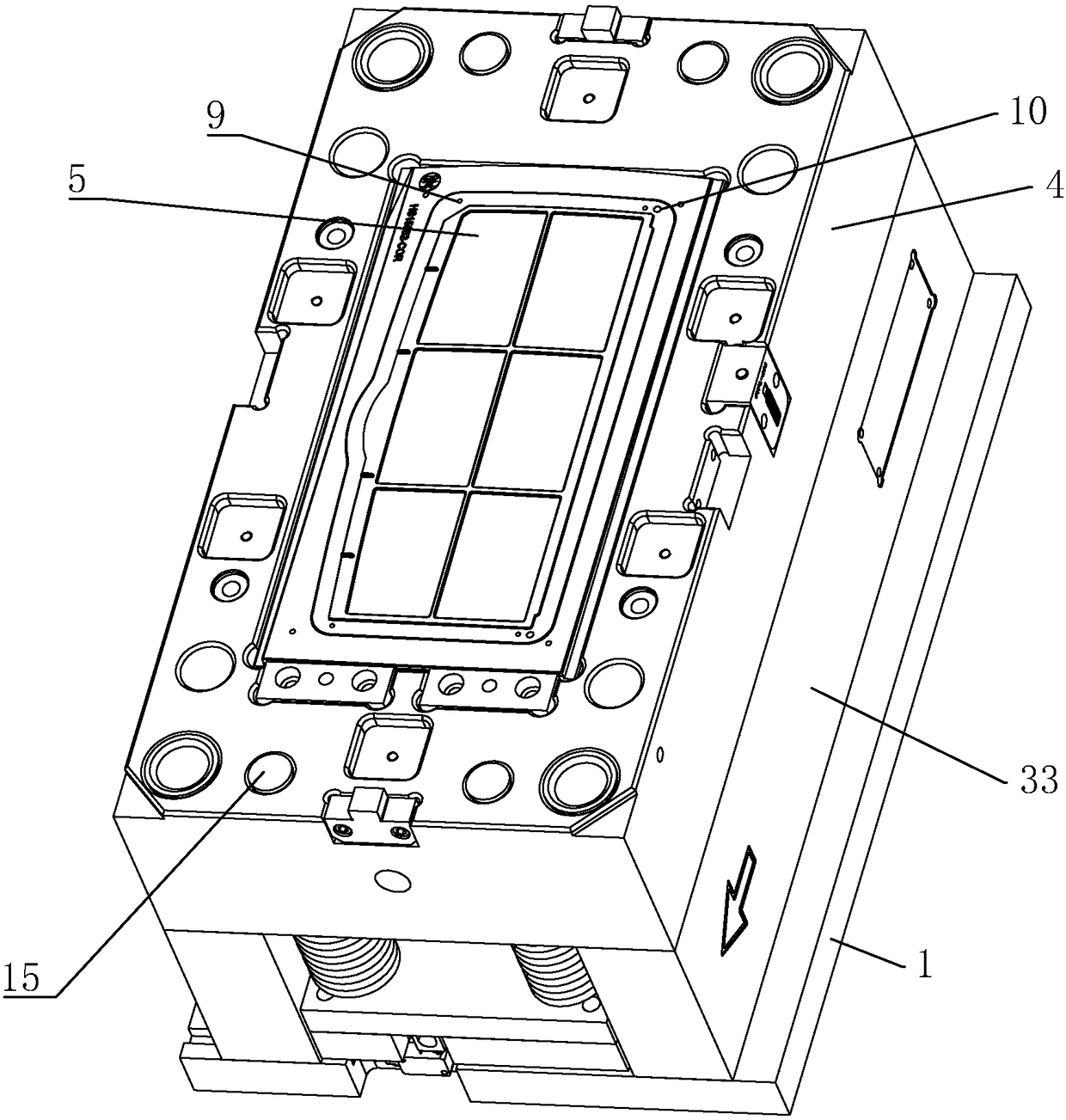

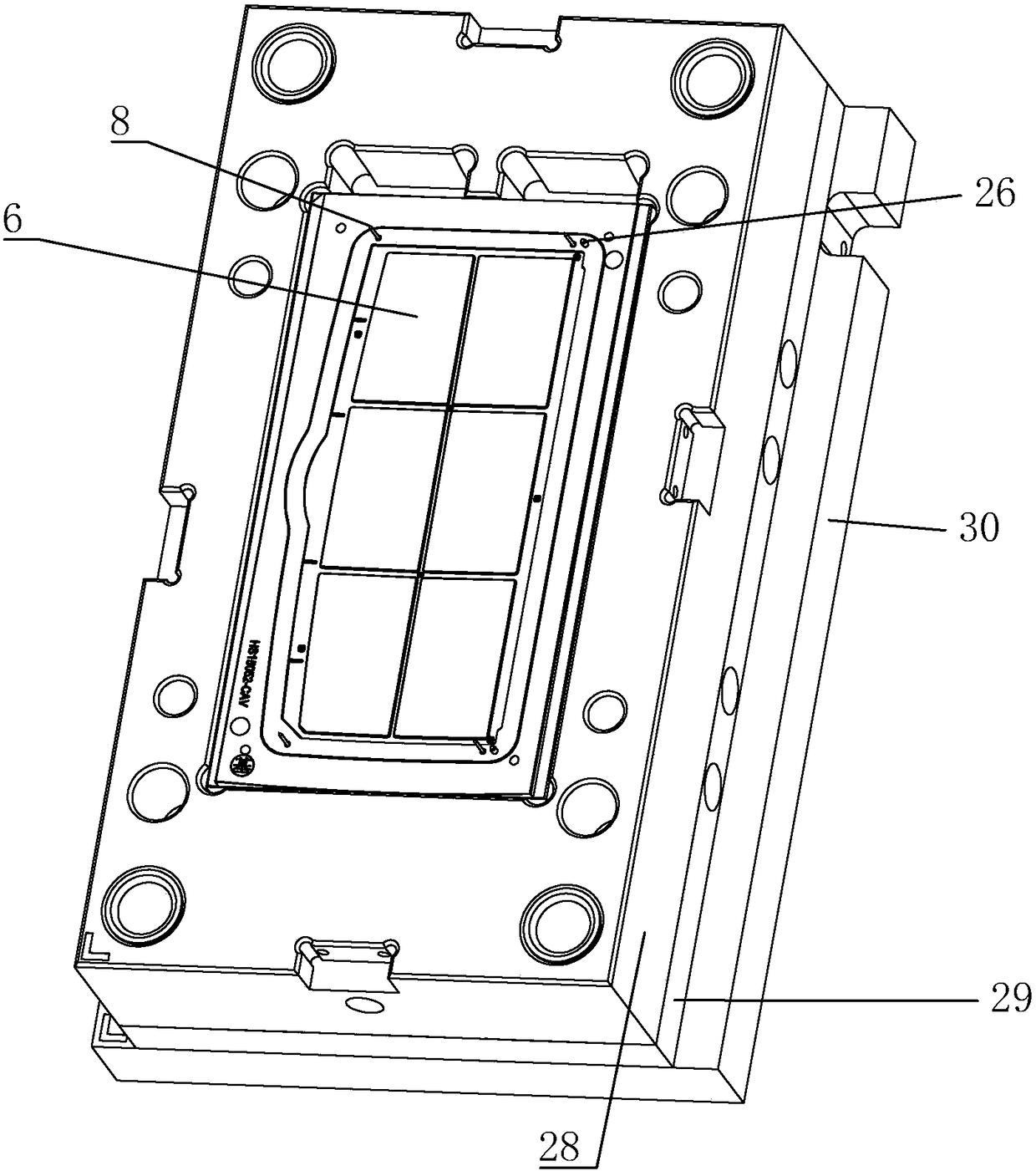

One-time forming system of spring bars former, and forming method of spring bars

ActiveCN103272903AReduce the clip forming processReduce molding processStructural engineeringMechanical engineering

The invention discloses a one-time forming system of a spring bars former. The one-time forming system comprises an upper die, a lower die, two upper positioning posts, two lower positioning posts, a middle push arm, two side push arms, and two limb push arms. The surface of the upper die faces the surface of the lower die. The upper positioning posts are fixed above the surface of the lower die in a bilaterally symmetric manner. The lower positioning posts are fixed below the surface of the lower die in a bilaterally symmetric manner. The middle push arm is disposed above the lower die. The side push arms are symmetrically disposed on two sides of the middle push arm. The limb push arms are symmetrically disposed on two sides of the lower die and are lower than the lower positioning posts in horizontal height. The invention further discloses a forming method of spring bars. The one-time forming system and the forming method of spring bars have the advantages that one-time forming of spring bars is achieved and production efficiency is improved.

Owner:ANHUI CHAOHU CASTING FACTORY

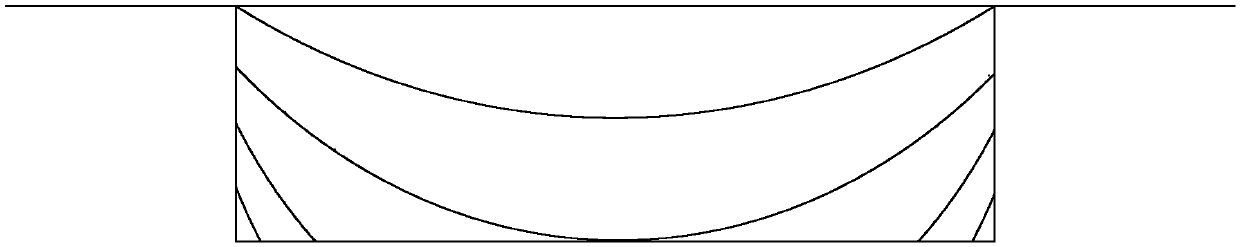

Super-plastic forming die and method thereof

ActiveCN103358433APrevent premature molding of protected areasGood one-piece formabilityMaterials scienceClosed space

The invention discloses a super-plastic forming die and a method thereof. The super-plastic forming die comprises: an upper die, wherein the upper die is provided with a preforming die cavity having a preforming structure; and a lower die, wherein the lower die is concavely provided with a forming die cavity, the forming die cavity corresponds to the preforming die cavity to make the forming die cavity and the preforming die cavity form a closed space during the closing of the lower die and the upper die, the upper die and the lower die are provided with an upper air inlet and a lower air inlet respectively, and the upper air inlet and the lower air inlet are communicated with the closed space. The super-plastic forming die can realize the completion of a super-plastic forming technology, the completion of preforming and final forming in a same die, and instant forming after preforming, has the advantages of good integral formability, good mechanical performances, uniform product thickness, abundant product kind, simple preparation technology, short production period, low rejection rate, and low production cost, is suitable for the industrialized production, and has a wide application space and a very large market popularization value.

Owner:北京超塑新技术有限公司

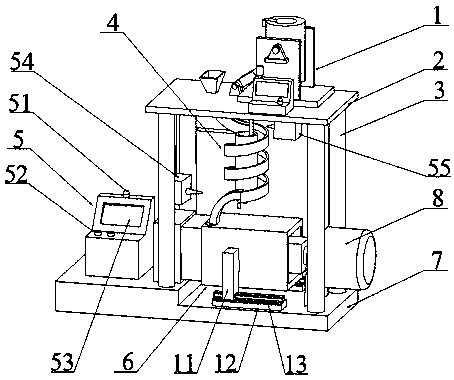

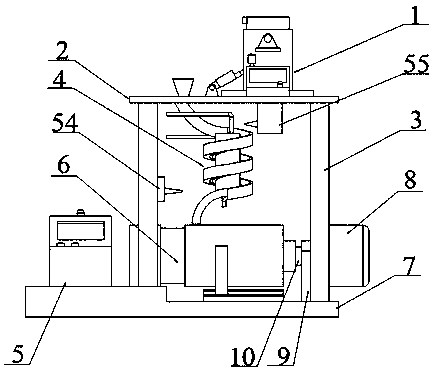

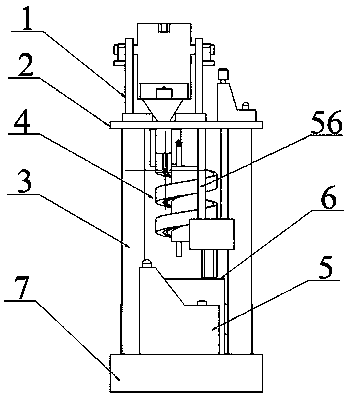

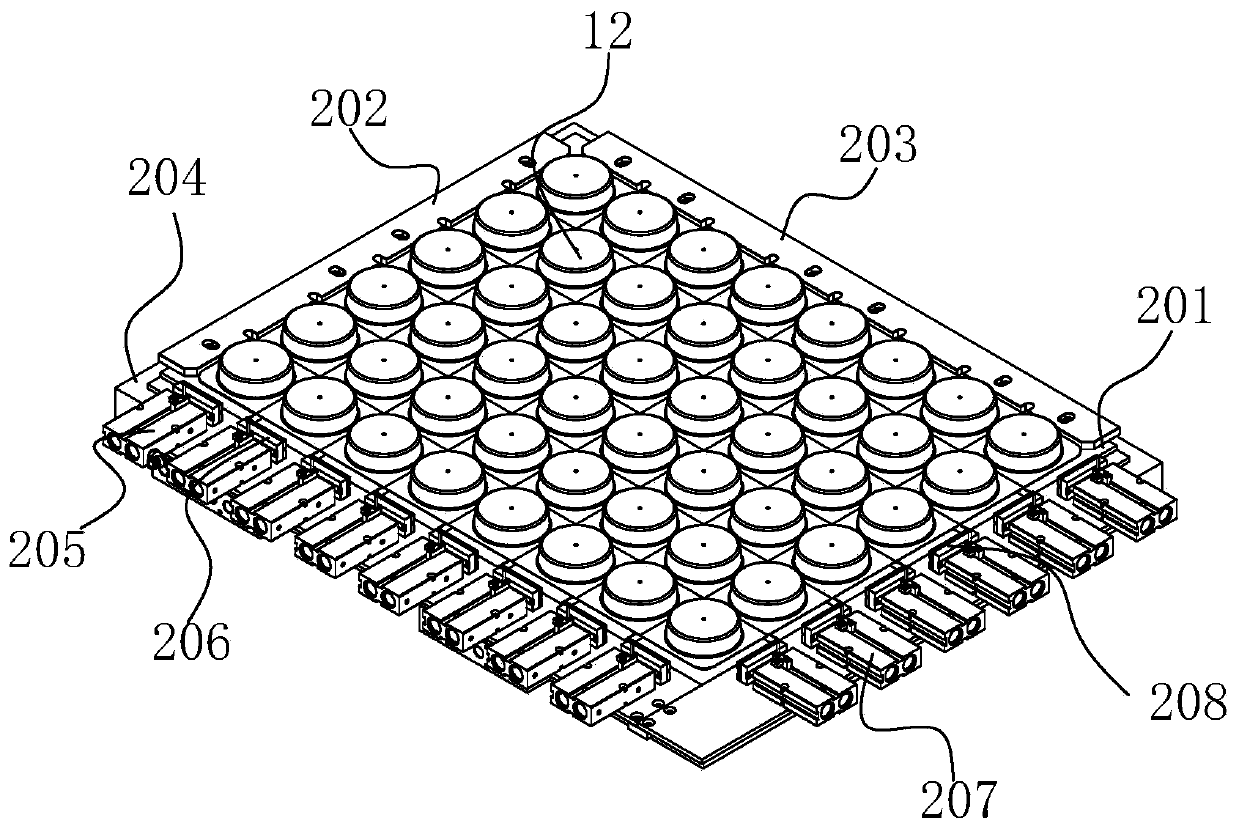

Semi-solid slurry preparation and forming integrated equipment

ActiveCN108273975AReduce manufacturing costReduce preparation energy consumptionNumerical controlSemi solid

The invention relates to semi-solid slurry preparation and forming integrated equipment, and belongs to the technical field of material processing. The equipment comprises a smelting device, a top plate, a supporting column, a slurry preparing device, a numerical control operation table, an extruding forming device and a base; the numerical control operation table is arranged on the base; the supporting column is arranged on the base and located on one side of the numerical control operation table; the top plate is horizontally arranged at the top end of the supporting column; the smelting device is arranged on the top plate; the extruding forming device is arranged on the base and located below the top plate; the pulp preparing device is arranged at the lower end of the top plate and located above the extruding forming device; and the smelting device, the slurry preparing device and the extruding forming device are sequentially communicated and are correspondingly connected with the numerical control operation table.

