Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

352results about How to "Good waterproof" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

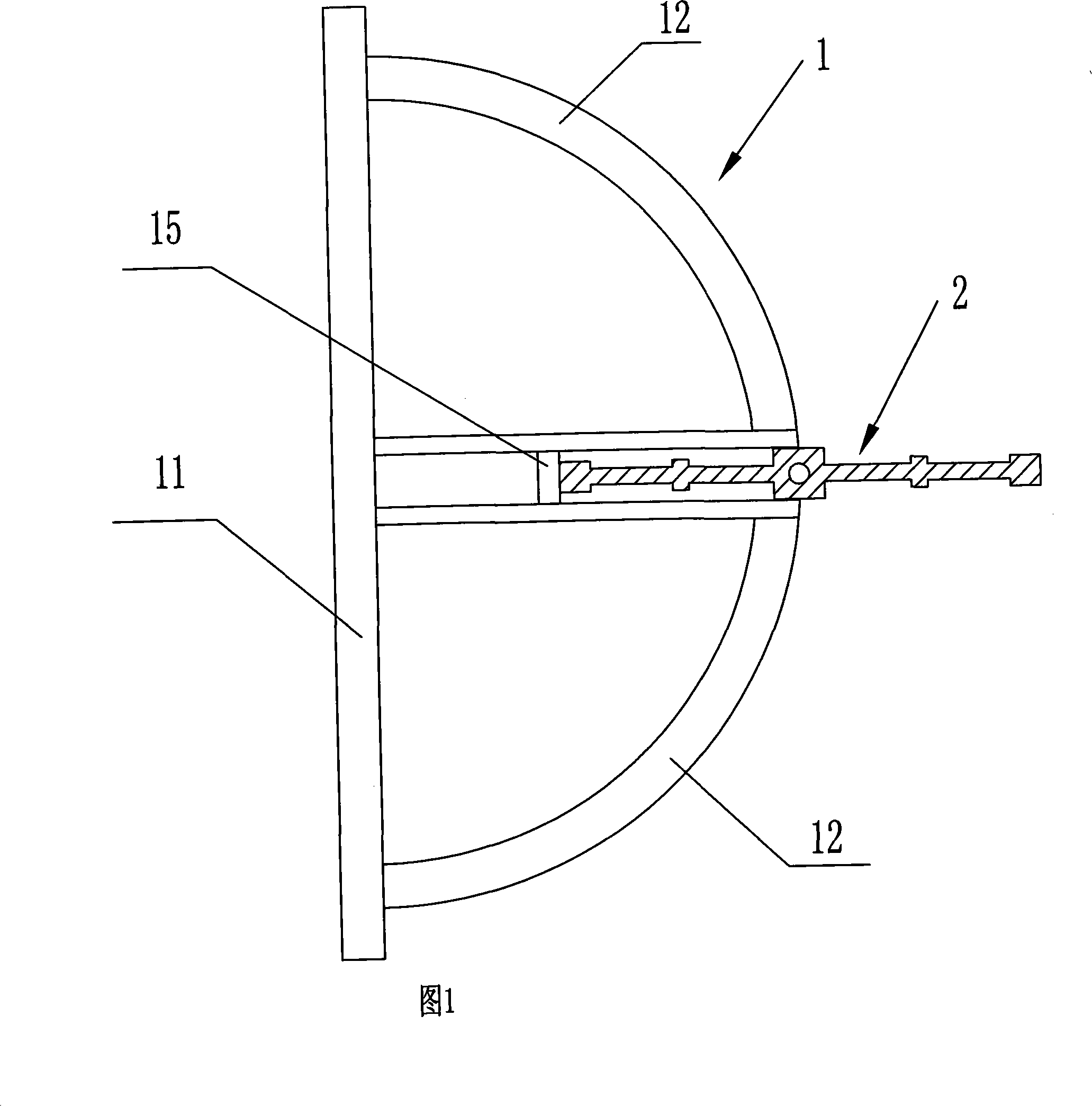

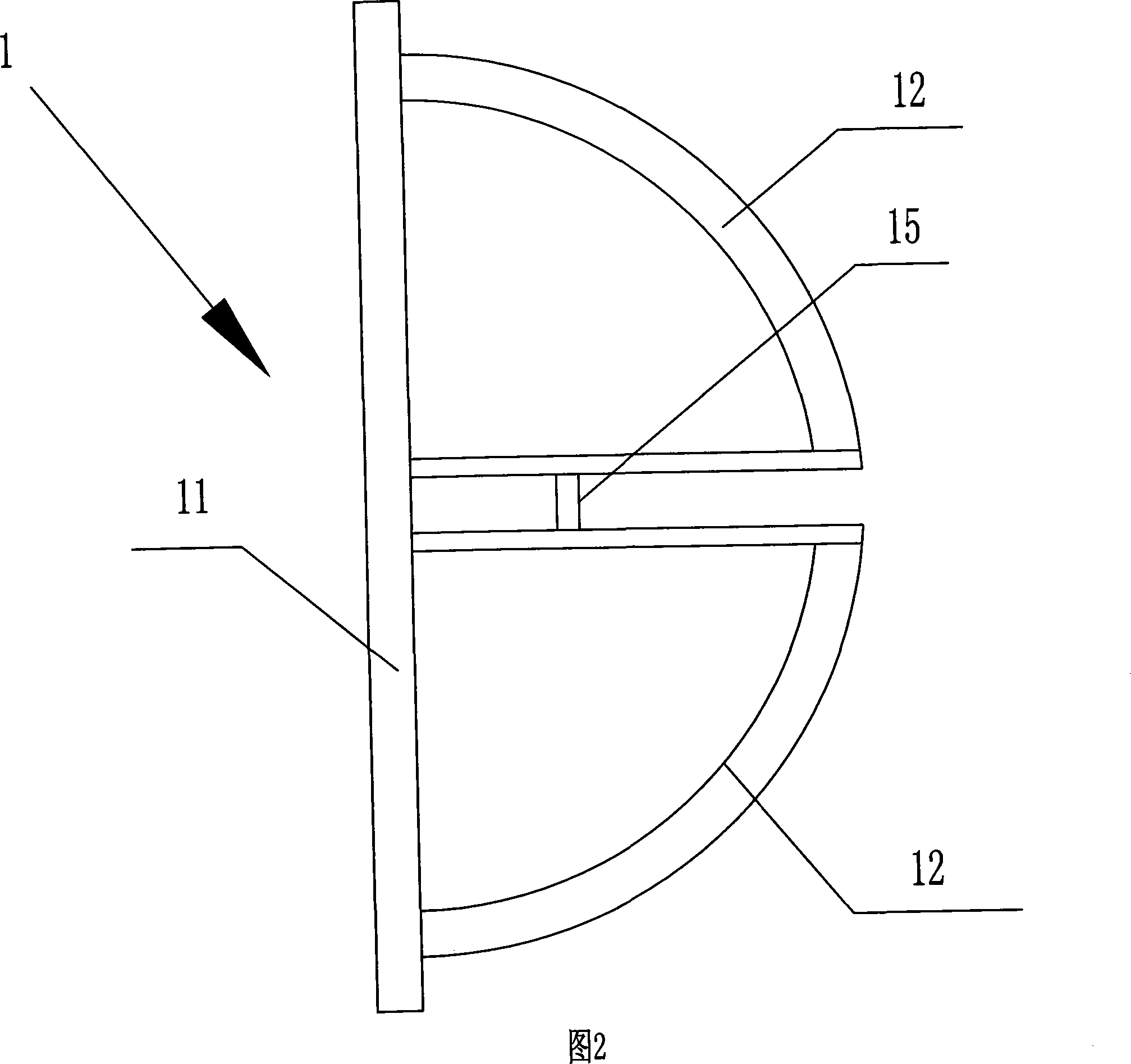

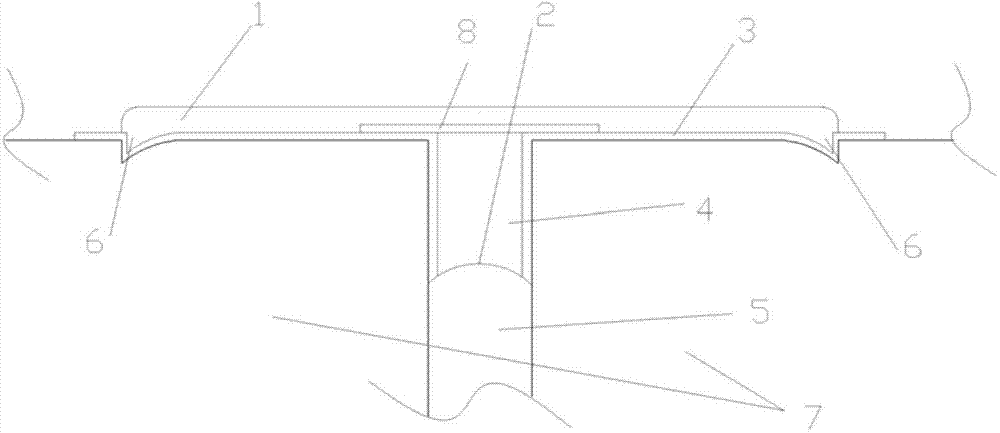

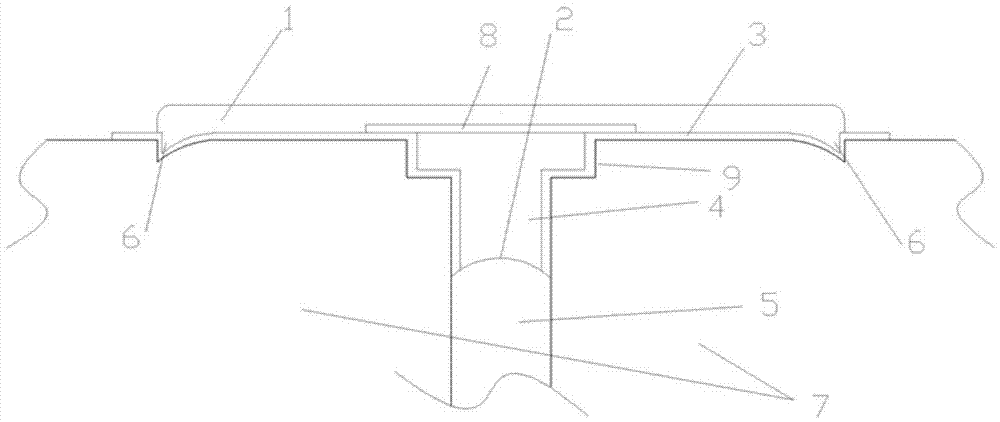

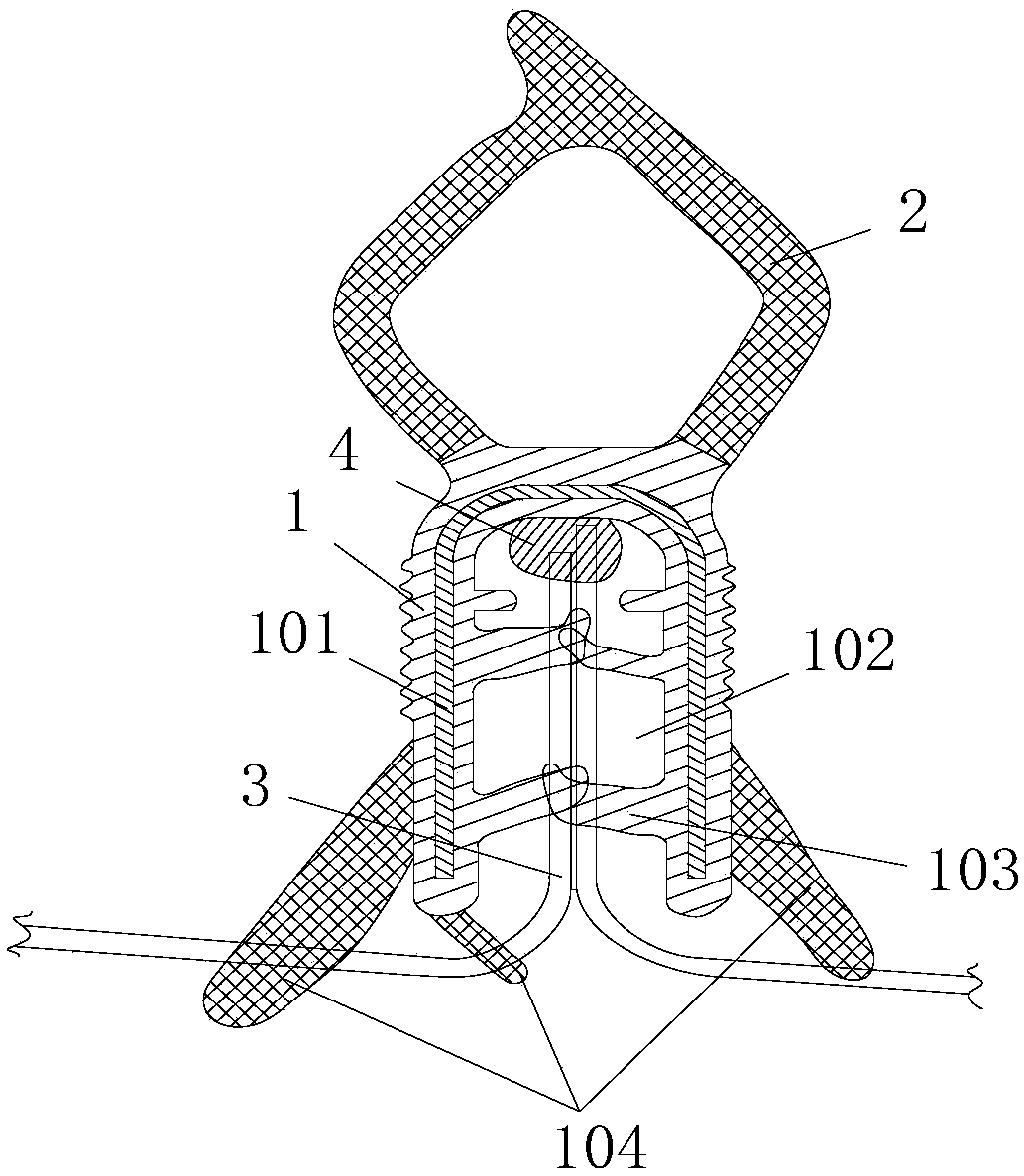

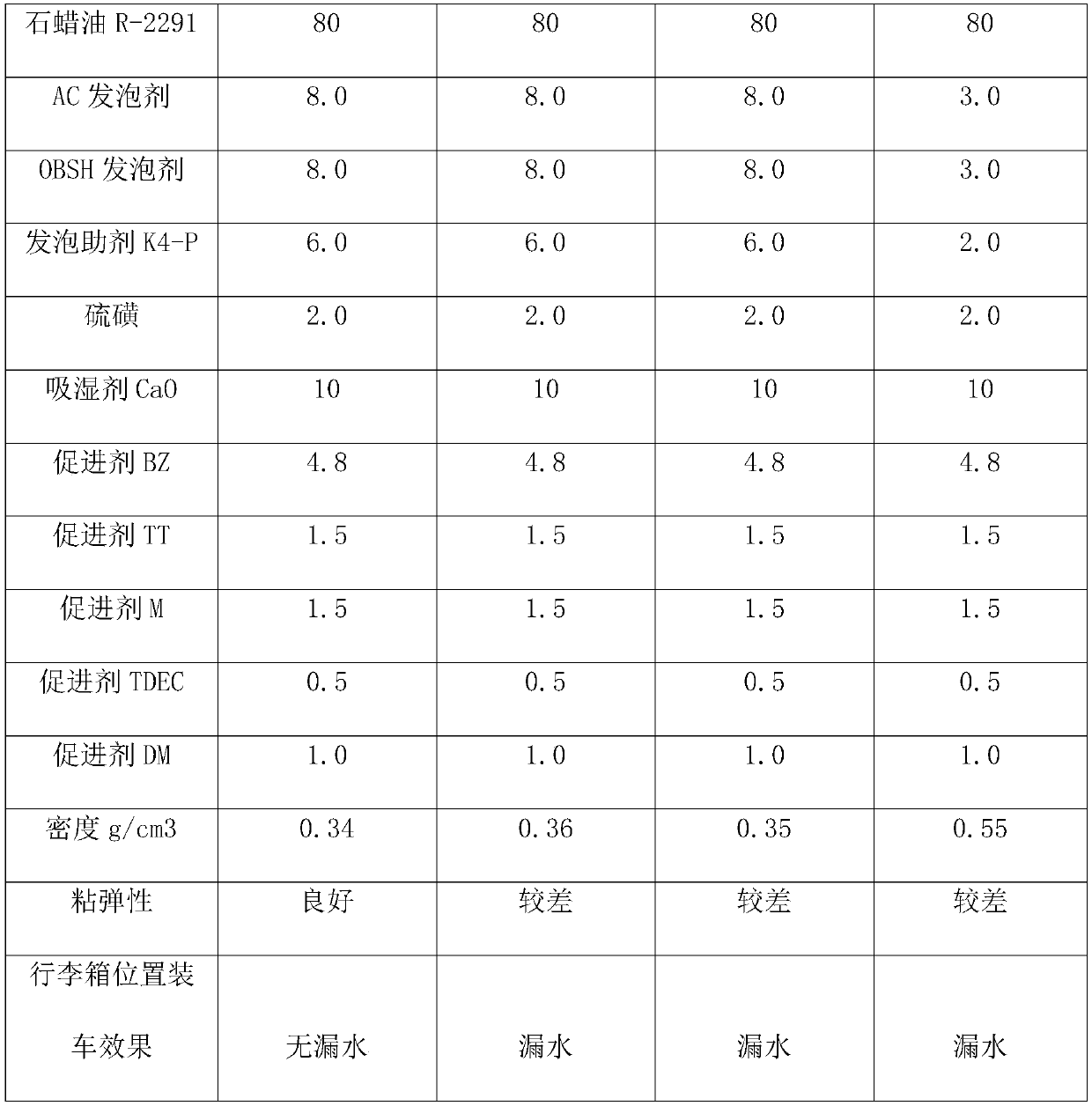

Large depth underground continuous wall water-stop joint device

ActiveCN101168963AAvoid generatingSave the process of brushing the wallArtificial islandsUnderwater structuresSlurry wallArchitectural engineering

The invention relates to a water sealing joint device of a large-depth underground continuous wall. The water sealing joint device consists of a water sealing connector plate and a rubber water stop; the water sealing connector plate comprises connector side plates connected in sequence, two arc shape plates, an H-shaped groove plate, an upper end plate and a lower end plate; the two arc shape plates are oppositely arranged in the middle at intervals along the width of a connector side plate, and the H-shaped groove plate is arranged in the middle between the two arc shape plates; the H-shaped groove plate has two opening ends, one end is fixed and connected with the two arc shape plates, and the other end is fixed and connected with the connector side plate; and the upper end plate and the lower end plate are arranged at the end parts of the two arc shape plates and the H-shaped groove plate. An opening slot is arranged at the middle part of the upper end plate and the lower end plate, and the rubber water stop is embedded in a gap between the opening slot and the opening end of the H-shaped groove plate. The connector side plate adopts a long strip shape thick steel plate, the upper end plate and the lower end plate adopt semi-circular steel plates, and the composite cross section of the two arc shape plates is matched with the shape of the upper end plate and the lower end plate. The depth of the opening slot of the upper end plate and the lower end plate is approximately identical to half of the width of the rubber water stop. The invention can improve the prior construction process, reduce the construction cost, and effectively improve the water sealing performance of the structure of the underground continuous wall.

