Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

88results about How to "Improve surface compactness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Self-levelling underlayment material

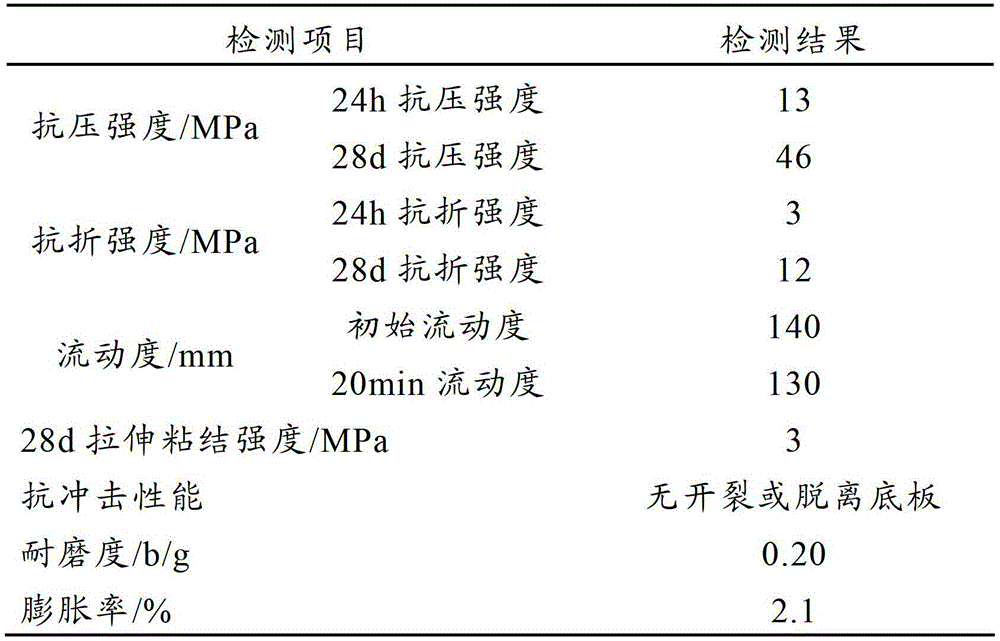

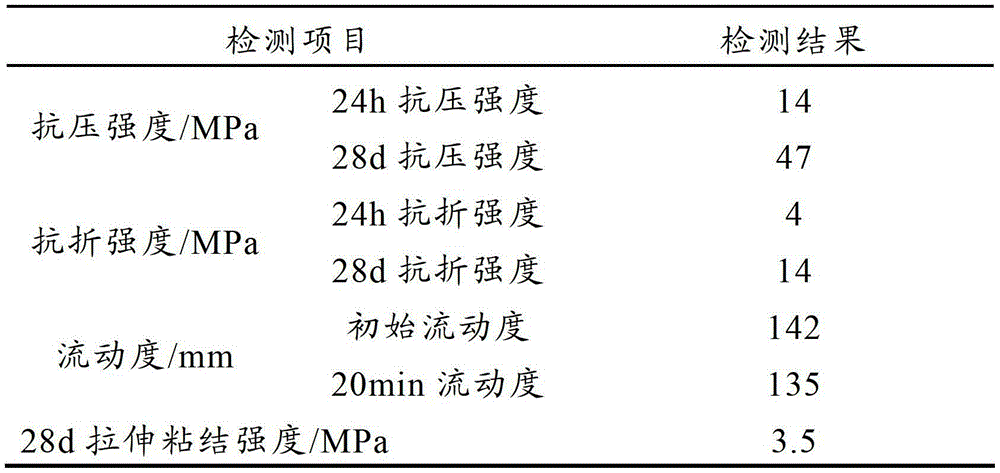

The invention relates to the technical field of chemical new materials for roads and bridges and provides a self-levelling underlayment material. The self-levelling underlayment material comprises 40-100 parts by weight of sand, 40-100 parts by weight of cement, 2-30 parts by weight of gypsum, 2-30 parts by weight of inorganic fluoride, 0.1-15 parts by weight of water reducer, 4-15 parts by weight of swelling agent, 0.1-10 parts by weight of tackification and water retention agent and 0.1-15 parts by weight of fibers. The self-levelling underlayment material has the following advantages: the swelling agent is added, so that the surface compactness of a self-levelling underlayment can be improved, cracks generated by contraction can be relieved, and thus the service life of the self-levelling underlayment is prolonged.