Owner:KUNMING UNIV OF SCI & TECH

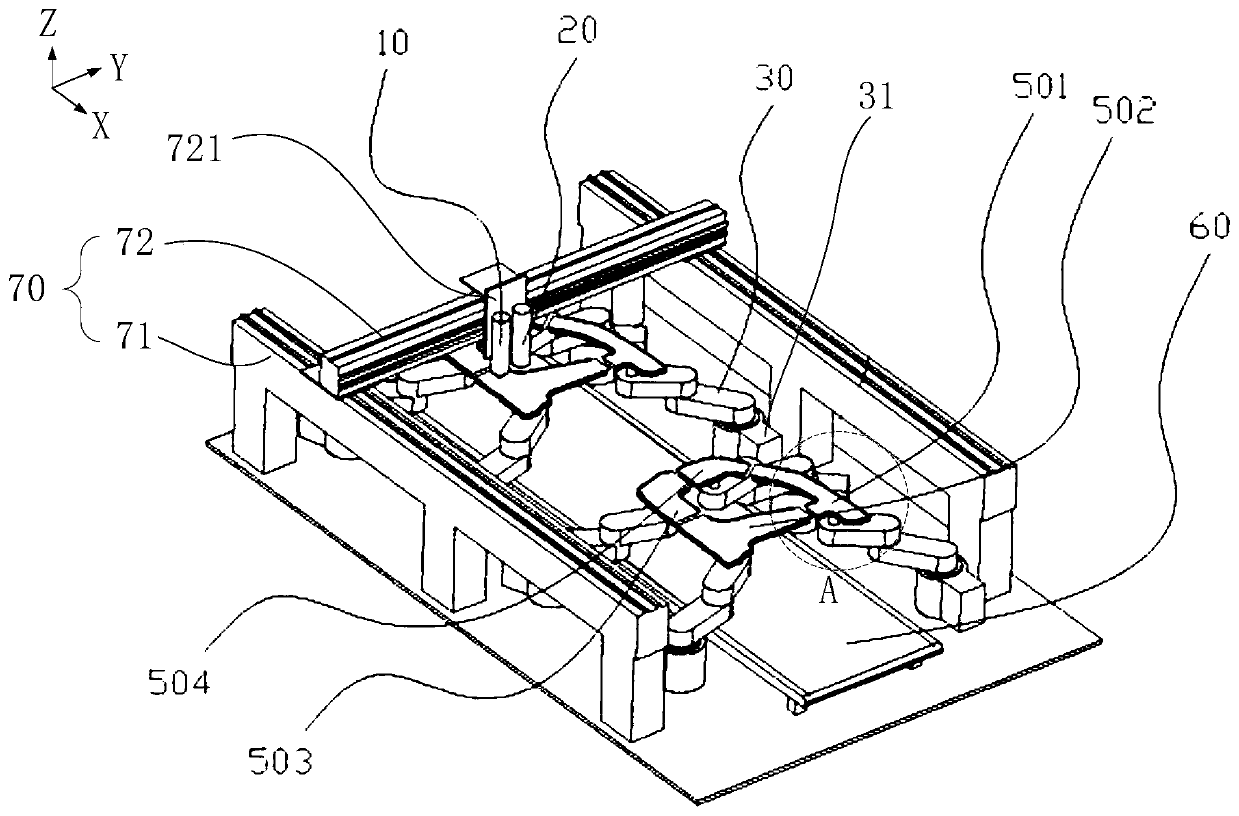

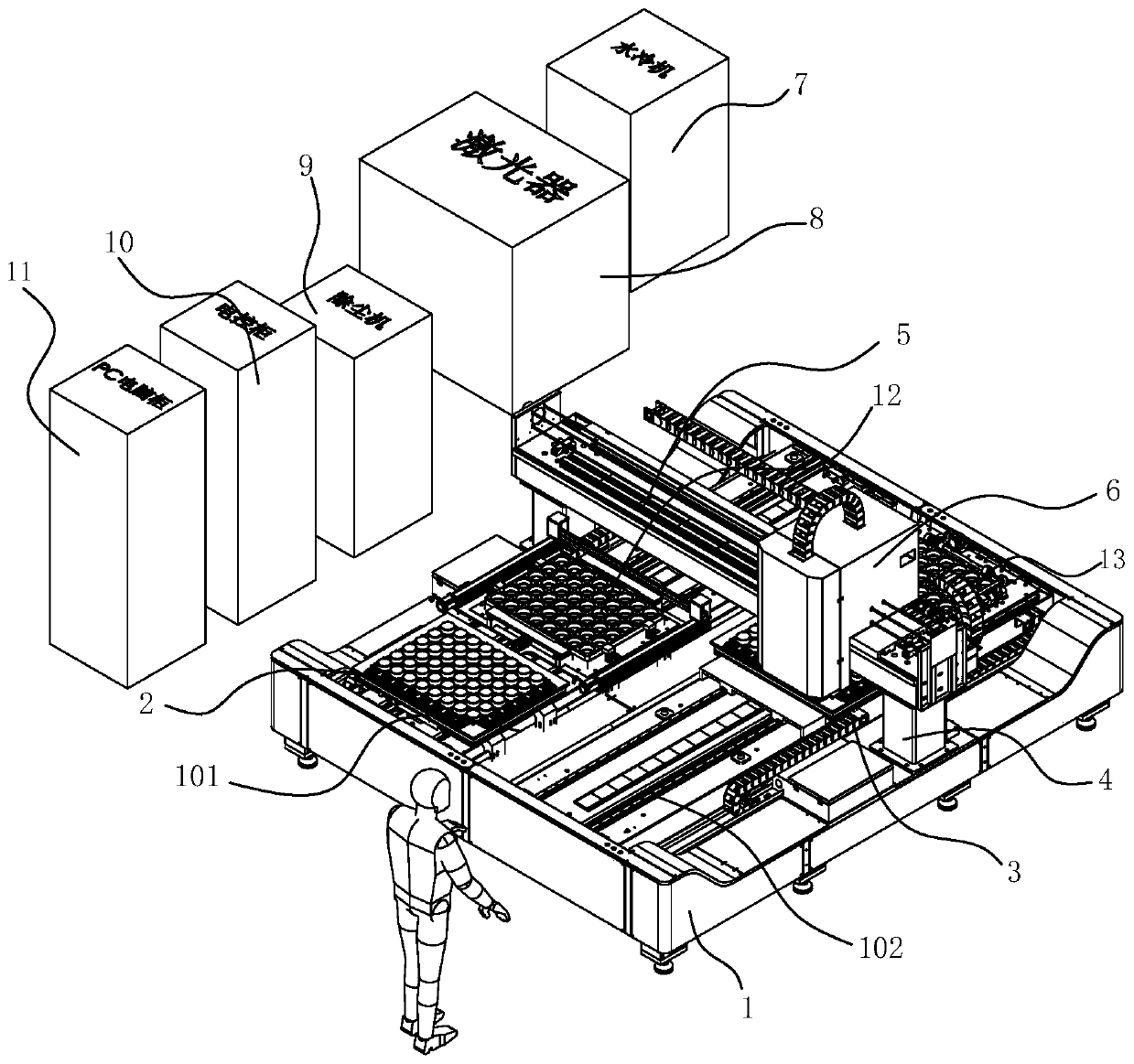

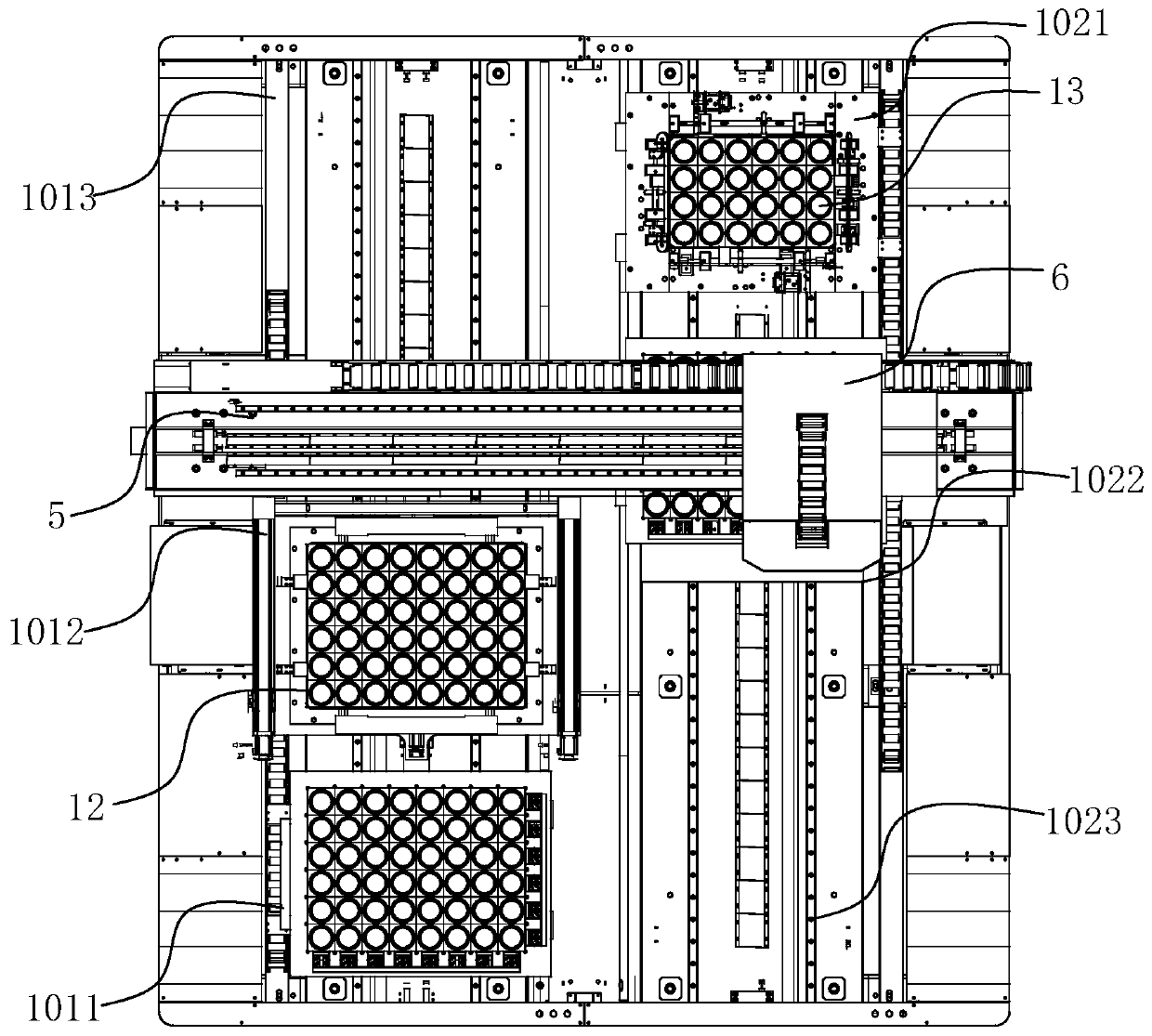

System and method for processing automobile door-ring tailor-welded plate blanks

InactiveCN110102888AGuaranteed accuracyReduce cumulative errorVehicle componentsMetal working apparatusManipulatorEngineering

The invention discloses a system and method for processing automobile door-ring tailor-welded plate blanks. The processing system comprises a discharging mechanism, a plurality of articulated manipulators, a plurality of plate tool clamps, a moving mechanism, a laser cutting mechanism and a laser welding mechanism, wherein a plurality of plates discharged by the discharging mechanism are providedwith cutting parts; the plates are positioned on the plate tool clamps; the parts to be cut of the plates are suspended outside the plate tool clamps; a laser cutting head of the laser cutting mechanism and a laser welding head of the laser welding mechanism are correspondingly arranged on the moving mechanism; the moving mechanism drives the laser cutting head to sequentially cut off each part tobe cut so that each plate can form a welding plate edge; each articulated manipulator can drive the corresponding plate tool clamps on the articulated manipulator to move in a horizontal direction sothat the welding plate edges of each two adjacent plates correspondingly abut to form a welding portion; and the moving mechanism drives the laser welding head to sequentially weld each welding portion. The system and the method have the advantages of high production efficiency, low tooling cost, high welding quality and the like.

