Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

709 results about "Dried meat" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Dried meat is a feature of many cuisines around the world. Examples include: Bakkwa or rougan, Chinese salty-sweet dried meat sheets. Biltong, a cured meat that originated in South Africa. Bindenfleisch, air-dried meat of Switzerland. Bògoǫ, a dried and smoked meat, often caribou, of the Dené people of northern Canada. Borts, air-dried strips horse or cow meat used as travel food or to last the winter in Mongolia. Often ground into powder and mixed with water to create soup. Bresaola, air-dried salted beef originally from the Valtellina valley in northern Italy. Carne-de-sol, sun-dried salt beef from Brazil. Carne seca, air-dried meat from Mexico. Cecina, lightly smoked, dried, and salted meat from northwestern Spain, Cuba, and Mexico. Charqui, made from llama or alpaca, in South America. Chipped beef, partially dried beef sold in small, thin, flexible leaves in jars or plastic packets. Hunter beef, a corned beef from Pakistan marinated and baked for use in sandwiches and salads. Jerky, meat that has been trimmed of fat, cut into strips, marinated, and dried or smoked. Kuivaliha, air-dried salted meat of northern Finland.

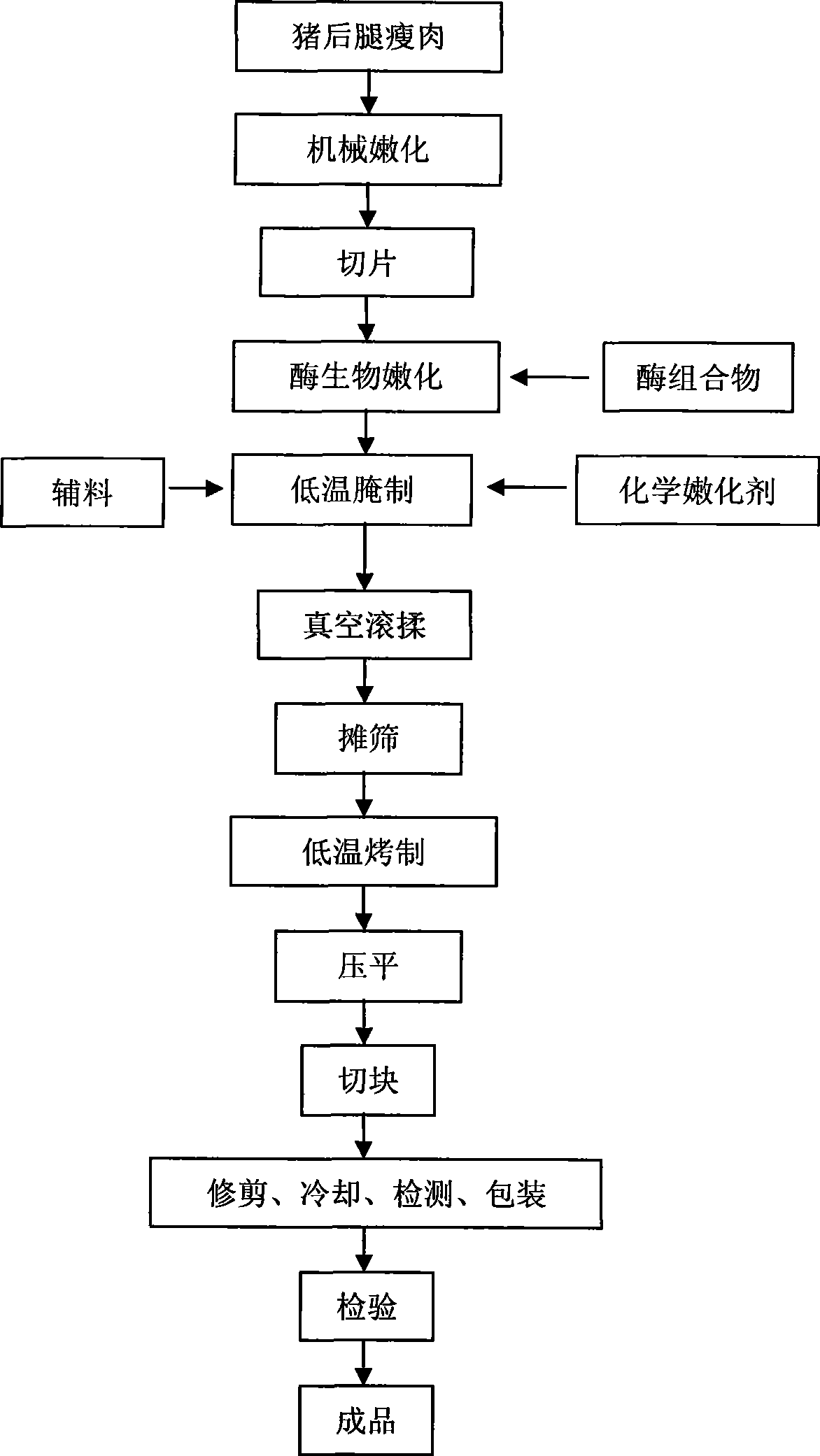

Method for processing tenderized fried pork crisps

InactiveCN101375724AImprove tendernessImprove textureFood preparationMeat tenderisingTemperature controlFiber

The invention discloses a processing method for tenderization of dried meat slices. The method comprises the following steps: step 1, selecting flesh lump, and using mechanical tenderization equipment to cut off the muscle fiber of the flesh lump, thereby facilitating absorption of curing liquid and tenderization of meat texture; step 2, utilizing a slicing machine to cut the flesh lump into meat slices, and then placing the meat slices into a combination containing enzyme mixture for enzyme bio-tenderization and enzymolysis treatment; step 3, adding a chemical tenderization agent and supplementary materials into the meat slices obtained from step 2, and pickling at a low temperature; step 4, placing the pickled meat slices from step 3 into a vacuum rolling machine for vacuum rolling; step 5, using a mesh sieve to spread and sieve the rolled meat slices obtained from step 4, and then carrying out dehydration under temperature control procedures, and baking to produce the dried meat slices; and step 6, cooling, compressing, slicing, testing and packing the baked meat slices.

