Fermented low-salt semi-dried tilapia mossambica, processing method thereof and application thereof

A processing method and technology of tilapia, which is applied in the field of food processing, can solve the problems affecting the sustainable development of the tilapia industry, fewer deep-processed products, and high salt content in products, so as to avoid rapid production, reduce moisture content, and taste Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

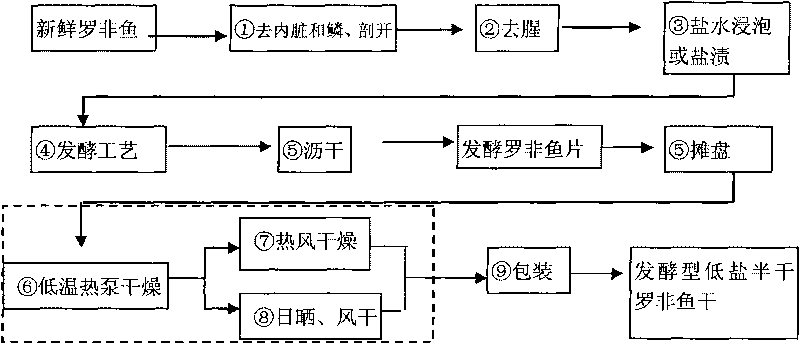

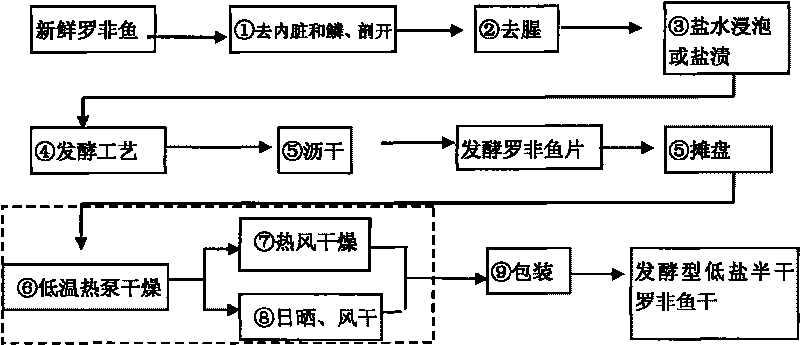

[0027] Preparation of fermented low-salt semi-dried tilapia, such as figure 1 Shown:

[0028] (1) Remove the viscera and scales of the tilapia, cut it along the back or abdomen (do not cut it), open it, and flatten it to form a nearly symmetrical fish fillet except for the tail, wash it with clean water, and use 2% salt water Wash to remove fishy smell, soak in 10% salt water for 8 hours, drain to obtain low-salt tilapia fillets;

[0029] (2) Activate Lactobacillus plantarum CICC 20022 (purchased from the China Industrial Microbiology Culture Collection Management Center) twice, inoculate 1% of the inoculum into the liquid medium for expanded cultivation, and count the strains by counting viable bacteria , put it in a refrigerator at 4°C and save it for later use; inoculate 10 per gram of fish 6 Amount of CFU Spray Lactobacillus plantarum starter onto the inner and outer surfaces of low-salt tilapia fillets, put them into a fermentation container, and ferment in a closed man...

Embodiment 2

[0035] (1) Take fresh tilapia, remove viscera and scales, cut open along the back or abdomen (do not cut off), turn over, flatten to form nearly symmetrical fish fillets except for the tail part, wash with water, and use Wash with 4% salt water to remove the fishy smell, sprinkle salt on the surface of the tilapia fillets, the amount of salt used is 5% of the weight of the fish fillets, and marinate for 20 hours to obtain low-salt tilapia fillets;

[0036] (2) Activate Lactobacillus plantarum CICC 20764 (purchased from the China Industrial Microorganism Culture Collection Management Center) and Pediococcus pentosaceae CICC 22227 (purchased from the China Industrial Microbiology Culture Collection Management Center) respectively, and inoculate them at 1% Inoculate in liquid medium (10 grams of peptone, 10 grams of beef extract, 5 grams of yeast extract, 20 grams of glucose, 2 grams of dipotassium hydrogen phosphate, 5 grams of sodium acetate, 2 grams of ammonium citrate, 0.2 gra...

Embodiment 3

[0042] (1) Remove the internal organs and scales of the tilapia, cut it along the back or abdomen (do not cut it), open it, and flatten it to form a nearly symmetrical fish fillet except for the tail part, wash it with clean water, and use 3% salt water Clean and remove the fishy smell, sprinkle salt on the inner and outer surfaces of the tilapia fillets, the consumption of salt is 3% of the fish weight, and marinate at 10°C for 8 hours to obtain low-salt tilapia fillets;

[0043] (2) Pediococcus pentosaceae CICC231908 is activated twice, inoculated in liquid medium (10 grams of peptone, 10 grams of beef extract, 5 grams of yeast extract, 20 grams of glucose, 2 grams of dipotassium hydrogen phosphate, 5 grams of sodium acetate, 2 grams of ammonium citrate, 0.2 grams of magnesium sulfate, 0.2 grams of manganese sulfate, 801 milliliters of Tween, distilled water to 1000 milliliters, pH6.2~6.6) to expand the culture, adopt the viable count method to count the bacteria Count the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com