Semi-solid slurry preparation and forming integrated equipment

A semi-solid slurry and equipment technology, applied in the field of semi-solid slurry preparation and molding integrated equipment, can solve the problems of inability to meet industrial production requirements, personal safety threats, long time consumption, etc., to save manpower and production time, The effect of shortening the molding process and reducing the energy consumption of preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

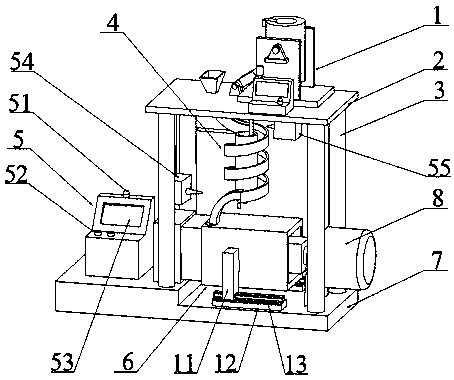

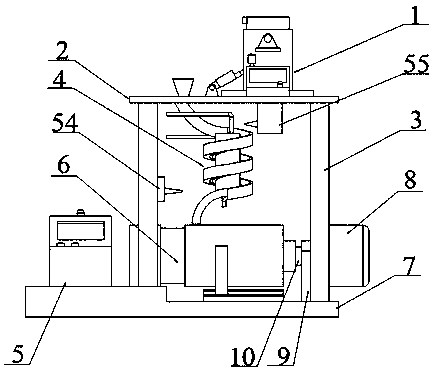

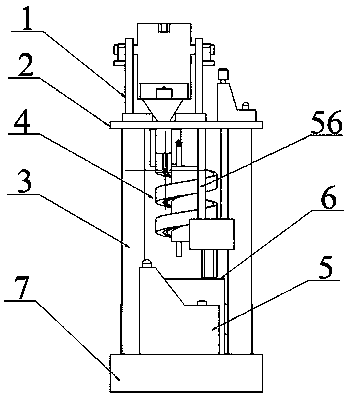

[0035] Embodiment 1: as Figure 1~9 As shown, an integrated equipment for semi-solid slurry preparation and molding, including a melting device 1, a top plate 2, a support column 3, a pulping device 4, a numerical control console 5, an extrusion molding device 6, a base 7, and a numerical control console 5 is set on the base 7, the support column 3 is vertically set on the base 7 and is located on the side of the numerical control console 5, the top plate 2 is horizontally set on the top of the support column 3, the melting device 1 is set on the top plate 2, and the extrusion molding device 6 Set on the base 7 and below the top plate 2, the pulping device 4 is set on the lower end of the top plate 2 and above the extruding device 6, the smelting device 1, the pulping device 4, and the extruding device 6 are connected in sequence and are respectively connected with the numerical control operation Station 5 connection;

[0036] The smelting device 1 includes a melting furnace ...

Embodiment 2

[0053] Embodiment 2: The structure of the semi-solid slurry preparation and molding integrated equipment in this embodiment is basically the same as the structure of the semi-solid slurry preparation and molding integrated equipment in Example 1. The difference is that the annular flow channel 29 in this embodiment The included angle with the horizontal direction is 60°, and the width of the annular flow channel 29 is 5 cm.

Embodiment 3

[0054] Embodiment 3: The structure of the semi-solid slurry preparation and molding integrated equipment in this embodiment is basically the same as the structure of the semi-solid slurry preparation and molding integrated equipment in Example 1. The difference is that the annular flow channel 29 in this embodiment The included angle with the horizontal direction is 45°, and the width of the annular flow channel 29 is 4cm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com