Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

39results about How to "Reduce reheating" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Hot forming steel produced through ESP production line and having tensile strength larger than or equal to 1800 MPa and method

The invention discloses hot forming steel produced through an ESP production line and having tensile strength larger than or equal to 1800 MPa. The steel comprises, by weight percent, 0.28 to 0.40% ofC, 0.15 to 0.40% of Si, 1.40 to 1.60% of Mn, not larger than 0.01% of P, not larger than 0.01% of S, 0.015 to 0.050% of Als, not larger than 0.80% of Cr, not larger than 0.005% of N, 0.002 to 0.005%of B, not larger than 0.50% of Mo, and 0.025 to 0.090% of Nb+Ti. The production method comprises the steps of smelting and continuous casting to form a plate blank; rough rolling; soaking; finish rolling after conventional high-pressure descaling; laminar cooling; heating; punching molding after acid pickling. Nb and Ti are added in a composite manner, elements of Cr, B, Mo and the like in the components are controlled, the ESP short-flow technology is adopted to produce hot stamping forming steel with the tensile strength being 1800 MPa, the mechanical property is ensured, the plate roll repeated heating, uncoiling and other procedures in the production process are reduced, cold rolling and annealing heat treatment procedures are omitted, and production cost is reduced.

Owner:武汉钢铁有限公司

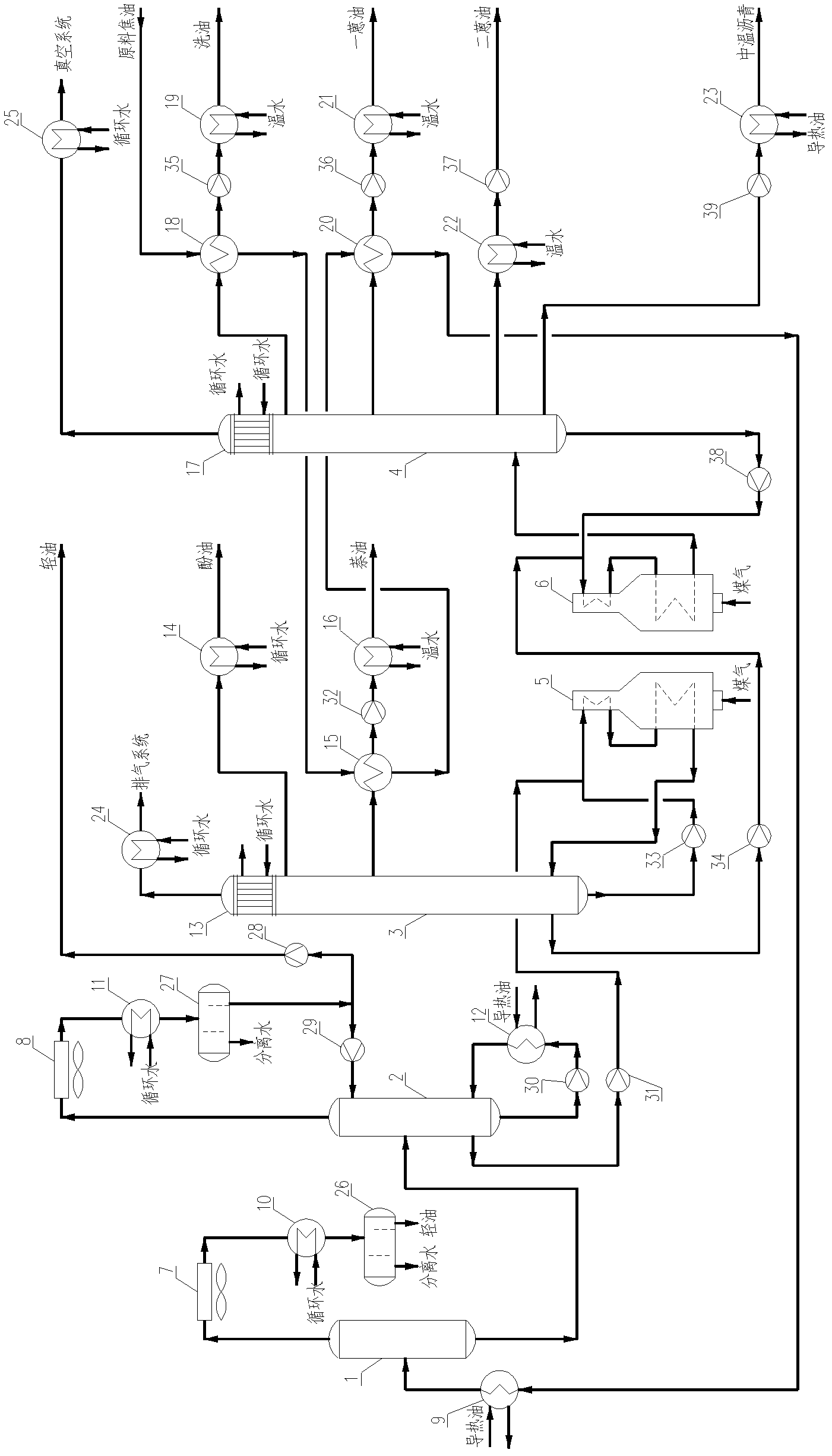

Three-tower type atmospheric-vacuum tar distillation process

InactiveCN102634363AReasonable distributionReduce consumptionTar working-up by distillationReboilerTar

The invention relates to a three-tower type atmospheric-vacuum tar distillation process. A raw material tar is dehydrated to obtain light oil fractions under constant pressure in a pre-dehydrating tower and a dehydrating tower, carrying out constant pressure operation in a No. 1 distillation tower to obtain carbolic oil and naphthalene oil fractions, and carrying out reduced pressure operation in a No. 2 distillation tower to obtain washing oil, primary anthracene oil, secondary anthracene oil and medium-temperature asphalt under or obtain the washing oil, the primary anthracene oil and maltha products. Heats of the pre-dehydrating tower and the dehydrating tower are provided by heat-conduction oil or steam; the heat of the No. 1 distillation tower is circularly provided by tower bottom mixing oil in a No. 1 tube-type heating furnace; and the heat of the No. 2 distillation tower is circularly provided by tower bottom asphalt in a No. 2 tube-type heating furnace. A main device comprises the dehydrating tower, the No. 1 distillation tower, the No. 2 distillation tower, a dehydrating tower reboiler, the No. 1 tube-type heating furnace, the No. 2 tube-type heating furnace, each fraction heat exchanger, a cooler, a pump and the like. The three-tower type atmospheric-vacuum tar distillation process disclosed by the invention has the advantages of being simple and quick in process flow, simple and convenient in operation, low in capital construction investment, energy-saving and environment-friendly, and is suitable for coal tar processing engineering capable of annularly processing anhydrous tar in the scale of more than 2,000,000 tons.

