Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

118results about How to "Solve mass production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

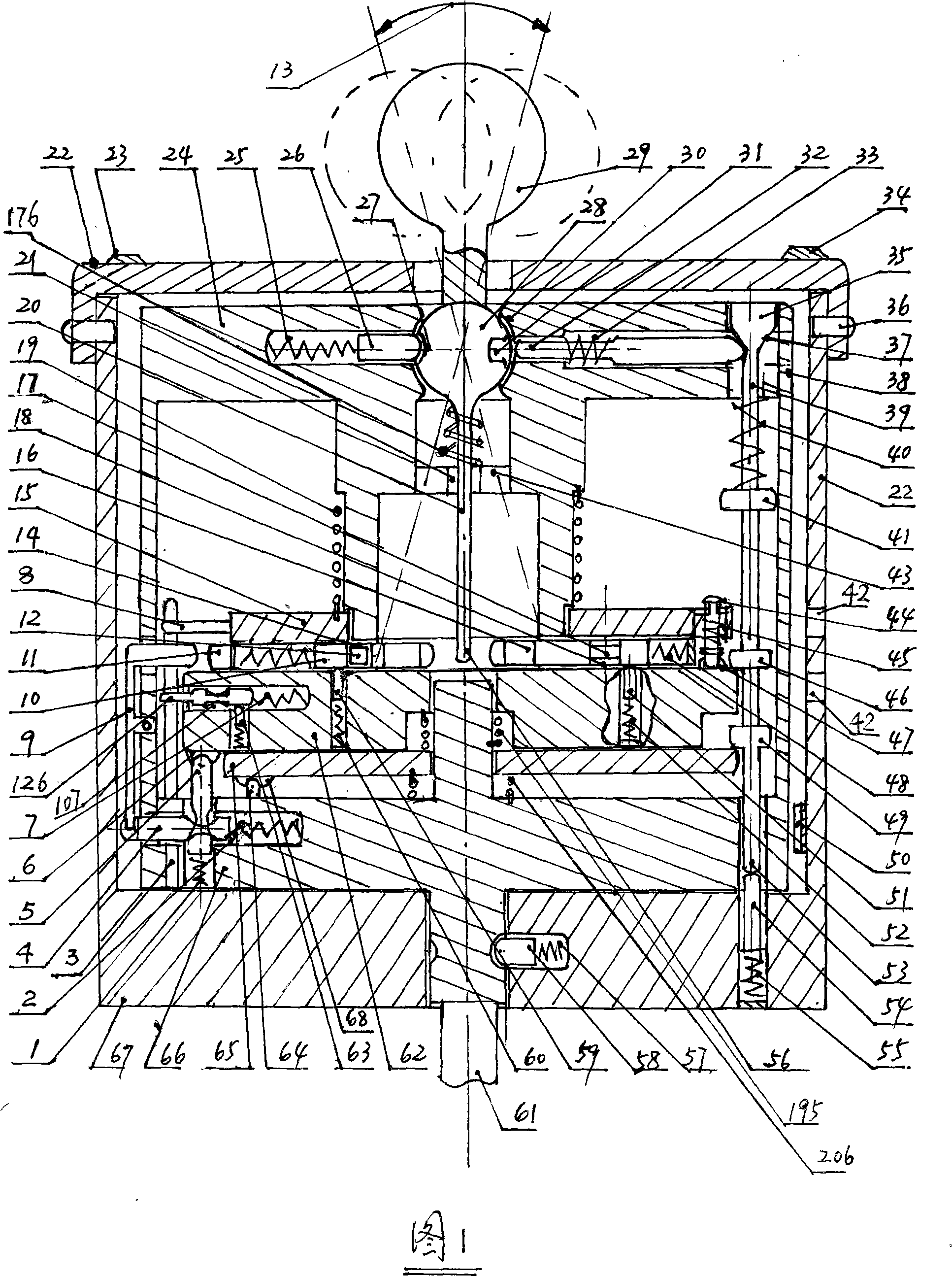

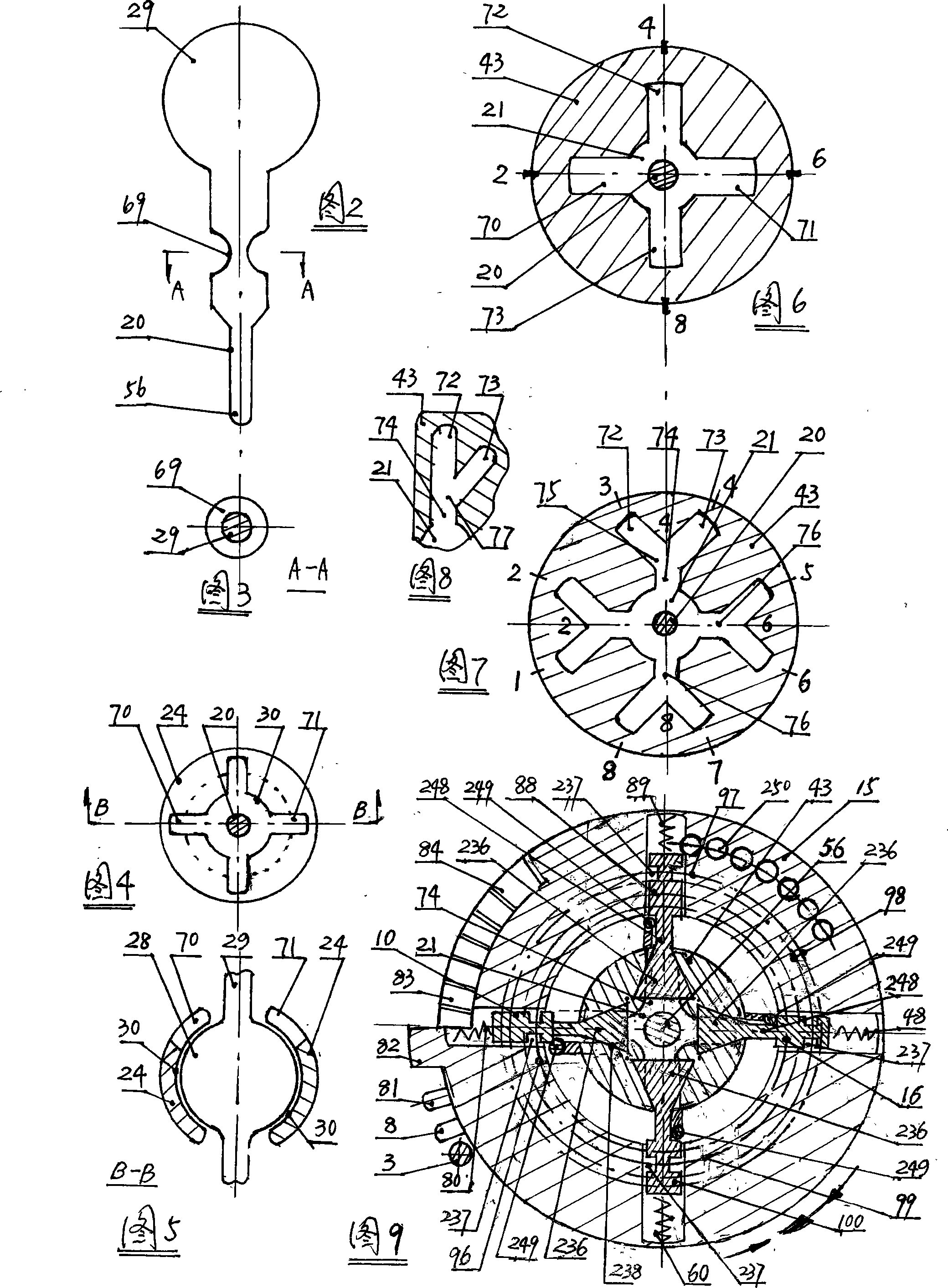

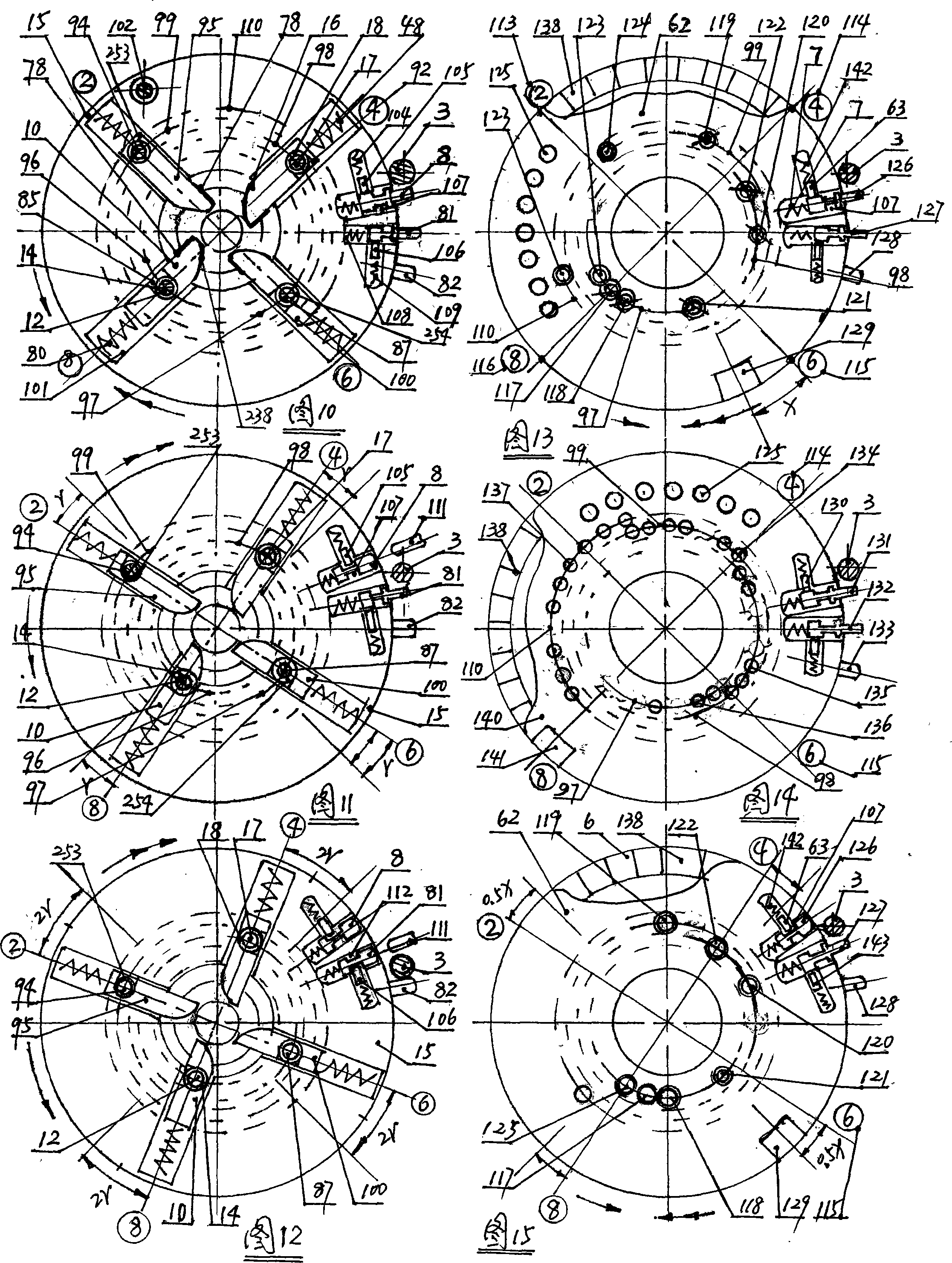

Casting method of large water turbine blade

ActiveCN101716655AUnique process methodRigid enoughFoundry mouldsFoundry coresWater turbineMaterials science

The invention relates to a stereoscopic core assembly casting method of a water turbine blade, in particular to a casting method of a large water turbine blade. The casting method is characterized in that the casting method comprises the steps of designing process, making a core box, making a core bar, making a core, patching a sand core, assembling the cores, putting the cores into a sand box, paving a spure, sounding the sand core with silica sand, assembling the box, pressing the box, pouring, cutting a dead head, tempering, detecting a mold line, grinding and shotblasting. The casting method obviously shortens production cycle, reduces equipment capacity requirements for blade production, is simple in operation and easy to control and achieves blade mass production.

Owner:KOCEL EQUIP

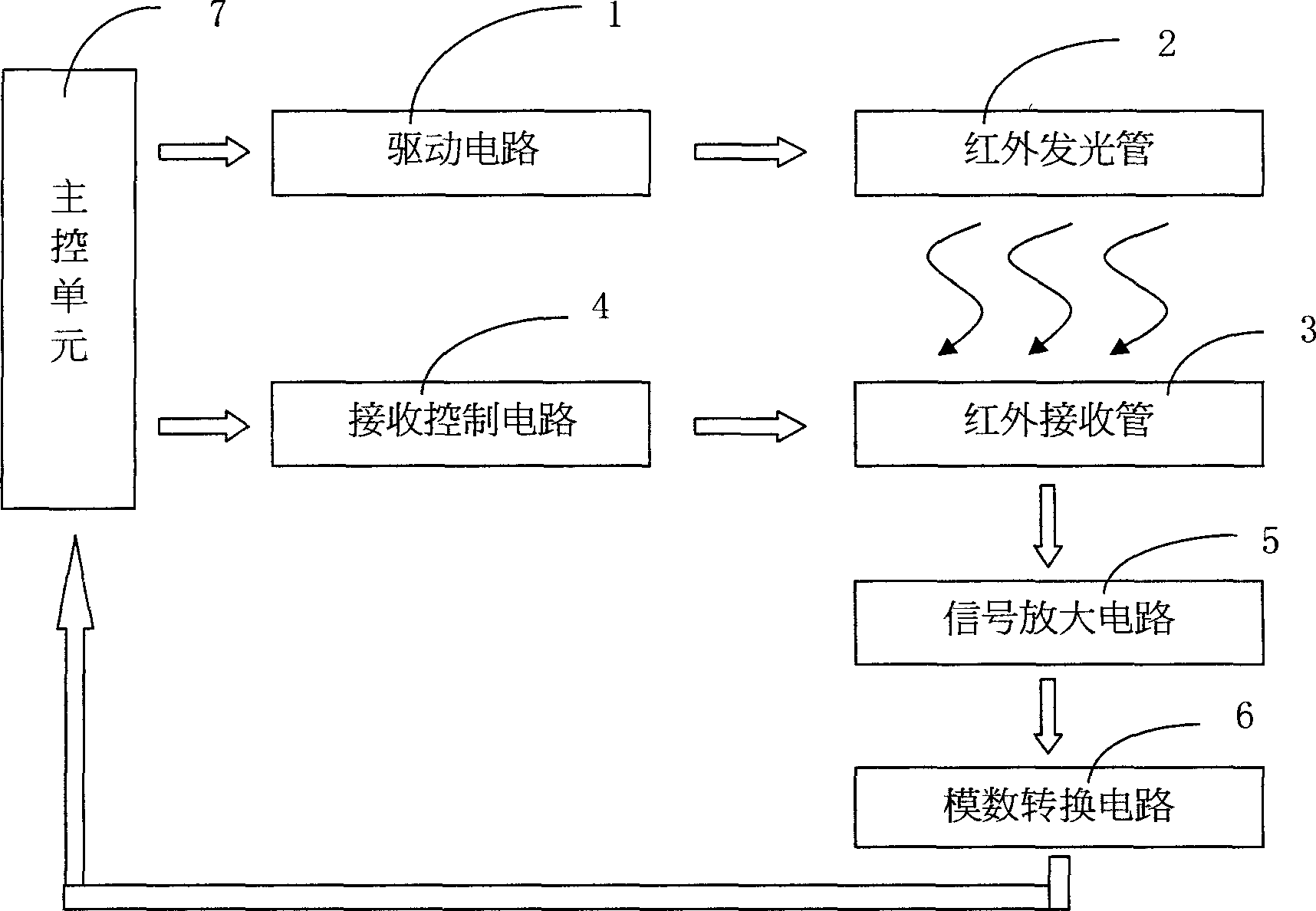

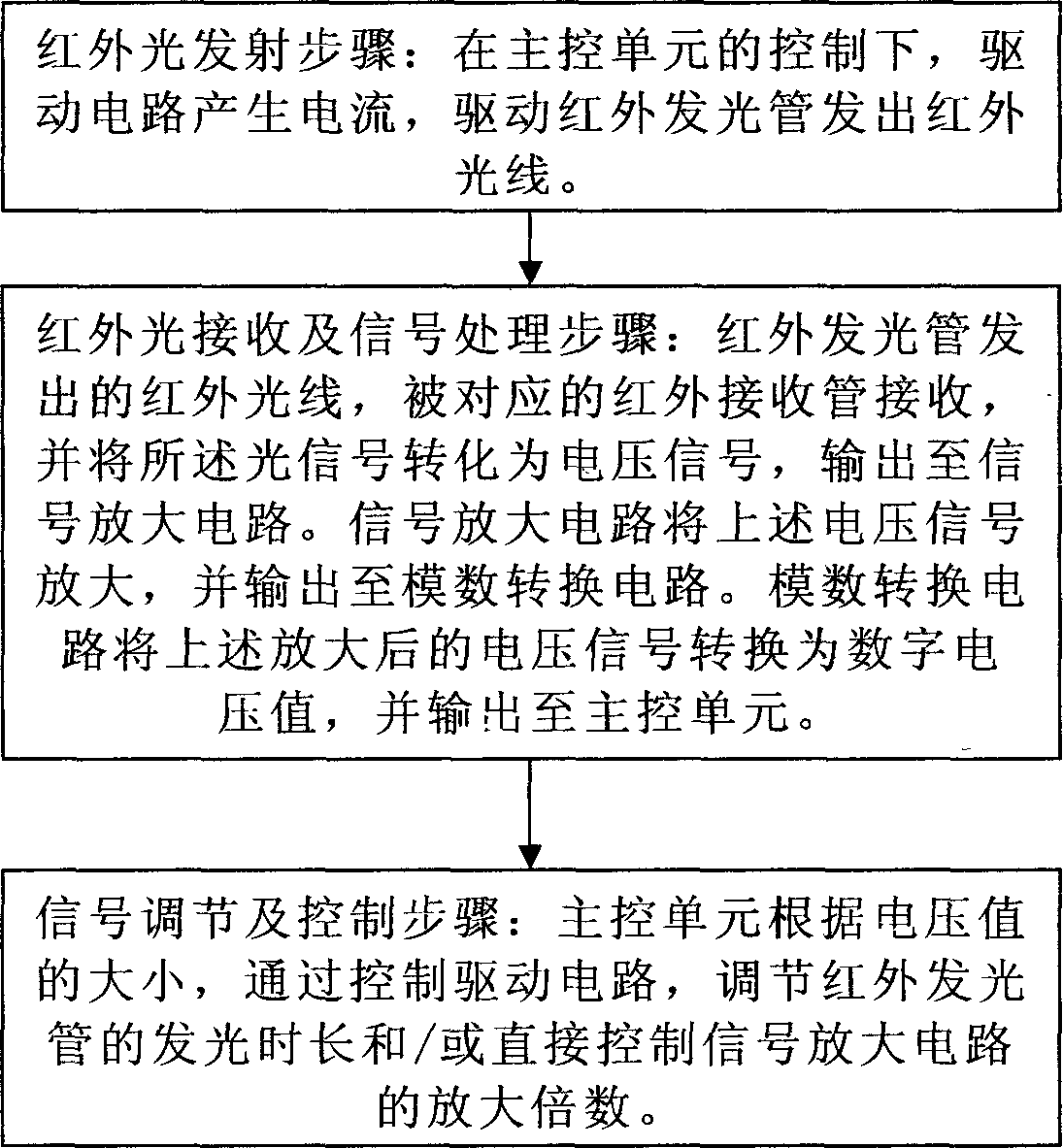

Signal processing and control method and signal processing and control device of infrared touch screen

InactiveCN103064563AImprove signal-to-noise ratioSolve mass productionInput/output processes for data processingDigital conversionAmplification factor

The invention provides a signal processing and control method and a signal processing and control device of an infrared touch screen. The signal processing and control method includes: under control of a main control unit, a drive circuit drives an infrared light-emitting tube to emit infrared; an infrared receiving tube receives a light signal sent by the infrared light-emitting tube, converts the light signal to a voltage signal and outputs the voltage signal to a signal amplification circuit; the signal amplification circuit amplifies the voltage signal and outputs the voltage signal to an analog-digital conversion circuit; the analog-digital conversion circuit coverts the amplified voltage signal to a digital voltage value and outputs the digital voltage value to the main control unit; and the main control unit regulates light-emitting duration of the infrared light-emitting tube and / or amplification factor of the signal amplification unit according to the size of the received voltage value. The problem of limitation that an automatic gain control circuit is simply used for regulating the amplification factor is solved, and additionally the problem of mass production due to inconformity of the infrared light-emitting tube and the infrared receiving tube is solved.

