Meat substitute food product and preparation method thereof

A meat and food technology, applied in food preparation, protein food processing, protein food ingredients, etc., can solve problems such as difficulty, imitation of texture properties, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

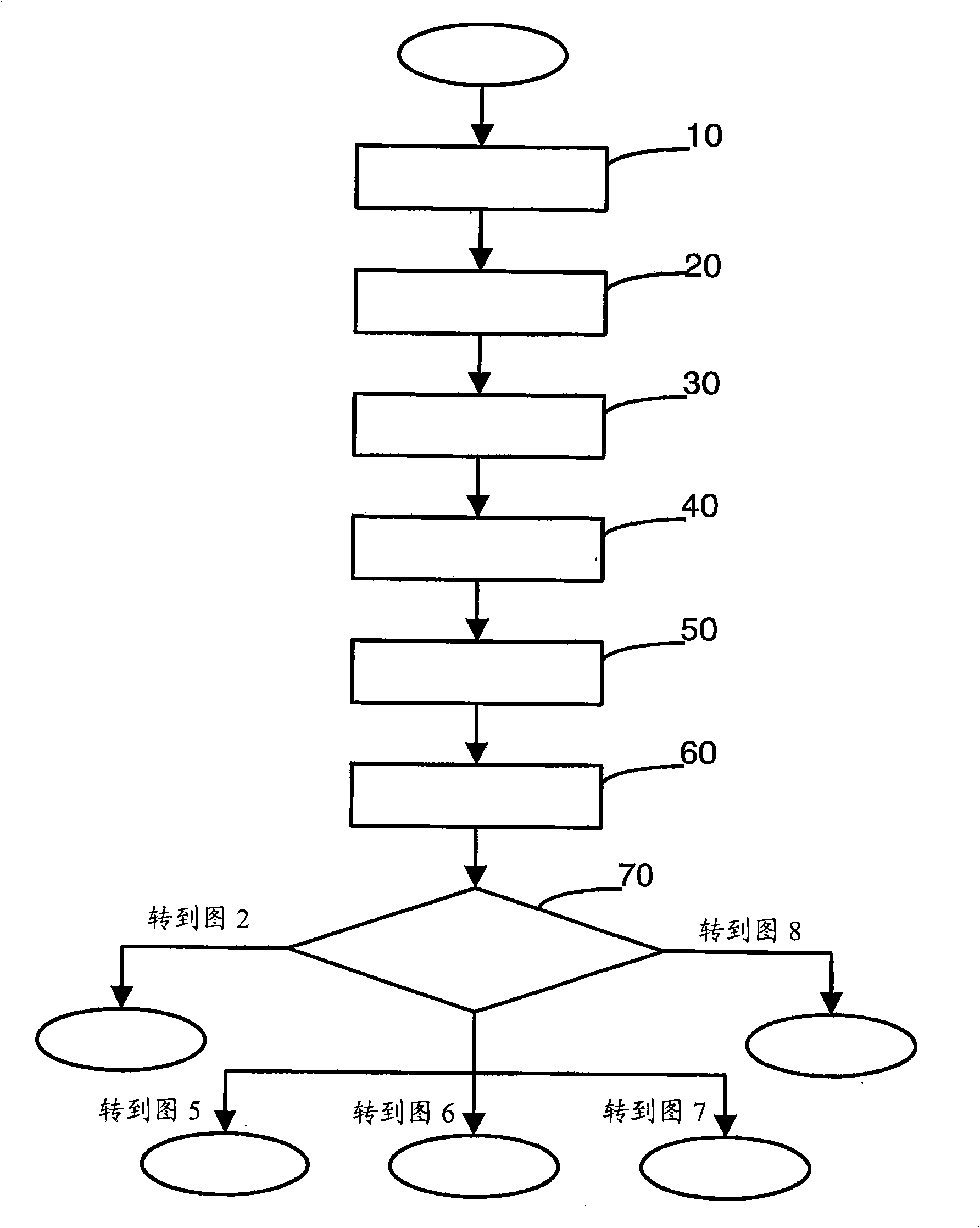

Method used

Image

Examples

preparation example Construction

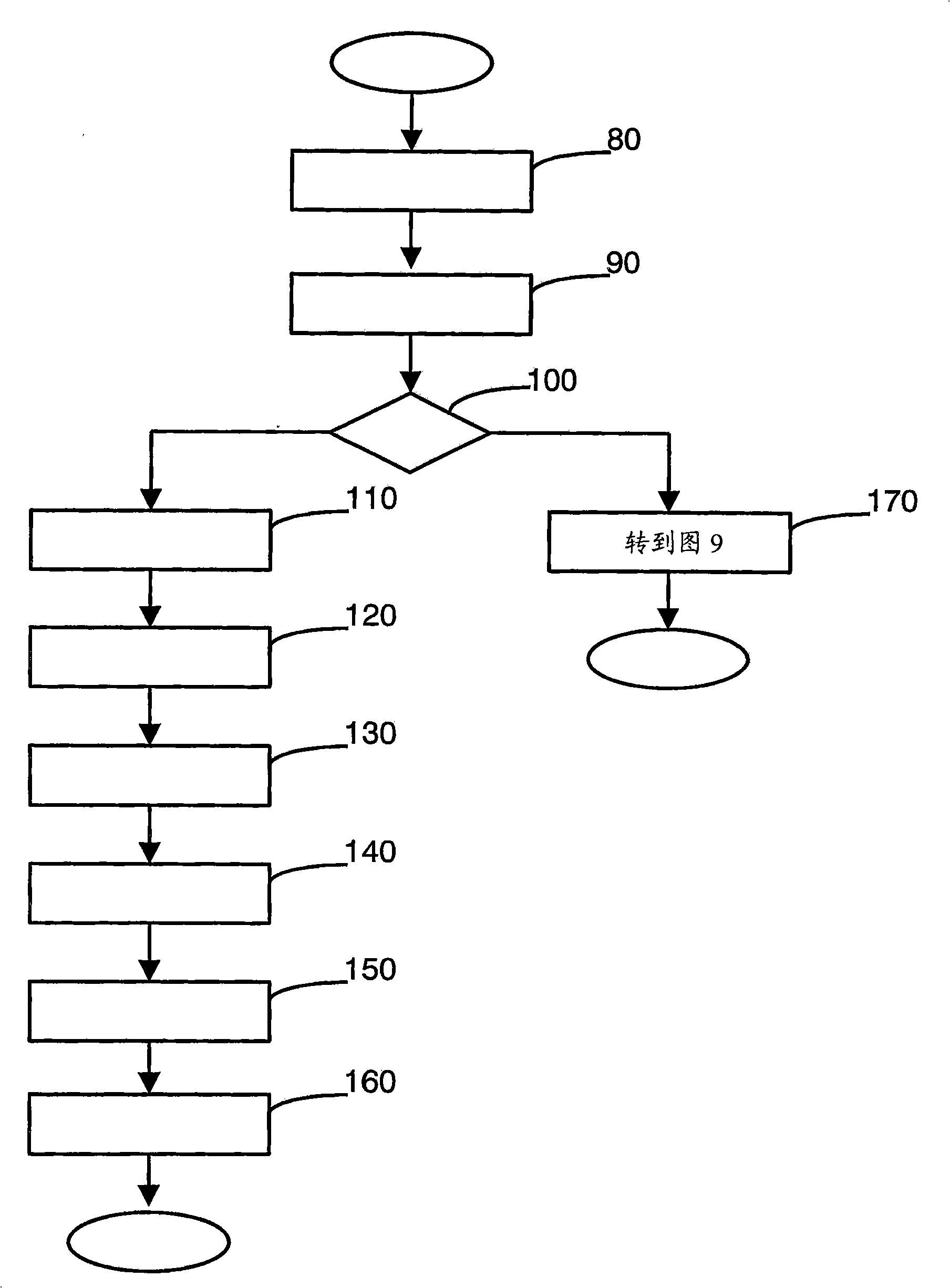

[0042] The prepared batter portion for the production of meat substitute food was subjected to the following operating conditions in the oven:

[0043] i) a residence time in the oven of about 10 seconds to about 120 seconds;

[0044] ii) The temperature of the upper and lower heating plates of the oven should be set at about 100°C to about 150°C so that the heating plates can heat the upper and lower conveyor belts of the oven within the temperature range of about 100°C to about 150°C;

[0045] iii) The distance between the upper conveyor belt and the lower conveyor belt of the oven must be adjusted within the range of 6mm to 15mm.

[0046] In step 100, after the prepared paste portion for the meat substitute food product has been rolled and cooked, one or more alternative embodiments are then selected which are suitable for imparting a final form to the cooked paste so that Get meat alternatives that have a similar appearance to your original meat product. In a first alter...

Embodiment approach

[0051] i) residence time in the fryer is from about 10 seconds to about 200 seconds;

[0052] ii) the frying temperature is from about 150°C to about 250°C;

[0053] iii) The molded or extruded batter in the fryer reaches an internal temperature of about 70°C to 80°C.