Owner:江苏畜牧兽医职业技术学院 +1

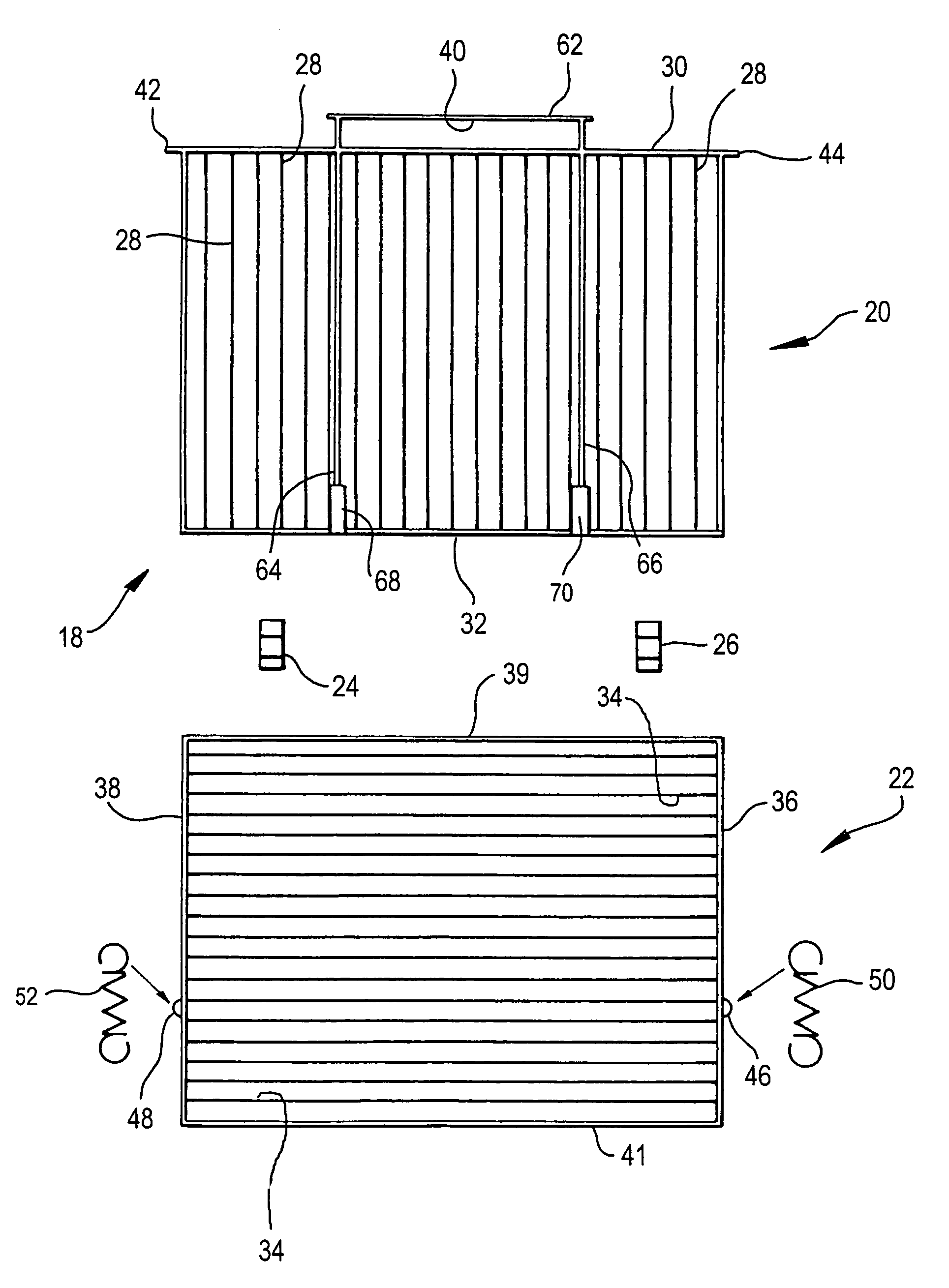

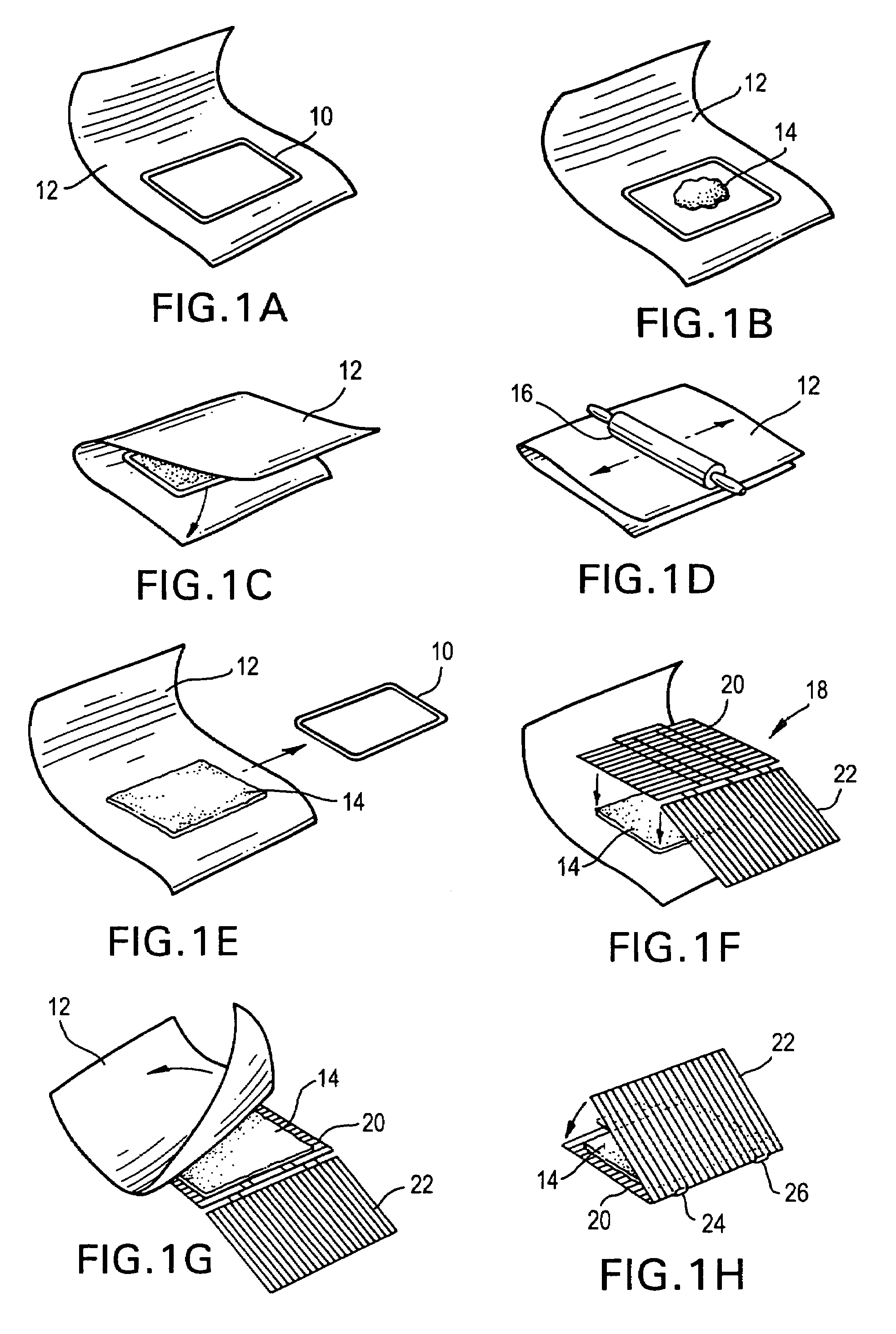

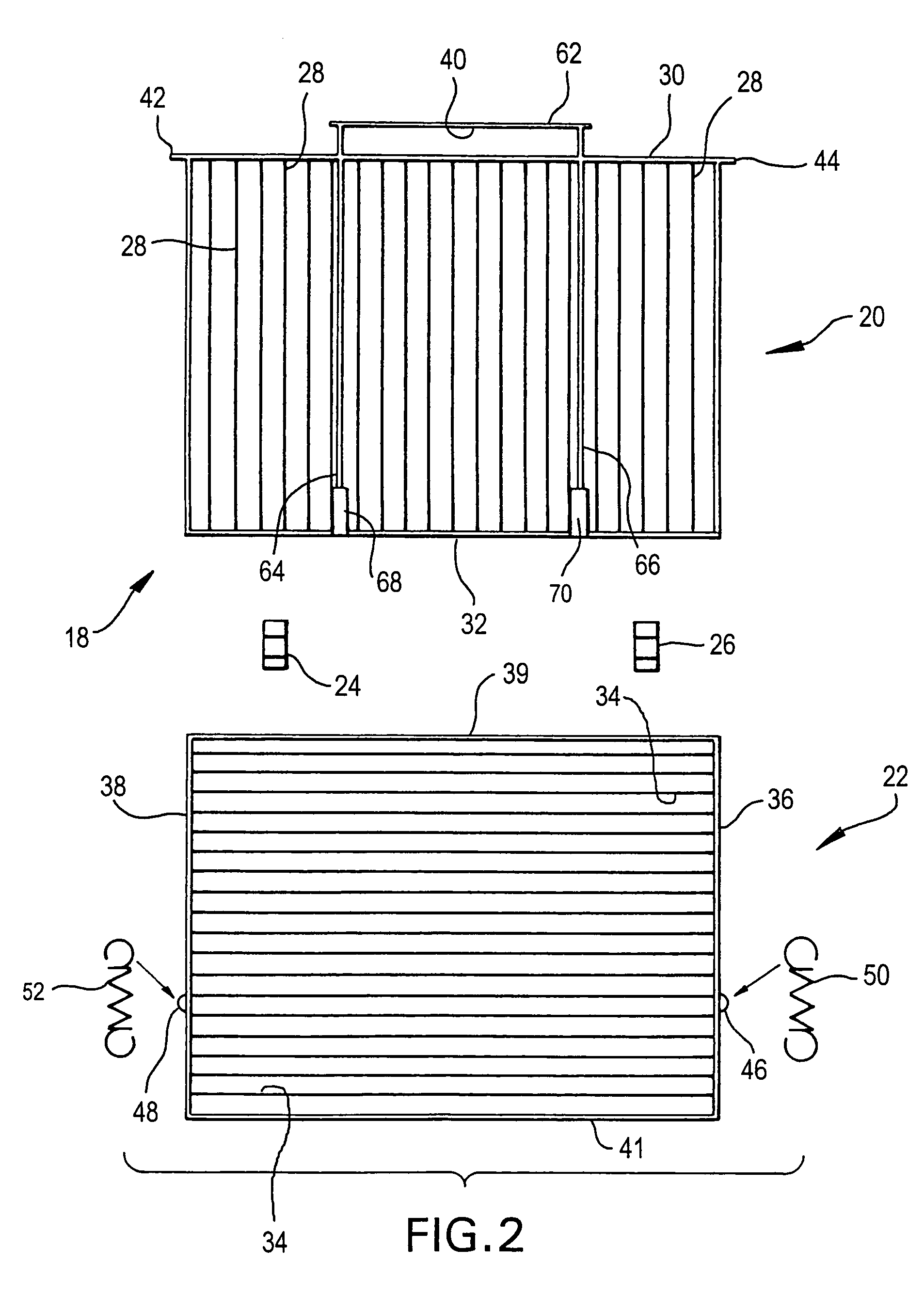

Vertically oriented jerky dehydrator

InactiveUS7159510B2Minimize timeSuccessful operation of the dehydration processMilk preservationMeat processingTrailing edgeMoisture