Owner:BEIJING IRTOUCH SYST CO LTD

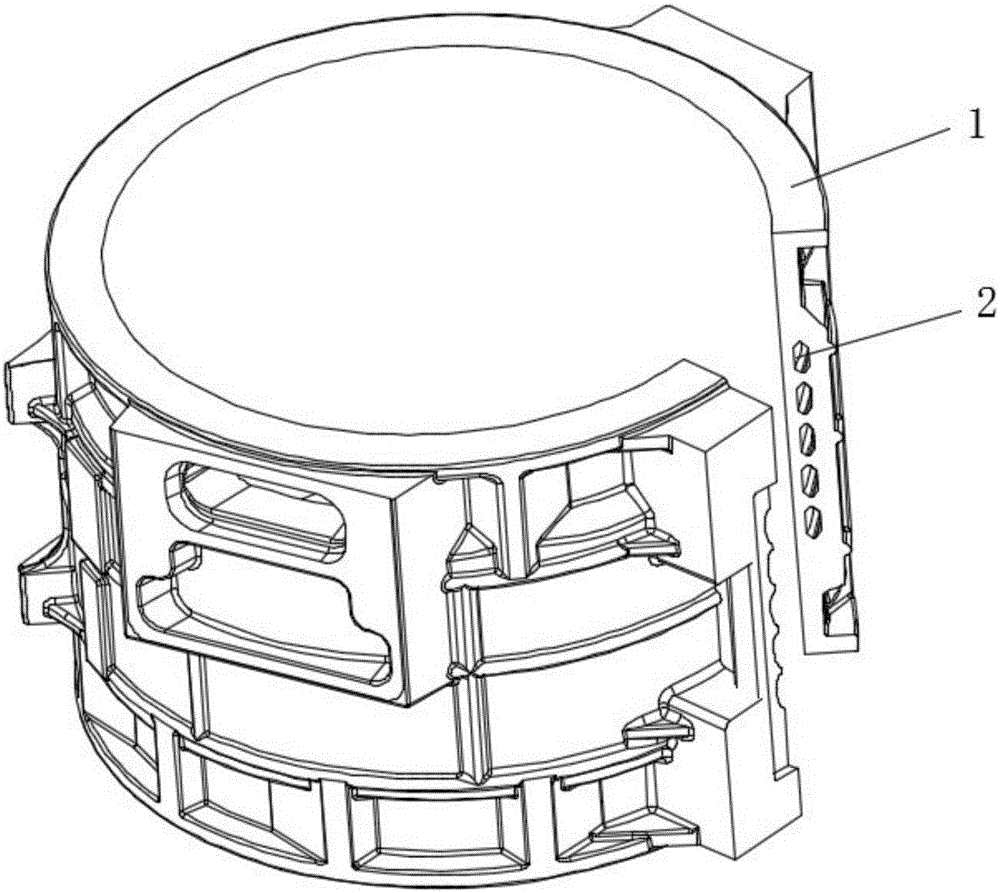

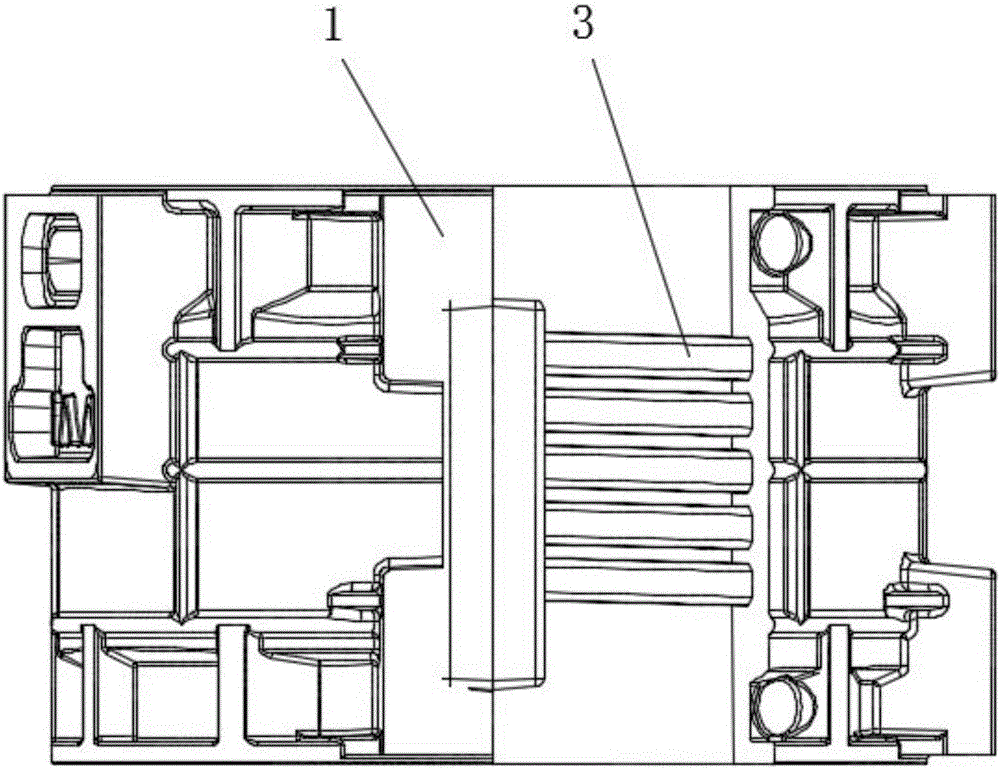

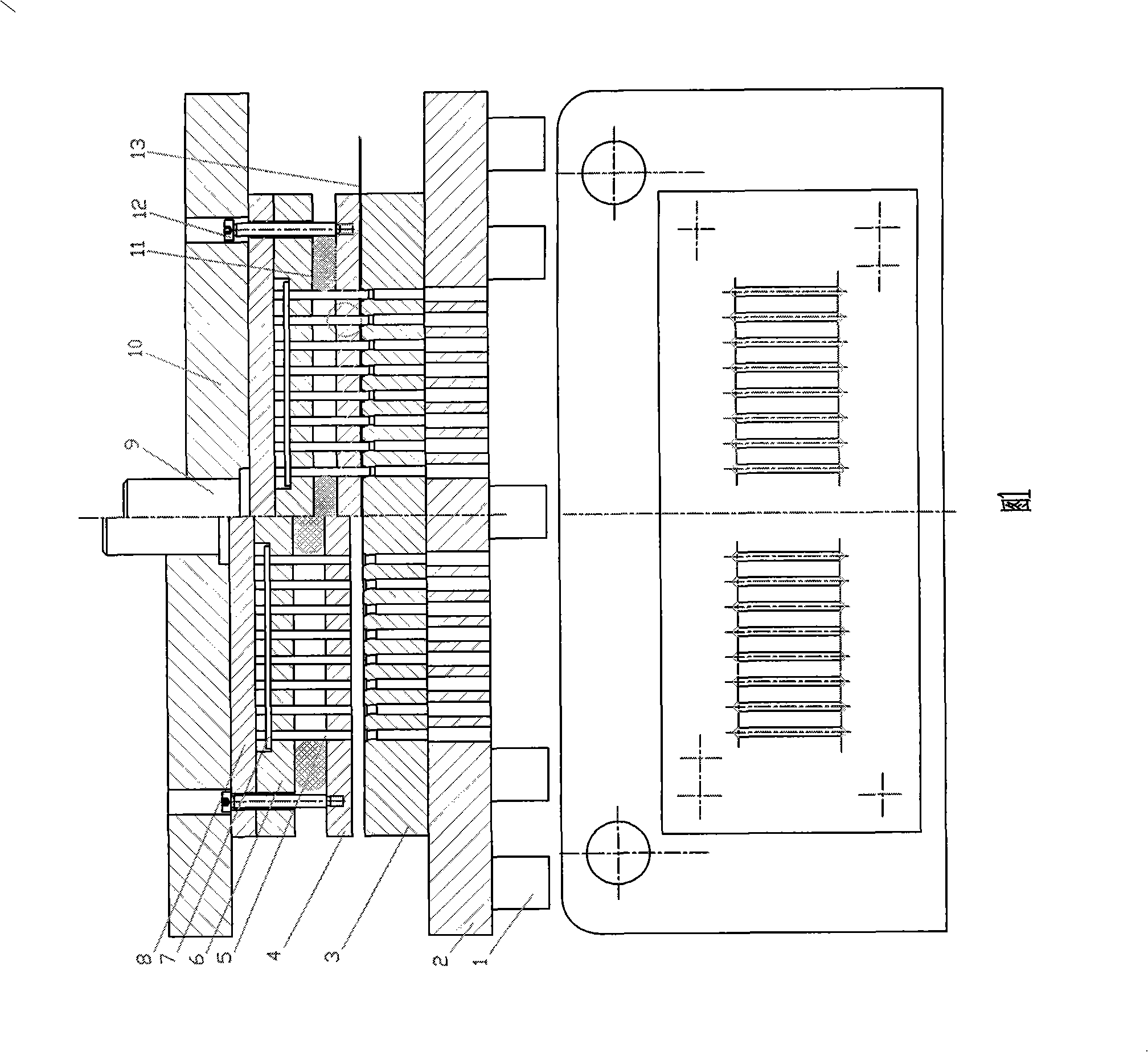

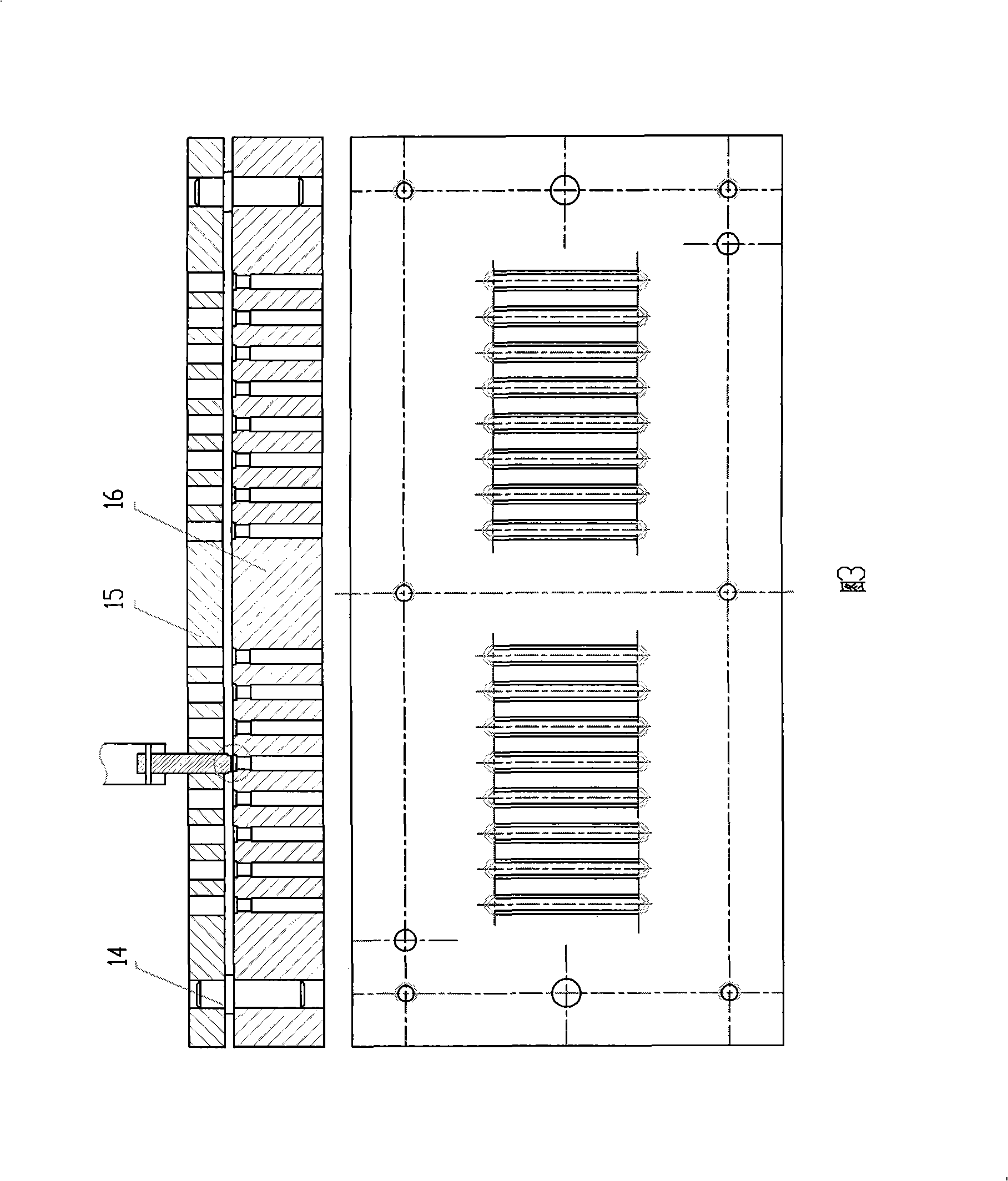

Low-pressure casting method for automobile motor casing and motor casing structure

ActiveCN104999051AMeet normal workGuaranteed cooling effectSupports/enclosures/casingsPressure castingElectric machinery

The invention discloses a low-pressure casting method for an automobile motor casing. The low-pressure casting method for the automobile motor casing includes the following steps that (1) a sand core structure of a spiral water channel is manufactured; (2) the sand core structure is placed on a lower mold body of a die-casting mold; (3) the automobile motor casing with the sand core structure of the spiral water channel is cast through a low-pressure casting device; (4) heat treatment is conducted on the automobile motor casing, then sand is vibrated out, and the automobile motor casing is provided with the complete spiral water channel; and (5) holes formed in the original sand core structure portion of the sidewall of the automobile motor casing are filled up through welding, so that the complete automobile motor casing with the spiral water channel is formed. The invention further discloses a motor casing structure. Through the low-pressure casting method for the automobile motor casing, the aluminum alloy low-pressure casting process is adopted and the spiral water channel is cast through the sand core of the spiral water channel, so that the cooling effect on a motor is guaranteed, the service life of the motor is greatly prolonged, the requirement for long-time working of an automobile can be met, and the weight of the whole motor is reduced by about 60%.

