A method for upgrading and reforming old cement concrete pavement

A technology of concrete pavement and old cement, which is applied to cohesive pavement paved on site, roads, roads, etc., to achieve excellent anti-rutting performance and fatigue resistance, long service life and good skid resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

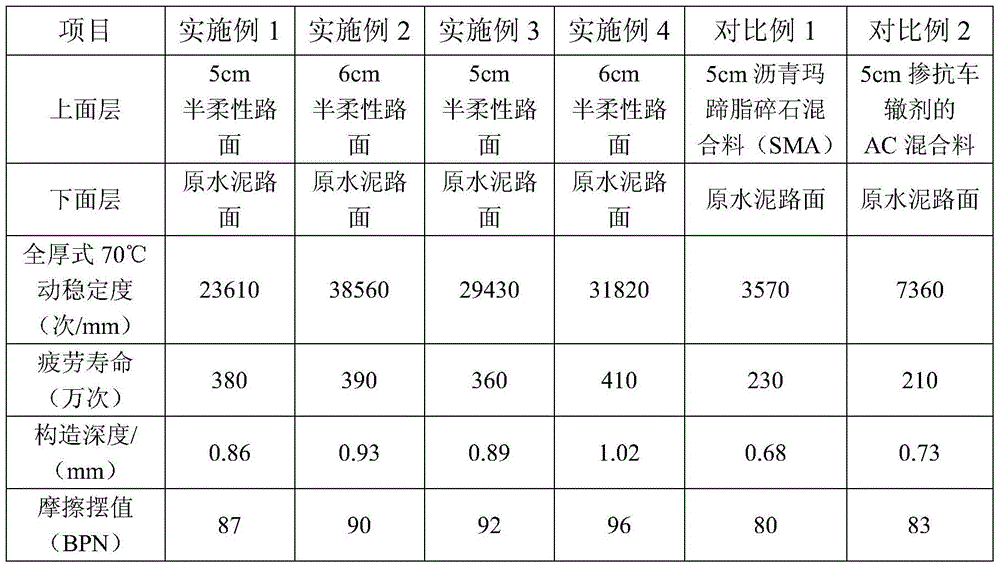

Examples

Embodiment 1

[0025] Treatment of old cement pavement diseases, including remediation of broken slabs on the original cement concrete pavement, treatment of voids at the bottom of slabs, repair of cracks, treatment of staggered platforms, etc., and then chisel surface treatment on the road surface, requiring the distance between chisel points on the surface to be controlled at 1.5 ~4cm, the depth of the chiseling point is controlled at 2~8mm.

[0026] Pavement of crack suppression functional layer: evenly spread a layer of rubber modified emulsified asphalt mixture, and roll on the old cement concrete pavement to form a crack suppression functional layer; in rubber modified emulsified asphalt mixture, the particle size is 5~10mm crushed stone, 3~5mm particle size crushed stone, particle size less than 3mm crushed stone, rubber modified emulsified asphalt, fiber, cement and water weight ratio is 10:40:50:12:0.001:0.5 : 5. The thickness of the pavement is 1cm. The gravel is produced in Liuhe ...

Embodiment 2

[0030] Treatment of old cement pavement diseases, including remediation of broken slabs on the original cement concrete pavement, treatment of voids at the bottom of slabs, repair of cracks, treatment of staggered platforms, etc., and then chisel surface treatment on the road surface, requiring the distance between chisel points on the surface to be controlled at 1.5 ~4cm, the depth of the chiseling point is controlled at 2~8mm.

[0031] Pavement of crack suppression functional layer: evenly spread a layer of rubber modified emulsified asphalt mixture, and roll on the old cement concrete pavement to form a crack suppression functional layer; in rubber modified emulsified asphalt mixture, the particle size is 5~10mm crushed stone, 3~5mm particle size crushed stone, particle size less than 3mm crushed stone, rubber modified emulsified asphalt, fiber, cement and water weight ratio is 20:30:50:16:0.003:1.5 : 10, the paving thickness is 1.5cm, the crushed stones are produced in Liu...

Embodiment 3

[0035] Treatment of old cement pavement diseases, including remediation of broken slabs on the original cement concrete pavement, treatment of voids at the bottom of slabs, repair of cracks, treatment of staggered platforms, etc., and then chisel surface treatment on the road surface, requiring the distance between chisel points on the surface to be controlled at 1.5 ~4cm, the depth of the chiseling point is controlled at 2~8mm.

[0036] Pavement of crack suppression functional layer: evenly spread a layer of rubber modified emulsified asphalt mixture, and roll on the old cement concrete pavement to form a crack suppression functional layer; in rubber modified emulsified asphalt mixture, the particle size is 5~10mm crushed stone, 3~5mm particle size crushed stone, particle size less than 3mm crushed stone, rubber modified emulsified asphalt, fiber, cement and water weight ratio is 15:35:50:8:0.002:1 : 8, the paving thickness is 1.2cm, and the crushed stones are all produced in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com