Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

176results about How to "Precise control of heating temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

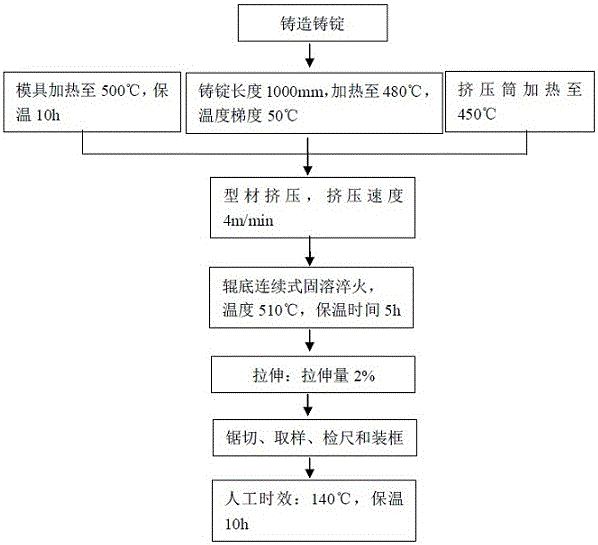

Preparing method for 6-series aluminum alloy sectional bar

InactiveCN105838938APrecise control of heating temperatureGuaranteed performanceAluminium alloyArtificial aging

Owner:广西南南铝加工有限公司

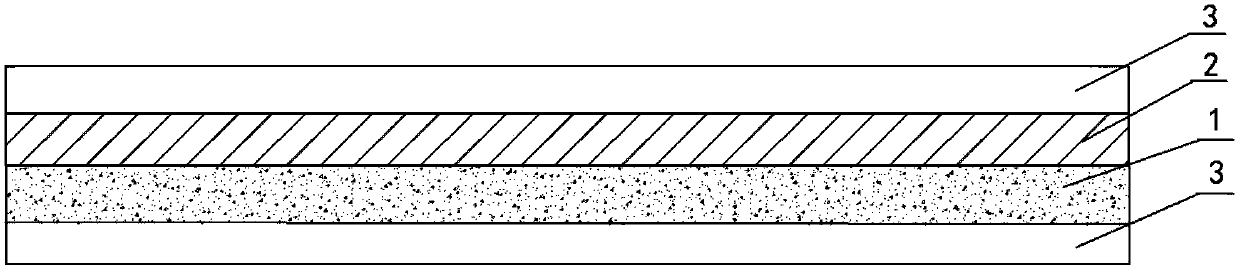

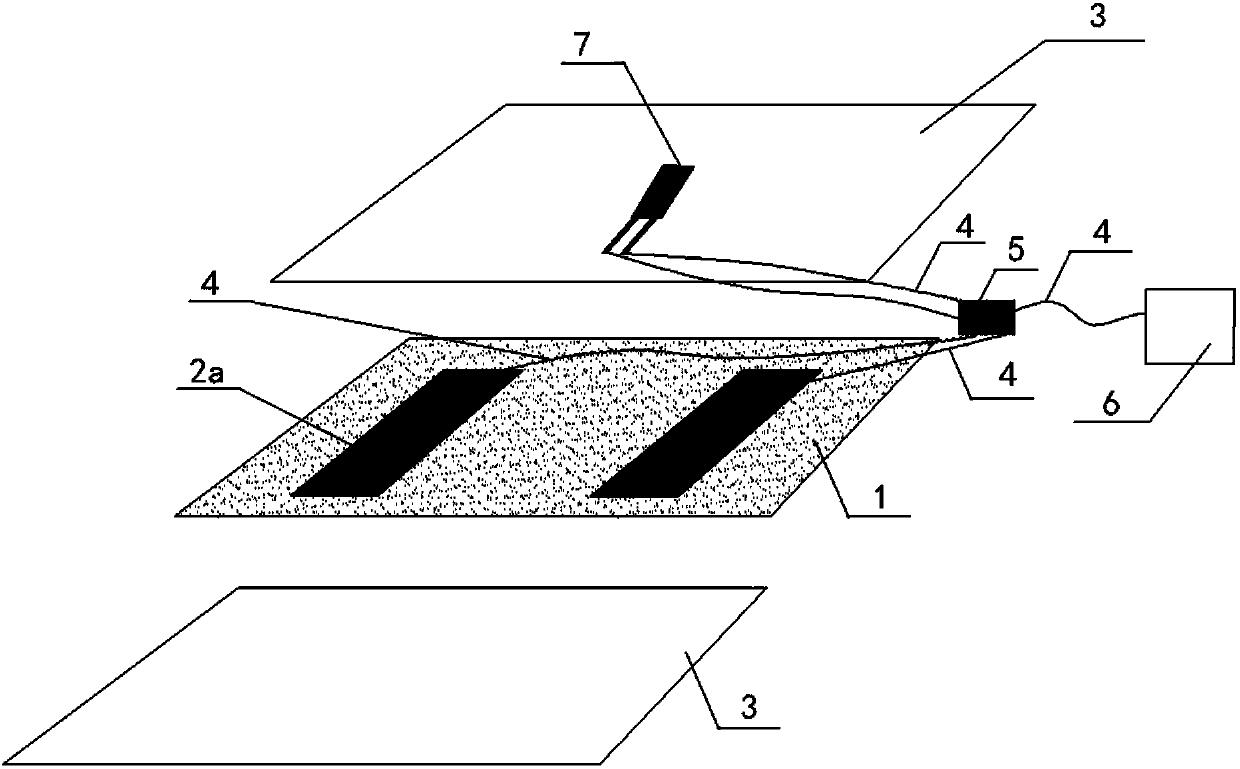

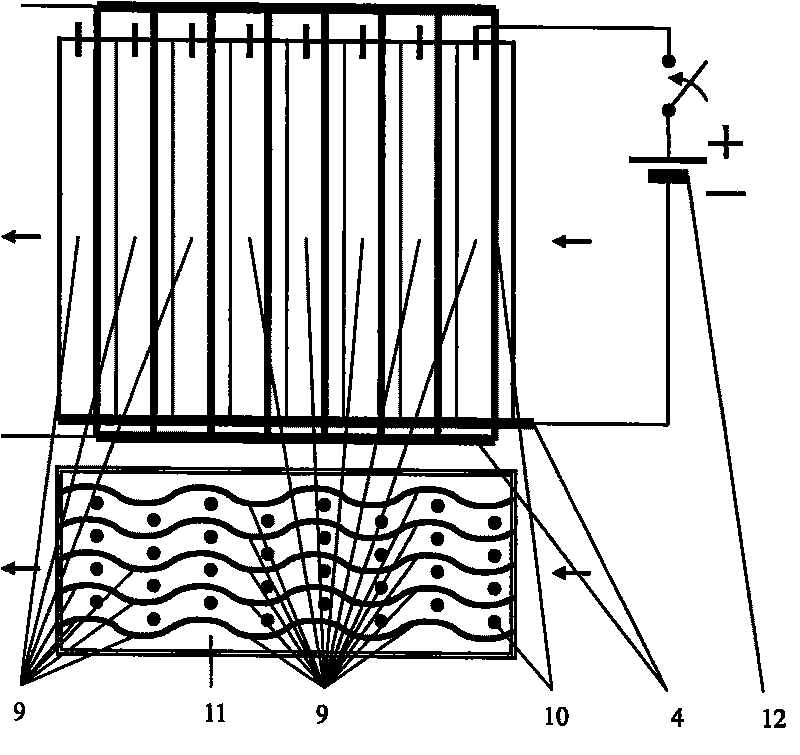

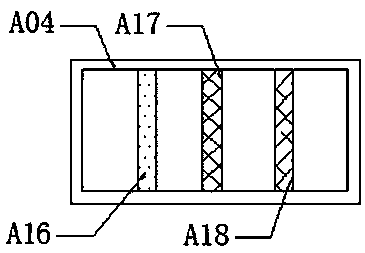

Graphene silver nanowire composite flexible heat-emitting film assembly

ActiveCN107635296AImprove securityEvenly heatedLight therapyHeating element materialsHeat stabilityGraphene

The invention discloses a graphene silver nanowire composite flexible heat-emitting film assembly. The assembly comprises a graphene silver nanowire composite flexible heat-emitting film; an electrodelayer is arranged on the graphene silver nanowire composite flexible heat-emitting film; the electrode layer is electrically connected with the graphene silver nanowire composite flexible heat-emitting film; and an insulating waterproof protective layer is arranged on the electrode layer, or insulating waterproof protective layers are arranged on both the electrode layer and one surface of the graphene silver nanowire composite flexible heat-emitting film which is not provided with the electrode layer. The flexible heat-emitting film assembly of the invention has the advantages of uniform heat emission, good heat stability, high flexibility, antibacterial performance and foldability. With the flexible heat-emitting film assembly adopted, the sizes of products can be customized according to actual needs.

Owner:合肥微晶材料科技有限公司

Accurate filling equipment and method for high temperature heat pipe requiring small amount of alkali metal working medium

InactiveCN102735084AEliminate throttling effectEasy accessIndirect heat exchangersProcess engineeringWater cooling

The invention discloses accurate filling equipment and an accurate filling method for a high temperature heat pipe requiring a small amount of alkali metal working medium and relates to a heat pipe technology. The accurate filling equipment comprises a main pipe, a branch, a branch sealing flange, a branch pipe storage tank, a branch pipe storage tank sealing upper flange, a heater, a first ultrahigh vacuum sealing valve, a second ultrahigh vacuum sealing valve, an ultrahigh vacuum molecule local unit, a main gas inlet pipe, an inert gas inlet pipe, an inert gas slim tube, a circulating water cooling pipe, an exhaust pipe and a transparent chamber for placing the solid working medium to be filled into the storage tank. The invention provides the high-efficiency accurate quantitative filling equipment and the high-efficiency accurate quantitative filling method for a small amount of alkali metal; and the oxidation of the alkali metal is reduced to the lowest degree.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

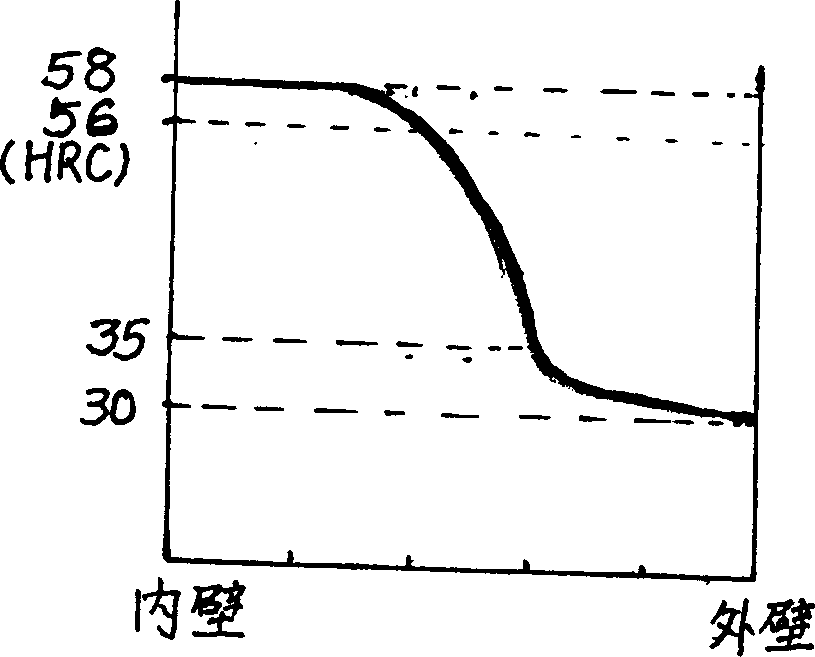

Cylinder shape pipe piece with inner harden layer and production method and equipment

InactiveCN1433942ALarge caliberSave materialIncreasing energy efficiencyFurnace typesFrictional coefficientEngineering

The present invention relates to a cylindrical pipe with internal hardened layer, its production method and special-purpose equipment. Said cylindrical pipe has small wall thickness and long length, its pipe wall has internal layer and external layer with different hardness, the hardness of its internal layer is greater than that of external layer, and said pipe is applicable for conveying material with high frictional coefficient. Its production method adopts the mode utilizing frequency to control pipe movement and proper hardening temp. range, and is special-purpose equipment is simple in structure, stable in operation, and can accurately control hardening temp., pipe moving speed nad depth of hardened layer.