Owner:HUIZHOU WEISHENG IND

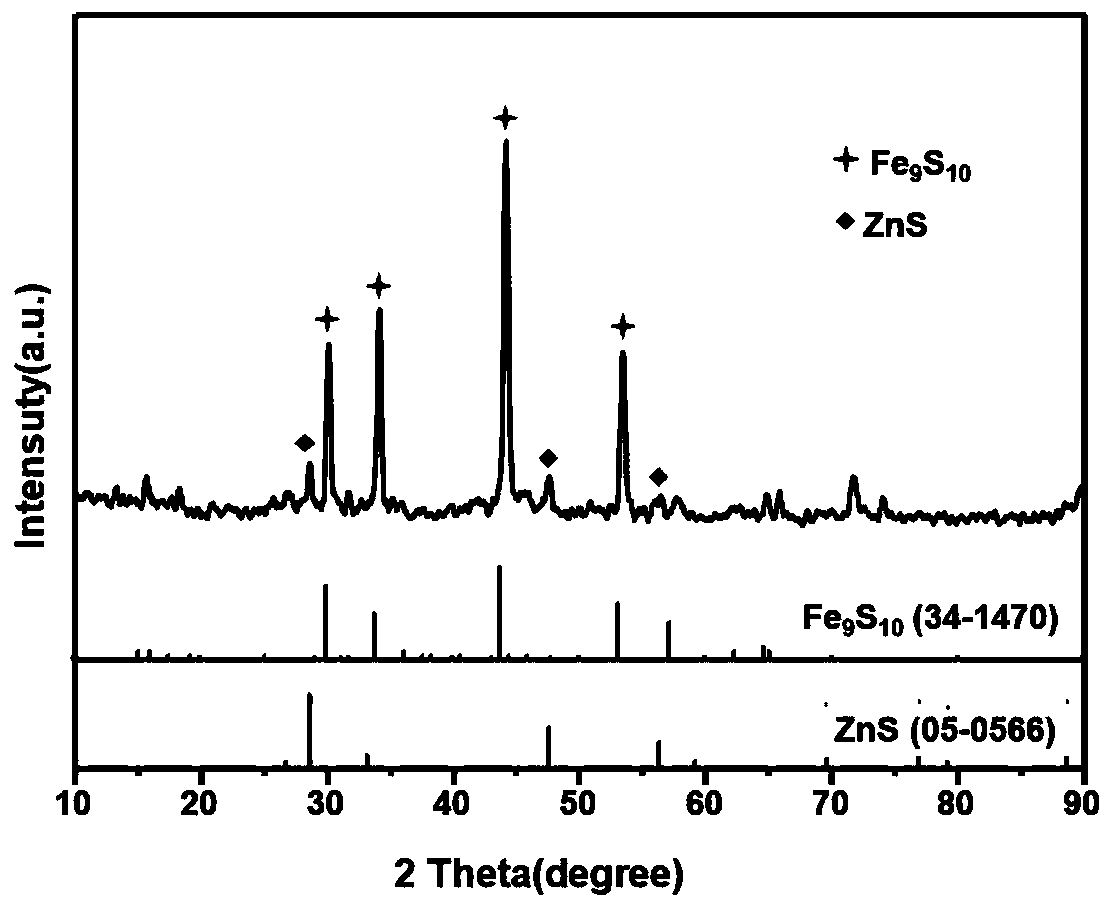

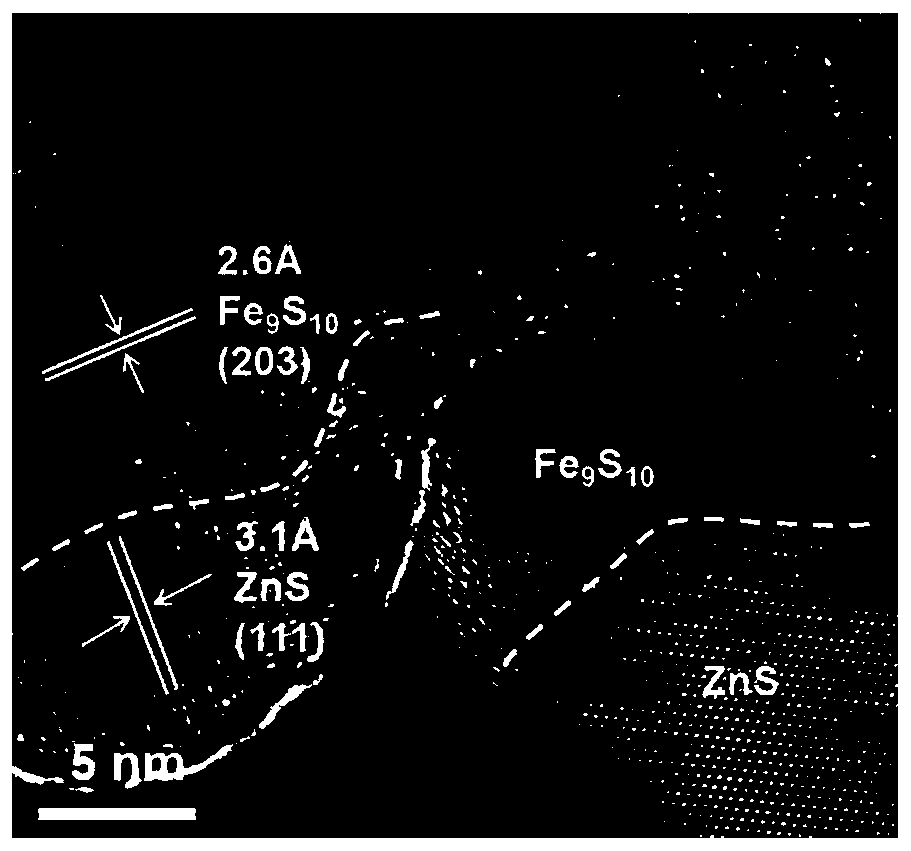

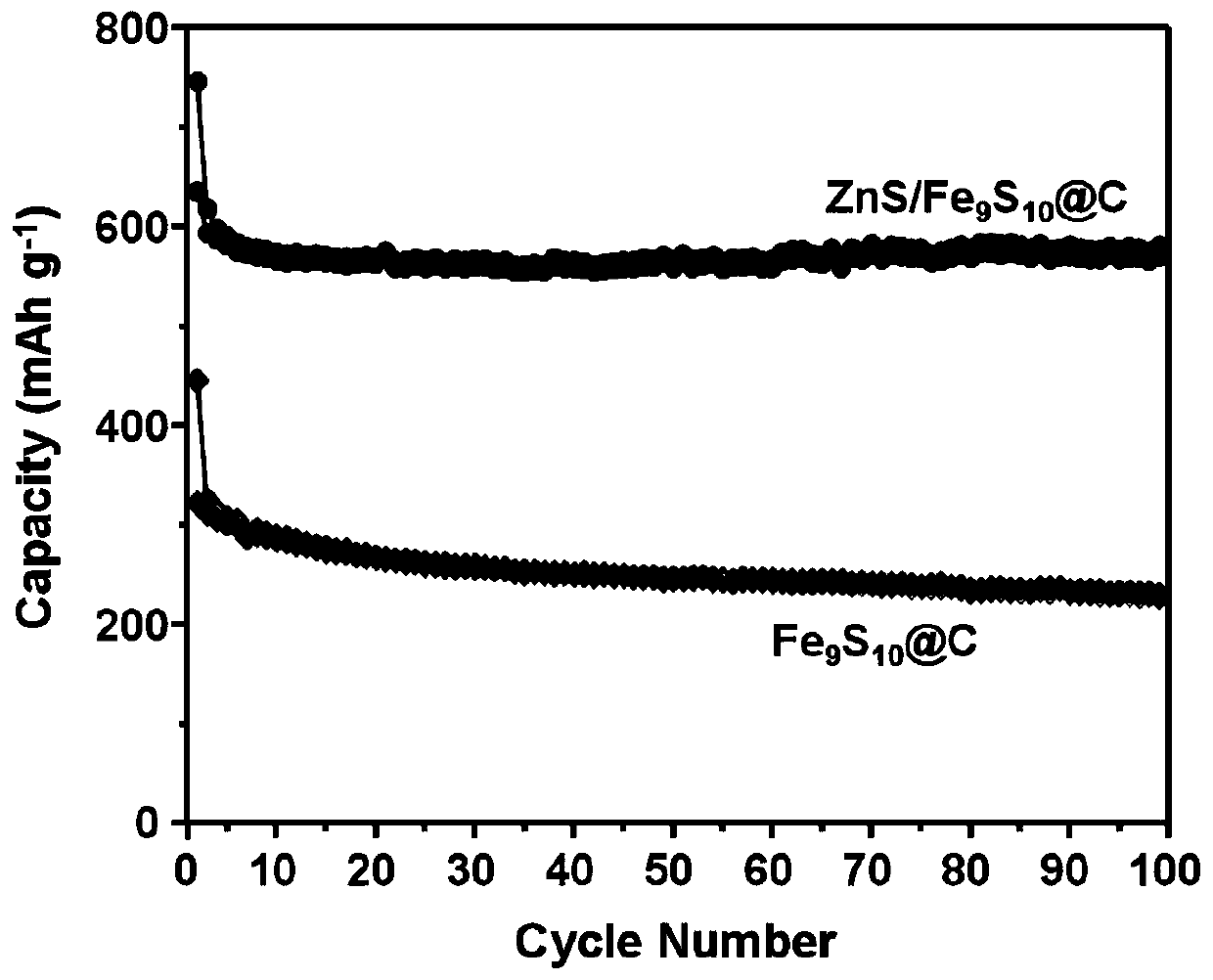

Carbon-coated polysulfide heterojunction material, preparation method and application

ActiveCN109935815ASimple processSignificant heterojunction effectCell electrodesSecondary cellsIonElectron transmission

The invention relates to the technical field of preparation of electrochemical cell electrode materials, and provides a carbon-coated polysulfide heterojunction material, which is composed of a core body and a shell body coating the outer side of the core body, wherein the core body is a polysulfide heterojunction and the shell body is a carbon layer. The polysulfide heterojunction is a mixture oftwo or more transition metal sulfides. The method for preparing the polysulfide heterojunction material is easy to operate, low in processing cost, good in treatment effect, wide in application range, recyclable and friendly to environment. The material is coated with carbon and is used as an electrochemical cell electrode material to solve the technical problem of low ion and electron transmission speed in the electrode material in the prior art, thereby achieving a high reversible capacity and good rate performance.

Owner:HUNAN UNIV

Method for producing Mengding Huangya tea

InactiveCN101889616AAchieve quality style characteristicsSimple technologyPre-extraction tea treatmentRoom temperatureEngineering

The invention discloses a method for producing Mengding Huangya tea. The method comprises the following steps of: selecting stout, strong, plump and solid simple buds; spreading, removing water, microwaving and heating slightly; bagging; performing primary stifling, secondary stifling and third stifling; intensively placing yellow tea after repeated stifling into a dustpan in which multiple layers of yellow paper are padded and covering the yellow tea with the multiple layers of the yellow paper; placing the dustpan in an air-conditioned room at the room temperature of between 25 and 28 DEG C for two days; keeping the temperature, performing oxidization and xanthochromia and adding fragrant; inspecting xanthochromia situation in stifling processes at any time; uniformly turning and stirring the bottom and the surface of the stifling yellow tea in the processes of the stifling so as to avoid non-uniform oxidization and xanthochromia; taking a tea sample out and molding manually after the tea sample has a basic style of the Huangya tea; slowly drying the molded Huangya tea at the low temperature of between 70 and 80 DEG C until the water content is between 5 and 6 percent; obtaining primarily processed Mengding Huangya tea; selecting to obtain genuine commodity Huangya tea; and cooling and storing at low temperature.

Owner:SICHUAN AGRI UNIV +1

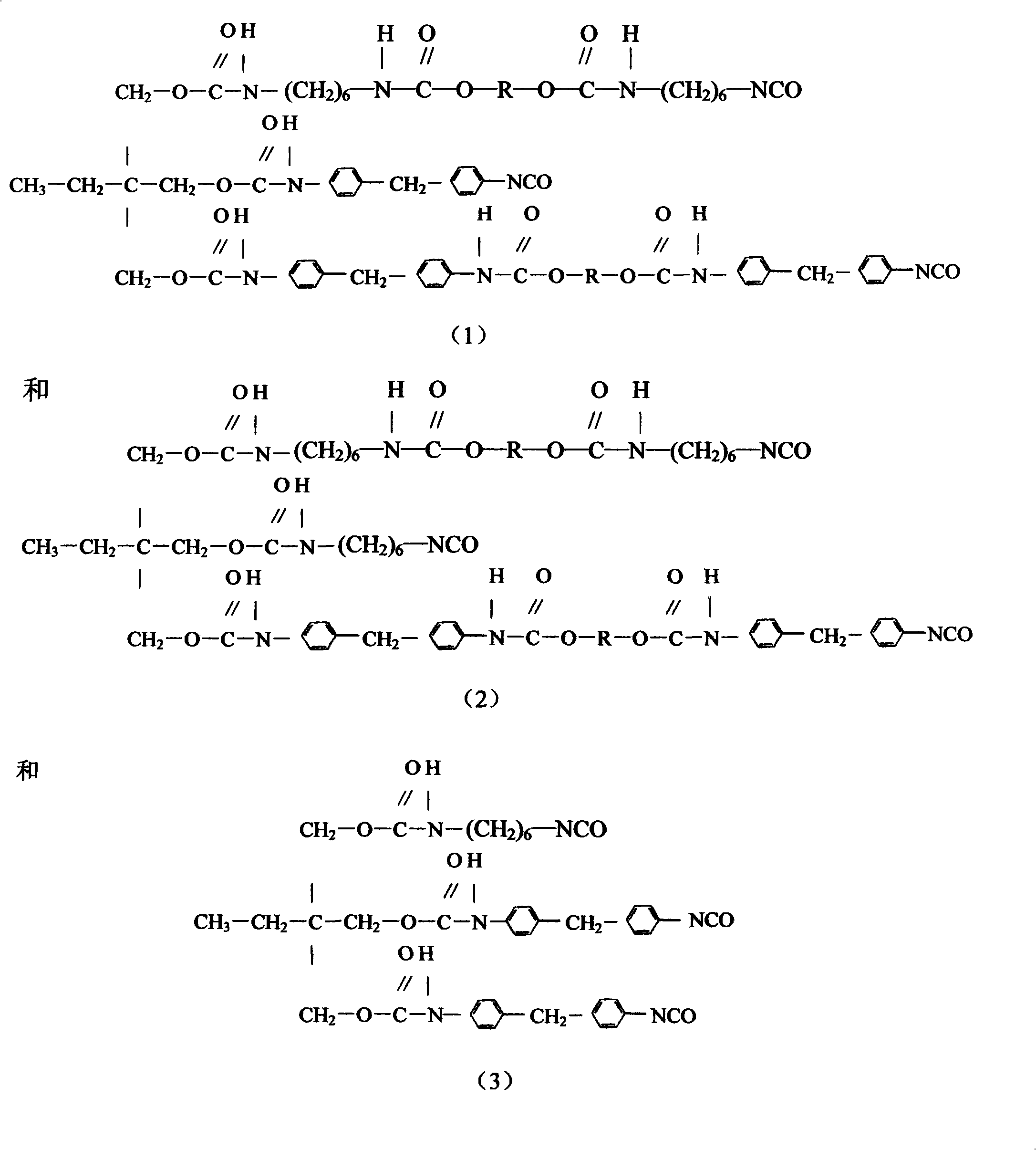

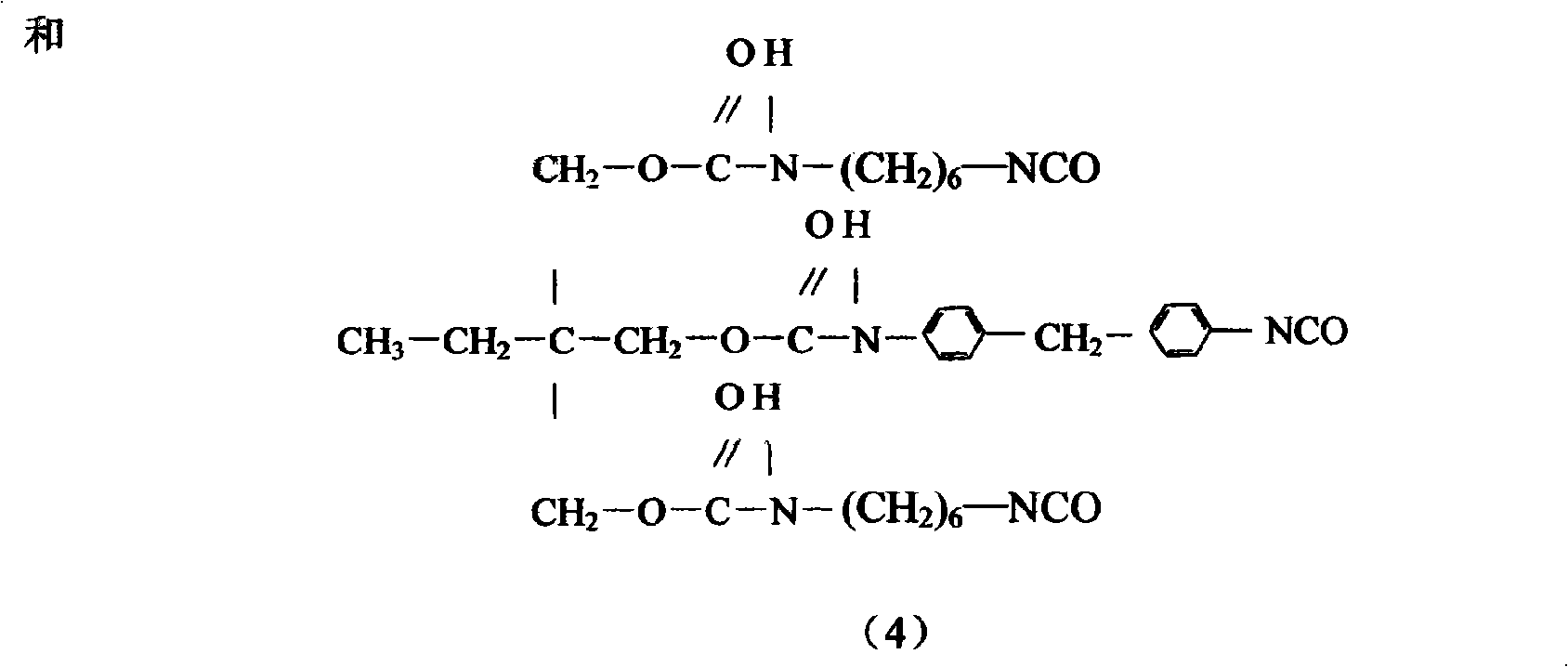

Mixed prepolymer of solidifying agent methyl diphenylene diisocyanate and 1,6-hexamethylene diisocyanate

The invention relates to a curing agent compound prepolymer composed of diphenylmenthane diisocyanate and 1, 6-hexamethylene diisocyanate and a preparation method thereof. The method comprises the following steps: MDI and an organic solvent are added and heated to 65 DEG C, polybasic alcohol is added and reacts with the mixture for 2 hours to 4 hours to obtain an MDI modifier; HID, an organic solvent and polybasic alcohol are added, heated and react for 2 hours to 5 hours, then the temperature is reduced below 70 DEG C, a TMP and organic solvent mixture is added, reaction at 70 DEG C lasts for 1 hour to 4 hours and 1 hour to 4 hours when the temperature is between 60 DEG C and 100 DEG C so as to obtain an HDI-MDI compound prepolymer curing agent. The method mixes and pre-polymerizes MDI and HDI, integrates the excellent performance of the two, produces a series of polyurethane curing agents with wide application range, high strength, good yellow-changing resistance, high curing speed, low toxicity, good storage stability and high solid content and has simple production technique.