Owner:HUBEI UNIV

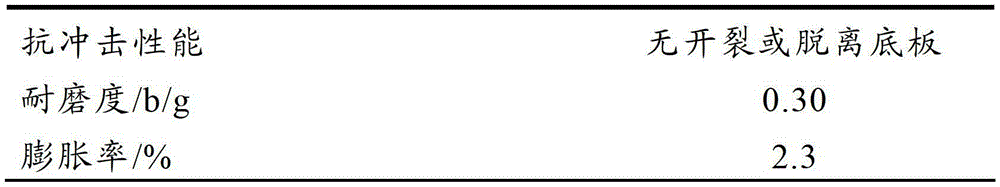

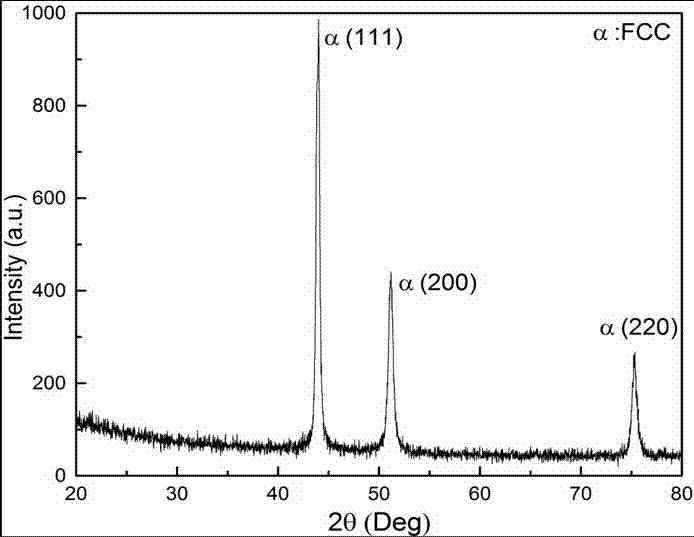

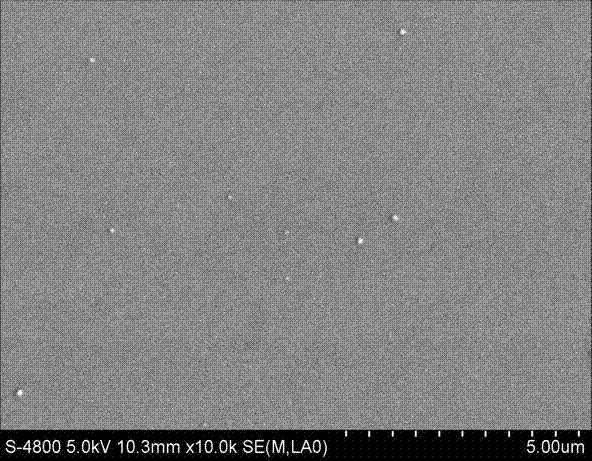

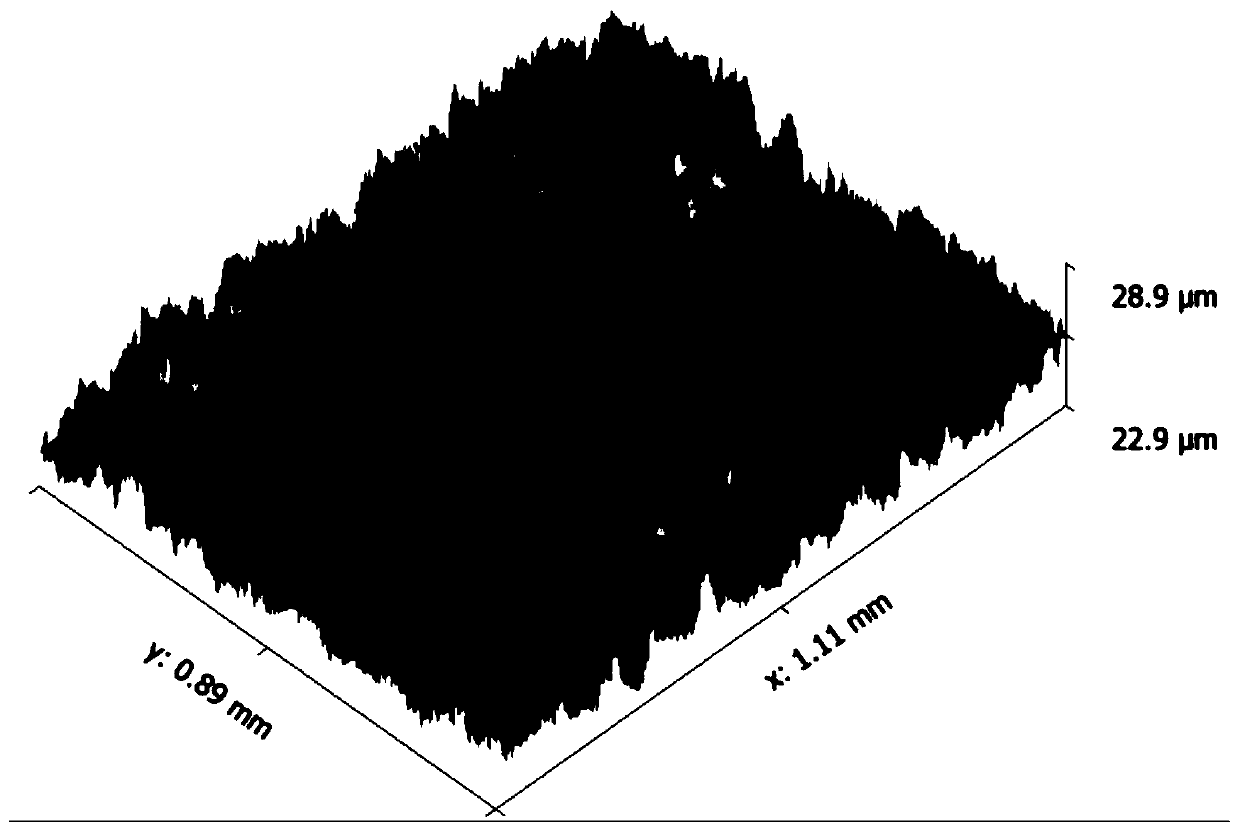

Zirconium cladding surface resistant to high temperature and oxidation ZrCrFe/AlCrFeTiZr composite gradient coating preparing technology

ActiveCN107513694AImprove the interface binding forceHigh strengthVacuum evaporation coatingSputtering coatingHigh entropy alloysAlloy coating

The invention discloses a zirconium cladding surface resistant to high temperature and oxidation ZrCrFe / AlCrFeTiZr composite gradient coating preparing technology. Ultrahigh vacuum multitarget co-sputtering technique is adopted, a ZrCrFe / AlCrFeTiZr composite gradient alloy resistant to high temperature and oxidation protecting coating is prepared on the surface of a zirconium alloy base body, and the zirconium cladding surface resistant to high temperature and oxidation ZrCrFe / AlCrFeTiZr composite gradient coating preparing technology comprises the steps of predepositional treatment, bias voltage anti-splash washing and ZrCrFe / AlCrFeTiZr composite gradient alloy coating deposition. The preparing process of the composite coating is divided into two