Owner:SUZHOU PRESSLER ADVANCED FORMING TECHNOLOGIES CO LTD

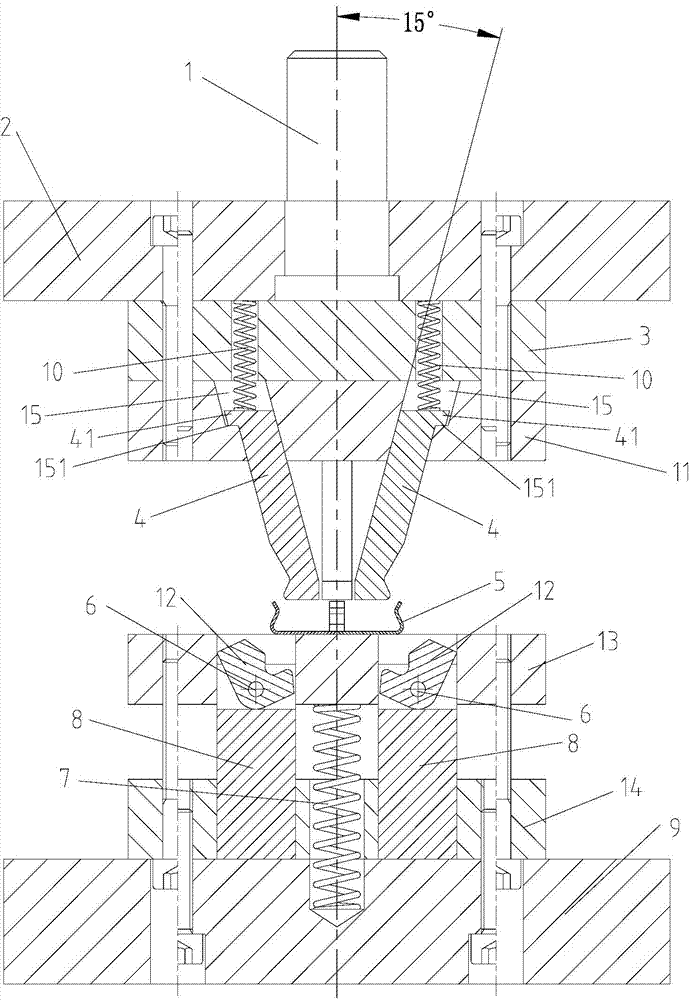

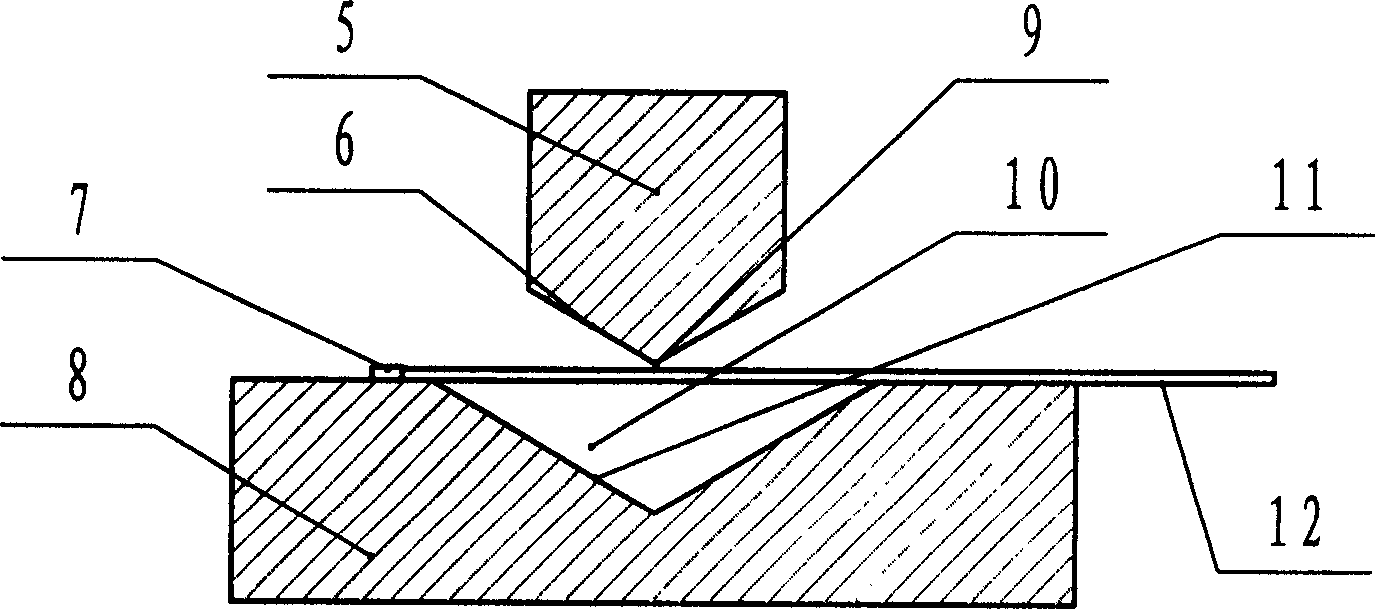

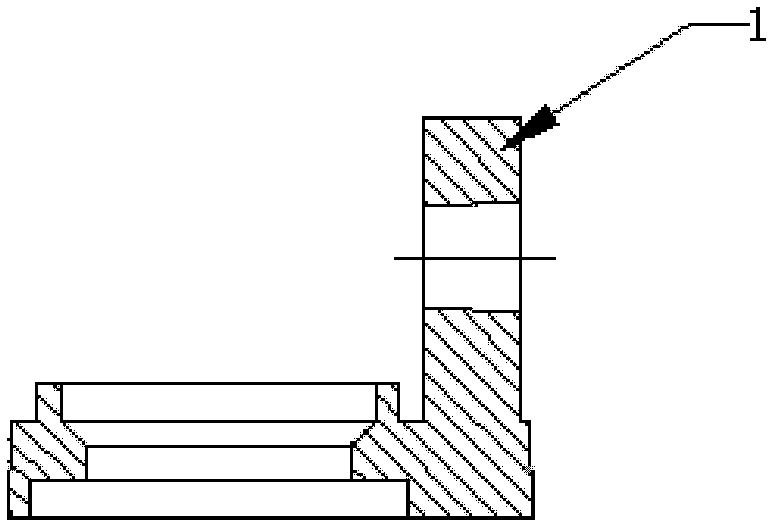

Stamping die used for stamping inverted-pothook-shaped structure

ActiveCN103611816AReduce molding processSmooth movementShaping toolsEjection devicesEngineeringMechanical engineering

The invention discloses a stamping die used for stamping an inverted-pothook-shaped structure. The stamping die comprises an upper die and a lower die; the lower die comprises a bottom board and a support fixing board arranged on the bottom board, and the support fixing board is fixedly provided with a support; the support is further provided with a swing block which is movably connected to the support. The swing block is provided with a formed surface matched with the inverted-pothook-shaped structure of a stamped part. An upper die guide board is provided with a set of inclined top blocks which can move vertically, and a formed surface which is matched with the swing blocks to form the inverted-pothook-shaped structure is arranged below the inclined top blocks. The lower die is further provided with a blank locating board which is arranged on the support in a sleeved mode, an elastic part is arranged between the blank locating board and the support fixing board, and the elastic part can be elastic rubber or a spring. According to the stamping die, the inverted-pothook-shaped structure can be formed at a time, the number of stamping procedures of the inverted-pothook-shaped structure is reduced, and production cost is lowered. The stamping die can be widely applied to the stamping field of the inverted-pothook-shaped structure.

Owner:HUANGSHAN AOTESI ELECTRICAL CO LTD

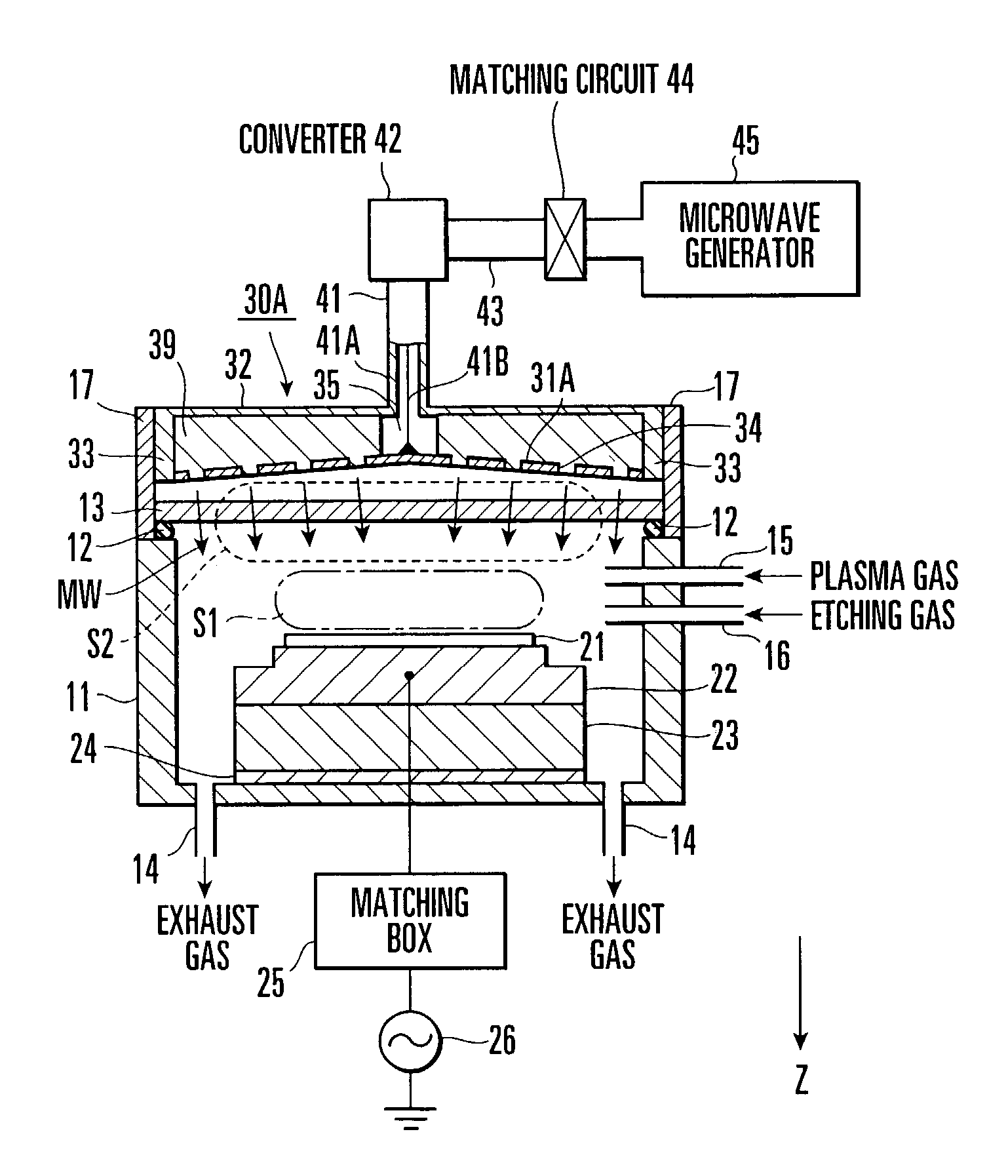

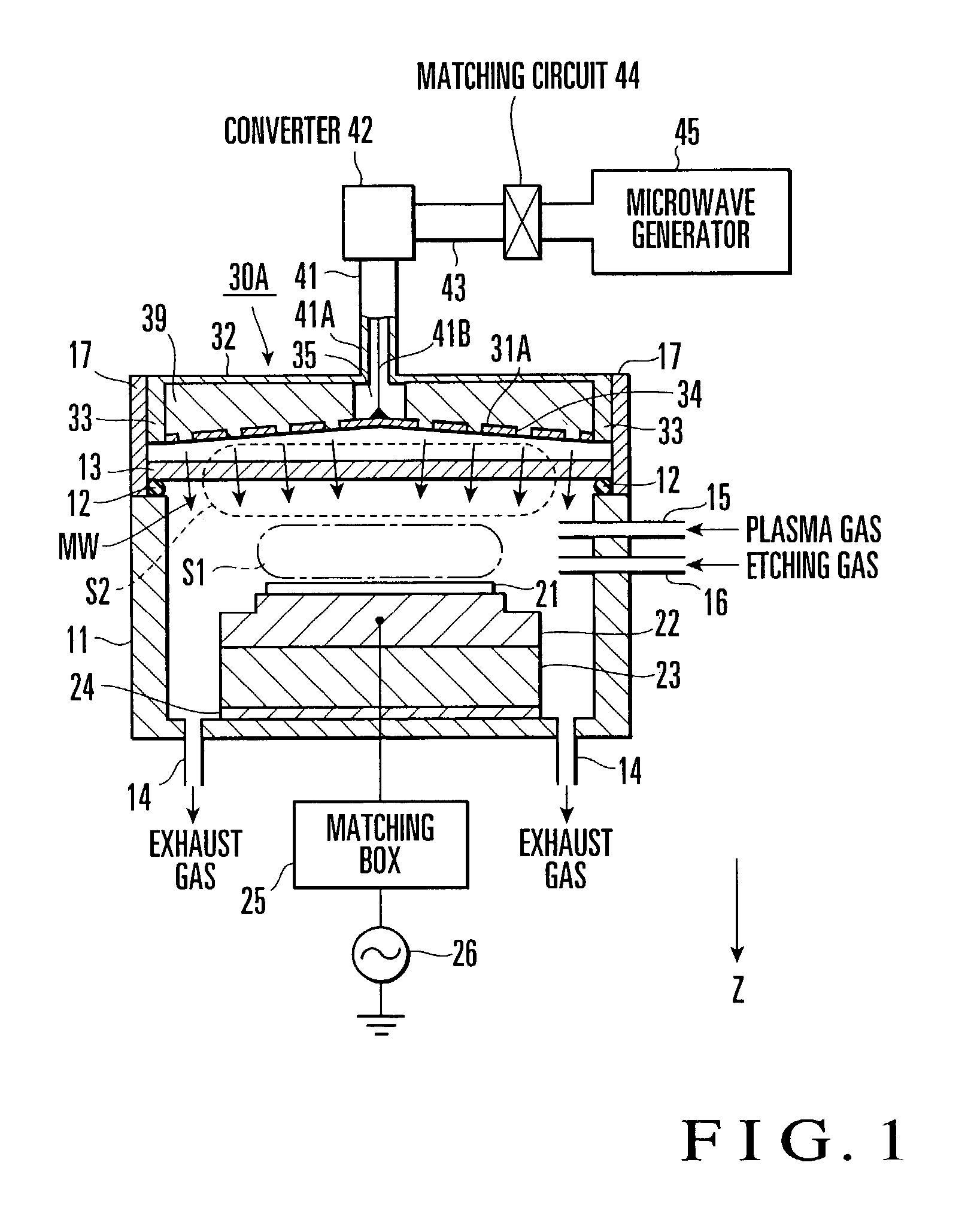

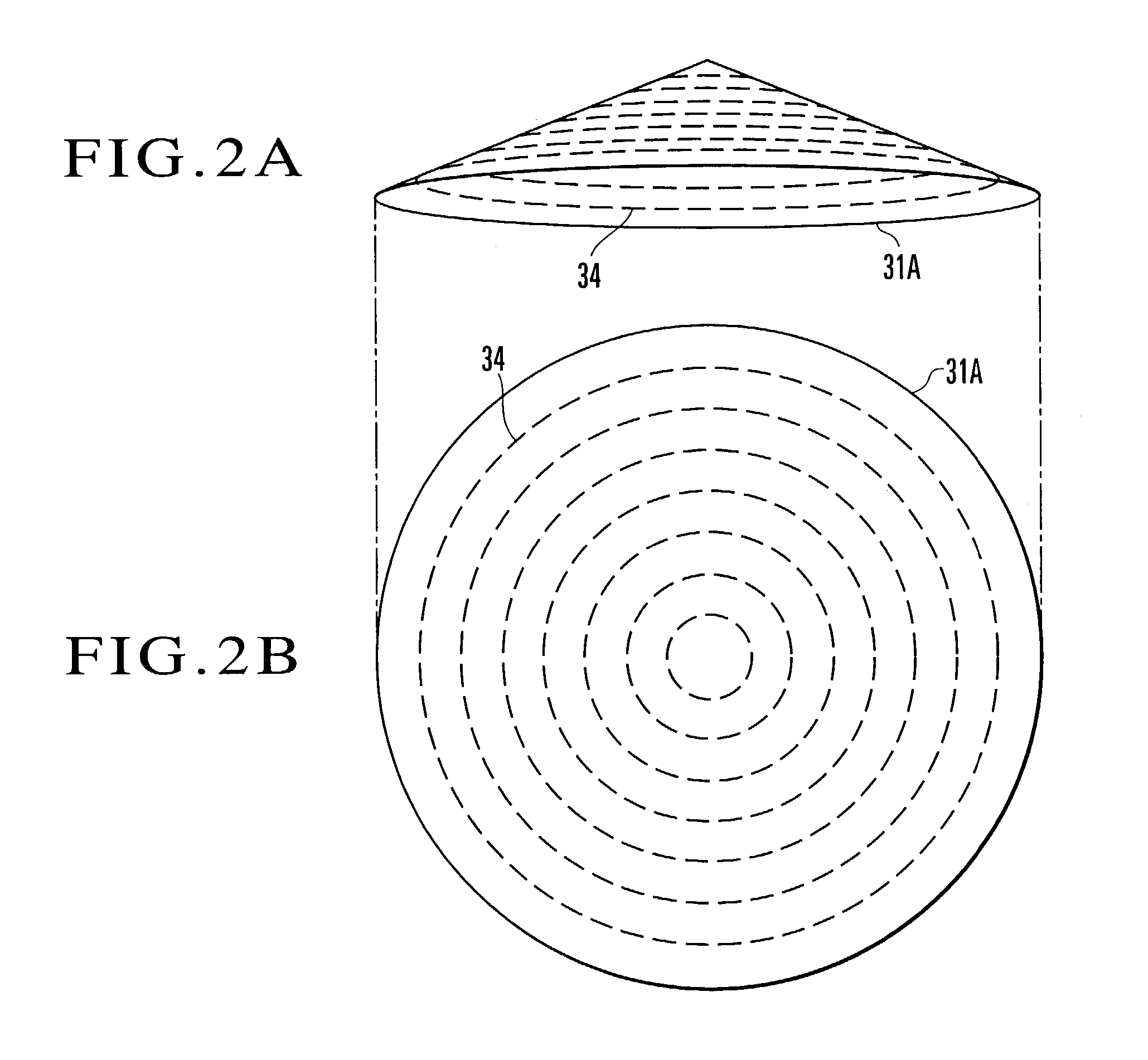

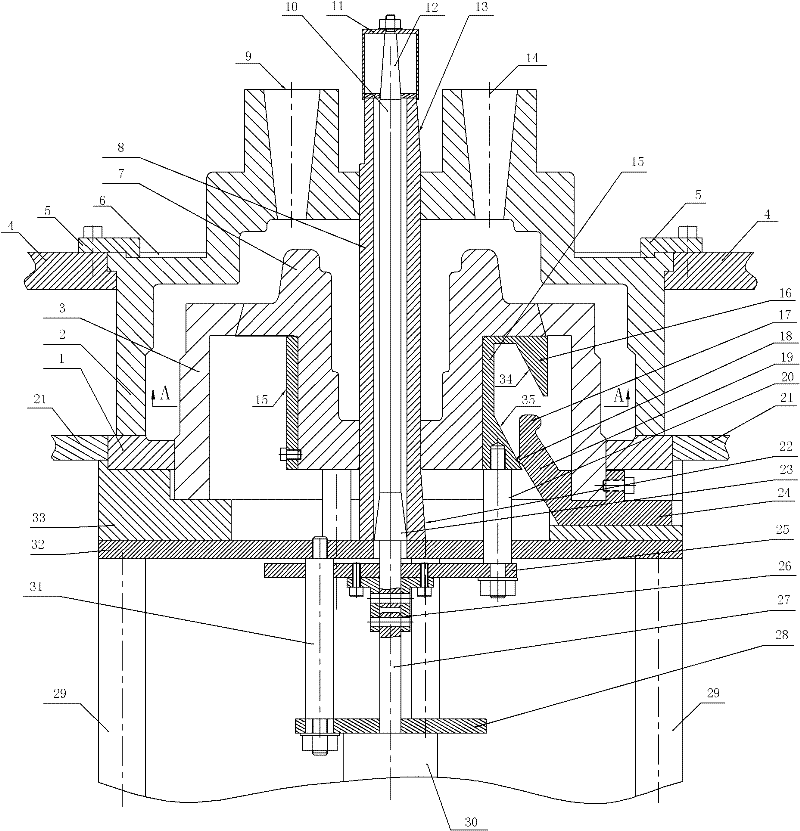

Plasma processing apparatus

InactiveUS7395779B2Increase the electric field strengthImprove electricity efficiencyElectric discharge tubesSemiconductor/solid-state device manufacturingElectricityElectromagnetic field

A first conductive plate (31A) constituting the radiation surface of a slot antenna (30A) inclines with respect to a first dielectric member (13) opposed to the radiation surface of the slot antenna (30A). Consequently, a plasma generated by the electric field of an electromagnetic field entering directly from the slot antenna (30A) can be set dominant over a plasma generated by the electric field of a standing wave formed in a processing vessel (11). Since the former can be controlled more easily than the latter, the plasma distribution can be improved.

