Lead-acid battery and manufacture method thereof

A lead-acid battery and battery cover technology, applied in lead-acid battery, lead-acid battery construction, battery pack components, etc., can solve problems such as safety accidents, burning of external terminals, easy ship vibration, etc., to achieve convenience and save molding process, the effect of reducing the welding process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

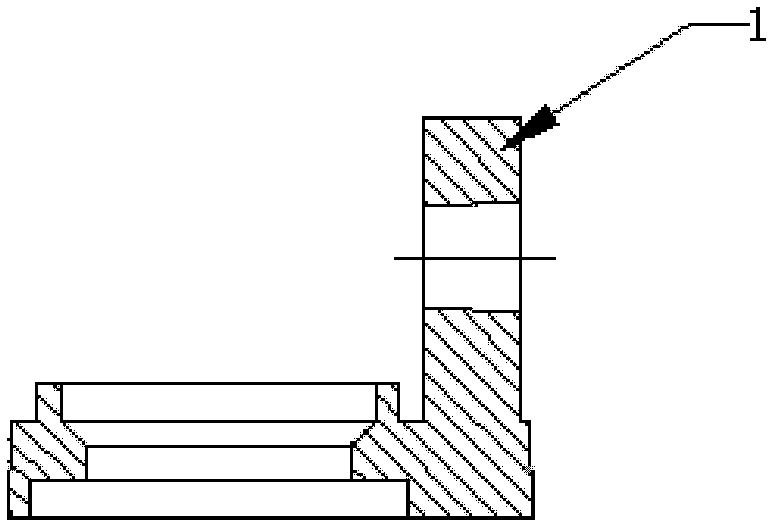

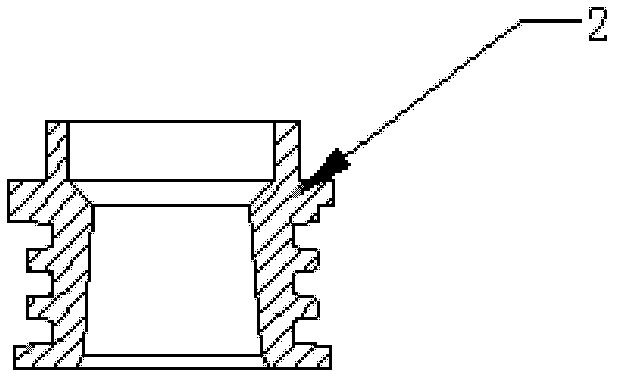

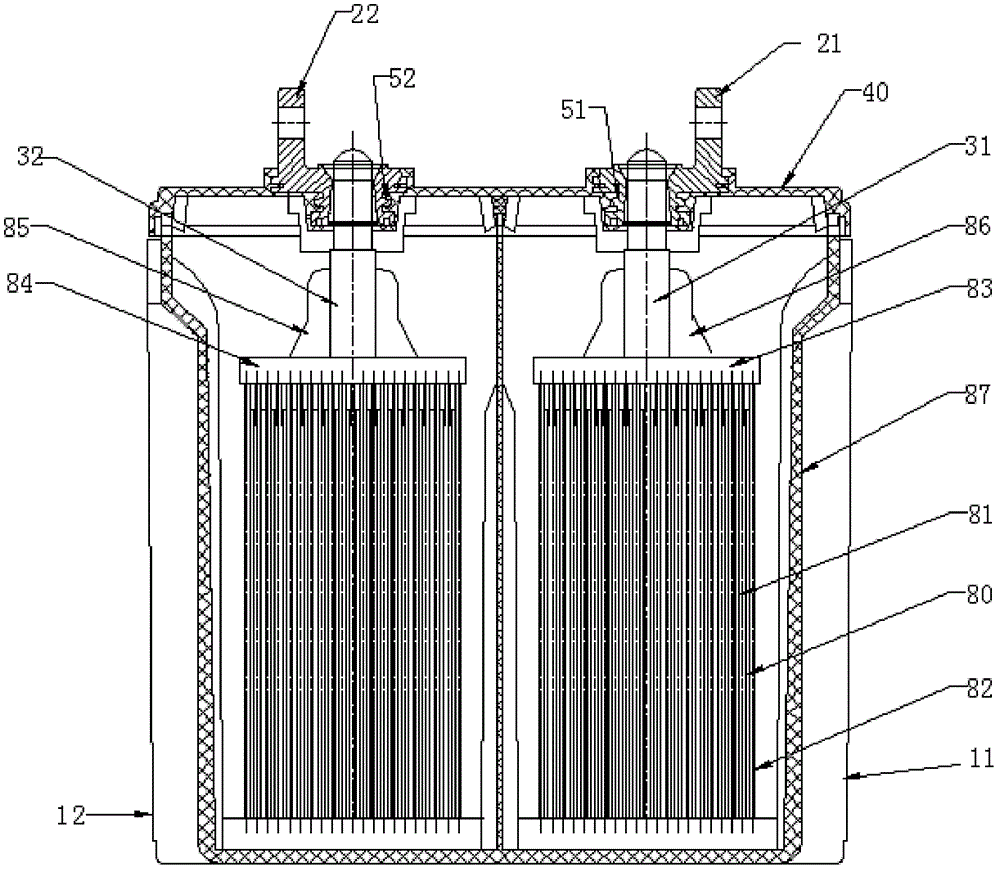

[0018] Example 1, please refer to image 3 with Figure 4 , a kind of lead-acid accumulator that the present embodiment provides, comprises: battery body and external connection terminal, and battery body comprises pole and battery cover 40, and battery cover 40 is provided with via hole, and external connection terminal comprises integrally formed lead sleeve 70 and terminal 60, the pole passes through the hole and connects with the lead sleeve 70; the battery body includes a positive pole part 11 and a negative pole part 12; The holes include positive vias 51 and negative vias 52 . The lead sleeve and terminal of the external terminal provided in this embodiment are integrally formed. Compared with the split design in the prior art, the forming process is saved, the welding process is reduced, and at the same time, air holes and cracks due to improper welding process or welding points are avoided. Or the potential safety hazard caused by impurities such as oxides.

[0019...

Embodiment 2

[0023] Example 2, please refer to Figure 5 to Figure 6 , a method for manufacturing a lead-acid battery provided in this embodiment, including methods such as external terminal casting, external terminal and battery cover joining, such as Figure 5 shown.

[0024] Wherein, the casting method of the external terminal is: pouring lead alloy melt into the mold of the external terminal, and forming the external terminal including the lead sleeve and the terminal after cooling.

[0025] The joining method of the external terminal and the battery cover is as follows: the lead sleeve on the external terminal is pre-placed in the battery cover mold, and then injected into the plastic melt, cooled and molded, and the external terminal and the battery cover are combined into one.

[0026] In this embodiment, it is preferable that the lead sleeve of the external terminal passes through the via hole on the battery cover. Therefore, in theory, as long as the size of the via hole on the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com