A phosphorus doped porous carbon-oxygen reduction catalyst, preparation method and application thereof

A catalyst, porous carbon technology, applied in electrical components, battery electrodes, circuits, etc., can solve the problems of limiting fuel cell reaction speed, slow kinetic control steps, high cost, etc., achieve good electrocatalytic performance, reduce catalyst cost, good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

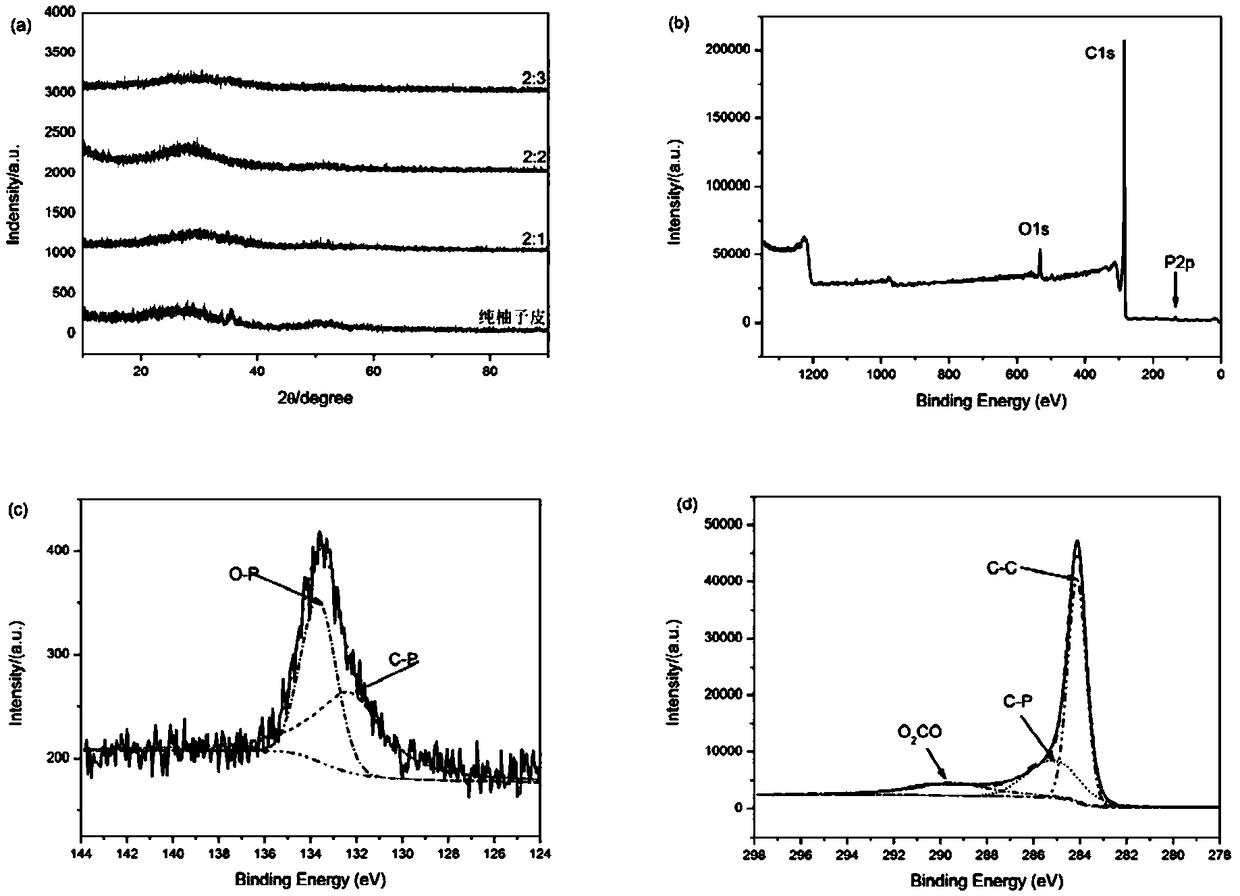

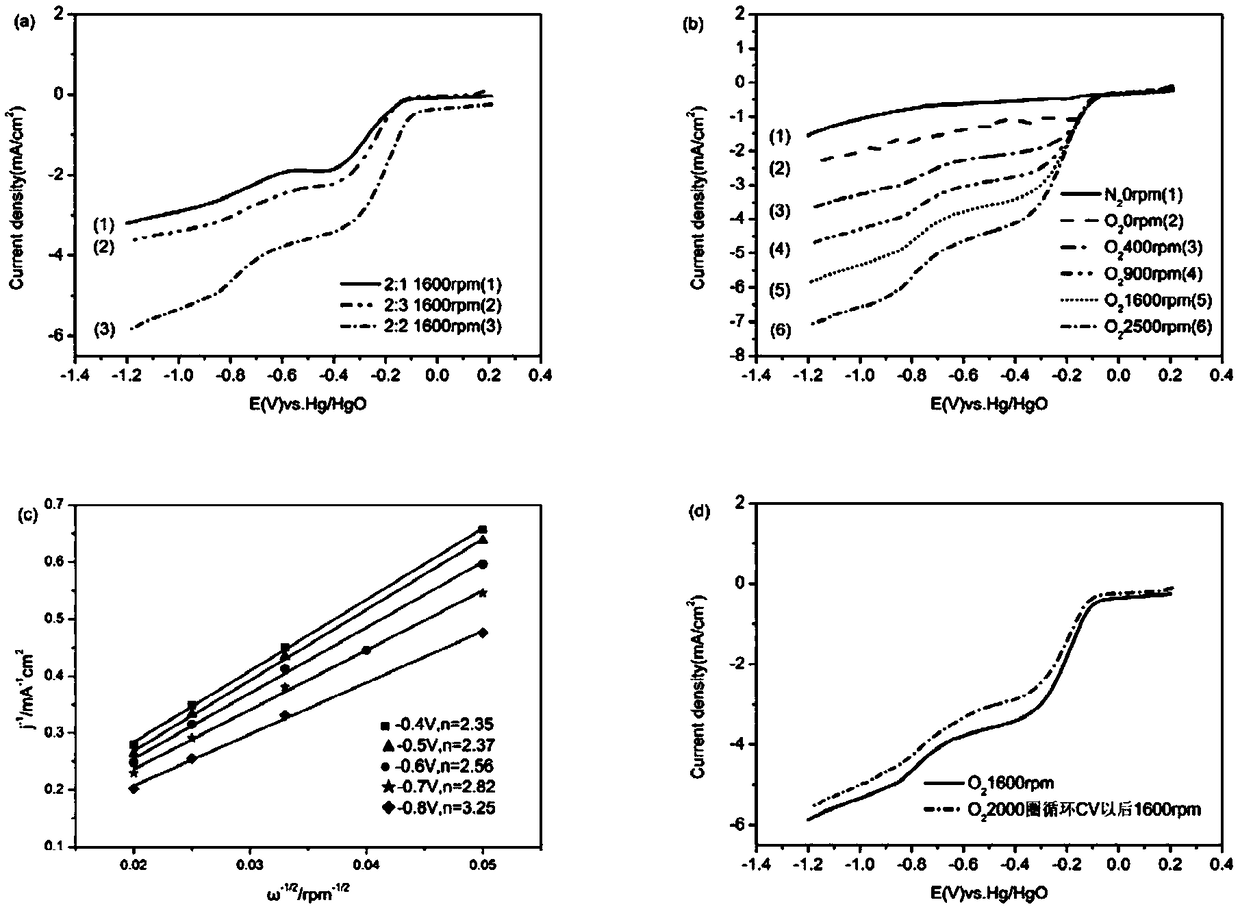

Embodiment 1

[0029] 1) Take out and collect the white flocs on the inner surface of the pomelo peel, wash them with deionized water, dry them in a drying oven at 80°C for 24 hours, and then use a grinder to grind them into white powder.

[0030] 2) Take 2g grapefruit peel powder, add 1g NaH 2 PO 2 , add 35ml of deionized water, stir evenly to get a uniform pomelo peel powder solution.

[0031] 3) Move the uniform pomelo peel powder solution into the reaction kettle, set the hydrothermal temperature to 180°C, keep it warm for 6h, then take it out, and dry it at 80°C for 12h until it becomes a brown solid.

[0032] 4) Carbonize the brown solid in a tube furnace with nitrogen, the carbonization procedure is as follows: from room temperature to 800 °C at a heating rate of 10 °C / min, keep it warm for 1 h, then cool to room temperature with the furnace, and take it out; Soak in 3mol / L HCl solution, centrifuge with deionized water at 4000r / min for 5min, repeat centrifugation until neutral, then...

Embodiment 2

[0034] 1) Take out and collect the white flocs on the inner surface of the pomelo peel, wash them with deionized water, dry them in a drying oven at 80°C for 24 hours, and then use a grinder to grind them into white powder.