Owner:TOKYO ELECTRON LTD +1

Relay device

InactiveUS20020125973A1Reduce molding processReduce the number of partsElectric switchesRelay detailsCommon baseElectricity

A relay device capable of reducing the manufacturing costs thereof by decreasing the number of parts and the number of electrical connections between these parts, and making the manufacturing process simple. The relay device has a plurality of electromagnetic relays and uses a common base plate with which stems of the electromagnetic relays are formed integrally, and on which a wiring member is formed by resin molding. The wiring member on the common base plate is projected from the molded resin to define a fixed contact member of each electromagnetic relay. Each relay unit assembly of each electromagnetic relay except for the fixed contact member thereof is secured to the common base plate such that a movable iron piece is driven in parallel with a surface of the common base plate. The construction of the resultant relay device is compact, the relay properties are readily adjusted, and the number of parts can be reduced.

Owner:ANDEN CORP

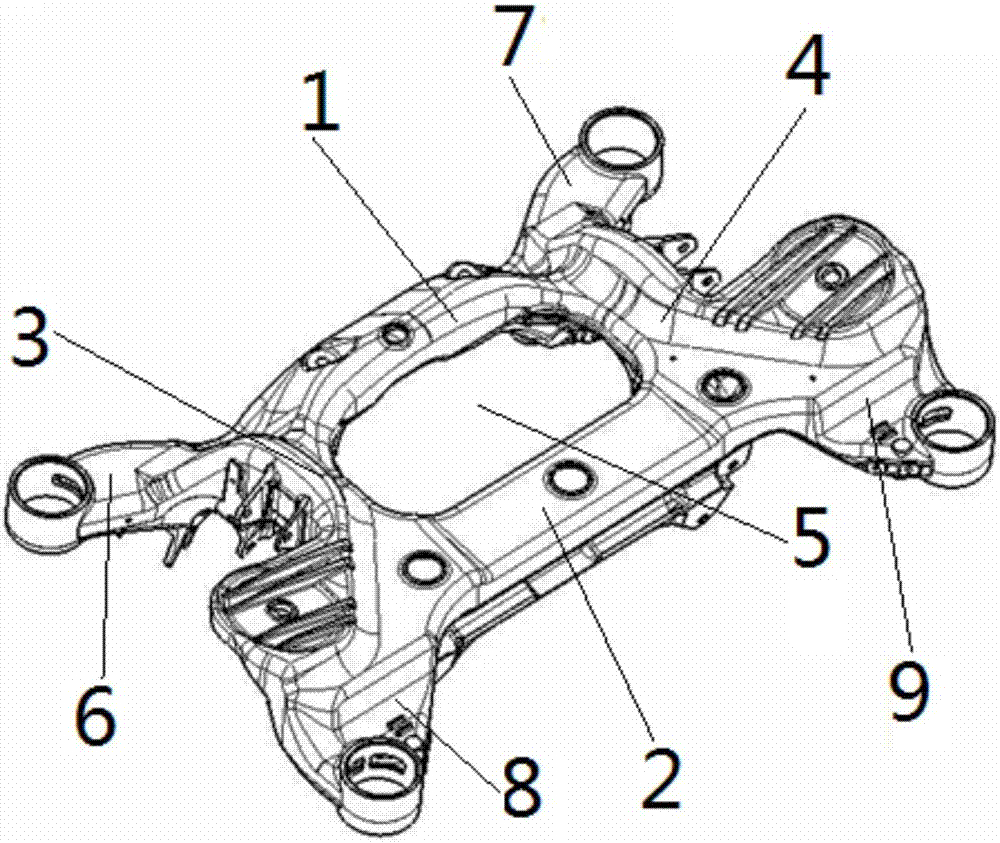

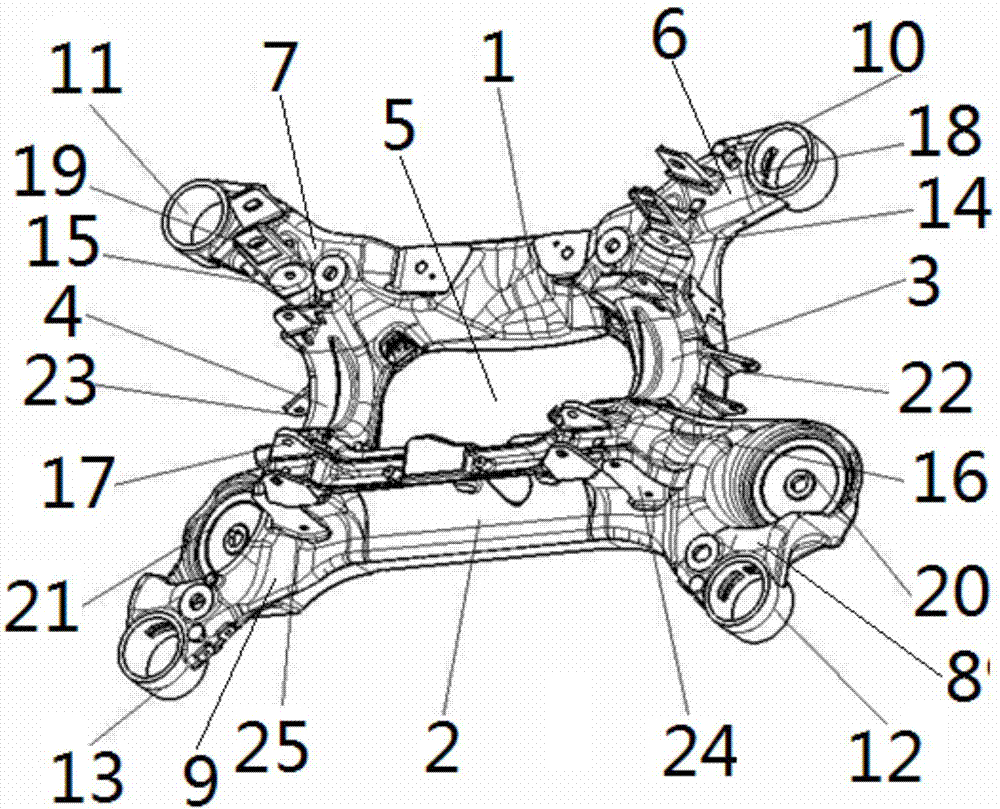

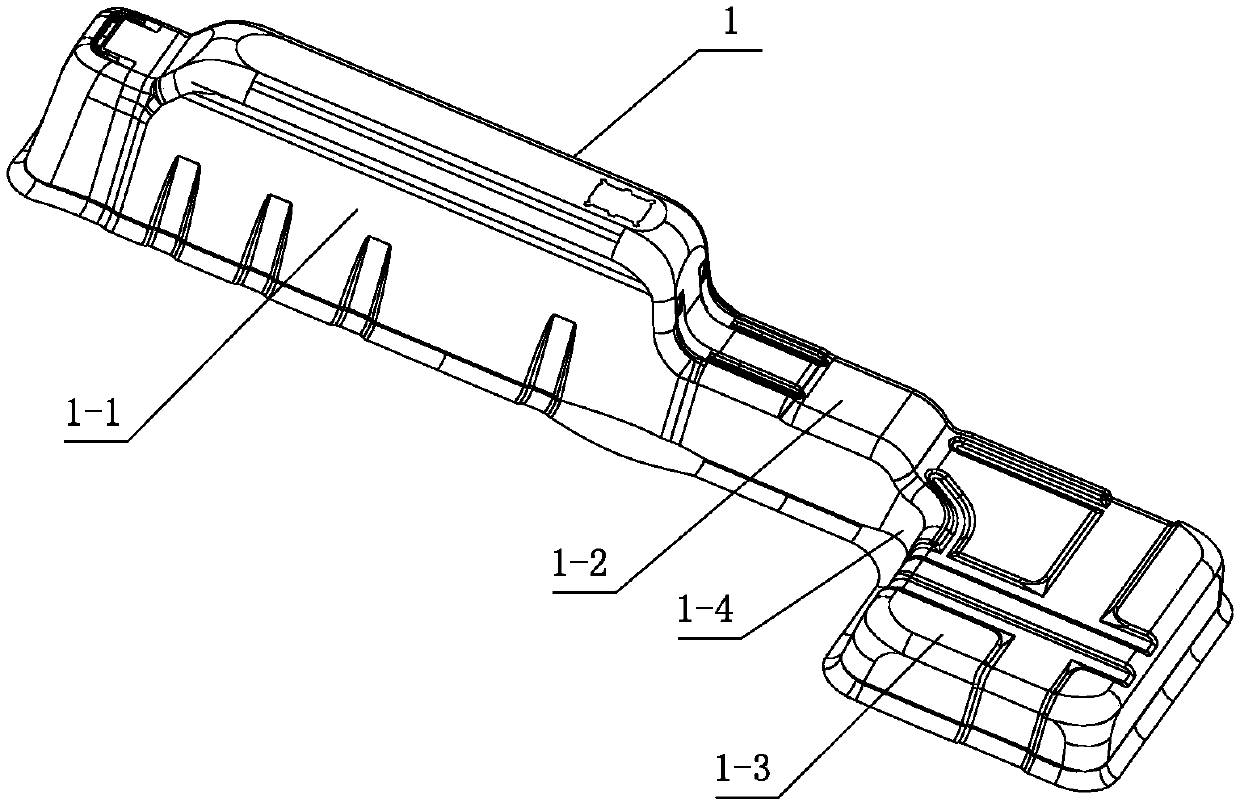

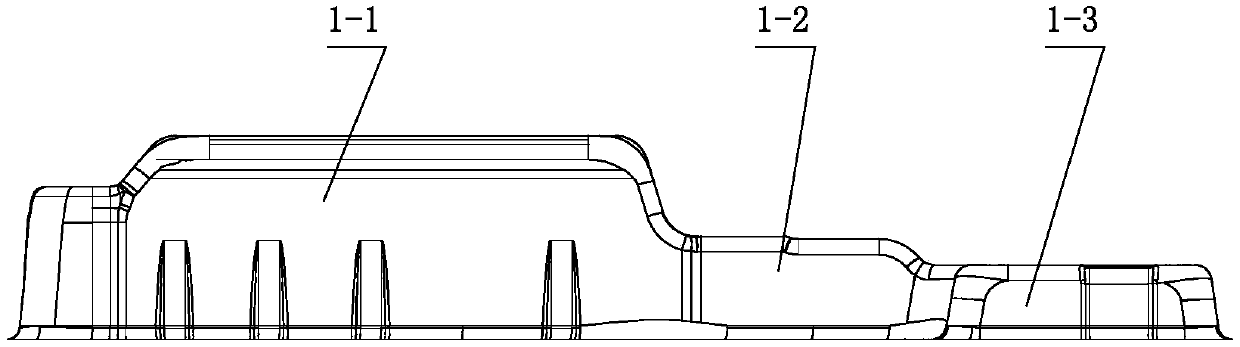

Rear sub-frame of automobile

The invention provides a rear sub-frame of an automobile applied to the technical field of auto parts. A front cross beam (1) is connected with one end of a left longitudinal beam (3) and one end of a right longitudinal beam (4) respectively, a rear cross beam (2) is connected with the other end of the left longitudinal beam (3) and the other end of the right longitudinal beam (4), after the front cross beam (1), the rear cross beam (2), the left longitudinal beam (3) and the right longitudinal beam (4) are connected, a mouth-shaped structure is formed, the front cross beam (1), the rear cross beam (2), the left longitudinal beam (3) and the right longitudinal beam (4) are structures made of aluminum alloy materials, and the rear sub-frame of the automobile is designed into a structure prepared through the integrated molding process. The rear sub-frame of the automobile is simple in structure and low in cost and has the advantages of being ligh, integrally formed, short in molding time, consistent in performance, free or connection defects, high in accuracy and the like. When collision occurs, the rear sub-frame of the automobile can effectively absorb external impact, and the safety of passengers is ensured when the whole automobile is in use.