Owner:王克发 +1

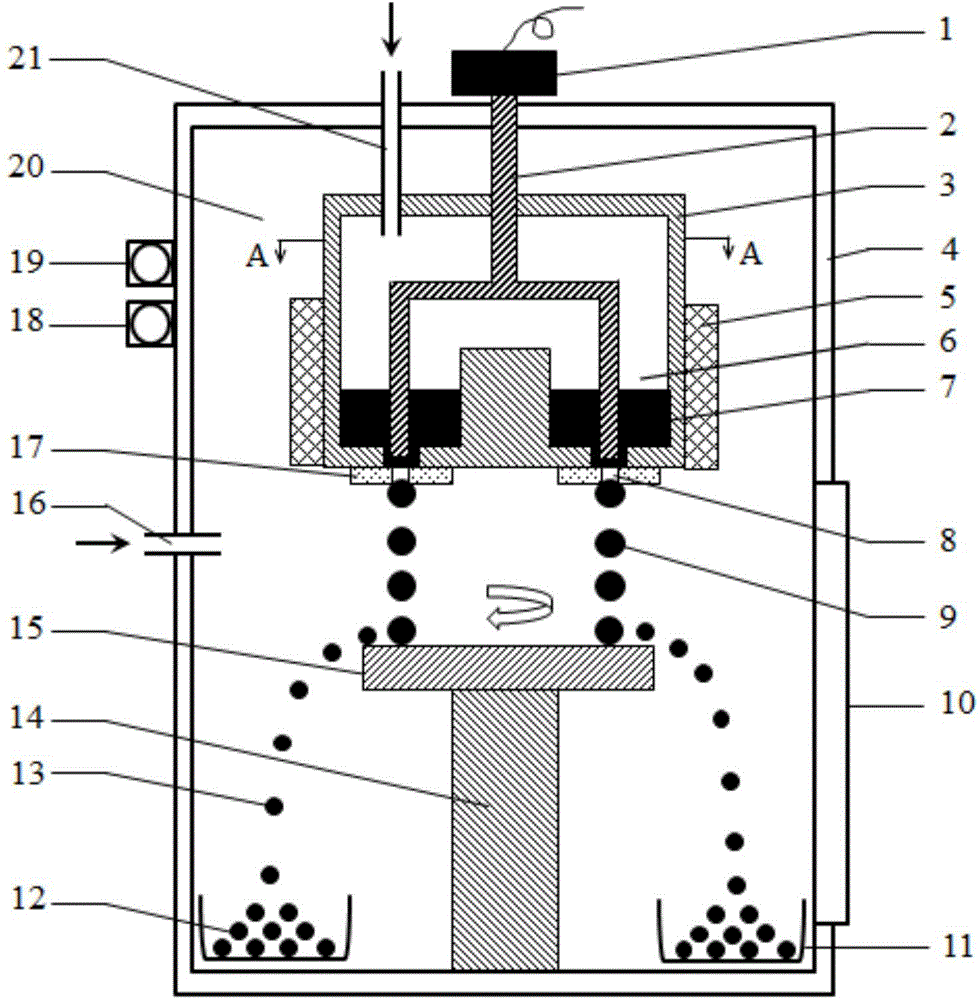

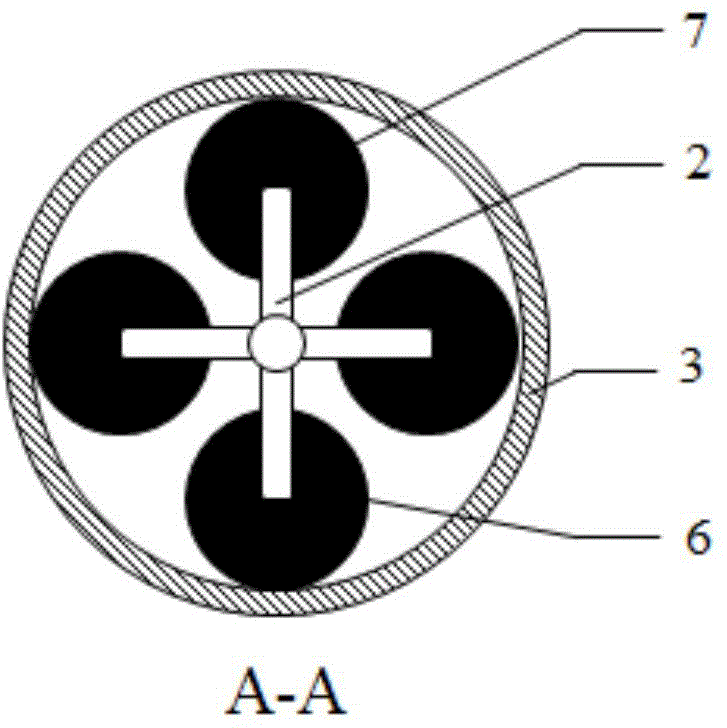

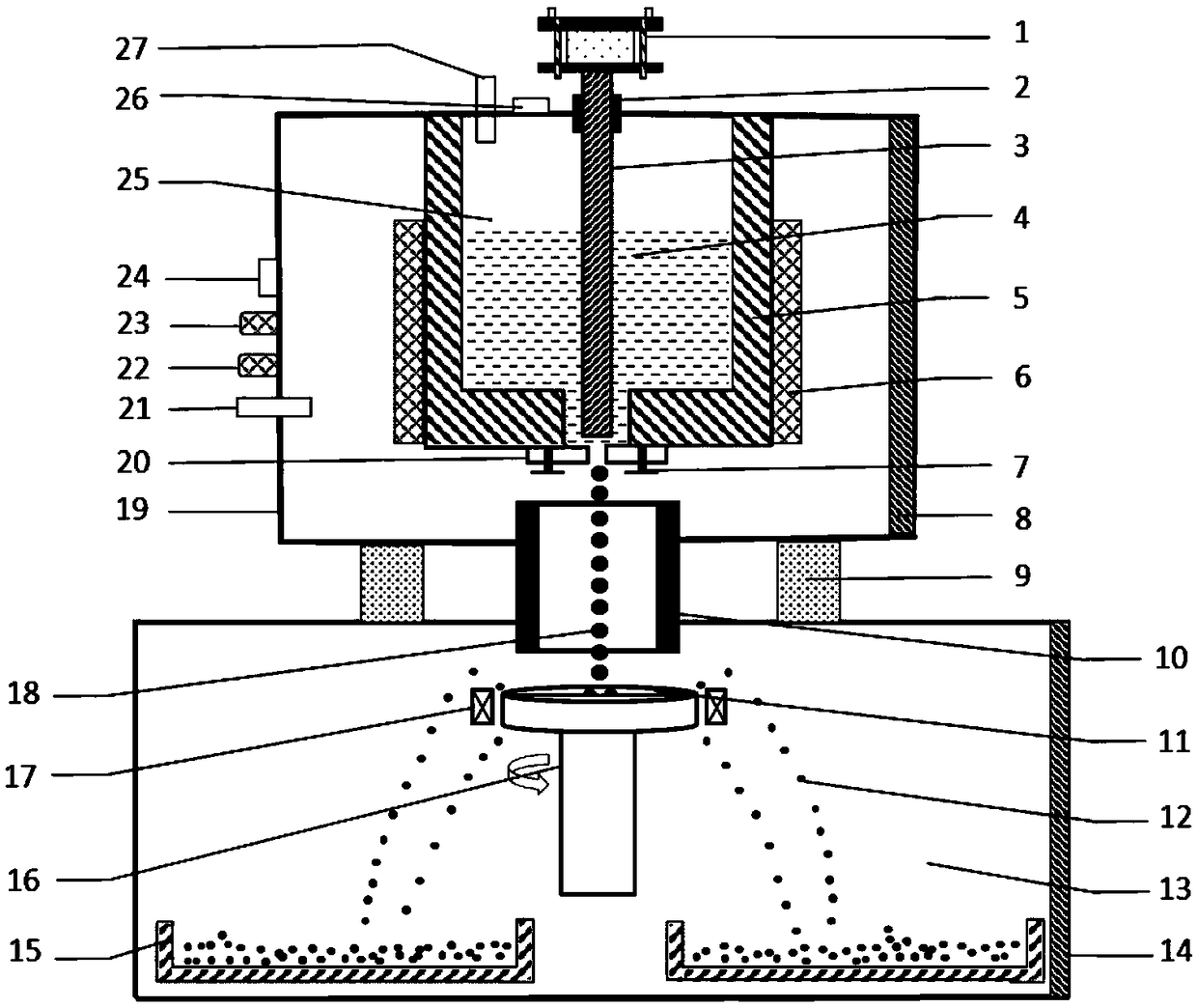

Method and device for efficiently preparing superfine spherical metal powder with high melting point

The invention discloses a device for efficiently preparing superfine spherical metal powder with a high melting point. The device comprises a shell, and a crucible and a powder collecting area which are arranged in a chamber of the shell, and is characterized in that a plurality of melting pools with the same volume are formed inside the crucible, and gaskets with small holes which are communicated with the chamber are fixed at the bottoms of the melting pools; a transmission rod comprises transmission support rods with the number the same as that of the melting pools, and the bottoms of the transmission support rods are aligned with circular holes in the gaskets with small holes; a thermocouple is arranged inside the crucible, and an induction heater is arranged outside the crucible; and the powder collecting area comprises a rotating disk which is used for atomizing metal droplets and is arranged at the bottom of the chamber and connected with a motor, and a collecting tank is also formed in the bottom of the chamber. The invention also discloses a method for efficiently preparing superfine spherical metal powder with the high melting point. By mainly combining a pulse micropore injection method with a centrifugal atomization method, the method can be used for preparing superfine spherical metal powder which is narrow in particle size distribution interval, high in sphericity, good in spreadability and liquidity, and high in production efficiency, and meets the 3D printing and using requirements.

Owner:DALIAN UNIV OF TECH +1

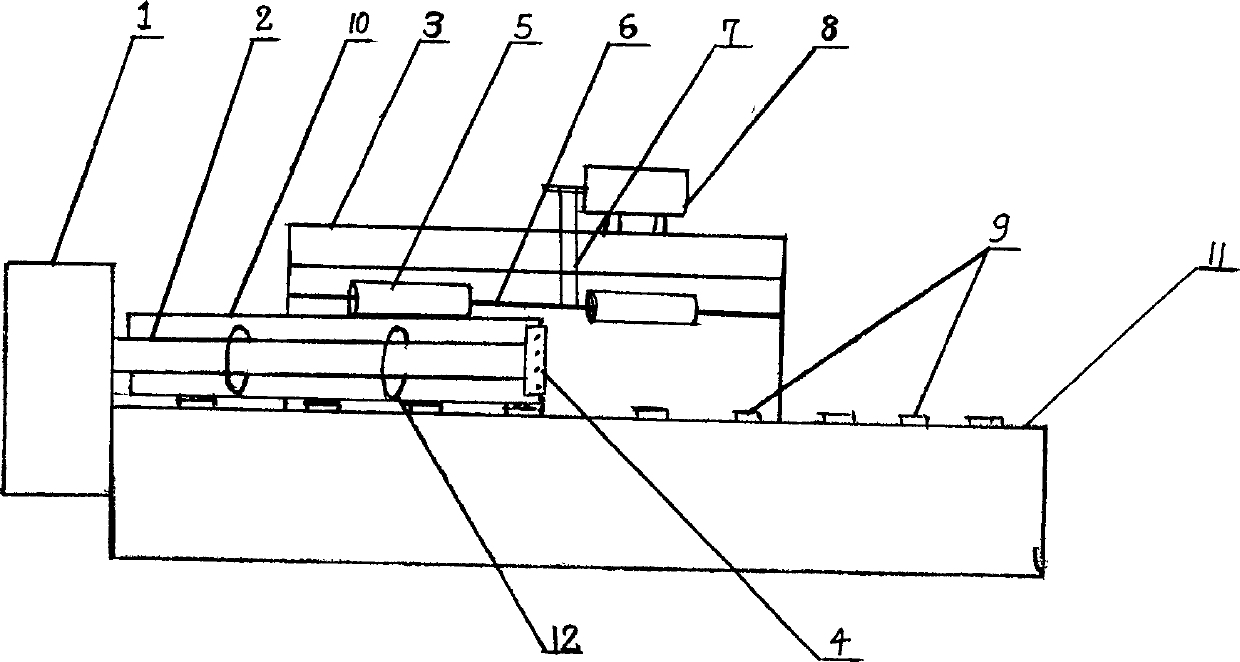

Hot bending machine

InactiveCN105776828AImprove processing qualityReduce labor intensityGlass reforming apparatusPower componentHeating temperature

The invention discloses a hot bending machine which comprises a hearth, a containing base located inside the hearth and used for containing a mold, a feeding device for pushing the mold from the exterior of the hearth to the feeding end of the containing base, a discharging device for receiving the mold from the discharging end of the containing base and a pushing device.The hearth is filled with inert gas.A preheating region, a molding region and an annealing region are sequentially arranged inside the hearth from the feeding end to the discharging end of the containing base.The containing base comprises a first heating section located in the molding region.The molding region is further provided with a first heating device located above the first heating section.The hot bending machine further comprises a first power component for driving the first heating device to move up and down.According to the hot bending machine, the machining efficiency can be improved, and the heating temperature of the heating device and the heating section can also be accurately controlled, so that the product quality is further improved.