Owner:ACRE COKING & REFRACTORY ENG CONSULTING CORP DALIAN MCC +1

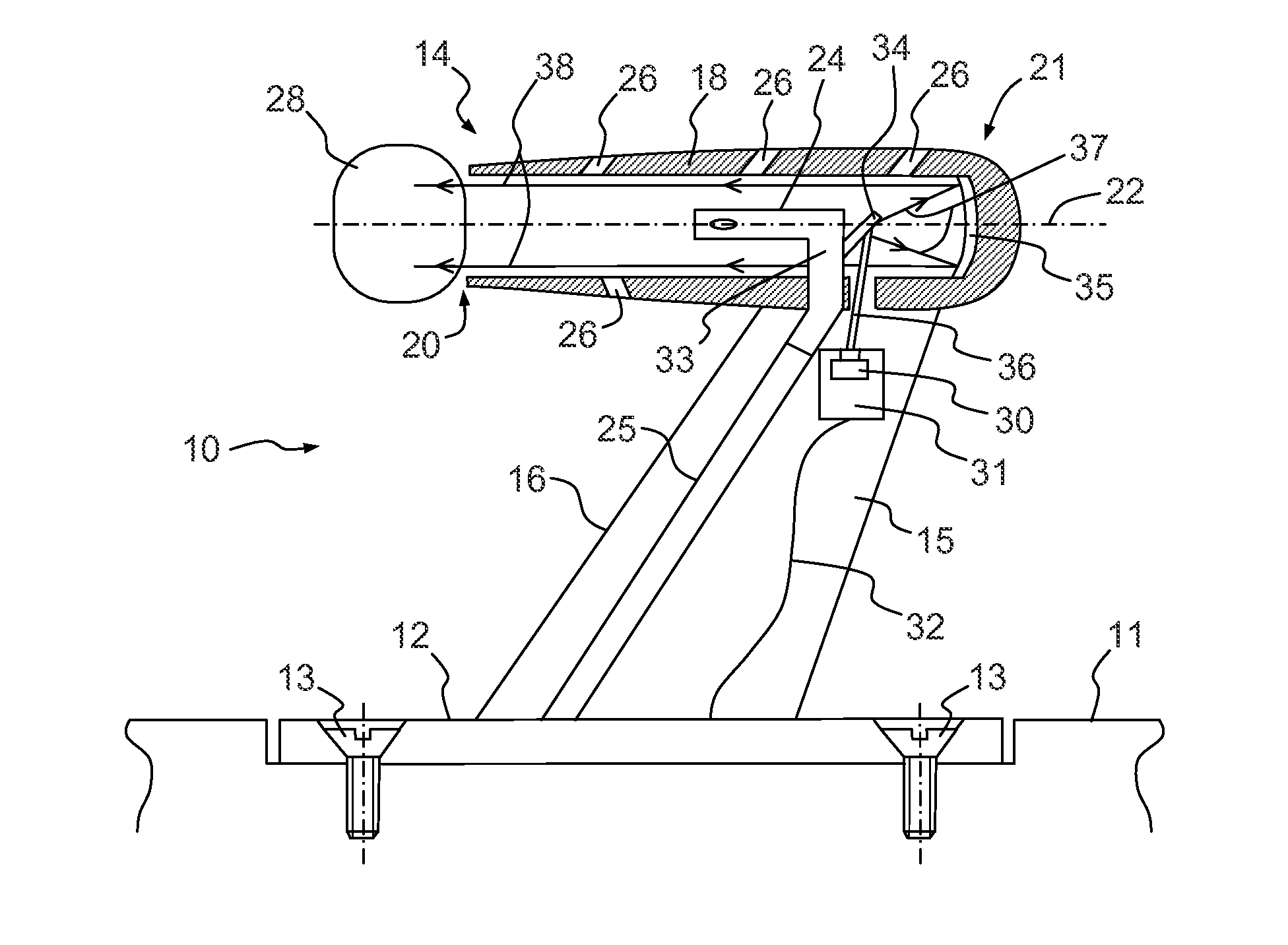

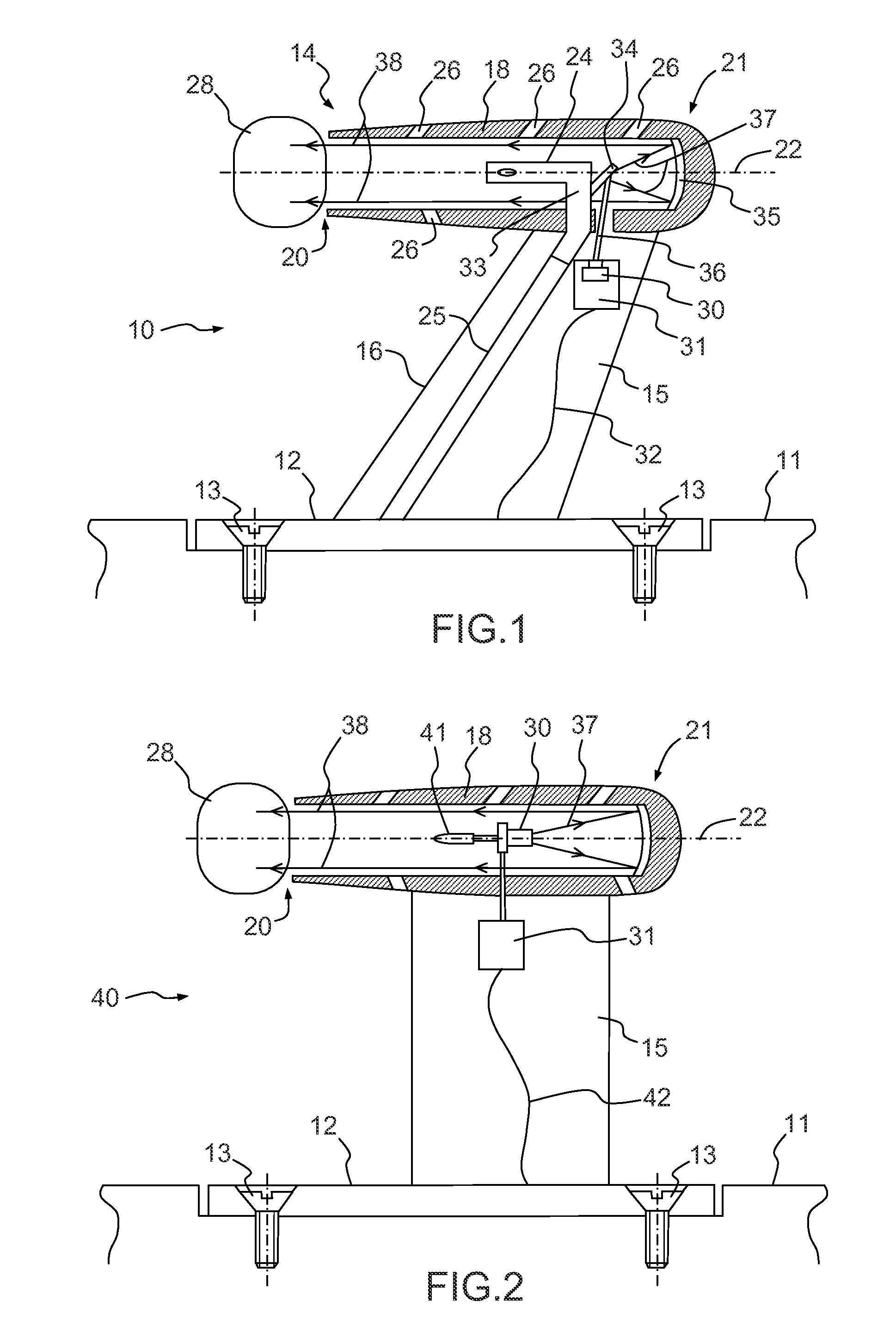

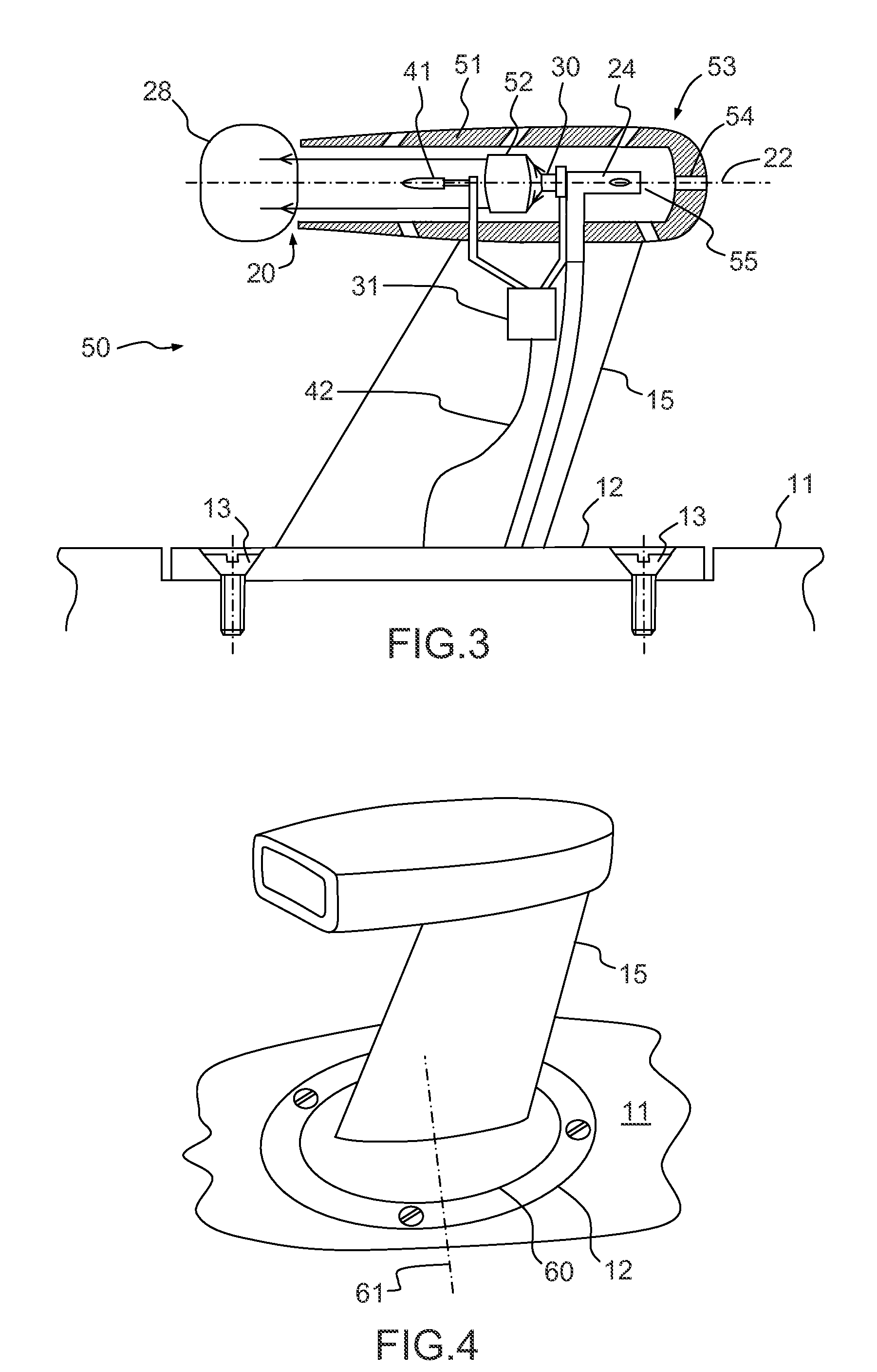

Aerodynamic measurement probe for aircraft

InactiveUS20150059465A1Electricity consumption is reducedSame level of performanceAircraft componentsIndication/recording movementFree zoneEngineering

An aerodynamic measurement probe intended to equip an aircraft. The probe comprises a tube intended to face substantially into a flow of air along the aircraft, the tube being open at a first of its ends. The probe further emits an electromagnetic wave directed towards a free zone situated in the extension of the tube on the side of the open end, the electromagnetic wave making it possible to reheat the water likely to be located in the free zone.

Owner:THALES SA

Wedge shaped casting block on-line cutting method and device

The invention discloses an on-line cutting method and an on-line cutting device for a wedged casting blank, which are applied to cutting wedged blanks when a continuous casting crystallizer is adjusted in width on line. The method comprises: a strut beam is arranged on a bracing frame on a large shift, and a wedged blank cutting machine is installed on the strut beam; the large shift moves the wedged casting blank to a storage frame of the large shift from a conveying roller way, and the position of the cutting machine is adjusted to cut the wedged casting blank; the wedged blank cut from the wedged casting blank falls onto a receiving groove trolley below the large shift to be transported out; and the qualified casting blank after cut is subjected to rolling procedure through being transported back the conveying roller way by the large shift. The cutting device is arranged on a large beam, the wedged blank can be cut on line and can be timely returned to the casting plan; therefore, the method and the device avoid quality degradation caused by cutting the wedged blank off line, can save secondary heating when rolling the casting blank, reduce energy consumption, and simultaneously solve the problem of cutting precision which can not be ensured by manual cutting, lighten working strength at a large degree, and ensure safe production.