Owner:LAMASTER ALAN L +1

Nutritional beef dried meat with high bone calcium and making method thereof

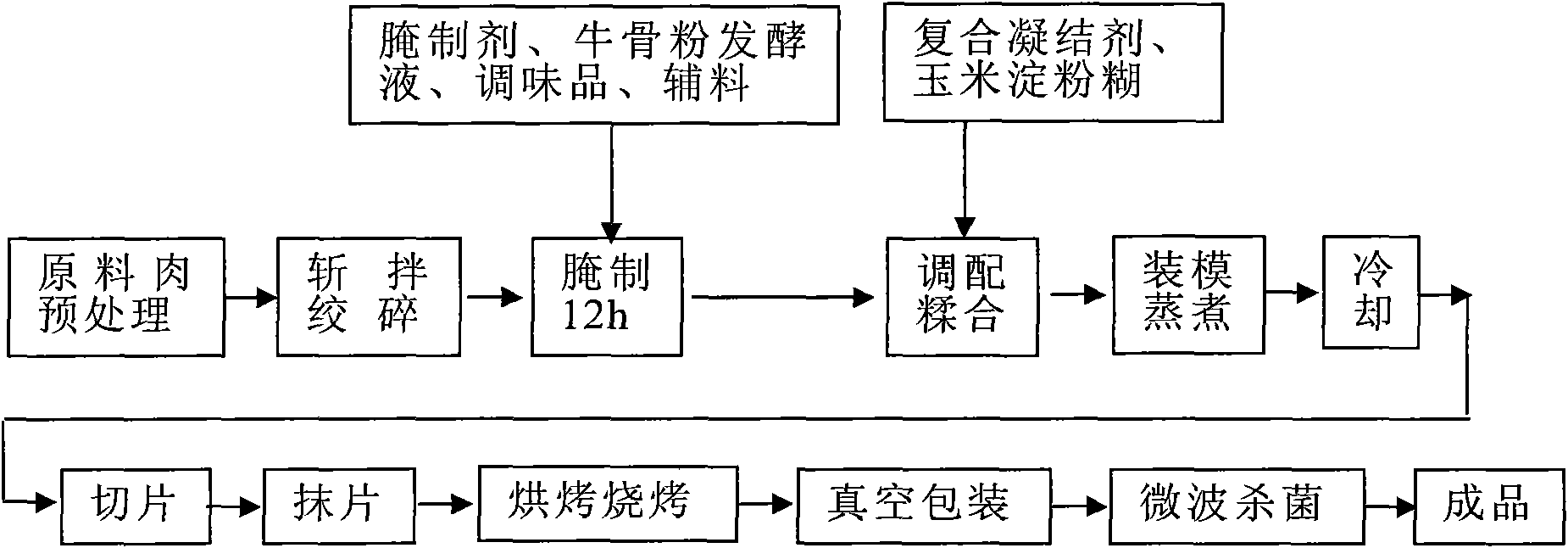

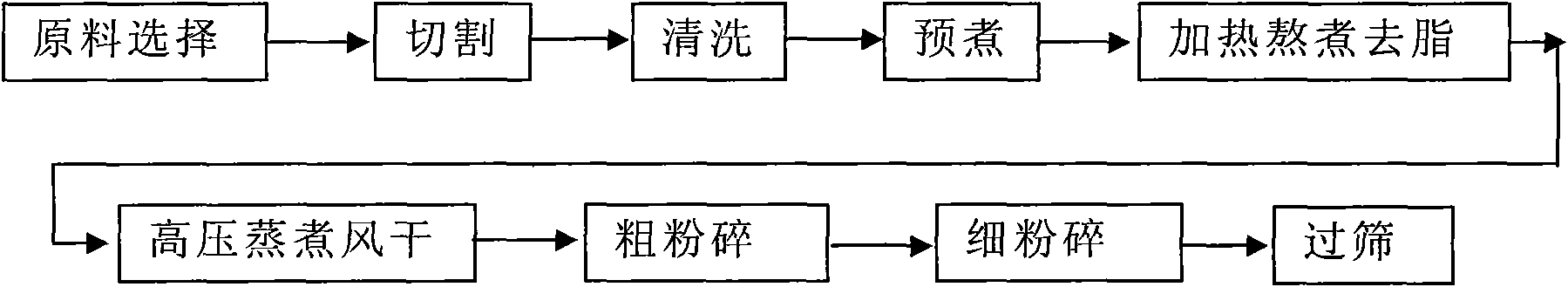

The invention relates to nutritional beef dried meat with high bone calcium and a making method thereof, belonging to a nutritional food and a processing technology thereof. The nutritional beef dried meat is formed by preparing and processing raw materials comprising ground beef, a curing agent, cattle bone powder fermentation liquid, corn starch paste, a compound coagulant, a flavoring agent and auxiliary materials according to a certain mixture ratio and a certain production technology. The product contains high calcium, high protein, abundant nutrition, delicate mouth feel, moderate rigidity, no residue after being chewed, special flavor, good and savory taste and thick aftertaste and adds a new variety of beef dried meat.

Owner:GUIZHOU UNIV

Soybean tissue albumin dried meat floss

ActiveCN103704463ACrisp textureUnique flavorCheese manufactureVegetable proteins working-upTissue proteinVegetarian diets

The invention discloses soybean tissue albumin dried meat floss. The vegetarian dried meat floss is prepared by performing immersion, cleaning, deodorization, peculiar smell removal, dewatering, chopping into strips, mixing, frying, drying, cooling, packaging and the like on a soybean tissue protein raw material. The soybean tissue protein is used as a full vegetable instead of a filler to be developed and applied; by virtue of rich soybean proteins, the prepared vegetarian dried meat floss is loose, is moderate in sweetness and saltness, tastes mellow and delicious and has a unique flavor; people of all ages can eat the soybean tissue albumin dried meat floss; particularly a new convenient and delicious option is supplied to vegetarians and is a meat-substitute product with rich nutrition.

Owner:ZUMING BEAN PROD

Meat substitute food product and preparation method thereof

InactiveCN101541187AEasy to pasteProteins working-up by texturisingVegetable proteins working-upFlavouring agentVegetable Proteins

The invention relates to a method for preparing meat substitute food products, including phases comprising: the hydration under vacuum of at least one vegetable protein mixed with water and at least one colouring agent; the mixing of at least one meat product with the hydrated and coloured vegetable protein mixture; the mixing of flavouring agents and texturing agents into the mixture comprising the meat products and the hydrated and coloured vegetable protein, such as to form a paste; the cooking of the paste; and the forming of said paste to produce an appearance similar to a meat product. The resulting meat substitute food product can have the appearance, for example, of steaks, breaded meat fillets, flank steaks, dried meats, breaded flank steaks, escalopes, shredded meat, ground meat, sirloin tips, meat strips or meatballs.

Owner:SIGMA ALIMENTOS S A DE

A kind of preparation method of dried chicken

InactiveCN102293411AImprove product added valueExtended shelf lifeFood preparationCapsicum annuumProtein molecules

The invention discloses a method for preparing chicken jerky. The steps are as follows: the raw materials of chicken jerky are prepared according to the following parts by weight: 90-100 minced chicken meat, 2-3 soybean protein isolate, 0.4-0.6 salt, and 0.4-0 glucose 0.6, glutamine transaminase 0.2~0.3, allspice powder 0.1~0.3, ginger powder 0.1~0.3, fried pepper 0.5~1.5; then make dried chicken; the present invention adopts glutamine transaminase to catalyze the cross-linking in the protein molecule , intermolecular cross-linking, connection between protein and amino acid, and hydrolysis of glutamine group in protein molecule, recombination and bonding of chicken minced meat; freezing section, frying and drying for dehydration and microwave sterilization Packing and storing effectively prolongs the shelf life of dried chicken products, and increases the added value of chicken minced meat products.