Owner:SHANGHAI URBAN CONSTRUCTION MUNICIPAL ENGINEERING (GROUP) CO LTD

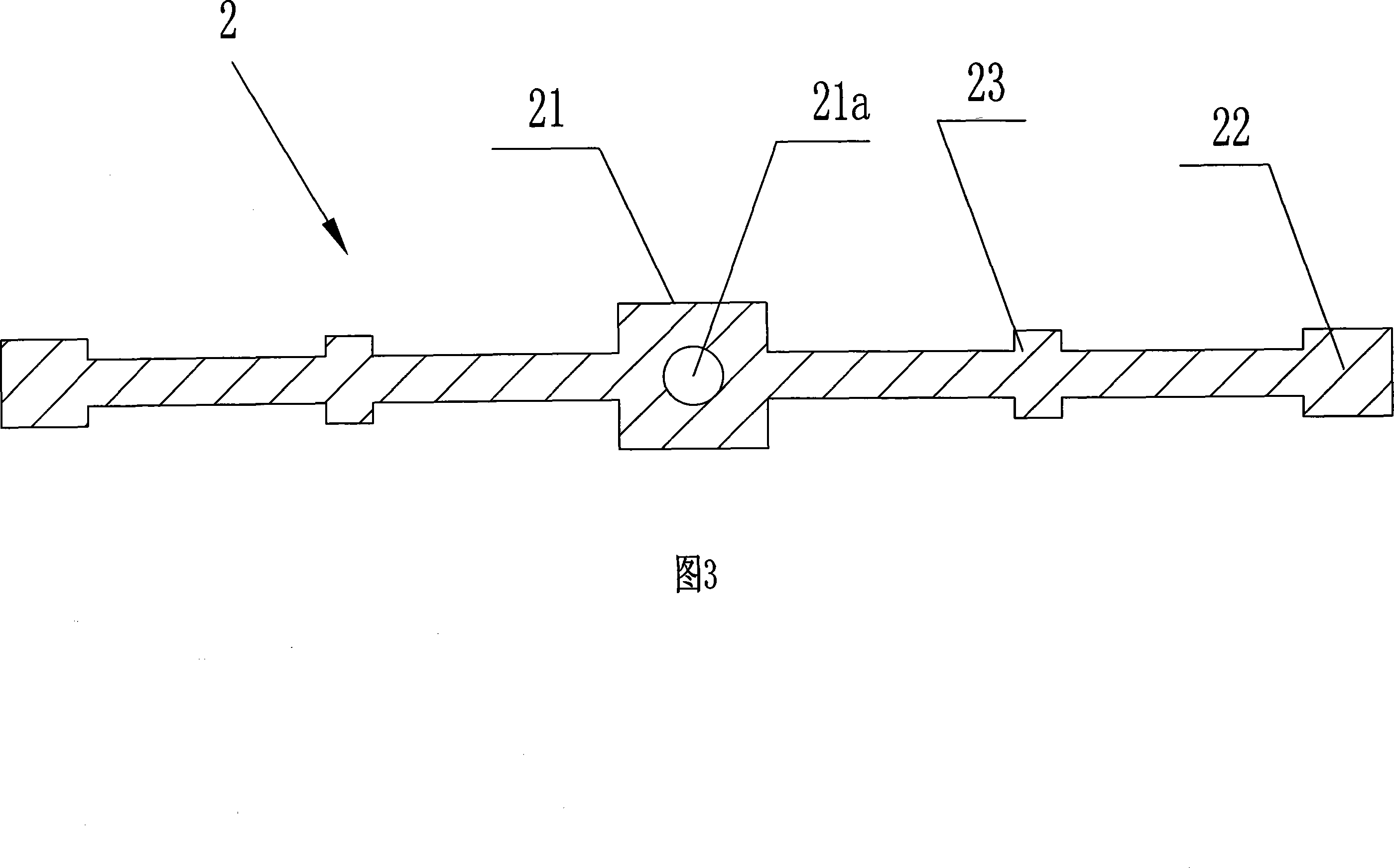

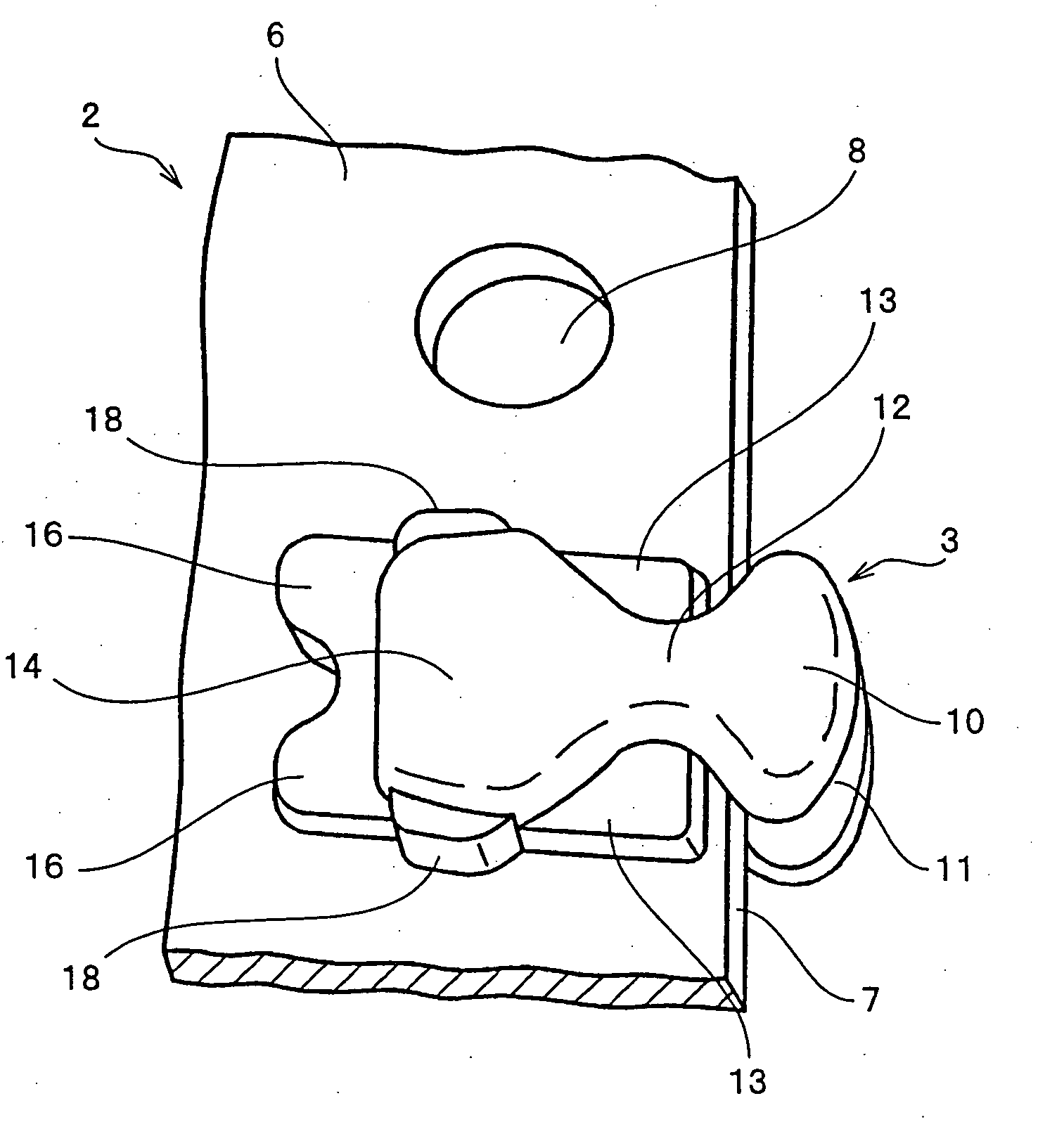

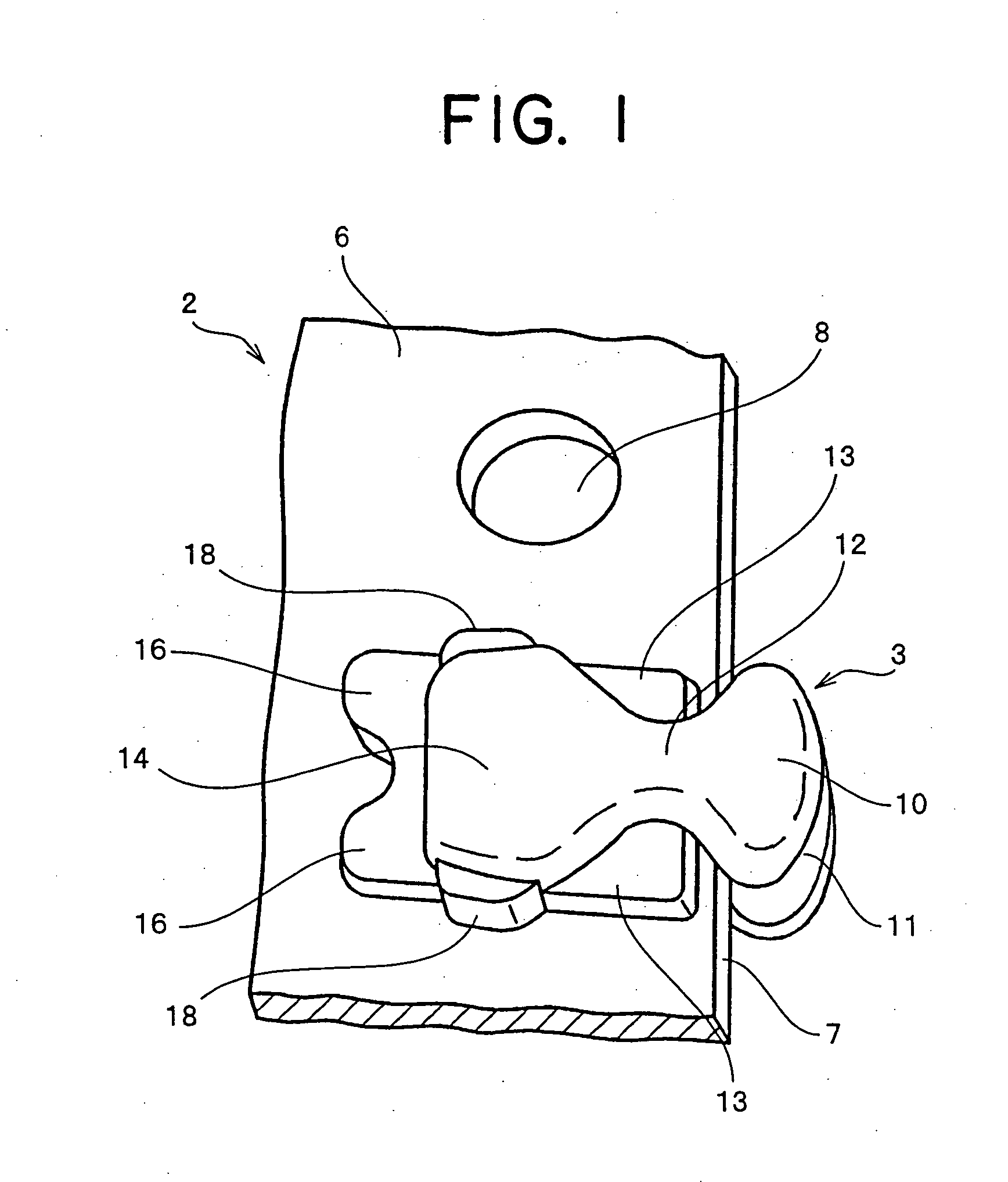

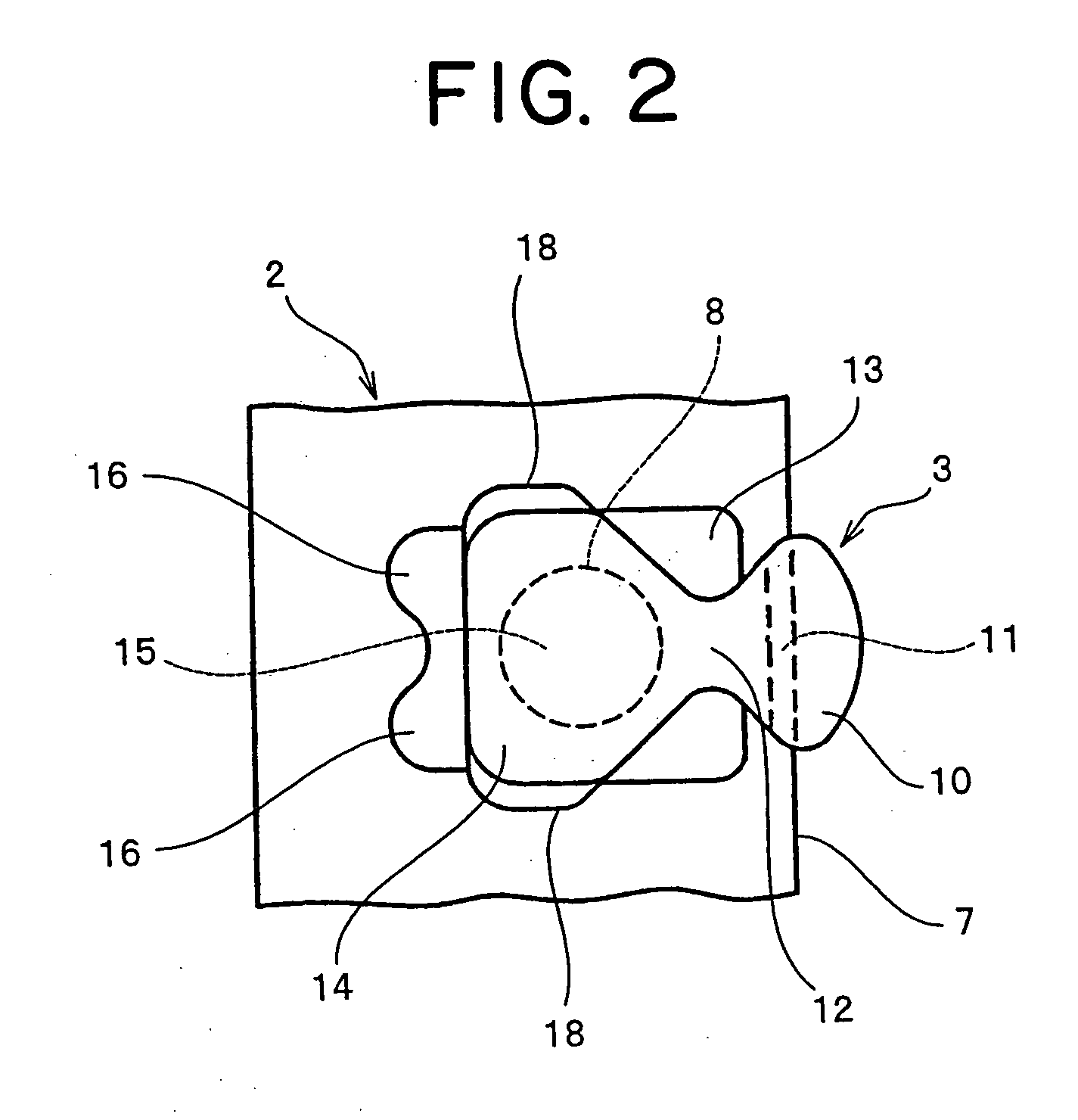

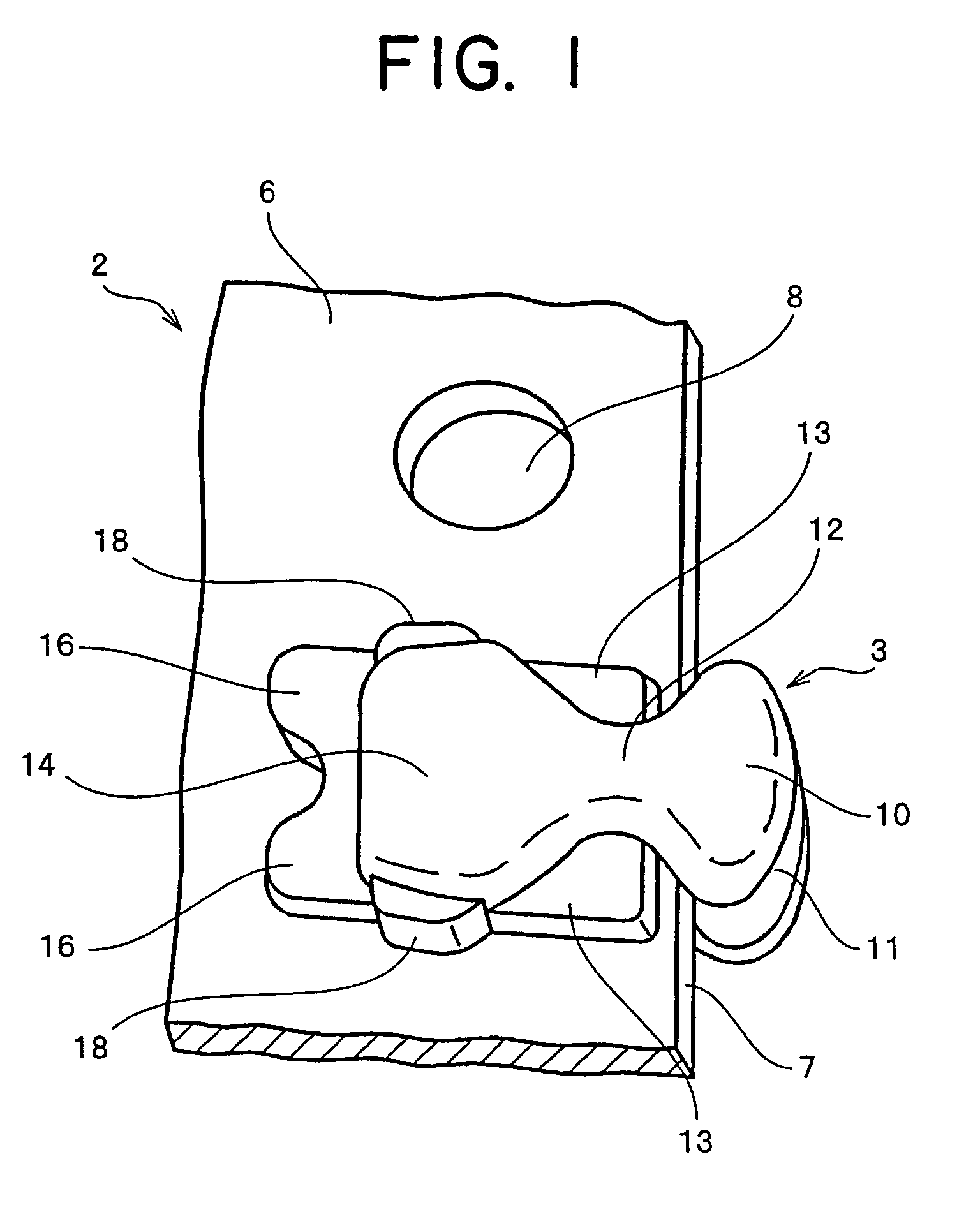

Waterproof slide fastener

A waterproof slide fastener in which an entire surface of a fastener tape is covered with elastomer, through holes are made in a side edge of the fastener tape, and fastener elements each comprising a coupling head, a neck portion, an engaging projection, a leg portion and a tongue piece, are molded by injection molding so as to cover the through holes. Reinforcing portions are provided projectingly from sides of the leg portion so as to cover at least a part of each of the through holes in a longitudinal direction of the through holes made in the fastener tape so that the reinforcing portions surround the through holes, so the reinforcing portions prevent the through holes from being exposed even when the fastener tape is bent, thereby maintaining water-tightness and airtightness.

Owner:YKK CORP

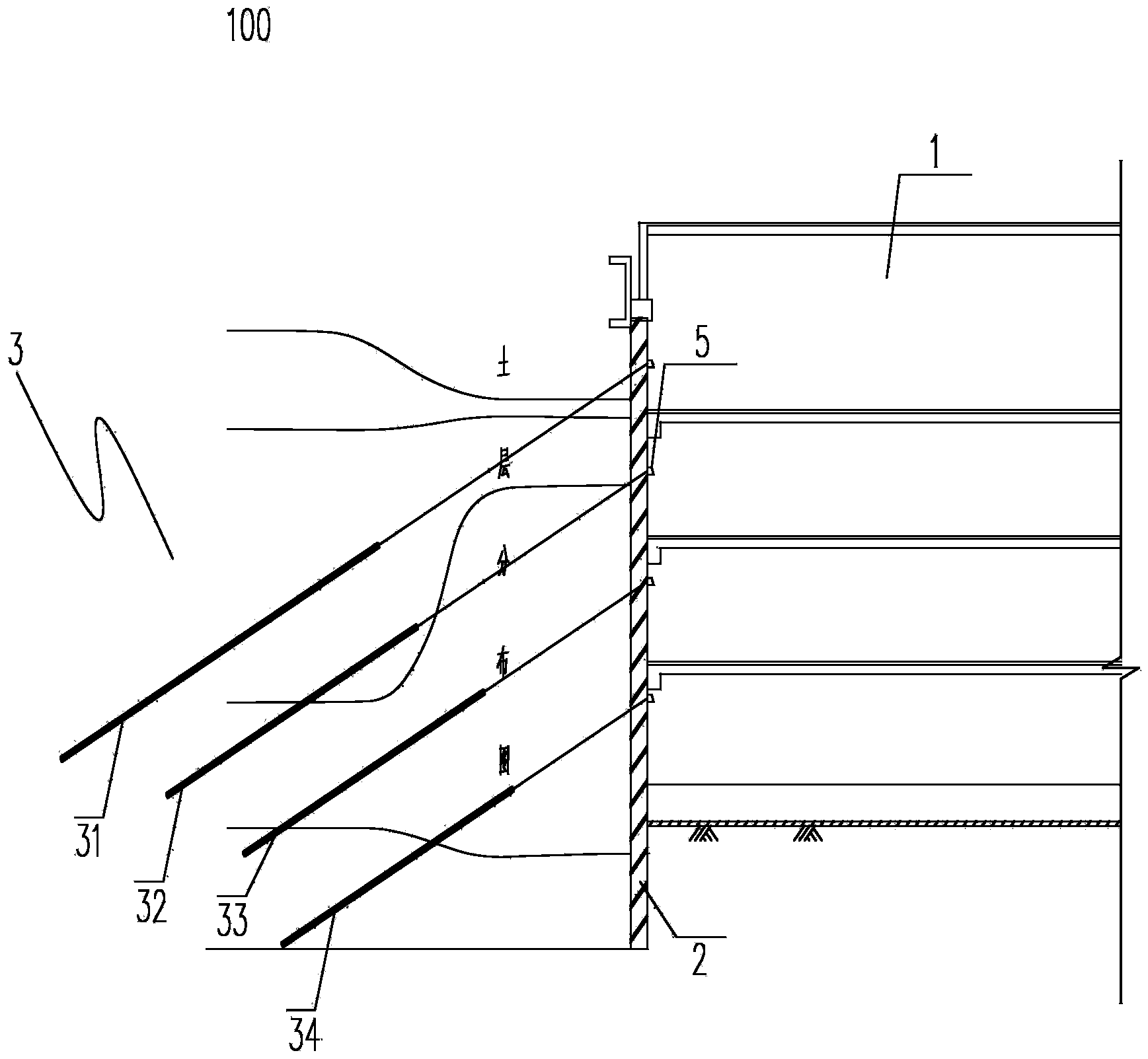

Offshore deep foundation pit supporting structure and construction method thereof

ActiveCN103726495AGood waterproofImprove waterproof performanceExcavationsBulkheads/pilesSlurry wallBuilding construction

The invention provides an offshore deep foundation pit supporting structure and a construction method of the offshore deep foundation pit supporting structure, and belongs to the technical field of deep foundation pit construction. The offshore deep foundation pit supporting structure comprises a plurality of underground continuous walls, a plurality of anchor ropes and anchors, wherein the underground continuous wall is located on the outer edge of a deep foundation pit and connected end to end in a surrounding mode, a plurality of sleeves are embedded into each underground continuous wall, one end of each anchor rope is fixed to the corresponding underground continuous wall through the corresponding anchor, the other end of each anchor rope penetrates through the corresponding sleeve and is fixed into soil outside the deep foundation pit, each anchor comprises a rubber sealing plate and a plurality of expansion bolts, a pipe opening in the side, close to the deep foundation pit, of each sleeve is covered with the corresponding rubber sealing plate, and each rubber sealing plate is fixed to the corresponding underground continuous wall through the corresponding expansion bolts. The offshore deep foundation pit supporting structure has a quite excellent water stopping effect.