Owner:ANGANG STEEL CO LTD

NMP gas recovery system and technology thereof

InactiveCN105797420AReduce reheatingImprove recycling ratesOrganic chemistryMultiple-effect/fractional condensationActivated carbonResource recovery

The invention belongs to the technical field of industrial production waste gas recovery, and particularly relates to a recovery system for N-methyl pyrrolidone in lithium battery industrial waste gas treatment and a technology of the recovery system. The recovery system comprises a precooling and exchanging unit, a condensing unit, an adsorption and regeneration unit and an NMP waste liquor recovery tank which are sequentially connected, and the precooling and exchanging unit and the condensing unit are both connected with the NMP waste liquor recovery tank. Compared with the prior art, according to the NMP gas recovery system, equipment is simple, the technological process is short, no activated carbon adsorbent is used, eluting tower waste liquor is not generated, and the primary recovery rate of NMP can reach 99% or above; the production environment is effectively improved, personnel body health is prevented from being harmed, the cost of enterprise consumables is reduced, and the resource recovery utilization rate is increased.

Owner:DONGGUAN TAFEL NEW ENERGY TECH CO LTD +1

Austenite valve steel and technique for producing the same

The invention discloses austenitic valve steel and a process for producing the same. The austenitic steel comprises the following components in mass percentage: 0.57 to 0.65 percent of C, less than or equal to 0.25 percent of S, 9.50 to 11.50 percent of Mn, less than or equal to 1.50 percent of Ni, 20.00 to 22.00 percent of Cr, less than or equal to 0.050 percent of P, less than or equal to 0.030 percent of S, 0.40 to 0.60 percent of N, 1.00 to 1.20 percent of Nb, 0.75 to 1.00 percent of V, and the balance being iron and inevitable impurities. The production process is to take the component materials and adopt an electric furnace smelting method to perform quenching and tempering, gas refining and continuous casting and tandem rolling. The austenitic valve steel has the advantages of reasonable component design, good product comprehensive performance and low nickel content; besides, the production process substantially reduces the power consumption in production, and the production cost is low.

Owner:JIANGSU XINGHAI SPECIAL STEEL

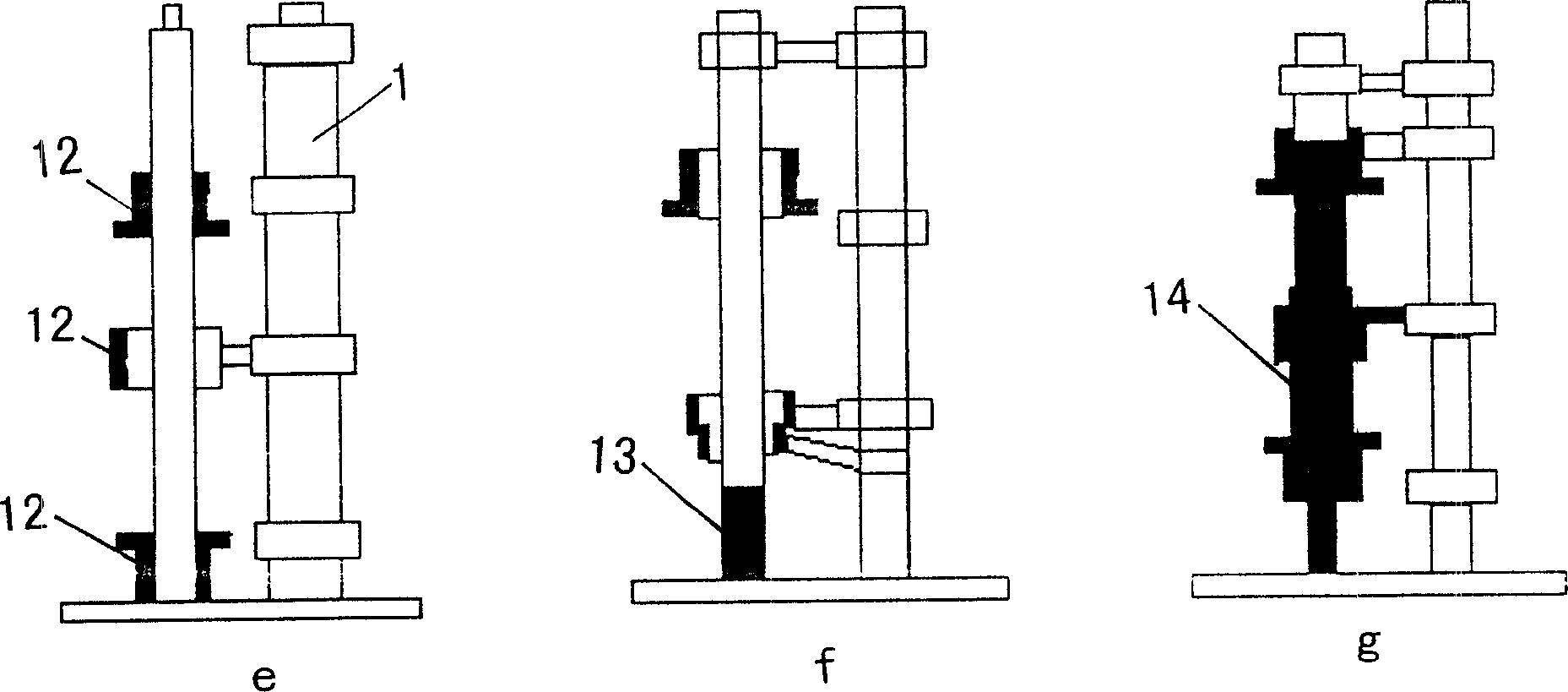

Production process for four-roll planetary hot-rolled tube machine

InactiveCN102247989AReduce areaReduce laborMetal rolling arrangementsPunchingPulp and paper industry

The invention discloses a production process for a four-roll planetary hot-rolled tube machine, and belongs to the technical field of production processes of hot-rolled steel tubes. The process is characterized by comprising the following steps of: checking a tube billet; grinding; cutting to length, and loading into a heating furnace and heating to the punching temperature; feeding into a puncher and punching; pre-punching a mandril, and feeding into the four-roll planetary hot-rolled tube machine and rolling; feeding into a stretch-reducing mill unit and reducing; cutting to length; uniformly cooling; straightening; and performing flat-head chamfering, detecting flaws and inspecting. Compared with the prior art, the process has the advantages that: (1) secondary heating is reduced, and fuel, power consumption, the heating furnace and plant area are saved; (2) the length of rolled pierced billets can reach 50 meters, so that the loss caused by cutting heads and tails is reduced, and the yield is improved; and (3) the wall thickness of rolled tubes can reach 2.3mm, so that the bottleneck that the wall thickness of the rolled tubes cannot be less than 3mm in the prior art is broken through.

Owner:太原磬泓机电设备有限公司

One-time thermal lamination molding device for middle rubber and covering rubber of rubber conveyor belt of steel wire rope core

The invention discloses a one-time thermal lamination molding device for middle rubber and covering rubber of a rubber conveyor belt of a steel wire rope core, aiming at solving the problem that the efficiency of an existing device is low. The one-time thermal lamination molding device is characterized by being sequentially composed of a canvas sending frame, a four-roller calender, a deviation correction and tensioning device, a three-roller calender, a six-roller cooling roller machine and a double-station crimping machine, wherein the canvas sending frame is used for sending a rubber piece cloth liner; the four-roller calender is used for molding the middle rubber; the deviation correction and tensioning device is used for deviation correction, conveying, tensioning and guiding of the cloth liner and a rubber piece of the middle rubber; the three-roller calender is used for rubber discharging of a covering rubber piece and thermal lamination of the middle rubber and the covering rubber; and the six-roller cooling roller machine is used for cooling the rubber piece, and the double-station crimping machine is used for crimping the two types of laminated rubber pieces. With the adoption of the one-time thermal lamination molding device, one path of procedure on a molding platform is reduced and a process is simplified; through one-time thermal lamination, the density and lamination quality of the rubber piece are guaranteed; and the staying time of the rubber pieces and secondary heating in a lamination process are reduced, energy conservation and environment protection are realized, and the sticking effect is relatively good.