Owner:河南省淇县永达食业有限公司

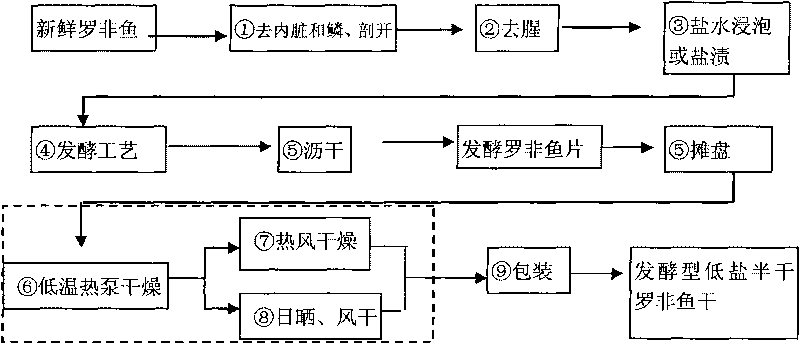

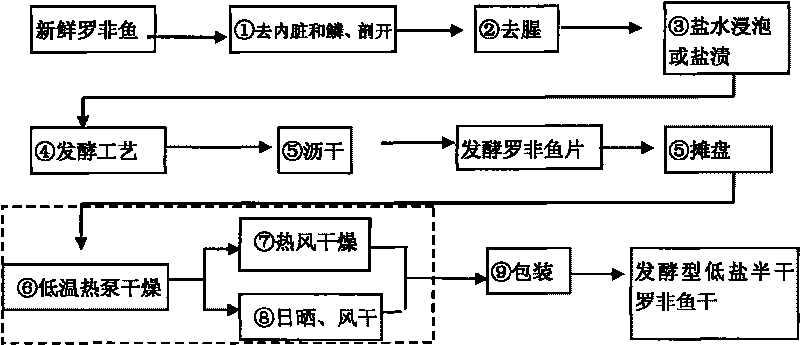

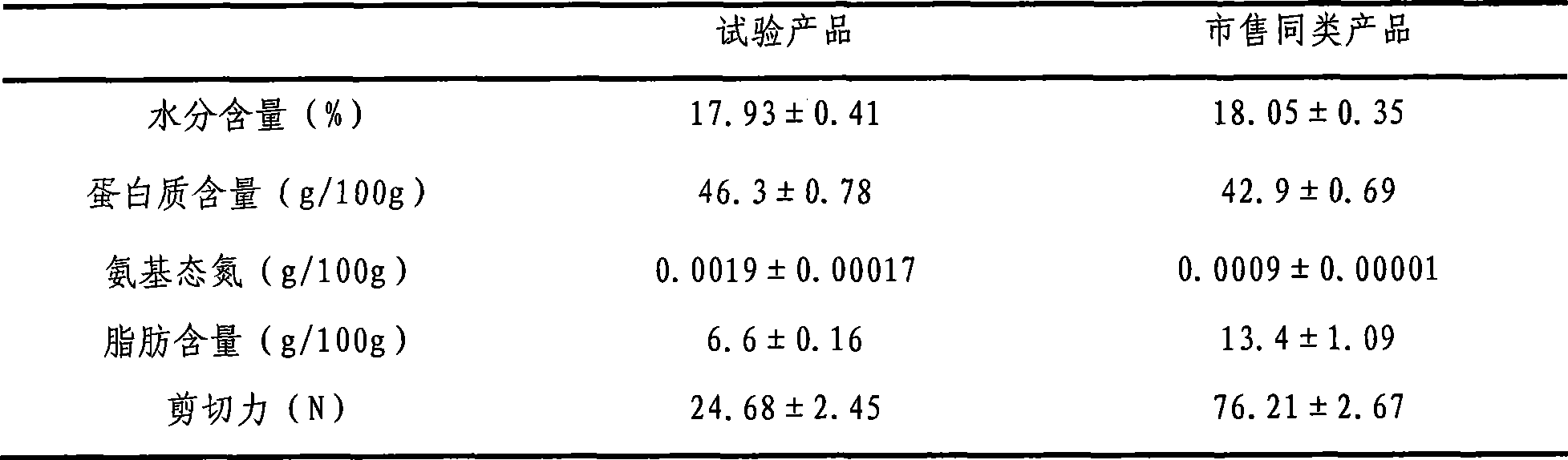

Fermented low-salt semi-dried tilapia mossambica, processing method thereof and application thereof

InactiveCN101744316AAchieving Controlled FermentationPromote dissolutionFood preparationSaline waterFlavor

The invention discloses a fermented low-salt semi-dried tilapia mossambica, a processing method thereof and application thereof. The processing method comprises the steps of: removing the internal organs and the scales of the tilapia mossambica; cutting along backside or abdomen; overturning; flatly pressing to form a symmetrical tilapia mossambica piece except the tail of the tilapia mossambica;washing with cleaning water; washing with salt water with 1%-4% of concentration to remove fishy smell and obtain the tilapia mossambica piece without the fishy smell; paving salt on the surface of the tilapia mossambica piece without the fishy smell, wherein the weight of the salt is equal to 3-8% of that of the tilapia mossambica; sousing for 8-24 hours; drying; or soaking for 8-24 hours with 5-10% of salt water to obtain the low-salt tilapia mossambica piece; spraying zymophyte on the surface of the tilapia mossambica piece, wherein the inoculum size of the zymophyte is 105-107 CFU / g fish meat; fermenting for 10-48 hours in a sealing way under the temperature of 12-20 DEG C; and drying the fermented tilapia mossambica piece to obtain the fermented low-salt semi-dried tilapia mossambicawith 30-60% of water content. The product has lubricating meat quality and typical flavor of dried meat. The processing method can be adapted to processing freshwater fishes.

Owner:汕尾市利群农业食品有限公司

Method for processing recombined dried meat

The invention discloses a manufacture method of recombinant dried beef. The method comprises the following steps: green beef or thawed beef is selected; regarding the beef sample quantity of 0.46mg / g as a reference, bromelain is weighed (specific activity unit: 1200Mu / g ) and diluted into bromelain solution, and then is injected into different parts of the beef; after being rolled and rubbed for 10 to 20 minutes, the beef reacts at the temperature of 40 DEG C for 1.5 hours; the beef is prickled; the prickled beef is dewatered and divided into two parts; one part is steamed and boiled until maturity, and cut and blended as beef grains; the other part of the green beef is dewatered and cut and blended as beef emulsion; the boiled and cut and blended beef grains and the green beef emulsion are evenly mixed; the proportion of the beef grains and the beef emulsion is 0.5-2: 1; TG enzyme is added to the beef by 2-10mg / g; the cooked and the fresh beef are jointed and shaped under the condition that the TG enzyme and the pressure are 1.5-3 N / cm<2>; and then the beef is steamed and boiled, roasted and packaged. The dried beef has the advantages of soft mouth feel, low hardness and bright color and luster.

Owner:GUIZHOU UNIV

Dried meat floss with straw mushroom and preparation method thereof

Disclosed is a dried meat floss of mushroom extract and its preparing process, which comprises 69% of mushroom stems and 31% of quelite, and the quelite comprises 18.6% of soy sauce, 16.3% of refined white sugar, 30.2% of table salt, 11.6% of ginger ale and 23.2% of vegetable oil. The preparation method consists of dressing mushroom stems, softening, parboiling and charging findings, then drying and packaging.

Owner:襄阳大山健康食品股份有限公司

Methods for preparing shredded mushroom and mushroom dried meat floss

The invention discloses methods for preparing shredded mushroom and mushroom dried meat floss by using stems of waste mushrooms generated during mushroom processing. The method for preparing shredded mushroom comprises the following steps of: sequentially carrying out softening process, acid soaking process, high-pressure saturated steam process and shredding process on the stems of mushrooms to prepare the shredded mushroom. The method for preparing mushroom dried meat floss comprises the following steps of: mixing the shredded mushroom with raw materials with different flavors, frying and twisting to be loose. Pyroligneous and high-pressure steam process in the method provided by the invention can soften and separate fibrous tissues of the stems of mushrooms furthest so that the fibers of the stems of the mushrooms are completely and thoroughly separated, and the diameter of the prepared shredded mushroom stem is between 0.4mm and 0.5mm. The mushroom dried meat floss prepared with the method provided by the invention is mellow and tasty, contains more dietary fibers, and has favorable practical value and popularization prospect.

Owner:健盛食品股份有限公司

Technique of preparing lactic acid bacteria zymolysis carrot and its products

InactiveCN101161109ARealize comprehensive utilizationIncrease product added valueConfectionerySweetmeatsFlavorAdditive ingredient

The present invention discloses a technics for preparing lactobacillus ferment carrot and its products. Using the carrot as raw material, to inoculate high effect complex lactobacillus ferment agent by manpower, and to ferment under the condition of non-oxygen, middle-temperature and slow speed, to produce acti-ferment carrot dried meat, carrot catsup and carrot drink after ferment. The ferment product keeps the connatural nutrition components of the carrot, has the special nutrition and flavor of lactobacillus ferment carrot, acid taste gentleness, aroma purity without any essence, pigment and antiseptic, it is a new type natural carrot ferment product. The present invention uses a new technics for carrot processing, adds new breed for lactobacillus ferment food as well as drink, and is easy to produce with industrialization.