Owner:SHANGHAI CONSTR NO 5 GRP CO LTD

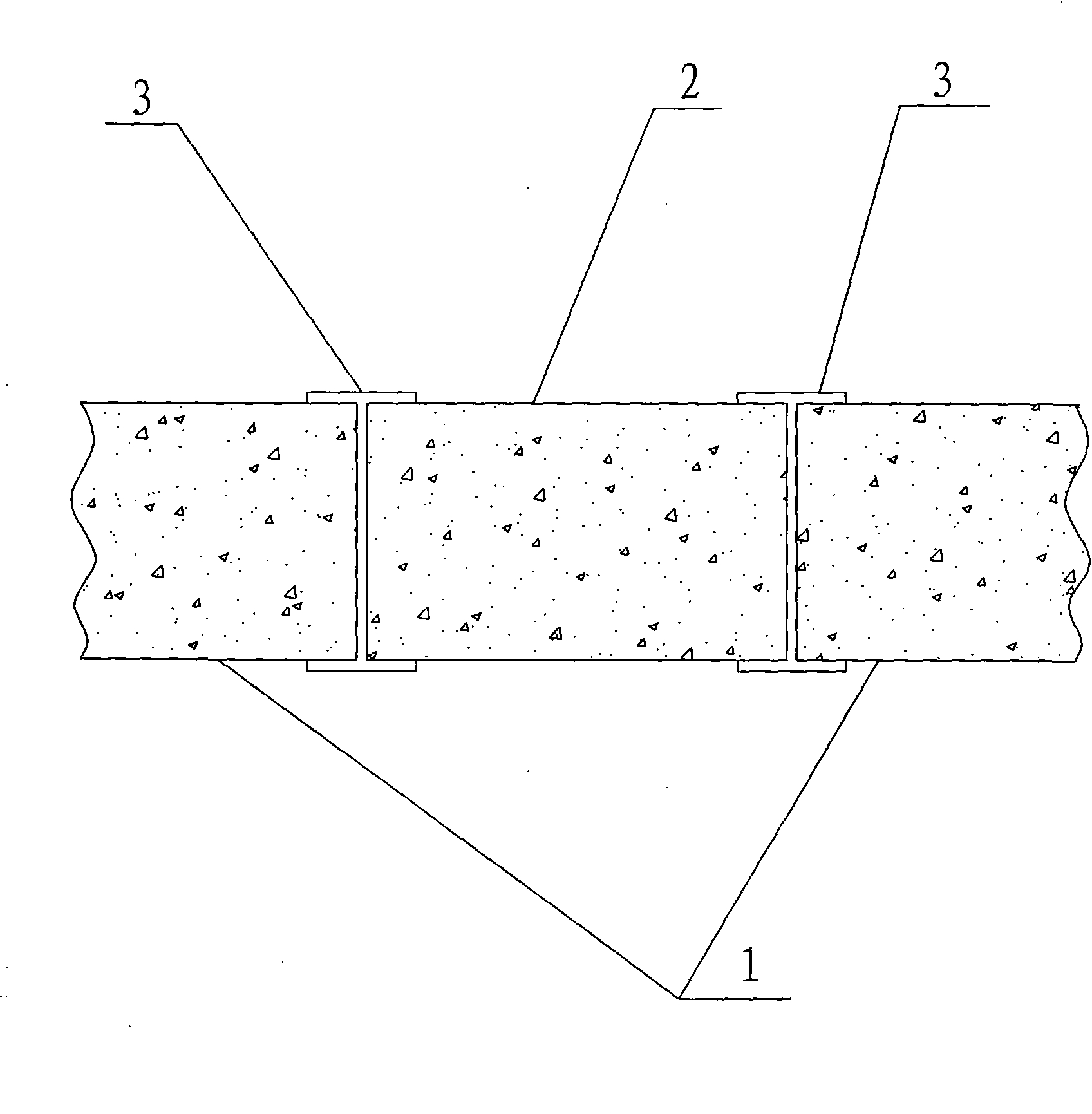

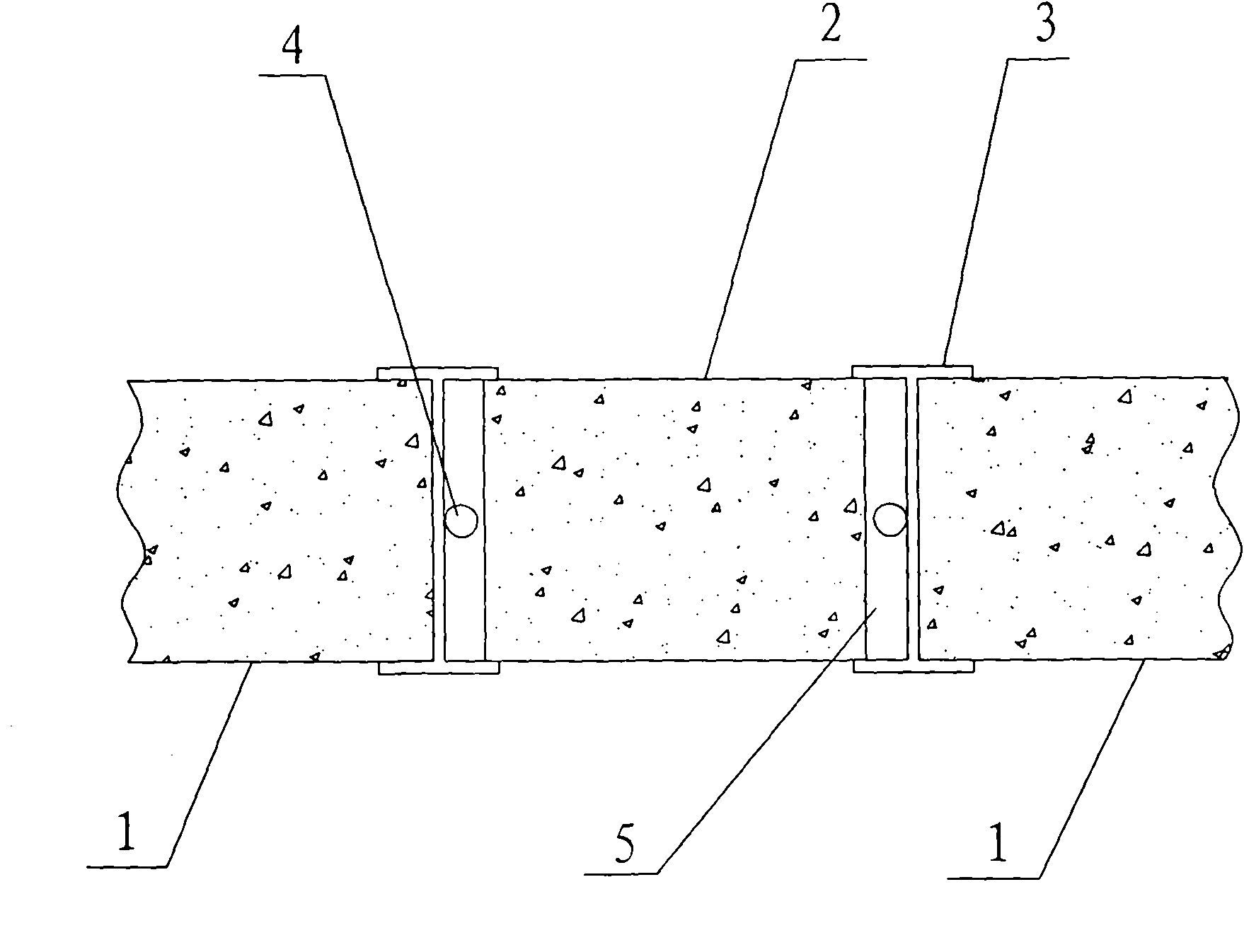

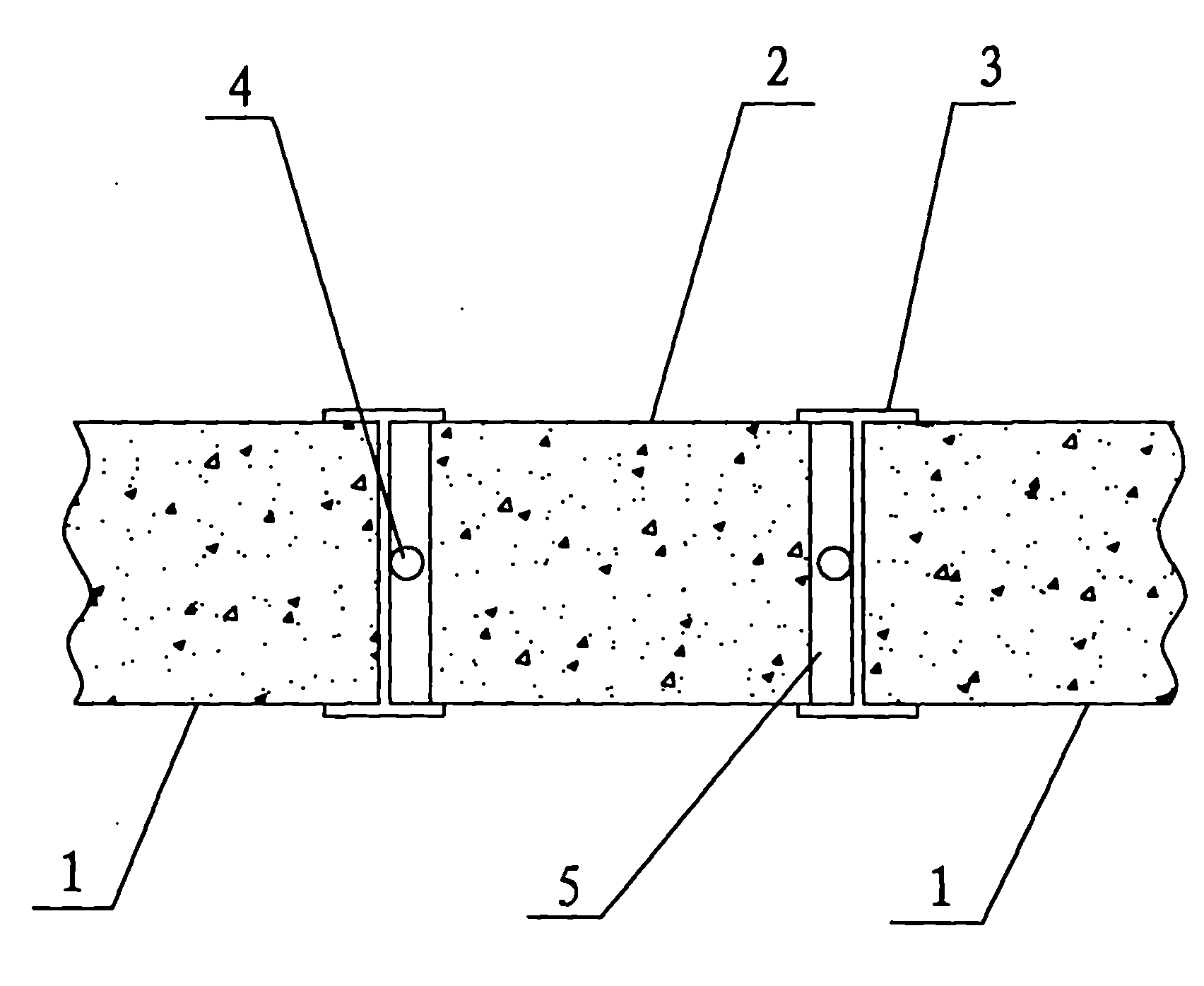

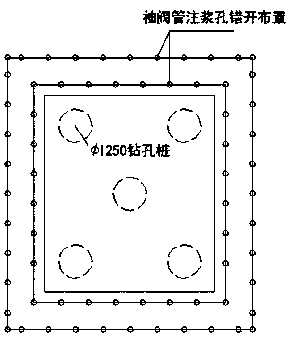

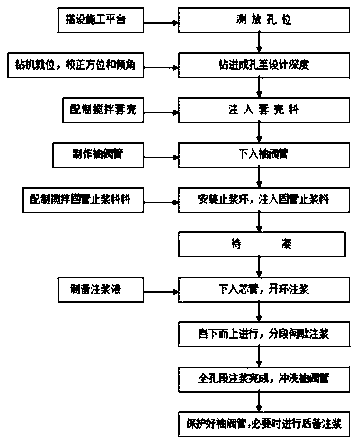

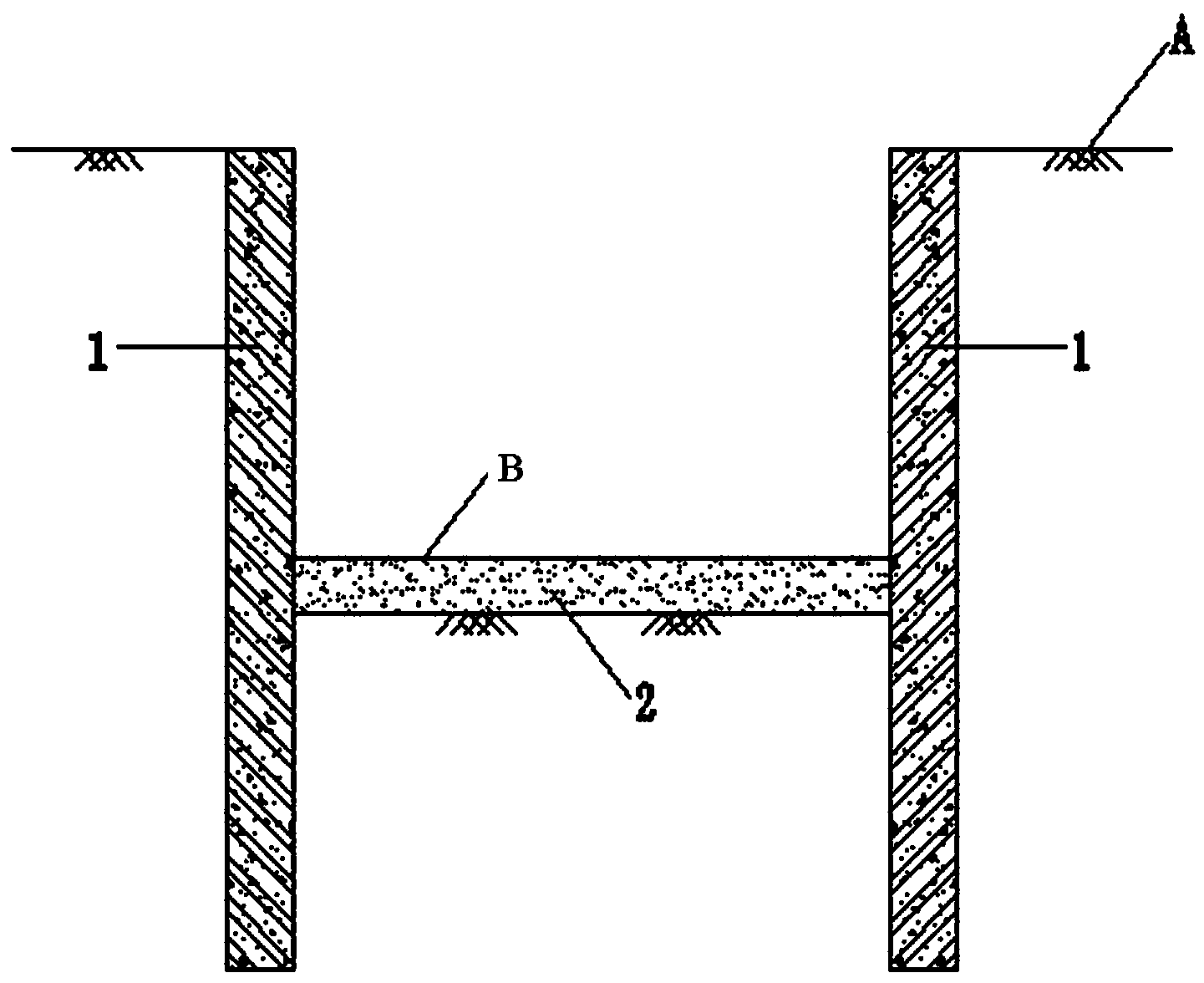

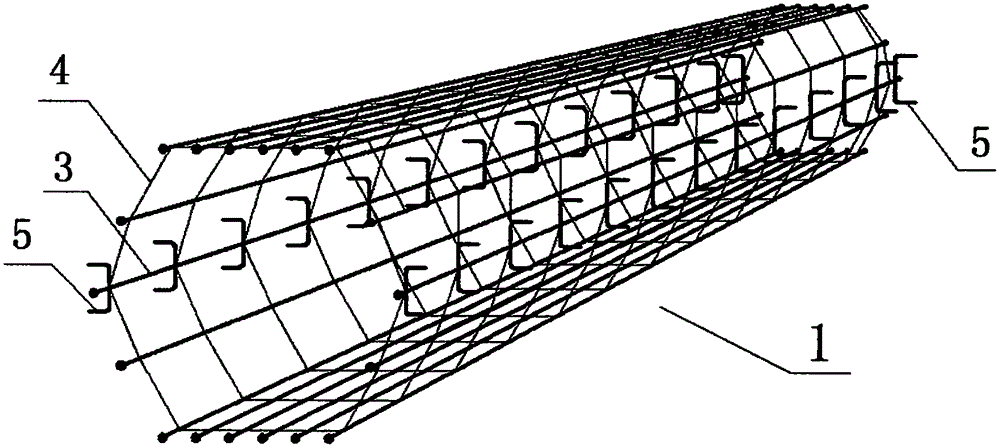

Diaphragm wall joint and manufacturing method of diaphragm wall

InactiveCN102061710AGood terrain adaptabilityNot easy to gushing water and sandArtificial islandsUnderwater structuresJoistWater leakage

The invention discloses a diaphragm wall joint and a manufacturing method of a diaphragm wall. The diaphragm wall joint comprises two sections of first-stage walls in one foundation pit, wherein the sides of the two sections of walls are opposite; the opposite sides of the first-stage walls are respectively and fixedly connected with two joist steel webs; one section of second-stage wall is arranged in a middle foundation pit; and the second-stage wall is connected with the joist steel webs by adopting a sleeve valve tube for grouting. The manufacturing method of the diaphragm wall aims to manufacture the diaphragm wall. For the diaphragm wall joint, the second-stage wall is utilized to transit; the connecting position is fixed by the joist steels and grouted by a sleeve valve tube, thus having good structure adaptability, no water leakage, low possibility of water burst and sand burst, good water-stopping effect, and safety and reliability. In the manufacturing method, substage grouting is carried out on wall sections in the joint, and the fillers of the joist steel webs are washed and then grouted, thus realizing fast forming and firm connection for the joint, and avoiding the water burst and the sand burst.