steps, the first step is to prepare ZrCrFe gradient transition layer coating, in a deposited ZrCrFe transition layer, the atomic percentage content of Zr element is changed from the gradient of 100 at%-35 at% in the thickness direction, the atomic percentage content of Cr element is changed from the gradient of 0 at%-33 at% in the thickness direction, and the atomic percentage content of Fe element is changed from the gradient of 0 at%-33 at% in the thickness direction; the second step is to prepare a AlCrFeTiZr high-entropy alloy coating, in a deposited AlCrFeTiZr high-entropy alloy coating, the atomic percentage content of Al element is controlled in 0.5 at%-1.0at %, and the atomic percentage of other elements is between 10 at%-35 at%. Bonding force of the coating prepared by the technology is excellent, the surface is dense and uniform, and the coating has excellent performance such as high strength, resistance to high temperature and oxidation and irradiation resistance.

Owner:田雨

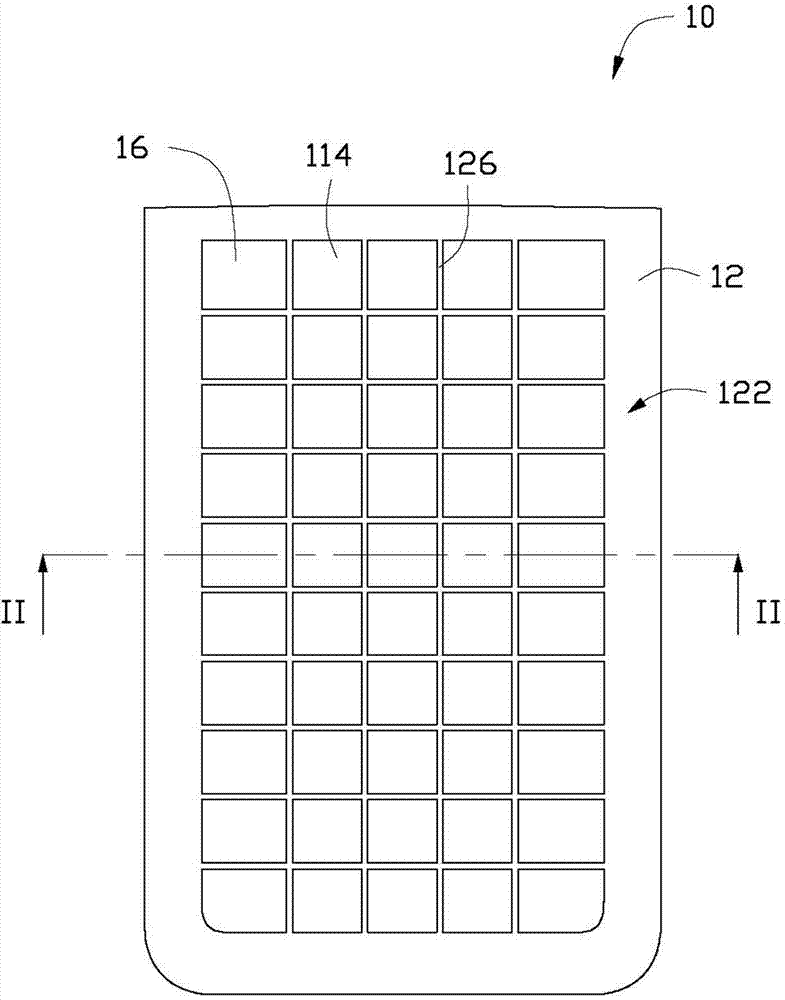

Electronic device shell and manufacture method thereof

InactiveCN103096650AImprove wear resistanceExcellent abrasion resistanceMolten spray coatingSubstation equipmentCeramic coatingMetallurgy