Owner:FOSHAN JINGXIN HUIMING TECH CO LTD

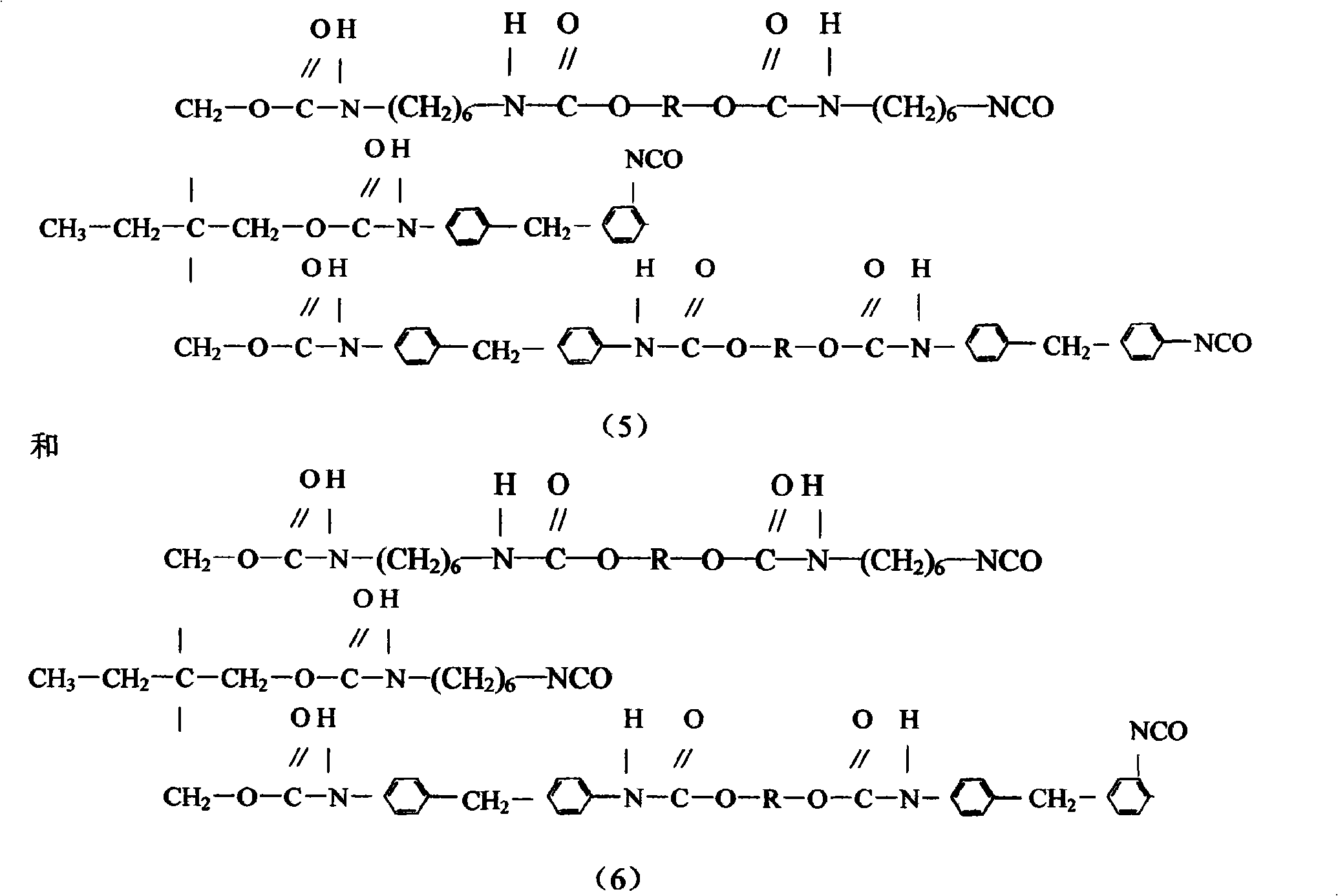

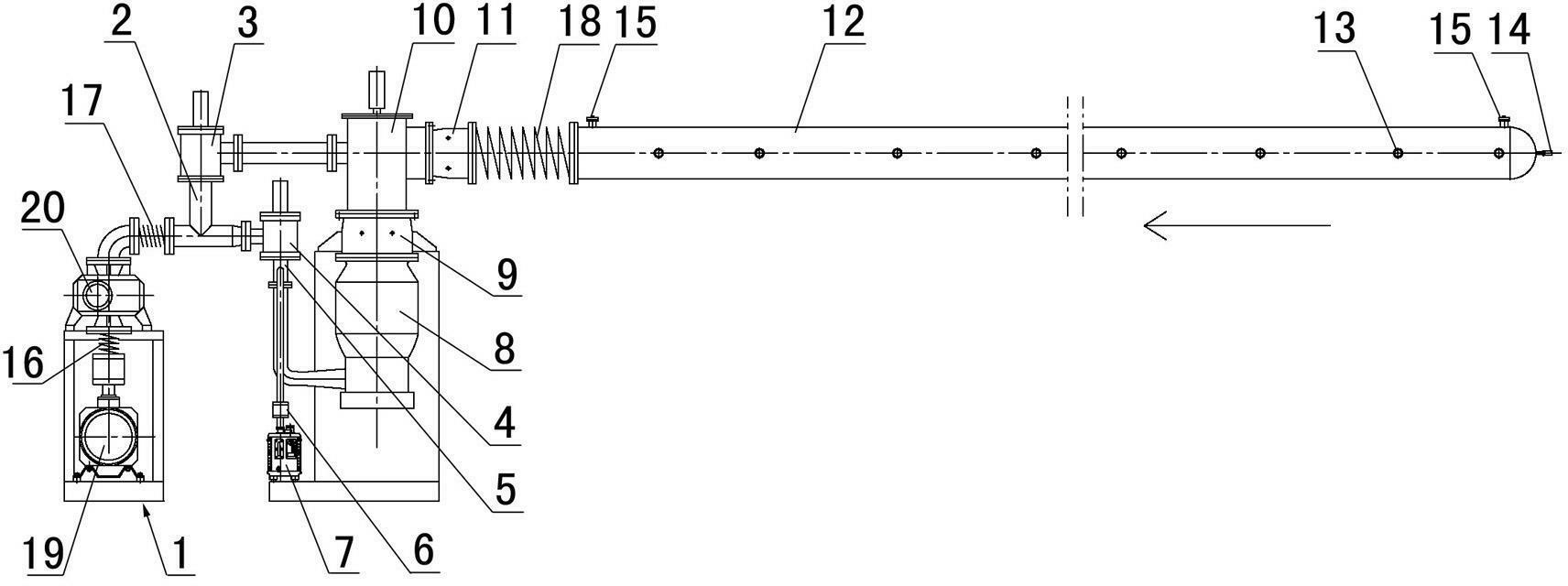

Vacuum-pumping system for multiple-dewar interlayer and vacuum-pumping method thereof

ActiveCN102518577ASolve mass productionIncrease vacuumPressure vesselsPump installationsVacuum pumpingHigh volume manufacturing

The invention relates to a vacuum-pumping system for multiple-dewar interlayer and a vacuum-pumping method thereof. The vacuum-pumping system comprises a vacuum unit, a three-way pipe fitting A, a bypass valve, a preceding stage valve, a three-way pipe fitting B, a holding valve, a holding pump, a system main pump, a water cold trap, a three-way system main valve, a liquid nitrogen cold trap and a vacuum system pipeline, wherein the vacuum unit comprises a main mechanical pump and a pressurizing pump, dewar interlayer opening ports are arranged on the vacuum system pipeline at intervals, and a hot nitrogen port is arranged on the vacuum system pipeline. The vacuum-pumping system can pump multiple dewars at one time, is high in efficiency, solves the problem of large-scale production of the dewars, and saves a great number of manpower and material resources. The vacuum-pumping method is simple in procedure so that operation time for pumping vacuum of the dewar interlayer is greatly shortened, and waste of resources is avoided.

Owner:北京华诚浩达真空空压设备有限公司

Preparation method of neodymium-iron-boron magnet

InactiveCN106782974ASolve mass productionControl particle size distributionInorganic material magnetismBatch productionAluminium

The invention provides a preparation method of a neodymium-iron-boron magnet, relating to the field of production of the neodymium-iron-boron magnet. By virtue of processes of formula optimization, oriented molding, magnet oxygen content control and the like, the invention provides a preparation method of a high-performance sintering neodymium-iron-boron magnet, which solves the problem of batch production of high-performance sintering neodymium-iron-boron products. The preparation method comprises the following steps: weighing 30.0-31.5% of praseodymium and neodymium, 0.9-1.0% of boron, 0-2.0% of terbium, 0.03-0.60% of aluminum, 0.05-0.25% of copper, 0.3-1.5% of cobalt, 0-0.2% of zirconium, 0-0.3% of niobium, 0.05-0.3% of gallium and 62.35-68.67% of iron, and melting and casting to obtain a cast sheet; putting the cast sheet into a rotary hydrogen smashing furnace for processing to obtain coarse powder; adding a lubricating agent into the coarse powder for grinding to obtain fine powder; adding a lubricating agent and an antioxidant into the fine powder, and mixing the powder with a double-cone powder mixer to obtain powder; and making a mold to obtain a billet product, and sintering and cooling to obtain a finished product.

Owner:ZHEJIANG ZHONGKE MAGNETIC IND

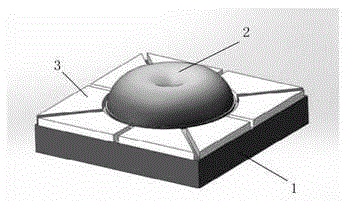

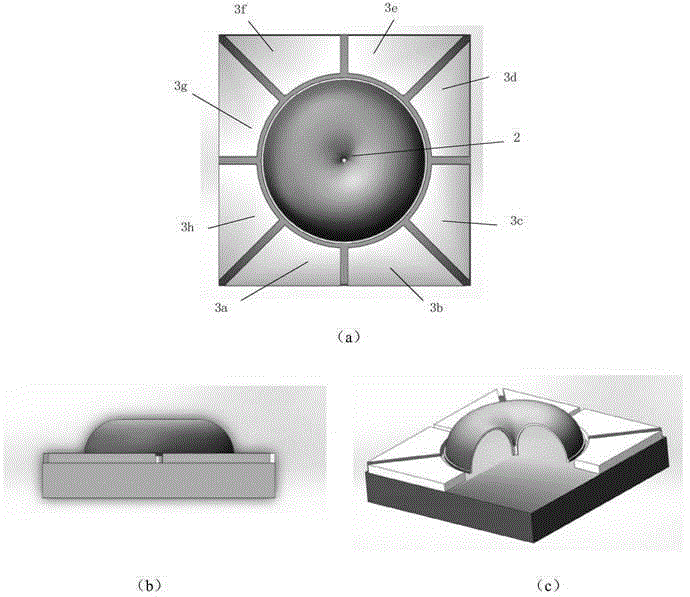

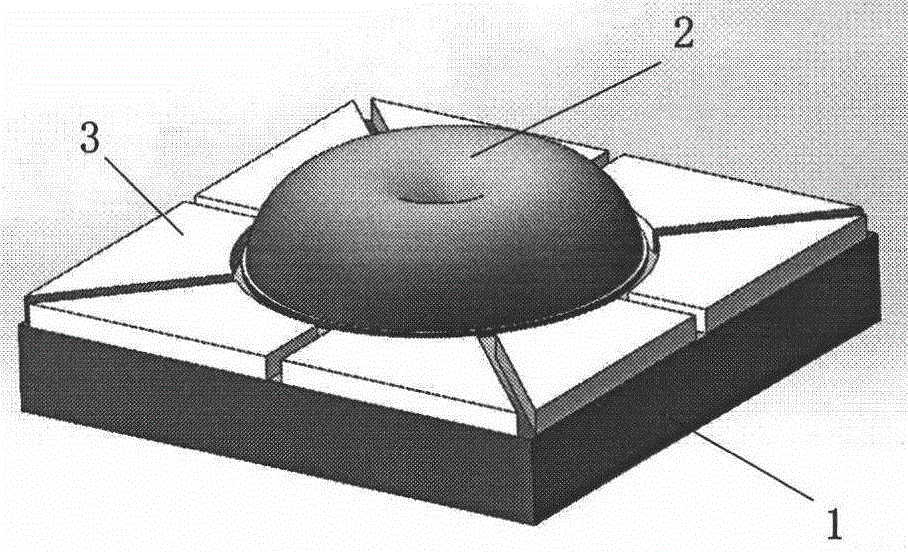

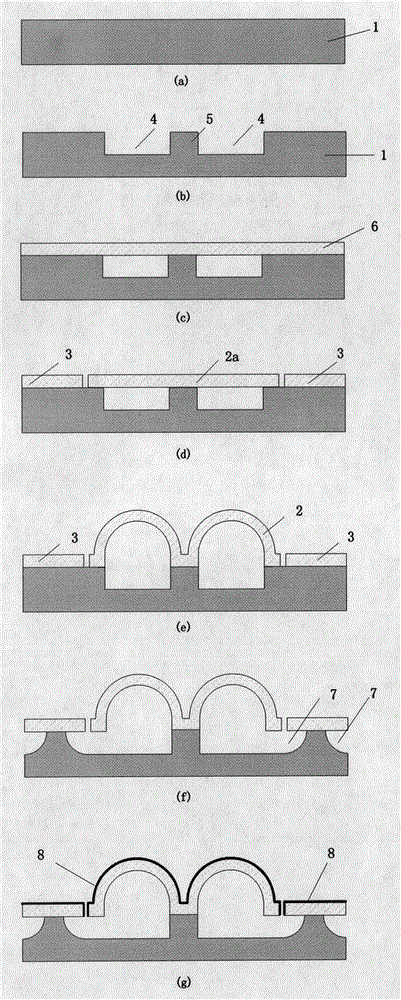

Micro-hemispherical resonant gyroscope based on borosilicate glass annealing forming and manufacturing method thereof

ActiveCN105424019AIncrease etch rateReduce surface stressSpeed measurement using gyroscopic effectsGyroscopes/turn-sensitive devicesSurface stressGyroscope

The invention discloses a micro-hemispherical resonant gyroscope based on borosilicate glass annealing forming and a manufacturing method thereof. A silicon wafer serves as a substrate to form a silicon substrate. A cylindrical cavity and a center supporting column in the circle center of the cavity are etched on the upper surface of the silicon wafer. The center supporting column is connected with the center of a hemispherical harmonic oscillator to form a suspended structure. Meanwhile, eight flat-plate electrodes are evenly distributed around the hemispherical harmonic oscillator and on the periphery of the cylindrical cavity of the upper surface of the silicon wafer. The eight flat-plate electrodes are composed of four drive electrodes and four detection electrodes, all the drive electrodes, the detection electrodes and the hemispherical harmonic oscillator are not in contact and have same gaps, and the drive electrodes and the detection electrodes are sequentially distributed at intervals. The glass metal blowing type micro-hemispherical resonant gyroscope manufactured through the method has stable performance and a wider application range because of the advantages of being simple in structure, low in surface stress, high in symmetry and the like.

Owner:NANJING UNIV OF SCI & TECH

Method for preparing SiC coating on surface of spherical graphite material

The invention provides a method for preparing a SiC coating on the surface of a spherical graphite material. The method comprises the steps of (1) mixing Si powder, SiC powder, Al2O3 powder and graphite powder, so as to obtain embedding powder; (2) embedding the spherical graphite material into the embedding powder, and jolt-ramming an embedded mixture, so as to obtain the embedded mixture after jolt-ramming; (3) performing sintering treatment on the embedded mixture after jolt-ramming in an argon atmosphere, so as to obtain sintering treatment products; (4) performing chemical vapor deposition on the sintering treatment products in a spouted fluidized bed in the condition that methyl trichlorosilane, hydrogen and argon are introduced, so as to form the SiC coating on the surface of the spherical graphite material. By utilizing the method, the SiC coating which has the advantages of integrity in coating, uniformity in thickness, good transitivity and high bonding strength with a substrate can be rapidly and effectively prepared on the surface of the spherical graphite material.

Owner:TSINGHUA UNIV

Frozen uncooked steamed stuffed buns and production method thereof

InactiveCN103598508ASimple process100% success rateFood coatingFood shapingProcess engineeringBaking powder

The invention relates to frozen uncooked steamed stuffed buns and a production method thereof. The frozen uncooked steamed stuffed bun comprises a wrapper and stuffing covered in the wrapper, wherein the wrapper is a shell formed by kneading dough, producing a flour sheet and covering the stuffing, and then directly frozen and molded at the temperature in a range from -16 DEG C to -18 DEG C from following raw materials in parts by weight: 4000-6000 parts of flour, 40-60 parts of high-glucose dried yeast, 20-30 parts of table salt, 50-70 parts of baking powder, 40-60 parts of white sugar and 2100-2300 parts of water. According to the method, the steamed stuffed buns are directly frozen in a warehouse after being molded; before the steamed stuffed buns are cooked, one time of fermentation is carried out; the technological process is simple and the success rate is a hundred percent; the mouth feel of a pastry product is guaranteed completely and the nutritional ingredients are not lost so that the uncooked steamed stuffed buns can be on a par with fresh steamed stuffed buns; the problems of large-batch production, storage, distribution and good sale of the steamed stuffed buns can be solved; the frozen uncooked steamed stuffed buns are very suitable for large-scale industrial production.

Owner:罗小勇

Micro-hemispherical resonator gyroscope based on borosilicate glass annealing forming and preparing method

InactiveCN105021179AIncrease etch rateReduce surface stressSpeed measurement using gyroscopic effectsGyroscopes/turn-sensitive devicesSurface stressHemispherical resonator gyroscope

The invention discloses a micro-hemispherical resonator gyroscope based on borosilicate glass annealing forming and a preparing method of the micro-hemispherical resonator gyroscope. A silicon wafer is used as a substrate to form a silicon substrate, a cylindrical cavity and a center supporting pillar in the circle center of the cavity are etched on the upper surface of the silicon wafer, and the center supporting pillar is connected with the center of a hemispherical resonator to form a suspension structure. Meanwhile, eight flat plate type electrodes are evenly distributed on the periphery of the cylindrical cavity in the upper surface of the silicon wafer and around the hemispherical resonator, and the eight flat plate type electrodes are composed of the four driving electrodes and the four detection electrodes. All the driving electrodes and all the detection electrodes are not in contact with the hemispherical resonator, identical gaps exist, and the driving electrodes and the detection electrodes are arranged in sequence alternately. The prepared glass metal blowing type micro-hemispherical resonator gyroscope has the advantages of being simple in structure, low in surface stress, high in symmetry and the like, and therefore the micro-hemispherical resonator gyroscope can have stable performance and a wider application range.

Owner:NANJING UNIV OF SCI & TECH

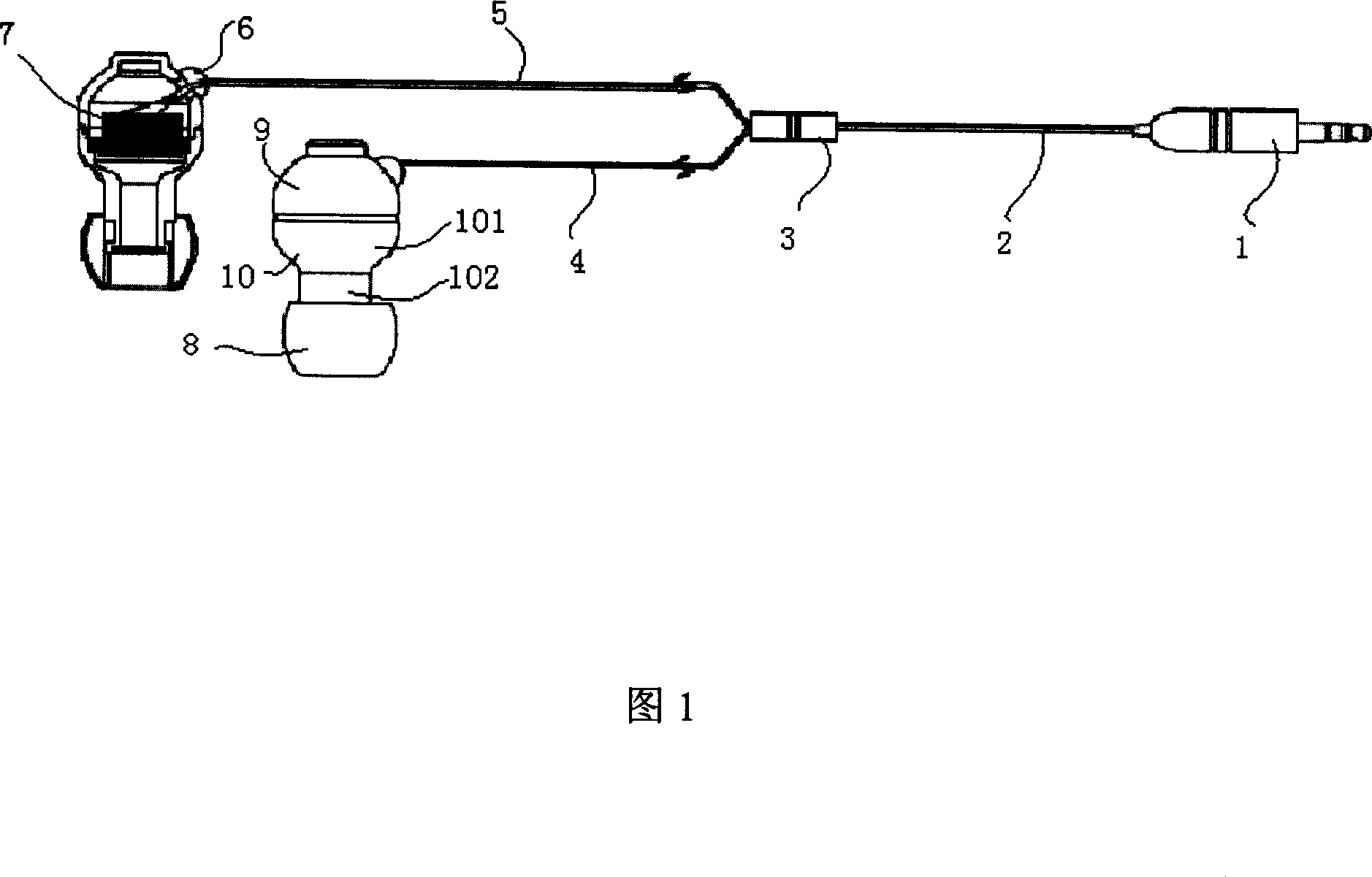

Built-in earphone

InactiveCN1929692AOvercoming technical biasUniform textureEarpiece/earphone attachmentsEngineeringSound quality

This invention discloses one ear small phone to process ear phone front and back shells, wherein, the materials is of good resistance property to absorb redundant vibration besides trumpet to make the sound quality more pure, clear; the materials quality is of good spring and tightness to absorb trumpet.