Owner:GUANGDONG FOUND ENG GRP CO LTD

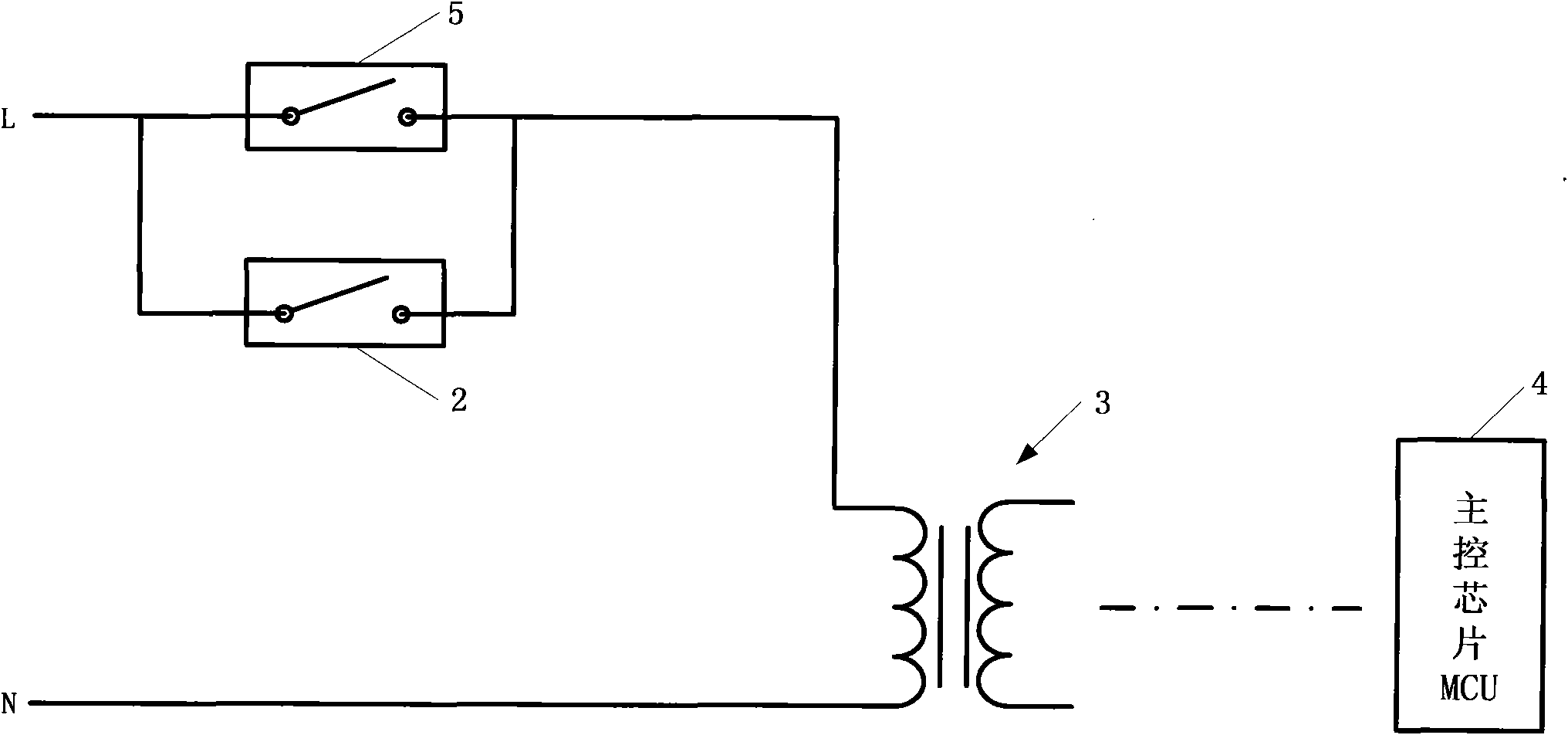

Power-on circuit for washing machine and power-on method thereof

InactiveCN101858025AGood waterproofSimple structureOther washing machinesControl devices for washing apparatusElectricityEngineering

The invention relates to a powder-on circuit for a washing machine. The circuit comprises a door cover plate and a control panel, wherein the door cover plate is hinged with a washing machine body; the control panel can be used for a user to operate; the control panel is provided with a touch key; a linked switch is arranged at the position where the washing machine body is contacted with the door cover plate or in a lock hole of a door lock; and the linked switch is connected with a master relay in parallel and is connected with a main control unit (MCU) through a transformer. The invention also discloses a power-on method for the power-on circuit of the washing machine. In the circuit and the method, the linked switch which can control the power on of the control panel is arranged on the washing machine body, and linkage is realized by the linked switch and an opening action of the door cover plate or the door lock; and when the door cover plate or the door lock is open, the MCU supplies power to the control panel so that the overall control panel becomes more coordinate and beautiful. The power-on circuit has the characteristics of high waterproofness, simple structure and convenient use, and can avoid a key damage phenomenon caused by long-term use.

Owner:WHIRLPOOL CHINA

Production method for fireproof and waterproof carbonized woods

InactiveCN102528878AReduce hygroscopicity and water absorptionGood waterproofWood charring/burningWeather resistanceHydroxyl radical

The invention discloses a production method for fireproof and waterproof carbonized woods, comprising the steps of preparing a using solution, wherein the using solution contains sodium silicate and water based on a mass ratio of 1:(4-7); absorbing the using solution by wood materials; solidifying the wood materials to fix the sodium silicate in the wood materials; and carbonizing the wood materials into the carbonized woods. The production method for fireproof and waterproof carbonized woods has the following advantages: the sodium silicate solution is absorbed by the wood materials, the sodium silicate is fixed in the wood materials, and the wood materials are carbonized; in a carbonizing process, sodium silicate can produce a silica gel solid with excellent water resistance and silicon dioxide, hemicelluloses in the wood materials are degraded, and hydroxyl radicals in cell walls of the wood materials are reduced, so that the production method has the following beneficial effects: 1) the moisture absorbability and the water absorbability of the wood materials are reduced, so that the water resistance is excellent; 2) the fireproof performance of the wood materials is improved, so that the fireproof performance is excellent; 3) the size stability is enhanced, so that the carbonized woods are hard; 4) the biological rotproofness is excellent; and 5) the weather resistance is excellent. Therefore, a wood product which has the advantages of excellent performance, beautiful color and environmental friendliness and is suitable for outdoor environment can be produced.

Owner:FUJIAN ZHANGPING KIMURA FORESTRY PROD

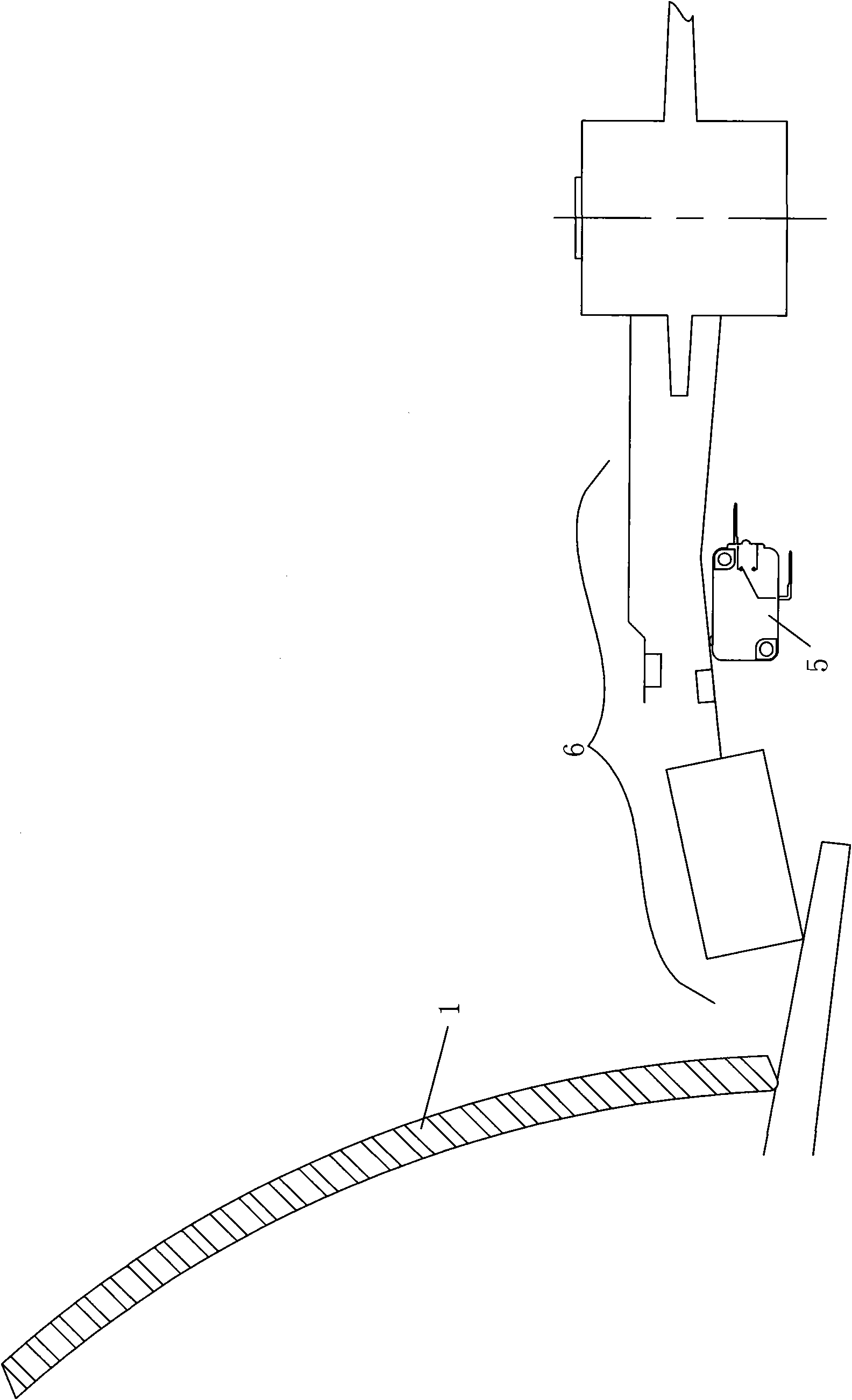

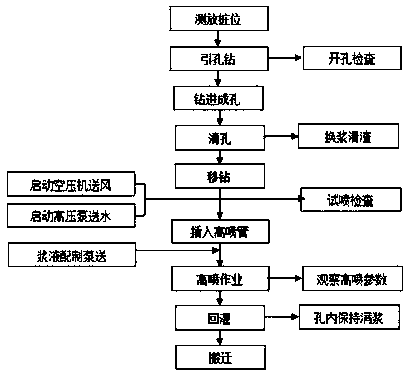

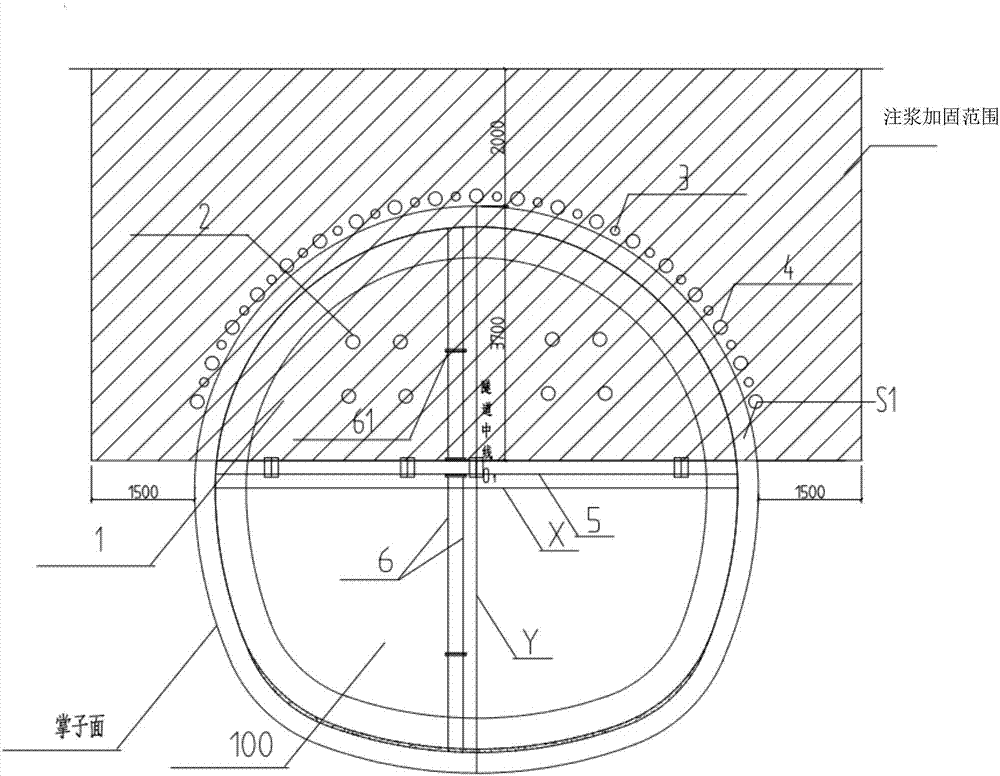

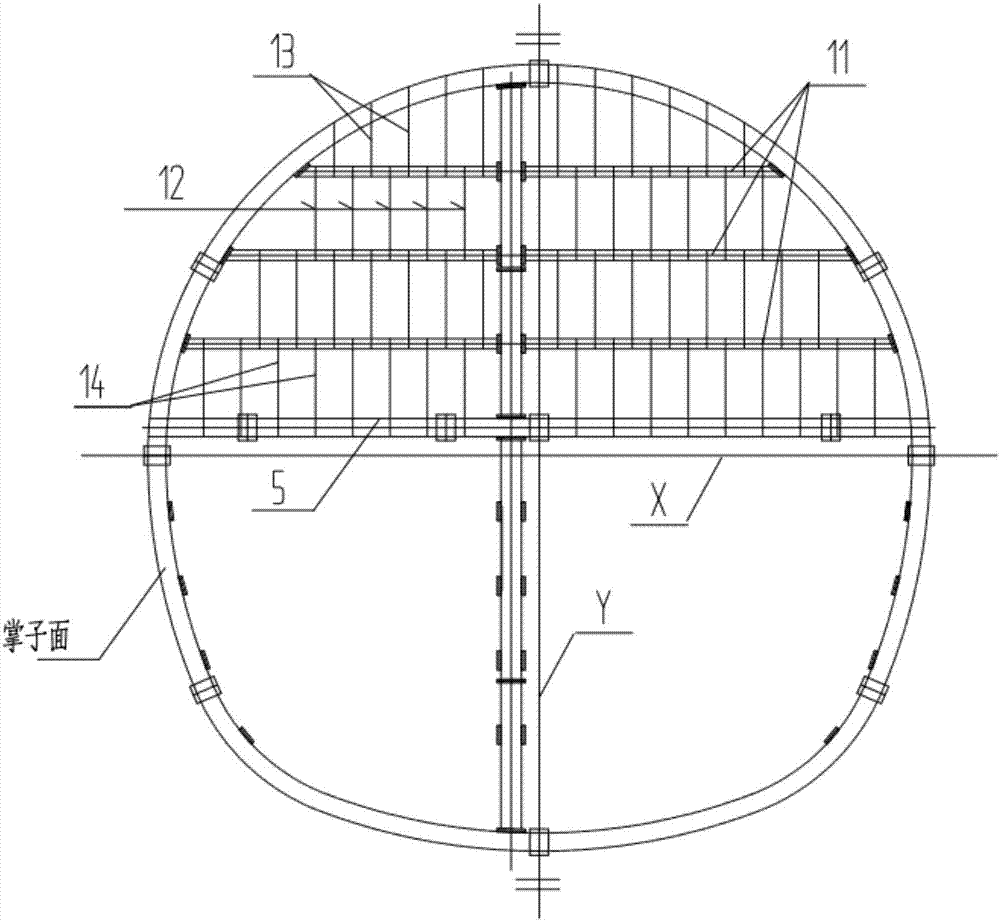

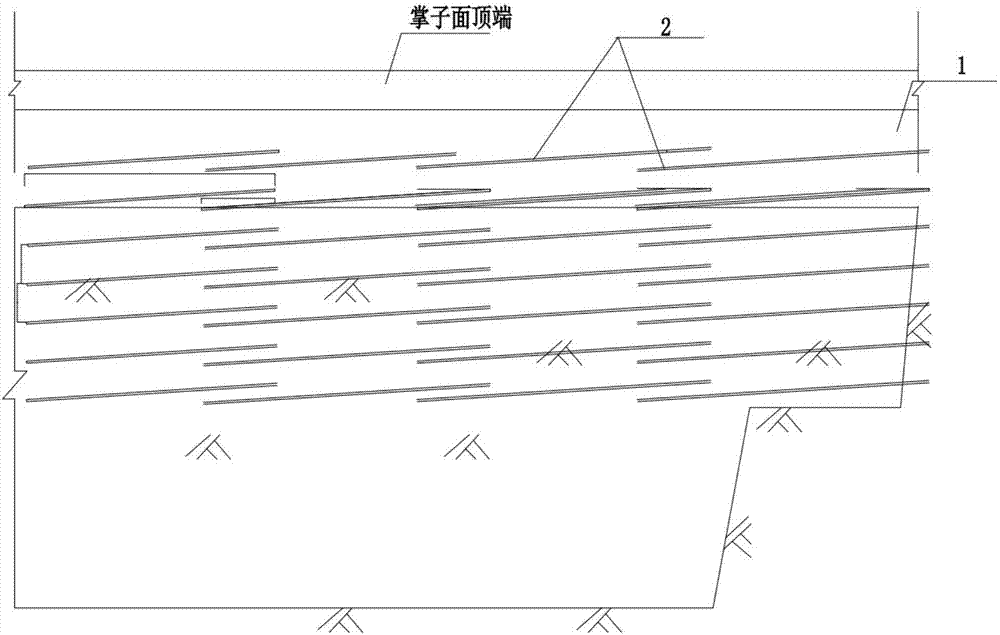

Subway tunnel shield end reinforcing method

InactiveCN108951612AImprove uniformityGood self-relianceTunnelsBulkheads/pilesSleeve valveCompressive strength

The invention discloses a subway tunnel shield end reinforcing method. The subway tunnel shield end reinforcing method comprises the following steps of reinforcing the shield end head, reinforcing thewater supply pipe and reinforcing the bridge pier, and the shield end reinforcing method is reinforced by using a high-pressure rotary spraying pile with Phi 800@600, the water supply pipe reinforcement and the bridge pier reinforcement are reinforced through a sleeve valve pipe. The reinforcing method has the advantages that the reinforced soil body has good uniformity, self-supporting propertyand water stopping property, the non-lateral limit compressive strength of the reinforced soil body is not less than 1 Mpa, and the permeability coefficient is less than 1.0*10 <-5> cm / s, no large bump or settlement exists on the ground after the soil body is reinforced, the construction period is short, and the safety of subsequent construction is ensured.

Owner:CHINA RAILWAY NO 3 GRP CO LTD +1

Water-seal structure with expansion joint and spraying and filling construction method for forming same

ActiveCN103696396AImprove the water-stop effectIncreased durabilityMarine site engineeringElastomerEngineering

The invention discloses a water-seal structure with an expansion joint. The side wall and upper edge of the expansion joint are provided with primer layers; an elastic waterproof filling body is filled in the expansion joint, the upper edge of the expansion joint is provided with a polyurea elastomer waterproof coating. The water-seal structure is good in water-seal property and durability and strong in impact and abrasion resistance, has capability of adapting to three-dimensional deformation of the expansion joint, and is simple in construction. The invention further provides a spraying and filling construction method for forming the water-seal structure.

Owner:CHINA INST OF WATER RESOURCES & HYDROPOWER RES

Organic and inorganic composite self-cleaning finishing agent and its uses

The invention involves a organic and inorganic composite self-cleaning finishing agent and its application method on fiber products, the organic and inorganic composite self-cleaning finishing agent includes 40% component A and 60%B component (weight percentage), its application method on fiber products includes: (1) freshly preparing component A and B organic and inorganic composite self-cleaning finishing agent, (2) slop padding work solution and fiber products, drying and curing, (3) characterizing the self-cleaning property of textiles through the water repellency, oil repellency and soil release property. The organic and inorganic composite self-cleaning finishing agent in the invention has good stability and repeatability, it has good water repellency, oil repellency and soil release property when it is applied in fiber products, it can meet the needs of developing various fiber high-grade self-cleaning rib fabrics.