Owner:SHENZHEN DAYUCNC TECH

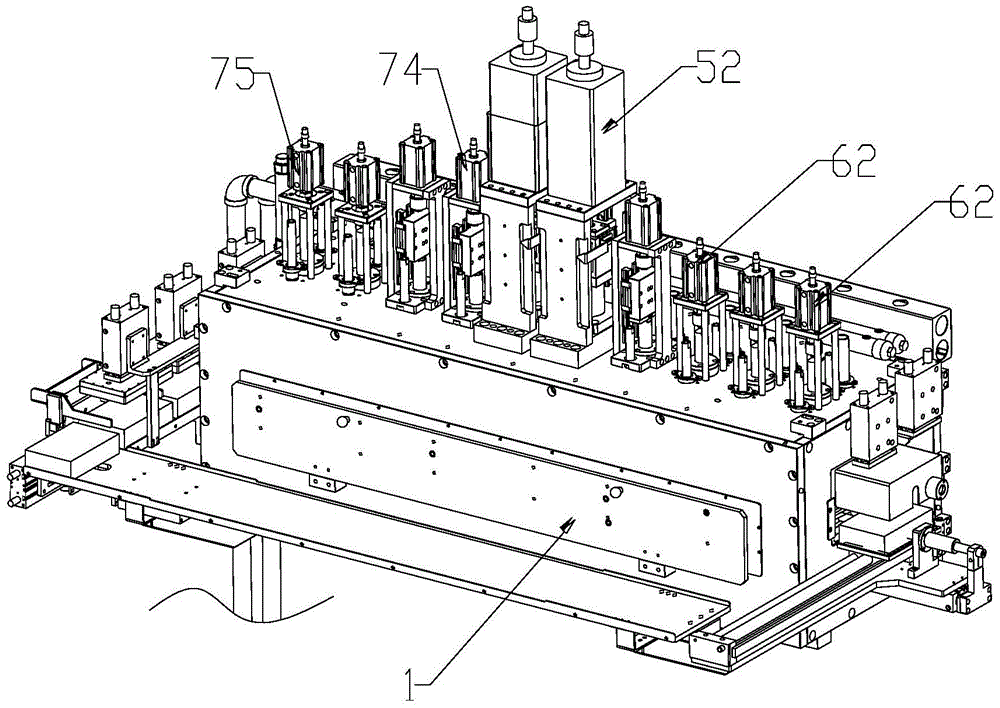

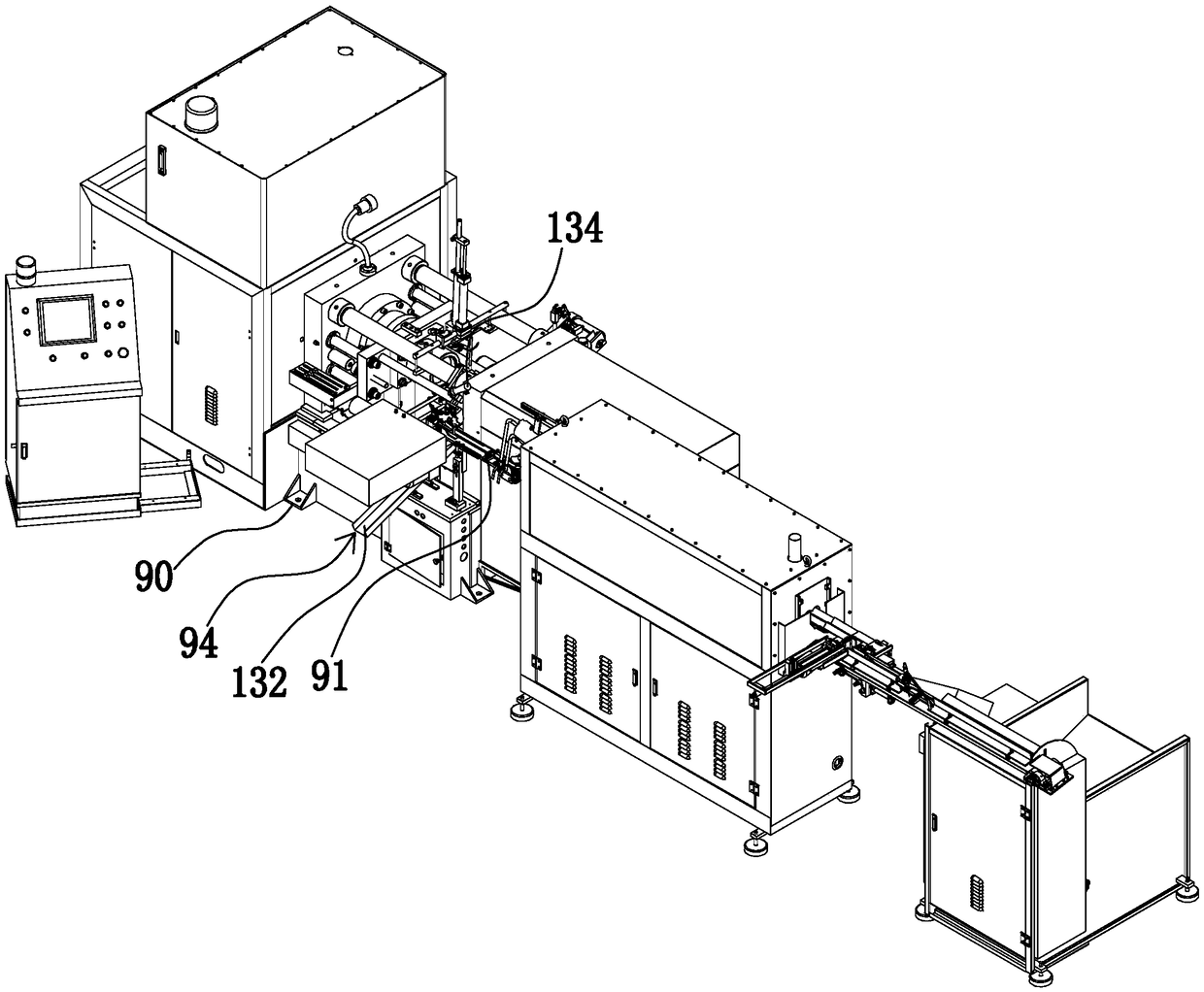

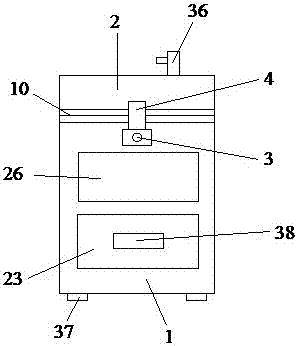

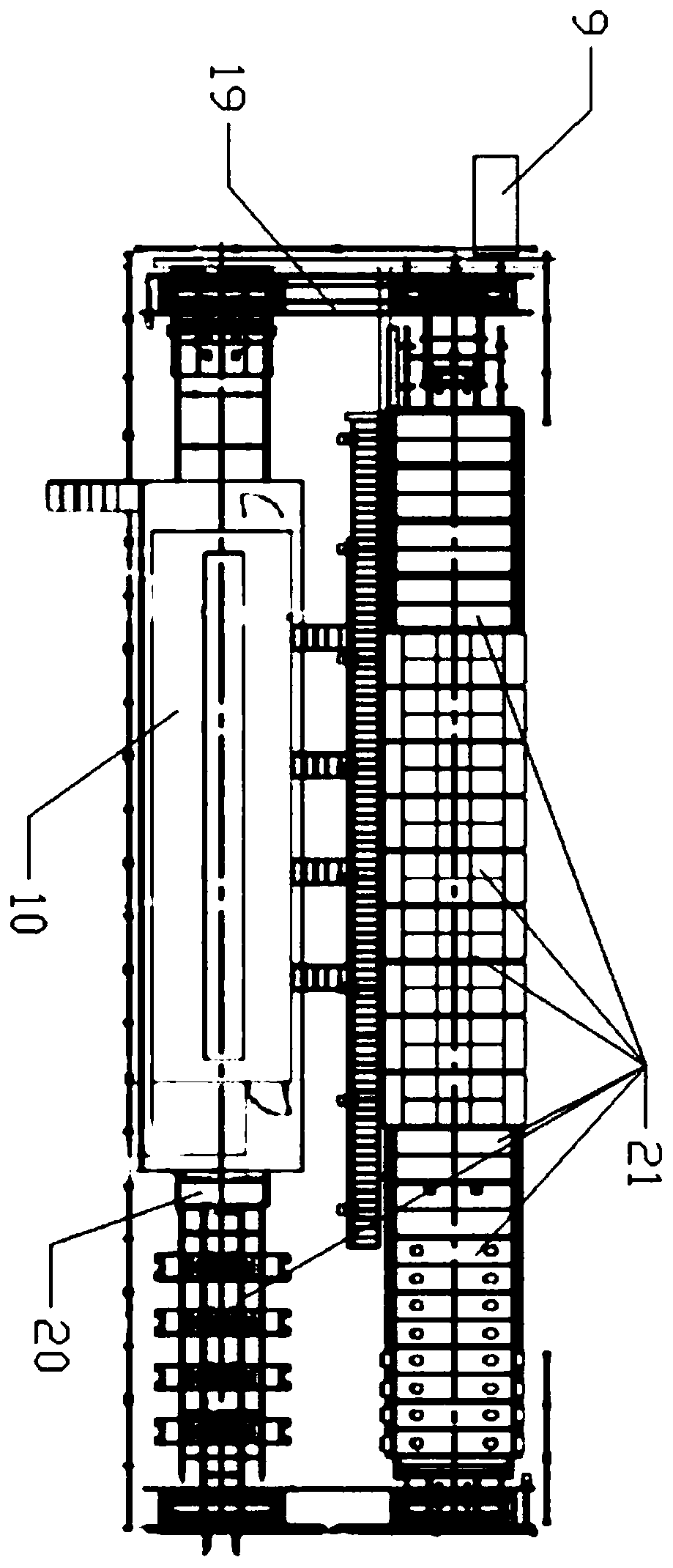

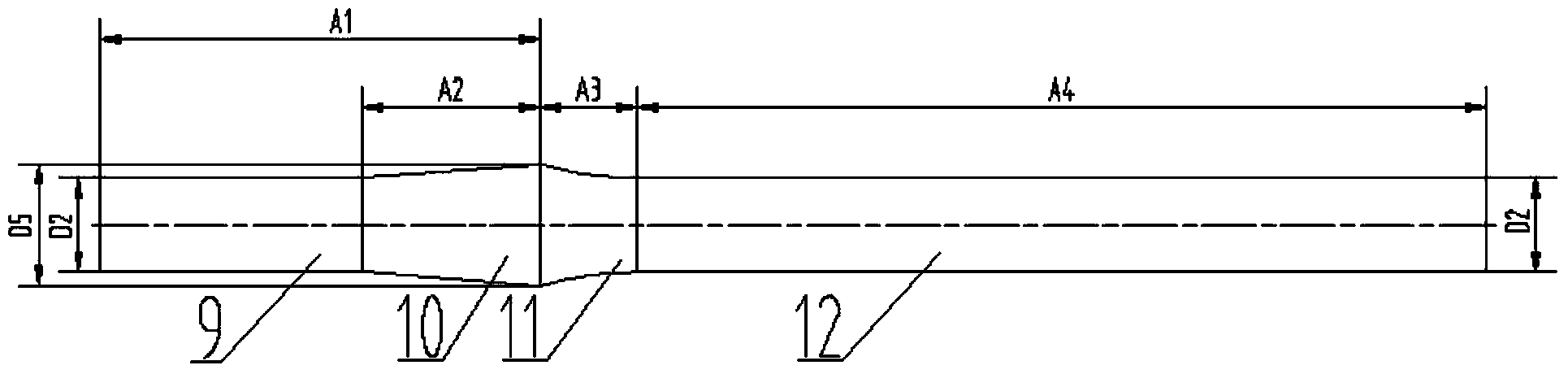

Full-automatic vertical type red punching equipment

ActiveCN108941228ASmall footprintHigh degree of automationExtrusion control devicesSortingPunchingEngineering

The invention relates to full-automatic vertical type red punching equipment. The equipment comprises a feeding rack assembly used for conveying workpieces, a raw material transmission device, a raw material pushing device and a raw material conveying device. The raw material transmission device is located at the upper end of the feeding rack assembly; the raw material pushing device and the raw material conveying device correspond to each other in position; and the raw material pushing device and the raw material conveying device are located at the end of the raw material transmission device.The equipment further comprises a red punching raw material heating furnace, a sliding chute device, a conveying mechanism and a machining mechanism which are connected in sequence. The full-automatic vertical type red punching equipment of a vertical structure is small in occupied space and high in automation degree. A protective cover and an observation groove are formed so that the personal safety of workers during machining can be ensured. Meanwhile, the working condition of the machining equipment can be observed at any time through the observation groove, the structure is simple, and the working process is safe and reliable.

Owner:彪马集团有限公司

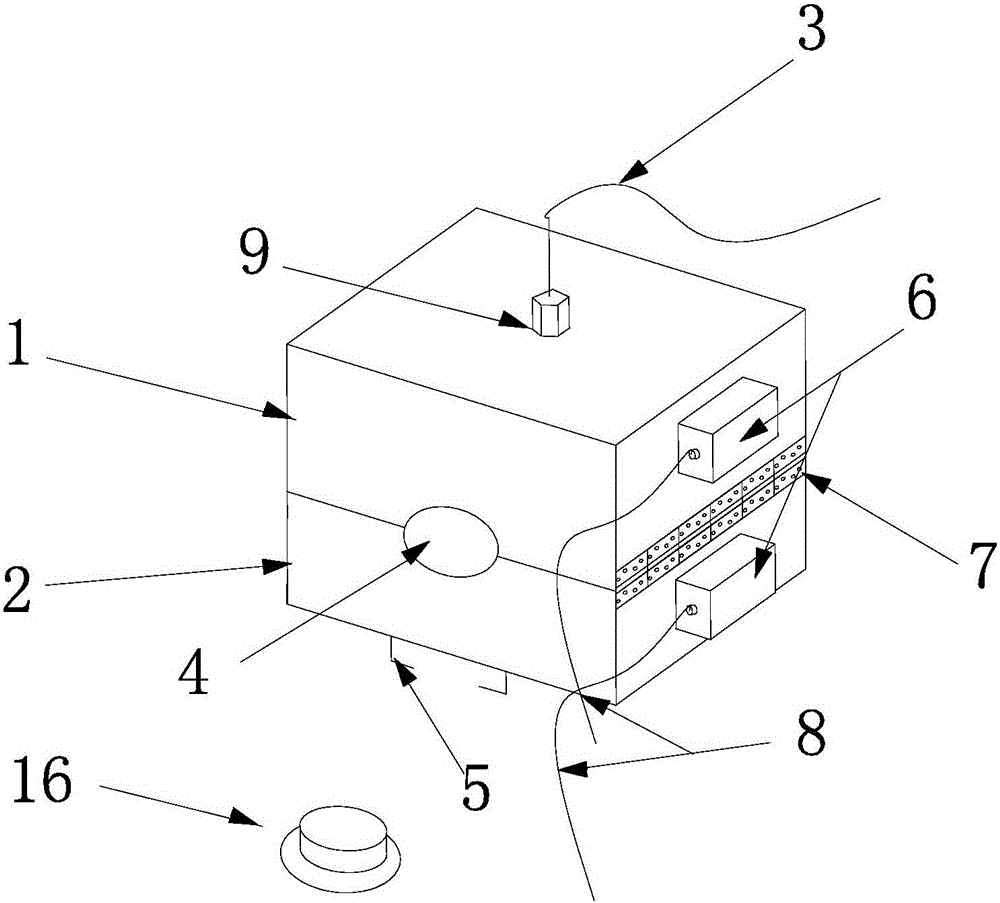

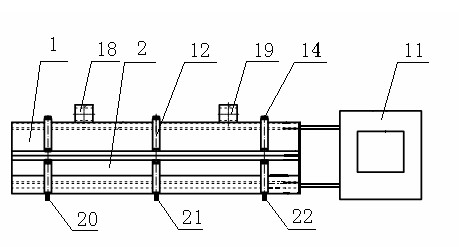

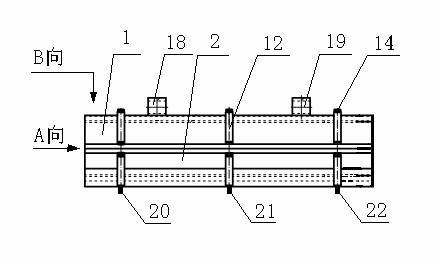

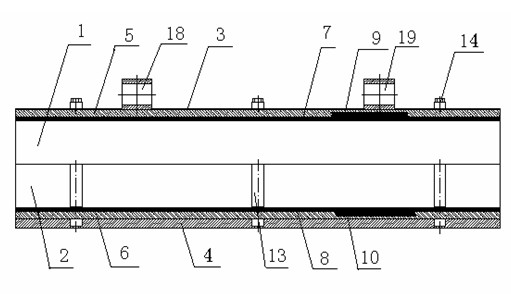

Quick heating device for high-temperature SHPB dynamic impact experiment

InactiveCN105699169AAdjustable temperaturePrecise control of heating temperaturePreparing sample for investigationTemperature controlEngineering

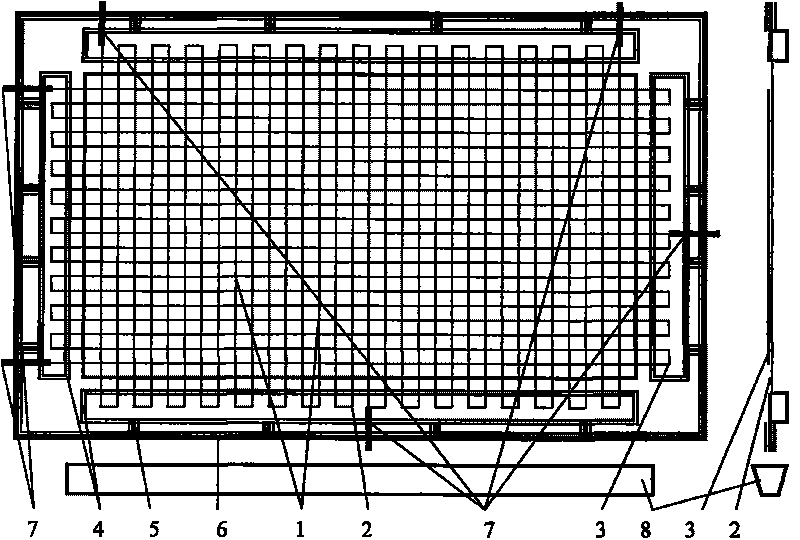

The invention discloses a quick heating device for a high-temperature SHPB dynamic impact experiment. The device comprises an upper box, a lower box, a temperature sensor, a heating channel, a guide rail, an electric-thermal conversion device, a hinge, a wire, a temperature measurement hole, a heating tile, heat insulation cotton, a wall, a handle, a ring, a fastener and a heat insulation plate, wherein the temperature sensor is connected with a temperature control device to regulate the temperature inside the heating device in real time, temperature is displayed through the temperature control device, and precise control of heating temperature is achieved; by arranging the heat insulation plate, dissipation of temperature does not occur easily, temperature inside a test piece and temperature outside the test piece can be made consistent, and the situation that the temperature of the test piece is uneven is avoided. The device not only can heat test pieces independently but also can quickly installing and heating test pieces, heating and impacting can be conducted at the same position, test pieces can be positioned accurately, the structure is simple and compact, operation is easy, working efficiency is high, capital input is low, and the device is economical and convenient to popularize.