Owner:张耀国

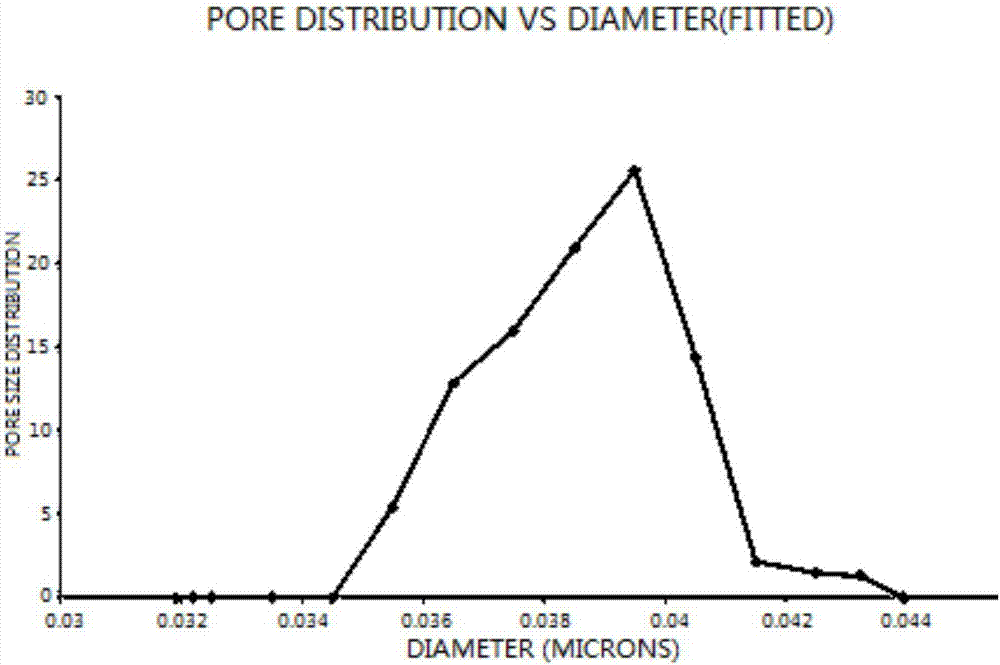

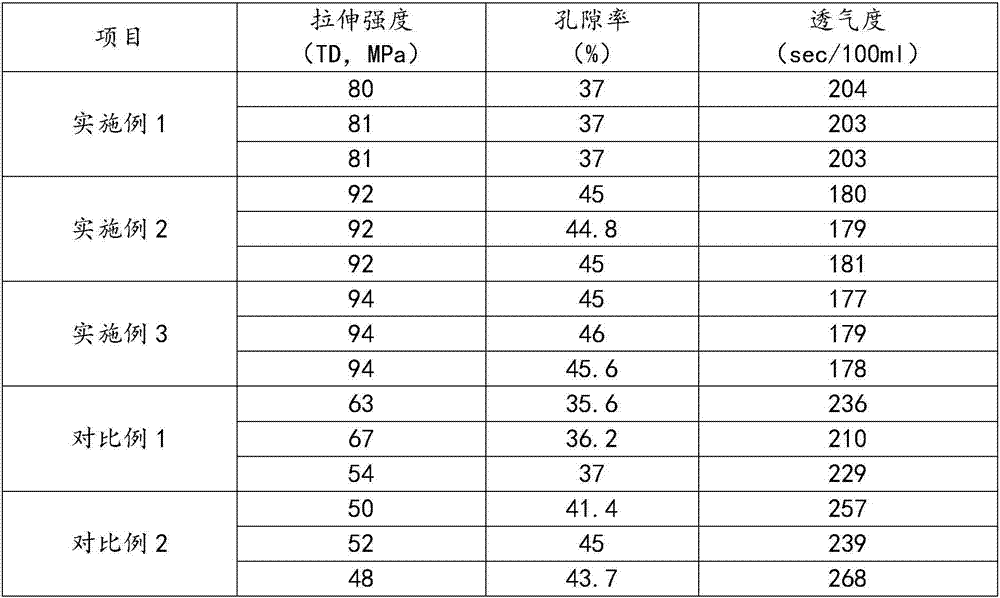

Preparation method for multilayer micro-porous membrane of lithium ion battery

ActiveCN106981608AImprove securityImprove rate discharge performanceSecondary cellsCell component detailsPolyolefinPorous membrane

The invention provides a preparation method for a multilayer micro-porous membrane of a lithium ion battery. The method comprises the following steps: taking polyolefin resin and auxiliary additive as raw materials, fusing and plastifying, thereby acquiring a flux; extruding by a die head and performing tape casting, thereby acquiring intermediate membranes; taking multiple coils of intermediate membranes and compounding by adopting a compounding device with a horizontal stretching function, thereby acquiring a compound intermediate; and performing annealing treatment under an effect of bidirectional micro-tension and longitudinally stretching, thereby acquiring the multilayer micro-porous membrane of the lithium ion battery. According to the invention, a compounding roll is heated in a compounding process of the intermediate membranes, the inner macromolecular structure crystallization of the intermediate membranes is further perfected, and meanwhile, the intermediate membranes horizontally extend under the effect of bidirectional micro-tension and the horizontal orientation degree is increased, so that the micro-pores of the prepared micro-porous membrane are uniform, the horizontal strength is promoted, the capacity of resisting against lithium dendrite puncture is effectively promoted, the micro-short circuit phenomenon is avoided and the micro-porous membrane is suitable for large-scale production. The multilayer micro-porous membrane prepared according to the invention is high in structure uniformity and is effective in promoting the safety of the battery.

Owner:SHENZHEN SENIOR TECH MATERIAL

Novel technique for producing bi-metal composite rod bar

ActiveCN101219502ASolve mass productionSolve long-standing technical problemsNon-electric welding apparatusSurface cleaningUltimate tensile strength

A new process of technology to produce a bimetal composite bar material is provided. The process of the technology is that: cleaning the inner and outer surface of the raw materials of multicoat metal tube and core metal bar-clearance matched stack-bimetal covering-hot rolling and compounding-finishing and shaping. The technology step solves the problem of batch production fundamentally as well as technical difficulty that has long bedeviled people. The input-output qualification rate is over 90 percent, anchoring strength is more than or equal to 130-250MPa and joint rate can be up to 99 percent.

Owner:宝鸡特钢钛业股份有限公司

Input controller for digital and character

InactiveCN101226843AEnter exactlyAvoid enteringElectric switchesPuzzle locksInput controlMobile phone

Owner:余义伦

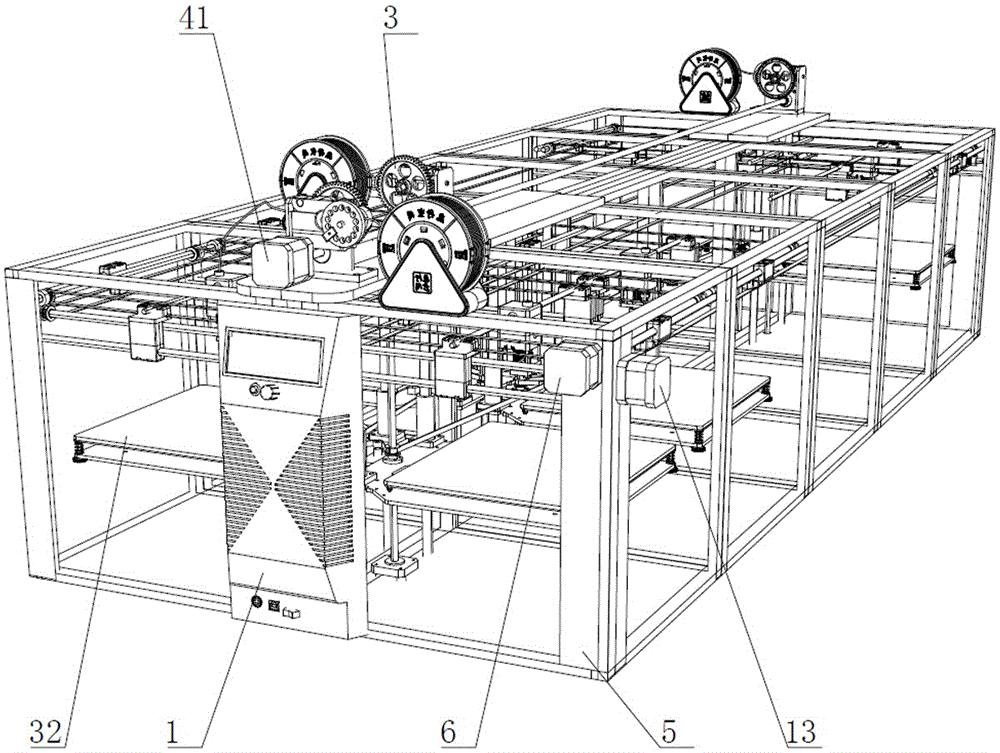

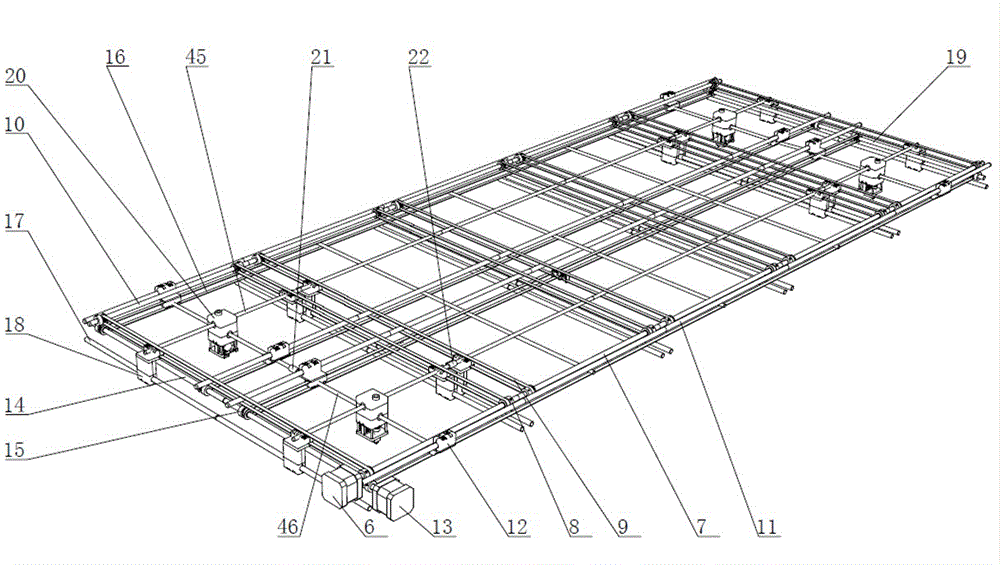

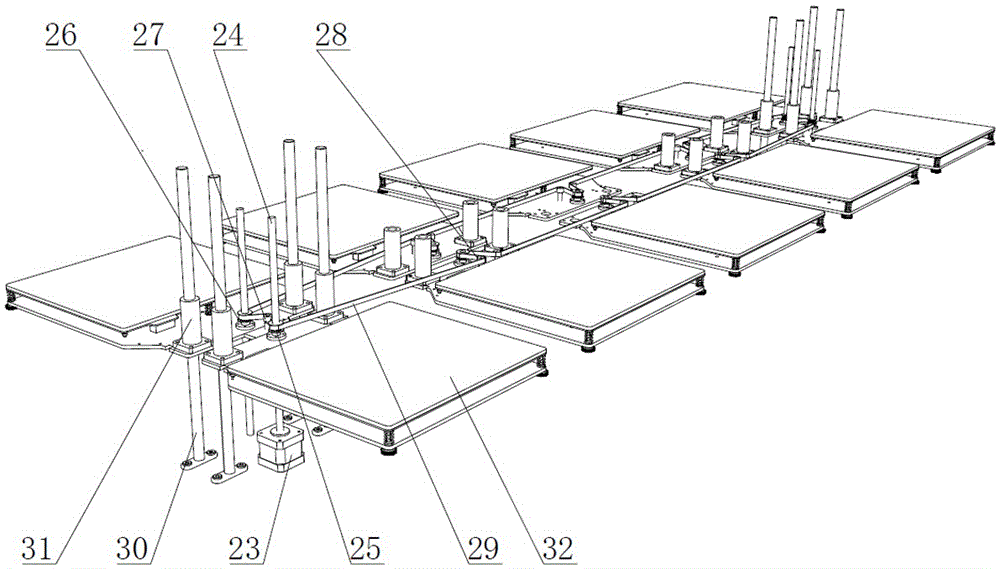

Matrix type 3D printer and printing method thereof

ActiveCN105128341ARealize batch printingImprove consistencyAdditive manufacturing apparatusEngineering3d printer

The invention provides a matrix type 3D printer and a printing method thereof. The matrix type 3D printer comprises printing platforms, a printing mechanism, an X axis driving mechanism, a Y axis driving mechanism, a Z axis driving mechanism, a feeding mechanism, a material abnormality processing mechanism and a control mechanism. The printing platforms are distributed in a matrix mode. The printing mechanism comprises a plurality of printing heads distributed in a matrix mode. The X axis driving mechanism and the Y axis driving mechanism are capable of making all the printing heads move synchronously in the same plane. The Z axis driving mechanism is capable of making all the printing platforms move up and down synchronously. The feeding mechanism is used for providing feeding wires for printing for each printing head. The material abnormality processing mechanism is used for giving an alarm when the feeding wire output is abnormal. The control mechanism is used for controlling operations of the X axis driving mechanism, the Y axis driving mechanism, the Z axis driving mechanism and the feeding mechanism. By means of the matrix type 3D printer and the printing method thereof, bulk printing of products can be achieved. The printing speed is increased and the uniformity of the quality and precision of the products is achieved at the same time. In addition, the matrix type 3D printer is capable of reducing energy consumption and cost.

