Preparing method for 6-series aluminum alloy sectional bar

A technology for aluminum alloy profiles and aluminum alloys, which is applied in the field of preparation of 6-series aluminum alloy profiles, can solve the problems of difficult online quenching control, poor quenching uniformity, and wide control range, and achieves reduction of process time and fast cooling rate. , the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

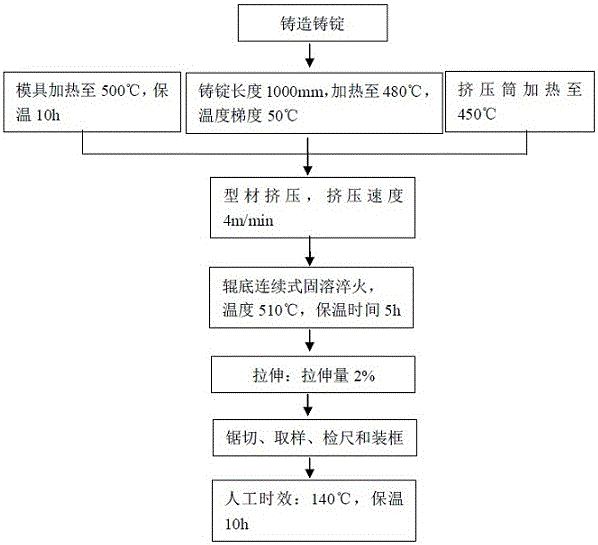

[0030] A kind of preparation method of 6 series aluminum alloy profiles, such as figure 1 As shown, there are the following steps:

[0031] (1) Casting ingots. The cast aluminum alloys are 6-series aluminum alloy ingots. The composition and weight percentage of the 6-series aluminum alloys are: 1% for Mg, 1.05% for Si, 0.75% for Mn, and 0.75% for Fe. 0.25%, Cr is 0.25%, Zn is 0.1%, Cu is 0.1%, Ti is 0.1%, V is 0.05%, Hf is 0.5%, Sc is 0.25%, Ag is 1.0%, and the rest is Al;

[0032] (2) Heating the ingot with a length of 1000mm, adopting the gradient heating method, the temperature difference between the head and the tail is 50°C, and the heating temperature of the ingot in the heating furnace is controlled at 480°C;

[0033] (3) Heat the mold to 500°C in a heating furnace and keep it warm for 10 hours;

[0034] (4) Heating the extrusion barrel, and controlling the temperature of the extrusion barrel at 450°C;

[0035] (5) Extrusion production: After the ingot and the mold a...

Embodiment 2

[0041] A preparation method of a 6-series aluminum alloy profile comprises the following steps:

[0042] (1) Casting ingots. The cast aluminum alloys are 6-series aluminum alloy ingots. The composition and weight percentage of the 6-series aluminum alloys are: 1% for Mg, 1.05% for Si, 0.75% for Mn, and 0.75% for Fe. 0.25%, Cr is 0.25%, Zn is 0.1%, Cu is 0.1%, Ti is 0.1%, V is 0.05%, Hf is 0.5%, Sc is 0.25%, Ag is 1.0%, and the rest is Al;

[0043] (2) Heating the ingot with a length of 1000mm, adopting the method of gradient heating, the temperature gradient is 50°C, and the heating temperature of the ingot in the heating furnace is controlled at 480°C;

[0044] (3) Heat the mold to 500°C in a heating furnace and keep it warm for 10 hours;

[0045] (4) Heating the extrusion barrel, and controlling the temperature of the extrusion barrel at 450°C;

[0046] (5) Extrusion production: After the ingot and the mold are heated, the upper mold is extruded after the extrusion cylinde...

Embodiment 3

[0052] A preparation method of a 6-series aluminum alloy profile comprises the following steps:

[0053] (1) Casting ingots. The cast aluminum alloys are 6-series aluminum alloy ingots. The composition and weight percentage of the 6-series aluminum alloys are: 1% for Mg, 1.05% for Si, 0.75% for Mn, and 0.75% for Fe. 0.25%, Cr is 0.25%, Zn is 0.1%, Cu is 0.1%, Ti is 0.1%, V is 0.05%, Hf is 0.5%, Sc is 0.25%, Ag is 1.0%, and the rest is Al;

[0054] (2) Heating the ingot with a length of 1000mm, adopting the method of gradient heating, the temperature gradient is 50°C, and the heating temperature of the ingot in the heating furnace is controlled at 480°C;

[0055] (3) Heat the mold to 500°C in a heating furnace and keep it warm for 10 hours;

[0056] (4) Heating the extrusion barrel, and controlling the temperature of the extrusion barrel at 450°C;

[0057] (5) Extrusion production: After the ingot and the mold are heated, the upper mold is extruded after the extrusion cylinde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com