Owner:ANHUI ZHONGYI RUBBER BELTS

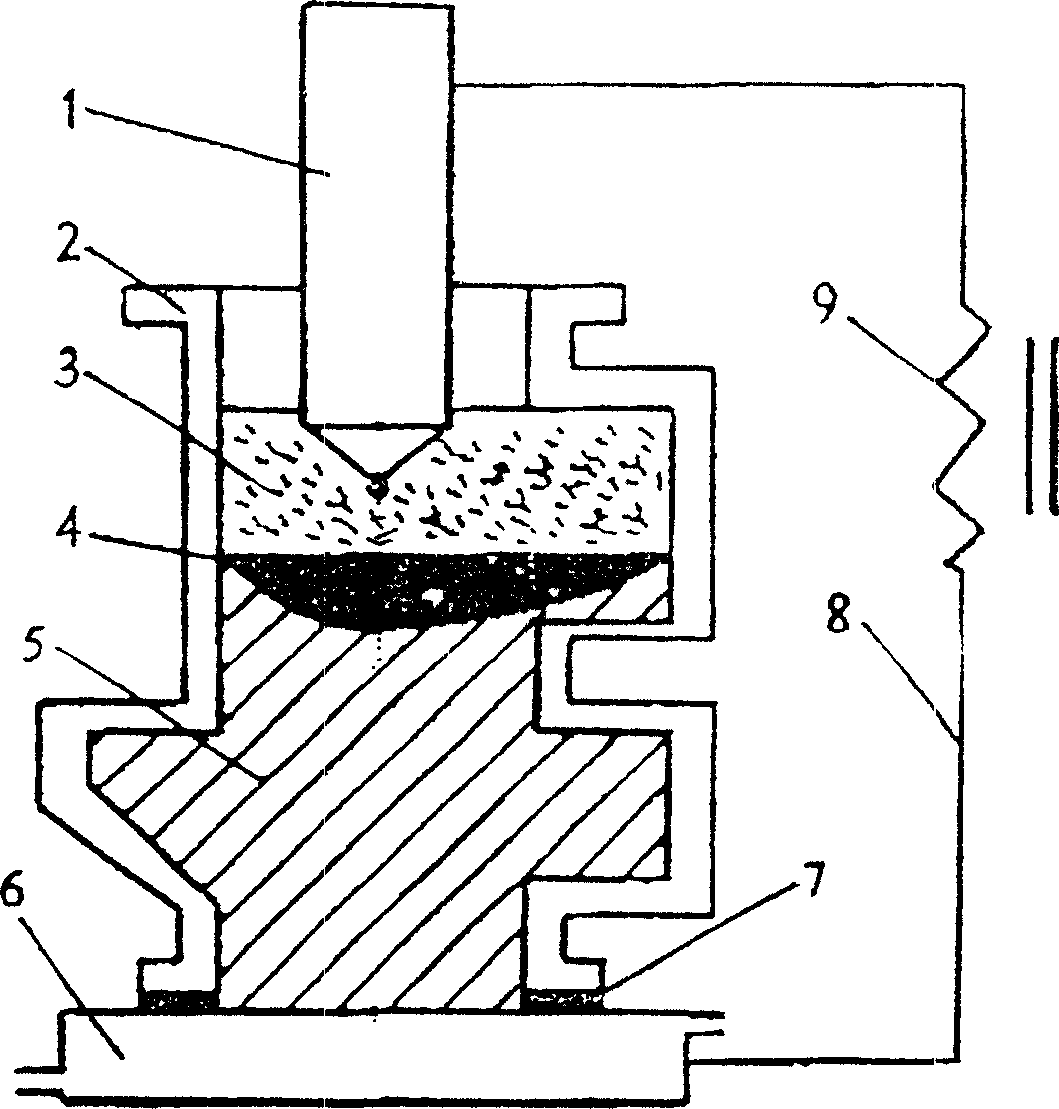

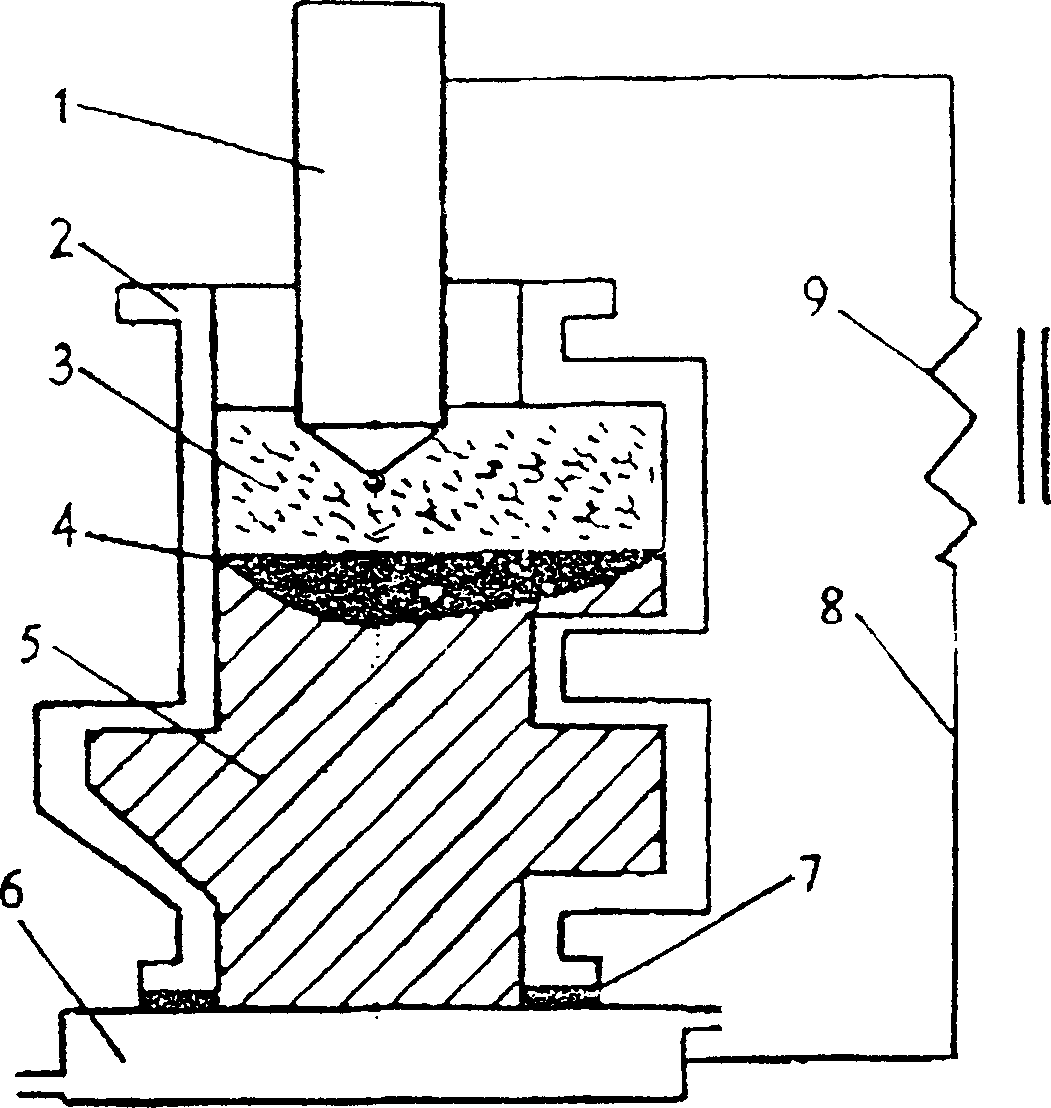

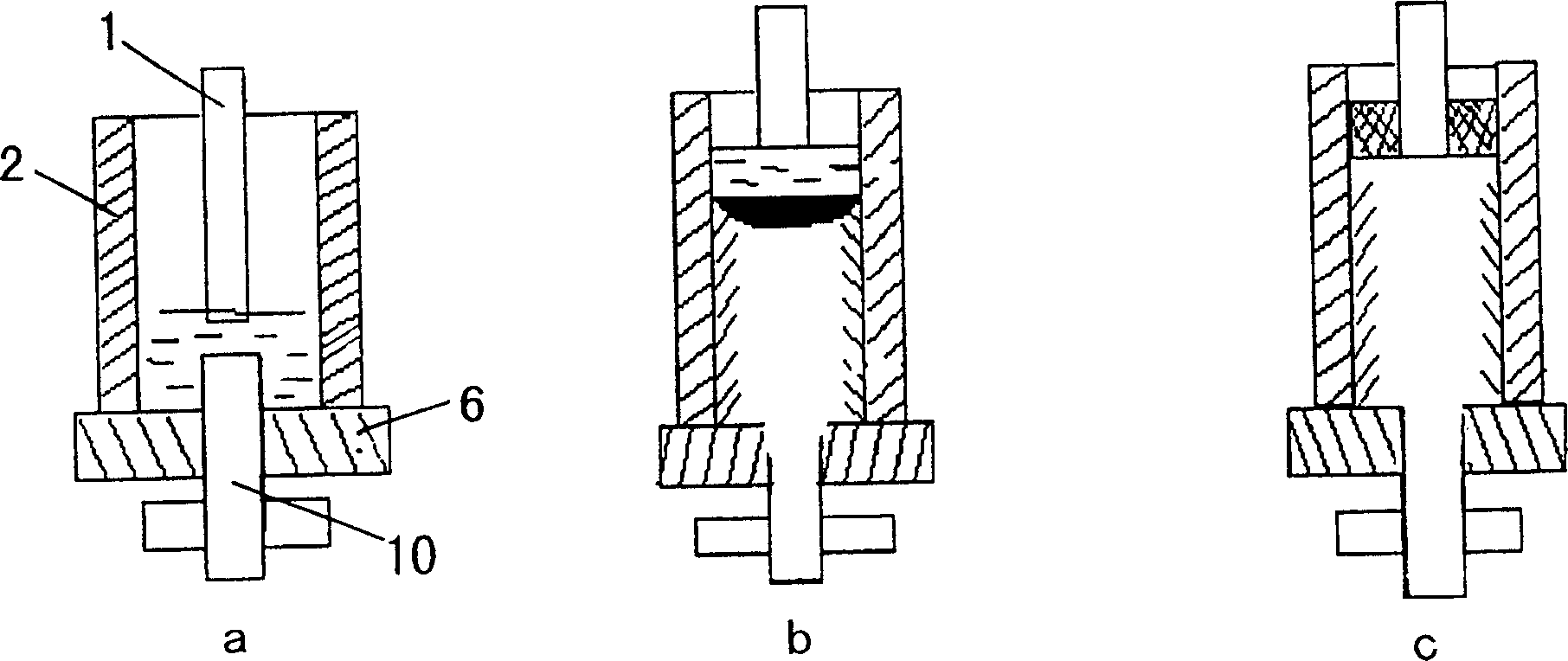

Casting-forging composite plastic forming process for brake disc

ActiveCN106077505AImprove mechanical propertiesEliminate stomataFoundry mouldsFoundry coresComposition analysisMechanical property

The invention belongs to the field of the manufacturing industry, and specifically discloses a casting-forging composite plastic forming process for a brake disc. The casting-forging composite plastic forming process comprises the following steps of metal smelting: component analyzing; casting; constant-temperature keeping; de-molding; clearing; blank forging; die-forging; de-molding; trimming; stack-cooling; surface treating; mechanical processing; thermal treatment; and finished product assembly. According to the casting-forging composite plastic forming process, internal defects, especially internal shrinkage cavity defects and shrinkage porosity defects, are extremely liable to integrate, and air holes inside a casting can be eliminated by utilizing a liquid curing and heat-release phenomenon, so that comprehensive mechanical property of a forged piece are improved.