Owner:ZOTYE INT AUTOMOBILE TRADING CO LTD

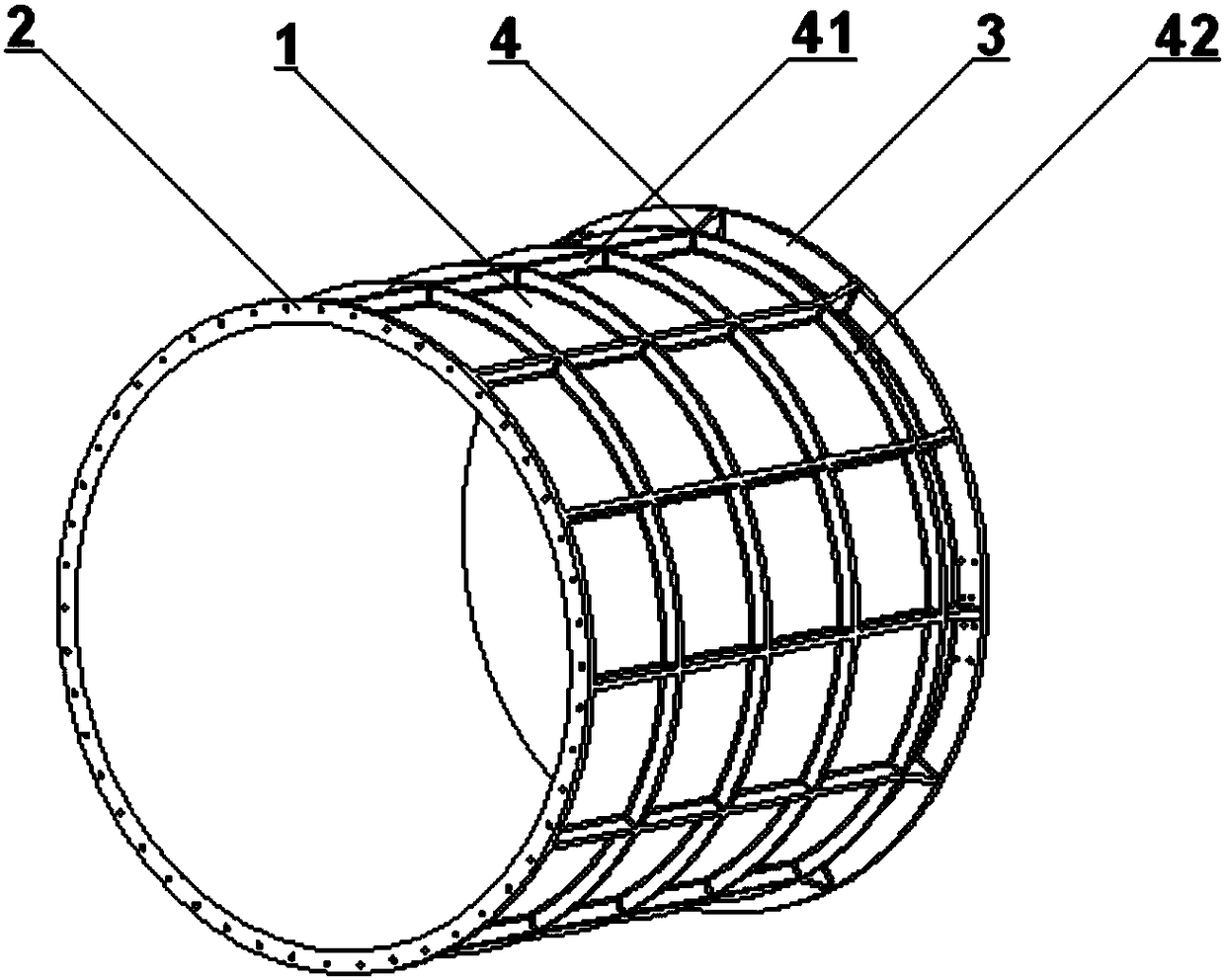

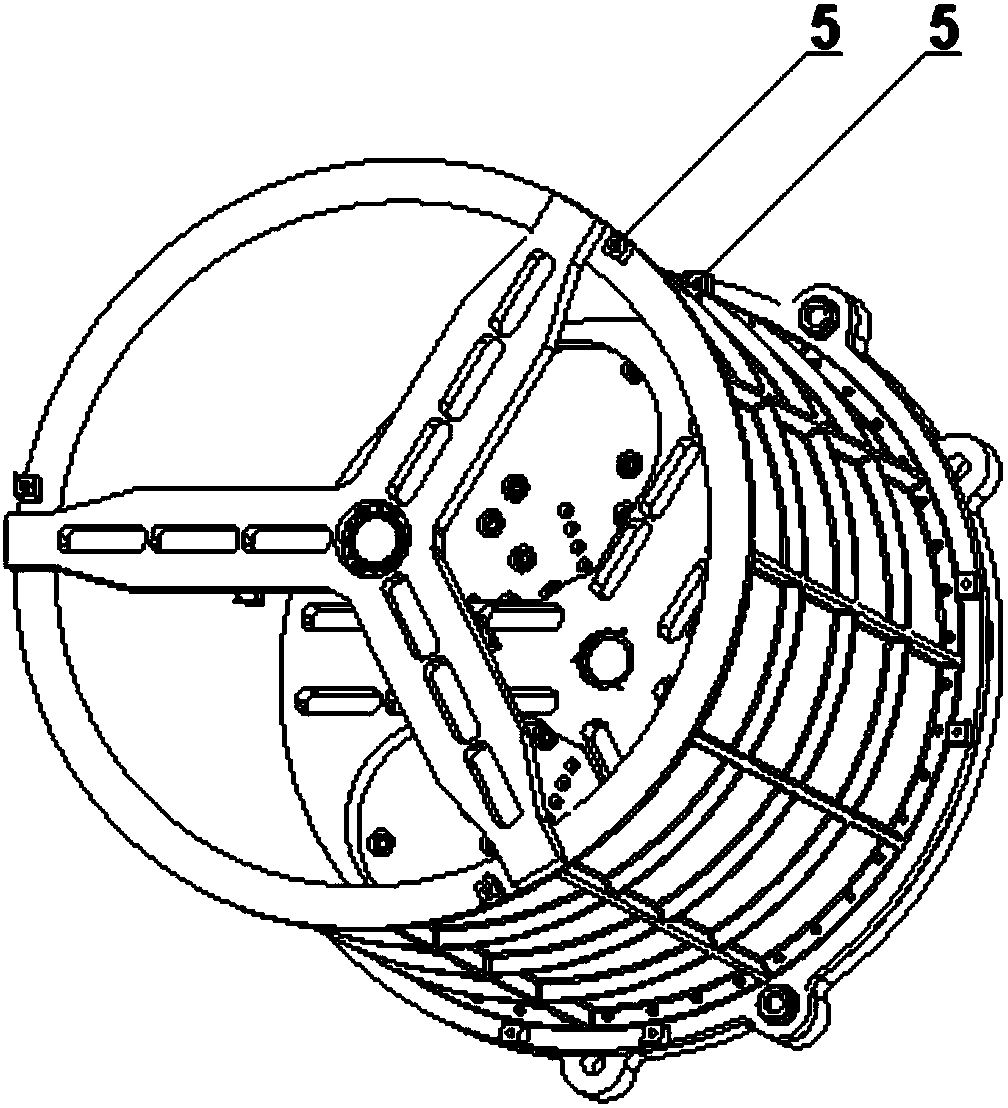

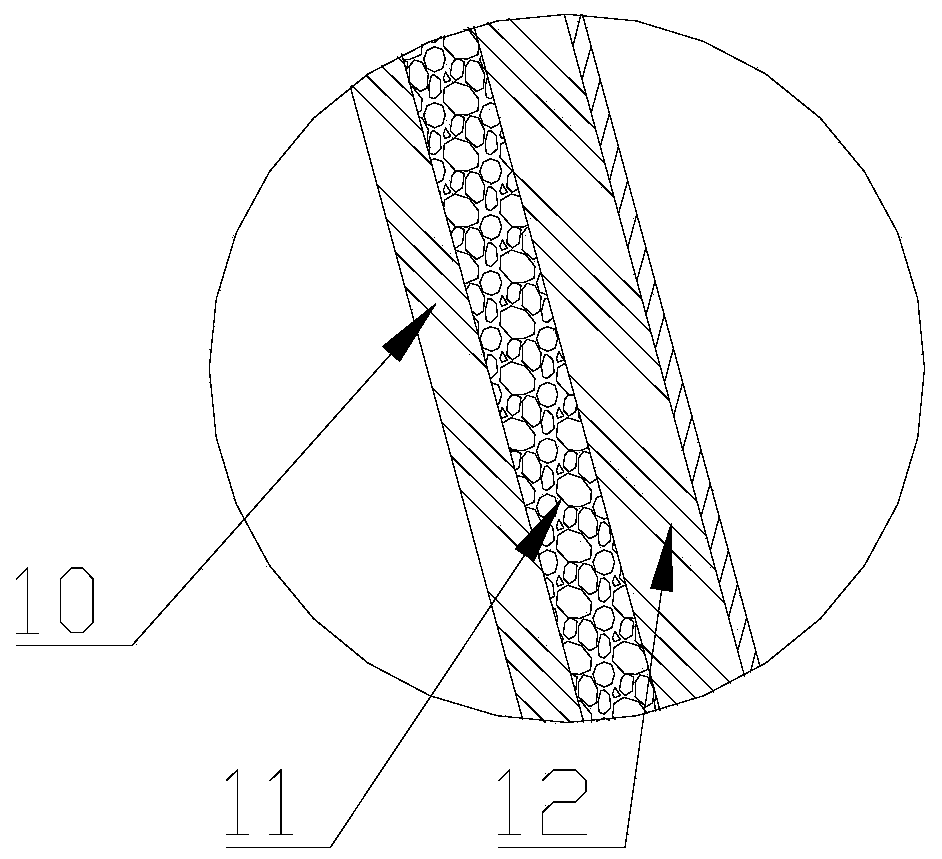

High rigidity and light space camera lens cylinder and test method for vibration resistance stability thereof

ActiveCN109387997AImprove stabilitySmall axial length changeOptical apparatus testingVibration testingCamera lensEntire lens

The invention discloses a high rigidity and light space camera lens cylinder and a test method for vibration resistance stability thereof. The cylinder comprises a cylinder body, a main mirror flange,a secondary mirror flange and a reinforcing rib. The cylinder body is a hollow cylinder. One end of the cylinder body is provided with a main mirror flange for connecting a space camera main mirror,and the other end of the cylinder is provided with the secondary mirror flange for connecting the space camera secondary mirror. The outer side of the cylinder body is provided with a reinforcing ribfor reinforcing the structure. The cylinder body, the main mirror flange, the secondary mirror flange and the rib are integrally formed by three-dimensional braiding silicon carbide. According to theinvention, the overall structure of the lens cylinder is optimized by integrally forming the cylinder body, the flanges and the reinforcing rib through using the three-dimensional braiding of siliconcarbide materials, and the defect that the traditional metal support structure is too heavy and has a large self-expansion coefficient is overcome; by designing the vibration resistance stability testmethod of the lens cylinder structure, the stability of the entire lens cylinder is ensured; and the problem of quite poor stability of the conventional resin-based composite material is solved.

Owner:BEIJING RES INST OF SPATIAL MECHANICAL & ELECTRICAL TECH

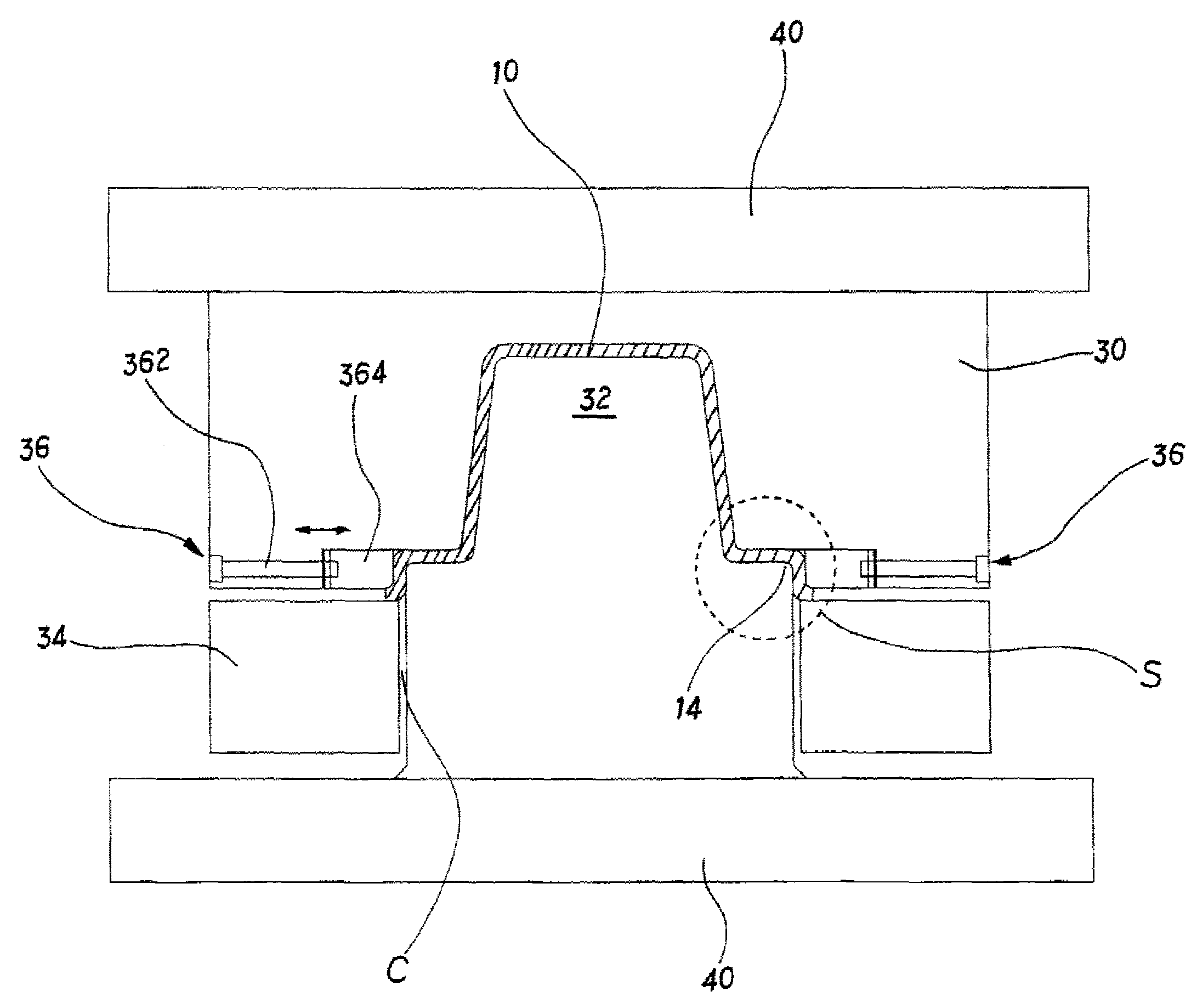

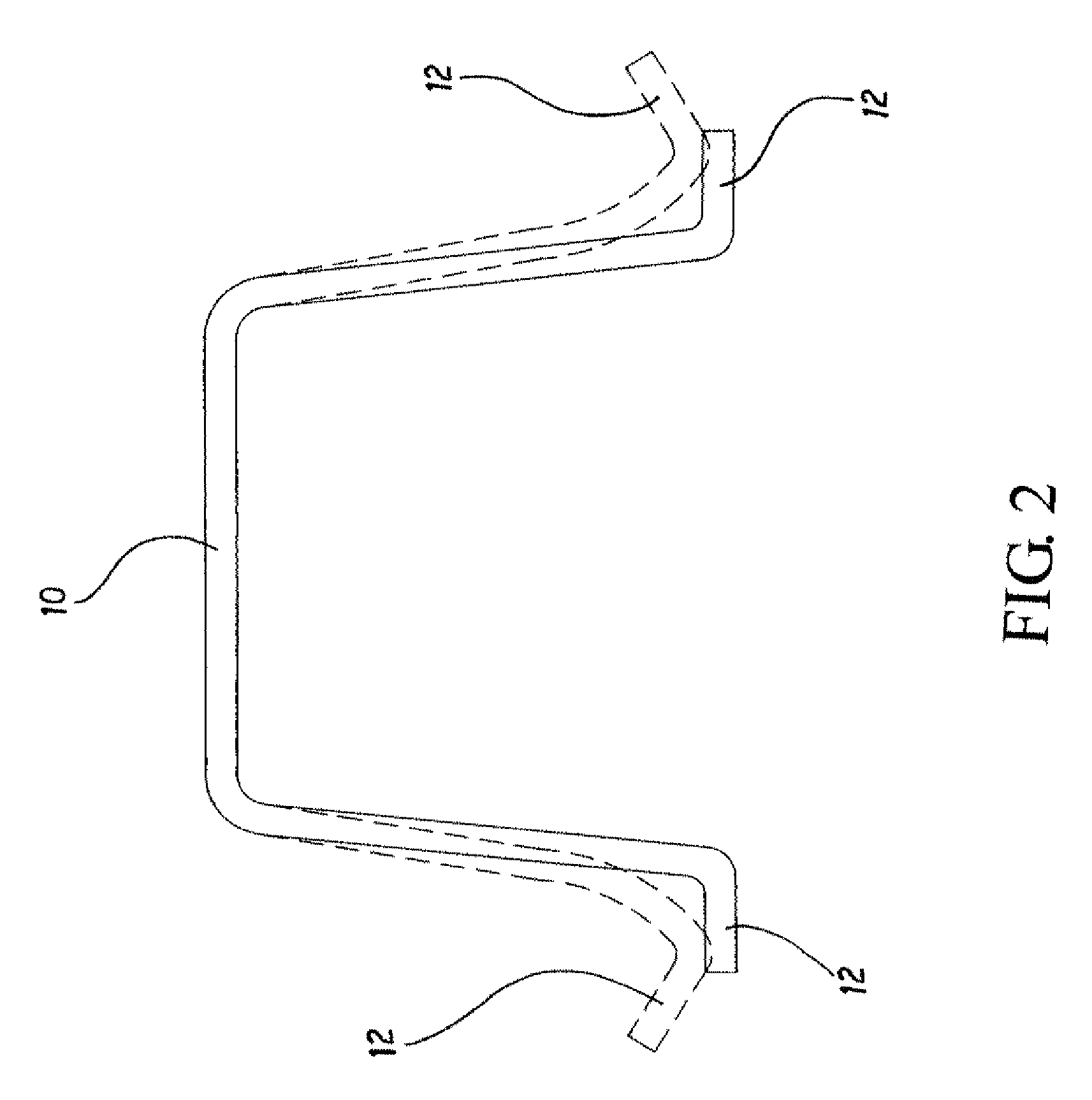

Method for forming high-strength steel into a C-shape

InactiveUS8857237B2Reduce molding processQuality improvementMetal-working feeding devicesPositioning devicesEngineeringHigh intensity

The method is performed by a power press machine composed of a concave die, a convex die with two shoulders and two depressors separately beside the convex die, and includes the steps of: a) placing the high-strength steel (HSS) on the convex die and under the concave die; b) moving the depressors to have two opposite side portions of the HSS clamped between the concave die and the depressors; c) moving the convex die to press the HSS and keeping the side portions immovable; d) forming two steps adjacent to the side portions by the shoulders; and e) cutting off the steps with the side portions.