Owner:辽宁省农业科学院食品与加工研究所

Method for processing low-salt dried poultry snack product

ActiveCN101606722ASimple manufacturing processSave the pickling processFood preparationSnack foodPotassium

The invention relates to a method for processing a low-salt dried poultry snack product. The method is characterized by adopting a new technical method which comprises steps of 'cutting and separating poultry, wringing, proportioning, low temperature cutting and mixing, shaping, infrared high temperature baking, intermediate temperature hot air drying, cooling, slitting, packing and outputting finished products', adopting food-grade compounded salt comprising potassium, sodium and calcium to replace traditional sodium salt so as to reduce the content of sodium salt in product and enhance the microelement composition of meat product while preserving original quality of meat product, and introducting the advanced methods such as low-temperature cutting and mixing, infrared high temperature baking and the like to simplify traditional process. The method is applicalbe to the preparation of dried poultry such as chicken, duck, goose and the like, and the low-salt dried poultry snack with easy-chewing property, strong meat flavor, even cutting section, clean appearance and salt content of not greater than 3.5 percent can be obtained while simplifying traditional dried meat preparing process and shorting process period. The method is positively significant for promoting technical development of traditional poultry food industry and meeting the requirement to health-keeping snack foods.

Owner:HEFEI UNIV OF TECH

Method for producing dried hawthorn roll meat paste slices

The invention discloses a method for producing dried hawthorn roll meat paste slices. The dried hawthorn roll meat paste slices are prepared by using lean pork as raw material, adding 8 to 10 weight parts of white granulated sugar, 1 weight part of monosodium glutamate, 0.5 weight part of salt, 1 to 1.5 weight parts of soy sauce, 0.5 weight part of pork refined cream, 0.1 to 0.2 weight part of composite phosphate and 0.1 to 0.2 weight part of ground cinnamon, pickling for 2.5 hours, carrying out batching on the pickled components and 30 to 50 weight parts of hawthorn paste and 3 to 4 weight parts of tomato sauce, uniformly mixing and then carrying out smearing, baking, roasting, cooling, cutting and packaging. The pork meat paste slices are processed by adopting a novel process; the dried hawthorn roll meat paste slices reach taste of conventional dried meat slices; cost of the dried meat slices is reduced; fruit and vegetable nutrition is added; varieties are increased; and flavor is improved. The production method not only is reasonable and practical, but also is simple to operate, has a good effect and is beneficial to be widely popularized.

Owner:ANHUI TRUELOVE FOODS

Tea-flavor dried meat floss muffin

InactiveCN103598303ASimple preparation processNatural materialsDough treatmentBakery productsFood additiveBiotechnology

A tea-flavor dried meat floss muffin is composed of, by weight, 270-280 parts of flour, 4-5 parts of yeast powder, 40-50 parts of polished round-grained rice powder, 20-30 parts of papaya powder, 8-10 parts of lotus leaf powder, 30-40 parts of red beans, 30-40 parts of coconut jelly, 60-70 parts of milk, 8-10 parts of green tea, 5-6 parts of dark plum fruit, 4-5 parts of rehmannia glutinosa libosch, 4-5 parts of folium mori, 5-6 parts of Chinese herbaceous peony, 5-6 parts of lucid ganoderma, 5-6 parts of angelica sinensis, 4-5 parts of pepper, 3-4 parts of piper longum, 4-5 parts of polygonum multiflorum, 5-6 parts of seen oroxyli, 3-4 parts of osmanthus fragrans, 5-6 parts of food additives, an appropriate amount of salt, an appropriate amount of white sugar and an appropriate amount of water. The tea-flavor dried meat floss muffin is simple in technology, natural in raw material and good in mouthfeel and is a healthy leisure food. The tea-flavor dried meat floss muffin has beautifying and slimming functions due to the addition of the papaya powder and the lotus leaf powder. The addition of extractives such as the green tea, the dark plum fruit, the rehmannia glutinosa libosch and the folium mori enables the special health care function to be achieved, and therefore the tea-flavor dried meat floss muffin is beneficial to human health.

Owner:王新新

Recombined fruit and vegetable coarse cereal instant food and machining method thereof

InactiveCN102960633APromote digestionFood convenienceFood preparationAdditive ingredientHuman health

The invention relates to a machining method of instant foods with comprehensive nutrition, and particularly relates to the recombined fruit and vegetable coarse cereal instant food and a machining method thereof. Fruits and vegetables, and meats are dehydrated by using a vacuum freezing and drying method; coarse cereals are cooked by using a puffing method; the frozen and dried fruits and vegetables, and the frozen and dried meats are mixed with the puffed coarse cereals, dextrin and milk powder to carry out superfine grinding; and compound probiotics are added so that the final products are obtained. The method disclosed by the invention keeps nutritional components in ingredients to the greatest extent and provides probiotics which are beneficial to human health. The formula is formed by natural raw materials and any preservative is added; and the recombined fruit and vegetable coarse cereal instant food is natural and healthy, has comprehensive and balanced nutrition, is easily digested, is suitable for being used by people of all ages, and is particularly suitable for being used for nutrition replenishing, used as extra meals or replaced meals for students or tourists.

Owner:SOUTHWEST UNIVERSITY FOR NATIONALITIES +1

Bean dreg biscuits

InactiveCN103371212AHas beauty benefitsGood for healthDough treatmentBakery productsBiotechnologyAdditive ingredient

Owner:梁伟

Processing method of polypeptides dried meat floss rich in nutrient

ActiveCN101305811AHigh yieldImprove biological nutritional potencyAnimal proteins working-upFood preparationFood flavorVitamin

The invention discloses a method for processing nutrition-rich polypeptide meat floss, which comprises following steps: processing the raw materials, cutting, stirring, emulsifying, heating, aging, hydrolyzing with enzyme to obtain polypeptide, preparing carrot paste, homogenizing and drying, flavoring, and packaging. The method combined with the prior bio-enzymolysis technology and conventional meat floss processing technology can process meat floss with rich nutrition, good absorption effect and unique flavor by adding vitamins such as carrot.

Owner:西藏林芝绝味食品有限公司

Preparation method of dried rabbit meat nutritional food

The invention relates to convenience food, and in particular relates to a preparation method of dried rabbit meat nutritional food, wherein rabbit meat is taken as a main raw material and nutritious Chinese herbal medicines are taken as auxiliary materials. The preparation method comprises the following steps: (1) preparing the materials; (2) arranging and soaking; (3) preserving; (4) marinating; (5) slicing; and (6) making dried rabbit meat. The rabbit meat food processed by the preparation method has diversified flavors, namely the flavors can be changed by adding flavorings according to different tastes of various groups; and the food has the characteristics of crispy outside and tender inside without greasiness and fragrant and sweet taste, and can be easily chewed without weariness, thus being suitable for people of all ages and realizing wide application range.

Owner:马小真

Purple sweet potato-meat floss rice crust and preparation method thereof

The invention discloses a purple sweet potato and meat floss-rice crust and a preparation method thereof. The purple sweet potato-meat floss rice crust is prepared from the following raw materials in parts by weight: 70-90 parts of rice, 50-60 parts of sticky rice, 30-40 parts of millet, 50-60 parts of purple sweet potato, 30-40 parts of sweet potato, 15-25 parts of dried meat floss, 5-10 parts of cassava starch, 3-5 parts of five spice powder, 2-3 parts of salt, 3-5 parts of xylitol and 10-20 parts of rapeseed oil. According to the purple sweet potato-meat floss rice crust, the process is simple and can be easily implemented, the finished product is uniform in thickness, the black and white colors are distributed uniformly, and the rice crust is fragrant and crispy, integrates the specific flavors of purple sweet potato and meat floss, has specific flavor and rich nutrition, can improve the intestine and stomach function, promote the digestion and improve the balance of the blood glucose and the blood fat, and can resist fatigue and restore the body function after being eaten commonly, and is beneficial to human health.