Owner:ANHUI UNIV OF SCI & TECH

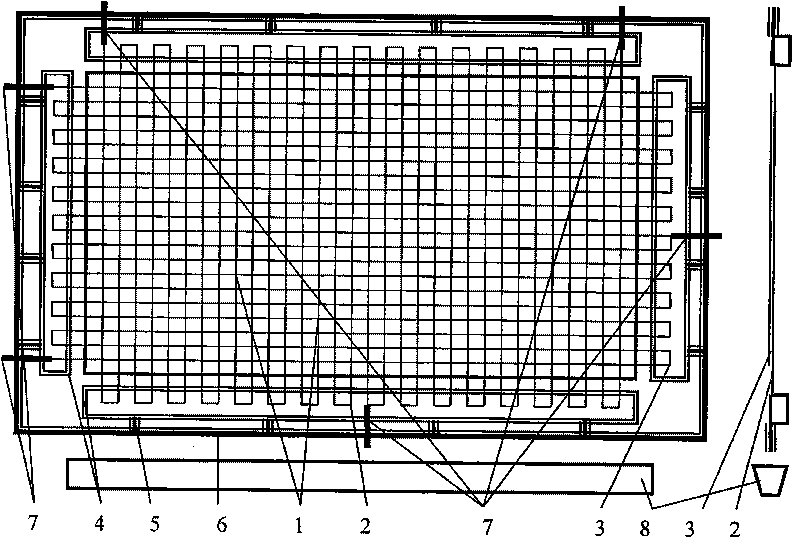

Electric heating cleaning method and device

InactiveCN101758044AGood cleaning effectAccelerateDomestic stoves or rangesPump componentsImpellerElectric heating

The invention discloses an electric heating cleaning method. An electric heating functional component is made of an electric heating or conductive and magnetizing ferromagnetic material, or a functional component is provided with an electric heating part made of an electric heating or magnetizing ferromagnetic material to form the electric heating functional part; the functional component is a device the pollution of which can be eliminated by heating comprises a filter screen, a static purifying device electrode and a blade impeller. The dirt on the surface of the electric heating functional component is dehydrated, inactivated, melted, tendered, carbonized, burnt, shed and stripped by loading the current on the electric heating functional component. A non-stick coating is arranged on the surface of the electric heating functional component. An electric heating cleaning device produced by the method consists of an electric heating functional component and a heating power source. The electric heating cleaning device is characterized in that the electric heating functional component comprises a connecting interface which forms an electric circuit with the heating power source or comprises an electromagnetic coil for forming electromagnetic coupling with the electric heating functional component. The invention has the advantages of favorable cleaning effect, high speed, non-relation to mechanism movement, compact and reliable structure, wide application range, environment friendlessness and no raise dust or waste liquor discharge. Two embodiments are provided by combining with attached drawings.

Owner:赵钦基

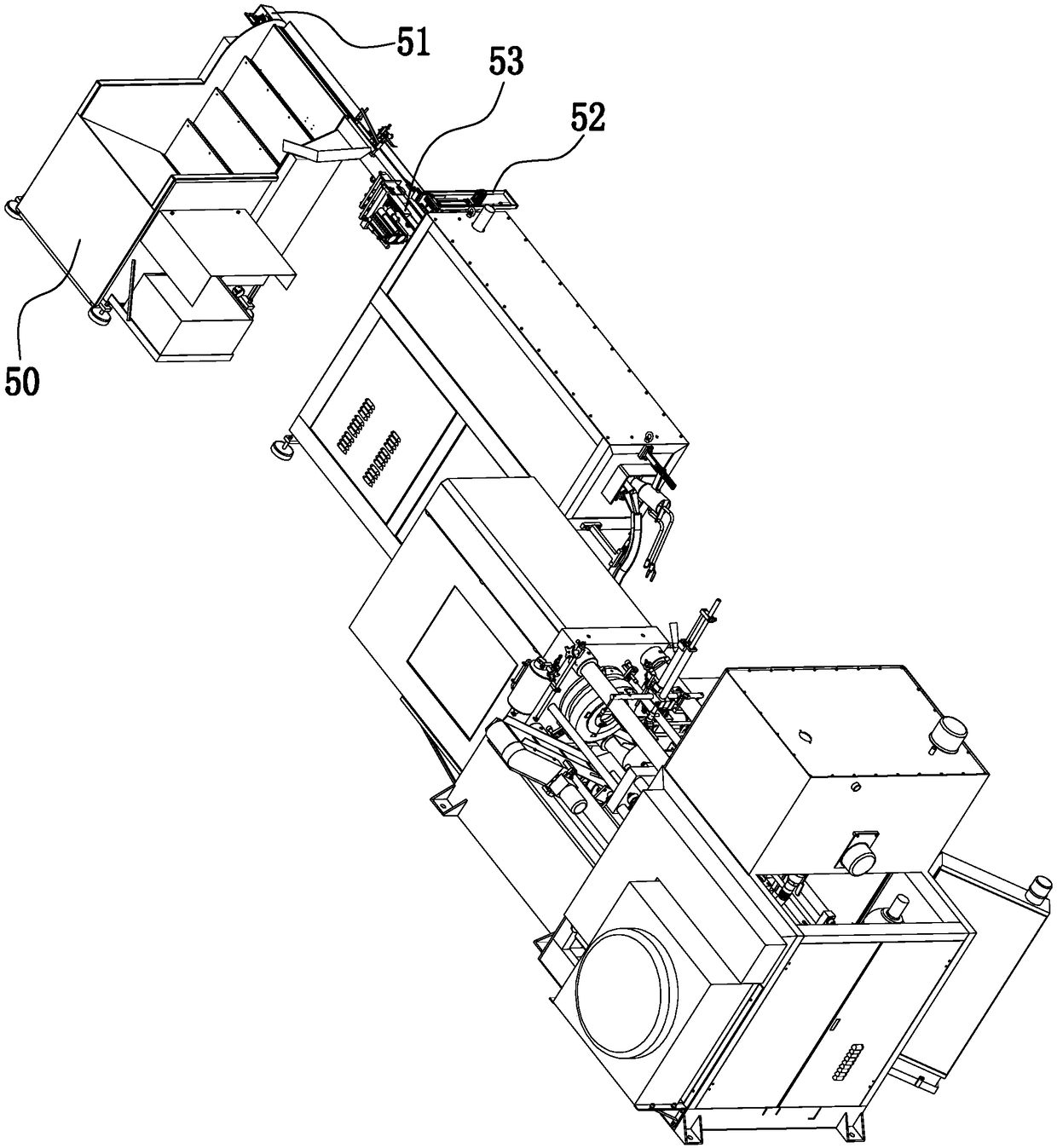

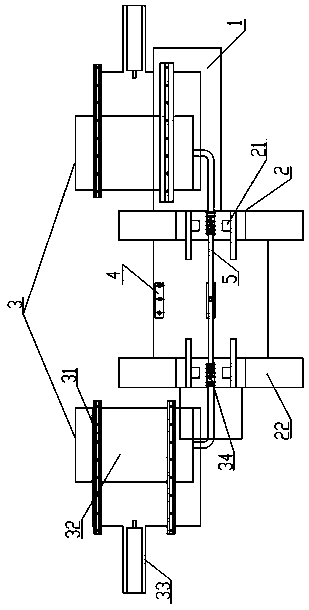

Fully-automatic hydraulic red punching apparatus

PendingCN108637029AReduced processing performanceDecrease stockExtrusion diesEngineeringFully automatic

The invention relates to a fully-automatic hydraulic red punching apparatus, comprising a loading frame assembly, a raw material transmission device, a raw material pushing device and a raw material feeding device, wherein the raw material transmission device is located on the upper end of the loading frame assembly; and the raw material pushing device and the raw material feeding device face eachother, and are located on the end of the raw material transmission device. The fully-automatic hydraulic red punching apparatus further comprises a mainframe mechanism, a punch molding device, a material returning beam device, a mold opening mechanism and a conveying device, wherein the output end of the conveying device is connected with a lateral pushing device, a pushing device matched with the lateral pushing device, and a rejecting mechanism matched with the lateral pushing device. The fully-automatic hydraulic red punching apparatus provided by the invention can realize rapid mold replacement and is applicable to small-batch multi-variety conversion production; and a blank is processed from a profile through straight-line cutting, so the processing and molding procedures and the inventory of intermediate blanks are reduced, process flow is shortened, and raw material loss is decreased.

Owner:浙江彪马自动化设备有限公司

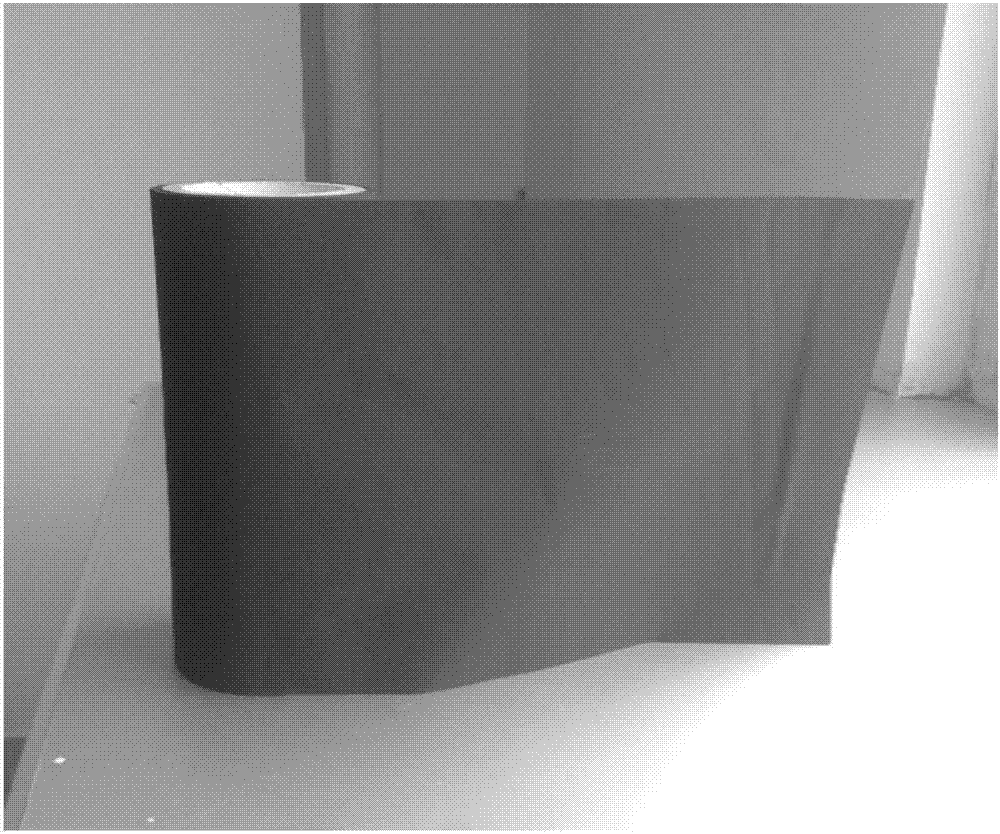

Graphene silver nanowire composite flexible foldable electrically conductive heating fabric and preparation method thereof

ActiveCN107880524ARealize large-scale large-scale applicationsUniform and stable heatingFlat articlesCoatingsEpoxyWater based

The invention provides a graphene silver nanowire composite flexible foldable electrically conductive heating fabric and a preparation method thereof. The heating fabric is prepared by performing tapecasting film forming on conductive heating slurry, wherein raw materials of the conductive heating slurry comprise silver nanowire dispersion liquid, graphene powder, carbon black, waterborne polyurethane resin, water-borne epoxy resin, water-based acrylic resin, water, a dispersing agent and a curing agent hexamethylenediamine. The electrically conductive heating fabric prepared by the inventionrealizes large-size application of graphene, and has the effects of being uniform in heating, excellent in heating stability, capable of accurately controlling the temperature, excellent in flexibility, foldable, washable, antibacterial, bactericidal and capable of realizing far-infrared physical therapy and body care.

Owner:合肥微晶材料科技有限公司

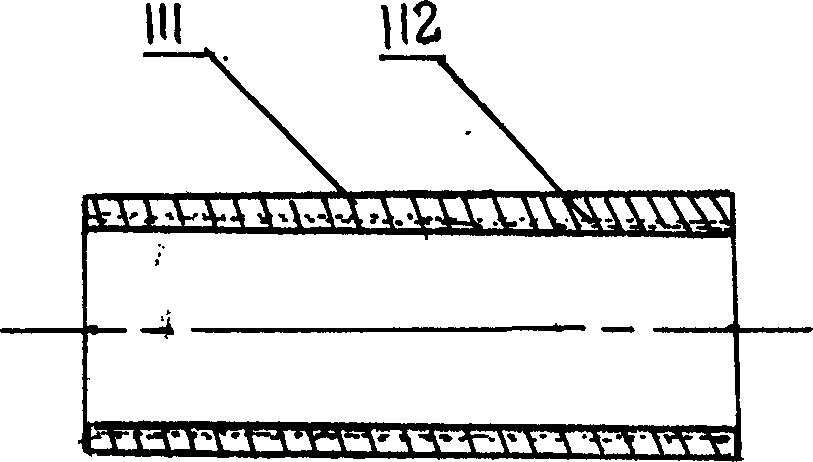

Heating device of lining

InactiveCN102497680AReduce difficultyEvenly distributedOhmic-resistance heating detailsFiberInsulation layer

The invention discloses a heating device of an over-long lining. The heating device comprises a heater, thermocouples and a control cabinet. The heater is divided into an upper part and a lower part. A metal casing, an alumina silicate fiber heat-insulation layer, and a rope shaped electric heating band are provided from an external layer to an internal layer in order. The rope shaped electric heating band is controlled by an electrical control cabinet. Double thermocouples are employed to measure temperature. When using, the upper part and the lower part are connected into one body through abolt and a nut, simultaneous heating and assembling of the lining can be realized. In an assembling process, the heater and the lining move together, constant temperature of the lining in the assembling process is ensured, and an aperture is prevented from deformation. The heating device has the advantages of simple structure and small energy consumption loss, and is especially suitable for heating a large scale over-long lining with the length of more than two meters.