Owner:DONGHUA UNIV +1

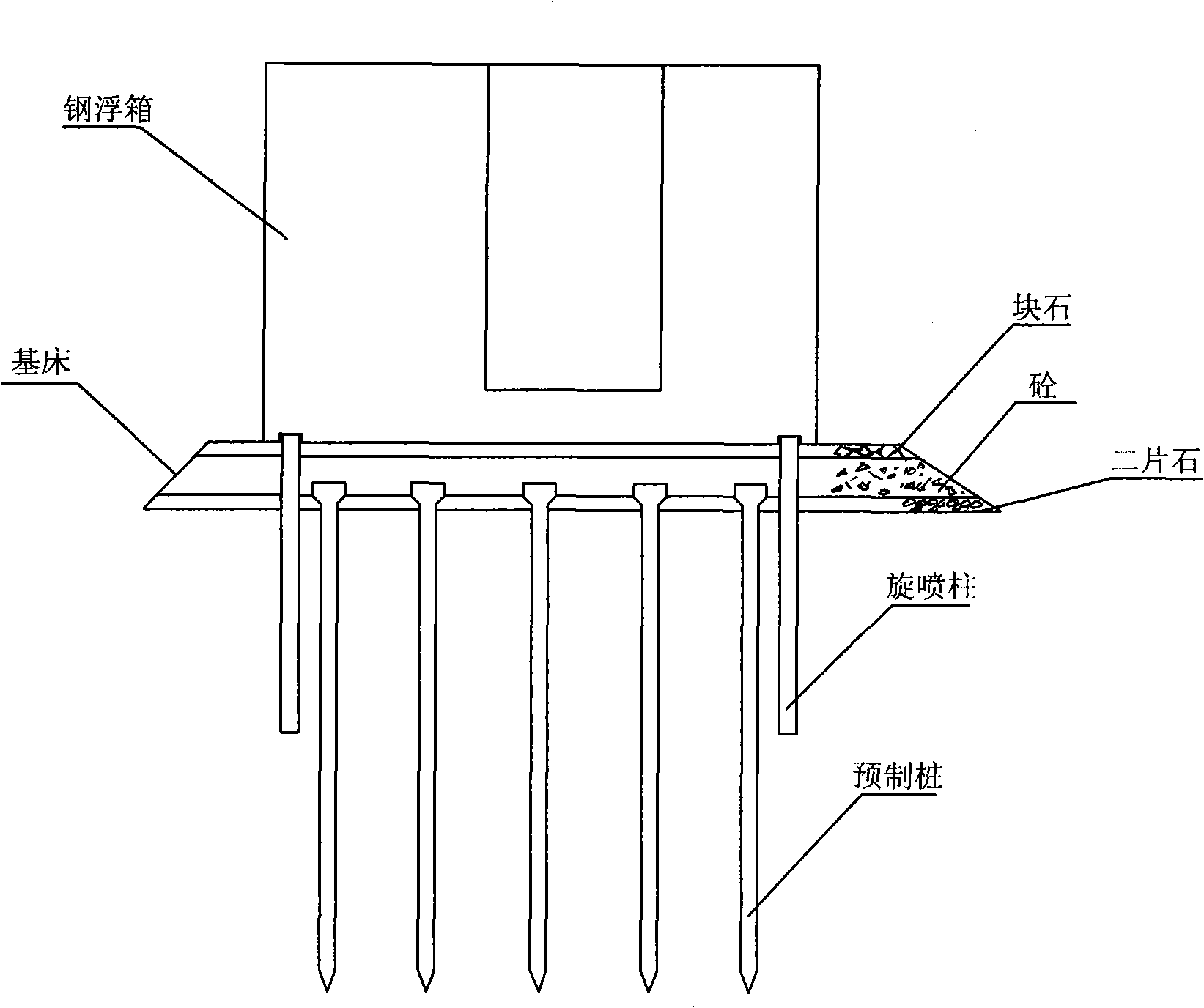

Soft soil foundation large scale steel float lock head construction method

InactiveCN101260664AAdaptableSave construction materialsDry-docksClimate change adaptationCushionWater depth

The invention discloses a soft soil base large-scale steel floating box lock head construction method, which is characterized in that the specific construction steps comprise that: a foundation trench is excavated and silt is removed; a precast pile is beaten; a foundation bed is ripraped and a concrete cushion coat is poured and tamped; a steel floating box is precast and submerged; a waterproof purdah is jet grouted. Compared with the prior art, the invention has the characteristics of strong applicability, mass construction material saving, low construction cost and reliable construction quality; a lock head steel floating box can be also used as construction cofferdam; the soft soil base large-scale steel floating box lock head construction method is in particular suitable for building the lock head in an area with a soft soil base and deep water and can achieve good waterproof effect no matter how depth the foundation bed is.

Owner:ZHONGCHUAN NO 9 DESIGN & RES INST

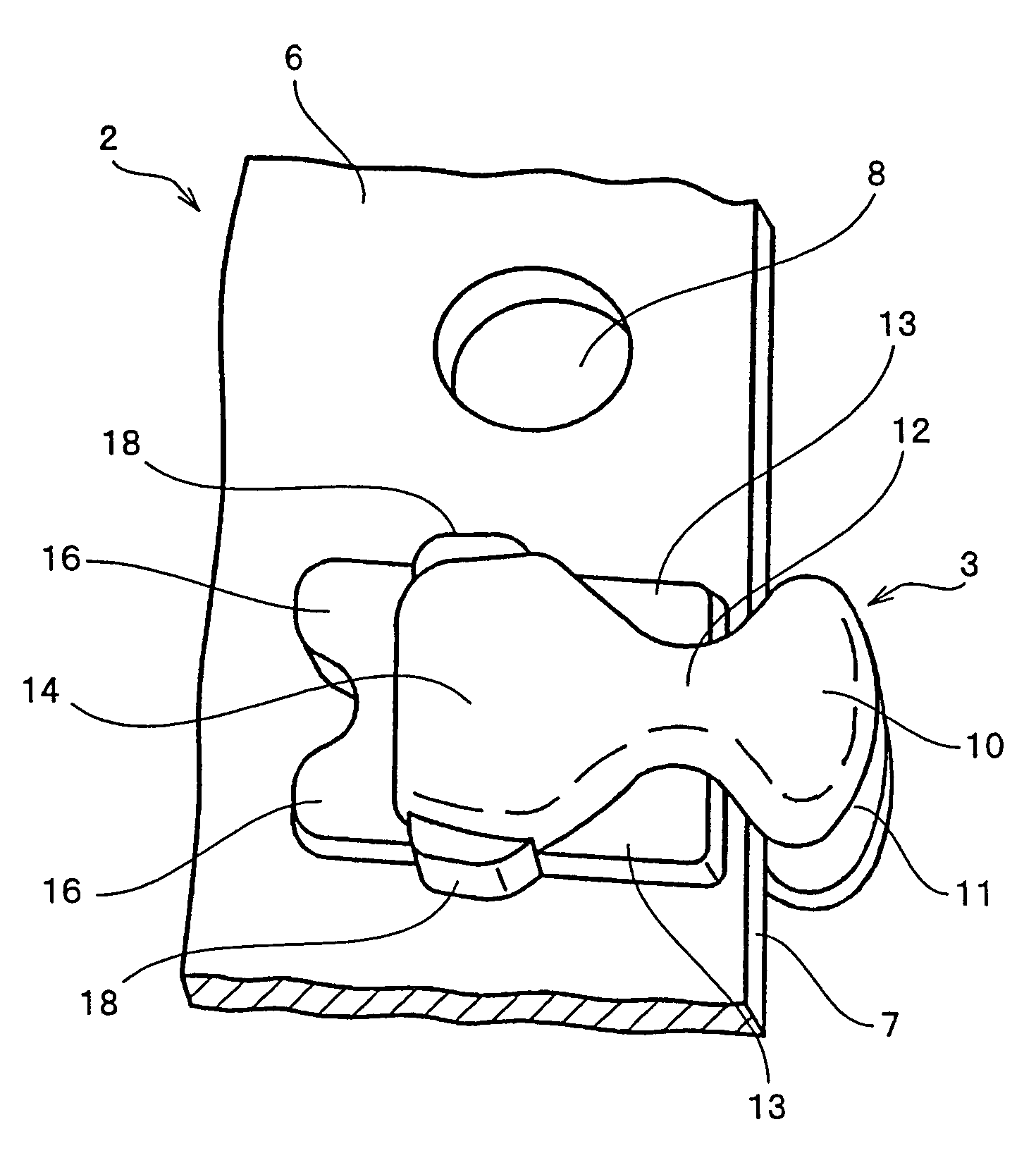

Waterproof slide fastener

ActiveUS7870649B2Waterproof propertyGood waterproofSnap fastenersSlide fastenersElastomerEngineering

A waterproof slide fastener in which an entire surface of a fastener tape is covered with elastomer, through holes are made in a side edge of the fastener tape, and fastener elements each comprising a coupling head, a neck portion, an engaging projection, a leg portion and a tongue piece, are molded by injection molding so as to cover the through holes. Reinforcing portions are provided projectingly from sides of the leg portion so as to cover at least a part of each of the through holes in a longitudinal direction of the through holes made in the fastener tape so that the reinforcing portions surround the through holes, so the reinforcing portions prevent the through holes from being exposed even when the fastener tape is bent, thereby maintaining water-tightness and airtightness.

Owner:YKK CORP

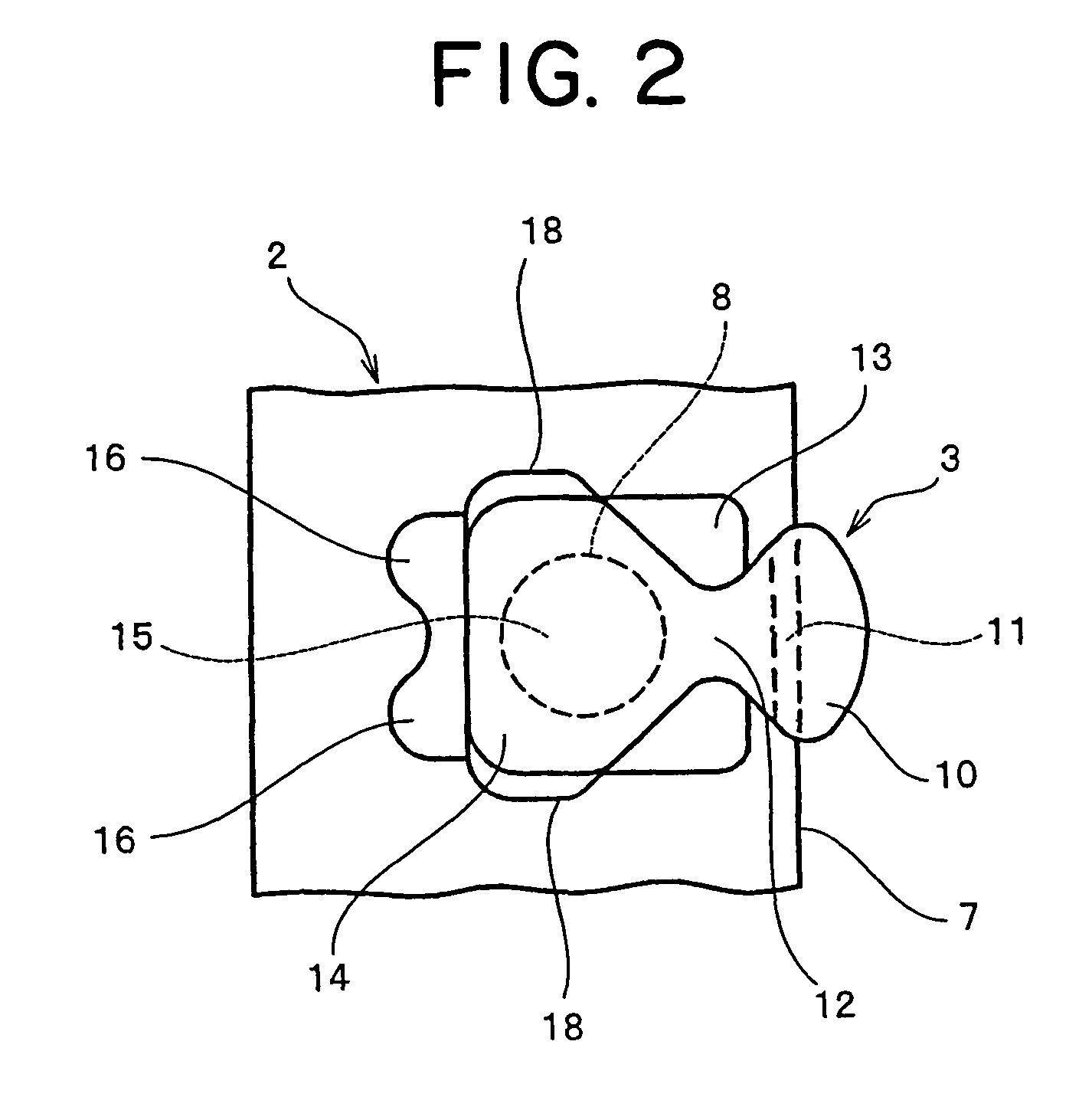

Method for preparing pectinate organic silicon-modified polyurethane grafted ethylene-vinyl acetate (EVA) water emulsion

ActiveCN103834038AGood waterproofImprove waterproof performancePolyurea/polyurethane coatingsEmulsionOrganosilicon

The invention relates to a method for preparing a pectinate organic silicon-modified polyurethane grafted ethylene-vinyl acetate (EVA) water emulsion. The method comprises the following steps: preparing isocyanate-terminated cation polyurethane from diisocyanate, polyether glycol and N-methyldiethanolamine; carrying out grafted reaction on the diluted acrylamide copolymer emulsion and an isocyanate-terminated polyurethane modified body after cationic chain extension modification; and finally modifying by adopting organic silane hydrolysate, so as to prepare an alkaline white emulsion. The prepared product disclosed by the invention has the advantages of EVA resin, polyurethane and polysiloxane, has high comprehensive performance, and can be applied to a water adhesive under a special environment, and preparation of a water-based paint with high performance.

Owner:INST OF APPLIED CHEM JIANGXI ACAD OF SCI

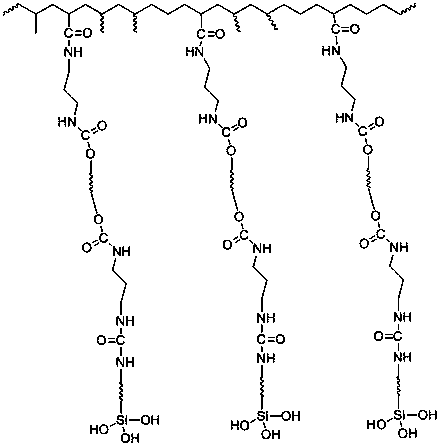

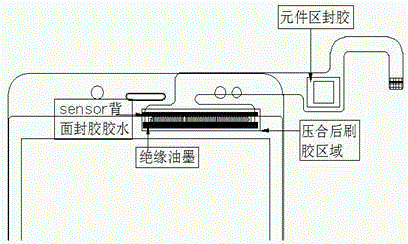

Waterproof treatment technology of capacitive touch screen

InactiveCN105260073ASimple processGood waterproofInput/output processes for data processingPhysicsElectrically conductive

The invention discloses a waterproof treatment technology of a capacitive touch screen. The waterproof treatment technology comprises the following steps: during the production of a sensor of the capacitive touch screen, insulation printing is added for a bonding area circuit as waterproof and anti-corrosion treatment, and the exposed conductive part of the sensor is treated only with silverglue PIN of the bonding area; after being subjected to SMT (surface mount technology) positioning, an FPC (flexible printed circuit) is treated with transparent sealing glue, and exposed bonding pads of a chip IC (integrated circuit), a capacitor, a resister and a diode element are sealed with the sealing glue; after the sensor is manufactured into small pieces and subjected to functional test, hot pressing is performed on the small pieces and the FPC, after pressing, functional test is carried out, then, insulating sealing glue is brushed, and UV drying is performed; the circuit formed through pressing the sensor and the FPC is adhered to a glass cover plate through small piece lamination process, the suspended parts between the FPC and the cover plate are stuck together through double faced adhesive tape, and few copper exposure parts of the FPC on the sensor surface are sealed with white sealing glue for sealing treatment. According to the waterproof treatment technology, the exposed conductive circuit of the touch screen and element bonding pad area are sealed, so as to achieve the waterproof function of the touch screen, and the waterproof treatment technology has the characteristics of easy technology and good waterproofness.