Owner:HEBEI DAAI INTELLIGENT TECH CO LTD

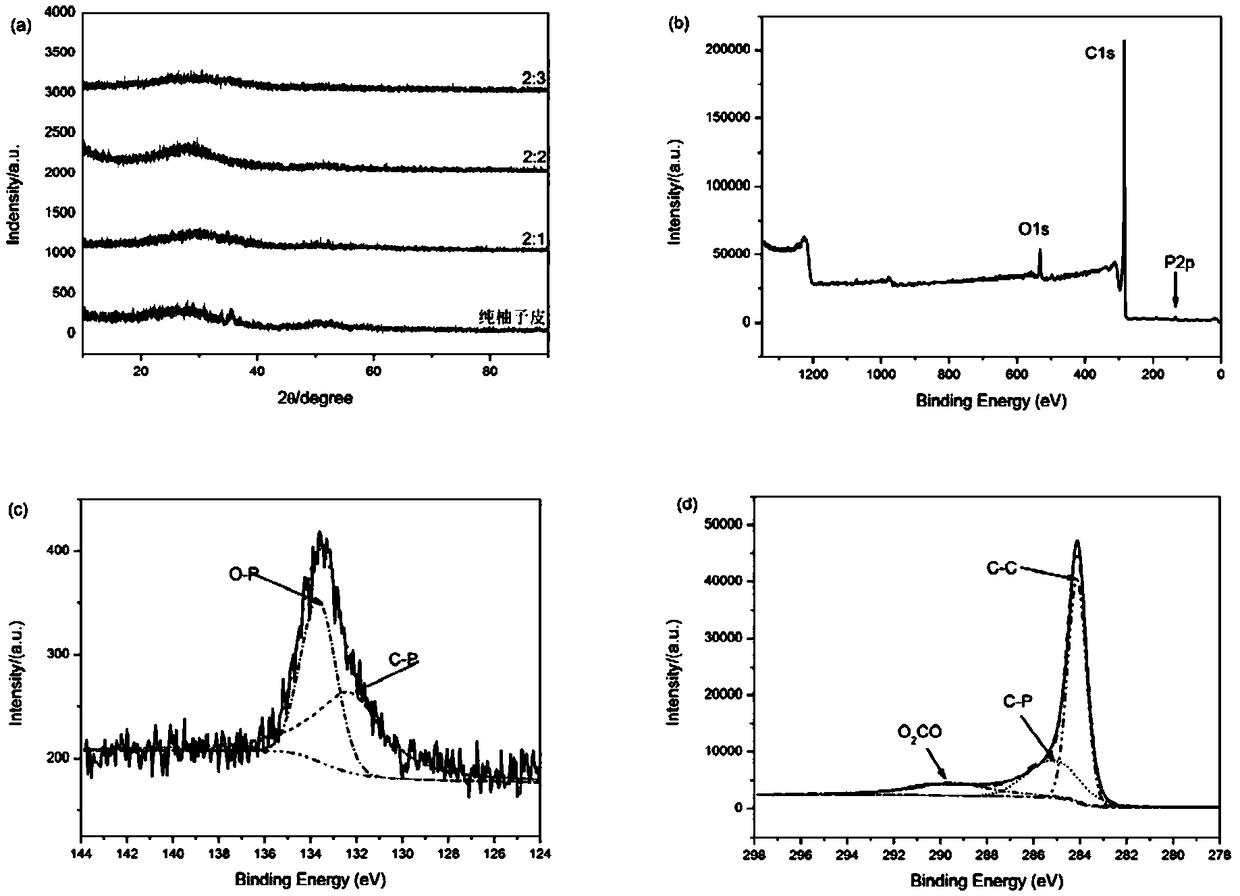

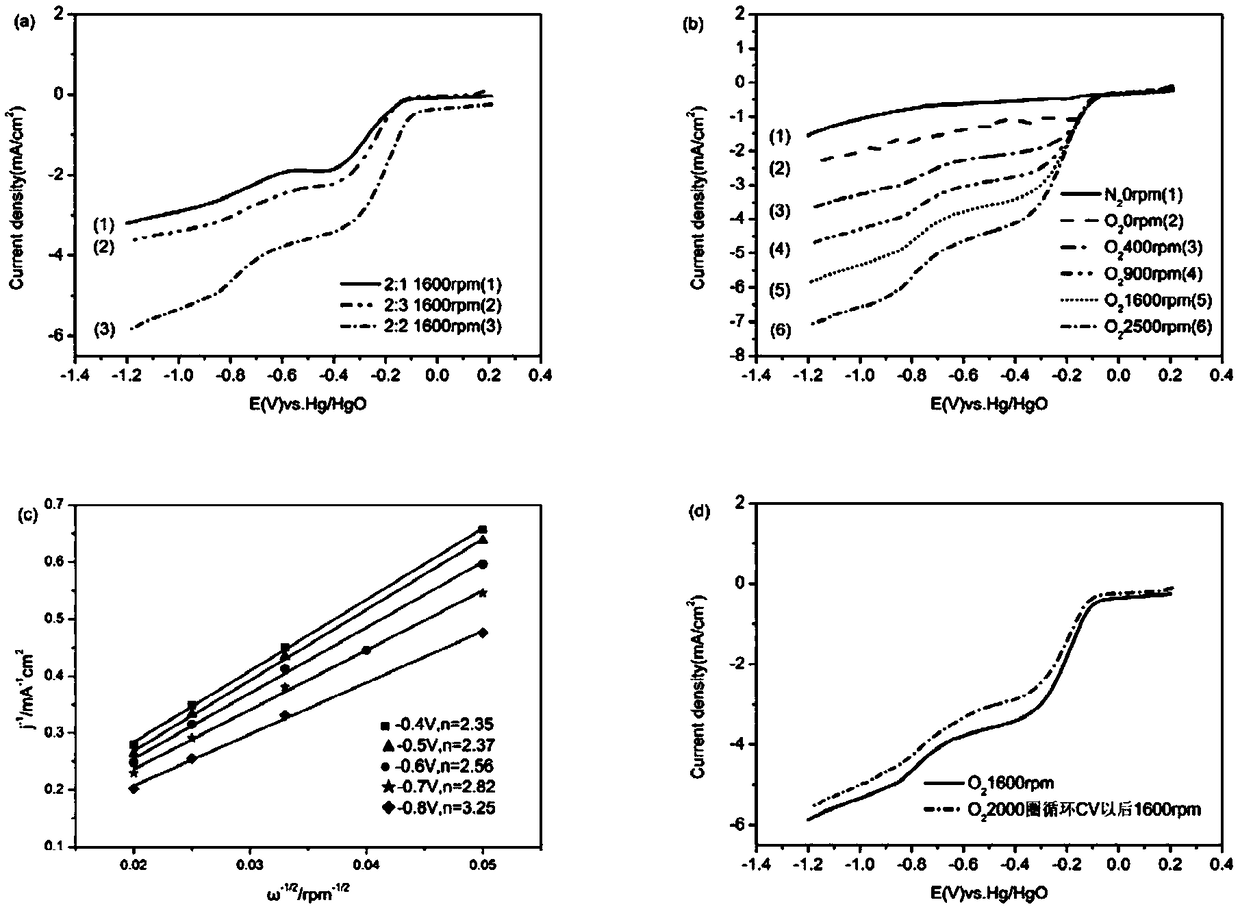

A phosphorus doped porous carbon-oxygen reduction catalyst, preparation method and application thereof

The invention relates to a phosphorus-doped porous carbon-oxygen reduction catalyst, a preparation method and an application thereof, belonging to the field of fuel cell catalyst materials. A method for prepare a phosphorus-doped porous carbon-oxygen reduction catalyst comprise mixing NaH2PO2 and pomelo peel powder, hydrothermal reaction to obtain intermediate product, drying that intermediate product to obtain lumpy substance; A mass substance is carbonized unde that condition of nitrogen, and the obtained product is washed, dried and grin to obtain the product. The phosphorus doped three-dimensional porous carbon material prepared by the invention has the advantages of simple operation, less process flow, less equipment investment and good repeatability, and is convenient to solve the problem of large-scale production.

Owner:DALIAN MARITIME UNIVERSITY

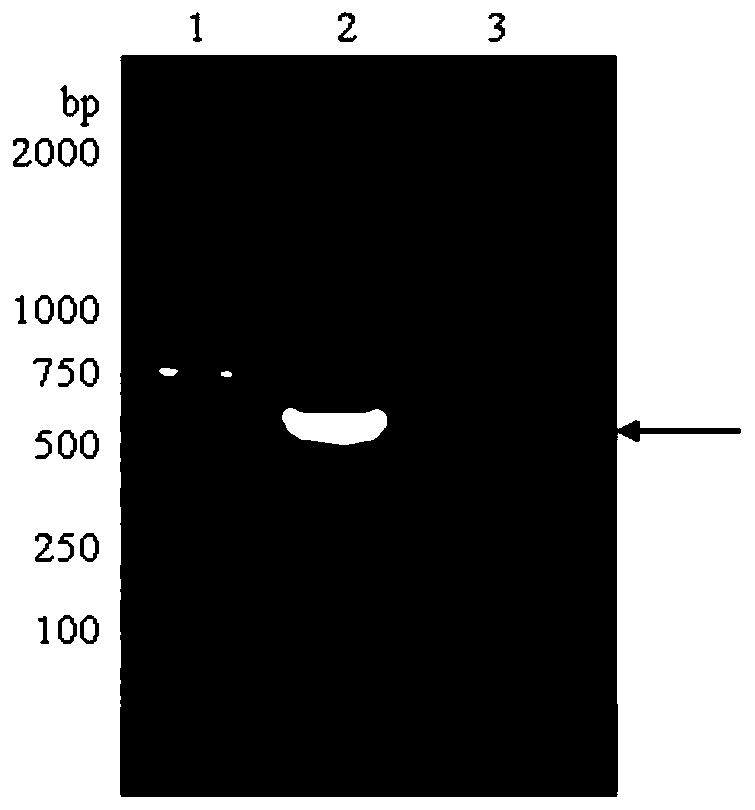

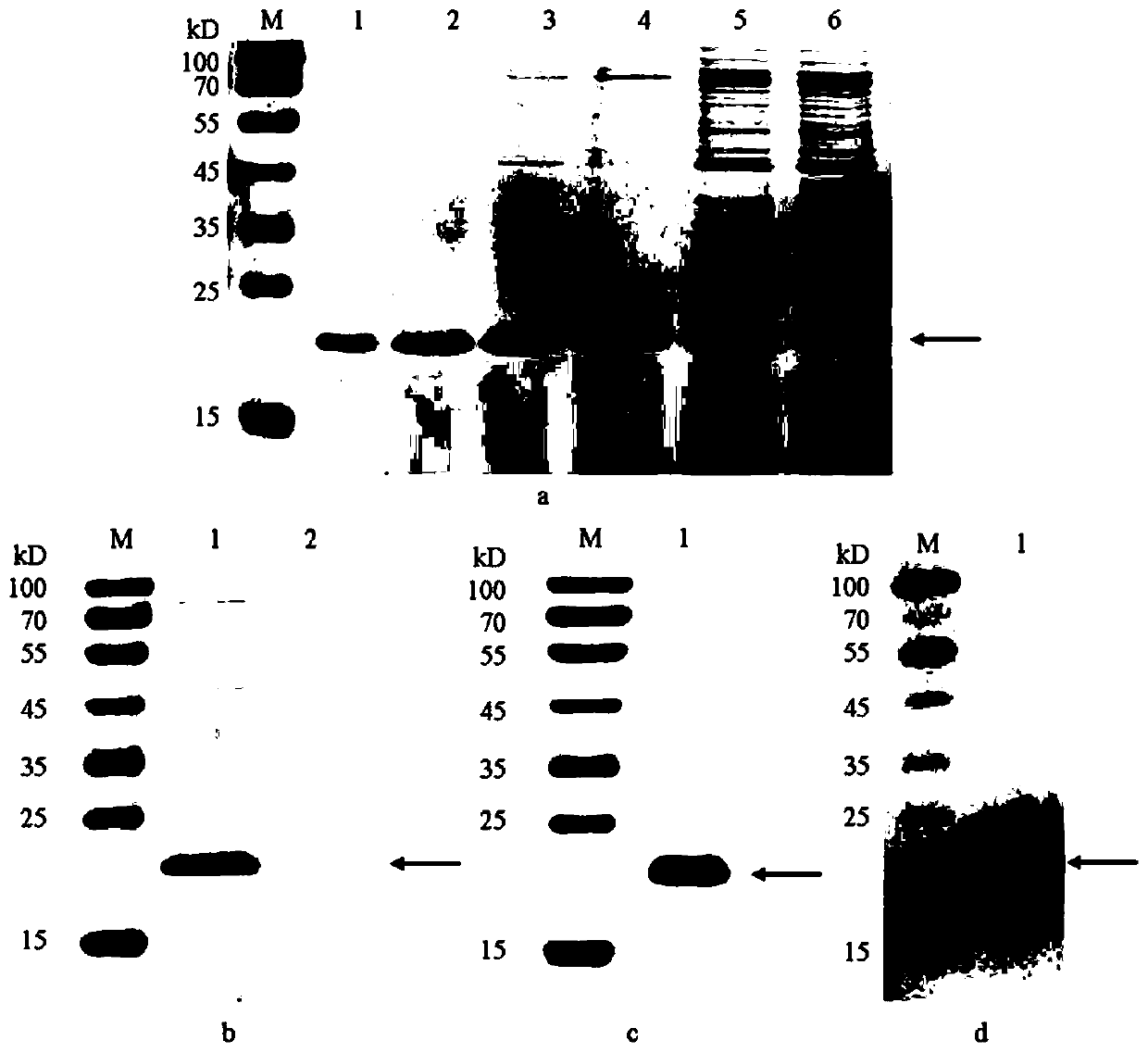

Method of obtaining human recombinant fibronectin by utilizing genetic engineering

The invention belongs to the field of genetic engineering, and more particularly discloses a codon optimized recombinant fibronectin gene for expression and purification in vitro through a genetic engineering method. For the codon optimized recombinant fibronectin gene, by taking pichia pastoris as an expression host cell, the technical defects of small amount and low biological activity of artificially extracting fibronectin can be solved.

Owner:BIOPHARM RES & DEV CENT JINAN +1

Forming die of porous flanging stamping procedure and forming method thereof

The invention relates to a forming die of a multi-hole flanging punching process and the forming method thereof. The forming die comprises an upper die holder and a lower die holder which are assembled together via a guide component; an upper padding plate, an upper fixing plate, an upper pressing plate and a forming male die are arranged on the bottom surface of the upper die holder, a forming female die corresponding to the forming male die is arranged on the upper surface of the lower die holder, and a padding iron is arranged on the bottom surface of the lower die holder. The invention changes the conventional punching method that requires two processes and two sets of dies to punch the bottom holes and flange the holes, and designs a punching method which comprises the steps of firstly deep drawing forming and then extrusion-shearing forming in one working position and requires only one process and one set of dies. The forming die of the invention realizes the one-shot punching forming of shutter holes, and the formed hole-flanging has smooth and neat edge without flash or burr; and after hole flanging, the outer surface of the whole panel is smooth without drawing deformation or corrugation, thereby conforming to the product technical requirements.