[0035] 2) Take 2g grapefruit peel powder, add 2g NaH 2 PO 2 , add 35ml of deionized water, stir evenly to get a uniform pomelo peel powder solution.

[0036] 3) Move the uniform pomelo peel powder solution into the reaction kettle, set the hydrothermal temperature to 180°C, keep it warm for 6h, then take it out, and dry it at 80°C for 12h until it becomes a brown solid.

[0037] 4) Carbonize the brown solid in a tube furnace with nitrogen, the carbonization procedure is as follows: from room temperature to 800 °C at a heating rate of 10 °C / min, keep it warm for 1 h, then cool to room temperature with the furnace, and take it out; Soak in 3mol / L HCl solution, centrifuge with deionized water at 4000r / min for 5min, repeat centrifugation until neutral, then...

Embodiment 3

[0039] 1) Take out and collect the white flocs on the inner surface of the pomelo peel, wash them with deionized water, dry them in a drying oven at 80°C for 24 hours, and then use a grinder to grind them into white powder.

[0040] 2) Take 2g grapefruit peel powder, add 3g NaH 2 PO 2 , add 35ml of deionized water, stir evenly to get a uniform pomelo peel powder solution.

[0041] 3) Move the uniform pomelo peel powder solution into the reaction kettle, set the hydrothermal temperature to 180°C, keep it warm for 6h, then take it out, and dry it at 80°C for 12h until it becomes a brown solid.

[0042] 4) Heat the brown solid in a tube furnace with nitrogen. The pyrolysis procedure is as follows: from room temperature to 800 °C at a heating rate of 10 °C / min, keep it warm for 1 h, then cool to room temperature with the furnace, and take it out; Soak in 3mol / L HCl solution, centrifuge with deionized water at 4000r / min for 5min, repeat centrifugation until neutral, then centrifu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com