Offshore deep foundation pit supporting structure and construction method thereof

A deep foundation pit support and construction method technology, applied in the offshore deep foundation pit support structure and its construction field, can solve the problems of unstoppable construction speed, slowness, poor integrity, etc., achieve good waterproof effect, and improve construction efficiency , the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

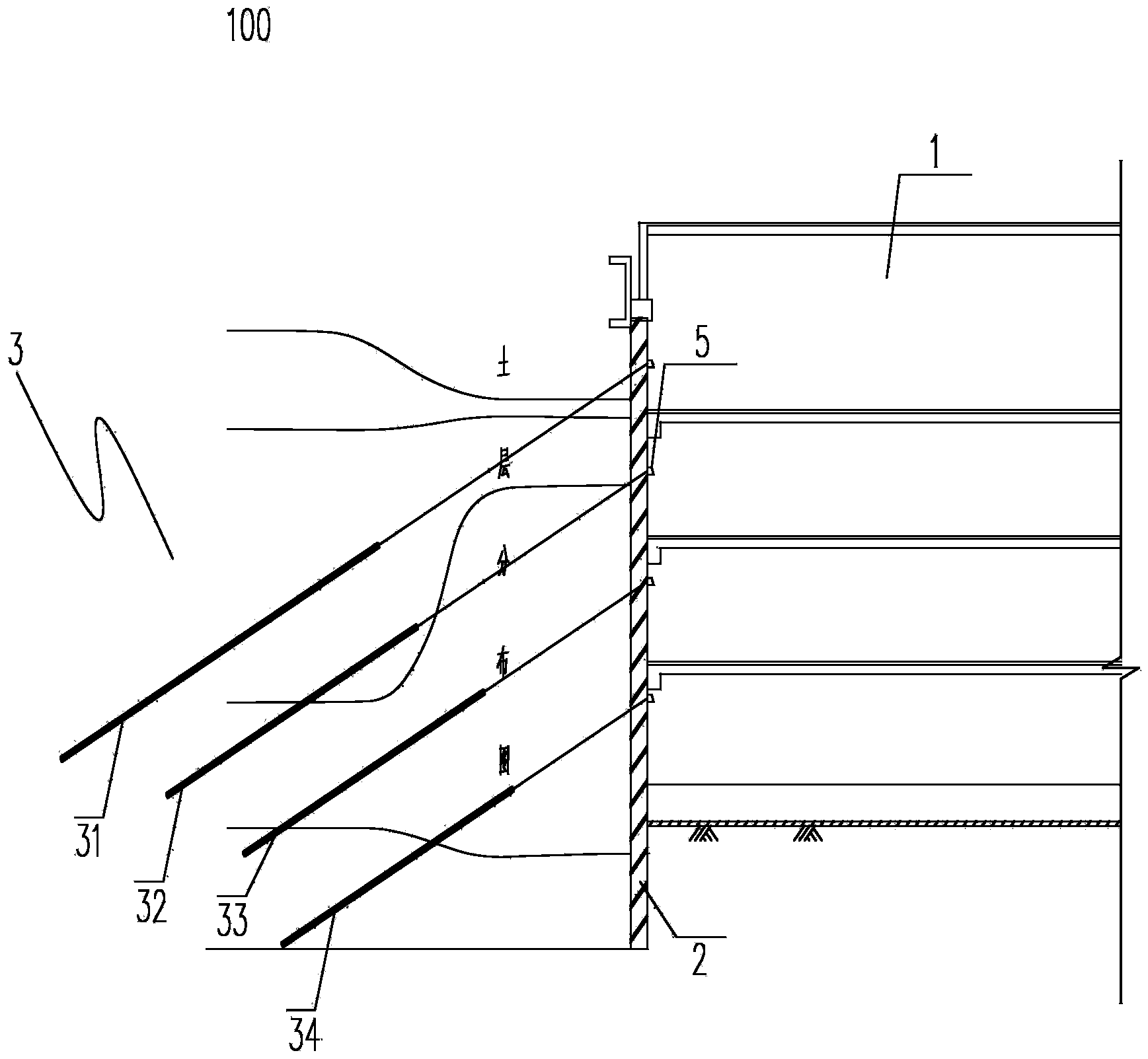

[0037] Such as figure 1 with figure 2 As shown, the offshore deep foundation pit support structure 100 of this embodiment includes: a multi-faceted underground diaphragm wall 2 and multiple anchor cables 3 located at the outer edge of the deep foundation pit 1; Multiple casings 4, one end of each anchor cable 3 is fixed on the underground diaphragm wall 2 through an anchorage 5, and the other end of the anchor cable 3 passes through the casing 4 and is fixed in the rock and soil outside the deep foundation pit 1; The tool 5 includes a rubber sealing plate 51 and a plurality of expansion bolts 52. The rubber sealing plate 51 covers the nozzle of the casing 4 near the side of the deep foundation pit 1. The expansion bolts 52 fix the rubber sealing plate 51 on the underground continuous wall 2. .

[0038] In the offshore deep foundation pit support structure 100 mentioned above, the technical scheme of integrating the underground diaphragm wall and the anchor cable is adopted....

Embodiment 2

[0042] Combine below Figure 3 to Figure 4 , describe in detail the construction method of the offshore deep foundation pit support structure 100 of embodiment one: specifically include the following steps:

[0043] Step a: milling grooves on the ground corresponding to the underground diaphragm wall 2 to form an underground groove;

[0044]Specifically, the groove milling machine is used to mill grooves on the ground. After hitting the underground rock layer, the underground rock and soil layer is broken in situ, and then pumped out to form an underground groove. Compared with the bored pile technology, the milling process can significantly improve the operation speed. The reason is that the milling process can form an underground continuous wall underground groove at a time, while the bored pile can only form one pile at a time. hole. For the hard rock in the coastal area, it takes more than 48 hours to form a 30m deep borehole. Taking 6 bored piles with a depth of 30m wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com