Owner:HENAN XINFEI ELECTRICAL EQUIP

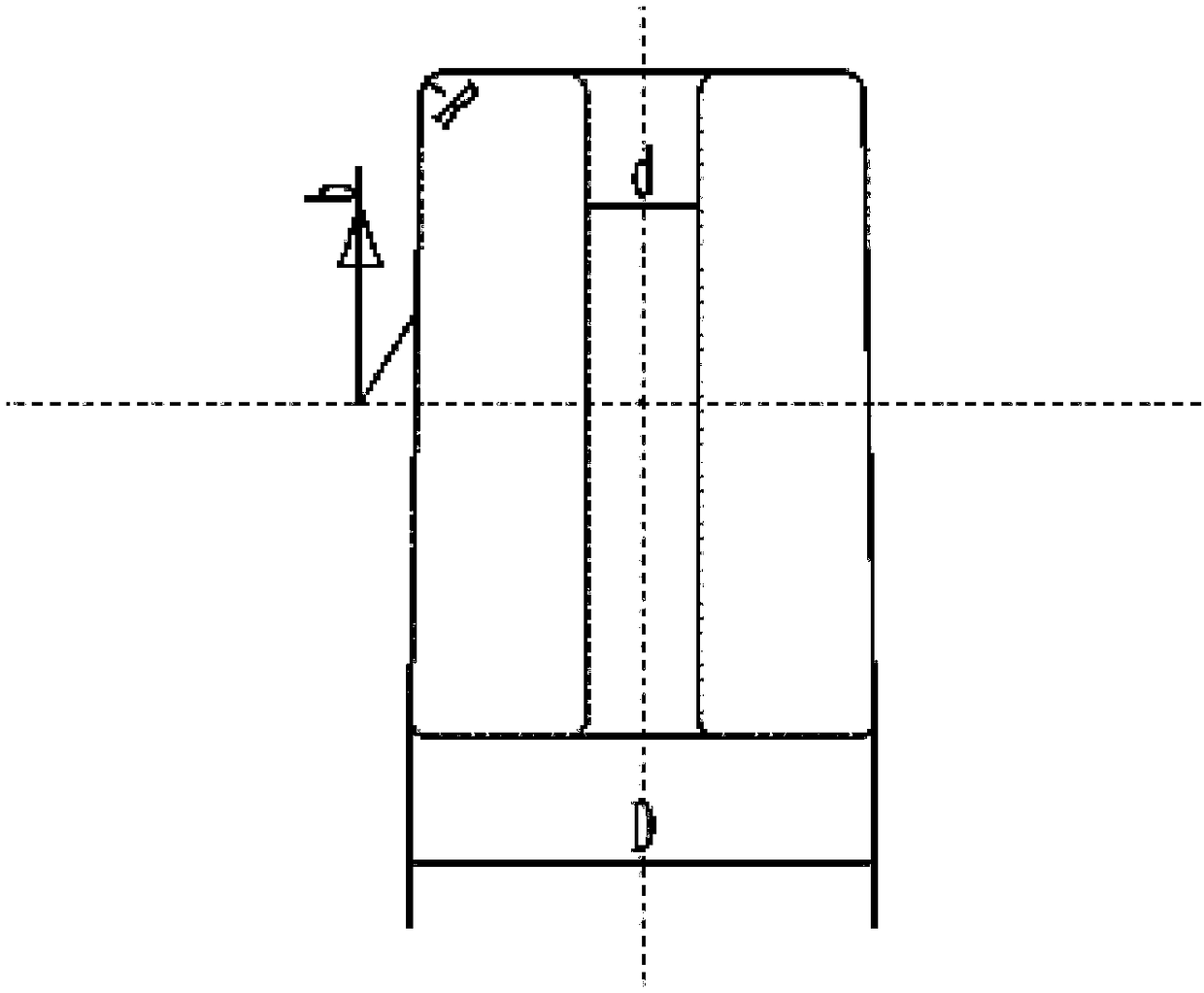

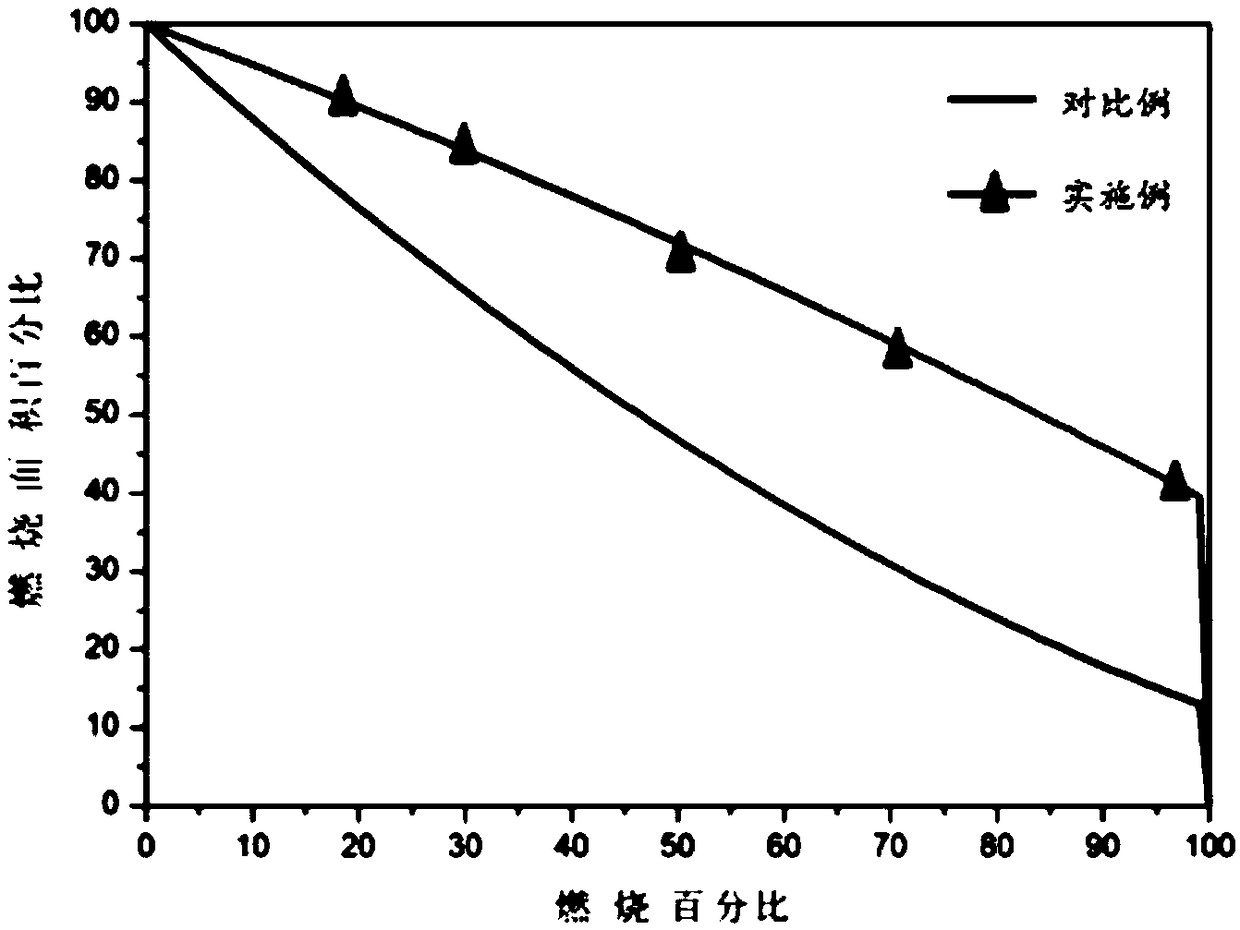

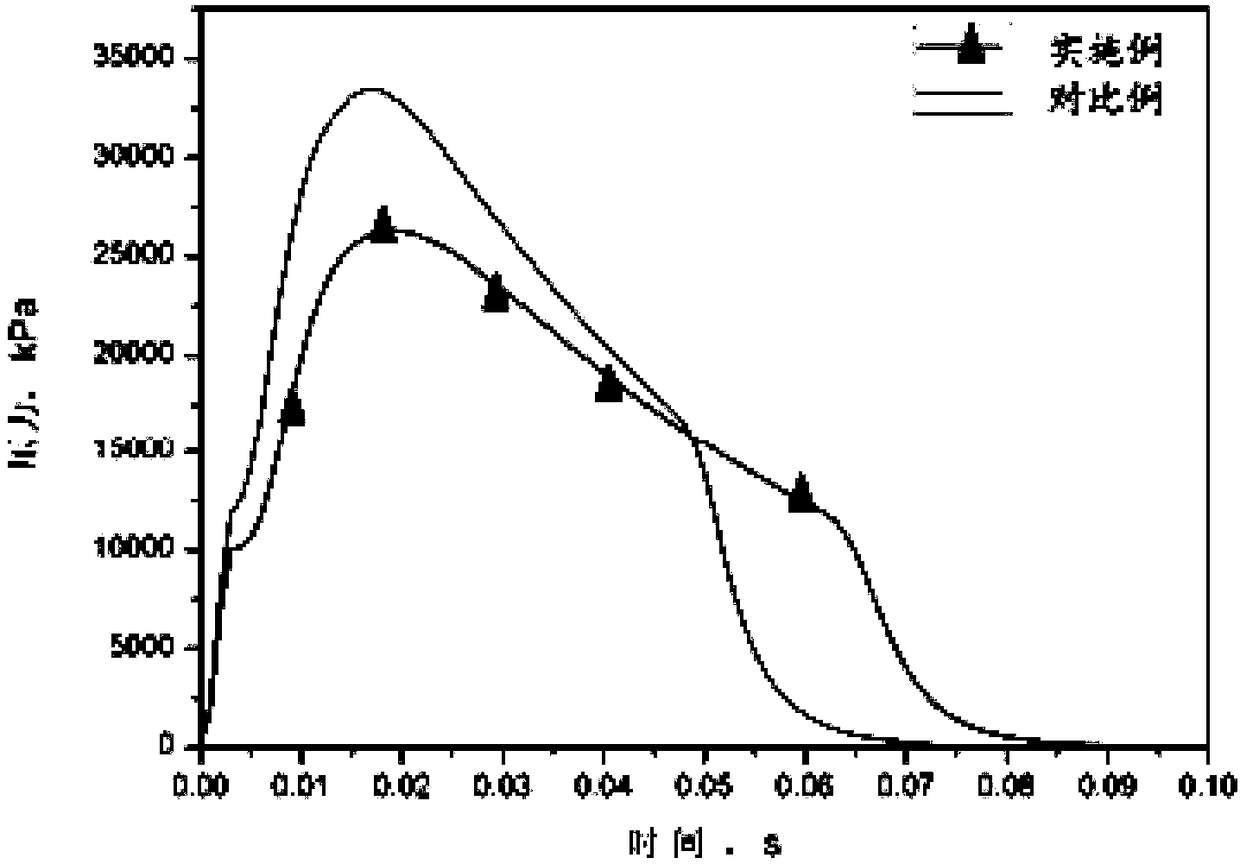

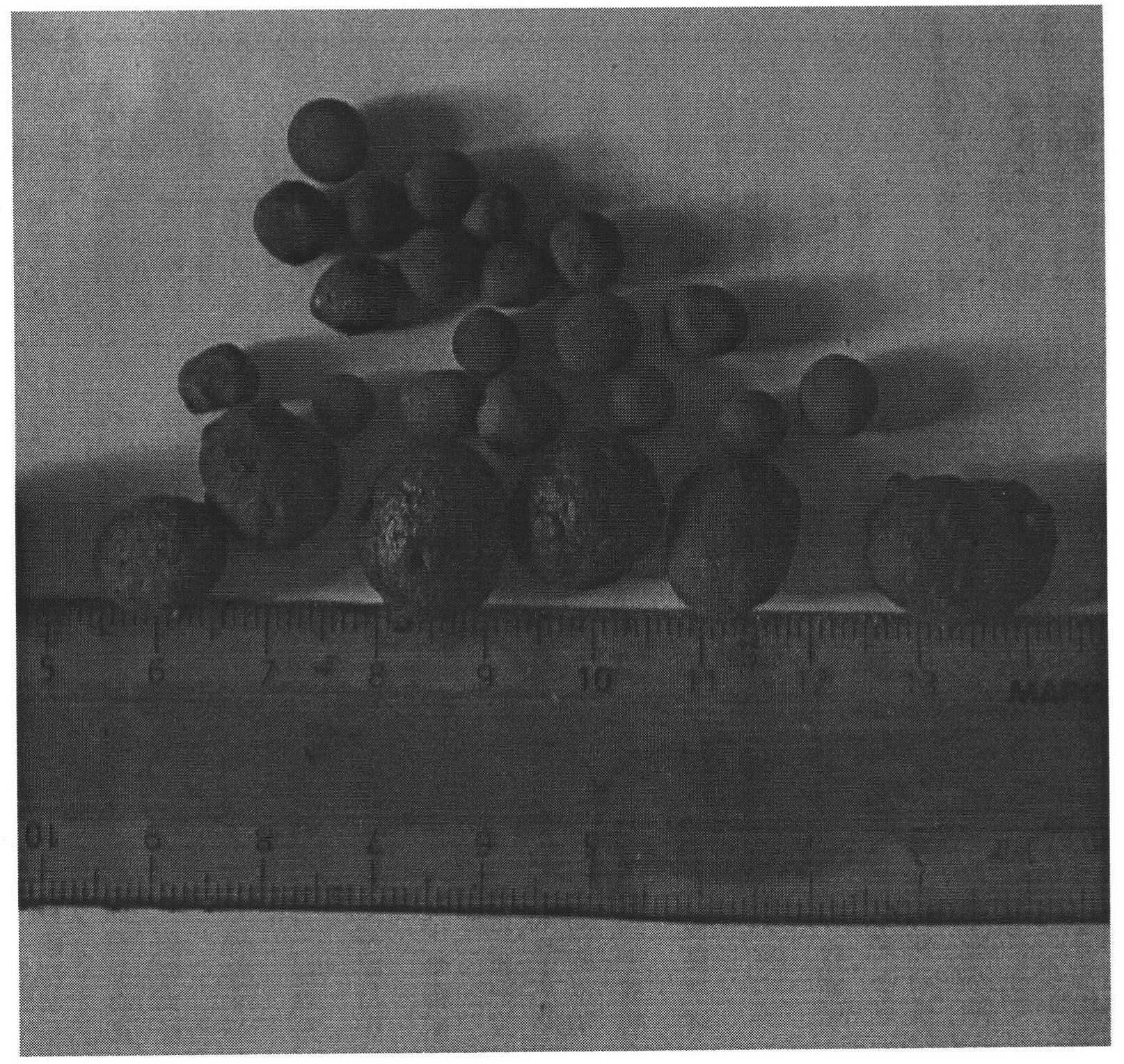

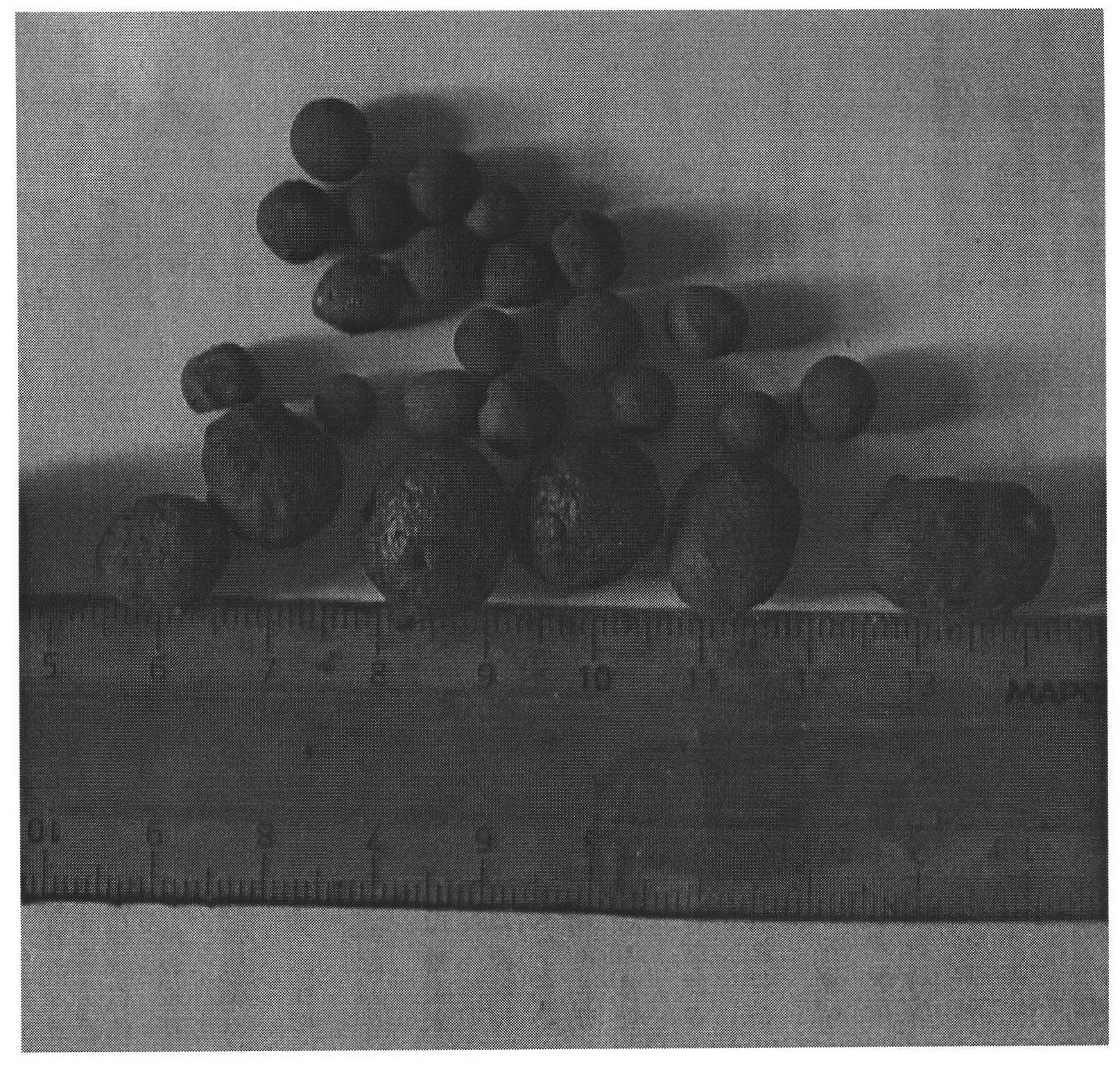

Gas-generating agent granules for air bags and pressing preparation method thereof

ActiveCN108863691AReduce performance and stabilityRelieve pressureExplosivesPressure gas generationEngineeringGas generator

The invention provides gas-generating agent granules for air bags and a preparation method thereof and belongs to the technical field of gas-generating agents. The gas-generating agent granules are characterized in that a gas-generating agent is round-platform-shaped granules; penetrating through holes are arranged in the centers of the bottom surfaces of the granules, so that the bottom surfacesof the granules form concentric circles with the outer diameters being 3.5-10mm and the inner diameters being 1.0-3mm. When the gas-generating agent provided by the invention is burnt, the air bag isslowly inflated at the initial stage of expansion, and is rapidly inflated at the later stage of expansion, so that the pressure-time curve of a gas generator is S-shaped; a pressing process is adopted for pressing and forming, the production efficiency is high, the side pressing strength is more than 120N, the breaking and dust generation are difficult under the severe environment of vibrating use, the reduced weight is less, and the property is stable after long-term use. The gas-generating agent provided by the invention has the beneficial effects that the pressure on a generator shell in burning also can be reduced, so that the shell with lower strength can be used and the weight of the generator can be reduced.

Owner:HUBEI INST OF AEROSPACE CHEMOTECHNOLOGY

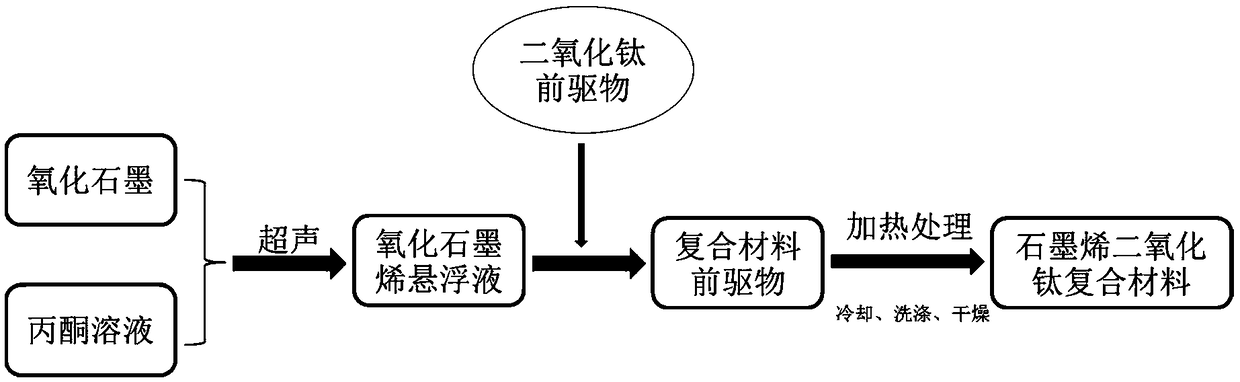

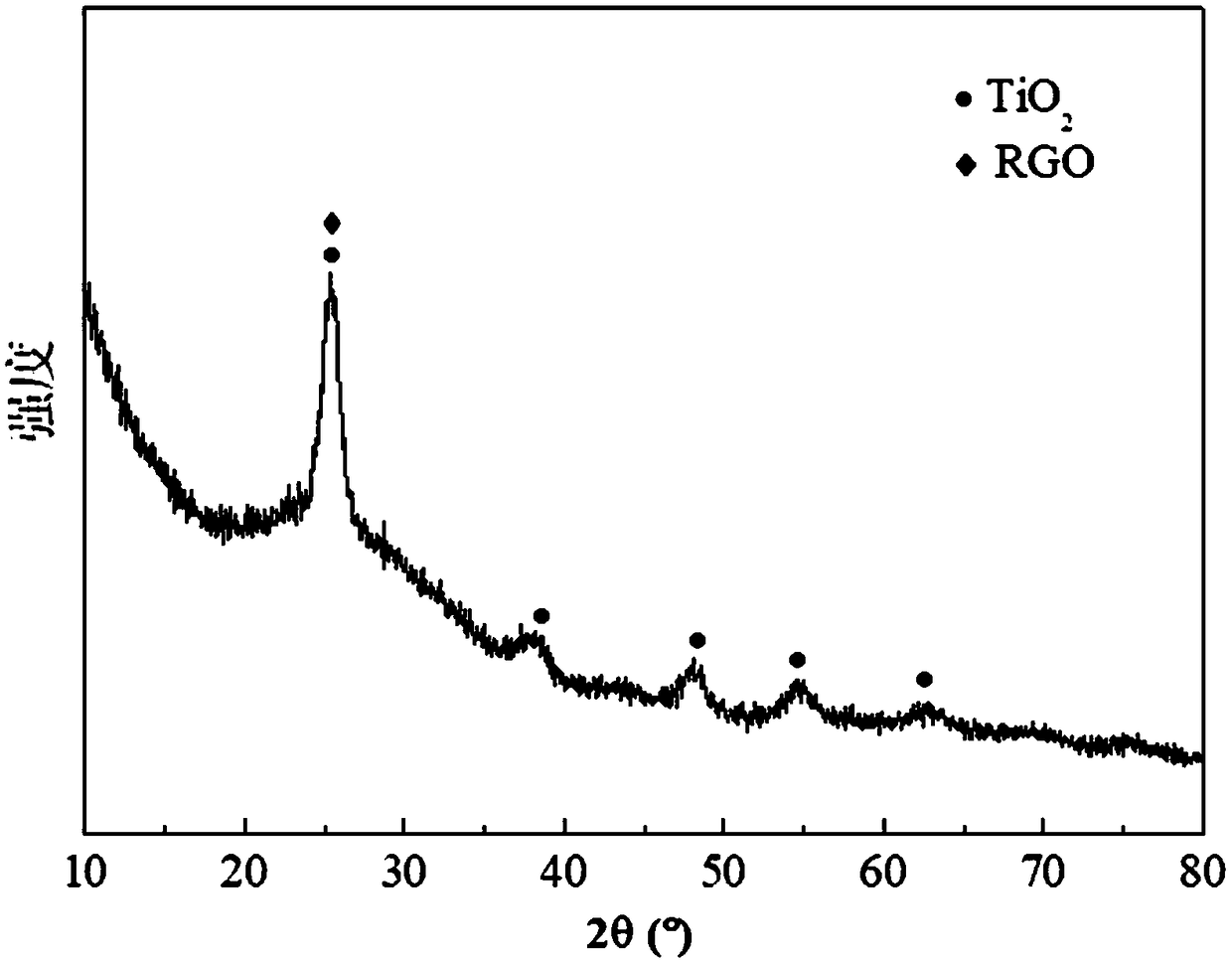

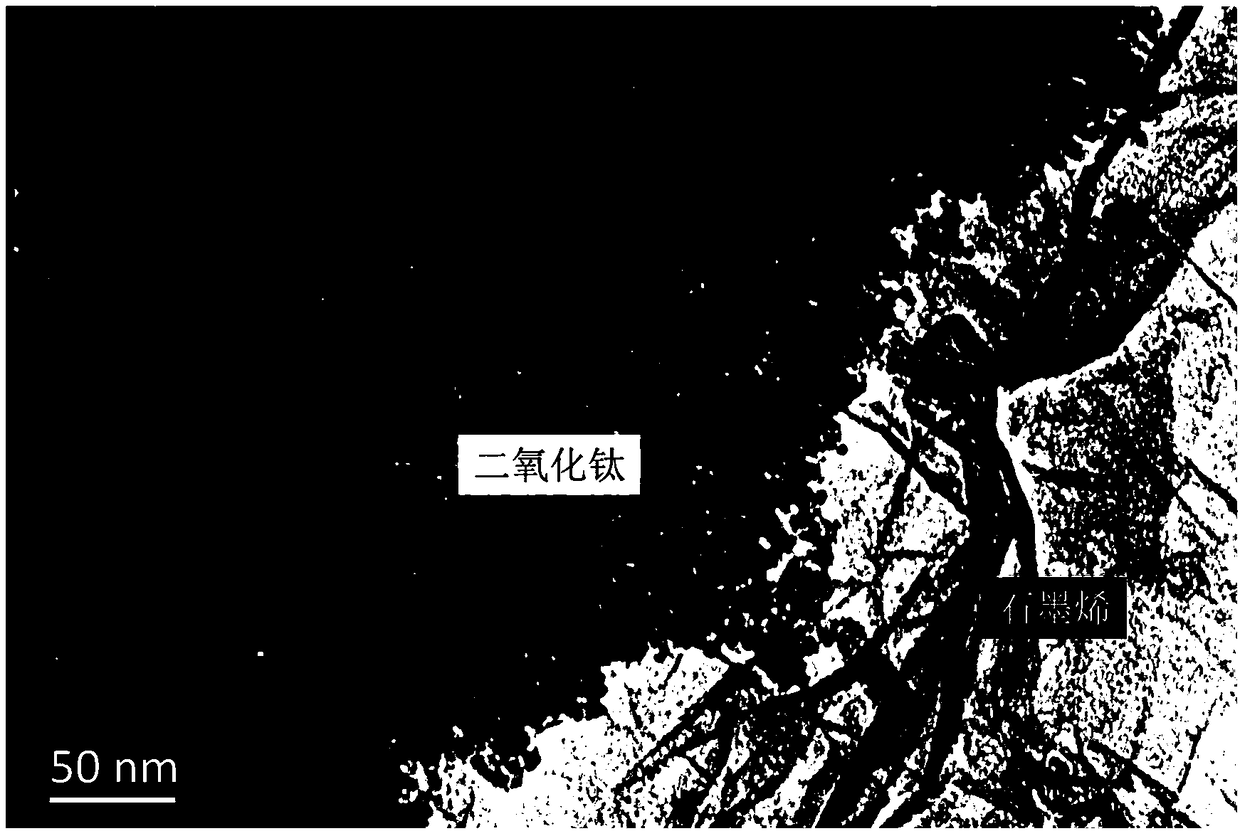

Graphene titanium dioxide composite nano material and preparation method thereof

InactiveCN108704635ALarge specific surface areaImprove photocatalytic performanceCatalyst activation/preparationUltrasonic dispersionMaterials science