The invention provides an electronic device shell which comprises a metallic matrix body. The electronic device shell further comprises a first ceramic coating and a second ceramic coating which are formed on the surface of the metallic matrix body. The metallic matrix body comprises a first surface, a plurality of concave portions and protrusions which are formed between each two concave portions are formed on the first surface, each concave portion comprises a plurality of first pattern areas and a plurality of second pattern areas, the first ceramic coating covers the first pattern areas, the second ceramic coating covers the second pattern areas, and the first ceramic coating and the second ceramic coating are of different colors. The invention further provides a manufacture method of the electronic device shell.

Owner:SHENZHEN FUTAIHONG PRECISION IND CO LTD

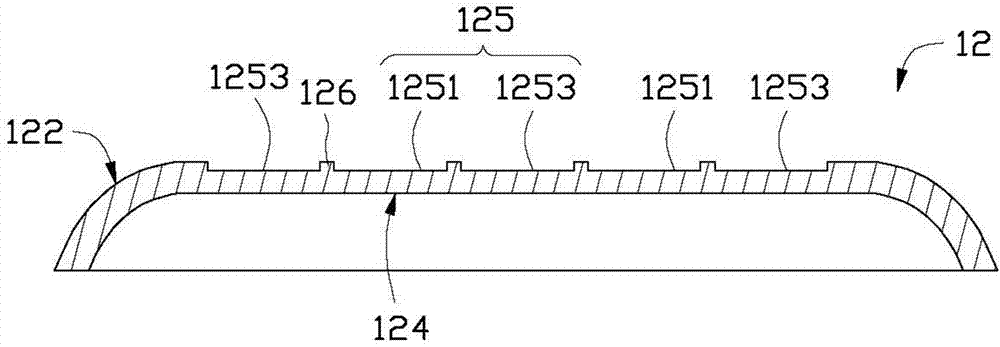

Housing of electronic device and manufacturing method thereof

InactiveCN102137554AImprove wear resistanceScratch resistantMolten spray coatingMetal casingsRough surfaceThermal spraying

The invention provides a housing of an electronic device, which comprises a metal matrix and a ceramic coating, wherein the thickness of the metal matrix is 0.4-0.6mm, the ceramic coating is directly formed on the surface of the metal matrix by hot spraying, and the surface of the metal matrix, which is in contact with the ceramic coating, is the rough surface after roughening treatment. The invention further provides a manufacturing method of the housing of the electronic device.