Owner:赵敬哲

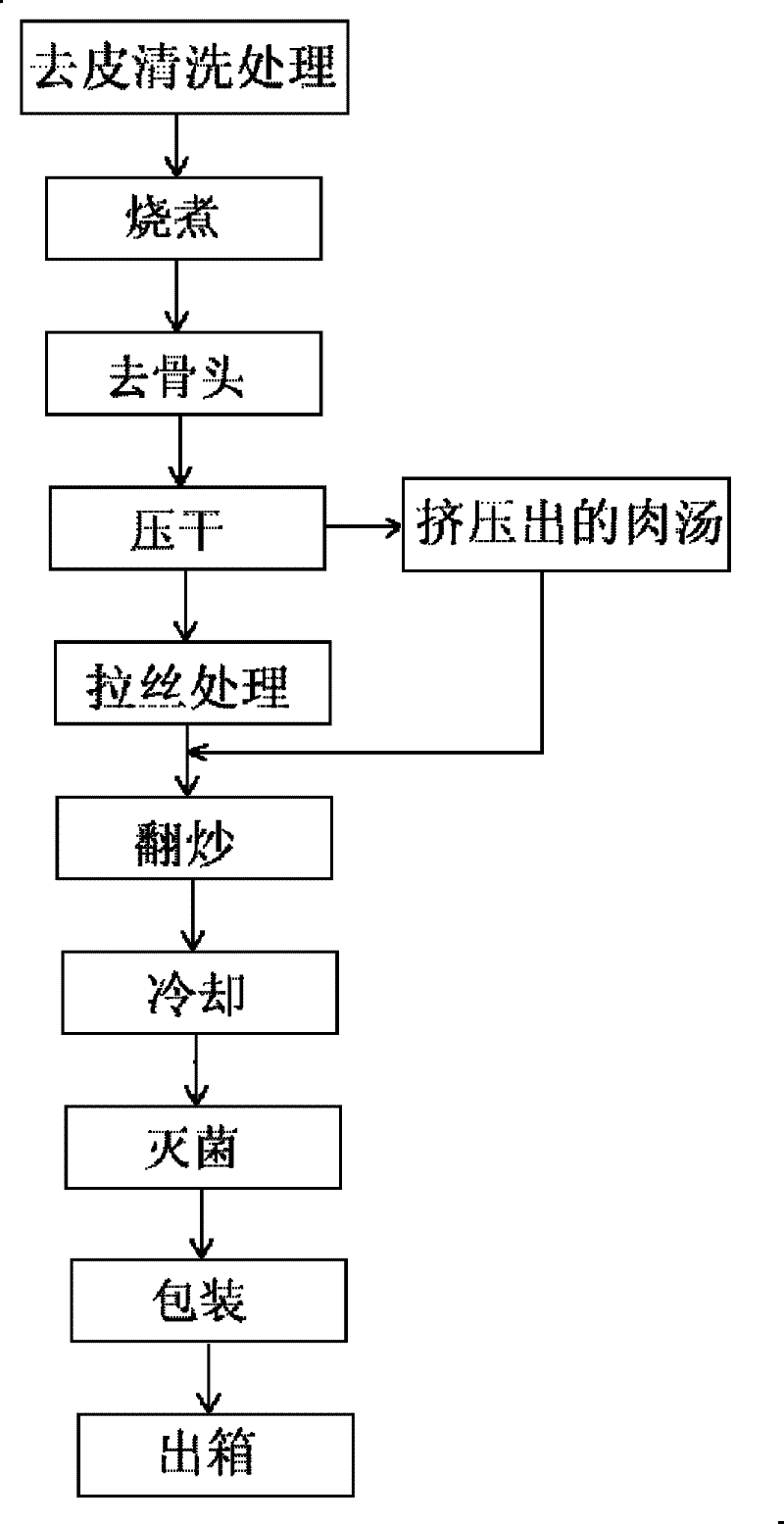

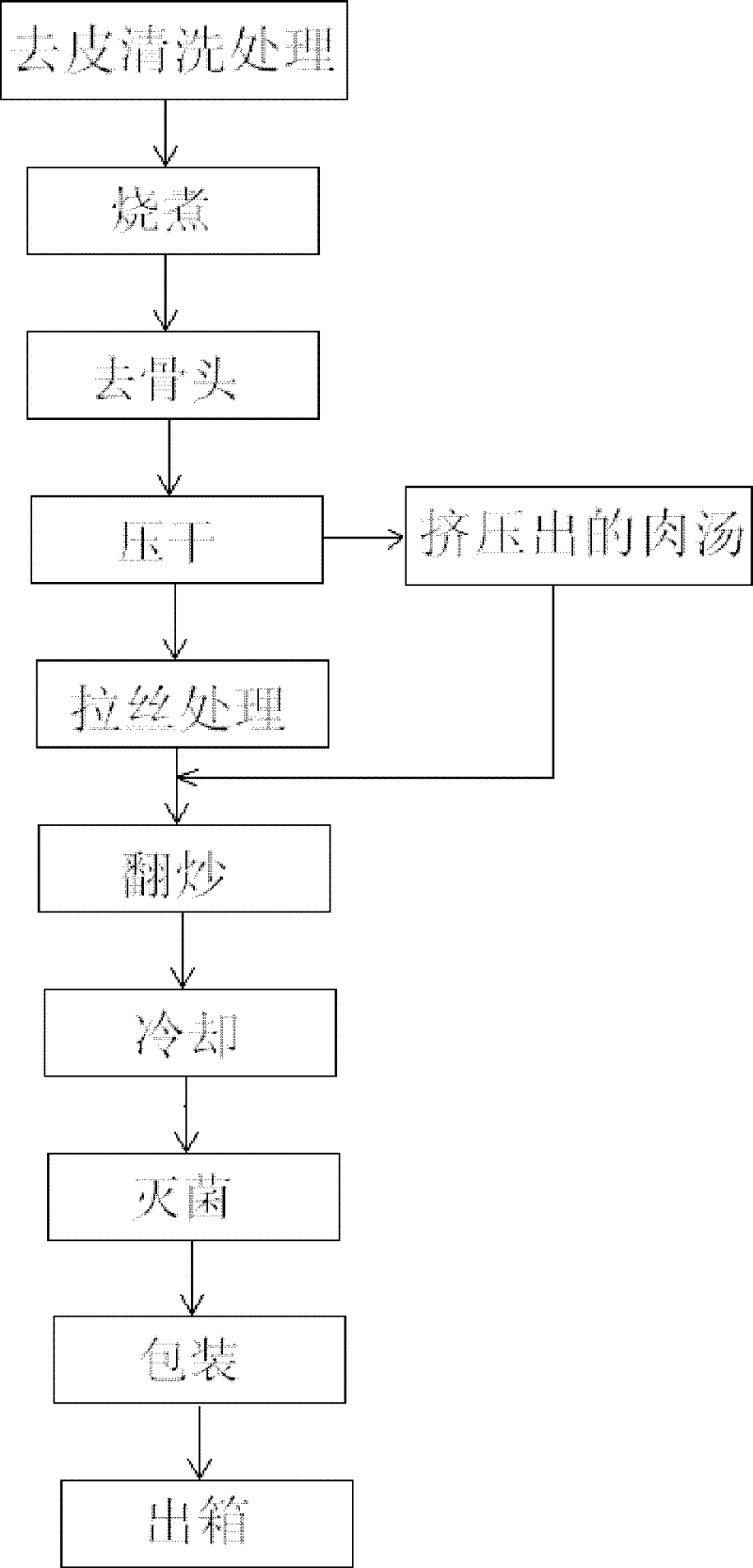

A kind of preparation method of meat floss

The invention discloses a method for making dried meat floss. The specific steps are as follows: take fresh pork leg meat and carry out peeling and cleaning treatment; add prepared soup material to the cleaned pork leg meat and stir for 2 to 3 hours; Pour the pork leg meat and soup into the pot, simmer for 8-10 hours, remove the bones; dry the boneless meat fibers until the water content is 20%-25%, and squeeze out the broth for use The dried meat fiber is drawn, and then the above-mentioned broth to be used is stirred evenly, and then stir-fried; the stir-fried meat floss is cooled, sterilized, packaged, and out of the box. Compared with the prior art, the present invention has the following advantages: the present invention uses fresh pork leg bones as raw materials, and braises with the bones, which not only reduces the damage to the meat fiber, but also presses out the bone oil to enhance the brightness of the meat floss , retain the nutritious flavor in the meat and bones, so that the produced meat floss keeps the original flavor, fresh and tender taste, rich in nutrition.

Owner:TAICANG FEIFENG FOOD

Matcha beef dried meat slice

The invention provides a matcha beef dried meat slice, comprising the following raw materials by weight: 200 to 230 part of beef, 50 to 70 parts of chicken breast, 60 to 80 parts of lotus root starch, 20 to 30 parts of black fungus, 30 to 40 parts of red date, 30 to 40 parts of green tea powder, 30 to 40 parts of black tea powder, 20 to 30 parts of banana, 4 to 5 parts of China rose, 5 to 6 parts of Sichuan lovage rhizome, 5 to 6 parts of wolfberry, 5 to 6 parts of Phlegmariurus petiolatus, 7 to 8 parts of dwarf lilyturf tuber, 7 to 8 parts of lily bulb, 3 to 4 parts of flax leaf, 3 to 4 parts of willow leaf, 100 to 130 parts of cola, 40 to 60 parts of salt, 50 to 60 parts of olive oil, 20 to 60 parts of white sugar and a proper amount of water. According to the invention, beef is used as a main raw material, a small amount of chicken breast is added to improve the taste of the dried meat slice, and fruits and vegetables like the red date and the banana are added to increase contents of vitamins and dietary fiber in the dried meat slice; meanwhile, the China rose especially added in the process of preparation of the dried meat slice has blood stasis removing, qi circulation promoting, swelling eliminating and toxin removing effects and the like, the wolfberry has eyesight improving and beauty fostering effects and the like, so the matcha beef dried meat slice provided by the invention has a good health care effect, is health food with good taste and is applicable to most people.