Owner:南京东电检测科技有限公司

Preparation method of two-sheet aluminum alloy rim

The invention discloses a preparation method of a two-sheet aluminum alloy rim. The preparation method includes the steps: preparing materials: placing a 6061 aluminum bar into an electric heating furnace, insulating the aluminum bar for at least three hours at the temperature of 500-550 DEG C, and heating a ring grinding mould to reach the temperature of 200-300 DEG C and keeping the temperature; placing the heated aluminum bar on an air hammer for upsetting to form a coarse material, and punching a center hole in the center of the coarse material; transferring the coarse material with the center hole onto a ring rolling mill for rolling a ring to form a ring rolling blank; placing the ring rolling blank into a spinning mould for spinning to form a semi-finished product; performing heat treatment and machining for the formed semi-finished product to form a finished product. The diameter of the 6061 aluminum bar ranges from 180mm to 250mm, the height of the coarse material is 1 / 2-2 / 3 of that of a hub needing to be formed, the diameter of the center hole ranges from 100mm to 150mm, and the diameter of the ring rolling blank reaches that of the hub needing to be prepared. The preparation method has the advantages of simplicity, high material use ratio and low cost.

Owner:宁波宝通轮业有限公司

Technology of slag fused casting train shaft

An electroslag casting technology for manufacturing the wheel axle of high-speed train includes using the water bottom tray of crystallizer as electrode, using the axle billet as consummable electrode, choosing slag system and filling ratio, and electroslag casting. Its advantages are high mechanical performance and long endurance life.

Owner:潘明忠 +2

Sintering process for magnet production

ActiveCN112038084AShort holding timeRapid gasification dischargeIncreasing energy efficiencyInductances/transformers/magnets manufactureMetallurgyGas quenching

The invention discloses a sintering process for magnet production. The sintering process specifically comprises the following steps of: S1, heating a magnet compact to a first temperature and keepingthe temperature, and discharging volatile substances in the magnet compact; S2, raising the temperature to a second temperature and keeping the temperature, and discharging gas impurities in the magnet compact; S3, heating the magnet compact to a third temperature, sintering the magnet compact in a vacuum environment, and keeping the temperature; and S4, subjecting the magnet to gas quenching andcooling through using a circulating inert gas, and subjecting the magnet to tempering treatment. According to the sintering process for magnet production, an induction coil is used for directly heating the magnet, an electric heating wire is used for preserving heat of the environment in a sintering furnace, and the problems that the magnet temperature rising speed is low, heating is uneven, the heating time is long, consequently, intercrystalline phase distribution of the magnet is uneven, crystalline grains are thick and the performance of the magnet is affectedin the prior art are solved; and by introducing the cooled inert gas into the sintering furnace, the problems that the magnet cooling speed is low and the magnet sintering production efficiency is affected are solved.

Owner:安徽万磁电子股份有限公司

Polymer composite material bipolar plate and preparation method thereof, and vanadium redox flow battery

InactiveCN110474067AImprove battery suitabilityLow resistivityRegenerative fuel cellsPolymer scienceMaterials science

The invention provides a polymer composite material bipolar plate. The polymer composite material bipolar plate is prepared from the following raw materials: 30-59wt% of polymer resin, 40-69wt% of a conductive carbon filler, 0.2-7wt% of a plasticizer and 0.15-3wt% of a coupling agent. The invention also provides a preparation method of the polymer composite material bipolar plate. The method comprises the steps of: proportionally mixing the polymer resin with the plasticizer, and the conductive carbon filler and the coupling agent respectively, mixing the mixtures, and adding the obtained mixture into a twin-screw extruder to process a bipolar plate. According to the bipolar plate provided by the invention, the mechanical strength and toughness are improved, the service life is prolonged,the production efficiency is greatly improved, and the bipolar plate is very suitable for uninterrupted large-scale production of the bipolar plate.

Owner:BEIJING PRUDENT CENTURY TECH CO LTD

Refined martensitic alloy for internal combustion engine valves and production technology thereof

The invention provides a refined martensitic alloy for internal combustion engine valves and a production technology thereof. The alloy is characterized by comprising the following chemical components by weight percent: 0.80-0.90 of C; 1.20-1.43 of Mn; 0.029 of P; 0.83-0.93 of Si; 0.016-0.018 of S; 16.80-18.80 of Cr; 2.20-2.53 of Mo; 0.32-0.58 of V; 0.13-0.19 of Re; and the balance Fe as well as inevitable impurities. The production technology consists of the steps of: vacuum induction furnace and bottom blowing argon refining, continuous casting and rolling, annealing, straightening and polishing. With rational component design, the refined alloy for internal combustion engine valves has good wear resistance, antioxidation and anti-high temperature corrosion performances. And after annealing, the alloy has a basically uniform tempered sorbite structure, which is dispersed in lumps with a particle size of less than 10 micrometers. Thus, the overall performance of the alloy provided in the invention is superior to congeneric martensitic alloys of other grades for valves.

Owner:JIANGSU XINGHAI SPECIAL STEEL

Energy-saving and environment-friendly thick plate glass float production process

PendingCN112679072AImprove product qualityQuality improvementGlass furnace apparatusDirt cleaningAluminium hydroxideDust control

The invention discloses an energy-saving environment-friendly thick plate glass float production system which is characterized in that a storage bin is connected with two first bucket elevators, one first bucket elevator is provided with a first stock bin, the other first bucket elevator is provided with a second stock bin, and discharge pipes are arranged at the lower parts of the first stock bin and the second stock bin; a first control valve is arranged on the discharge pipes; the second stock bin is connected with a second bucket elevator, and a treatment box is arranged at the second bucket elevator; a feeding hole is formed in one end of the treatment box, two vertical partition plates are arranged in the treatment box, the treatment box is divided into a dust removal cavity, a drying cavity and a crushing cavity by the partition plates, and circulating slotted holes are formed in the vertical partition plates. Silica sand, aluminum hydroxide, dolomite, limestone, sodium carbonate, mirabilite and pulverized coal are adopted as raw materials, and a proper production process is selected, so that the glass is convenient to prepare.

Owner:河南省中联玻璃有限责任公司

Method for preparing vegetarian dried meat floss product from cordyceps millitaris fermented glycine max dregs

InactiveCN111374305ASolve the problem of extremely low levelsImprove biological activityFood ingredient as mouthfeel improving agentBiotechnologyCellulose

The invention discloses a method for preparing a vegetarian dried meat floss product from cordyceps millitaris fermented glycine max dregs. A glycine max processing byproduct, namely glycine max dregs, is adopted as a raw material, through solid fermentation, flavor blending and frying with cordyceps millitaris, contents of two soy isoflavones, namely daidzein and glycitein, can be remarkably increased, the content of insoluble cellulose can be reduced, and the vegetarian dried meat floss product which is rich in aglycone isoflavones, proteins and edible fungi, is cotton-like and fluffy and has sensitive, physical and chemical and microorganism indexes similar to those of dried meat floss is prepared. The product prepared by using the method is "natural, nutrient and low-grease", and expectation of different customers on nutrient and healthy foods can be met. Solid fermentation used in the method is a traditional and modern biological technology, is efficient and low-carbon, good in applicability and simple to operate, and is free of secondary sterilization; the cordyceps millitaris can be used as an edible fungus, the mycelia of the cordyceps millitaris is rich in nutrition, and the flavor and the drawing feeling of the product can be also improved. By adopting the method, the nutrition and functional value of the vegetarian dried meat floss leisure food can be effectively intensified, and great significances in increasing additional values of the vegetarian dried meat floss product and promoting comprehensive utilization of the glycine max dregs can be achieved.

Owner:JIANGSU ACADEMY OF AGRICULTURAL SCIENCES

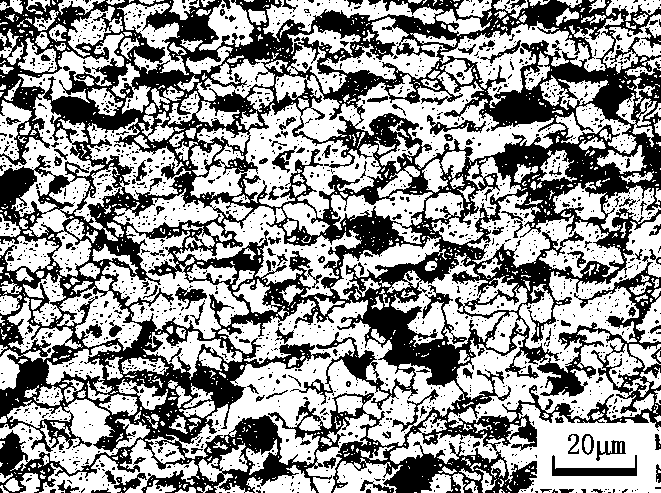

Heat treatment method for improving room temperature plasticity of composite prepared high-silicon steel sheet

InactiveCN107828948ALess reheating processSimple processFurnace typesHeat treatment furnacesAir coolingCooling medium

The invention discloses a heat treatment method for improving room temperature plasticity of a composite prepared high silicon steel sheet. The method comprises the three links of heating and heat preservation, rapid cooling and low-temperature tempering. Heat preservation is carried out on a high-silicon steel composite board for 30-120 minutes in a temperature field which is not lower than 950 DEG C by utilizing the waste heat of the high-silicon steel composite board and the environment after the high-silicon steel composite board is subjected to diffusion annealing; the high-silicon steelcomposite board is cooled to the room temperature with the cooling speed of 100-200 DEG C / s by adopting a cooling medium; and the high-silicon steel composite board is heated to 150-250 DEG C again and heat preservation is carried out on the high-silicon steel composite board for 20-50 minutes, and air-cooling is carried out to cool the the high-silicon steel composite board to the room temperature. According to the heat treatment technology, transformation of the ordered phase can be inhibited, the order degree is reduced, and the residual stress is eliminated, so that the room temperature plasticity of the 6.5% high-silicon steel composite board can be remarkably improved.