Owner:SHENZHEN FUTAIHONG PRECISION IND CO LTD

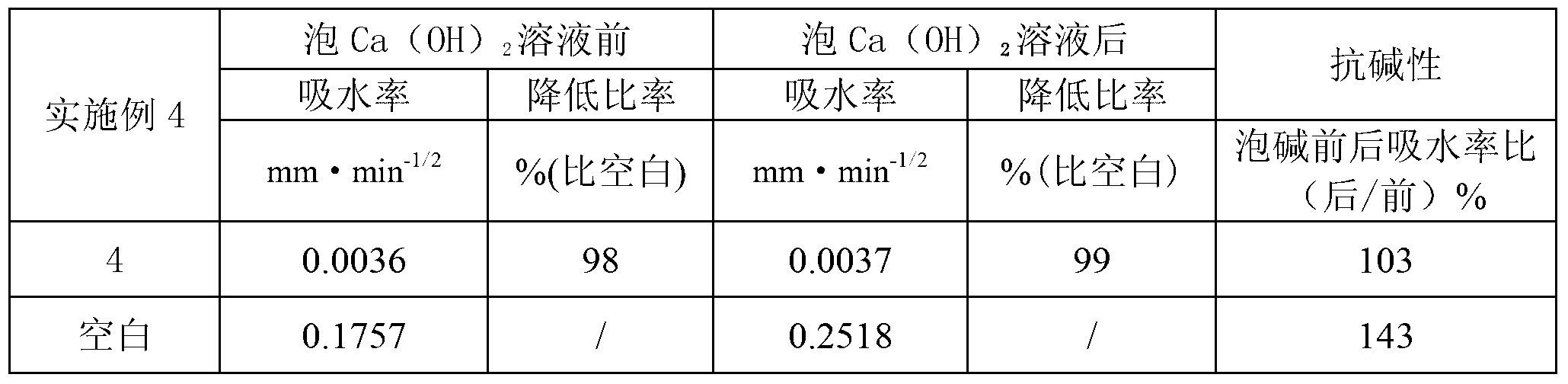

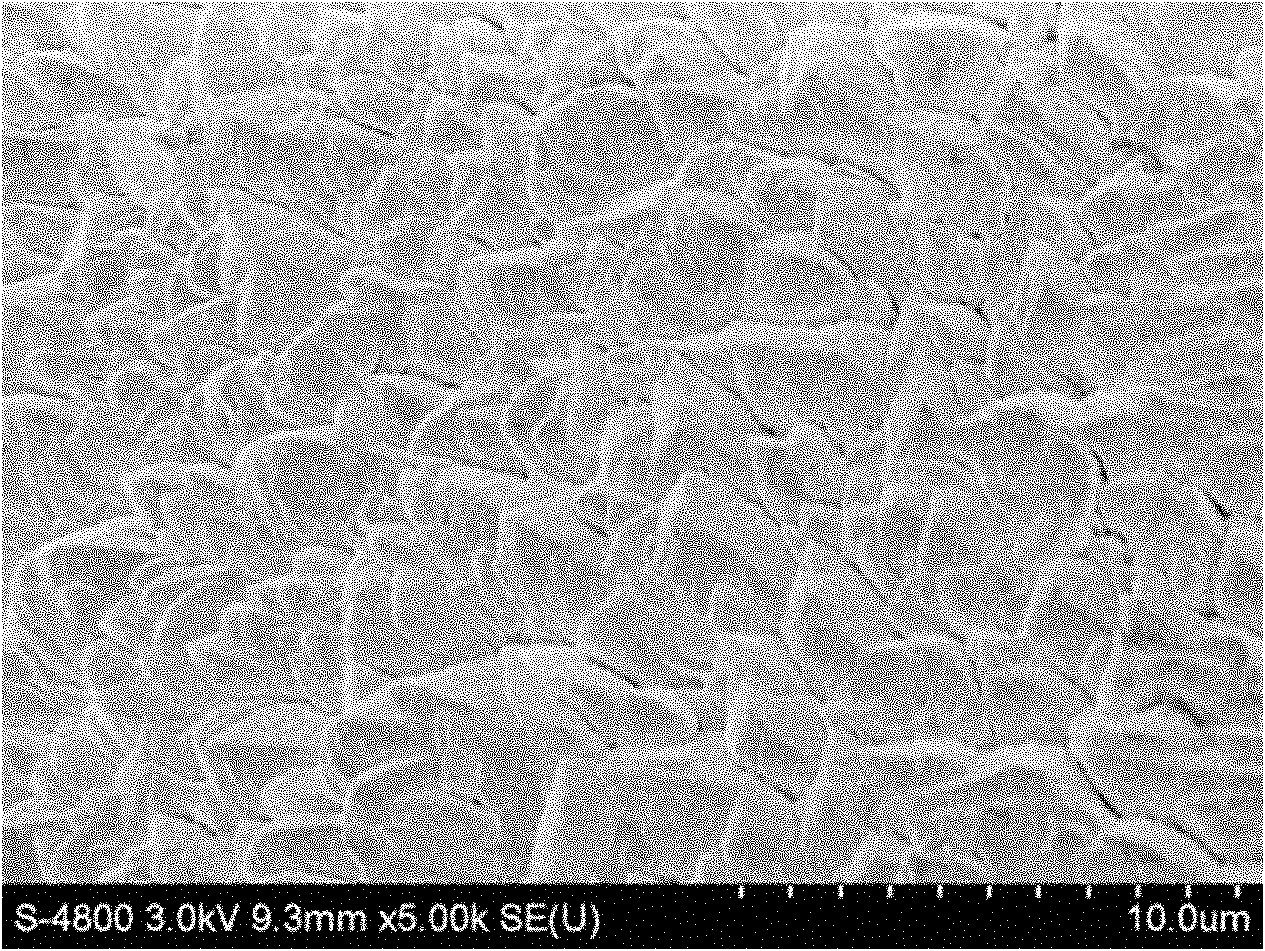

Penetration type transparent concrete protection paint and preparation method thereof