Owner:HEFEI FULAIDUO FOOD

Method for improving dried meat slice sensory quality

The present invention provides a method for improving dried meat slice sensory quality, and belongs to the technical field of food processing. According to the present invention, the method includes adding 1-5% by weight of trehalose in dried meat slice production, the trehalose wholy or partly replaces sucrose in the dried meat slice formula, and is added together with accessories or food additives in the process of salting, wherein the salting is at low temperature or room temperature, and then the dried meat slice is produced by a conventional dried meat slice production process or a meat paste production process. The method of the present invention can slow hardening of protein and decomposition and oxidation of unsaturated fatty acid, reduce non-enzymatic browning occurrence, improve drying speed of the meat slice, improve baking performance of the dried meat slice, improve rehydration performance of the dried meat slice, and achieve good sensory quality including good elasticity, bright color, delicate tissue, tender quality and good taste.

Owner:HANSHAN NORMAL UNIV

Preparation method of edible jerky and calfskin, pigskin and fish skin biting chew for pet

ActiveCN102630827AImprove freshnessReduce fishy smellAnimal feeding stuffWorking-up animal fodderRaw meatBiting

The invention relates to the field of pet food, and in particular relates to a preparation method of edible jerky and calfskin, pigskin and fish skin biting chew for a pet. According to the preparation method disclosed by the invention, poultry, livestock meat or bright flesh of fish or fresh skin of animals such as pig, calf and fish is taken as raw material, the raw material is minced and chopped, moulded and frozen and then split, or the raw material is directly split and then frozen, or the raw material is split into the required shape and then frozen, subsequently microwave vacuum dryingis carried out, and sterilizing and packaging are carried out, and thus the edible jerky or calfskin, pigskin and fish skin biting chew for the pet is obtained. The edible jerky or calfskin, pigskin and fish skin biting chew finished product can show primary colour of raw meat, has a strong meat flavour and maintains nutrition of a meat product while a food calling function is realized. The edible jerky or calfskin, pigskin and fish skin biting chew can be taken as a meat snack for the pet and also can be taken as a nutritional supplement for an old-aged dog or little dog after being rewatered and torn up.

Owner:JIANGSU YIHE PET PROD CO LTD

Method for preparing semi-dry conditioning shredded beef by combination of medium-short wave infrared vacuum drying and flexible sterilization

InactiveCN105146553AHas a long shelf lifeThe production process is environmentally friendly and efficientFood preparationMeat/fish preservation by dryingFiberProduct processing

The invention relates to a method for preparing semi-dry conditioning shredded beef by combination of medium-short wave infrared vacuum drying and flexible sterilization, and belongs to the field of meat product processing. The semi-dry conditioning shredded beef is prepared by the following steps: with fresh beef as a main raw material, carrying out raw material pretreatment, pickling, boiling, slicing, frying, medium-short wave infrared vacuum drying, vacuum packaging, and nano-zinc oxide combined with radio flexible sterilization, so as to prepare the product semi-dry conditioning shredded beef. According to the conditioning shredded beef processed by the method provided by the invention, the moisture content is 40%-50%, and conforms to the characteristics of semi-dry meat products; the shearing force is relatively small and is about 4kg; the shredded beef is fresh and tender in meat; and the shredded beef is good in fiber tenacity, has obvious shredding feel in texture, and has natural tan of beef in color and luster. The method is a preparation method of the semi-dry conditioning shredded beef, which is high in yield, long in quality guarantee period, simple in technological process, low in energy consumption and suitable for industrial production.

Owner:JIANGNAN UNIV +1

Technique for preparing yam convenient porridge

InactiveCN101642212AFully maintain nutrientsEasy to carryFood shapingFood preparationAdditive ingredientGlucose polymers

The invention belongs to the field of foods, which in particular relates to a technique for preparing yam convenient porridge. The yam convenient porridge comprises the components of rice, yam and corn starch. The method comprises the following steps: firstly, sieving with a sieve of 80 meshes after pulverizing the rice and the yam respectively, mixing the rice after being pulverized again, the yam after being pulverized again and the corn starch in the proportion of 50-80 parts of rice, 10-30 parts of yam and 15-30 parts of corn starch according to parts by weight, pulping, then delivering into a roller drier for curing and forming after milling with colloids, and preparing porridge pieces of 5*5mm by a pulverizer; taking the porridge pieces as a basis and adding glucose and pregelatinized starch into the porridge pieces; or, adding flavoring dry meat; or, adding flavorings; or, adding the glucose, the pregelatinized starch, the flavoring dry meat and the flavorings and also adding dewatered scallion and the like to prepare the yam convenient porridge with various tastes. The invention can fully keep the nutritional components of the yam, has convenient carrying, light weight, long storage period and convenient and easy infusion and is a convenient food conforming to the modern quick-rhythm life.

Owner:JIANGXI AYING JINSHANYAO FOOD GRP CO LTD

Making method of dried duck meat slices with excellent taste

The invention discloses a making method of dried duck meat slices with excellent taste. The making method comprises the following production steps of: removing skin and fat of fresh dust breast meat, eliminating bones, trimming, shaping and mincing duck skin for later use; uniformly mixing to prepare sauce for later use; cutting the duck breast meat into meat slices; placing the meat slices into the sauce for soaking, further increasing the temperature of the sauce for stewing the meat slices, taking out the meat slices, draining and then placing into a refrigerating chamber; preparing auxiliary materials for later use; placing the auxiliary materials and the meat slices into a vacuum rolling and kneading machine for rolling and kneading; loading the meat slices which are well rolled and kneaded into a mold, and placing into a freezing chamber for freezing; cutting the meat slices which are well frozen into the meat slices, and then placing into a drying room for drying; placing the meat slices after drying into a far-infrared dried meat slice roasting machine for roasting; and cooling the meat slices to normal temperature, then packaging through an automatic packaging machine, and further performing conventional microwave sterilization to prepare a product disclosed by the invention. The dried duck meat slices made by the making method disclosed by the invention have the advantages of aromatic flavor, abundant nutrition, good product elasticity, excellent taste and broad market prospects.

Owner:广东真美食品股份有限公司

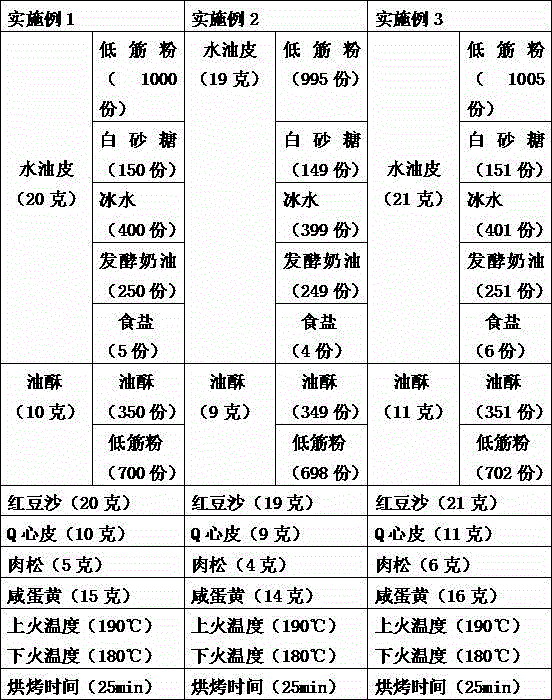

Filling-in-filling mooncake and preparation method thereof

The invention discloses a filling-in-filling mooncake. According to the technical scheme, the filling-in-filling mooncake is characterized by comprising a wrapper, fried crisp and filling, wherein the wrapper comprises water-oiled wrapper; the water-oiled wrapper comprises 995 to 1,005 parts of weak strength flour, 148 to 152 parts of white granulated sugar, 4 to 6 parts of table salt, 399 to 401 parts of ice water, and 249 to 251 parts of cultured butter; the fried crisp comprises 349 to 351 parts of butter, and 698 to 702 parts of weak strength flour; the filling is prepared through the following raw materials: 19 to 21 parts of red bean paste, 9 to 11 parts of elastic core cover, 4 to 6 parts of dried meat floss, and 14 to 16 parts of salted egg yolk. The filling-in-filling mooncake has the advantages of being crispy, rich in filling, and diversified in tastes.