Owner:WUHAN MARINE MACHINERY PLANT

Method for preparing resistance heating element

InactiveCN108411296ASimple processSignificant environmental benefitsAdditive manufacturing apparatusMolten spray coatingElectrical resistance and conductanceSand blasting

The invention relates to a method for preparing a resistance heating element. The method includes the steps that (1) a substrate material is prepared and cleaned, and then sand-blasting texturing is conducted; (2) a resistance heating layer material is prepared into powder through a gas atomization method to be screened and dried, and then laser cladding and / or 3D printing deposition are / is carried out to form an S-shaped pattern; and (3) and finally a conductive lead is welded and accordingly the resistance heating element can be obtained. Compared with a PTC heater, the resistance of the resistance heating element obtained through the method cannot be affected by temperatures basically, and thus the heating temperature and heating power can be accurately controlled conveniently. The method is wide in applied range, a resistance heating layer can be manufactured on a metal, ceramic, glass and plastic substrate, and the application prospects are good.

Owner:上海楚越机械设备有限公司

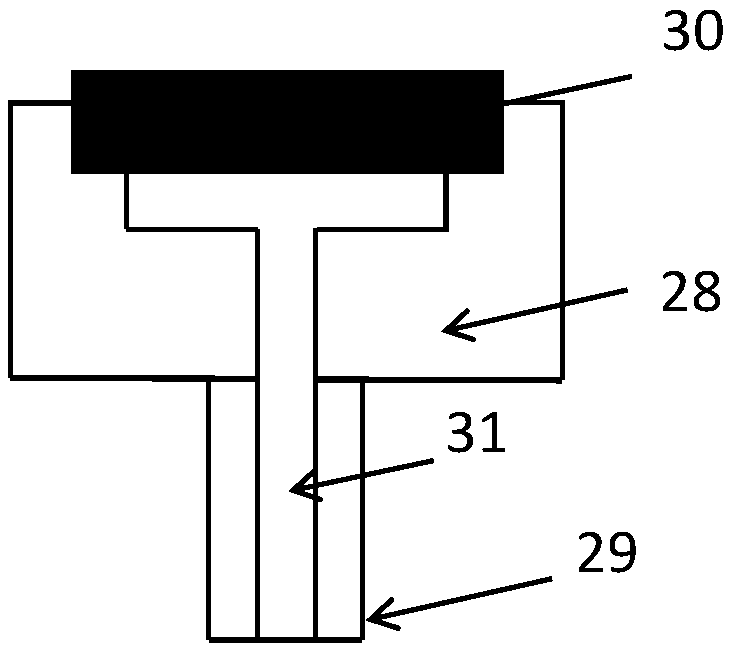

Device and method for preparing spherical metal powder for 3D printing

The invention provides a device and method for preparing spherical metal powder for 3D printing. The device for preparing the spherical metal powder comprises a shell, a crucible and a collecting bin,wherein the crucible is arranged in the shell, and the collecting bin is arranged on the lower portion of the shell. The device for preparing the spherical metal powder for the 3D printing is characterized in that a rotating disc arranged in a powder collection area is of a inlaying structure, materials with poor thermal conductance are selected as a substrate part of the rotating disc, metal materials with a wetting angle less than 90 degrees with liquid drops are selected to be inlayed into a main part to be used as an atomized plane, and a ventilation hole is formed in the rotating disc. The invention further discloses a method for preparing the spherical metal powder for the 3D printing, a pulse microporous injection method and a centrifugal atomization method are mainly combined, a rotating disc structure is matched, and the surface of the rotating disc is subjected to induction heating, so that molten metal breaks through a split mode of traditional molten metal, a fibrous splitmode which can be realized only when an atomization medium is an aqueous solution or an organic solution is realized, high melting point metal powder which meets requirements is prepared, the particle size is fine and grain size is controllable, the sphericity is high, no satellite droplet is achieved, the mobility and the spreadability are good, and the preparation method is suitable for industrialized production.

Owner:DALIAN UNIV OF TECH +1

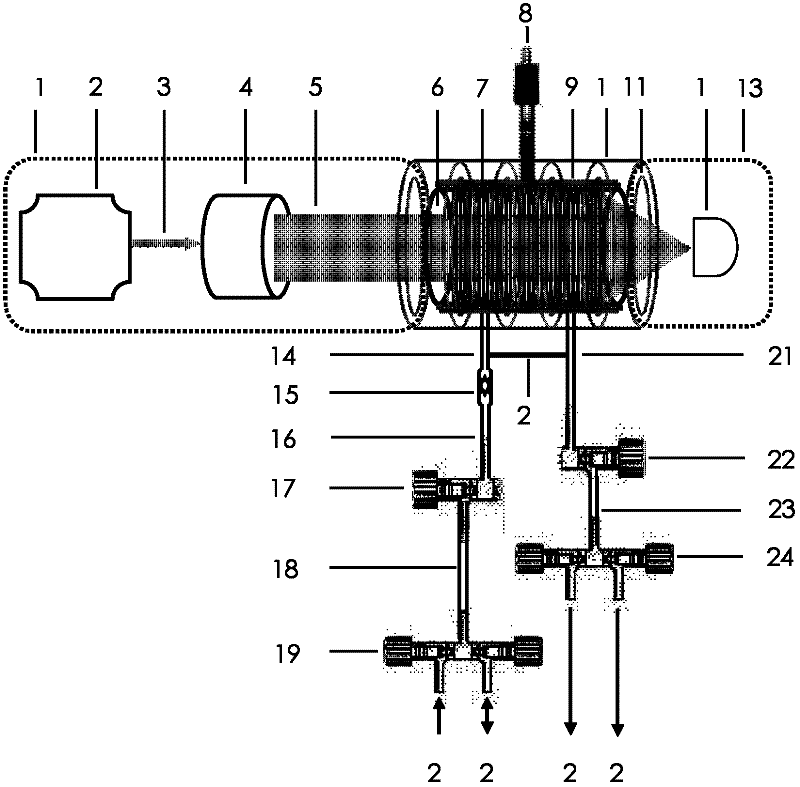

Permanent magnet polarizer

ActiveCN102364333AReduce weightCompact structureSpectrum investigationMagnetic property measurementsGratingPolarizer

The invention discloses a permanent magnet polarizer. In the permanent magnet polarizer, an internally-etched grating laser, a multicore optical fiber and a circular polarization / beam expander are arranged in a first light shield; a spectrometer is arranged in a second light shield; two ends of the multicore optical fiber are connected with the internally-etched grating laser and the circular polarization / beam expander respectively; a single-opening vacuum valve is connected with a steam / gas chamber; a first three-opening vacuum valve with an operating gas inlet and a vacuum gas distribution opening is connected with a third glass pipe, a first dual-opening vacuum valve, a second glass pipe, a deoxidation pipe and a first glass pipe sequentially and then is connected to the steam / gas chamber; a second three-opening vacuum valve with a first polarization gas outlet and a second polarization gas outlet is connected with a fifth glass pipe, a second dual-opening vacuum valve and a fourth glass pipe sequentially and then is connected to the steam / gas chamber; an electric heating wire and a heat-preserving membrane are wound on the outer wall of the steam / gas chamber sequentially; and a magnetic shielding cylinder is positioned outside a magnetic ring group, the heat-preserving membrane, the electric heating wire and the steam / gas chamber.

Owner:武汉中科极化医疗科技有限公司

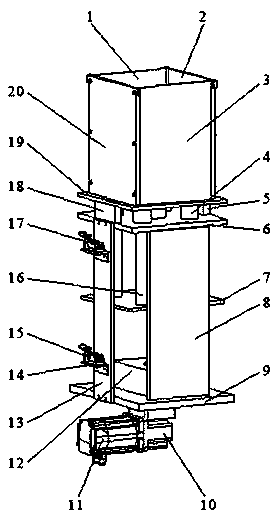

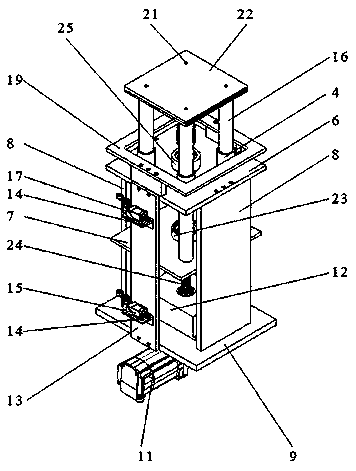

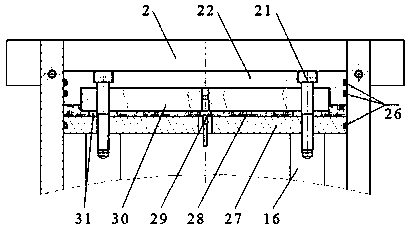

Forming cylinder system structure in SLM rapid forming equipment

InactiveCN111283198APrecise liftingEasy to controlAdditive manufacturing apparatusIncreasing energy efficiencyMachined surfaceBall screw

The invention discloses a forming cylinder system structure in SLM rapid forming equipment. According to the forming cylinder system structure in the SLM rapid forming equipment, a lifting mechanism is driven by the corresponding servo motor, a ball screw nut pair is driven by a right-angle speed reducer to move, then up-down movement of a preheating system structure is achieved, and the relevantthickness of the powder laying layer is controlled. The preheating system structure heats a base plate through a cast aluminum heating plate, a thermocouple is adopted as a temperature sensor, real-time control over the temperature is achieved, heat insulation silk floss and a heat insulation plate are additionally arranged below the heating plate for relevant heat insulation, and sealing rubber strips are installed on the side edges of the base plate and the heat insulation plate to prevent machined metal powder from falling along a forming cavity. According to the forming cylinder system structure in the SLM rapid forming equipment, the lifting mechanism is used for accurately controlling the thickness of the powder laying layer, the preheating system structure is used for accurately controlling the machining temperature of the metal part, the machining environment of the whole metal part is optimized, and the machining surface quality of the metal part is controlled and improved.

Owner:HANGZHOU DIANZI UNIV

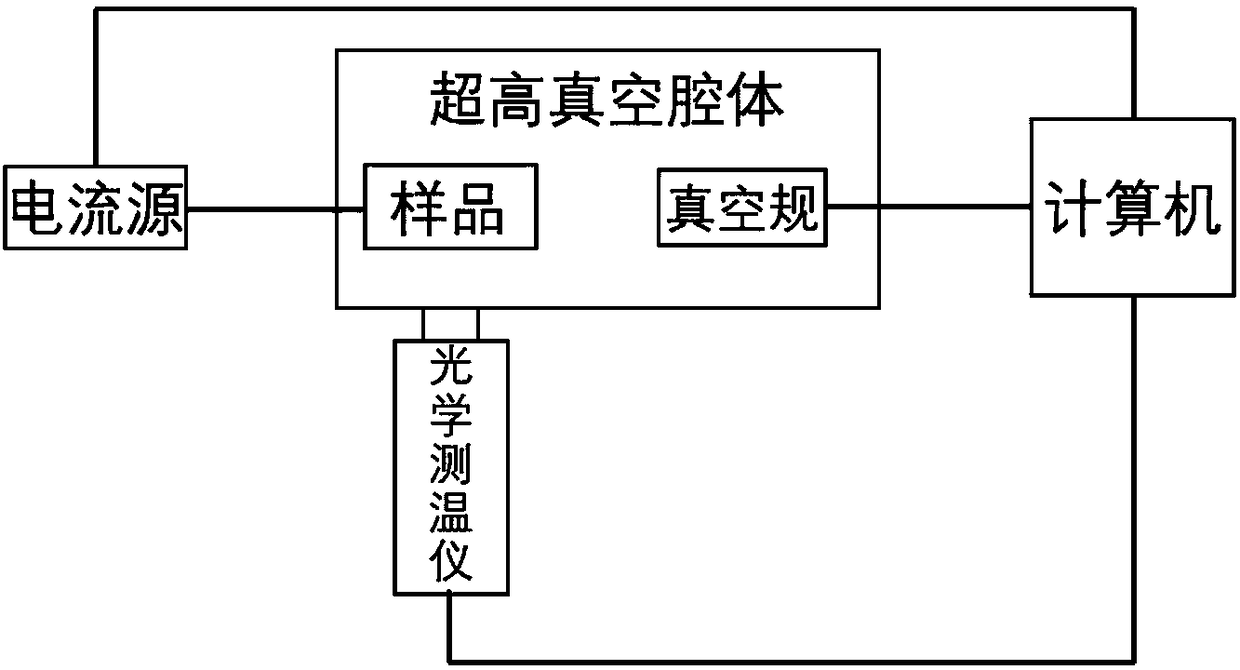

Automatic temperature control system and method for sample heat treatment process under ultrahigh vacuum

PendingCN108427453AImprove experimental efficiencyImprove experimental accuracyTemperatue controlControllers with particular characteristicsTemperature controlAutomatic train control

The invention discloses an automatic temperature control system and method for a sample heat treatment process under ultrahigh vacuum, and belongs to the field of temperature control. The system comprises an optics thermodetector, a vacuum gauge, a computer and a current source, the optics thermodetector and the vacuum gauge are located in ultrahigh vacuum sampling heating equipment, an infrared thermodetector and the vacuum gauge are connected with the computer, the computer is connected with the current source, and the current source is connected with a sample. Temperature negative feedbackto current of the heated sample is utilized, thereby achieving simple, quick and accurate temperature control, an RS232 serial port is used for connecting various instruments, a temperature differencevalue between a sample temperature measured by the optics thermodetector and a preset sample temperature is calculated, and a PID algorithm is used for feeding back and setting the applied current onthe sample by the current source. Although different types of current is required for heating samples due to sizes, manufacture and the like, the system can accurately control the sample temperatureto a set temperature within 1 DEG C in half a minute.