Owner:XI'AN PETROLEUM UNIVERSITY +1

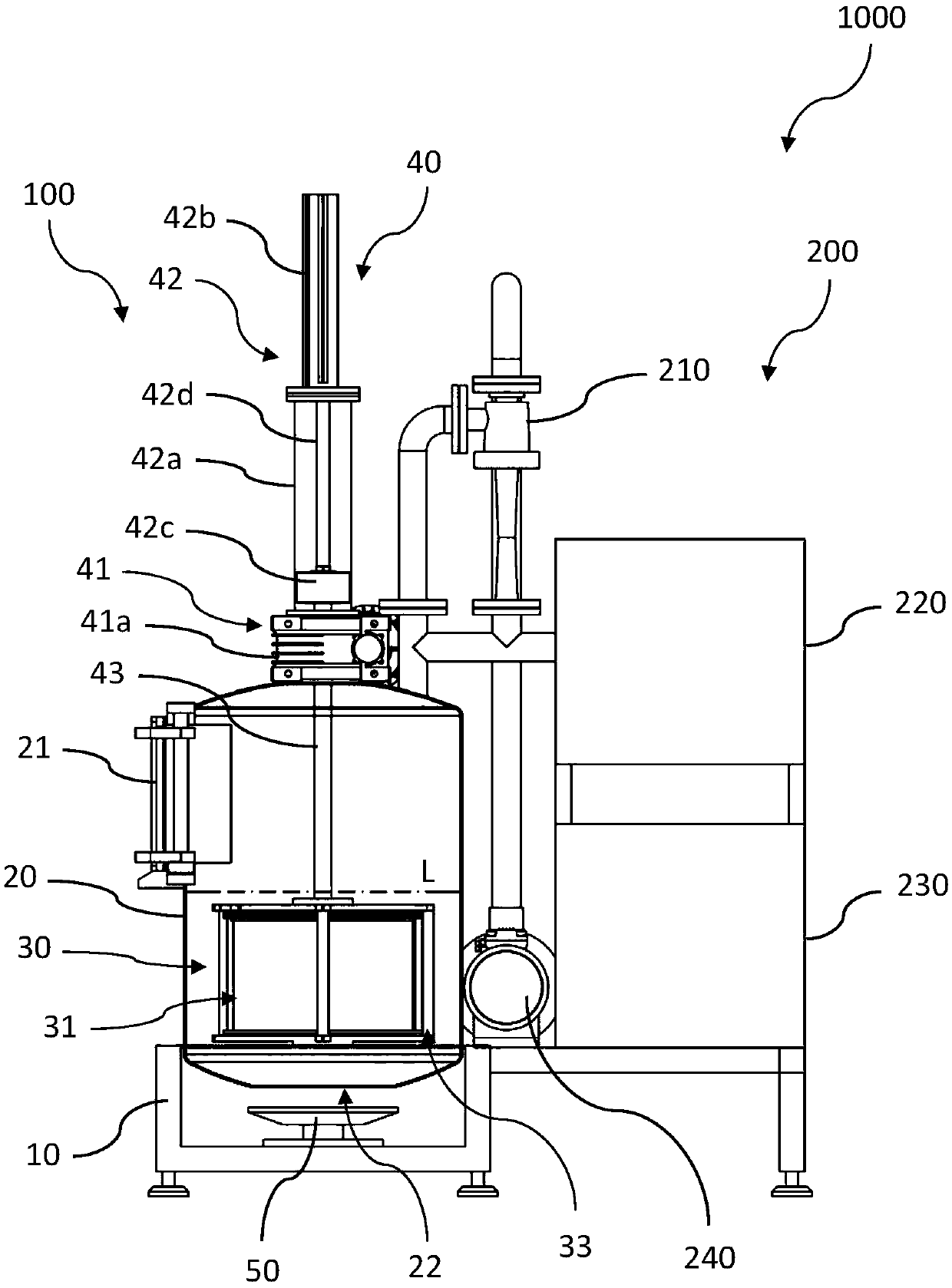

Basket lifting deoiling assembly, vacuum frying tank and vacuum frying equipment

PendingCN109090167ASmall footprintLow processing and manufacturing costsOil/fat bakingReduction driveEngineering

The invention provides a basket lifting deoiling assembly, a vacuum frying tank containing the basket lifting deoiling assembly, and vacuum frying equipment containing the vacuum frying tank. The basket lifting deoiling assembly comprises a rotary unit, a lifting unit, and a basket rotary shaft, wherein the rotary unit comprises a speed reducer and a rotary driving component; the lifting unit hasa supporting sleeve and a lifting driving component; the lower end of the basket rotary shaft is connected with a basket component; an output shaft is arranged on the speed reducer; an axial mountinghole is formed in the output shaft; the free end of each a driving rod of the lifting driving component extends downwards into the supporting sleeve; the upper end of the basket rotary shaft penetrates through the axial mounting hole and is connected with the free end of each the driving rod along an axial fixed circumferential direction in a rotary manner; and the basket rotary shaft is mounted in the axial mounting hole along a circumferential fixed axial direction in a lifting manner. When the lifting driving component drives the basket assembly to complete the lifting action, the rotary driving component drives the basket assembly to rotate to realize deoiling.

Owner:全氏食品机械(上海)有限公司

Two-tower type pressure reducing coke tar distillation process and apparatus therefor

ActiveCN101475819BSolve the technical problems of dealing with large-scale tarShort processTar working-up by distillationHeat conductingReboiler

The invention relates to a two-tower type process for distilling vacuum tar and a device thereof. The process comprises the following steps: removing the moisture and light oil distillate of raw tar in a pre-dehydration tower and a dehydration tower at normal pressure; performing decompressing operations in a No.1 distillation tower to obtain carbolic oil, naphthalene oil and light washing oil distillate; and performing decompressing operations in a No.2 distillation tower to obtain heavy washing oil, first anthracene oil, second anthracene oil and mid-temperature pitch. The heat for the pre-dehydration tower and the dehydration tower is supplied by heat conducting oil; the heat for the No.1 distillation tower is supplied by heating the mixed oil on the bottom of the tower circularly in aNo.1 tubular heating furnace; and the heat for the No.2 distillation tower is supplied by heating the mixed oil on the bottom of the No.1 distillation tower in a No.2 tubular heating furnace and thenperforming flash distillation on the mixed oil on the bottom of the No.2 tower. The main devices comprise the dehydration tower, the No.1 distillation tower, the No.2 distillation tower, a dehydration tower reboiler, the No.1 tubular heating furnace, the No.2 tubular heating furnace, a heat exchanger for each distillate, a cooler, a steam generator and the like. The process has the advantages of short technological flow, less device investment, and less energy consumption, thus the process is applicable to large scale coal tar processing engineering.

Owner:ACRE COKING & REFRACTORY ENG CONSULTING CORP DALIAN MCC

Method for producing smelting flux by using manganese-containing melt

InactiveCN105154695AReduce construction costsReduce labor intensityWelding/cutting media/materialsSoldering mediaManganesePollution

The invention discloses a method for producing a smelting flux by using a manganese-containing melt. The method comprises the following steps: making use of a high-temperature manganese-containing melt generated in a smelting process of a blast furnace or an electric furnace, namely collecting the manganese-containing melt by virtue of foundry ladles, and then pouring into a flux furnace; adding an appropriate amount of manganese, magnesium, silicon and fluorite raw material components; heating to about 1700 DEG C by virtue of the electric furnace to smelt for about 30 minutes; and performing water quenching to prepare the smelting flux. According to the method disclosed by the invention, the consumption of manganese minerals is low, the electricity consumption is low, the production cycle is short, the production efficiency is high, and meanwhile, the emission of harmful gases can be effectively reduced, so that the method is an environment-friendly type flux preparation method; the consumption of heat energy can be effectively reduced, the labor intensity is reduced, the working efficiency is improved, heat pollution, discharge pollution and space occupation of waste residues are avoided, 70% of the production cost is saved, the utilization ratio of the manganese minerals is improved by 8-30%, the emission of waste gases is reduced by 30-60%, the convenience for waste gas treatment is significantly improved, and the waste gas treatment cost is reduced by 60-80%.

Owner:HUNAN UNIV OF SCI & ENG

Refined austenitic alloy for internal combustion engine valve and its production process

The invention discloses a refined austenitic alloy for internal combustion engines. 0.027, S0.013, Cr20.16~21.86, N0.41~0.58, Nb1.03~1.13, Ni1.06~1.36, V0.75~0.87, the balance is Fe and impurities. The method includes the following steps: vacuum induction furnace, bottom blowing argon refining, continuous casting, continuous rolling, solid solution, water cooling, straightening and polishing. The object of the present invention is to provide an austenitic alloy for gas valve with reasonable composition design, good product comprehensive performance, low nickel content, greatly reduced energy consumption in production, and low preparation cost and its production process.