Owner:WUU SHIANG INDAL

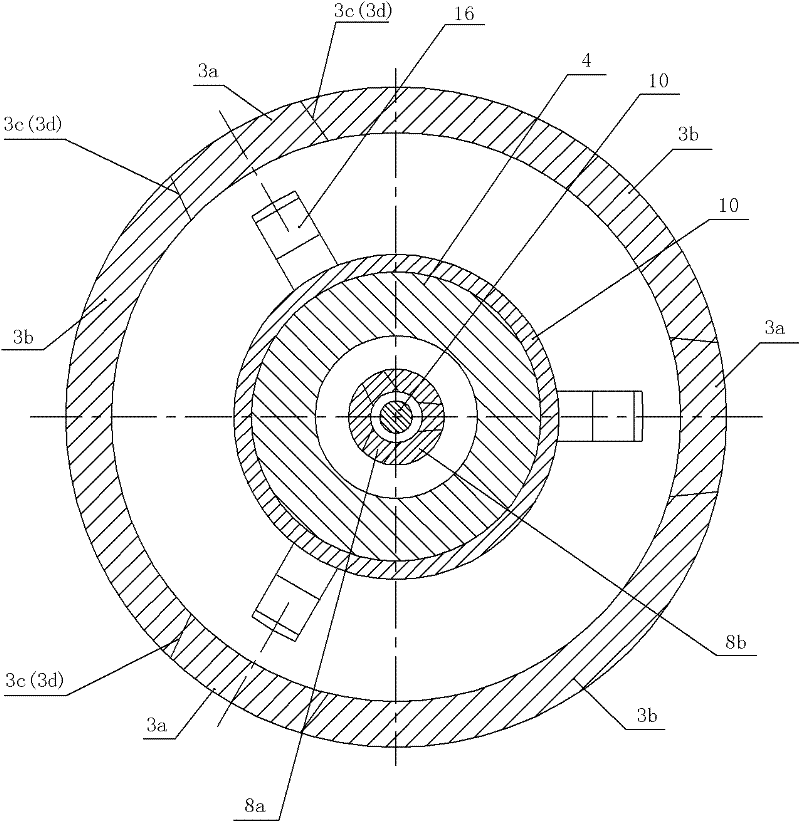

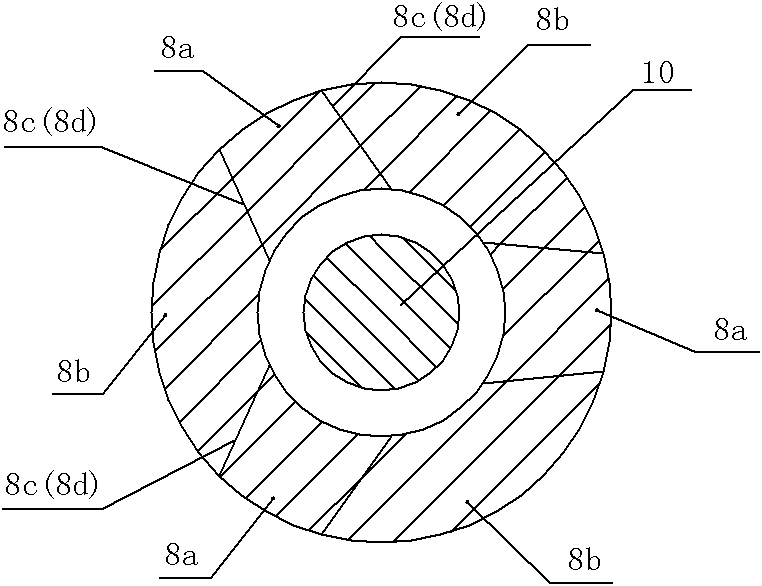

Brake wheel full metal casting mold

InactiveCN102284682AReduce molding processReduce manufacturing costFoundry mouldsFoundry coresPush and pullMetallurgy

The invention provides a brake wheel all metal casting die and relates to a die. The brake wheel all metal casting die comprises an outer metal die, an inner metal die and an inner hole metal die, wherein the outer metal die is used for forming the outer surface of the outer wall of the brake wheel; the inner metal die is used for forming the wall of the inner cavity of the brake wheel; the innerhole metal die is used for forming an inner hole of the brake wheel; the outer metal die comprises an outer metal die I for forming the side face and the upper end face of the outer wall of the brakewheel and an outer metal die II for forming the lower end face of the outer wall; the inner metal die comprises an inner metal die I for forming the outside cavity wall of the inner cavity of the brake wheel and an inner metal die II for forming the inside cavity wall of the inner cavity of the brake wheel and connected with the inner metal die I; the outer wall of the inner metal die II is connected with a control piece capable of pulling the inner metal die II to demold; and through holes for accommodating the inner hole metal die are formed in the middle parts of the outer metal die I and the inner metal die II respectively. The casting die also comprises a pull rod, a pressing sleeve and a piston rod, wherein the pull rod is arranged in the through holes of the inner hole metal die; the pressing sleeve is fixedly connected with the top of the pull rod; and the piston rod is connected with the bottom end of the pull rod and is used for pushing and pulling the pull rod and the pressing sleeve so as to demold the inner hole metal die conveniently.

Owner:LIUZHOU ZHIBAO MACHINERY

Method for preparing macromolecule compound die family in use for ceramics

InactiveCN1760008AReduce manufacturing costQuality improvementDomestic articlesUltimate tensile strengthToughness

A process for preparing the composite high-molecular mould used to make ceramic products includes such steps as providing unsaturated polyester resin or silicone rubber, solidifying agent, promoter and filler, copying a sample mould, coating demoulding agent, coating the mixture of gum resin, solidifying agent and promoter, solidifying until it is not adhesive, pouring the mixture of unsaturated polyester resin, solidifying agent, promoter and filler into said sample mould, solidifying and demoulding. Its advantages are high finish degree, strength, toughness and resistance to corrosion and water, and long service life.

Owner:汪志申

Hollow polygon body forming method

InactiveCN1554512ASolve the problem of taking outLow costOther manufacturing equipments/toolsRoadway safety arrangementsPunchingButt joint

The hollow prism forming method includes punching one side of metal plate with one upper punching mold and one lower punching mold to form one folded angle for two planes of the prism, punching the other side of the metal plate with the molds to form the other folded angle, repeating the punching process for several times to form one prism with opened mouth, and finally welding the two butt jointed planes. Similarly, hollow prism with circular surface may be formed. The said forming process has less steps, and the formed prism has high strength and high quality.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

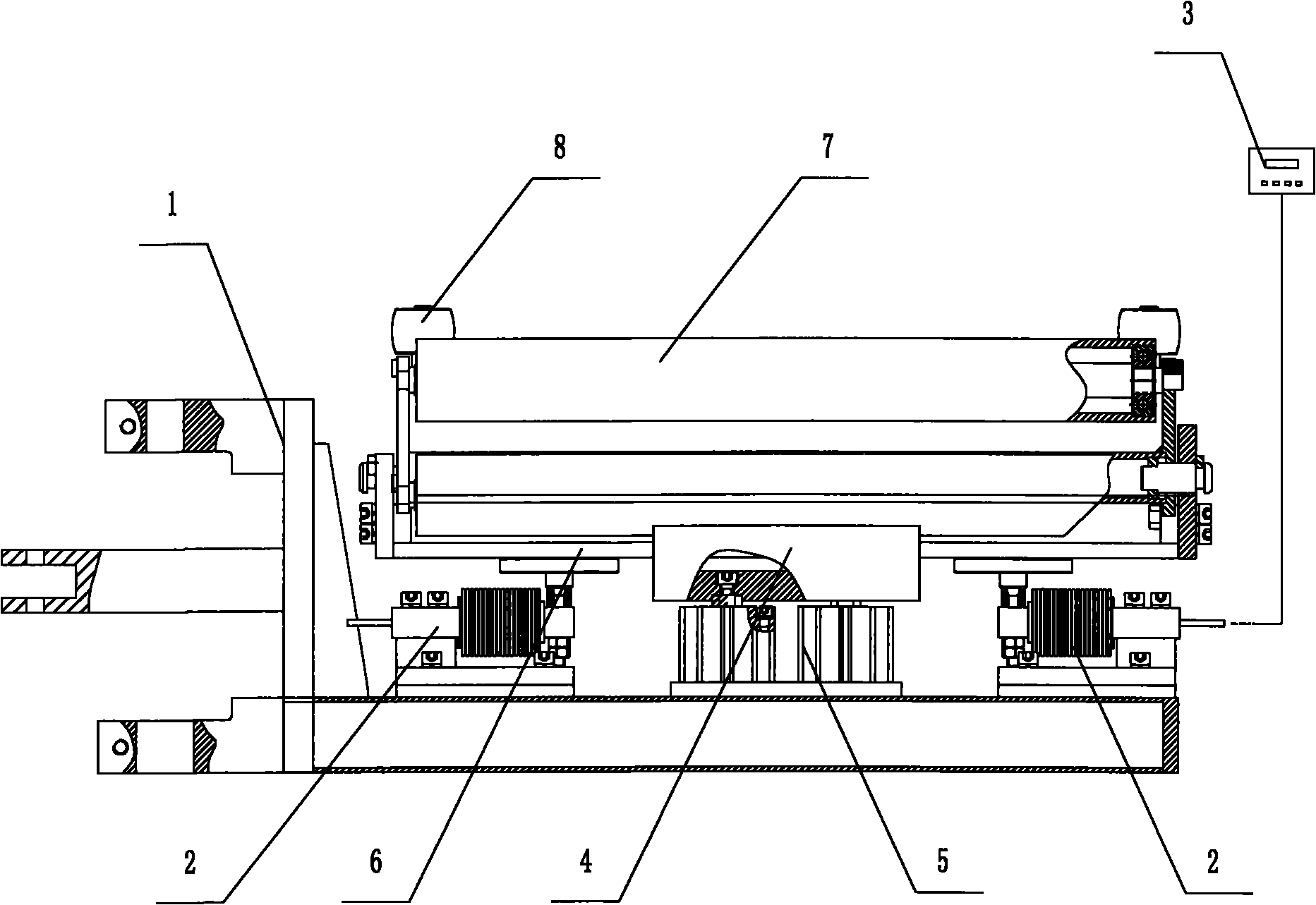

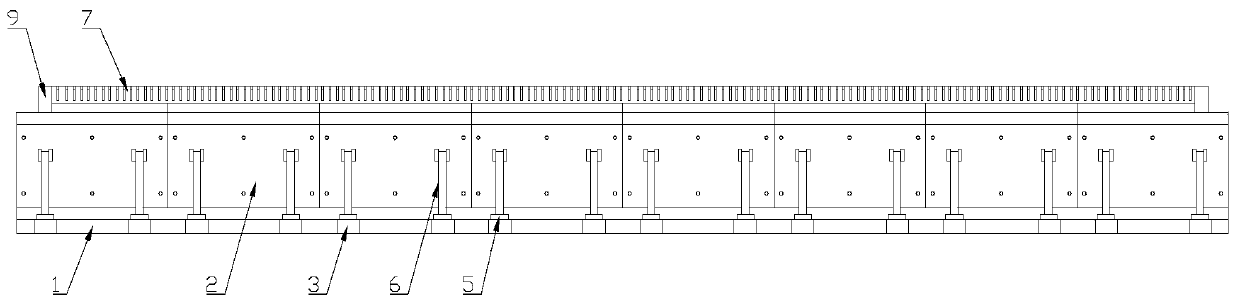

One-time thermal lamination molding device for middle rubber and covering rubber of rubber conveyor belt of steel wire rope core

The invention discloses a one-time thermal lamination molding device for middle rubber and covering rubber of a rubber conveyor belt of a steel wire rope core, aiming at solving the problem that the efficiency of an existing device is low. The one-time thermal lamination molding device is characterized by being sequentially composed of a canvas sending frame, a four-roller calender, a deviation correction and tensioning device, a three-roller calender, a six-roller cooling roller machine and a double-station crimping machine, wherein the canvas sending frame is used for sending a rubber piece cloth liner; the four-roller calender is used for molding the middle rubber; the deviation correction and tensioning device is used for deviation correction, conveying, tensioning and guiding of the cloth liner and a rubber piece of the middle rubber; the three-roller calender is used for rubber discharging of a covering rubber piece and thermal lamination of the middle rubber and the covering rubber; and the six-roller cooling roller machine is used for cooling the rubber piece, and the double-station crimping machine is used for crimping the two types of laminated rubber pieces. With the adoption of the one-time thermal lamination molding device, one path of procedure on a molding platform is reduced and a process is simplified; through one-time thermal lamination, the density and lamination quality of the rubber piece are guaranteed; and the staying time of the rubber pieces and secondary heating in a lamination process are reduced, energy conservation and environment protection are realized, and the sticking effect is relatively good.

Owner:ANHUI ZHONGYI RUBBER BELTS

Forming die for upper shell of automobile battery box

The invention discloses a forming die for an upper shell of an automobile battery box. A first stretching die assembly for stretching a section I with the maximum height part on the upper shell of theautomobile battery box for the first time, a second stretching die assembly used for secondary stretching for integrally forming the upper shell of the automobile battery box and a shaping die assembly used for carrying out shaping of arc transition on corners of a formed product are sequentially arranged between an upper die assembly and a lower die assembly, wherein a first upper die of the first stretching die assembly, a second upper die of the second stretching die assembly and a shaping upper die of the shaping die assembly are all connected to the upper die assembly, and a first lowerdie of the first stretching die assembly, a second lower die of the second stretching die assembly and a shaping lower die of the shaping die assembly are all connected to the lower die assembly. Therefore, the production efficiency is greatly improved, the production cost is saved, the welding defect is avoided, and the risk of airtight leakage is also avoided.