Owner:NANJING UNIV

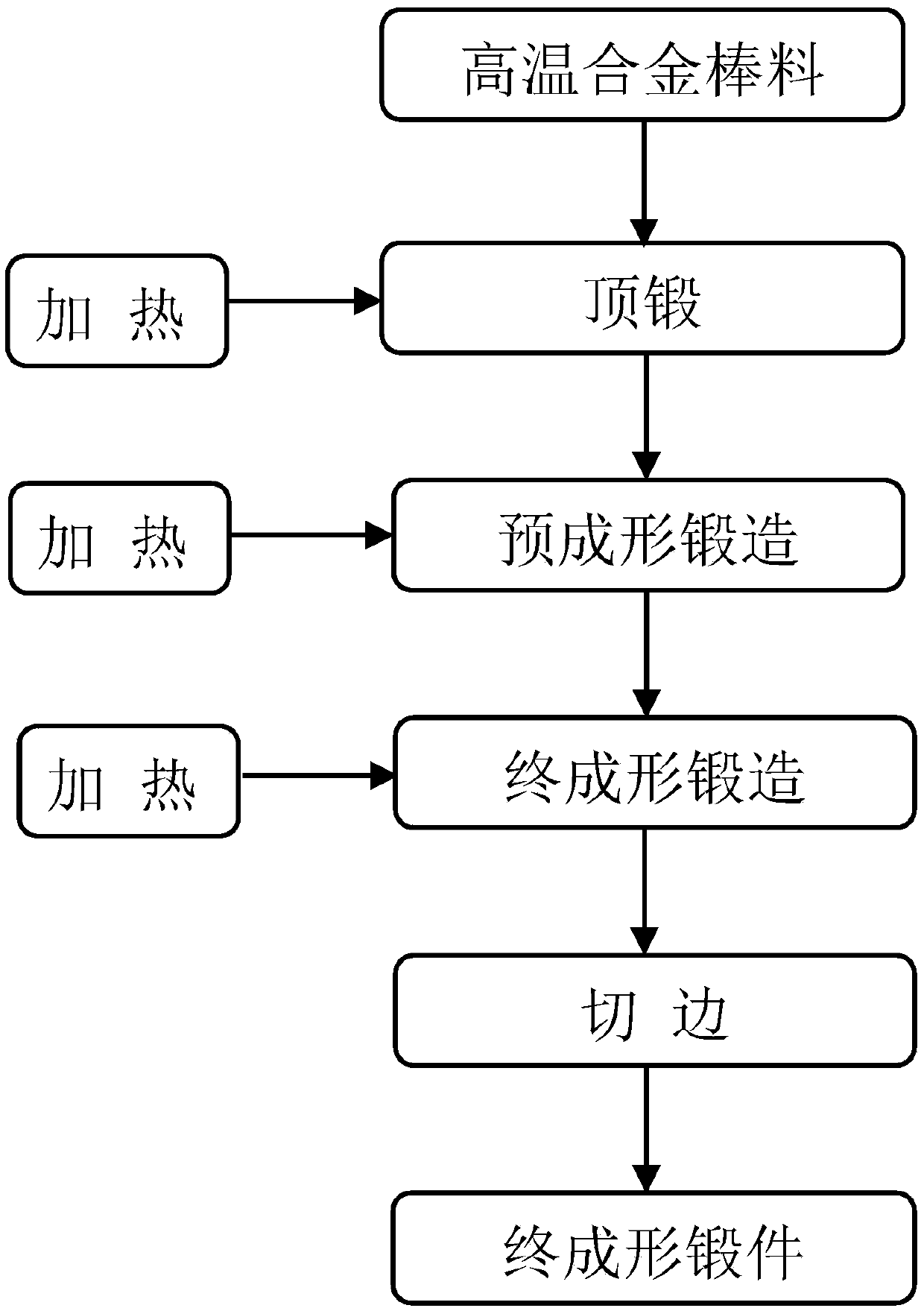

Precise forging method for nozzle shell

ActiveCN109676069APrecisely control the amount of deformationPrecise control of heating temperatureForging/hammering/pressing machinesHeating/cooling devicesMechanical propertyMaximum size

The invention discloses a precise forging method for a nozzle shell. The method comprises four forging stages, and molds are designed in all the processes for achieving precise forging. According to the method, in the step of local coarse heading, that is, upset forging blank making, the appearance size of a blank making part can be precisely controlled, and the maximum size precision can reach 0.1 mm; and in addition, a forging press is more stable compared with a forging hammer, the deformation amount of each working step is precisely calculated, therefore, forge piece streamlines can be evenly distributed along the appearance, the mechanical property of the blank making part is greatly improved, the deformation amount of each step such as upset forging, pre-forging and finish forging isprecise, and the overall size control precision of a forge piece is improved.

Owner:AECC AVIATION POWER CO LTD

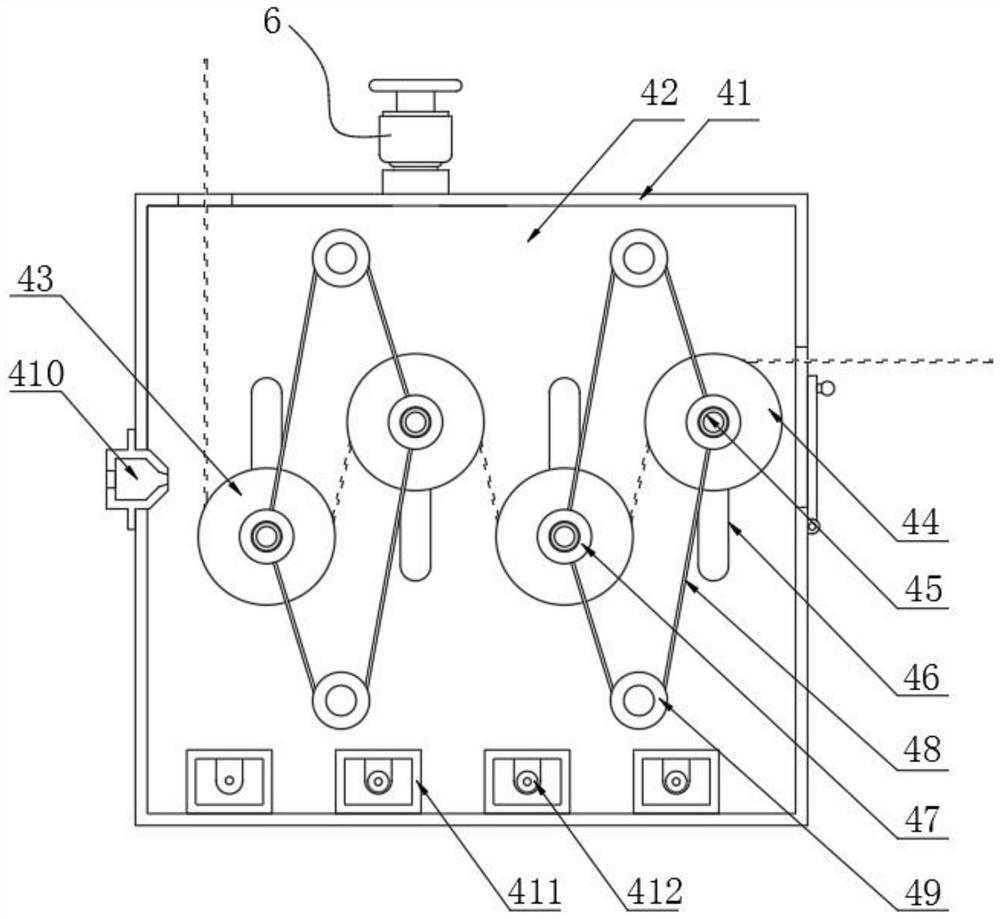

Production system of ultra-low shrinkage bright FDY and operation method thereof

ActiveCN111926403AHeight adjustableControl tensionNew-spun product collectionArtificial thread manufacturing machinesFiberIndustrial engineering

The invention discloses a production system of ultra-low shrinkage bright FDY and an operation method thereof. The production system comprises a spinneret box, an oil rolling tank, a network box, a heating shaping box and a package mechanism, wherein the spinneret box is fixedly connected to the top of the oil rolling tank. The invention relates to the technical field of textile equipment. According to the production system of the ultra-low shrinkage bright FDY and the operation method thereof, pulleys are arranged to be matched with digging ropes to connect two heating rollers and two shapingrollers correspondingly, when switching to a working mode, fiber filaments move in an S shape between the heating rollers and the shaping rollers, contact area is enough for heating shaping, before processing, a group of heating rollers and shaping rollers are pulled up by a lifting device, and a horizontal gap can be formed between the upper and lower two groups of heating rollers and shaping rollers, under the blowing of airflow, the fiber filaments can quickly pass through the heating rollers and the shaping rollers to extend to the right side, and traction and limit of the filaments are quick and convenient without the need of turning on equipment, the chance of dust pollution is reduced, and the efficiency is improved.

Owner:杭州辰泽新材料有限公司

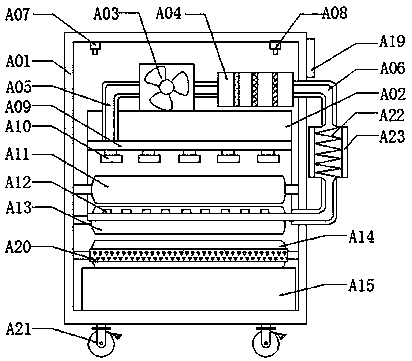

Printing machine with function of quickly drying printing ink and method for applying printing machine

InactiveCN108032616AImprove drying efficiencyPrevent heat lossPrinting press partsPrinting inkPrinting press

The invention provides a printing machine with a function of quickly drying printing ink and a method for applying the printing machine. The printing machine comprises a printing machine shell, a temperature control circulating air device, a fan, a drum, a transfer printing roller, an ink transfer roller and an ink supply box. Four universal self-lock wheels are mounted at the bottom of the printing machine shell, the temperature control circulating air device is arranged inside the printing machine shell, a circulating air supply pipe is arranged in the middle of the temperature control circulating air device, a plurality of air outlets are uniformly formed in the lower end of the circulating air supply pipe, a side of the upper end of the circulating air supply pipe is communicated and connected with an air inlet pipe, the fan is arranged on the air inlet pipe, the portion, which is positioned on a side of the fan, of the air inlet pipe is connected with one end of a filter, a circulating air pipe is arranged at the other end of the filter, a dehumidification filter screen plate, a printing ink filter screen plate and a dust removal filter screen plate are sequentially arranged in the filter from the left to the right, and the circulating air pipe penetrates the printing machine shell to extend to the outer side of the printing machine shell. The printing machine and the method have the advantages that polyurethane rigid foam plastic heat-insulation layers are coated on the outer sides of the air inlet pipe and the circulating air pipe, accordingly, heat loss can be effectively prevented, and the printing ink drying cost of the printing machine can be reduced.

Owner:池州市小康人家科技有限公司

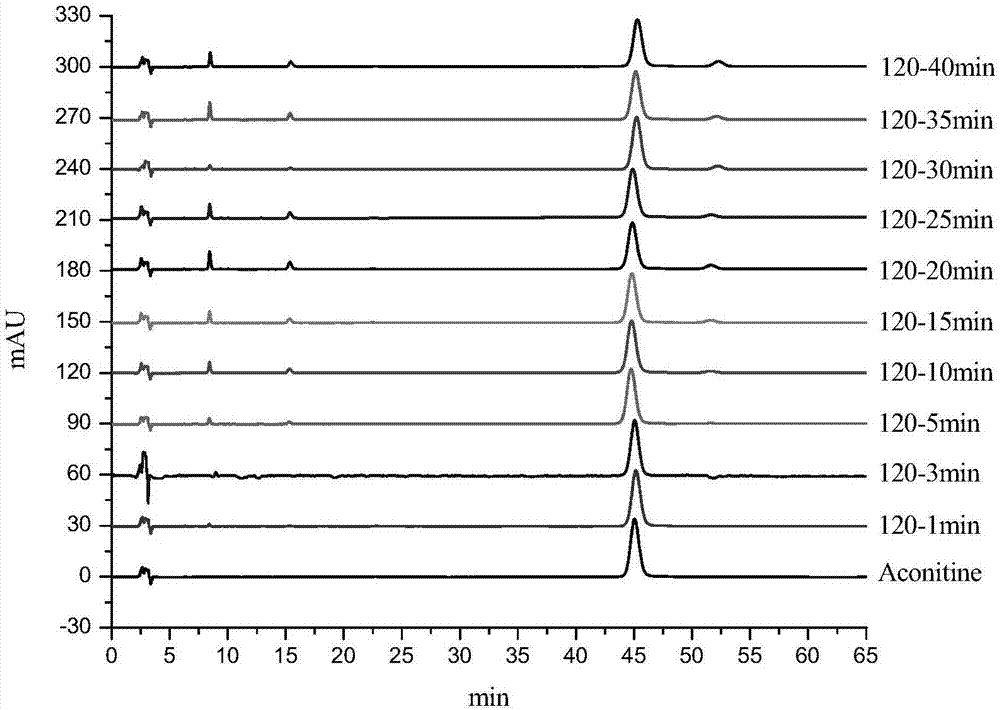

Method for simulating processing process of stir-fried medicinal materials

InactiveCN107115388AEvenly heatedPrecise control of heating temperaturePlant ingredientsTime conditionAlkaloid

The invention provides a method for simulating a processing process of stir-fried medicinal materials. The method comprises the following steps: a, selecting index components in medicinal materials; b, simulating stir-frying conditions by adopting an oil bath and uniformly adhering the index components to the bottom of a flask; c, detecting the content of the index components under different oil bath temperature and time conditions and analyzing detection results to obtain optimal stir-frying temperature and time of the medicinal materials. According to the method for simulating the processing process of the stir-fried medicinal materials, provided by the invention, conditions of a processing process of medicinal materials containing toxic alkaloids are especially screened and the stir-frying temperature and time of the medicinal materials can be accurately predicated under the condition that the medicinal materials are not used, so that the cost is saved and guarantees are provided for industrialized amplified processing.

