Preparation method of two-sheet aluminum alloy rim

A two-piece, aluminum alloy technology, used in rims, transportation and packaging, vehicle parts, etc., can solve the problems of only material utilization, consuming machining hours, and high costs, reducing mold investment and reducing costs. The effect of stability and improving material utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] A method for preparing an aluminum alloy two-piece wheel rim, comprising the following steps:

[0018] (1) Material preparation: see Figure 1a As shown, put a 6061 aluminum rod with a diameter of 180mm into an electric heating furnace and keep it warm at 500°C for 3 hours. At the same time, heat the rolling ring mold to 200°C and keep it warm;

[0019] (2) Place the heated aluminum rod on an air hammer to forge a rough material so that its height reaches 1 / 2 of the height of the hub to be formed, and punch out a center hole with a diameter of 100mm in the center of the rough material , see for details Figure 1b shown;

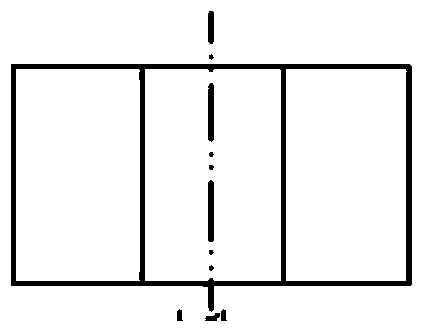

[0020] (3) Within 60 seconds, transfer the rough material with a central hole formed in step (2) to a D51-350 ring rolling machine for ring grinding to form a ring blank, and the diameter of the ring blank reaches the required hub diameter, see figure 2 shown;

[0021] (4) Put the rolling ring blank into the spinning mold for spinning to form a se...

Embodiment 2

[0024] A method for preparing an aluminum alloy two-piece wheel rim, comprising the following steps:

[0025] (1) Material preparation: see Figure 1a As shown, put a 6061 aluminum rod with a diameter of 220mm into an electric heating furnace and keep it at 530°C for 5 hours. At the same time, heat the rolling ring mold to 300°C and keep it warm;

[0026] (2) Place the heated aluminum rod on the air hammer to forge a rough material so that its height reaches 2 / 3 of the height of the hub to be formed, and punch out a center hole with a diameter of 150mm in the center of the rough material , see for details Figure 1b shown;

[0027] (3) Within 90 seconds, transfer the rough material with a central hole formed in step (2) to a D51-350 ring rolling machine for ring grinding to form a ring blank, and the diameter of the ring blank reaches the required hub diameter, see figure 2 shown;

[0028] (4) Put the rolling ring blank into the spinning mold for spinning to form a semi-f...

Embodiment 3

[0031] A method for preparing an aluminum alloy two-piece wheel rim, comprising the following steps:

[0032] (1) Material preparation: see Figure 1a As shown, put a 6061 aluminum rod with a diameter of 250mm into an electric heating furnace and keep it at 550°C for 8 hours. At the same time, heat the rolling ring mold to 250°C and keep it warm;

[0033] (2) Place the heated aluminum rod on an air hammer to forge a rough material so that its height reaches 7 / 12 of the height of the hub to be formed, and punch a center hole with a diameter of 130mm in the center of the rough material , see for details Figure 1b shown;

[0034] (3) Within 80 seconds, transfer the rough material with a central hole formed in step (2) to a D51-350 ring rolling machine for ring grinding to form a ring blank, and the diameter of the ring blank reaches the required hub diameter, see figure 2 shown;

[0035] (4) Put the rolling ring blank into the spinning mold for spinning to form a semi-finis...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com