Vacuum-pumping system for multiple-dewar interlayer and vacuum-pumping method thereof

A vacuum pumping system and vacuum system technology, applied in fixed-capacity gas storage tanks, pressure vessels, liquid variable-capacity machines, etc., can solve the problems of long operation time of vacuum extraction process, low efficiency of vacuum extraction process, and difficulty in batching of Dewar tanks. Production and other problems, to achieve the effect of reducing the operation time of vacuum extraction, stable product quality and accurate vacuum degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

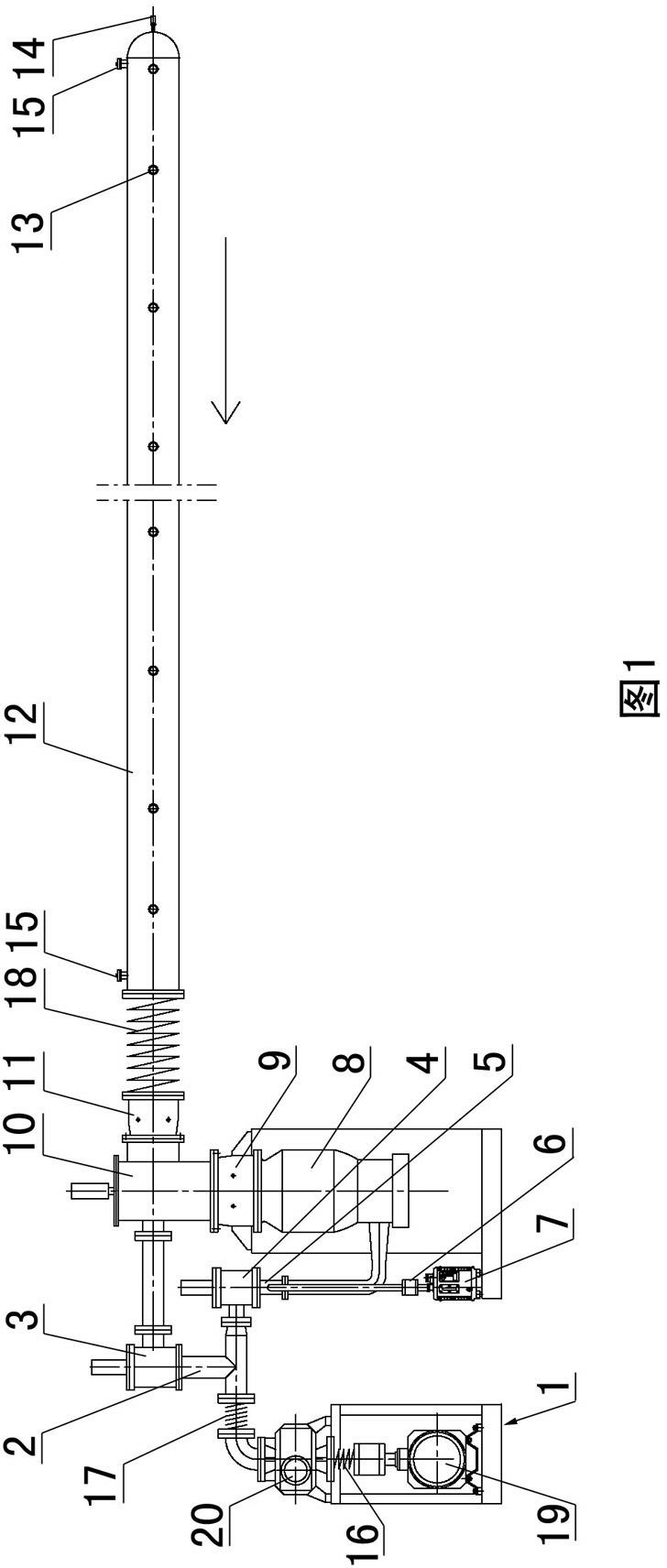

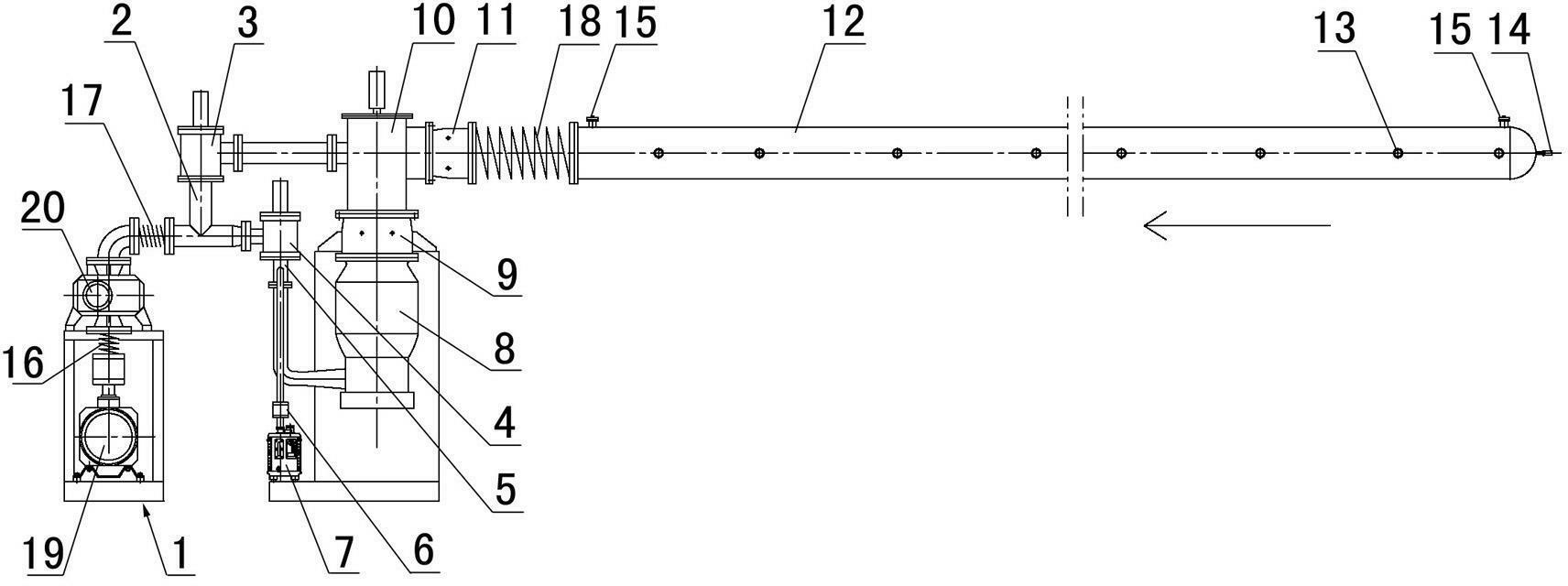

[0026] Examples see figure 1 , figure 2 As shown, this multi-bottle dewar interlayer vacuum pumping system includes a vacuum unit 1, a three-way pipe fitting A2, a bypass valve 3, a front valve 4, a three-way pipe fitting B5, a maintenance valve 6, a maintenance pump 7, and a system Main pump 8, water-cooled trap 9, three-way system main valve 10, liquid nitrogen cold trap 11 and vacuum system pipeline 12, wherein the vacuum unit 1 includes a main mechanical pump 19 and a booster pump 20, on the vacuum system pipeline 12 Dewar interlayer ports 13 are provided at intervals, and the vacuum system pipeline 12 is also provided with hot nitrogen ports 14 and resistance gauge and ionization gauge measuring point ports 15 .

[0027] The suction end of the main mechanical pump 19 communicates with the outlet end of the booster pump 20, the suction end of the booster pump 20 communicates with the first port of the three-way fitting A2, and the second port of the three-way fitting A2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com