Owner:JIANGXI TIANYI PHOTOELECTRIC

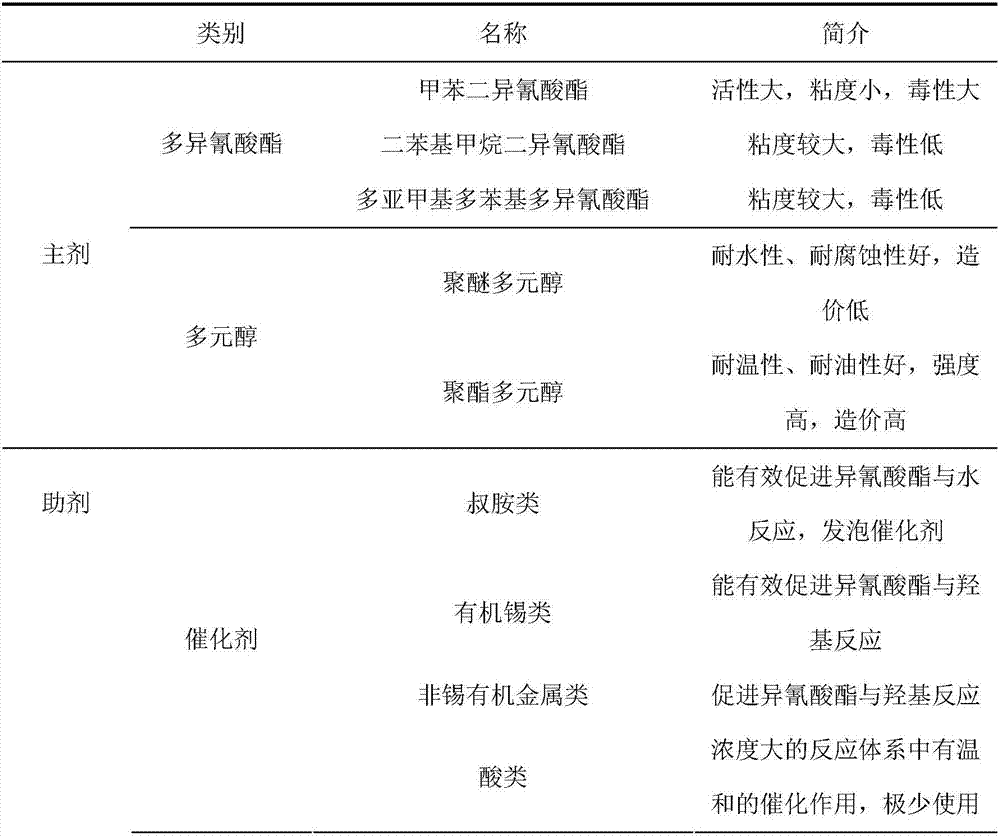

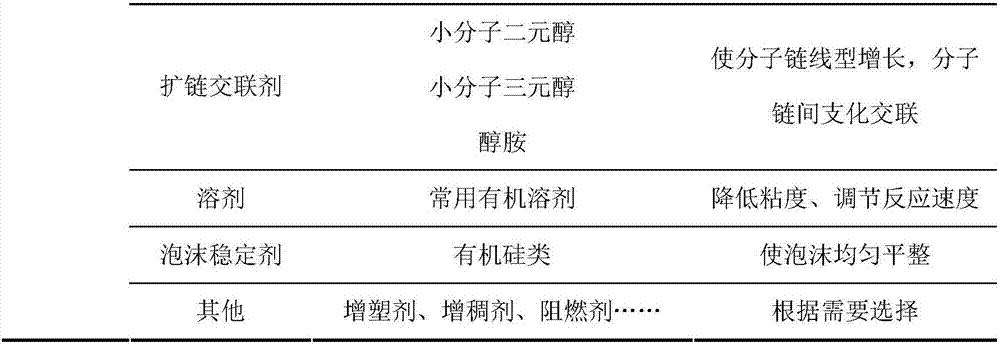

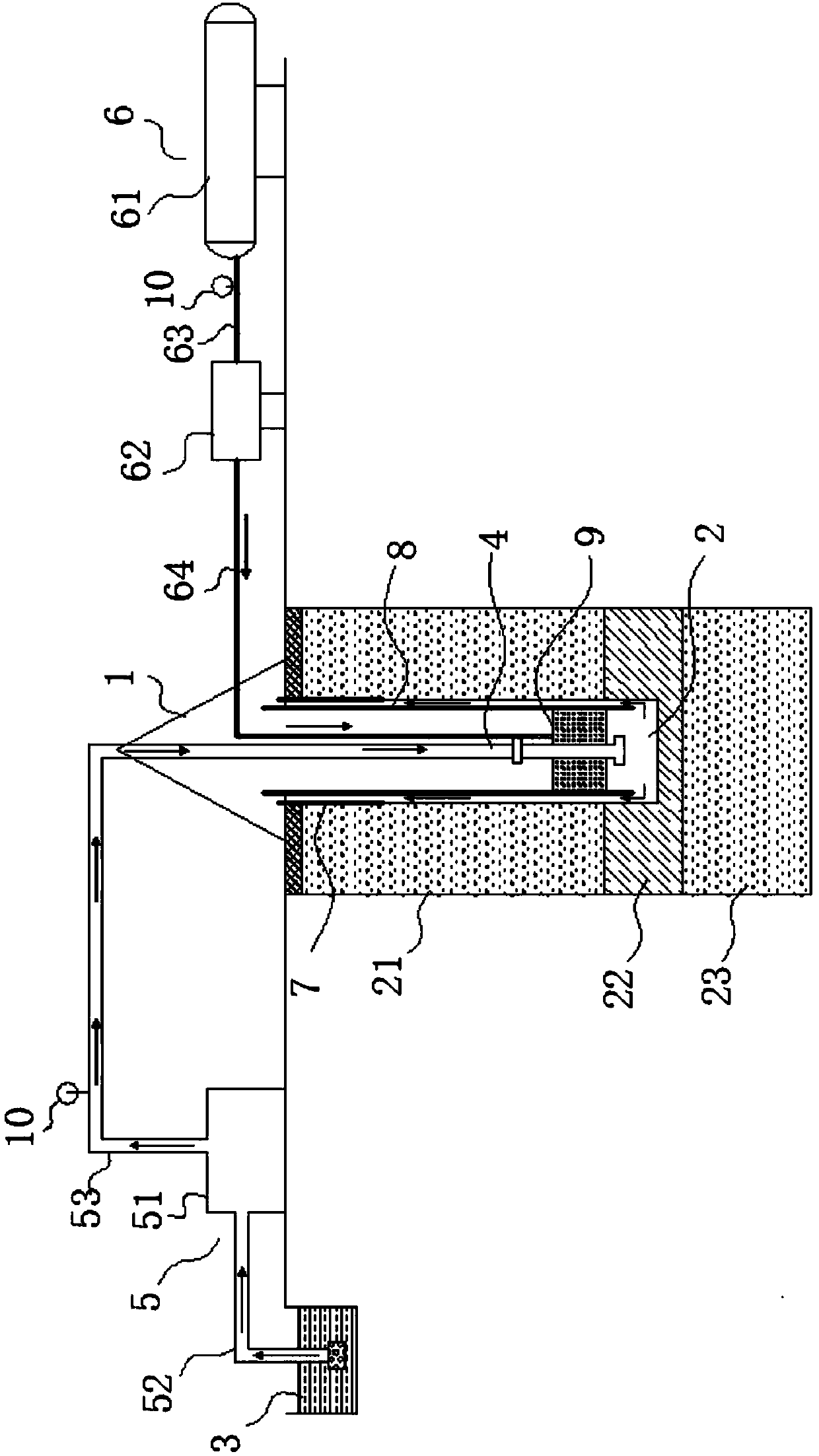

Polyurethane grouting material and preparation method thereof

The invention discloses a polyurethane grouting material and a preparation method thereof. The polyurethane grouting material comprises polyhydric alcohols, polyisocyanates, an organic amine catalyst, an organic tin catalyst, a chain extender and a foam stabilizer. The content of the components is as follows: 1 part of polyhydric alcohols and 1 part of polyisocyanates are contained; the content of the organic amine catalyst is 0.3% of the mass of the polyhydric alcohols; the content of the organic tin catalyst is 1.6% of the mass of the polyhydric alcohols; the content of the chain extender is 0.6% of the mass of the polyhydric alcohols; the content of the foam stabilizer is 1.0% of the mass of the polyhydric alcohols. The preparation method comprises the following steps: dividing the raw materials into two components, wherein the component A includes polyisocyanates and the component B includes the polyhydric alcohols and the additives; adding a defined amount of water into the component B; mixing the components A and B and quickly and fully stirring. The polyurethane grouting material prepared according to the preparation method has the advantages of low toxicity, low pollution, excellent grouting performance, low cost, convenience in construction, and the like, and meets national relevant standard and requirement for water plugging construction in China.

Owner:CHINA UNIV OF GEOSCIENCES (BEIJING)

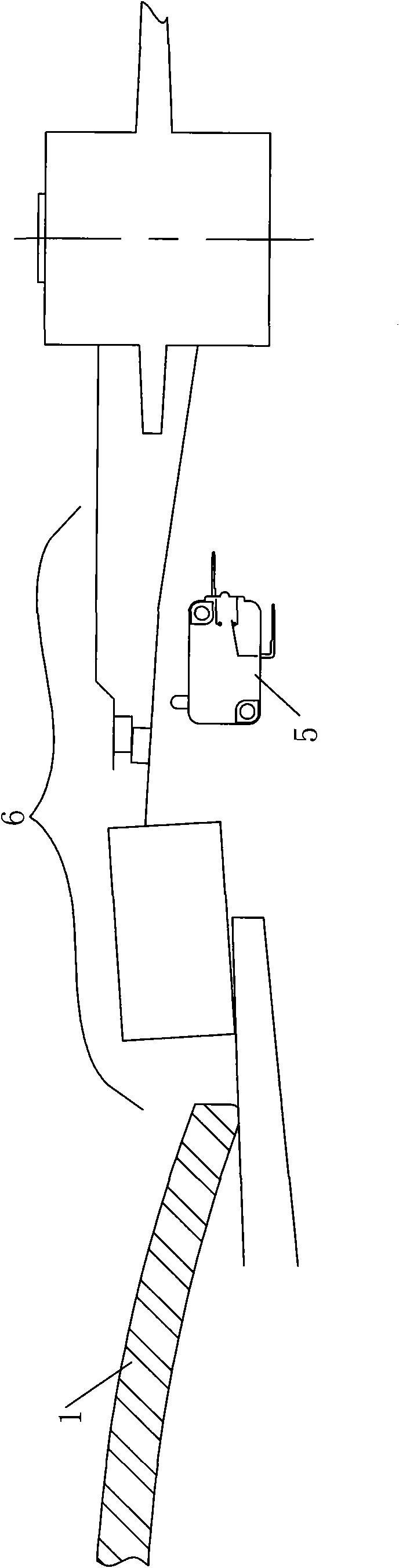

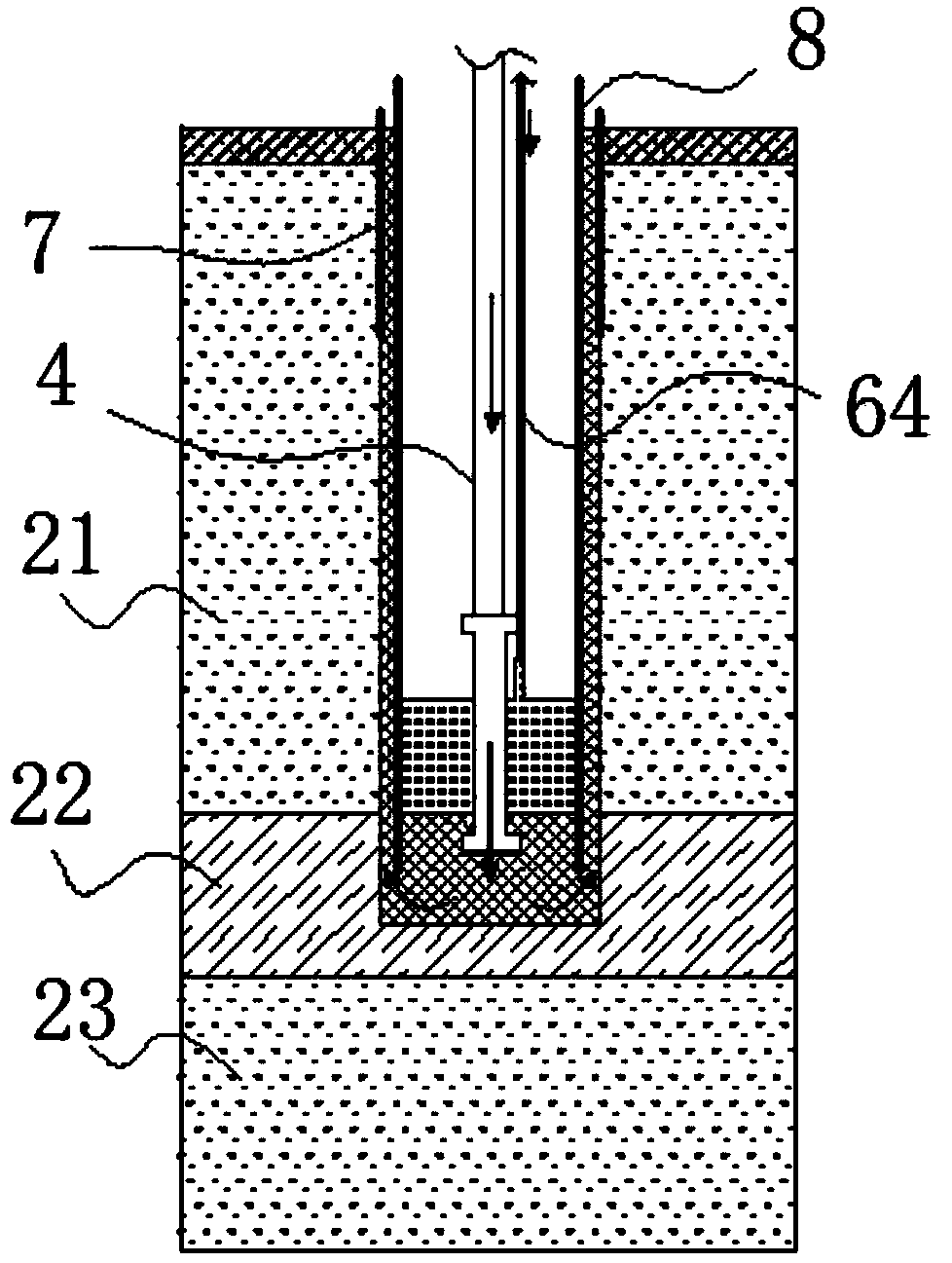

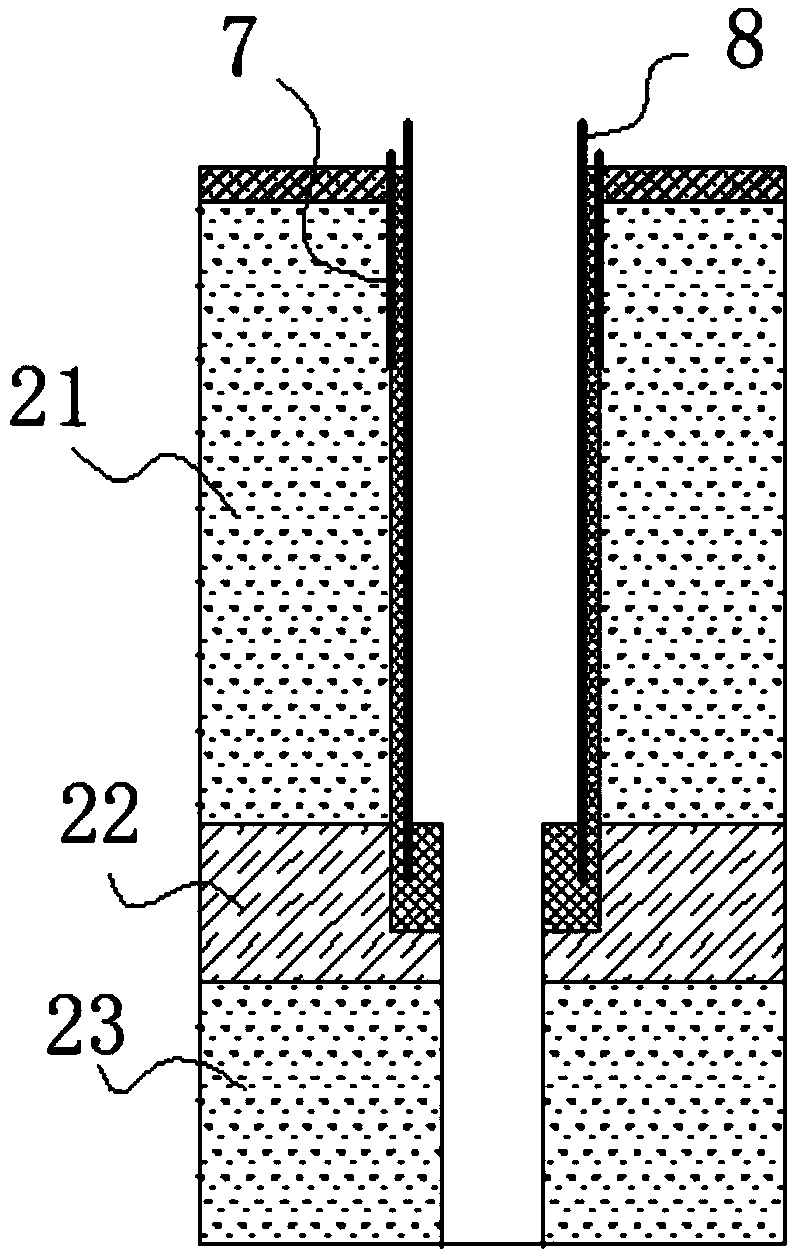

Drill-hole waterstop device and method

The invention relates to a drill-hole waterstop device. The drill-hole waterstop device comprises a drilling machine, a drill pipe, a packer and a casing pipe, wherein the drill pipe is connected withthe drilling machine, one end of the drill pipe is connected with a slurry supply device, the other end of the drill pipe is used for extending into a drill well, the packer is arranged on the drillpipe in a sleeving mode and located in the drill well, the packer communicates with an air supply unit, the casing pipe is arranged on the periphery of the packer in a sleeving mode, and a certain gapis left between the casing pipe and the inner wall of the drill well. The slurry supply device is used for injecting slurry into the drill well through the drill pipe, and the packer is configured tobe that when the air supply unit supplies air to the packer, the packer expands and the size of the packer is increased, so that a channel between the drill pipe and the casing pipe is closed. The invention further relates to a waterstop method utilizing the drill-hole waterstop device. The waterstop method comprises the steps that the casing pipe is down into the drill well, then the packer is down into the casing pipe, the channel between the casing pipe and the drill pipe is blocked off, the slurry is supplied into the drill well through the drill pipe, and therefore a gap between the casing pipe and the well wall is filled with the slurry. According to the waterstop method, the waterstop time can be shortened, the slurry using amount is decreased, and the good waterstop effect is achieved.

Owner:QINGDAO PROSPECTING INST OF GEOLOGICAL ENG +1

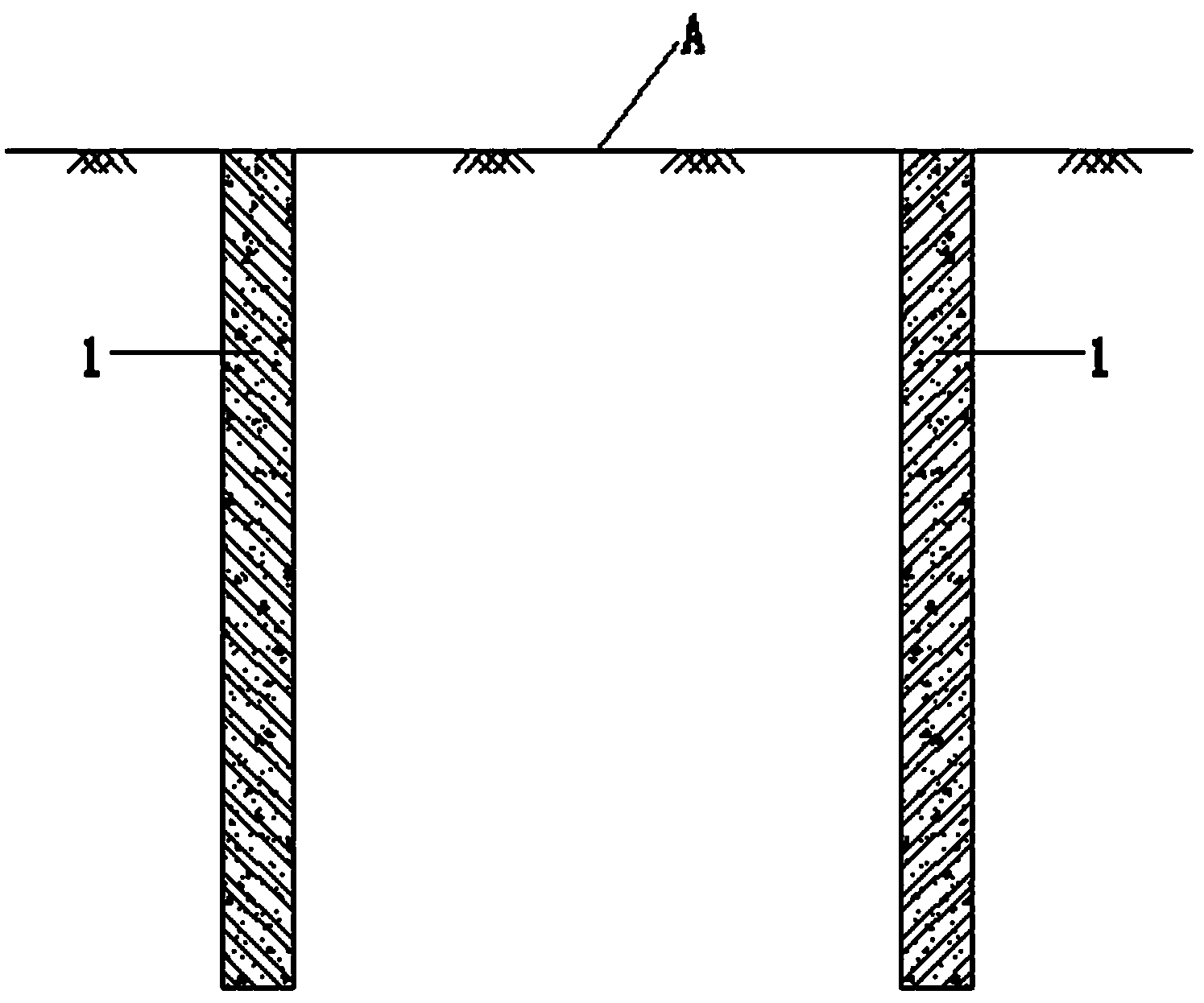

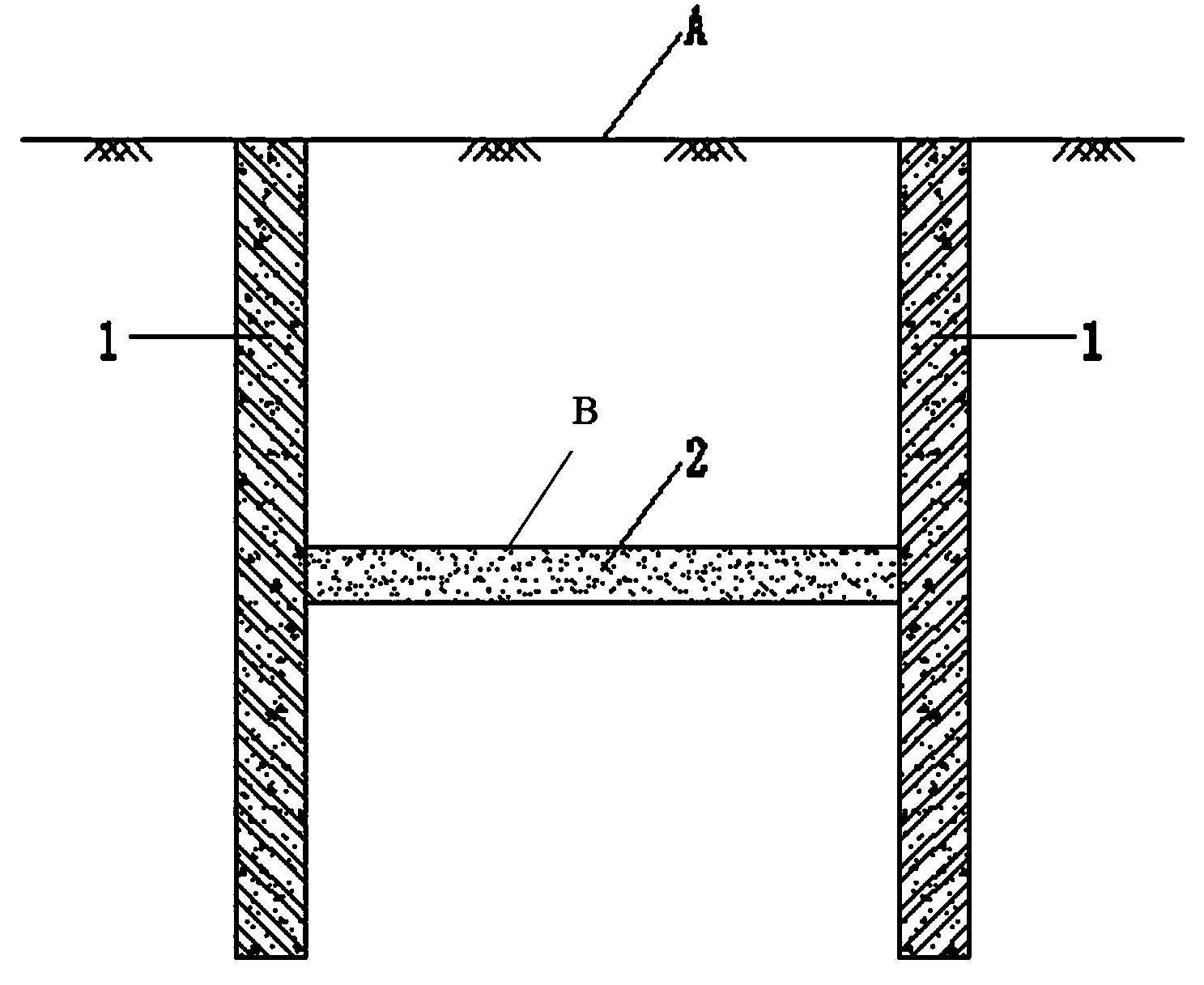

Deep function pit supporting structure in karst geology condition and construction method thereof

InactiveCN104314082AImprove the support effectReduce distortionExcavationsSoil preservationSlurry wallWater leakage

The invention provides a deep foundation pit supporting structure in a karst geology condition and a construction method thereof. The deep foundation pit supporting structure comprises an encircled underground continuous wall (1), and a horizontal grouting reinforcing body (2) which is poured into an encircling area of the underground continuous wall. With the adoption of the deep foundation pit supporting structure, the problem due to serious water leakage occurring in the excavating of the foundation pit under the karst geology condition can be effectively solved; the underground continuous wall has a good effect, and the supporting structure is small in deformation; in addition, the water stopping effect of the sidewall of a foundation pit is obvious, so that the circumstance of water leaking nearly not occurs; the area in the bottom of the foundation pit is subjected to foundation processing by the grouting mode to form a grouting reinforcing body, and thus the channel for water in karst fissures at the bottom of the pit can be effectively cut, and as a result, the problem that water runs from the bottom of the pit can be completely solved; the cement and soluble glass grout is used as the grouting material which can effectively prevent the cement grout from be washed out by the groundwater, and the water blocking and permeating preventing performances of the grouting reinforcing body can be obviously improved.