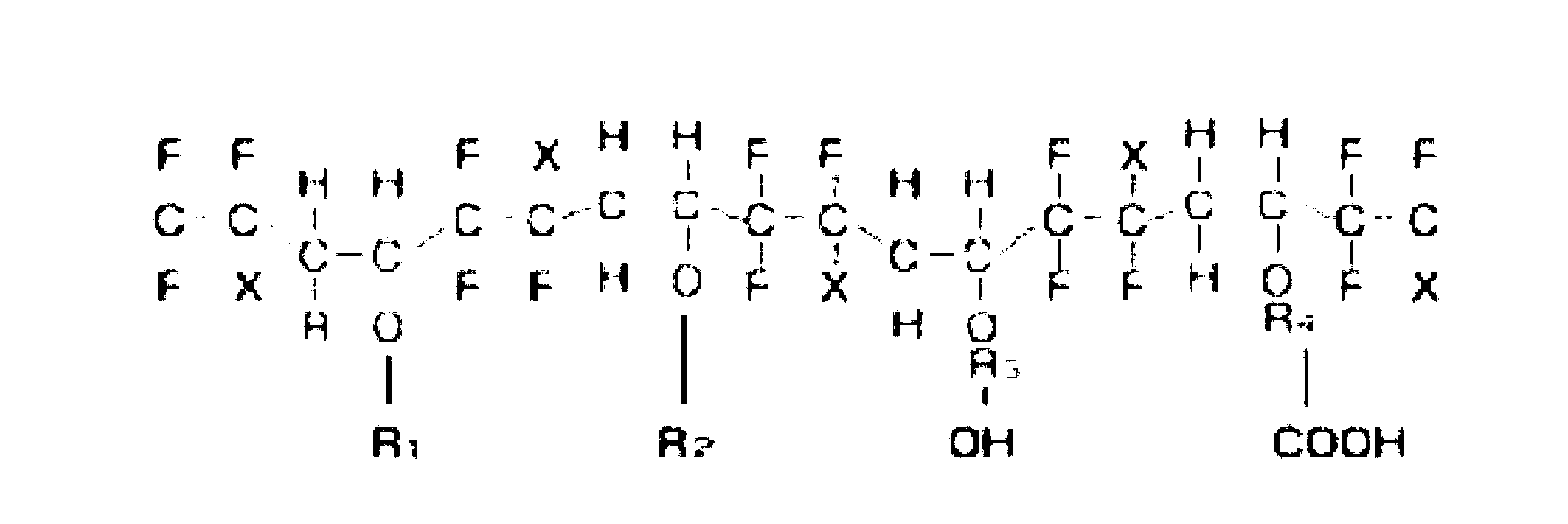

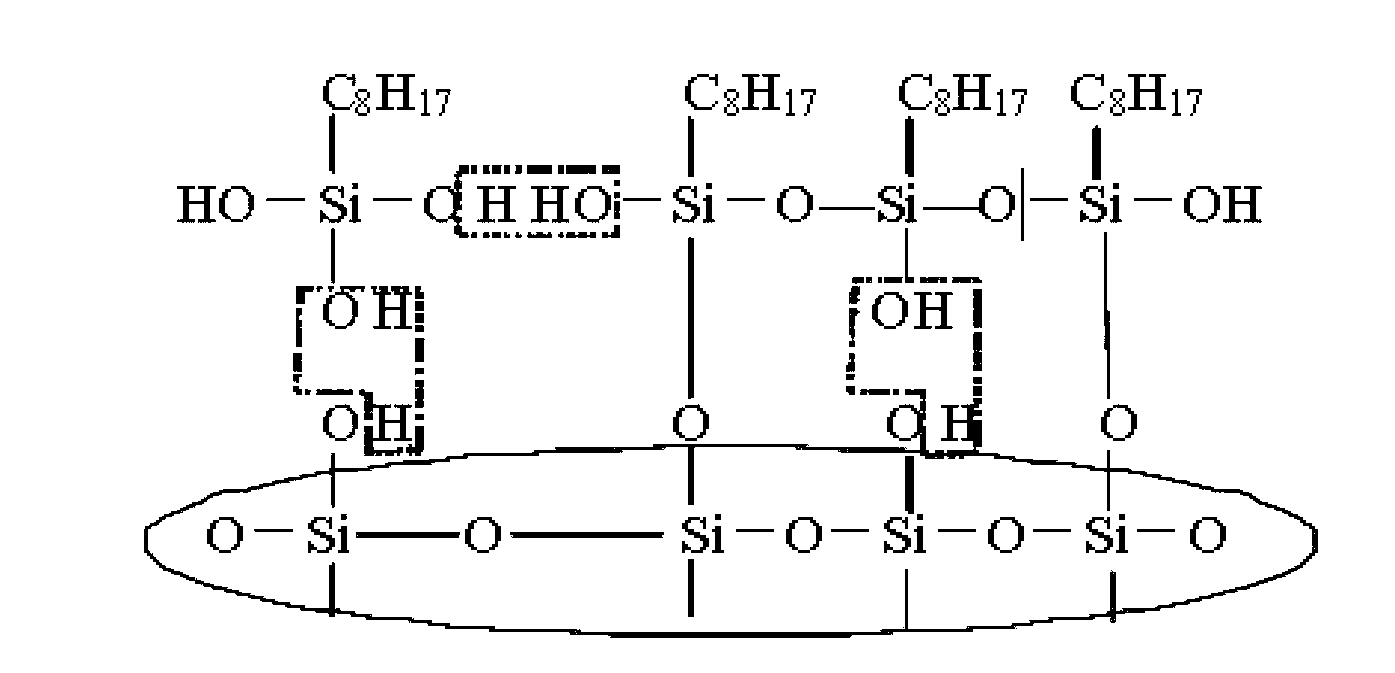

InactiveCN103224742ADoes not affect appearanceImprove waterproof performancePolyurea/polyurethane coatingsFrostCarbonization

The invention relates to a penetration type transparent concrete protection paint and preparation method thereof, which comprises the following steps: diluting a fluoropolymer by diluents, adding a curing agent, mixing as the first component, and then adding silane which is used as the second component, mixing uniformly; the product is coated on the concrete surface and penetrates into the concrete for combining into one body, thereby forming a deep protection, effectively reducing water absorption of concrete, increasing packing of concrete surface, improving resistance to chemical corrosion, resistance to carbonization and resistance to frost, especially blocking the channel by which the extraneous moisture can enter into the internal part of the concrete, substantially improving waterproofness of the concrete, and effectively prolonging the service life.