Owner:ZHEJIANG SHUNSHI AUTOMOBILE TECH

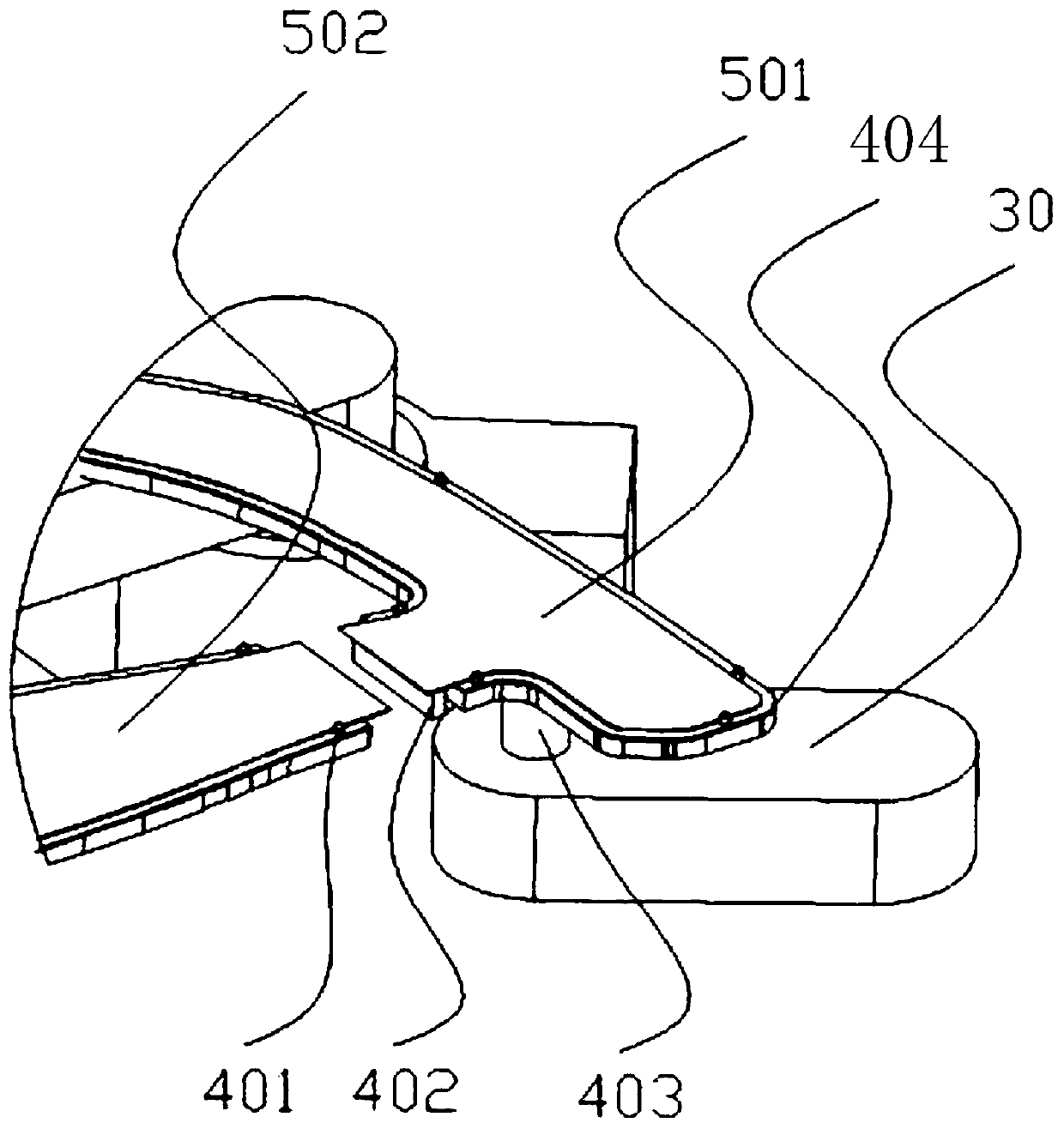

Different-direction flattening forming device for hot pipe

PendingCN107413956AImprove performance yieldReduce consumptionShaping toolsHeat exchange apparatusEngineeringHorizontal orientation

The invention relates to a different-direction flattening forming device for a hot pipe. The different-direction flattening forming device comprises an upper die plate, a horizontal-direction flattening assembly, a horizontal-direction flattening conversion assembly, a vertical-direction flattening assembly and a lower die plate. The horizontal-direction flattening assembly comprises two horizontal-direction flattening blocks. The horizontal-direction flattening conversion assembly comprises two horizontal-direction flattening conversion blocks. The vertical-direction flattening assembly comprises a first vertical-direction flattening block and a second vertical-direction flattening block. The two horizontal-direction flattening conversion blocks and the first vertical-direction flattening block are fixed to the upper die plate, the two horizontal-direction flattening blocks are symmetrically located on the lower die plate, and the second vertical-direction flattening block is fixed to the lower die plate. By means of the different-direction flattening forming device for the hot pipe, the different-direction flattened hot pipe is directly formed at a time, the forming process is omitted, labor force is saved, energy consumption is reduced, the manufacturing cost is saved, the product production efficiency is improved, meanwhile, the problem that the surface of the hot pipe is inwards concaved is solved, and the performance yield of the different-direction flattened hot pipe is greatly improved.

Owner:SUZHOU YONGTENG ELECTRONICS PROD

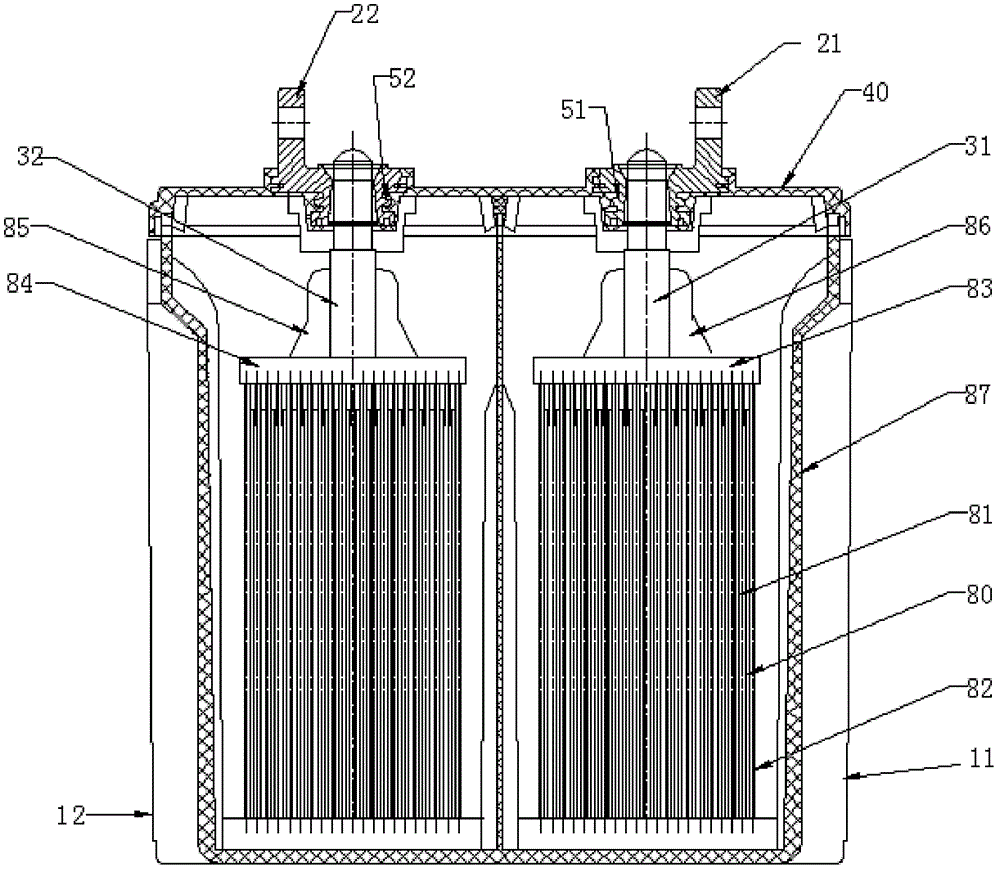

Lead-acid battery and manufacture method thereof

InactiveCN102723529AEasy to implementReduce molding processFinal product manufactureCell component detailsState of artEngineering

The invention discloses a lead-acid battery, which includes a battery body and an external terminal. The battery body includes poles and a battery cover; the battery cover is provided with through holes; the cell body comprises an anode part and a cathode part; the poles comprise a positive pole in the anode part and a negative pole in the cathode part; the through holes include an anode hole and a cathode hole; the external terminal includes integrally molded lead sleeve and terminal; and the poles pass through the through holes and are connected with the lead sleeve. The external terminal and the lead sleeve provided by the invention are integrally molded, so as to save a molding process and reduce a welding procedure compared with the prior art of split design, thereby avoiding safety hidden dangers caused by improper welding process or pores, cracks or oxide inclusions in welding point.

Owner:ANHUI LEOCH POWER SUPPLY

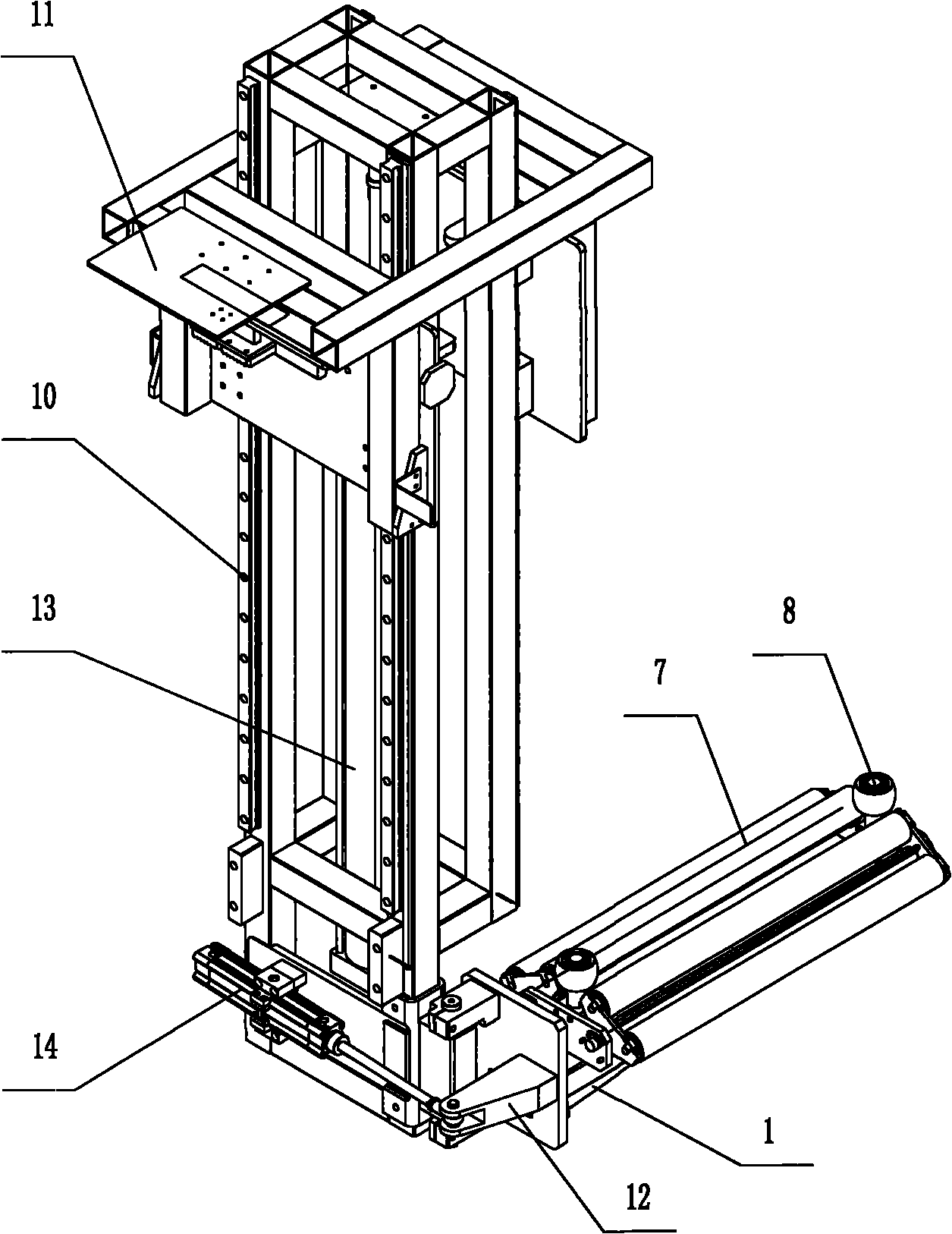

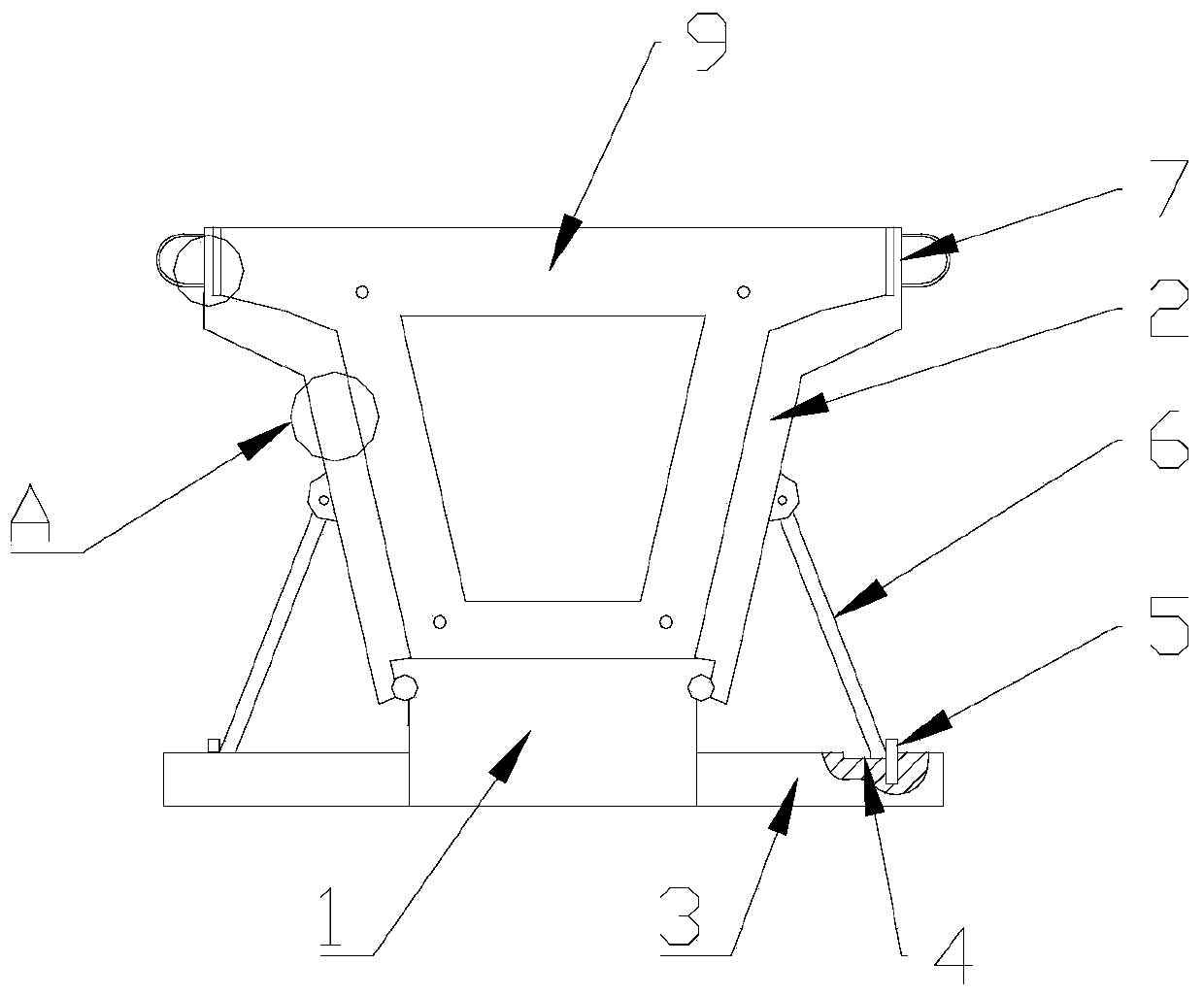

Tire removing apparatus for realization of on-line weighing measurement and method used by same

InactiveCN102371694ARealize online weighing measurementImprove accuracyTyresEngineeringControl circuit

The invention provides a tire removing apparatus for realization of on-line weighing measurement and a method used by the same. According to the invention, a weighing measurement sensing mechanism and tire removing parts are integrated so as to realize on-line weighing measurement during the process of tire removal, which enables on-site operation space to be saved, measurement data to be accurate and extra labor of operation staff not to be needed. Tire weight data obtained in on-line weighing measurement can be directly displayed on a measurement control circuit to provide references for on-site production management and evaluation of molding quality of tires. According to the invention, the tire removing apparatus comprises a hanger connected with a tire building machine and used for horizontal movement, a support vertically connected with the hanger and a cantilever arranged at the end of the support and used for unloading tires from the tire building machine; at least two sets of sensor assembly symmetrically arranged and connected with an external weighing measurement circuit are installed at a horizontal end of the lateral part of the cantilever; at least two sets of tire holding roller assembly used for unloading tires are fixedly installed above the sensor assembly through a horizontal connection rack.