Owner:WENZHOU XIWEITE FOOD

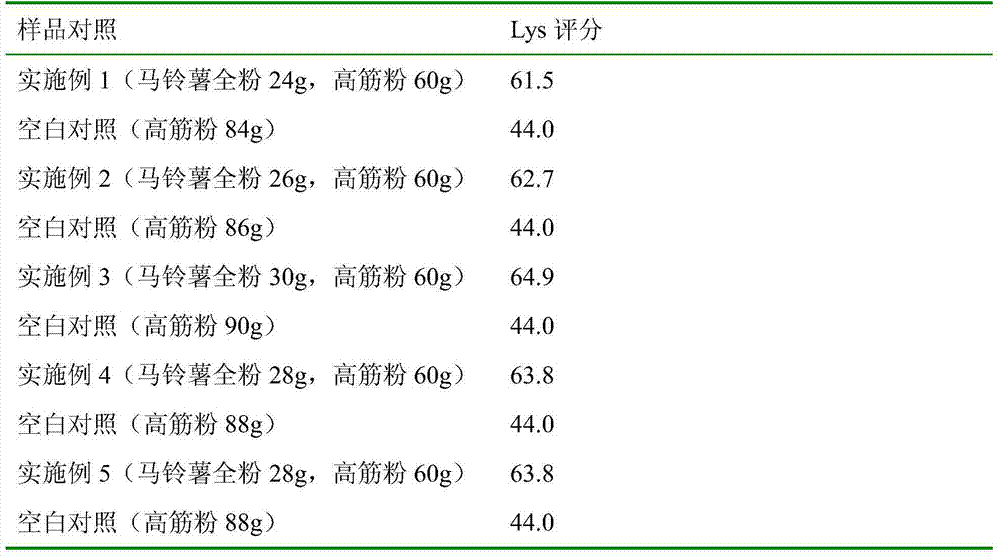

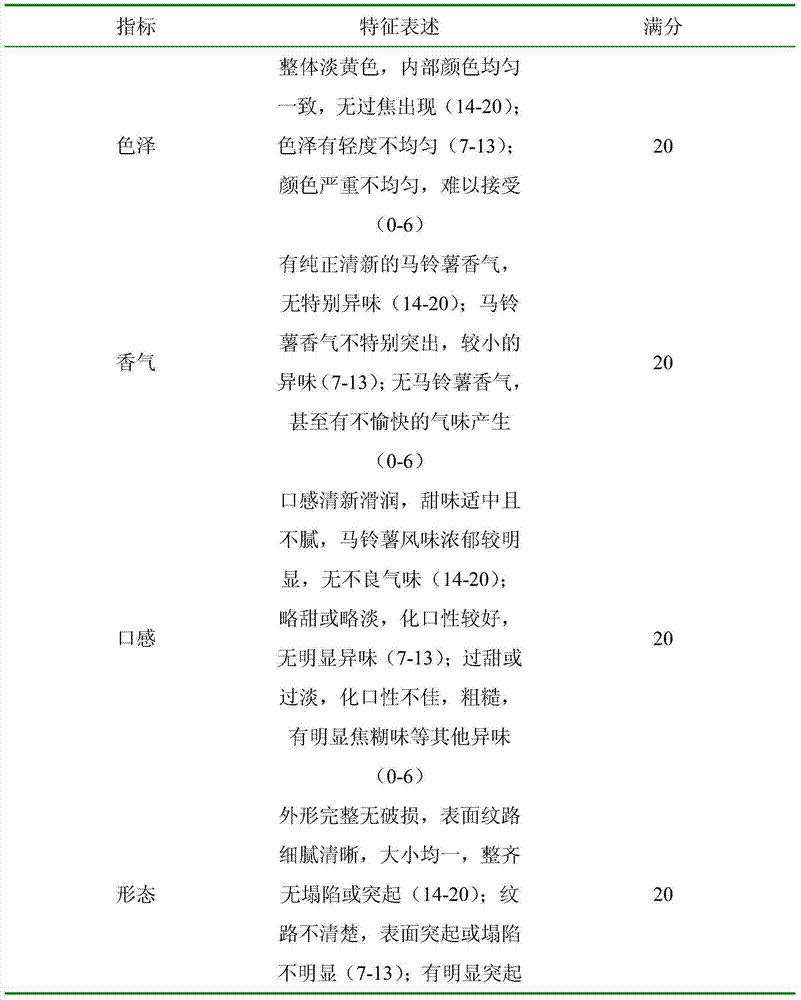

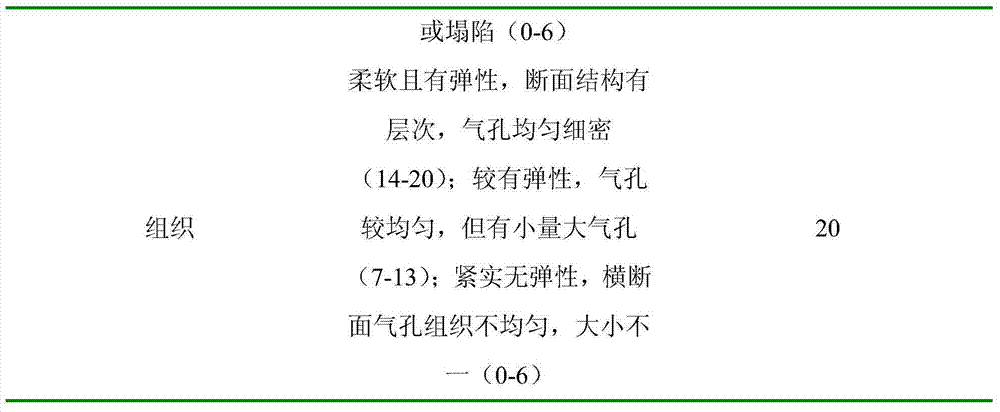

Potato staple food cake and making method thereof

InactiveCN104770452AIncrease contentRich in nutrientsDough treatmentBakery productsPhosphatePhosphoric acid

The invention provides potato staple food cake and a making method thereof. The potato staple food cake comprises, by weight, 20-50 parts of potato flour, 30-80 parts of high gluten flour, 80-240 parts of eggs, 0.1-1.5 parts of baking powder, 0.1-1.8 parts of edible slat; 80-135 parts of white sugar, 1-12 parts of milk powder, 3-10 parts of compound cake emulgator, 10-60 parts of edible oil, 5-35 parts of water, 10-40 parts of dried meat floss and 5-35 parts of watermelon seeds. According to the potato staple food cake, the potato four and whet flour are used cooperatively, compared with cake made of ordinary low-gluten wheat flour, the protein efficiency ratio can be improved, and the content of dietary fiber, vitamins and mineral substances is increased; because the potato flour contains natural phosphate groups, the water absorbing performance and the oil absorbing performance are good, after rehydration, rich natural fragrance is generated, and a smooth taste like bean paste is achieved; in this way, the staple food cake containing the potato flour has the light potato fragrance, compared with the cake made of the ordinary low-gluten wheat flour, the sensory quality is better, and the potato staple food cake is suitable for wide popularization.

Owner:天津桂发祥十八街麻花食品股份有限公司

Spicy dried meat floss bread

InactiveCN103931693AThe preparation process is simple and environmentally friendlyFull of nutritionDough treatmentBakery productsBiotechnologyNutrition

Spicy dried meat floss bread comprises, by weight, 230-240 parts of flour, 55-65 parts of black rice flour, 10-15 parts of pine nut flour, 4-5 parts of yeast powder, 20-25 parts of lentinus edodes, 30-40 parts of cauliflower, 10-15 parts of pickled peppers, 60-70 parts of rice wine, 20-30 parts of dried beef floss, 4-6 parts of polygonum multiflorum, 5-7 parts of Flos rosae rugosa, 3-5 parts of glossy ganoderma, 4-6 parts of lotus flowers, 3-5 parts of peach blossom, 4-6 parts of mulberries, 3-5 parts of spina date seeds, 2-3 parts of peach kernels, 2-3 parts of fragrant thoroughwort and the like. According to the spicy dried meat floss bread, the making process is simple and environmentally friendly; food materials such as the lentinus edodes and the cauliflower are added and processed with the rice wine and the pickled peppers, so that a spicy taste is achieved; besides, the spicy dried meat floss bread is rich in nutrition, and the spicy dried meat floss bread has certain life cultivation and health preservation efficacy and is beneficial for human health due to the addition of traditional Chinese medicine extracts such as the polygonum multiflorum, the Flos rosae rugosa, the glossy ganoderma and the lotus flowers.

Owner:柳培健

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com