Owner:TONGJI UNIV

Ceramic coating with high-temperature resistance and wear resistance and preparation method of ceramic coating

ActiveCN106007678AImprove high temperature resistanceWide temperature rangeCeramic coatingBond properties

The invention discloses a ceramic coating with high-temperature resistance and wear resistance. The ceramic coating is prepared from components in parts by weight as follows: aluminum oxide, silicon oxide, silicon carbide, silicon nitride, boron carbide, titanium carbide, magnesium oxide, zinc oxide, calcium oxide, a binder, a stabilizer and a thickener; the preparation method comprises steps as follows: aluminum oxide, silicon oxide, silicon carbide, silicon nitride, boron carbide, titanium carbide, magnesium oxide, zinc oxide and calcium oxide are subjected to ball milling respectively, then dried, sintered, ground, sieved and mixed, and mixed powder is prepared; the binder, the stabilizer, a defoaming agent and the thickener are added to the mixed powder and mixed uniformly. The ceramic coating has the advantages that the prepared coating has high high-temperature resistance and wear resistance, good surface compactness and high bonding capability; besides, the prepared coating is applied to the surface of equipment, so that the hardness and the surface compactness of the coating are increased after the equipment runs for a period of time, and the bonding property of the coating with a metal matrix is enhanced; besides, materials used during preparation are simple, and site operation is convenient.

Owner:南京亮而彩新材料有限公司

Preparation method of rear-earth magnesium alloy product

The invention relates to a preparation method of a rear-earth magnesium alloy product. The preparation method comprises the following steps of: placing dehydrated rear-earth chlorate in a melting electrolysis device; adding dehydrated magnesium chloride, potassium chloride and titanium dichloride for dispersing, mixing and carrying out melting electrolysis, so that rear-earth magnesium intermediate alloy is generated by co-electrodeposition of rear-earth ion and magnesium ion at a negative electrode; burdening and mixing the rear-earth magnesium intermediate alloy and the metal magnesium in a smelting device, wherein a molar ratio of the rear-earth metal to the magnesium is (0.1-1.0):100; heating up the rear-earth magnesium alloy mixture for melting, immersing the smelting agent inside the melt and stirring, increasing the temperature to 780 DEG C and stewing for 20 minutes for dividing the melt into an upper layer, a middle layer and a lower layer, wherein the middle melt layer is used as the rear-earth magnesium alloy melt; casting after pre-cooling, cooling and forming, and carrying out surface treatment after carrying out mechanical processing and thermal processing, so that a compact proactive film layer is covered on the surface of the rear-earth magnesium alloy product. The preparation method of the rear-earth magnesium alloy product is high in preparation efficiency, safe and reliable in process, environment-friendly and low in energy consumption.

Owner:YANGZHOU FENG MING METAL PROD

Treatment method of improving oxidation resistance of thermal barrier coating

InactiveCN101994078APromote growthImprove high temperature service performanceMolten spray coatingVacuum evaporation coatingElectron beam physical vapor depositionGas phase

The invention relates to a treatment method of improving oxidation resistance of a thermal barrier coating, belonging to the technical field of thermal barrier coating surface treatment and modification. High current pulse electron beam irradiation is utilized to realize electron beam physical vapor deposition to prepare a yttrium oxide stabilizing zirconium oxide thermal barrier coating to cap ceramic layer columnar crystals, thus the heat-shielding performance and the high temperature oxidation resistance of the coating are improved. The process conditions are shown as follows: the vacuum is 3.5*10<-2>Pa, the voltage is 15kV, the frequency is 1Hz, the pulse width is 120-150ms, the energy density is 10J / cm<2>-20J / cm<2>, the pulse time is 30-40 and the remelting layer thickness reaches at least 10 micrometers. The invention has the advantages that the electron beam physical vapor deposition layer columnar crystals are capped after the high current pulse electron beam irradiation is ended, and thus, the surface of the thermal barrier coating becomes smooth, no penetrable microcracks are generated, the oxygen element diffusion is effectively stopped, the growth of a thermal growth oxidation layer is relieved and the heat-shielding performance and the high temperature oxidation resistance of the thermal barrier coating are obviously improved.

