A kind of reinforcing material for pavement base course and preparation method thereof

A technology for reinforcing materials and pavement base, which is applied in the field of road construction materials and its preparation, can solve the problems of long maintenance period, high price and high cost, and achieve good anti-rutting performance, good water stability and good life cycle Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] The bitumen used in this example is No. 50 bitumen, and the properties of the bitumen such as penetration, softening point, dynamic viscosity at 60°C, and ductility at 15°C were tested. Measured: penetration 40.5 mm; softening point 52°C; dynamic viscosity 220pas at 60°C; ductility 110cm at 15°C. Therefore, the No. 50 asphalt meets the performance requirements of the asphalt required for making reinforcing materials.

[0036] The corresponding mixture of the reinforcing material in this embodiment is weighed according to the following parts by mass:

[0037] Above-mentioned No. 50 asphalt gets 3.5 mass parts;

[0038] 1 part by mass of cement;

[0039] 98 parts by mass of limestone;

[0040] 1 part by mass of limestone powder.

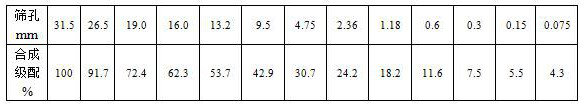

[0041] The above-mentioned limestone mineral material is composed of synthetic graded aggregates as shown in Table 1, which are in accordance with the reinforcing material of the present invention Synthetic grading requirements for mineral ...

Embodiment 2

[0054] The bitumen used in this example is No. 30 bitumen, and the properties of the bitumen such as penetration, softening point, dynamic viscosity at 60°C, and ductility at 15°C were tested. Measured: penetration 30.5 mm; softening point 65°C; dynamic viscosity 280pas at 60°C; ductility 102cm at 15°C. Therefore, the No. 30 asphalt meets the performance requirements of asphalt for making reinforcing materials.

[0055] The corresponding mixture of the reinforcing material in this embodiment is weighed according to the following parts by mass (each part by mass is 1 kg):

[0056] 3.75 parts by mass of above-mentioned No. 30 asphalt, namely 3.75 kilograms;

[0057] Cement gets 1.5 parts by mass;

[0058] 97 parts by mass of limestone;

[0059] 2 parts by mass of limestone powder.

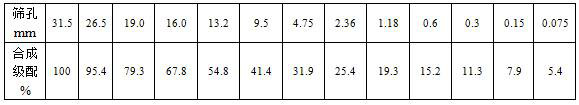

[0060] The above-mentioned limestone ore materials are composed of synthetic graded aggregates as shown in Table 2, which are in accordance with the reinforcing material of the present invention. ...

Embodiment 3

[0073] The bitumen used in this example is No. 50 bitumen, and the properties of the bitumen such as penetration, softening point, dynamic viscosity at 60°C, and ductility at 15°C were tested. Measured: the penetration is 48 mm; the softening point is 56°C; the dynamic viscosity is 290pas at 60°C; the ductility at 15°C is 120cm. Therefore, the No. 50 asphalt meets the performance requirements of the asphalt required for making reinforcing materials.

[0074] The corresponding mixture of the reinforcing material in this embodiment is weighed according to the following parts by mass:

[0075] Above-mentioned No. 50 asphalt 4.0 mass parts;

[0076] 1.75 parts by mass of cement;

[0077] 95 parts by mass of basalt;

[0078] 3 parts by mass of basalt rock powder.

[0079] The above-mentioned limestone mineral materials are synthetically graded aggregates as shown in Table 3 formed by particle size grades of 0~5mm (that is, particle size<5mm), 5~-10mm, 10~-20mm, and 20~-31.5mm, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| penetration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com