Owner:YUNNAN CONSTR ENG GRP +2

Fireproof heat insulation composite lightweight sheet material and preparation method thereof

ActiveCN104249496ALight weight strengthGood waterproofLayered productsAcupuncturePhenol formaldehyde resin

The invention belongs to the technical field of composite fireproof heat insulation materials, and relates to a composite lightweight sheet material and a preparation method thereof. The composite lightweight material comprises a plurality of layers of structure acupuncture fiber felt layers and thermosetting phenolic resin layers which are alternatively paved, wherein the uppermost layer and the lowermost layer of the lightweight composite sheet material respectively are the thermosetting phenolic resin layer. Compared with existing heat insulation materials, the fireproof heat insulation composite lightweight sheet material provided by the invention has the advantages of light weight, high strength, good waterproof property, good fireproof property, and good heat and sound insulation property, overcomes the disadvantages of inflammability, easy effloresce and large brittleness of the existing heat insulation materials, improves the compression strength of products, and is convenient to construct.

Owner:SHANGHAI GENIUS ADVANCED MATERIAL (GRP) CO LTD

Prestressed high-strength concrete hollow support pile and manufacturing method thereof

InactiveCN105544531AGuaranteed stabilityBeautiful seamsCeramic shaping apparatusBulkheads/pilesHigh strength concretePre stress

The invention provides a prestressed high-strength concrete hollow support pile and a manufacturing method thereof. The prestressed high-strength concrete hollow support pile comprises a reinforcement cage framework and a concrete pile body. The cross section of the prestressed high-strength concrete hollow support pile is of a polygonal hollow pipe shape. The prestressed high-strength concrete hollow support pile comprises an upper pile body flange plate, a lower pile body flange plate, a left pile body supporting leg, a right pile body supporting leg, a pile body tenon and a pile body mortise, wherein the upper pile body flange plate and the lower pile body flange plate are arranged symmetrically; each pile body flange plate is formed by welding two or more longitudinal prestress main ribs and two or more hoop ribs in a crossed mode; hoop ribs are evenly distributed between the upper pile body flange plate and the lower pile body flange plate in a surrounding mode; the pile body tenon is located on one side of the left pile body supporting leg, the pile body mortise is located in one side of the right pile body supporting leg, and the pile body tenon and the pile body mortise are in engaged fit; reserved grouting slots are formed in the middle of the pile body tenon and the middle of the pile body mortise symmetrically. The prestressed high-strength concrete hollow support pile is firm in structure, good in soil conserving and water stopping effect, easy and convenient to construct and low in project cost, and by adoption of the mechanical and automatic producing and processing procedures, the construction period is short and efficiency is high.

Owner:湖南卓工建材科技有限公司

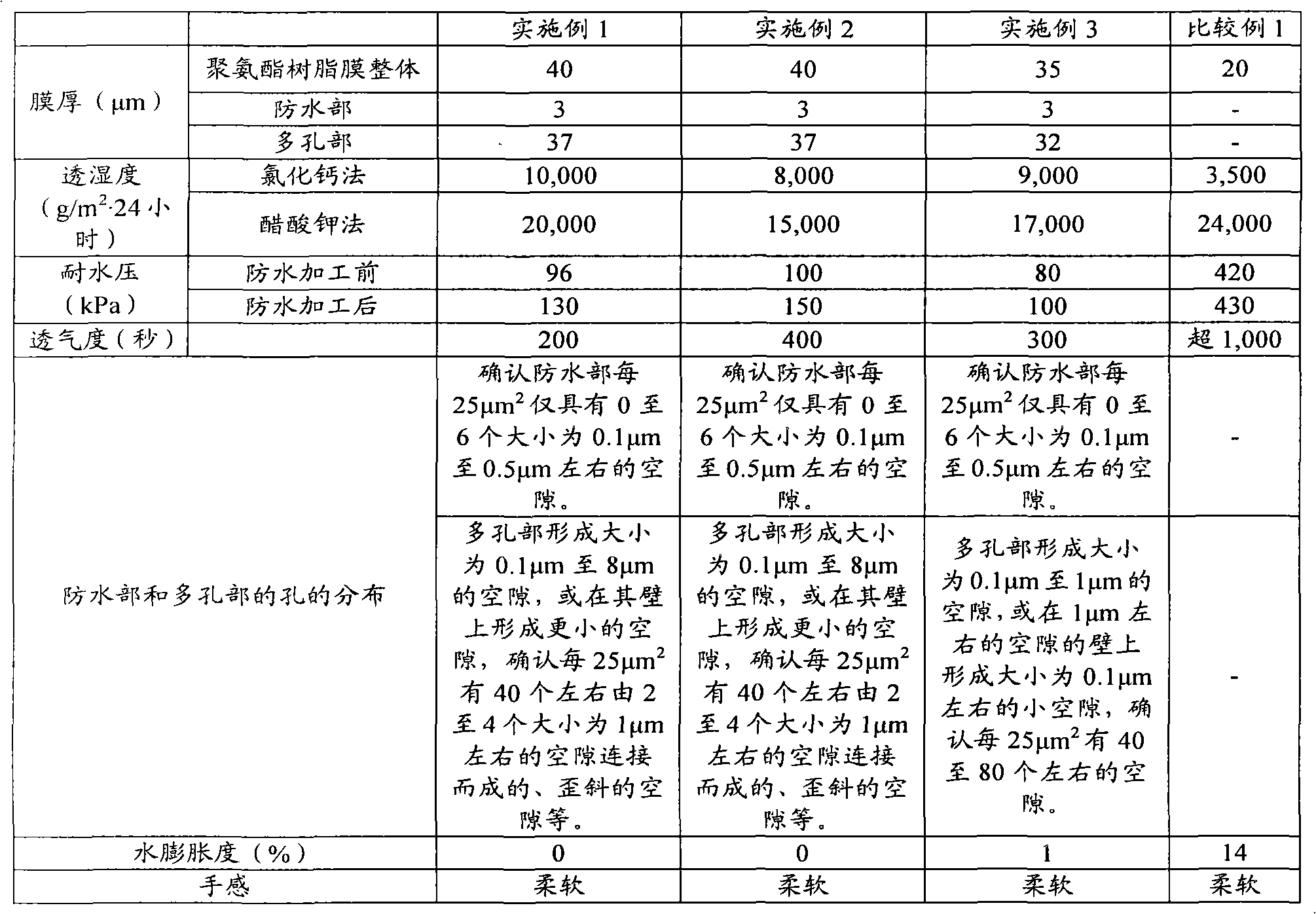

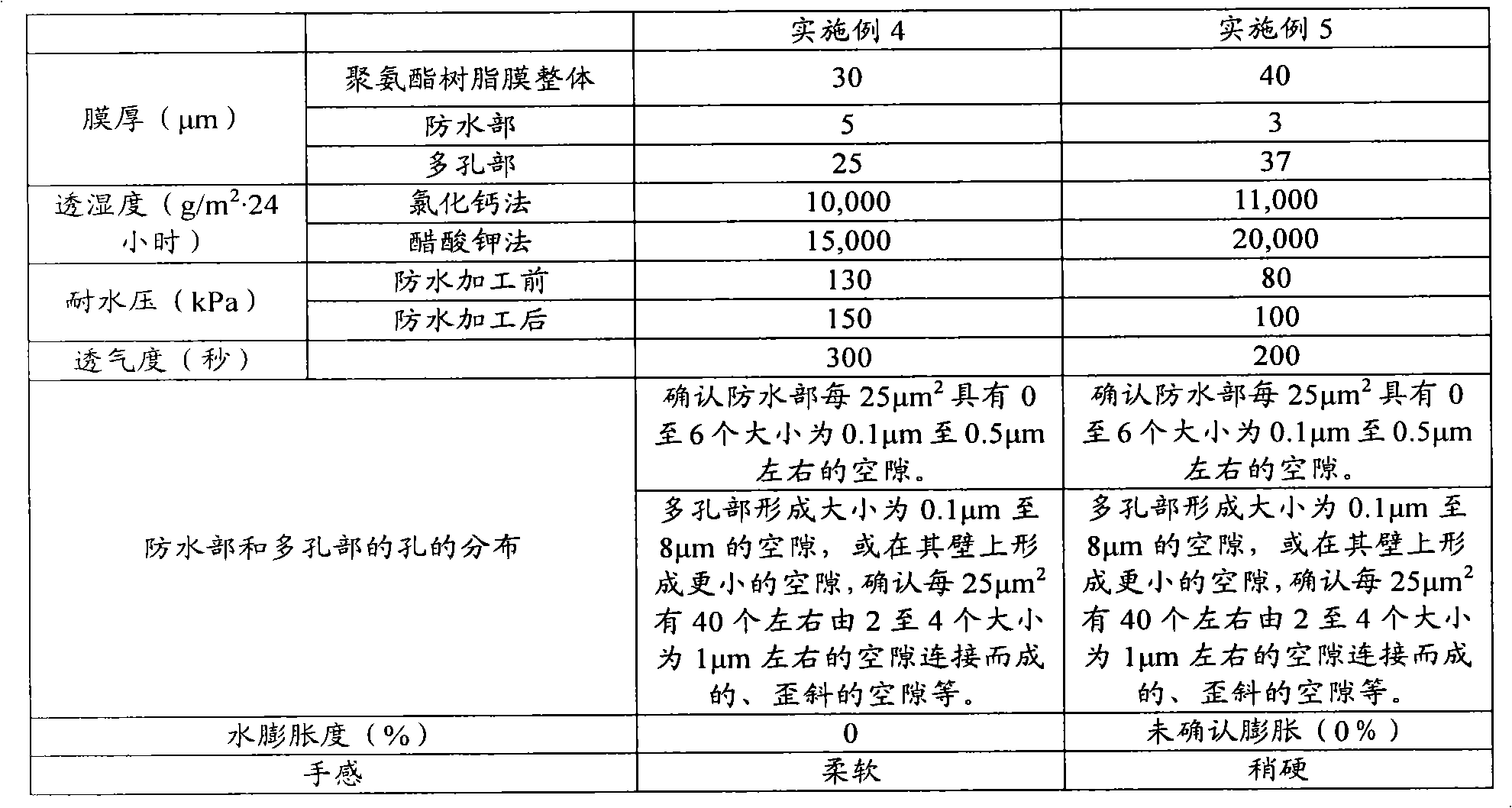

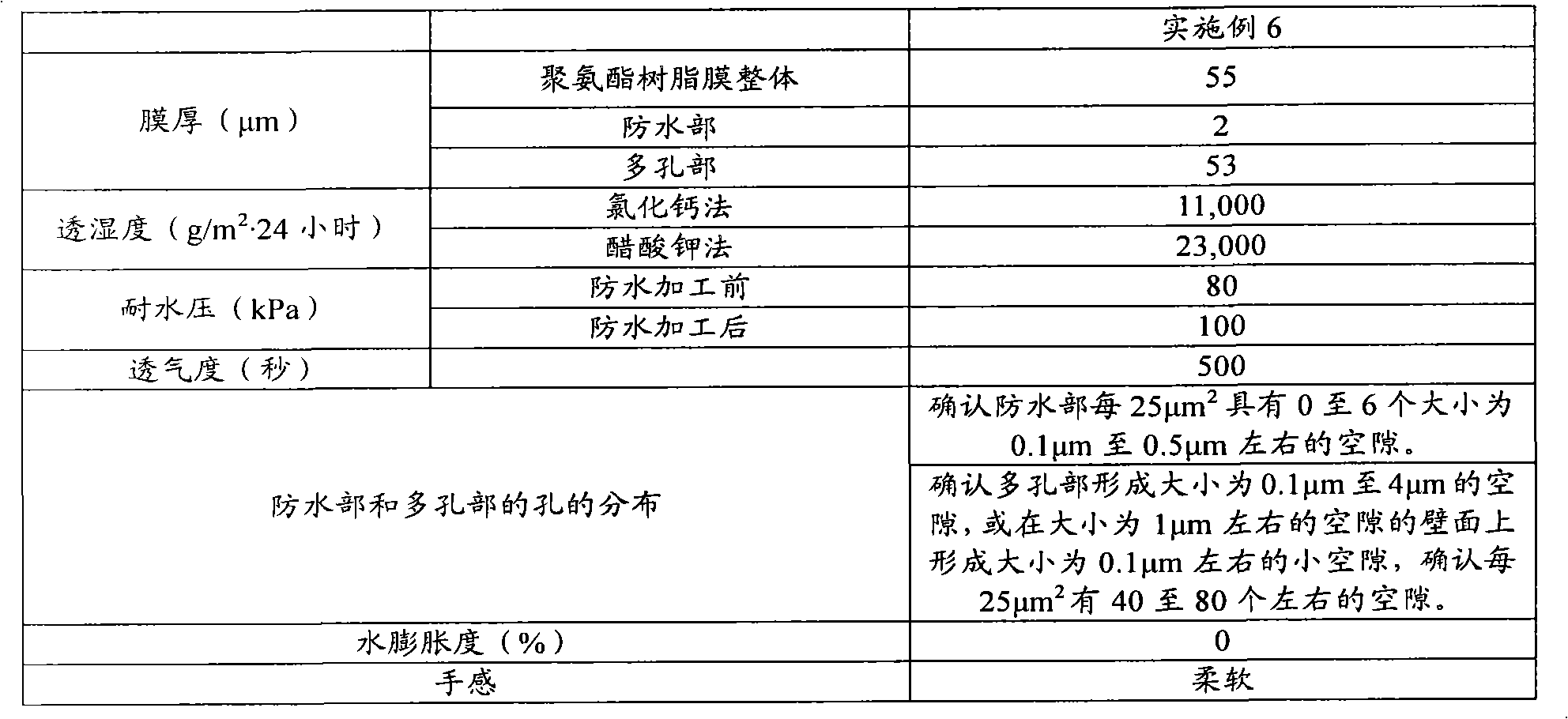

Vapor permeable waterproof sheet and method for producing the same

ActiveCN101588924AGood waterproofCurb the stuffinessSynthetic resin layered productsChemistryMoisture permeability

Disclosed is a vapor permeable waterproof sheet which is high in both water vapor permeability determined by a calcium chloride method and water vapor permeability determined by a potassium acetate method. This vapor permeable waterproof sheet is excellent in waterproof properties and hardly damaged in appearance quality since it is suppressed in water swelling. This vapor permeable waterproof sheet comprises a urethane resin film which is composed of a lamellar porous portion with pores having an average size of 0.1-8.0 [mu]m, and a lamellar waterproof portion formed on one or both sides of the porous portion and having a total pore amount less than that of the porous portion.

Owner:KOMATSU SEIREN CO

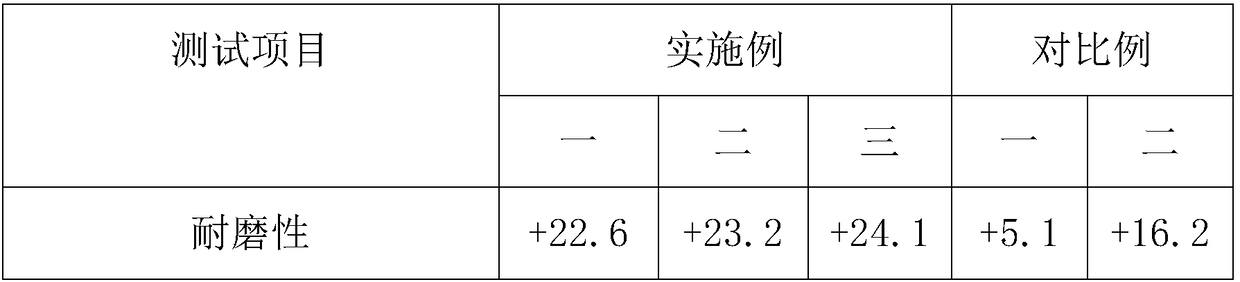

Sofa cover PU leather fabric for yacht, and preparation method thereof

InactiveCN108547156AGood waterproofNot easy to mildewWaterborne vesselsAnti-corrosive paintsCarbon blackWoven fabric

The invention discloses a sofa cover PU leather fabric for a yacht, and a preparation method thereof. The sofa cover PU leather fabric is formed by compounding a base cloth and a modified PU coating,wherein the base cloth is any one selected from a woven fabric or a non-woven fabric, the modified PU coating is formed by coating with a modified PU coating material, and the modified PU coating material comprises the following raw materials: a PU resin, glass fiber powder, silicon dioxide, white carbon black, ethylenebis(stearamide), higher alcohol, chitosan oligosaccharide, nanometer silver, water and dimethylformamide. The preparation method comprises: S1, preparing the raw materials of a modified PU coating material; S2, preparing the modified PU coating material; and S3, compounding witha modified PU coating. According to the present invention, the sofa cover PU leather fabric has adavantages of excellent water resistance, excellent gas permeation, excellent wear resistance, excellent antibacterial performance and simple production, wherein the modified PU coating material preparation efficiency is high, and the adhesion between the base cloth and the modified PU coating is strong.

