Ice inhibiting and snow melting type asphalt concrete phase-change overlay material and preparation method and application thereof

A technology of asphalt concrete and concrete base material, which is applied to the coagulation pavement, buildings, roads and other directions of on-site paving, can solve the problems of the research progress of application methods and application methods, etc., so as to delay the harmful conditions of the road and prolong the pavement structure. Longevity and durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

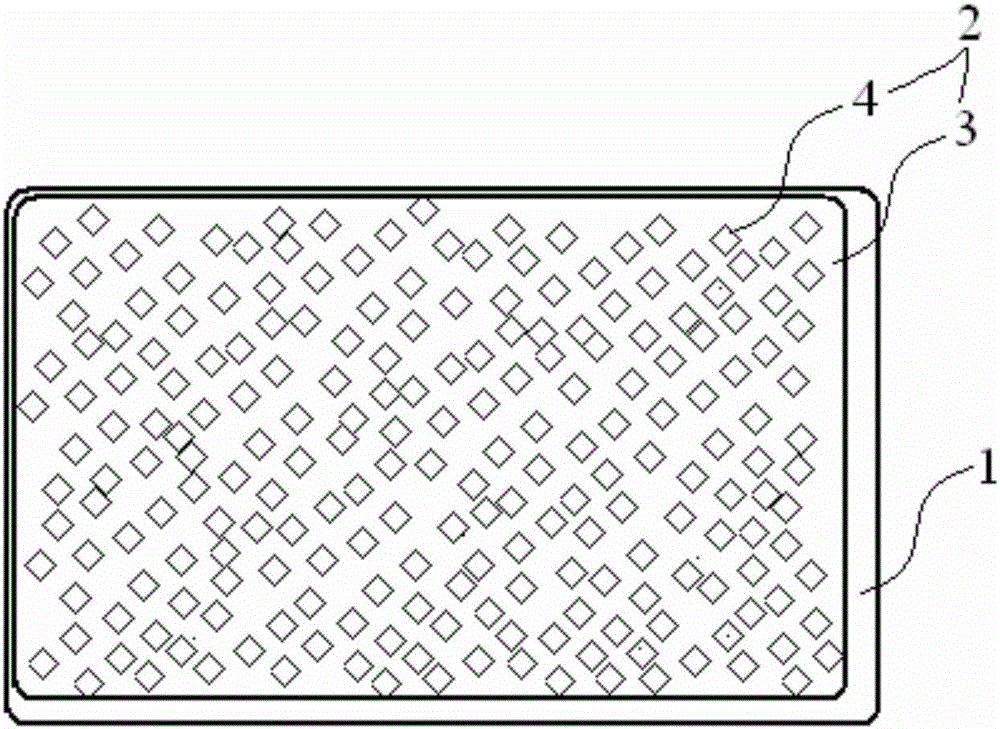

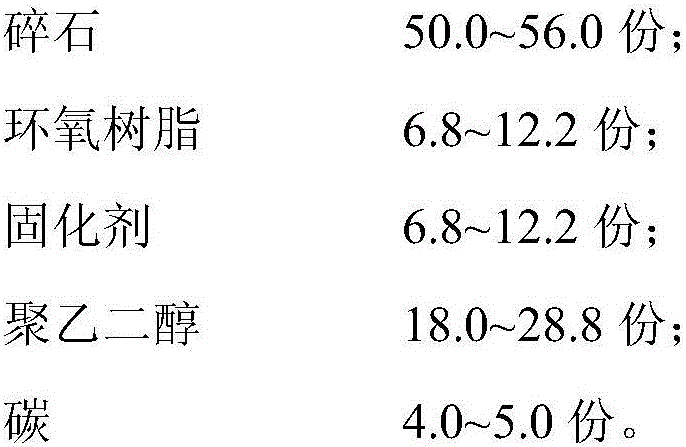

[0064] According to the T0703 asphalt mixture specimen preparation method (wheel rolling method) in the highway engineering asphalt and asphalt mixture test regulations (JTG E20-2011), the dense asphalt concrete AC- 13 gradation standard, using basalt aggregates to make asphalt concrete slabs. Further apply a self-regulating asphalt concrete thin layer overlay (such as figure 1 shown), the specific steps are: configure the self-regulating asphalt concrete thin-layer overlay material according to the formula in Table 2, and coat the self-temperature-regulating asphalt concrete thin-layer overlay material on the surface of the asphalt concrete slab with a thickness of about 10mm, and Sprinkle gravel evenly on the concrete overlay material, remove unbonded gravel after curing, and prepare the control group and experimental groups 1-3. The control group and the experimental group were tested for performance. Specifically, the control group and the experimental group were immersed...

Embodiment 2

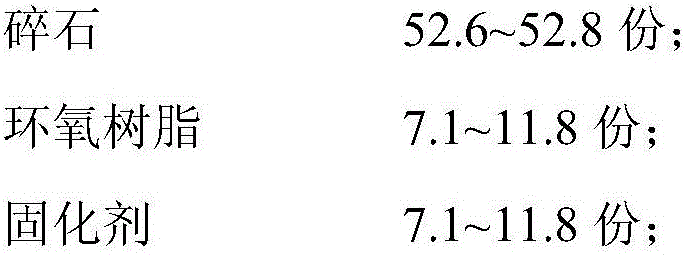

[0070] According to the T0703 asphalt mixture specimen preparation method (wheel rolling method) in the highway engineering asphalt and asphalt mixture test regulations (JTG E20-2011), the dense asphalt concrete AC- 13 gradation standard, using basalt aggregates to make asphalt concrete slabs. Further apply a self-regulating asphalt concrete thin layer overlay (such as figure 1 shown), the specific steps are: configure the self-regulating asphalt concrete thin-layer overlay material according to the formula in Table 4, and coat the self-regulating asphalt concrete thin-layer overlay material on the surface of the asphalt concrete slab with a thickness of about 10mm, and Sprinkle gravel evenly on the concrete overlay material, remove unbonded gravel after curing, and prepare experimental groups 4-9. Performance tests were performed on the prepared experimental groups, and the performance of each experimental group was similar to that of the implementation groups 1-3.

[0071]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| epoxy value | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com