Owner:MESNAC

Large-span box girder forming die and forming process

InactiveCN109797656AEasy to assembleEasy to splitBridge erection/assemblySurface stressWeather resistance

The invention discloses a wet joint dabbing-free conveniently assembled and disassembled large-span box girder forming die and a forming process using the die for casting a box girder to overcome theshortcomings of the prior art. The box girder forming die is conveniently assembled and disassembled. Besides, the actual die is not easy to damage or deform and high in reuse rate. Side plates of thebox girder have heat insulation and shock absorption functions, on one hand, weather resistance is greatly enhanced, on the other hand, part of surface stress formed in the casting and vibrating process can be offset, and the surface quality of the box girder is comprehensively improved. A wet joint baffle plate is matched with a reticulated stainless steel plate, an original manual dabbing process can be omitted, a wet joint connecting surface is more uniform and reliable, manpower, material resources and construction period are reduced by the forming process provided according to a designedformwork, construction cost is reduced, and the forming process has higher economic values.

Owner:江苏瑞沃建设集团有限公司

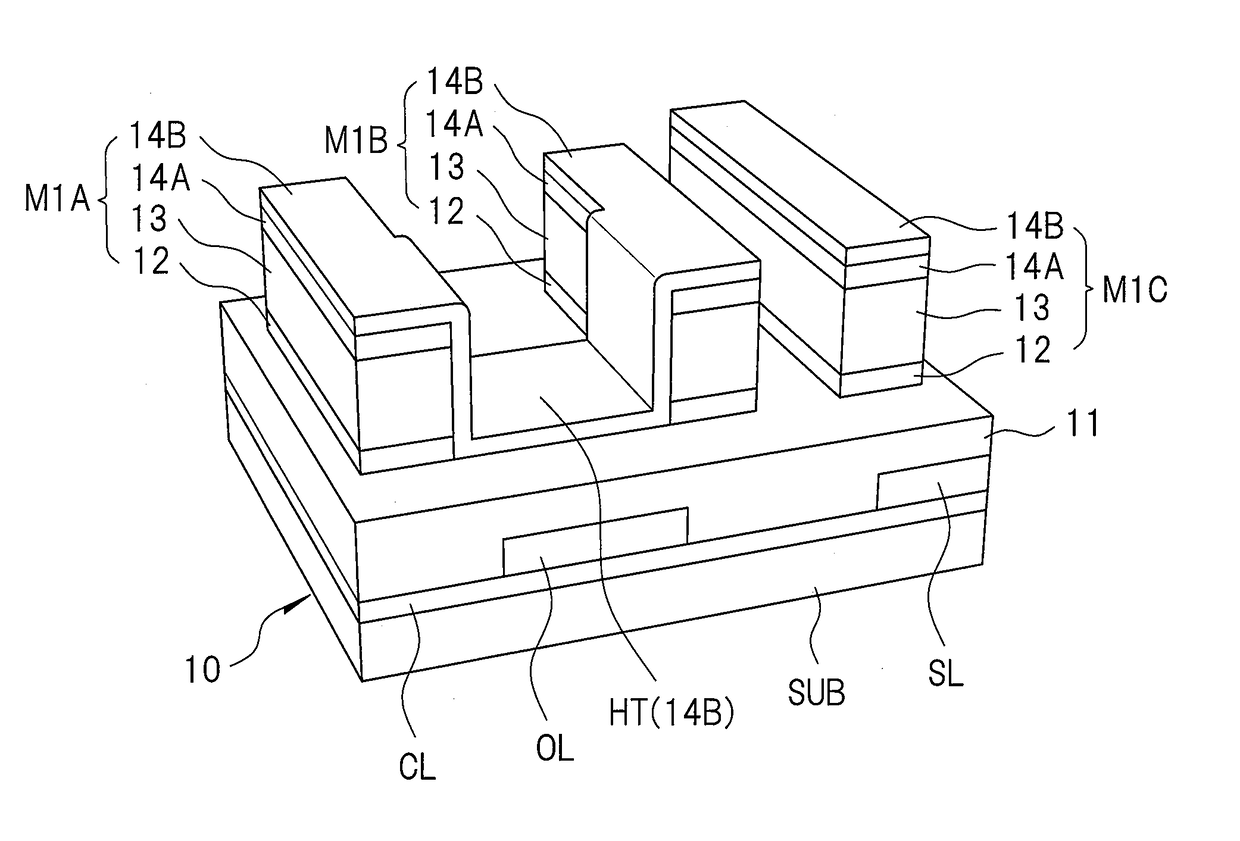

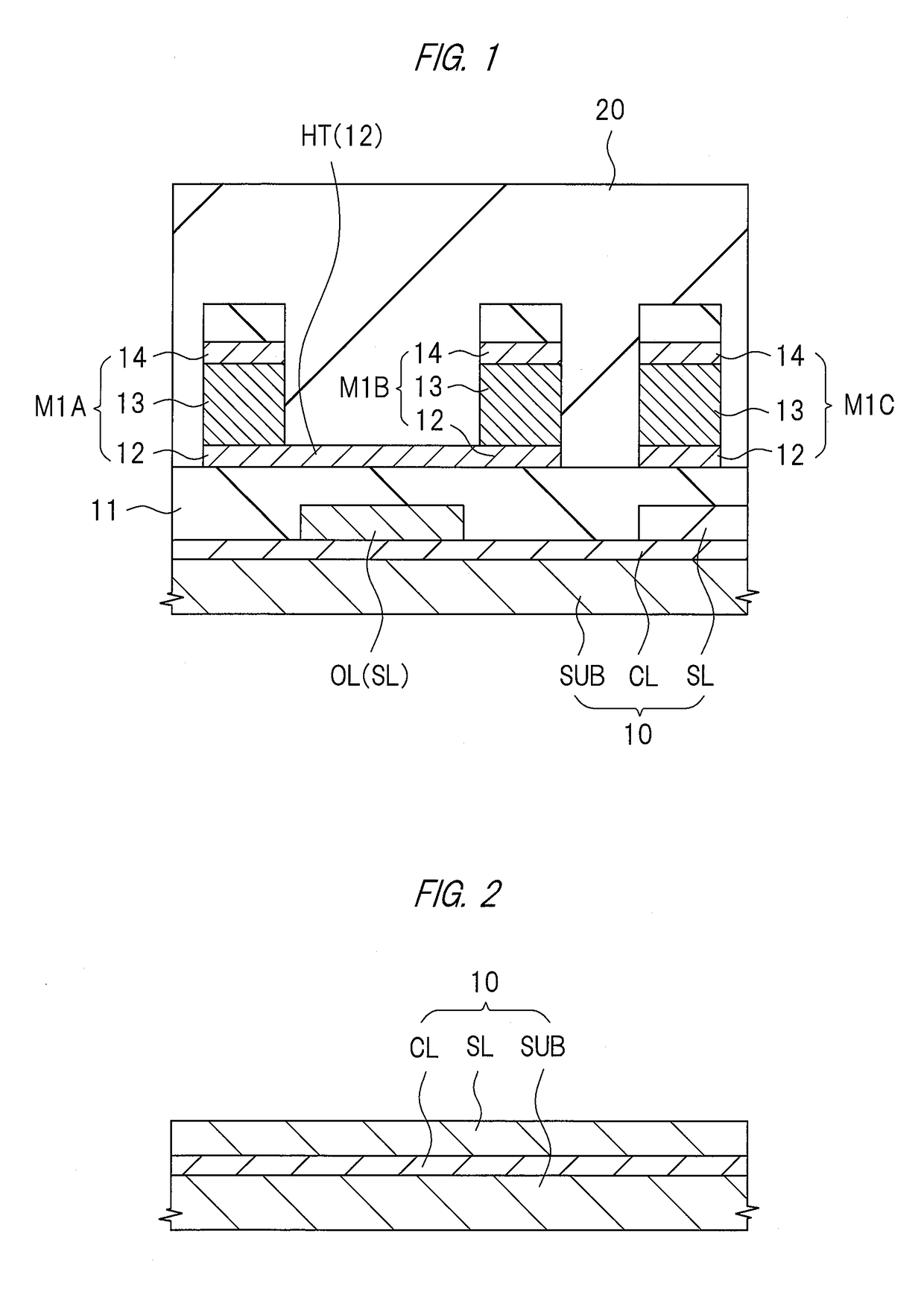

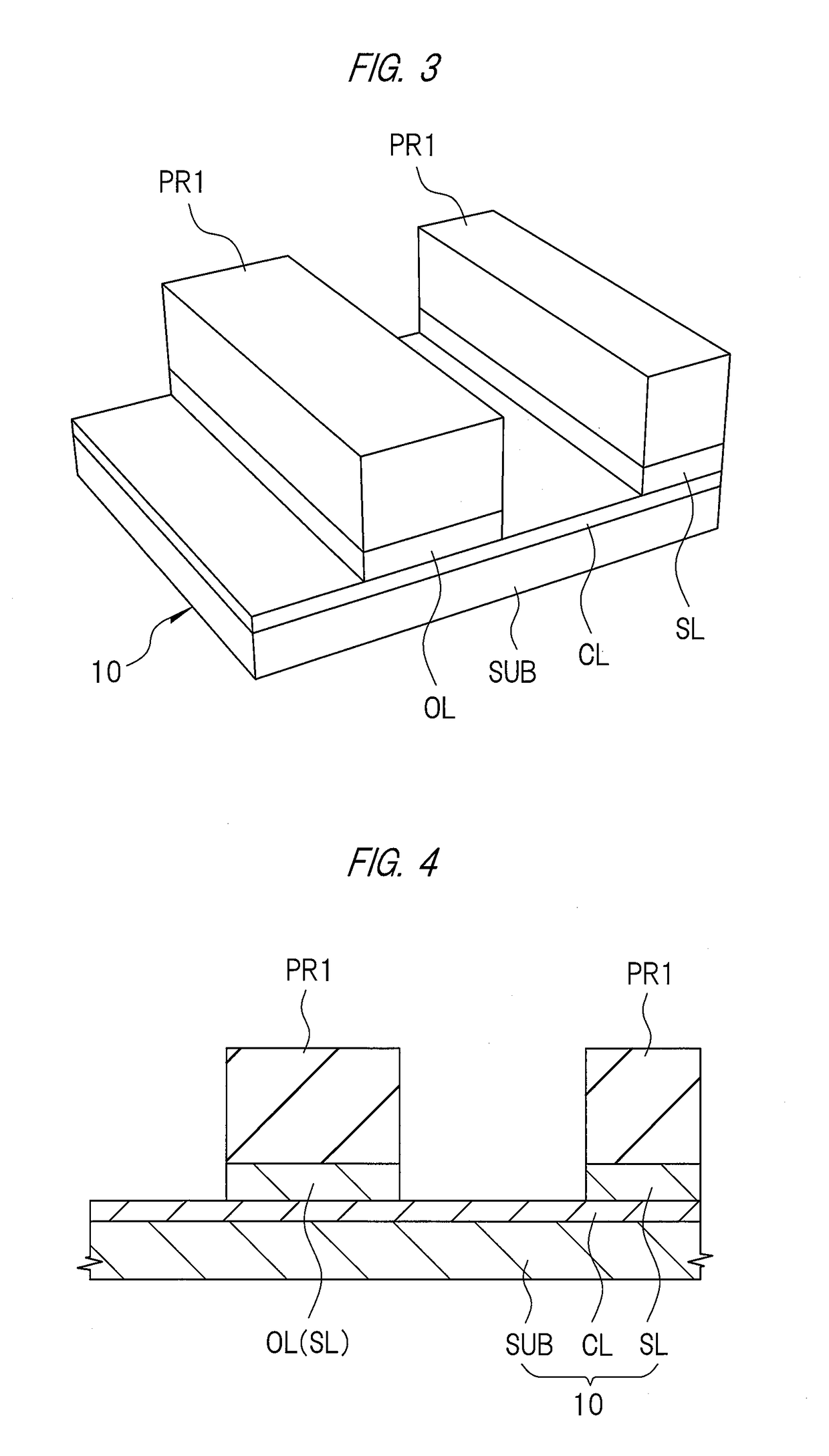

Semiconductor device and manufacturing method thereof

ActiveUS20170287934A1Increase manufacturing costReduce molding processSemiconductor/solid-state device detailsSolid-state devicesSoi substrateSilicon oxide

An optical waveguide for optical signals is formed in a semiconductor layer of an SOI substrate, a heater for heating the optical waveguide is formed on a silicon oxide film which covers the optical waveguide, and wirings for supplying power to the heater are connected to both ends of the heater. Each of the wirings is constituted of a laminated film of a bottom barrier metal film, an aluminum-copper alloy film serving as a main conductive film and a top barrier metal film, and the heater is constituted integrally with the bottom barrier metal film constituting a part of each of the wirings.

Owner:RENESAS ELECTRONICS CORP

Catalyst for synthesizing 2,3,6-trimethylphenol and preparation method thereof

InactiveCN102974354BExtended service lifeReduce usageOrganic chemistryOrganic compound preparationMetacresolAlkali metal oxide

The invention discloses a method for preparing 2,3,6-trimethylphenol, and the 2,3,6-trimethylphenol is an important intermediate of vitamin E. The method comprises the following steps of: enabling a mixture of metacresol, methanol and water to pass a fixed bed reactor containing an o-position methylation catalyst in a liquid space velocity of 0.4-10 h<-1>, and preparing the 2,3,6-trimethylphenol by carrying out a gas solid phase catalytic reaction under a temperature of 280-450 DEG C and a pressure of 0-10 MPa, wherein the o-position methylation catalyst consists of iron oxide, silicon dioxide and alkali metal oxide, and in the oxides, the metal ion molar ratio of iron, silicon, aluminum and alkali metal is equal to 100:(0.1-10):(0.2-5):(0-1). According to a catalyst for synthesizing the 2,3,6-trimethylphenol and a preparation method thereof, the conversion rate of the metacresol for compounding the 2,3,6-trimethylphenol is 100%, the yield of the 2,3,6-trimethylphenol is above 99.9%, and the service life of the catalyst is longer than 3000 hours.

Owner:SOUTHEAST UNIV

A filter injection mold

The invention discloses an injection mold for a filter screen and belongs to the technical field of injection molds. By means of the injection mold for the filter screen, the filter screen can be molded at a time and a cavity is made to be filled with materials. According to the technical scheme, the injection mold is characterized by comprising a movable mold, an intermediate plate and a fixed mold; the movable mold comprises a concave mold fixing plate; the fixed mold comprises a cushion plate; the concave mold fixing plate is provided with a first concave mold; the side, facing the concave mold fixing plate, of the intermediate plate is provided with a second concave mold matched with the first concave mold; the side, deviating from the second concave mold, of the intermediate plate is provided with a runner; the inner side, facing the intermediate plate, of the runner is provided with a secondary runner perpendicular to the intermediate plate; the side, facing the first concave mold, of the intermediate plate is provided with a plurality of fixing rods used for suspension of the filter screen, and the fixing rods are perpendicular to the intermediate plate; and the concave mold fixing plate is provided with first fixing holes matched with the fixing rods.

Owner:NANJING HUASHUN PRECISION MOLD CO LTD

Baking box and forming device and method thereof

InactiveCN111531060AImprove welding efficiencyImprove the efficiency of edge seam weldingOther manufacturing equipments/toolsLaser beam welding apparatusStructural engineeringLaser soldering

The invention discloses a baking box and a forming device and method thereof. The baking box comprises multiple subsidiary boxes, each subsidiary box comprises a tank body provided with an accommodation cavity and a turnup which is arranged around a dead head of the tank body and has a rectangular profile, and a master box which is formed after placing and aligning the subsidiary boxes and weldingthem along a linear splicing seam is installed in a square-shaped framework. The forming device of the baking box comprises a forming platform, wherein the forming platform is provided with a first linear guide rail, a first clamp is slidably arranged on the first linear guide rail, and comprises a first mounting box used for bearing the subsidiary boxes, and a first squeezing mechanism arrangedon the first mounting base, and the first squeezing mechanism is used for pressing the rectangular turnups of the subsidiary boxes to be fitted on the same horizontal plane and closely distributed onthe first mounting base in the mode of transverse and longitudinal arrangement, and is used for welding the linear welding seams among the subsidiary boxes to obtain a laser welding box of the masterbox. By means of the baking box and the forming device and method thereof, the forming procedures of the baking box are reduced, and the processing efficiency is improved.

Owner:ZHEJIANG HOLY LASER TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com