Owner:JIANGSU XINGHAI SPECIAL STEEL

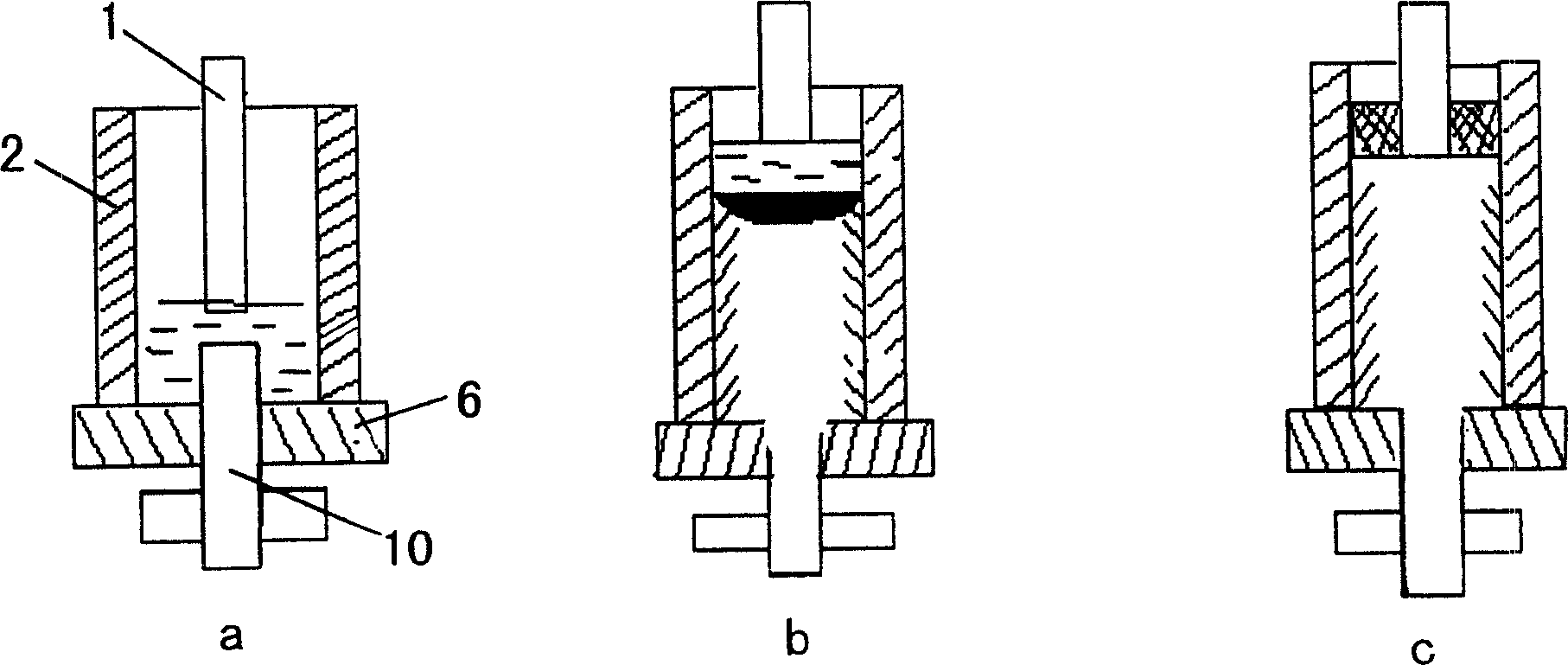

Powder injection molding feeding manufacturing equipment

ActiveCN104148638AAvoid intercooling and solidificationAvoid it happening againHigh volume manufacturingEngineering

The invention discloses powder injection molding feeding manufacturing equipment which comprises a kneading device, an extruding device and a grain cutting device. A discharge outlet of the kneading device is communicated with a barrel inlet end of the extruding device, the grain cutting device is connected to a barrel outlet end of the extruding device, and powder materials are kneaded by the kneading device, then are directly fed into the extruding device, pass the extruding device and then are directly fed into the grain cutting device to be subjected to hot-cutting air-cooled granulation. The powder injection molding feeding manufacturing equipment for realizing powder injection molding feeding manufacturing effects has the advantages that large-scale continuous operation with high production efficiency can be carried out; the hot-state materials can be directly fed into follow-up machining links, accordingly, reheating temperature rise required by granulation procedures can be reduced, and energy consumption can be greatly decreased; labor can be saved, the efficacy of the equipment can be improved, the productivity can be enhanced, and the production cost can be reduced; crushing procedures which are carried out after intermediate cooling and solidifying can be reduced, dust can be prevented in material crushing procedures, and accordingly operation environments can be improved.

Owner:DONGGUAN HUAJING POWDER METALLURGY

Melt-blown fabric manufacturing device and method

PendingCN111485327AIncrease productivityImprove efficiencyNon-woven fabricsChemistryComposite material

The invention discloses a melt-blown fabric manufacturing device and a melt-blown fabric manufacturing method. The melt-blown fabric manufacturing device comprises an extruder (1), a plurality of meltpumps (2) and a plurality of melt-blowing die heads (3), wherein the plurality of melt pumps (2) respectively communicate with the output end of the extruder (1); and the plurality of melt-blowing die heads (3) respectively communicate with the melt pumps (2), and the extruder (1) is a double-screw extruder or a multi-screw extruder. According to the melt-blown fabric manufacturing device, a PP raw material can be directly machined into melt-blown fabric, the using of a single-screw extruder for secondary heating is not needed, so that the production efficiency is improved, one line can be matched with multiple groups of die heads, so that the efficiency is improved by several times, meanwhile, starting can be realized by one person, and thus labor is saved. According to the technical scheme, the use of the single screw for secondary heating in the traditional process is saved, the performance of materials is further kept, meanwhile, a set of single-screw device is saved, moreover, one extruder is matched with two or more melt-blown fabric production lines, thus energy conservation and emission reduction are realized, the structure is simple, and the production efficiency is greatly improved.

