A semi-flexible pavement material for rapid opening of traffic and its method for paving

A semi-flexible pavement and open traffic technology, which is applied in the field of rutting treatment and road rutting treatment, can solve the problems that cannot meet the rapid opening of municipal roads to traffic, and achieve the effects of reducing the risk of cracking, good bonding ability, and simple construction technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

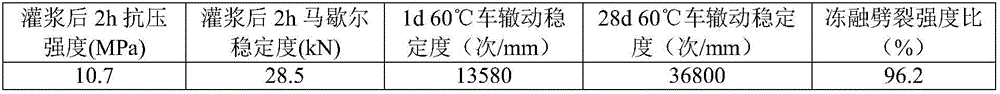

Embodiment 1

[0029] Preparation of water-based epoxy resin porous mixture: first, mix standard liquid epoxy resin, water-based epoxy curing agent and water in a weight ratio of 1:1.1:0.2, and continue stirring until the mixture is uniform to obtain water-based epoxy resin ; Then add SBR styrene-butadiene latex to the water-based epoxy resin, the ratio of water-based epoxy resin to SBR latex is 3.5:1, stir until the mixture is uniform; then add the prepared water-based epoxy resin to the aggregate in the stirring pot and SBR styrene-butadiene latex mixture, stir evenly, and then add mineral powder for secondary mixing until uniform. The mass ratio of aggregate, water-based epoxy resin and SBR styrene-butadiene latex mixture to mineral powder is 92:4.5:3.5 Paving the mixed porous mixture, the paving thickness is 5cm, using low-tonnage compaction machinery in the paving, reducing the number of rolling times, and controlling the porosity of the porous mixture at about 16%.

[0030] Preparation...

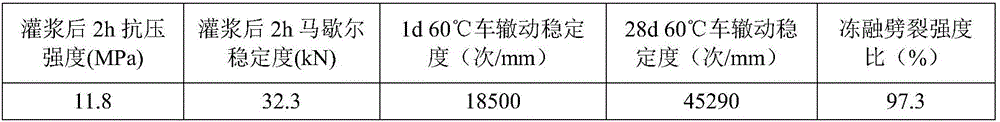

Embodiment 2

[0039] Preparation of water-based epoxy resin porous mixture: first, mix standard liquid epoxy resin, water-based epoxy curing agent and water in a weight ratio of 1:1.3:1, and keep stirring until the mixture is uniform to obtain water-based epoxy resin ; Then add SBR styrene-butadiene latex to the water-based epoxy resin, the ratio of water-based epoxy resin to SBR styrene-butadiene latex is 7:1.8, stir until the mixture is uniform; then add the prepared water-based epoxy resin to the aggregate in the stirring pot epoxy resin and SBR styrene-butadiene latex mixture, stir evenly, and then add mineral powder for secondary mixing until uniform, wherein the mass ratio of aggregate, water-based epoxy resin and SBR styrene-butadiene latex mixture to mineral powder is 87:8.8 : 4.2; Pave the mixed porous mixture, the paving thickness is 12cm, adopt low-tonnage compacting machinery in the paving, reduce the number of times of rolling, and control the porosity of the porous mixture at a...

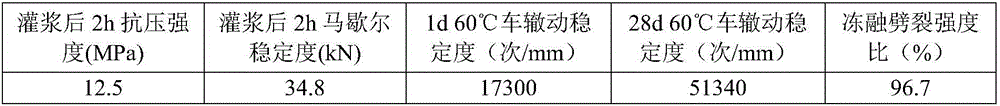

Embodiment 4

[0059] Preparation of water-based epoxy resin porous mixture: first, mix standard liquid epoxy resin, water-based epoxy curing agent and water in a weight ratio of 1:1.2:0.4, and continue stirring until the mixture is uniform to obtain water-based epoxy resin ; Then add SBR styrene-butadiene latex to the water-based epoxy resin, the ratio of water-based epoxy resin to SBR styrene-butadiene latex is 4:0.5, stir until the mixture is uniform; then add the prepared water-based epoxy resin to the aggregate in the stirring pot epoxy resin and SBR styrene-butadiene latex mixture, stir evenly, and then add mineral powder for secondary mixing until uniform, wherein the mass ratio of aggregate, water-based epoxy resin and SBR styrene-butadiene latex mixture to mineral powder is 90.5:4.5 : 5; Pave the mixed porous mixture, the paving thickness is 8cm, adopt low-tonnage compacting machinery in the paving, reduce the number of times of rolling, and control the porosity of the porous mixture...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com