Owner:CHENGDU UNIV OF TRADITIONAL CHINESE MEDICINE

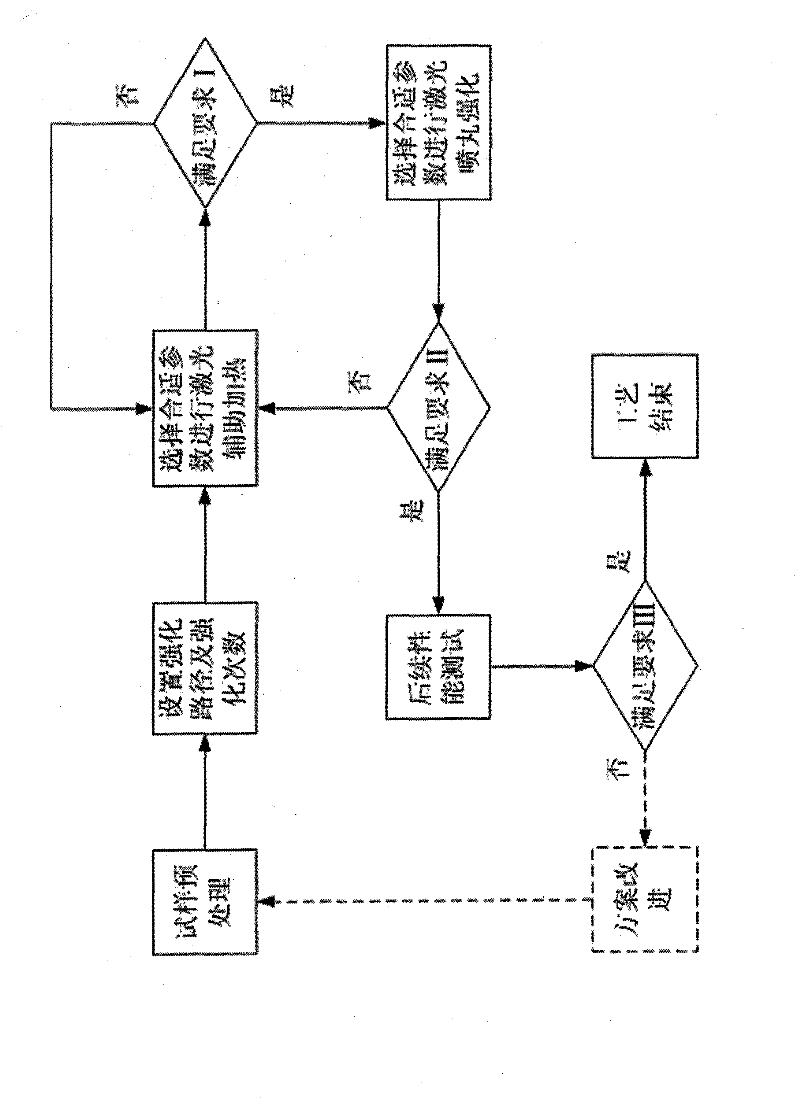

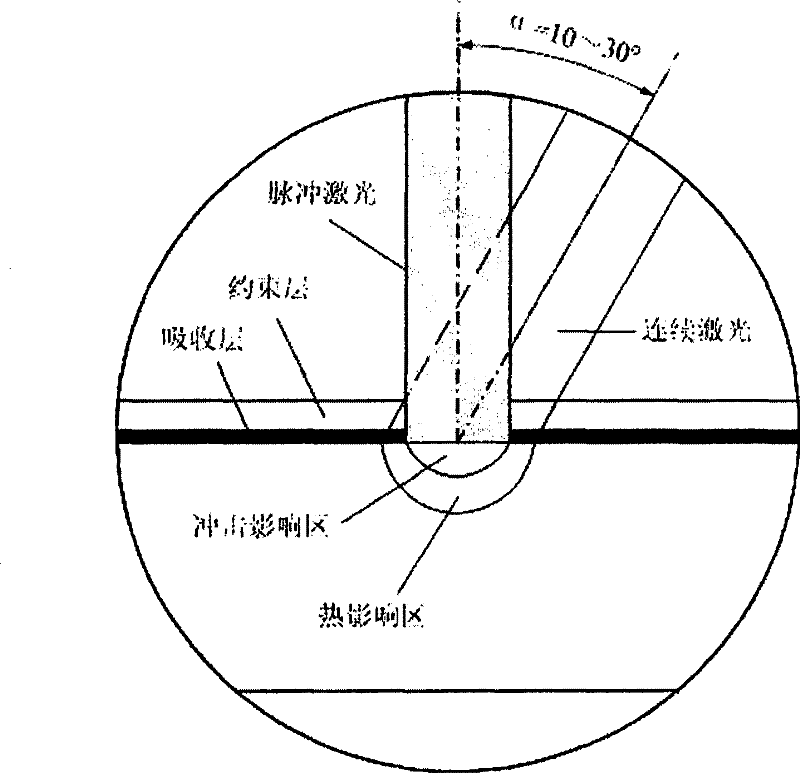

Device and method for laser shot blasting reinforcement of hard and brittle material

The invention discloses a device and a method for laser shot blasting reinforcement of a hard and brittle material, and relates to the field of mechanical manufacture of hard and brittle material processing and laser application. The device comprises a laser aid heating system, a laser shot blasting reinforcement system, a workpiece clamp system, a computer numerical control system, a measurementfeedback system and a protective gas circulating system. The method comprises a laser aid heating stage and a laser shot blasting reinforcement stage, namely performing aid heating treatment on the area to be reinforced by adopting high-power continuous laser, wherein for most metal materials, the plastic performance is improved along with the rise of temperature; and after the temperature of theheating area reaches a predetermined heating temperature, implementing laser shot blasting reinforcement treatment by adopting high-power pulse laser. The device and the method can implement the laser shot blasting reinforcement on the hard and brittle material so as to broaden the application range of the laser shot blasting reinforcement technology, and meanwhile compound the advantages of continuous laser and pulse laser so as to broaden the application field and the application prospect of laser manufacture.

Owner:JIANGSU UNIV

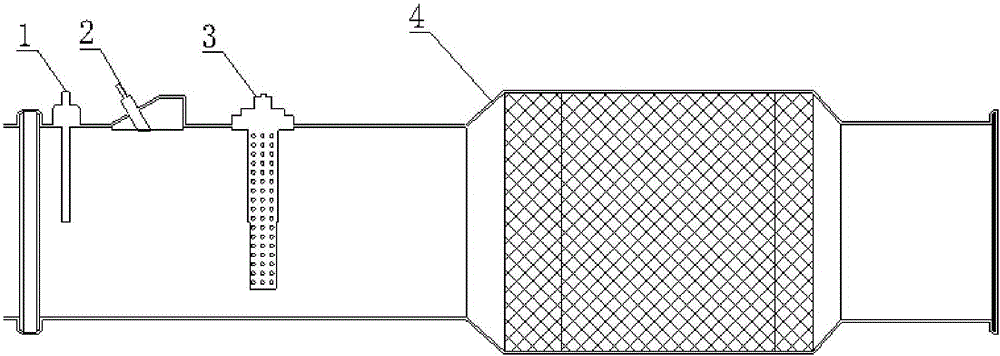

Urea heating device for efficient SCR, and use method thereof

InactiveCN105697106AFully pyrolyzedPrevent crystallizationInternal combustion piston enginesExhaust apparatusHeat managementProcess engineering

The invention relates to a urea heating device and a use method thereof, and particularly relates to a urea heating device for efficient SCR, and a use method thereof. The device comprises a temperature sensor, a urea nozzle, a metal carrier catalyst and an SCR device, wherein the temperature sensor, the urea nozzle and the metal carrier catalyst are arranged in front of the SCR device, and are sequentially arranged on an exhaust pipeline from the front to rear. According to the device disclosed by the invention, through the method of adding the metal carrier catalyst close to the urea nozzle, and carrying out ECU control heating, the crystallization risk of the efficient SCR is reduced, the energy consumed for engine heat management is reduced, and accurate control for the heating temperature and time is realized.

Owner:WEICHAI POWER CO LTD

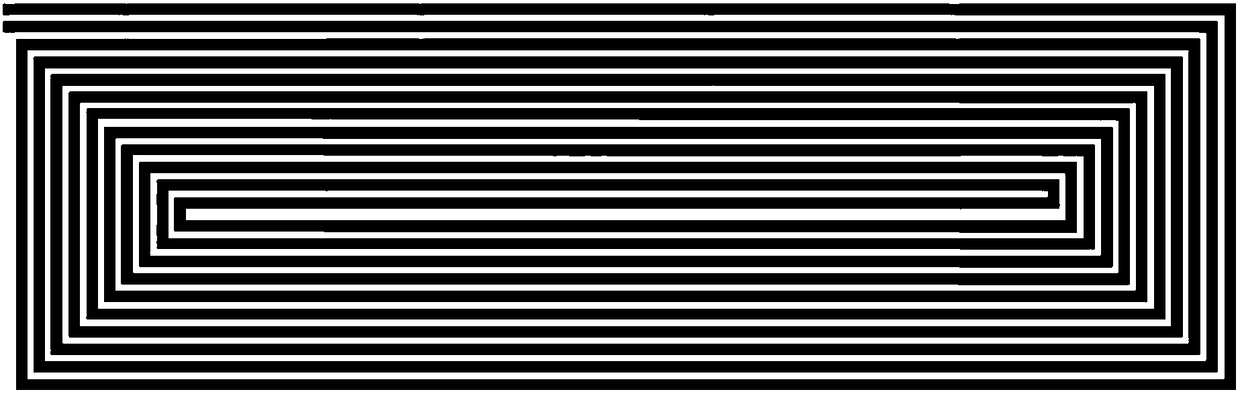

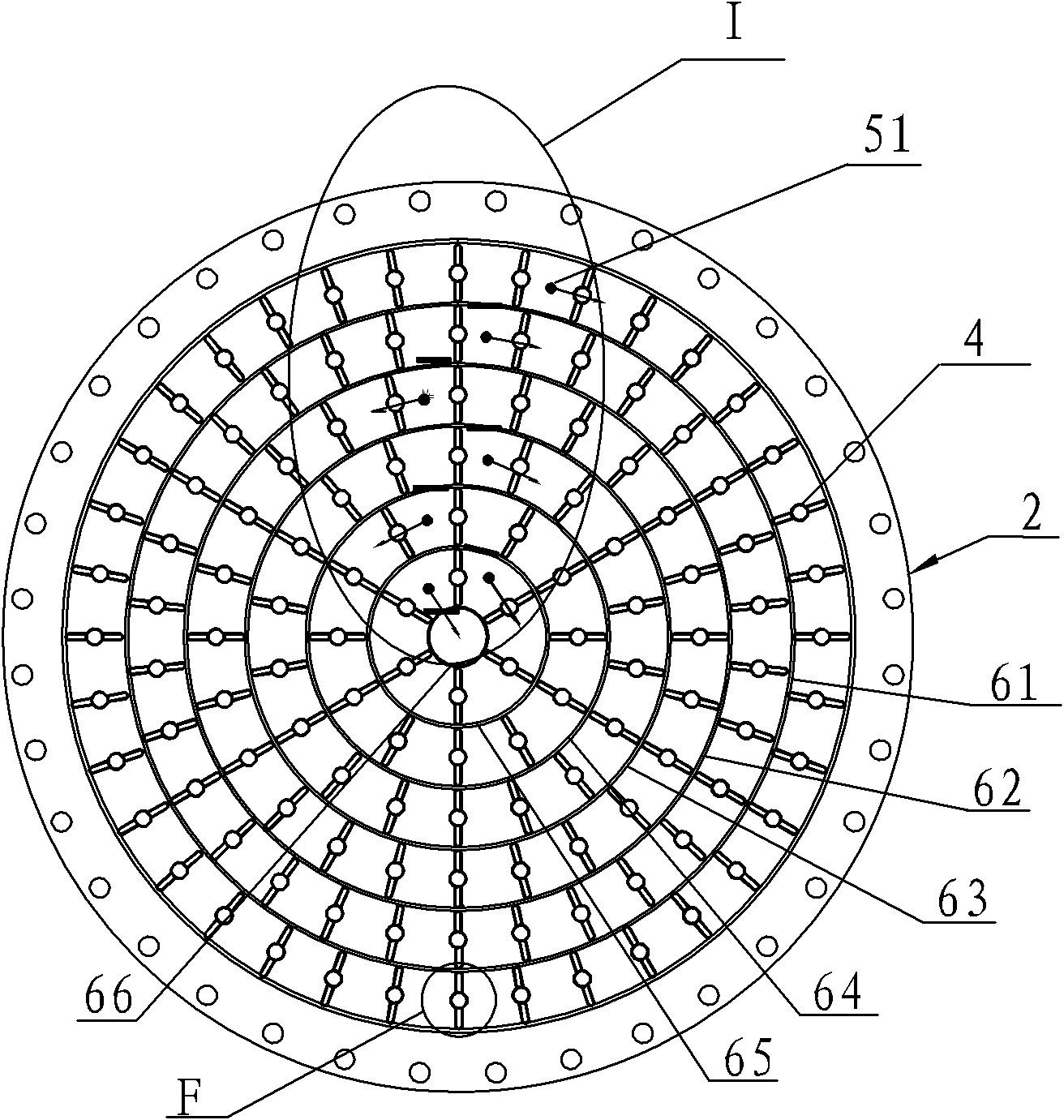

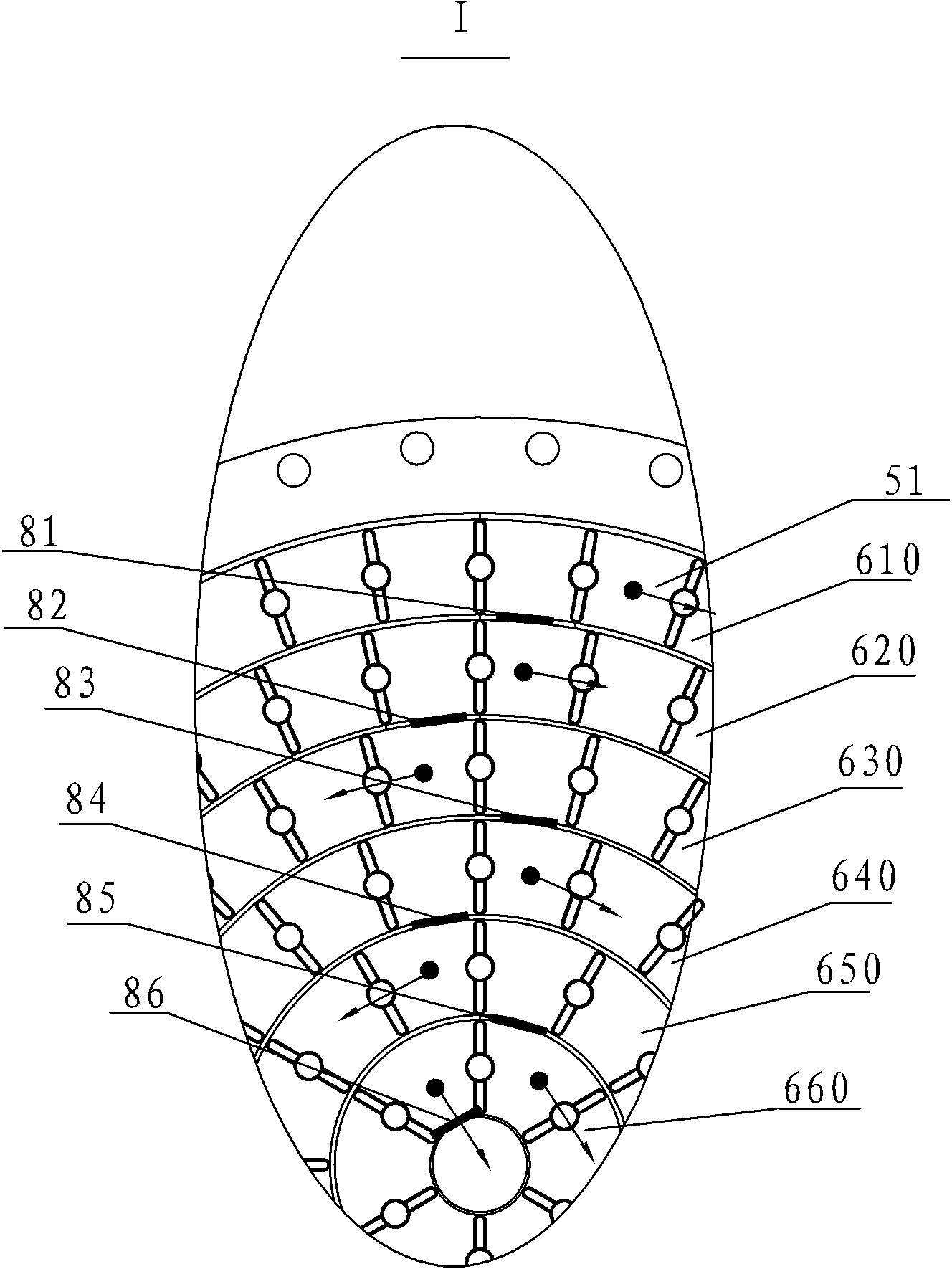

Electromagnetic wave heater for asphalt heating

ActiveCN102002247AAdequate heat exchange areaHigh emissivityChemical industryWorking-up pitch/asphalt/bitumen by meltingEngineeringAsphalt

The invention relates to an electromagnetic wave heater for asphalt heating, which is characterized by comprising a cylindrical housing, wherein more than five layers of cylindrical clapboards for forming annular flow ways are arranged between an upper cover and a lower cover of the housing and are coaxial with the cylindrical wall; a plurality of strip-shaped vertical clapboard-type electromagnetic wave heaters penetrate through the upper and lower covers of the housing and are arranged between the adjacent cylindrical clapboards along a radial direction; the annular flow ways are divided into a plurality of fan-shaped section heat exchanging regions; an overflowing opening is arranged at the upper end or the lower end of each electromagnetic wave heater; the overflowing openings of the adjacent electromagnetic wave heaters are arranged at upper and lower opposite ends; a layer exchanging gap is arranged at an asphalt flowing tail end on the upper edge of each of the electromagnetic wave heaters corresponding to the front annular flow way; the bottom of the outermost annular flow way is connected with an asphalt inlet; the upper end of the central cylindrical clapboard is connected with an asphalt outlet; an insulating layer is arranged on the outer side of the housing; and each electromagnetic wave heater consists of a heat exchanging sheet and an infrared electromagnetic wave heating tube. The electromagnetic wave heater has the advantages of obtaining enough heat exchanging area, exactly controlling the temperature, saving the energy, reducing the consumption and ensuring the safe production.

