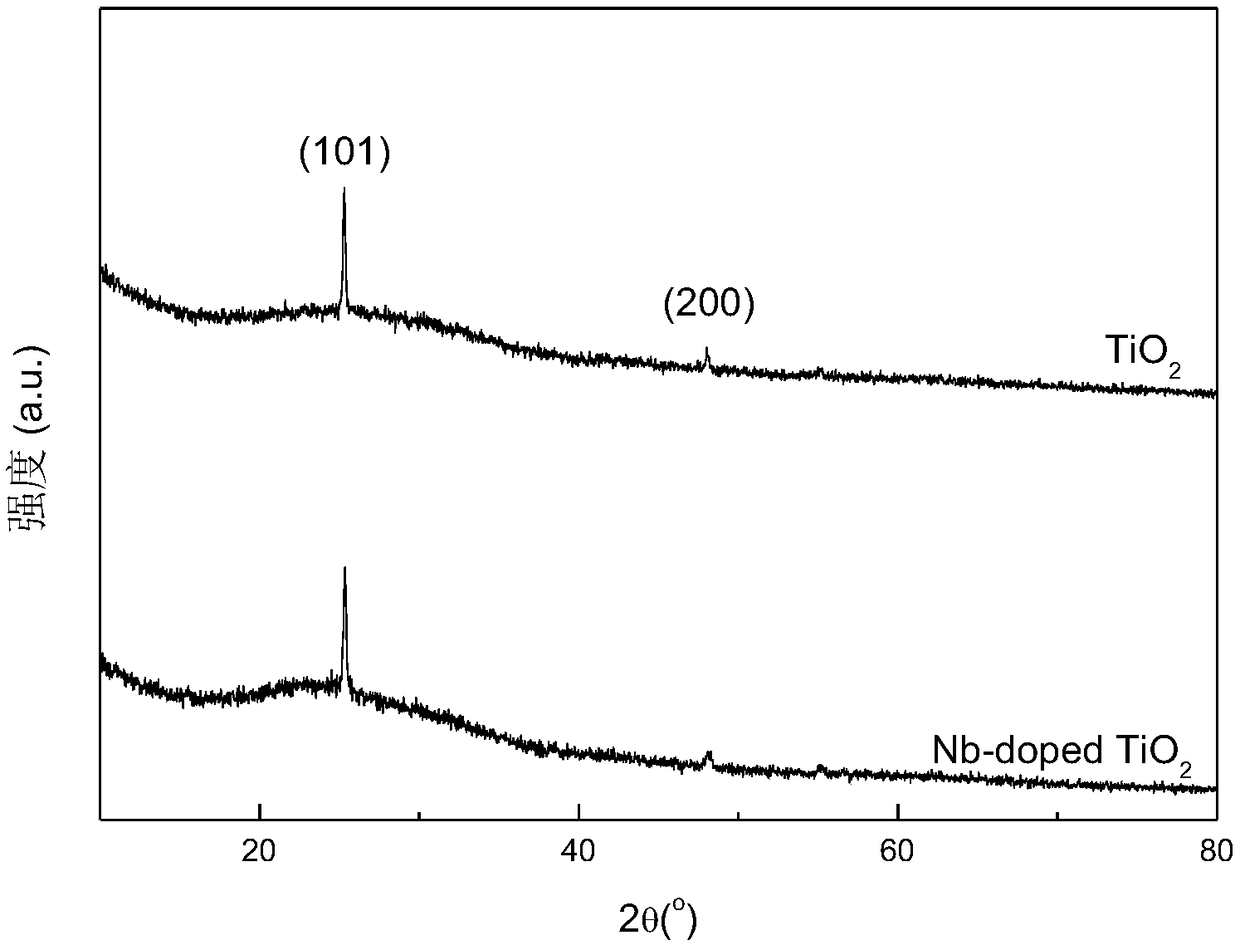

Niobium-doped titanium dioxide coated glass and preparation method thereof

A technology of titanium dioxide and coated glass, applied in coating and other directions, can solve the problems of unsuitability for large-scale industrialization, unsuitable for large-scale continuous production, serious environmental pollution, etc., and achieves improved photo-induced hydrophilicity and excellent spectral selection. characteristics, the effect of improving the doping efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] 1) Substrate cleaning: use white glass with a thickness of 5mm to cut into 100mm×75mm size, put it into a beaker to moisten, then add 2 drops of detergent to fill it with water and cover the glass substrate with ultrasonic soaking for 30min, then rinse off the foam with tap water Put the substrate into the prepared dilute hydrochloric acid (1:10 volume ratio) for ultrasonic cleaning for 30 minutes, then put the substrate into a beaker filled with deionized water to soak and rinse, and finally put it into absolute ethanol and ultrasonically clean it for 30 minutes , take it out and dry it in a 120°C oven for later use.

[0039] 2) Liquid mixture source material configuration: use titanium tetraisopropoxide as the titanium source, and niobium ethoxide as the niobium source. Before configuration, use high-purity nitrogen to flush the material tank, and reduce the contact between titanium source and niobium source and air, seal immediately after filling, and the material ra...

Embodiment 2

[0050] 1) Substrate cleaning: use white glass with a thickness of 5mm to cut into 100mm×75mm size, put it into a beaker to moisten, then add 2 drops of detergent to fill it with water and cover the glass substrate with ultrasonic soaking for 30min, then rinse off the foam with tap water Put the substrate into the prepared dilute hydrochloric acid (1:10 volume ratio) for ultrasonic cleaning for 30 minutes, then put the substrate into a beaker filled with deionized water to soak and rinse, and finally put it into absolute ethanol and ultrasonically clean it for 30 minutes , take it out and dry it in a 120°C oven for later use.

[0051] 2) Liquid mixture source material configuration: use tetrabutyl titanate as the titanium source, and niobium pentachloride as the niobium source. Before configuration, use high-purity nitrogen to flush the material tank, and reduce the contact between titanium source and niobium source and air, seal immediately after filling, and the material rati...

Embodiment 3

[0056] 1) Substrate cleaning: use white glass with a thickness of 5mm to cut into 100mm×75mm size, put it into a beaker to moisten, then add 2 drops of detergent to fill it with water and cover the glass substrate with ultrasonic soaking for 30min, then rinse off the foam with tap water Put the substrate into the prepared dilute hydrochloric acid (1:10 volume ratio) for ultrasonic cleaning for 30 minutes, then put the substrate into a beaker filled with deionized water to soak and rinse, and finally put it into absolute ethanol and ultrasonically clean it for 30 minutes , take it out and dry it in a 120°C oven for later use.

[0057] 2) Liquid mixture source material configuration: titanium chloride is used as titanium source, niobium ethanol is used as niobium source, and ethanol is used as solvent. Before configuration, use high-purity nitrogen to flush the material tank, and reduce the contact between titanium source and niobium source and air, seal immediately after fillin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Grain size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com