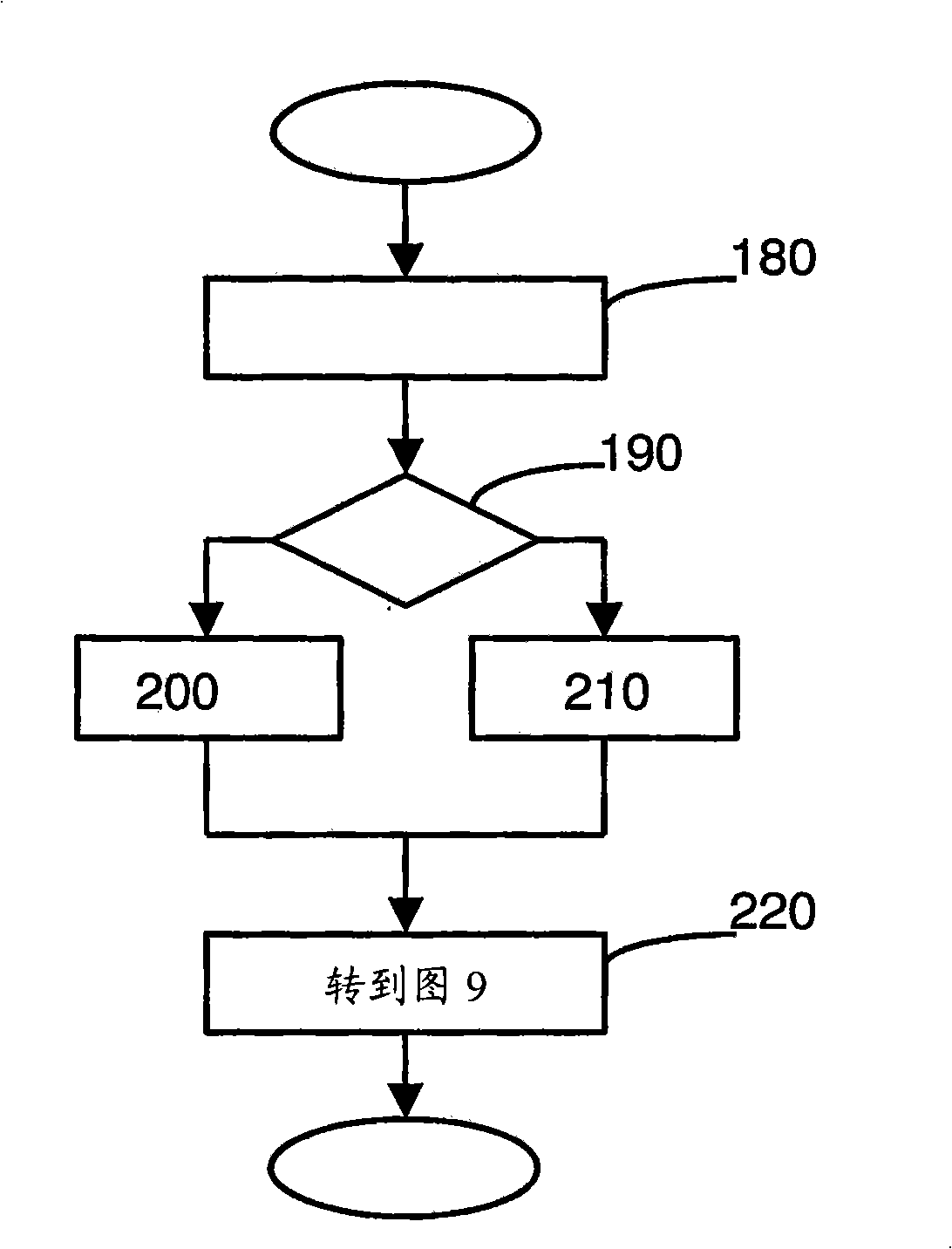

[0054] In the alternative embodiment of frying and cooking the extruded or molded batter (step 210), said embodiment is preferably carried out in a convection oven under the following operating conditions:

[0055] i) a residence time in the convection oven of about 10 seconds to about 200 seconds;

[0056] ii) the frying and cooking temperature is from about 130°C to about 250°C;

[0057] iii) The molded or extruded paste reaches an internal temperature of about 70°C to 80°C in a convection oven.

[0058] In step 220, after the prepared paste for the meat substitute food has been extruded or molded and cooked, then start selecting the following Figure 9One or more alternative embodiments described in , wh...

Embodiment 1

[0077] A quantity of 500 kg of vegetable protein in granular form was vacuum hydrated and mixed with 1500 liters of water and 15 kg of caramel color. Hydration and mixing were performed under vacuum over a period of about 70 minutes, with the paddle of the mixer rotating at 18 minutes in alternating cycles. -1 Rotation was performed with each cycle lasting approximately 3 minutes with an applied pressure of approximately -90 kPa.

[0078] After hydration and mixing, the vegetable protein is mixed with the following ingredients added in certain amounts:

[0079] Beef fat 150kg

[0080] Cut beef 100kg

[0081] Chicken Paste 1900kg

[0082] Refined salt 45kg

[0084] Preservative 25kg

[0085] Mixing is carried out first in a mixer with an open lid and over 40 minutes, with the paddle of the mixer rotating at 18 minutes in alternating cycles -1 Rotate with each cycle lasting about 7 minutes. Next, the mixer is turned off to perform a second mix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com