Owner:TIANJIN HI TECH ENVIRONMENT DEV CO LTD

Storage box for medical equipment

InactiveCN107361969AGuaranteed all-round sterilizationGuaranteed tightnessDiagnosticsNursing accommodationMedical equipmentEngineering

The invention discloses a storage box for medical instruments, which comprises a box body and a box cover. The side top of the box body is movably connected with the side bottom of the box cover. The position of the slot is provided with a buckle matching the card slot. The top surface of the inside of the box cover is provided with a lighting lamp, an ultraviolet lamp holder and a heating base. The ultraviolet lamp holder is between the lighting lamp and the heating base. There is an ultraviolet lamp tube 1 connected between the heating bases, a heating tube is connected between the heating bases, an annular soft gasket 1 is fixedly connected to the edge of the bottom surface of the box cover and the edge of the top surface of the box body, and a partition plate is arranged inside the box body. A cavity is formed between the inner bottom surfaces of the box body, a storage battery is arranged inside the cavity, and a power plug is arranged at the side bottom of the box body. The beneficial effects are: simple structure, easy operation, antivirus function and refrigeration function, strong antivirus effect, reduced work intensity, and time and labor saving.

Owner:CHENGDU PUJIANG KEXIAN TECH

Overall heating device for automotive stabilizer bar with variable-section end part

ActiveCN103667657AAvoid wastingAvoiding Fatigue Failure SituationsIncreasing energy efficiencyFurnace typesThermodynamicsEngineering

Owner:安庆市恒瑞达汽车零部件制造有限公司

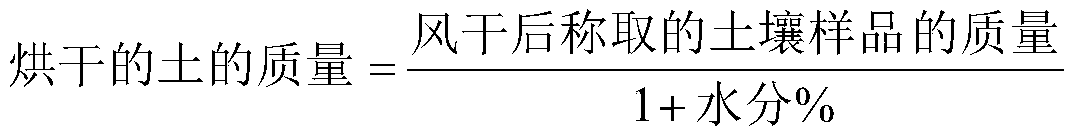

Method for measuring soil organic matter

InactiveCN110470665AAvoid the risk of harmAvoid burnsChemical analysis using titrationMaterial analysis by observing effect on chemical indicatorDigestionHeating temperature

The invention relates to a method for measuring soil organic matter, which comprises the following steps: putting a soil sample into a dry triangular flask; adding a potassium dichromate sulfuric acidsolution with a preset molar concentration into the triangular flask; putting the triangular flask filled with mixed solution into a drying oven for heating; after heating, taking out and cooling thetriangular flask; adding a preset volume of distilled water to enable the volume of the mixed solution in the triangular flask to reach a preset volume; adding an o-phenanthroline ferrous indicator with the volume matched with the acidity of the mixed solution according to the acidity of the mixed solution; and titrating the mixed solution in the triangular flask by using a ferrous sulfate solution. Through heating by the drying oven, the risk of fire possibly occurring in the heating process of the oil bath can be avoided. The soil sample in the triangular flask is accurately heated at constant temperature, so that the heating temperature can be accurately controlled. The triangular flask is directly heated in the heating process, there is no need to transfer the soil sample from a testtube to the triangular flask, and the risk of harm to the human body and clothes caused by digestion liquid transfer is avoided.

Owner:SOUTH CHINA AGRI UNIV

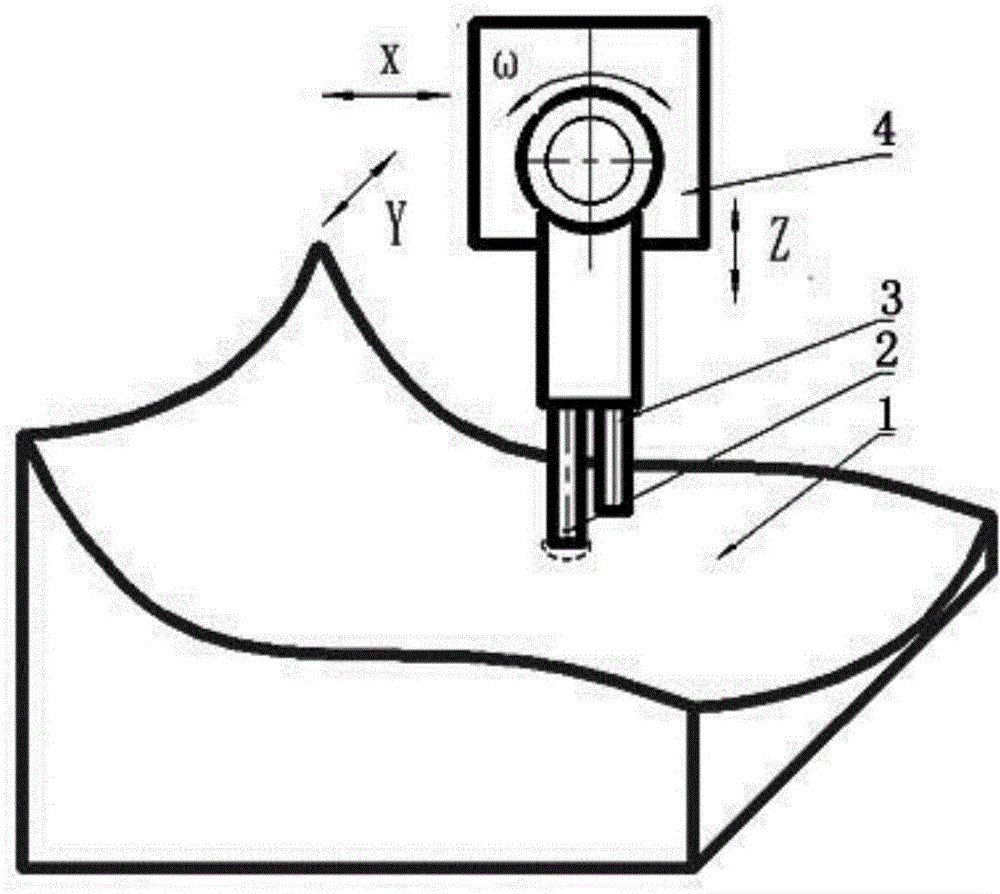

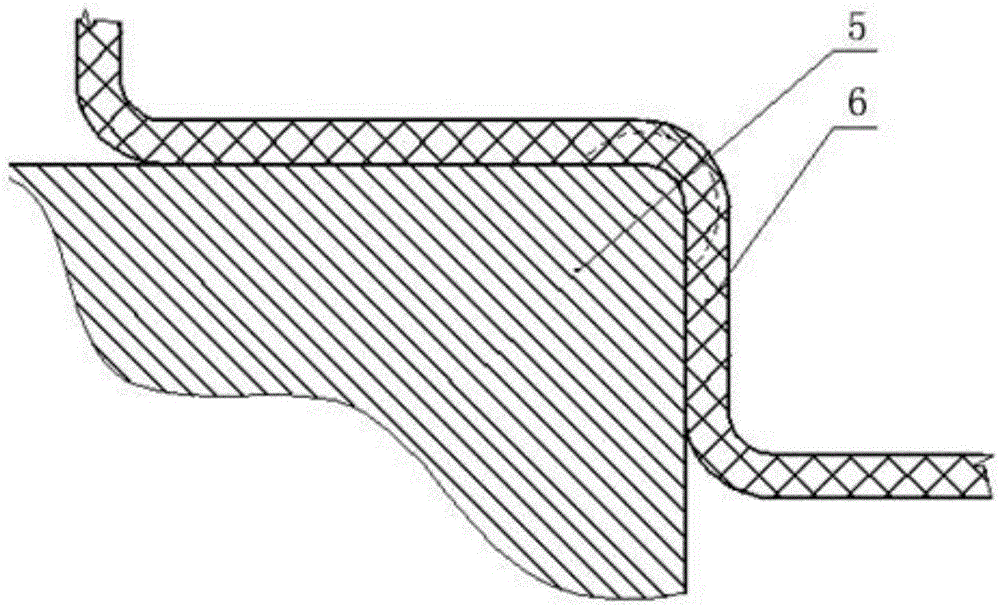

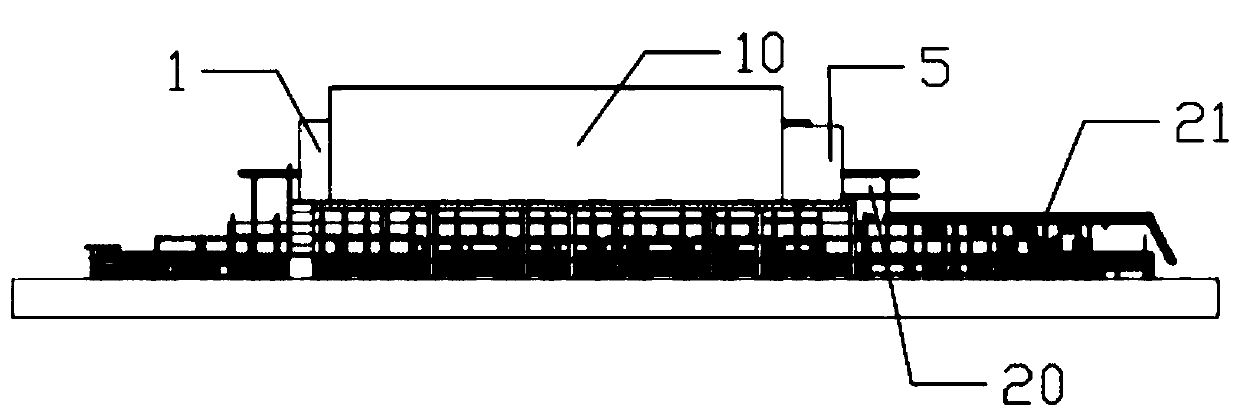

Method for strengthening molded surface of auto-body panel forming die by induction heat quenching

InactiveCN104388655AShorten the manufacturing cycleFavors selective reinforcementIncreasing energy efficiencyFurnace typesInduction heaterQuenching

The invention provides a method for strengthening a molded surface of an auto-body panel forming die by virtue of induction heat quenching. The method comprises the steps of designing and processing an induction heater and cooling spray heads matched with the induction heater; configuring an induction heating power supply and a cooling liquid feeding device; mounting the induction heater and the cooling spray heads on a driving device; switching on the induction heating power supply so that the induction heater is energized and controlling the induction heater and the cooling spray heads to do space curve movement along the designed moving path so that the molded surface of the die is subjected to induction heating by virtue of the induction heater and the temperature of to-be-treated molded surface of the die is raised to above a phase transition temperature; and after a certain time is delayed, spraying the cooling liquid towards heated molded surface of the auto-body panel forming die by virtue of the cooling spray heads mounted on the driving device. By the method, the selective strengthening of different regions of the molded surface of the die can be achieved according to the conditions that the molded surface of the auto-body panel forming die has uneven distribution of loads and different failure processes.

Owner:WUHAN UNIV OF TECH

Gravity forming continuous thermal bending furnace and using method thereof

PendingCN110342794AReduce lossesIngenious structural designGlass reforming apparatusGlass productionMotor driveEngineering

The invention discloses a gravity forming continuous thermal bending furnace and a using method thereof.The technical problems that the existing thermal bending furnace is unreasonable in structural design, during thermal bending forming,glass is likely to be broken, the curvature cannot be guaranteed, the straightness of the edge cannot be guaranteed, optical quality of the glass is poor, the yield rate is low, the production process is not continuous, and the production efficiency is low are solved. The gravity forming continuous thermal bending furnacecomprisesa furnace body frame, whereinaheat insulating material is closely arranged in the interior of the furnace body frame to form a closed cavity, the furnace body frame comprises sequentially from front to back a preheating station device, a pre-bending station device, a forming station device, a quenching station device, and a cooling station device; a trolley arranged in a single layer in the longitudinal direction of the furnace body frame and a motor-driven mobile system device are arranged in a furnace body, a mold is mounted on the trolley and driven to move from front to back by the movement of the motor-driven mobilesystem device; andmeanwhile the using method of gravity forming continuous thermal bending furnace is provided and can be widely applied to the field ofautomotive glass manufacturing.

Owner:MING CHI GLASS CO LTD

Method for manufacturing large titanium alloy fan damping platform blade blank

ActiveCN103586392AImprove surface qualityGuaranteed accuracyEngine componentsSurface oxidationImproved method

The invention belongs to forging technologies, and relates to an improvement of a method for manufacturing large titanium alloy fan damping platform blade blank. The method is characterized in that a horizontal die splitting horizontal forging machine is used for conducting machining; the method comprises the machining steps of preparing blade upset original blank and conducting primary upsetting, secondary upsetting, tertiary upsetting, quaternary upsetting, quinary upsetting and senary upsetting. By means of the improved method for manufacturing the large titanium alloy fan damping platform blade blank, the precision of the size of the blank is guaranteed, the heating temperature is controlled accurately, the surface oxidation phenomena are eliminated, consumption of raw materials is lowered and the surface quality of the blank is improved.

Owner:AECC AVIATION POWER CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com