Fully-automatic hydraulic red punching apparatus

A fully automatic, red punching technology, applied in the direction of metal extrusion dies, etc., can solve problems such as inconvenient maintenance, low control accuracy, and complex structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

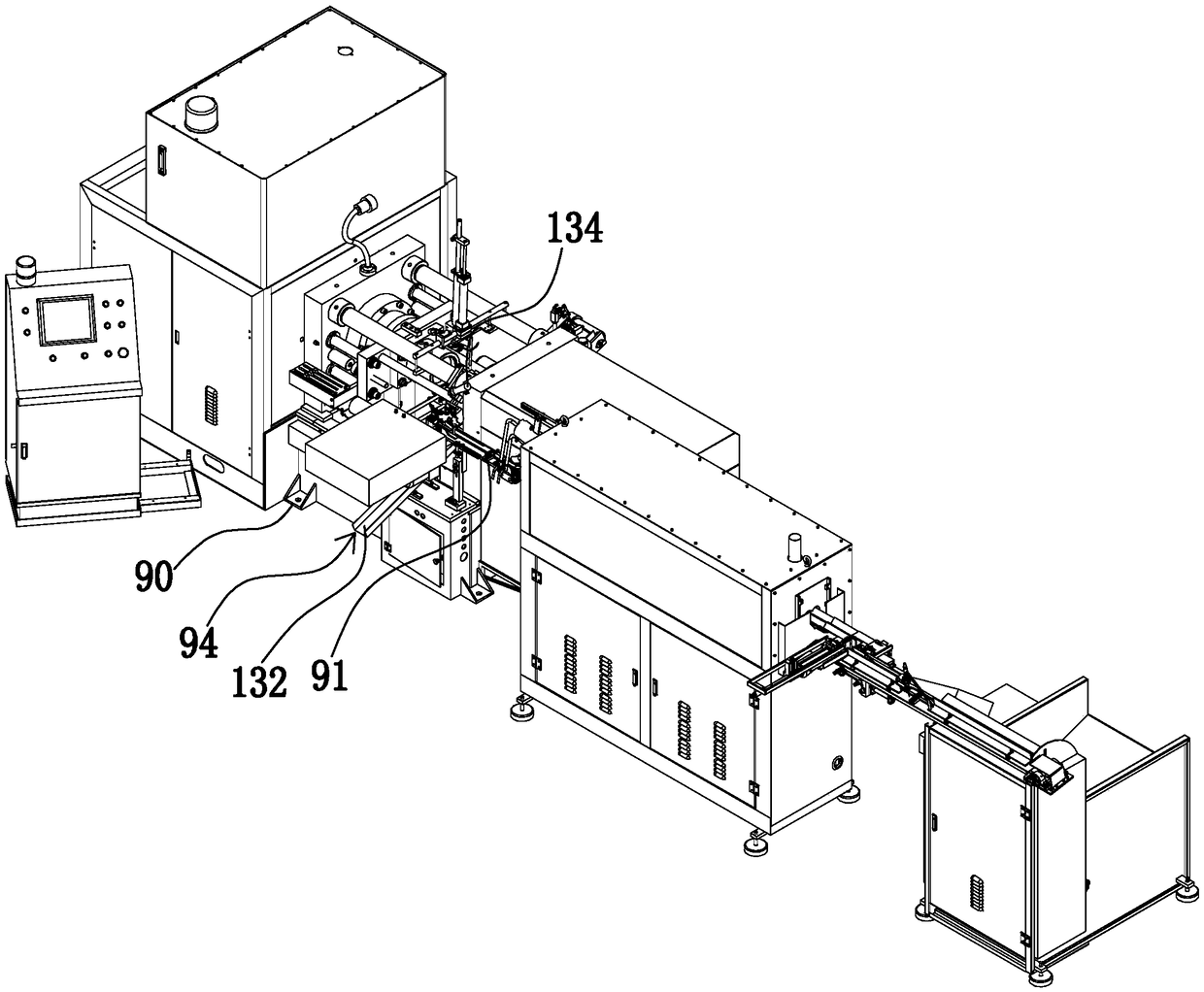

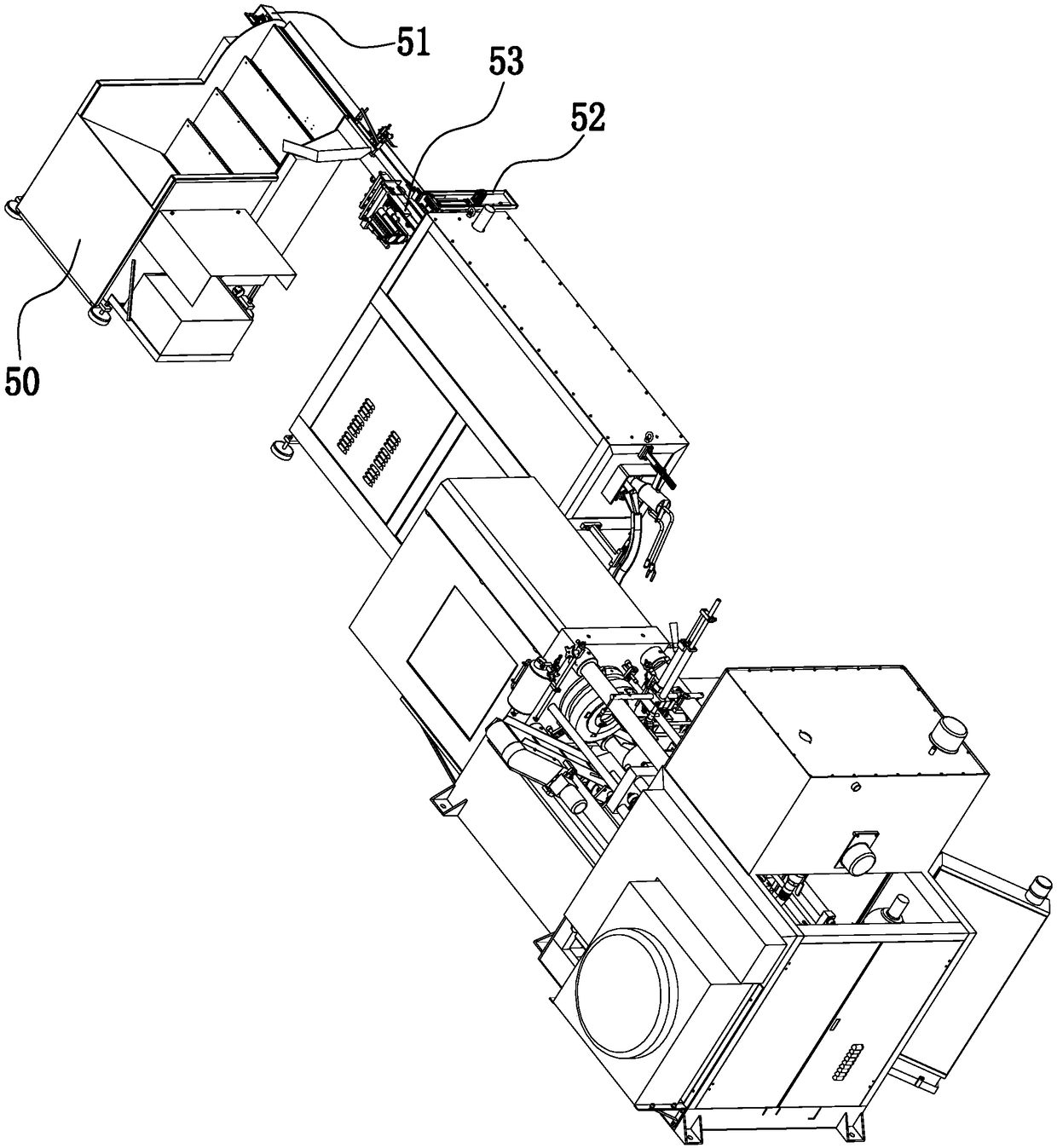

[0057] Example: such as Figure 1-2 As shown, a fully automatic hydraulic red punching equipment includes a loading frame assembly 50 for transferring workpieces, a raw material transmission device 51, a raw material pushing device 52 and a raw material feeding device 53; the raw material transmission device 51 is located at the loading The upper end of the frame assembly 50; the raw material pushing device 52 is corresponding to the raw material feeding device 53; the raw material pushing device 52 and the raw material feeding device 53 are located at the end of the raw material transmission device 51; The red punch raw material is lifted from the material box 201 to the conveyor belt 21 of the raw material transmission device 51, and then the conveyor belt 21 is driven by a driving motor to transport the raw material to the position of the raw material pushing device 52. The raw material pushing device 52 is used to push the raw material driving device 51 The red punch raw m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com