Owner:HAINING MEILI KNITTING CO LTD

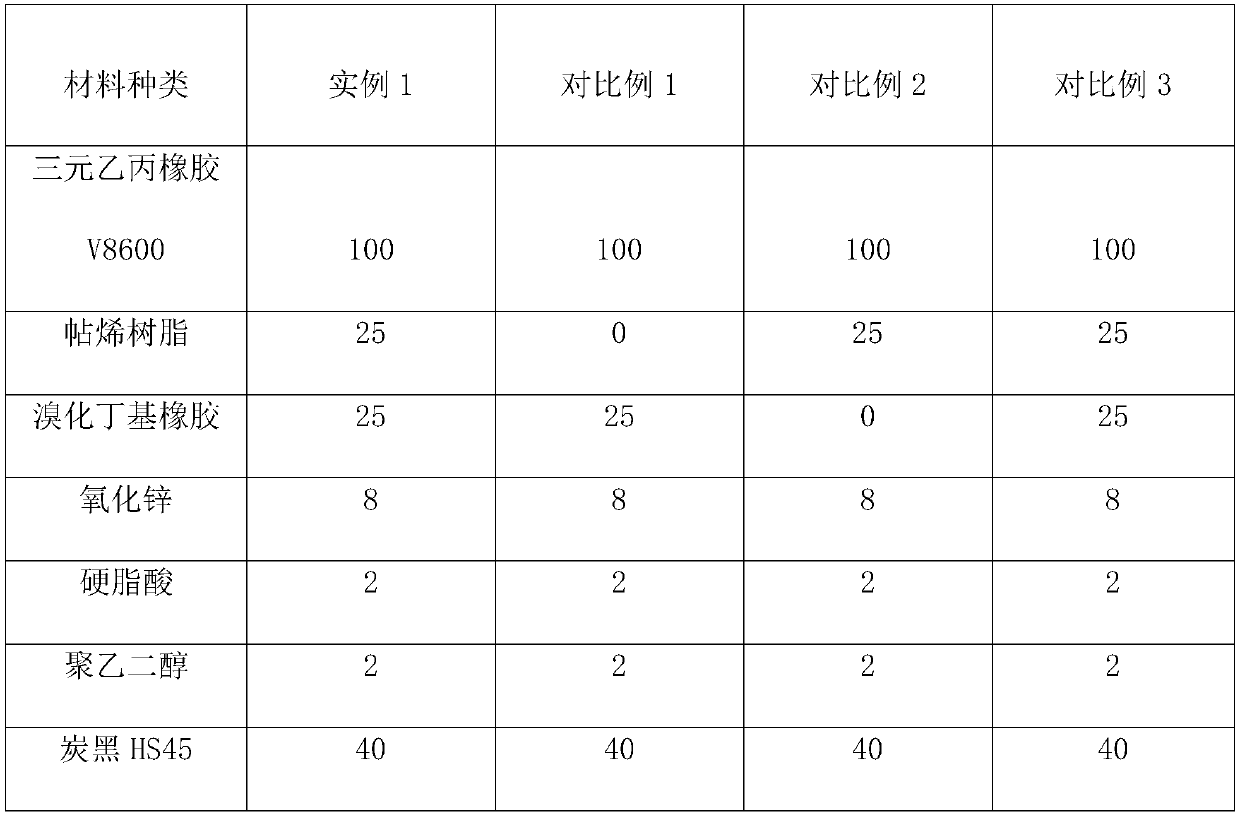

Water-stopping sponge rubber material and preparation method thereof, sealing strip and preparation method thereof, and automobile

ActiveCN109651642AEasy to processReduced durabilityEngine sealsVehicle sealing arrangementsRubber materialPolyethylene glycol

The invention provides a water-stopping sponge rubber material, a preparation method thereof, a sealing strip and a preparation method of the sealing strip and an automobile, the water-stopping spongerubber material is prepared from the following components in parts by weight: 100 parts of ethylene-propylene-diene monomer v8600, 20-30 parts of terpene resin, 20-30 parts of brominated butyl rubber, 6-10 parts of zinc oxide, 1-3 parts of stearic acid, 1-3 parts of polyethylene glycol, 30-50 parts of carbon black HS45, 70-90 parts of R-2291 paraffin oil, 6-10 parts of an OBSH foaming agent, 6-10parts of an AC foaming agent, 5-7 parts of foaming assistant K4-P, 1.5-2.5 parts of sulfur, 7-12 parts of hygroscopic agent CaO and 6-10 parts of an accelerant. The water-stopping sponge rubber material disclosed by the invention has the characteristics of low density, low damping and high viscosity, can be conveniently arranged in a sealing sleeve, has good water stopping performance, and has very good practicability.

Owner:NUOBO RUBBER PRODION

Combined box type steel sheet pile construction method of dock wall

InactiveCN1869340ASolve quality control difficultiesSave painting costsFoundation engineeringEngineeringSheet pile

The invention supplies a boatyard dock wall combination type steel sheet piling construction method that includes the following steps: fixing guiding frame, inserting pile into the frame and locating to form folding screen type pitching of pile; after one group pile pitching, pitching the first pile of the next group next to the last pile to make part of the first pile on ground being used as the location pile and removing guiding frame; fixing the second guiding frame according to the first pile, and taking steel sheet piling, repeating the process. The invention could make the appearance of the combination type steel sheet piling flat and water seal.

Owner:SHANGHAI NO 7 CONSTR

Kit for electrical wire water-sealing material, electrical wire water-sealing material, water-sealing member, water-sealed electrical wire, and water-sealing method

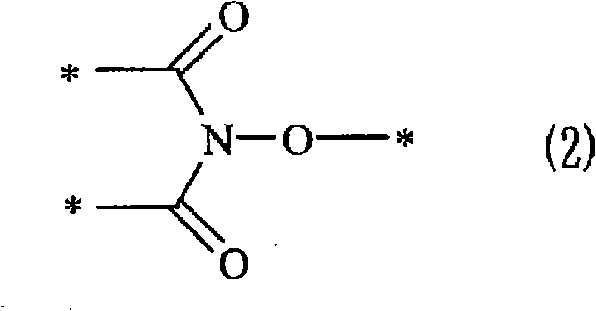

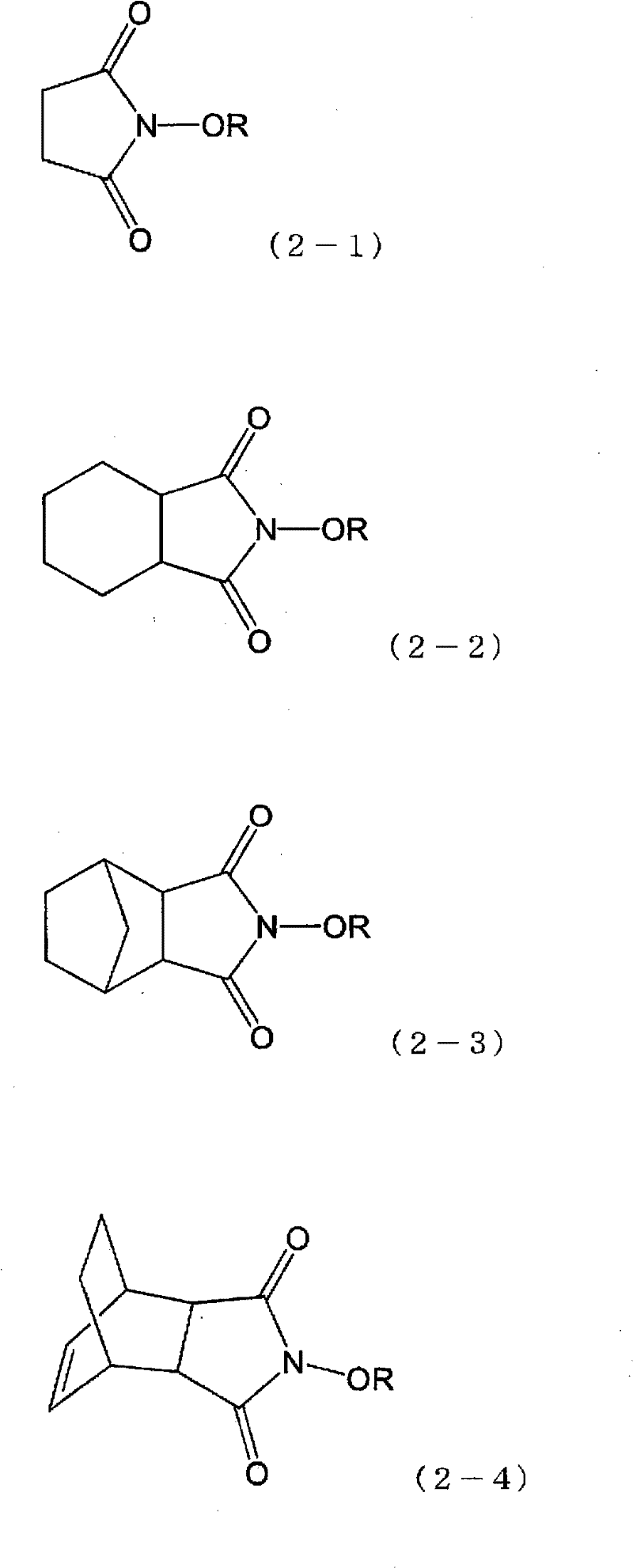

ActiveCN102414947AEffective water stop treatmentSimple water stopOther chemical processesInsulated cablesAcrylateRadiation

Provided are a kit for a water-sealing agent, an electrical wire water-sealing material, a water-sealed electrical wire, and a water-sealing method, used for insulated wires and the like. A kit for an electrical wire water-sealing material comprises composites (I) and (II) and is used to prepare the undermentioned electrical wire water-sealing material by mixing (I) and (II) in an arbitrary volume ratio. (I) is a liquid composite that contains (D) and at least one of (A), (B), and (C), but does not contain (E). (II) is a liquid composite that contains (E) and at least one of (A), (B), and (C), but does not contain (D). (A) is a urethane (metha)acrylate, (B) is a compound having one ethylene unsaturated group, (C) is a radiation polymerization initiator, (D) is an organic peroxide, and (E) is a polymerization accelerator. The electrical wire water-sealing material is a hardening liquid composite containing, by mass, 5-50% of (A), 30-90% of (B), 0.01-10% of (C), 0.1-5% of (D), and 0.01-0.5% of (E).

Owner:JSR CORPORATIOON

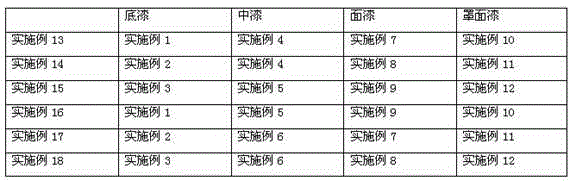

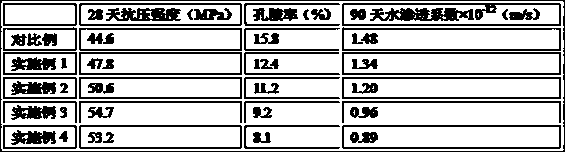

Concrete surface protection system

ActiveCN104530972AGuaranteed surface effectGood waterproofCoatingsSilicone resinCorrosion prevention

The invention belongs to the field of protection of concrete surfaces and relates to a durable and corrosion-proof concrete surface protection system. The protection system comprises four parts, namely, a priming paint, an inter paint, a finish paint and a finish-coat paint, wherein the priming paint mainly comprises a silane emulsion, a siloxane emulsion, a dispersant, a corrosion-resistant agent and water; the inter paint mainly comprises a silicon resin emulsion, a siloxane emulsion, a coalescing agent, a dispersant, a corrosion-resistant agent and water; the finish paint mainly comprises a silicon resin emulsion, an acrylic emulsion and / or a modified acrylic emulsion, a dispersant, a corrosion-resistant agent, a coalescing agent and water; and the finish-coat paint mainly comprises a fluorine-silicone resin polymer, a dispersant, a corrosion-resistant agent, a coalescing agent and water. The protection system can be immersed at 3-8mm from the concrete surface and is cured and cross-linked to form a protective layer, and the protection system has the advantages of excellent air permeability, water-repellent property, immersion resistance, weather resistance, freeze-thawing resistance and corrosion resistance; by the protection system, early carbonation and morbid change of concrete are prevented, the weather resistance is improved and the durability and practicability of concrete are prolonged.

Owner:CHONGQING JINHONG CONSTR ENG

High-density concrete and preparation method thereof

ActiveCN108529992AGood waterproofGood extensibilitySolid waste managementCement productionPorosityHigh density

The invention provides high-density concrete. The high-density concrete is prepared from 220-270 parts of superfine cement, 180-230 parts of modified coal gangue, 15-35 parts of hole plugging agent, 740-800 parts of sand, 1,100-1,300 parts of pebbles and 100-160 parts of water. The superfine cement is prepared from 400-450 parts of cement, 30-50 parts of sericite powder, 5-10 parts of sodium stearate and 40-85 parts of sugar beet pulp. The sugar beet pulp is residues obtained after sugar beet root tubers and stems are soaked and squeezed to extract sugar liquid, the fineness ranges from 500 m<2> / kg to 600 m<2> / kg, and the sugar mass percentage content ranges from 2% to 5%. The porosity of the prepared concrete is reduced by about 12% to 35%, meanwhile, the strength is improved by 5% to 15%, and the 90-day water permeability coefficient is reduced by 10% to 35%.

Owner:UNIV OF JINAN

Tile-seam filling

The invention belongs to the technical field of construction materials, and relates to tile-seam filling which is prepared from the following raw materials in parts by weight: 35 to 60 percent of ordinary Portland cement (P.042.4R), 30 to 65 part of quartz sand, 0.01 to 0.2 parts of mineral oil type deformer, 10 to 30 parts of redispersible latex powder, 0.1 to 0.5 parts of HPMC (hydroxypropyl methyl cellulose), 0.2 to 1 part of organosilicon water repellent, 0.2 to 1 part of anti-whiskering agent, 1 to 3 parts of anhydrite, and 3 to 10 parts of ferric oxide series pigment. The tile-seam filling has the characteristics of being good in waterproofness, not liable to blacken, high in adhesive force, alkali-resistant and low in cost, capable of applying to decorating and seam filling of materials such as various ceramic tiles, floor tiles, wall tiles, mosaic tiles, marble and granite, and cultured stones.

Owner:DONGGUAN WEIYE CEMENT CO LTD

Expansive soil tunnel supporting structure and method

ActiveCN107201909AAvoid deformationPrevent collapseUnderground chambersHydro energy generationSoil scienceStructural engineering

The invention discloses an expansive soil tunnel supporting structure and method. The expansive soil tunnel supporting structure comprises a wall for grouting and a plurality of grouting pipes, wherein the wall for grouting is disposed on an upper half section of a tunnel face of an expansive soil tunnel; and the grouting pipes are embedded in the wall for grouting and are used for performing pre-grouting on expansive soil surrounding rock on the periphery of the upper half section of the expansive soil tunnel. The grouting pipes are arranged in the extending direction of the expansive soil tunnel, and the cross sections of the grouting pipes are towards the upper half section of the tunnel face. When the pre-grouting is performed through the grouting pipes, the wall for grouting is used for preventing slurry for grouting from flowing outwards to the tunnel face. According to the expansive soil tunnel supporting structure, deformation and collapse of the tunnel face caused by too high grouting pressure are avoided mainly through the wall for grouting, and problems of expansion and shrinkage deformation and damage to the expansive soil tunnel caused by mechanical property of expansive soil are solved.

Owner:中铁二十四局集团安徽工程有限公司 +1

Ultrasonic control earth pillar pressure chamber system

InactiveCN104007051AMeet the requirements of the soil column testMeet testing needsMaterial analysis using sonic/ultrasonic/infrasonic wavesPermeability/surface area analysisPeristaltic pumpPorous medium

The invention discloses an ultrasonic control earth pillar pressure chamber system. The ultrasonic control earth pillar pressure chamber system comprises a pressure chamber, an earth pillar, an ultrasonic device, a liquid supply device and a liquid outlet device. The pressure chamber is provided with a cavity filled with water, and the earth pillar is arranged inside the cavity; the ultrasonic device comprises an ultrasonic generator, an ultrasonic transducer, an ultrasonic amplitude-change pole and an ultrasonic emission tool head, and the ultrasonic emission tool head extends into the cavity and makes contact with the top end of the earth pillar; the liquid supply device comprises a liquid inlet pipe, a liquid storage tank, a peristaltic pump and a flowmeter; the liquid outlet device comprises a turbidimeter and a liquid outlet pipe, the turbidimeter is connected to the liquid outlet pipe, and the liquid outlet pipe extends into the cavity and is connected with the bottom end of the earth pillar. The system can accurately measure the evolution situation of rubber concentration along with time, the ultrasonic attenuation situation, the temperature change situation and the earth pillar deformation situation in the process of ultrasonic load changes, earth pillar height changes and earth pillar confining pressure changes, and then research on rubber migration and deposition characteristic in porous media under the multi-factor coupling action is carried out.

Owner:HUAQIAO UNIVERSITY

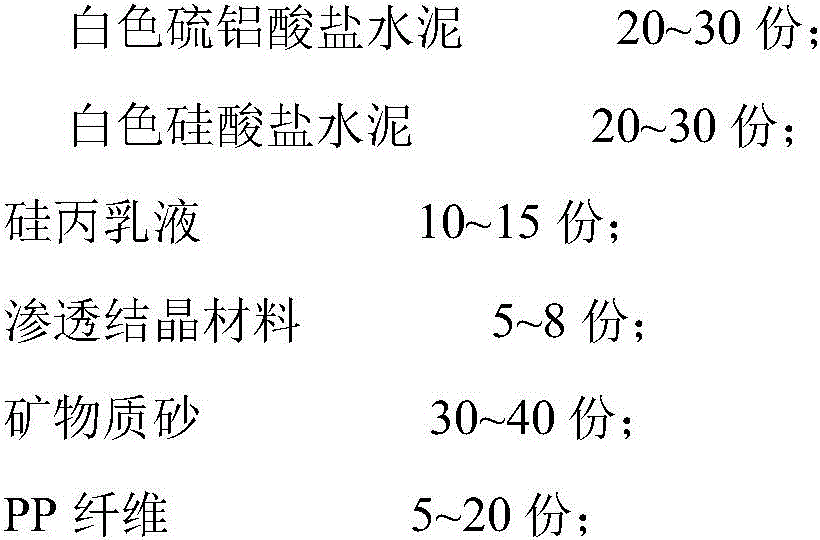

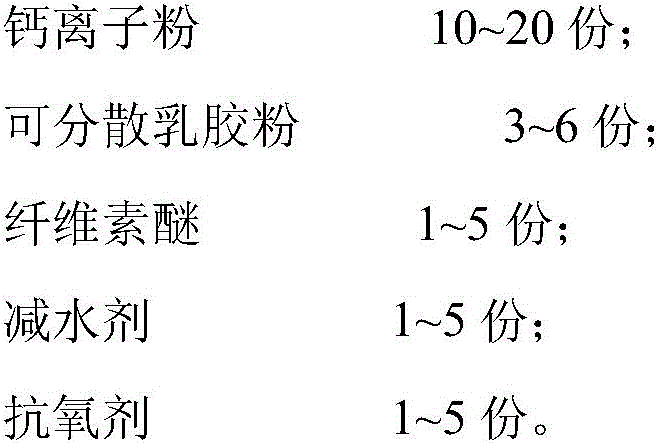

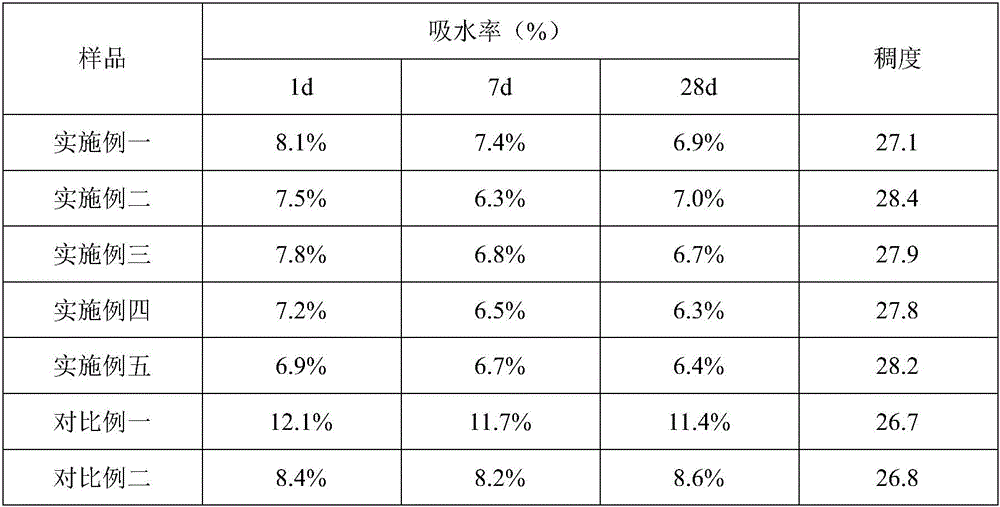

Waterproof early-strength decoration mortar and preparation method thereof

The invention discloses waterproof early-strength decoration mortar. The defect that traditional mortar cannot have both advantages of bright color and excellent waterproof early-strength effect at the same time is solved. According to main points of the technical scheme, the waterproof early-strength decoration mortar comprises the following ingredients (by weight): 20-30 parts of white sulphate aluminium cement, 20-30 parts of white portland cement, 10-15 parts of a silicon-acrylate emulsion, 5-8 parts of a permeable crystalline material, 30-40 parts of mineral sand, 5-20 parts of PP fiber, 10-20 parts of calcium ion powder, 3-6 parts of dispersible latex powder, 1-5 parts of cellulose ether, 1-5 parts of a water reducer and 1-5 parts of an antioxidant. The prepared mortar has excellent waterproofness and high strength, and has a decoration effect. According to the invention, defects of decoration mortar in the market, such as poor waterproofness and low early-strength, are compensated; and the waterproof early-strength decoration mortar with excellent properties is prepared.

Owner:苏州大乘环保新材有限公司

Grinding aid used for refractory material and preparation method thereof

The invention relates to a grinding aid used for refractory material. The adopted technical proposal is as follows: the grinding aid comprises the following components by content: 42-70 wt% of oleic acid, 20-38 wt% of mother solution and 5-30 wt% of triisopropanolamine; based on the components and contents, first the oleic acid is added to the mother solution and stirred for 15-30min at room temperature; and then the triisopropanolamine added, and the mixed solution is stirred for 10-20min at room temperature to consequently obtain the grinding aid used for refractory material. The grinding aid can remove the surface static electricity of the refractory material in grinding process, solve the phenomenon that the refractory material adheres to a can or a ball, improve the grinding efficiency by about 20-30 percent and save energy. Coated on the surface of the refractory material, a layer of macromolecular coating film can play a role of preventing hydration, thus extending the application range of the refractory material.

Owner:WUHAN UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com