Hollow polygon body forming method

A molding method and prism technology, which can be used in other manufacturing equipment/tools, roads, road safety devices, etc., can solve the problems of non-compliance with requirements, few processes, and large molding molds, so as to improve strength and product quality, reduce Forming process, the effect of reducing twisting force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

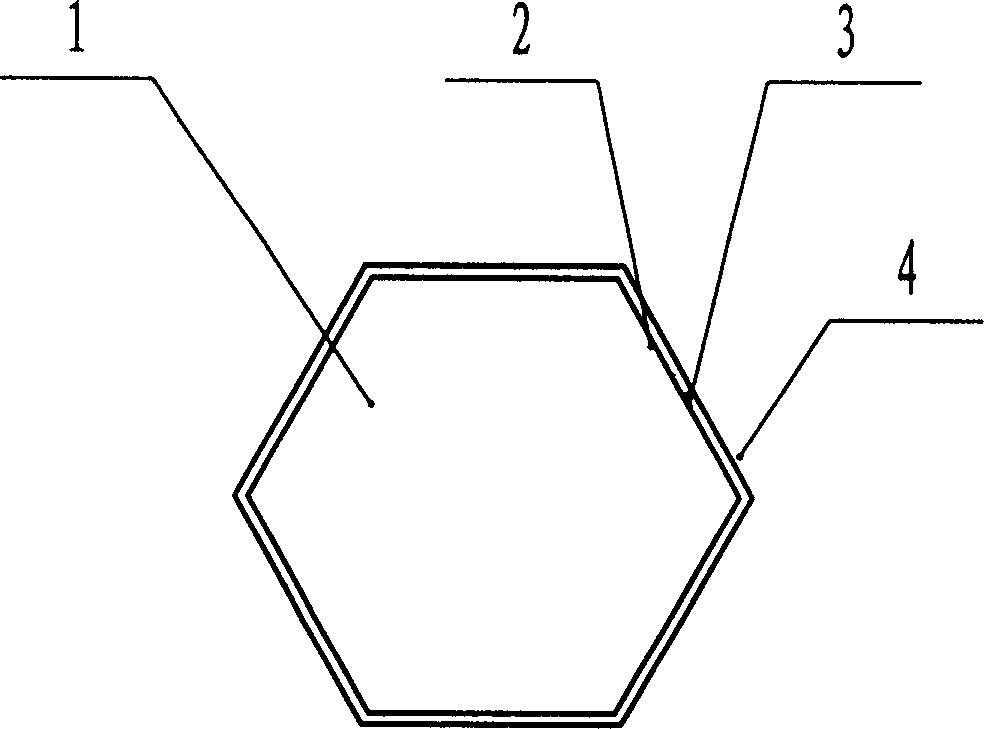

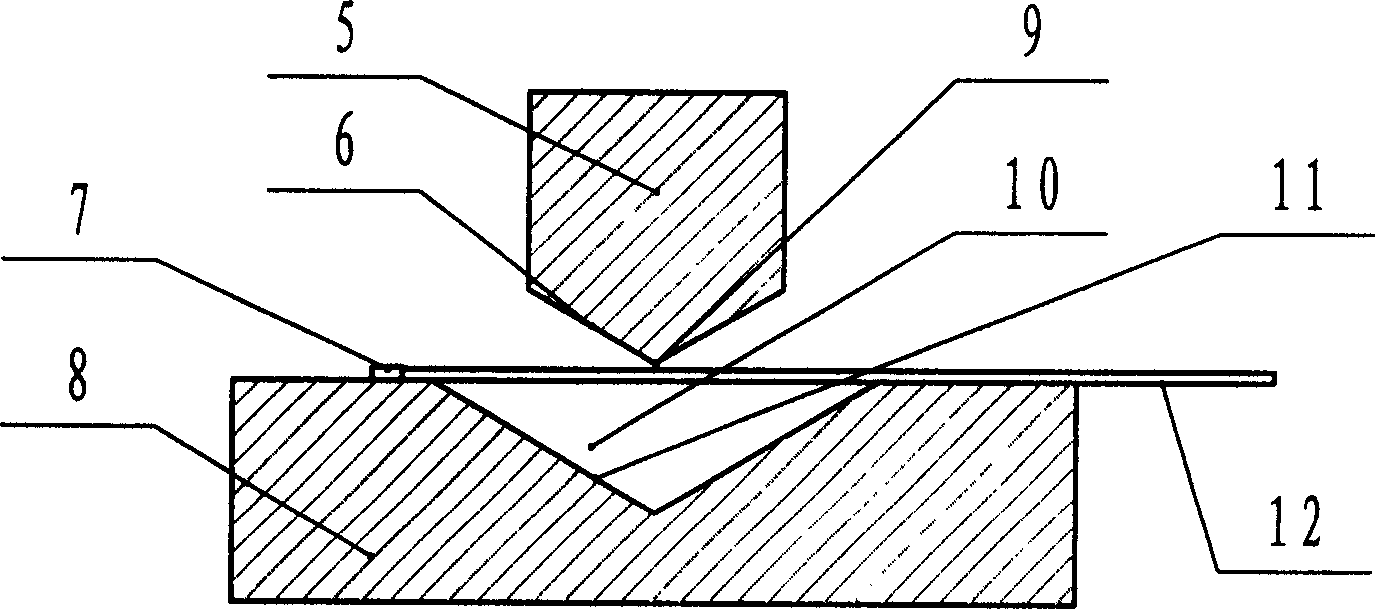

[0038] Embodiment one is the molding method of hollow hexagonal body, and what present embodiment molding is that edge length is 200 millimeters, and the width of side is the hollow regular hexagonal body of 108 millimeters, see figure 1 , figure 2 . The forming method of the present invention is single forming. According to the conventional method, the steel plate is first stamped into a strip steel plate 12. The width of the strip steel plate 12 is 200 millimeters, and the length is 108 × 6 millimeters. On the lower die 8 of the stamping die, one side of the strip steel plate 12 is used to have the upper die 5 of the corner forming stamping die with the corner forming stamping head 6 protruding laterally and the lower part of the corner forming stamping die with the dihedral angle groove 10 Die 8 laterally punches and folds into a corner plate with a first corner edge 13 of 120° dihedral angle, and the width of the first corner edge 2 is 54 millimeters, see image 3 , the...

Embodiment 2

[0041] Embodiment two is the molding method of arc-shaped plate hollow hexagonal body 18, and what it forms is that the edge length is 200 millimeters, and the width of side is 108 millimeters, and wherein one side is the hollow hexagonal body of arc-shaped plate 21, arc The radius of the shaped plate 21 is 60 mm, see Figure 6 , Figure 7 . Earlier the strip steel plate 36 that has planted is placed on the lower die 33 of the arc stamping die that is installed on punch press, see Figure 8 , one side of the strip steel plate 36 is stamped with a punch to form an arc-shaped plate 21 with a first angled edge 22 and a second angled edge 20 on both sides, see Figure 9 , one side of the first corner edge 22 is the first corner edge 23, the width of the first corner edge 23 is 54 millimeters, and one side of the second corner corner edge 20 is the second corner edge 19, that is, a flat plate that is not stamped. The included angle between a folded edge 23 and the second folded ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com