The invention discloses a graphene titanium dioxide composite nano material and a preparation method thereof. The preparation method of the graphene titanium dioxide composite nano material includes the steps of: dissolving graphite oxide prepared by a Hummers method in an acetone solution, and conducting ultrasonic dispersion to prepare graphene oxide suspension A; adding a titanate compound to an alcohol solution, and stirring at room temperature to prepare a titanium dioxide precursor solution B; adding the titanium dioxide precursor solution B into the graphene oxide suspension A to be evenly mixed and stand still, and performing centrifugal separation of precipitates to obtain the precipitates; adding deionized water to the precipitates, and cooling to room temperature after hydrothermal reaction is over to obtain reaction liquid C; separating products from the reaction liquid C by centrifugation, carrying out ultrasonic dispersion, washing, conducting separation and precipitation, and drying the precipitates to obtain the graphene titanium dioxide composite nano material. The preparation method of the graphene titanium dioxide composite nano material has the advantages of being simple, suitable for large-scale production, and capable of performing one-step synthesis of the graphene titanium dioxide nano composite material with high specific surface and good photocatalyticproperties by a hydrothermal method under mild conditions.

Owner:NORTHEASTERN UNIV

Method for preparing ultra-light high-strength ceramic aggregate from dredged bottom mud and nearshore high-sand content mud

ActiveCN102030491AHigh strengthOvercoming the disadvantages of low intensitySolid waste managementGranularityFree cooling

The invention provides a method for preparing ultra-light high-strength ceramic aggregate from dredged bottom mud and nearshore high-sand content mud, which comprises the following steps: (1) uniformly mixing dried bottom mud dredged from a lake, a river or an ocean and straws of water plants according to a volume ratio of 5-12:1-0.2 to obtain fresh pellets, adding nearshore high-sand content mud to the fresh pellets used as seed pellets, and rolling into finished fresh pellets; and (2) burning the prepared finished fresh pellets at 950-1350 DEG C for 30-60 minutes, and naturally cooling to obtain the ultra-light high-strength ceramic aggregate. The invention solves the problem of mass production caused by scarce resources, and solves the problem on stacking and processing polluted bottom mud dredged from lakes and rivers. At the same time, the invention overcomes the defect of the low strength of the traditional ultra-light ceramic aggregate, and achieves the purposes of the harmless processing and the recycling of waste. Besides, the prepared ultra-light high-strength ceramic aggregate has the characteristics of low specific gravity, adjustable particle size, high strength and high stability.

Owner:戴勇鹏

Method for preparing persistent inhibition carbon fiber dressing

ActiveCN104611786ASilver loading is firmImprove bindingFibre treatmentLiquid/solution decomposition chemical coatingActivated carbonHigh volume manufacturing

The invention relates to a method for preparing activated carbon fiber medical dressing. The method specifically comprises the following steps: (1) carrying out pretreatments on a clean raw material fiber, such as deoiling, roughening and activating, and cleaning the clean raw material fiber; (2) chemically silvering the fiber, and supplementing related consumed functional components in the plating solution after the plating operation; (3) washing, dewatering and drying the silver-loaded fiber; (4) pre-treating, carbonizing and activating the silver-loaded fiber. The method is simple in process and principle, the used chemical silvering solution is stable and is suitable for mass production, and granules in the prepared silver-loaded carbon fiber material are firm in binding force with the matrix, moderate in mechanical strength, excellent in antibacterial ability and continuous in stability, so that the silver-loaded carbon fiber material has a broad application prospect in the healthcare industry.

Owner:GUANGDONG TAIBAO MEDICAL SCI TECH

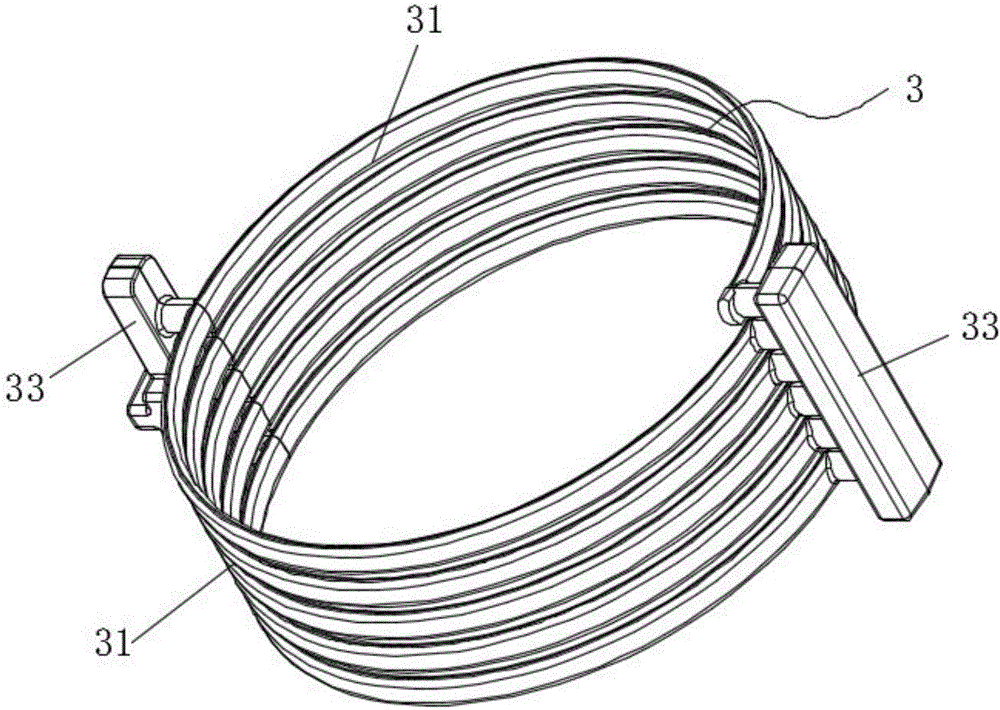

Impeller device

InactiveCN105179312AImprove work efficiencySimple structurePump componentsPumpsImpellerHigh volume manufacturing

The invention discloses an impeller device comprising a front disc and a rear disc, wherein the rear disc is fixedly connected with a wheel hub through a connecting piece, the wheel hub is located in the center of the rear disc, and the rear disc is fixedly provided with blades by taking the central axis of the rear disc as a reference axis; the blades are shaped like straight plates, the outer side edges of the blades form a round, the blades are provided with intersection points on the round, and the extension lines of the blades and the tangent lines at the intersection points of the round form an included angle of 59-61 DEG; and an air outlet is formed in the middle of the front disc, the periphery of the front disc is fixedly connected with the blades to form a closed structure, the periphery of the front disc is shaped like a circular arc, and the circle center of the circular arc is located at the side far away from the blades. The impeller device has the beneficial effects that the blades arranged at the included angle ensure that air flow more smoothly enter the blades, air resistance is reduced, and the noise is effectively reduced. The blades are simple in structure, easy to machine and beneficial to large-scale production, so that the production cost can be effectively reduced. The impeller device is of the closed structure and capable of effectively avoiding air flow loss so as to be relatively high in air outlet volume and higher in working efficiency.

Owner:天津尼特风机有限公司

Comfortable inflatable pillow

The invention discloses a comfortable inflatable pillow which comprises a supporting frame manufactured by slow rebound memory cotton. The section of the supporting frame is a right-angled triangle with the acute angles being smaller than 45 degrees. The outer side of the supporting frame is provided with a fabric pillowcase. The upper portion of the supporting frame is provided with padding. The supporting frame is internally provided with an air bag. According to the comfortable inflatable pillow, the pillow is set to be an automatic inflatable pillow with an acute-angle inclined face, snoring, generated due to the fact that the pillow is excessively high, of a user can be effectively relieved, the requirement for a high pillow of the user is met, the inclined-face pillow is made of the slow rebound memory cotton and is comfortable, the user can fall asleep more conveniently through the smooth inclined-face pillow, when snoring begins, a sound control sensing device starts a driving device to discharge some air, the healthy pillow height is achieved, sleeping of the user is not affected, sleeping of other people is not affected as well, and the pillow is comfortable and healthy.

Owner:XIAN TENGJI BIO TECH

Overall quenching process of car closed torsion beam

ActiveCN107419065AHigh mechanical strengthReduce manufacturing costSolid state diffusion coatingPunchingLaser cutting

The invention discloses an overall quenching process of a car closed torsion beam. The overall quenching process comprises the steps: 1) blanking; 2) stamping; 3) heat treatment; 4) straightening; 5) shot blasting; 6) punching; and 7) laser cutting. According to the overall quenching process disclosed by the invention, from the point of validity and innovation of equipment, a high frequency furnace is replaced with a multi-purpose furnace for heat treatment production of the closed torsion beam, and resources are utilized effectively; the production cost of the closed torsion beam is reduced, and the effect of batch production is achieved; the overall quenching is achieved, and the structure uniformity is improved effectively; the problems of uneven metallographic structures and grain sizes caused by power fluctuation and local output difference of the high frequency furnace are solved. The test shows that the mechanical strength of the car closed torsion beam produced with the overall quenching process is high, the tensile strength reaches 1330-1360 MPa, Rp0.2 reaches 1220-1250 MPa, and the elongation is 12%; the fatigue property is excellent after heat treatment, and the requirements of main engine plants are met.

Owner:天人汽车底盘(芜湖)股份有限公司

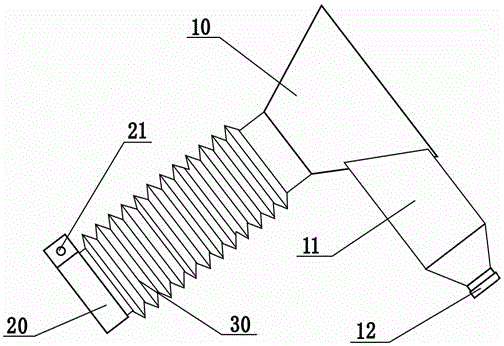

Electric drill drilling dust collector for wall punching

InactiveCN107520815AGood for healthSimple structurePortable percussive toolsPortable power-driven toolsPunchingEngineering

The invention discloses an electric drill drilling dust collector for wall punching. The electric drill drilling dust collector comprises a wall attaching cover, an annular hoop and a corrugated cover; the wall attaching cover is in a horn shape, a dust collecting barrel is arranged on the outer wall of the wall attaching cover, and a dust leakage opening is formed in the bottom of the dust collecting barrel; a plug is arranged at the dust leakage opening, the corrugated cover is installed at the tail end of the wall attaching cover, and the annular hoop is installed at the tail end of the corrugated cover; and the annular hoop can be fixed to the root of a drill bit of an electric drill, and the corrugated cover is a retractable plastic corrugated pipe. According to the electric drill drilling dust collector, the structure is simple and reasonable, use is convenient and fast, the manufacturing cost is pretty low, batch production is facilitated, and the electric drill drilling dust collector can be suitable for electric hand drills of various types; through the electric drill drilling dust collector, the situation that when drilling is conducted on the wall through an electric hand drill, dust flies upwards can be effectively prevented, the situation that the dust falls on the body of an operator or the dust is inhaled by the operator into the body is avoided, and the electric drill drilling dust collector is good for the health of the operator accordingly.

Owner:周琳桓

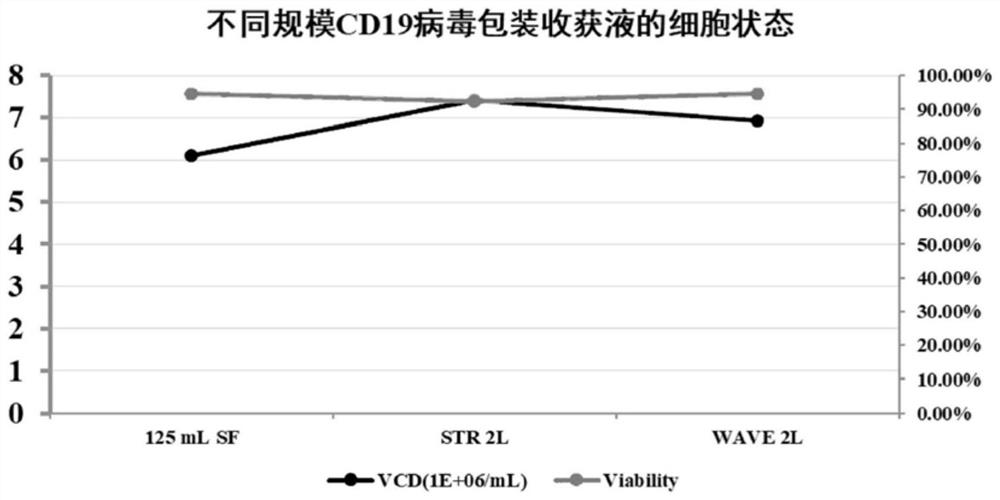

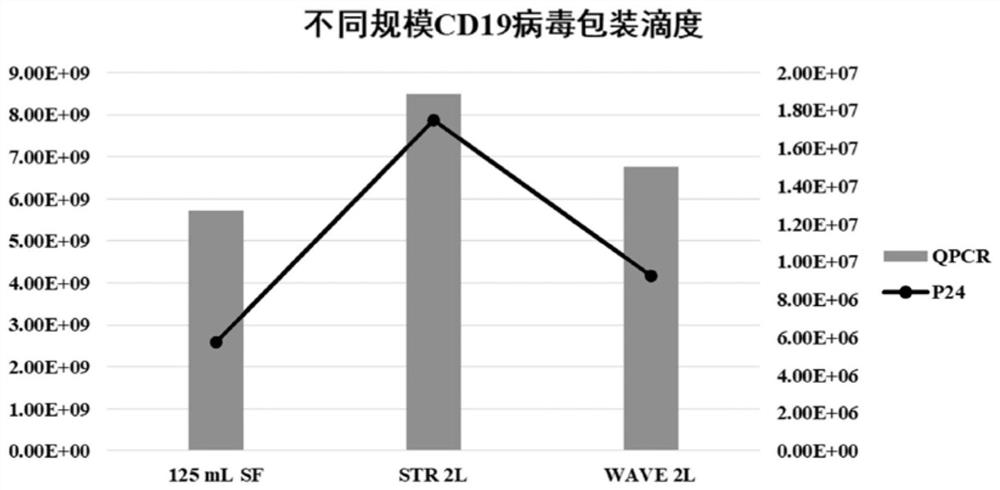

Suspension cell-based CAR-CD19 lentivirus preparation process

PendingCN113265425ASolve mass productionAvoids the disadvantages of relying on fetal bovine serum (FBS)Artificial cell constructsNucleic acid vectorLentivirusCell culture supernatant

The invention discloses a suspension cell-based CAR-CD19 lentivirus preparation process, which comprises the following steps: S1, recovering HEK293 cells, and carrying out adaptive domestication culture in a domestic culture medium; S2, domesticating the well cultured HEK293 cells to establish a cell bank; S3, amplifying the HEK293 cells until the density of the HEK293 cells reaches the required density; S4, in a four-plasmid system, carrying out transfection on the HEK293 cells; and S5, after transfecting the CAR-CD19 lentivirus plasmid for 48 hours, harvesting a cell culture supernatant, thereby obtaining a lentivirus harvesting solution with the cell viability of 90% or more and the titer of 5*10<6> TU / mL or more. According to the CAR-CD19 lentivirus preparation process, the viability of the cultured lentivirus cells reaches 90% or above, the lentivirus titer of the obtained supernatant reaches 5*10<6> TU / mL or above, and impurities released by cell death can be greatly reduced, so that the pressure of downstream purification is relieved.

Owner:PORTON BIOLOGICS LTD

Nano gold-silver alloy solution having affinity for fibers and preparing method thereof

ActiveCN110153442AImprove solution stabilityThe preparation process is continuousTransportation and packagingMetal-working apparatusWoolChitin

The invention relates to a nano gold-silver alloy solution having affinity for fibers and a preparing method thereof. The preparing method comprises the steps that silver ions and gold ions are addedinto a deionized aqueous solution of amino end group hyperbranched polymer, stirring heating is carried out, a nano silver solution and a nano gold solution are made, and are mixed according to the proportion, a high-temperature hydrothermal reaction is carried out, cooling is carried out, and the nano gold-silver alloy solution of a core-shell structure is made; the nano gold-silver alloy is torispherical, and the grain size ranges from 2 to 30 nm; the nano gold-silver alloy solution can be completely absorbed on the fiber surface at the high temperature, in the use process, silver ions are not released, good biosecurity is achieved, the solution has the strong molecular recognition and combining capacity for fibers such as cotton, silk, wool, calcium alginate fiber, and chitin, through normal temperature or high-temperature water bath, the solution can be completely assembled on the fiber surface, and the problems that the nano material and the fibers are poor in affinity, load efficiency is low, and environment is polluted are solved.

Owner:NANTONG UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com