Owner:SICHUAN ADVANCE TECH CO LTD

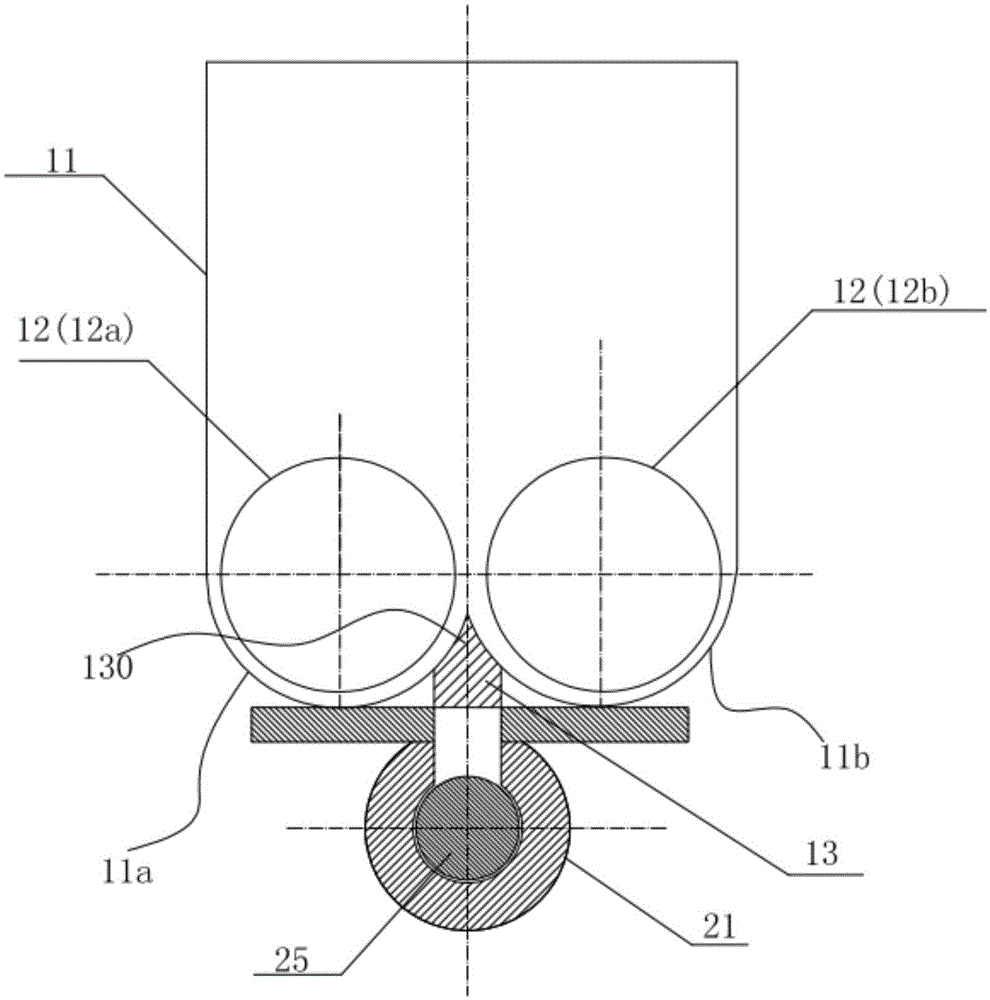

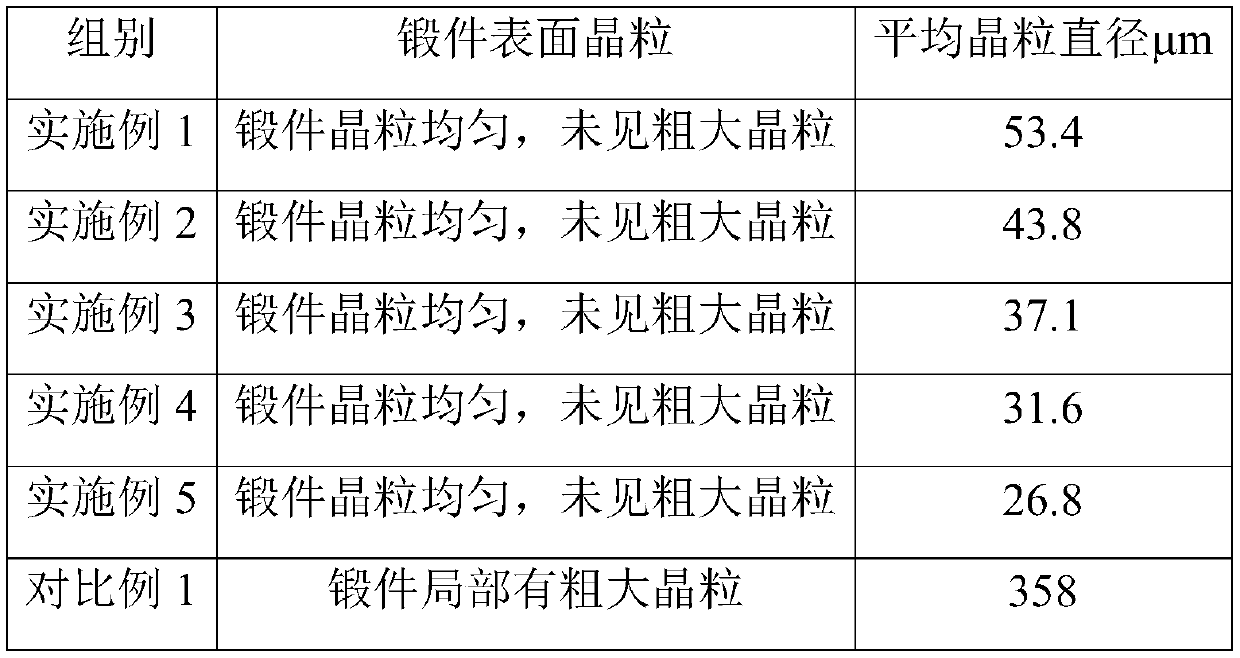

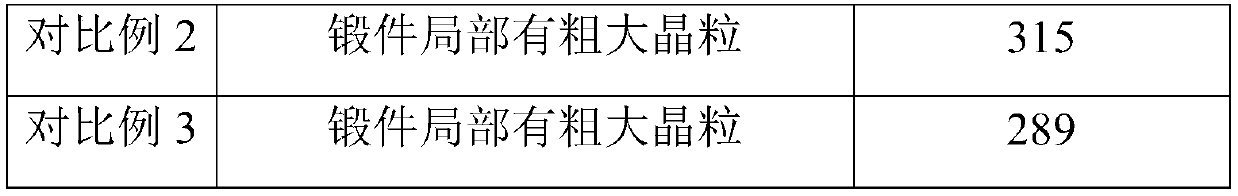

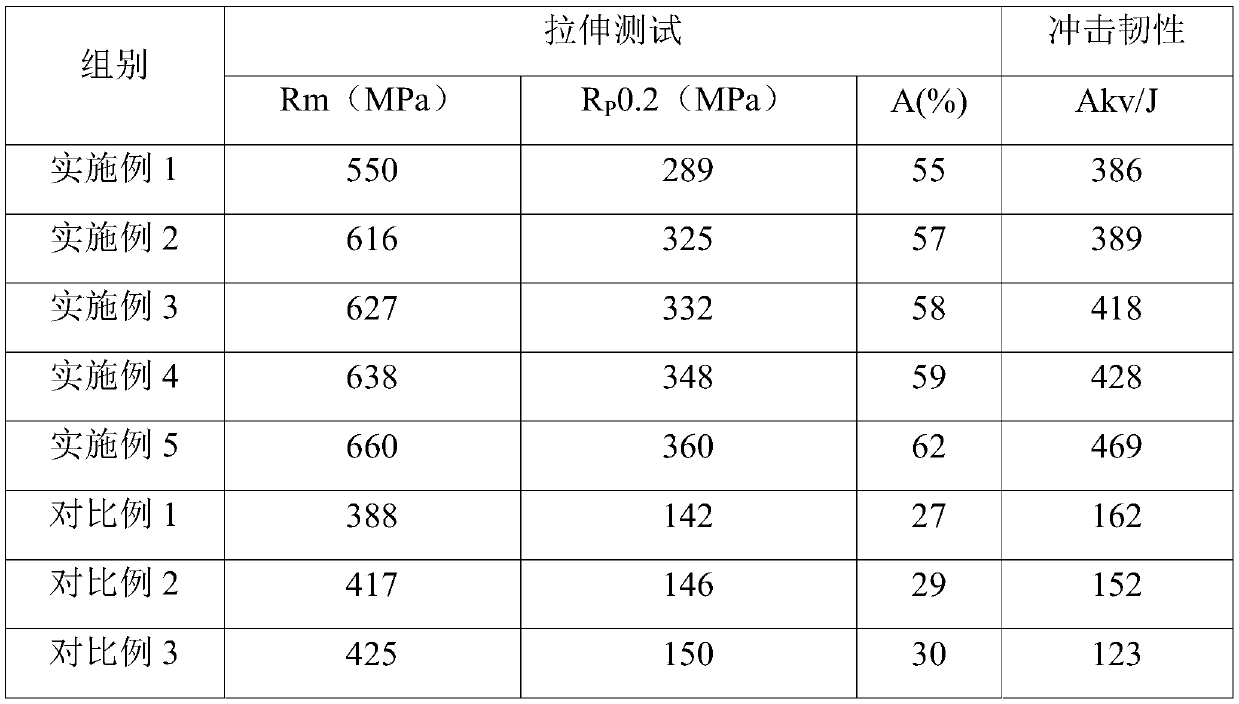

Method for refining grains of austenitic stainless steel forged pieces

The invention discloses a method for refining grains of austenitic stainless steel forged pieces. The method comprises the following steps of S1, forging and S2, heat treatment, wherein in the step S1, stainless steel ingots are forged, the initial forging temperature for forging is 1,000-1200 DEG C, the final forging temperature is 720-850 DEG C, the deformation rate is 0.01-0.45S<-1>, the totalforging ratio is not less than 3, and the forging ratio of the last fire is not less than 20% of the total forging ratio; and in the step S2, the forged pieces obtained in the step S1 are subjected toheat treatment at 1000-1200 DEG C for 1.0-2.0 min / mm to obtain the austenitic stainless steel forged pieces. Compared with the prior art, the austenite stainless steel forged pieces have more uniformand finer grain and good intergranular corrosion resistance, the tensile strength, the yield strength and the impact work of the austenite stainless steel forged pieces are increased at the same time, and the comprehensive performance of the austenite stainless steel forged pieces is improved.

Owner:无锡市法兰锻造有限公司

A method for grain refinement of austenitic stainless steel forgings

The invention discloses a method for refining grains of austenitic stainless steel forged pieces. The method comprises the following steps of S1, forging and S2, heat treatment, wherein in the step S1, stainless steel ingots are forged, the initial forging temperature for forging is 1,000-1200 DEG C, the final forging temperature is 720-850 DEG C, the deformation rate is 0.01-0.45S<-1>, the totalforging ratio is not less than 3, and the forging ratio of the last fire is not less than 20% of the total forging ratio; and in the step S2, the forged pieces obtained in the step S1 are subjected toheat treatment at 1000-1200 DEG C for 1.0-2.0 min / mm to obtain the austenitic stainless steel forged pieces. Compared with the prior art, the austenite stainless steel forged pieces have more uniformand finer grain and good intergranular corrosion resistance, the tensile strength, the yield strength and the impact work of the austenite stainless steel forged pieces are increased at the same time, and the comprehensive performance of the austenite stainless steel forged pieces is improved.

Owner:无锡市法兰锻造有限公司

Forming process of a large-diameter, high-strength, heat-resistant magnesium alloy thick-walled cylindrical part

The invention discloses a forming process of a large-diameter, high-strength, heat-resistant magnesium alloy thick-walled cylindrical part. The process route is: large furnace smelting, semi-continuous casting, homogenizing annealing, variable temperature multi-directional forging, mechanical piercing, ring rolling forming and aging treatment, among which variable temperature multi-directional forging is carried out on a hydraulic press, and the ingot is kept at 500-530°C before forging 6-10h, reduction speed 200-400mm / min, upsetting pass reduction 30-40%, elongation pass reduction 5-10%, 480-500℃ insulation ingot before ring rolling forming 3- 5h, the rolling deformation is 60-80%, and a thick-walled cylindrical piece with an outer diameter of Ф700-1100mm, a wall thickness of 50-100mm, and a height of 300-700mm is rolled. The invention prepares a thick-walled cylindrical part with high strength and high heat resistance, the tensile strength in the vertical direction and the tangential direction at 200°C is ≥330MPa, and the elongation is ≥8%.

Owner:CENT SOUTH UNIV

Technology of slag fused casting train shaft

An electroslag casting technology for manufacturing the wheel axle of high-speed train includes using the water bottom tray of crystallizer as electrode, using the axle billet as consummable electrode, choosing slag system and filling ratio, and electroslag casting. Its advantages are high mechanical performance and long endurance life.

Owner:潘明忠 +2

A preparation equipment for powder injection molding feed

ActiveCN104148638BAvoid intercooling and solidificationAvoid it happening againHigh volume manufacturingEngineering

Owner:DONGGUAN HUAJING POWDER METALLURGY

A sintering process for magnet production

ActiveCN112038084BShort holding timeRapid gasification dischargeIncreasing energy efficiencyInductances/transformers/magnets manufactureHeating timeSlow cooling

The invention discloses a sintering process for magnet production, which specifically includes the following steps: step S1: heating up to the first temperature and keeping it warm, and discharging volatile substances in the magnet compact; step S2: heating up to the second temperature and keeping it warm, and discharging the magnet Gas impurities in the compact; step S3: heating up to the third temperature, sintering the magnet compact in a vacuum environment and keeping it warm; step S4: cooling the magnet with circulating inert gas gas quenching, and tempering the magnet. The present invention directly heats up the magnet by using the induction coil, and uses the electric heating wire to keep the environment in the sintering furnace warm, which solves the problem of slow magnet heating, uneven heating, and long heating time in the prior art, which leads to intergranular The problem of uneven phase distribution and coarse crystal grains affects the performance of the magnet; by passing the cooled inert gas into the sintering furnace, the problem of slow cooling of the magnet and affecting the production efficiency of the magnet sintering is solved.

Owner:安徽万磁电子股份有限公司

A Casting-Forging Composite Plastic Forming Process for Brake Disc

ActiveCN106077505BImprove mechanical propertiesEliminate stomataFoundry mouldsFoundry coresMechanical propertyMaterials science

The invention belongs to the field of the manufacturing industry, and specifically discloses a casting-forging composite plastic forming process for a brake disc. The casting-forging composite plastic forming process comprises the following steps of metal smelting: component analyzing; casting; constant-temperature keeping; de-molding; clearing; blank forging; die-forging; de-molding; trimming; stack-cooling; surface treating; mechanical processing; thermal treatment; and finished product assembly. According to the casting-forging composite plastic forming process, internal defects, especially internal shrinkage cavity defects and shrinkage porosity defects, are extremely liable to integrate, and air holes inside a casting can be eliminated by utilizing a liquid curing and heat-release phenomenon, so that comprehensive mechanical property of a forged piece are improved.

Owner:南京东电检测科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com