Owner:DALIAN UNIV OF TECH

High-sphericility, compact-surface and low-impurity Ni-Co-Mn ternary material precursor and preparation method and application thereof

The invention discloses a high-sphericility, compact-surface and low-impurity Ni-Co-Mn ternary material precursor and preparation method and application thereof, and belongs to the technical field oflithium ion battery preparation. The preparation method comprises the following steps of dissolving a nickel source, a cobalt source and a manganese source compound in deionized water to prepare a solution with certain concentration; mixing the prepared solution and concentrated ammonia water, and combining with a precipitant and an ammonium salt solution to enter a reaction kettle for reaction; washing, re-pulping and re-washing the obtained precursor paste, and adding a certain amount of alkali solution during the re-pulping process; and performing spray drying, thereby obtaining the Ni-Co-Mn ternary material precursor. With the adoption of the method, the prepared Ni-Co-Mn ternary material precursor can be good in crystallinity, high in product sphericility, compact in surface and extremely low in impurity content in a product and can be used for a lithium ion battery positive electrode material-lithium nickel cobalt manganate with more excellent performance.

Owner:安徽同心新材料科技有限公司

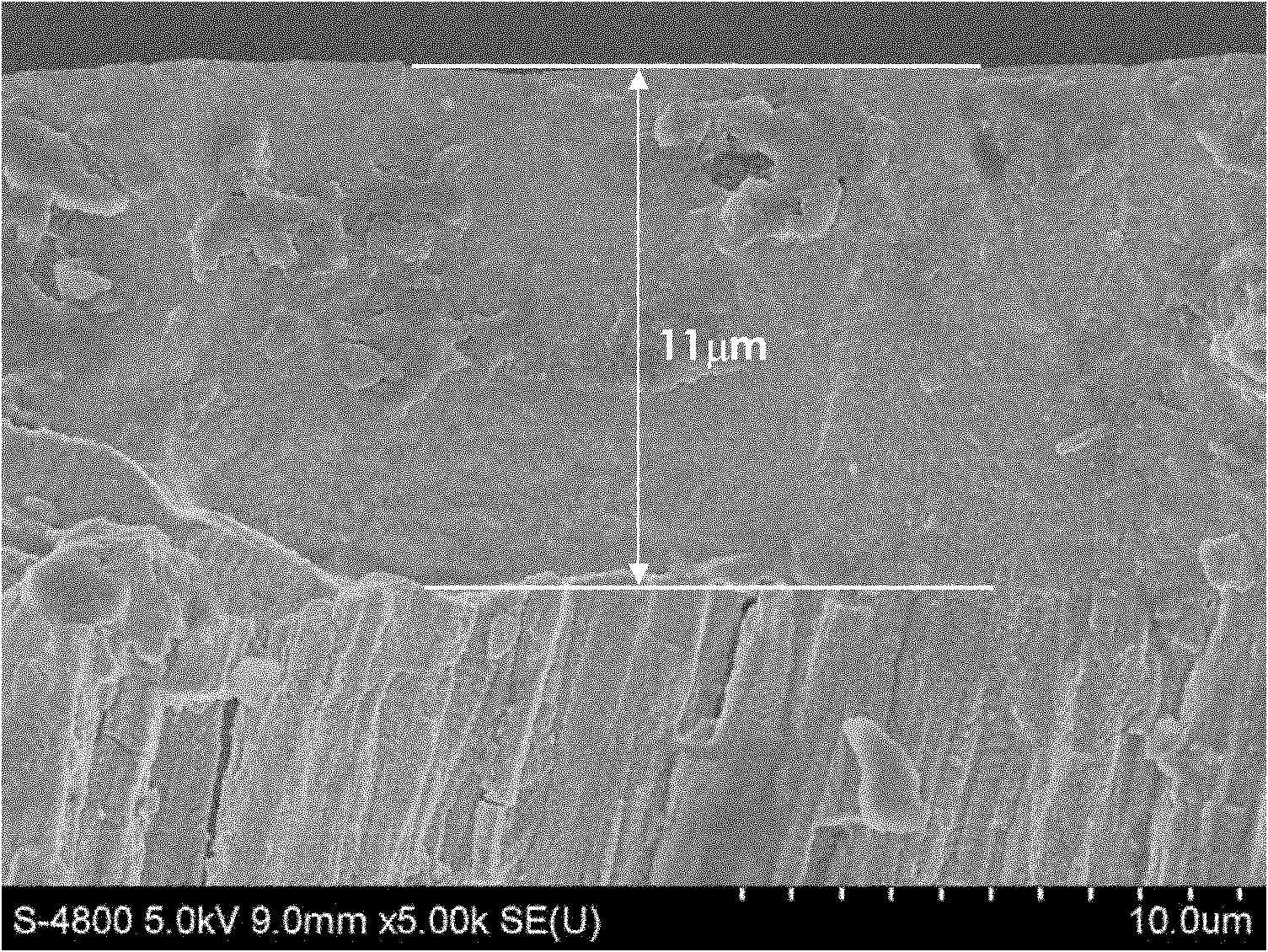

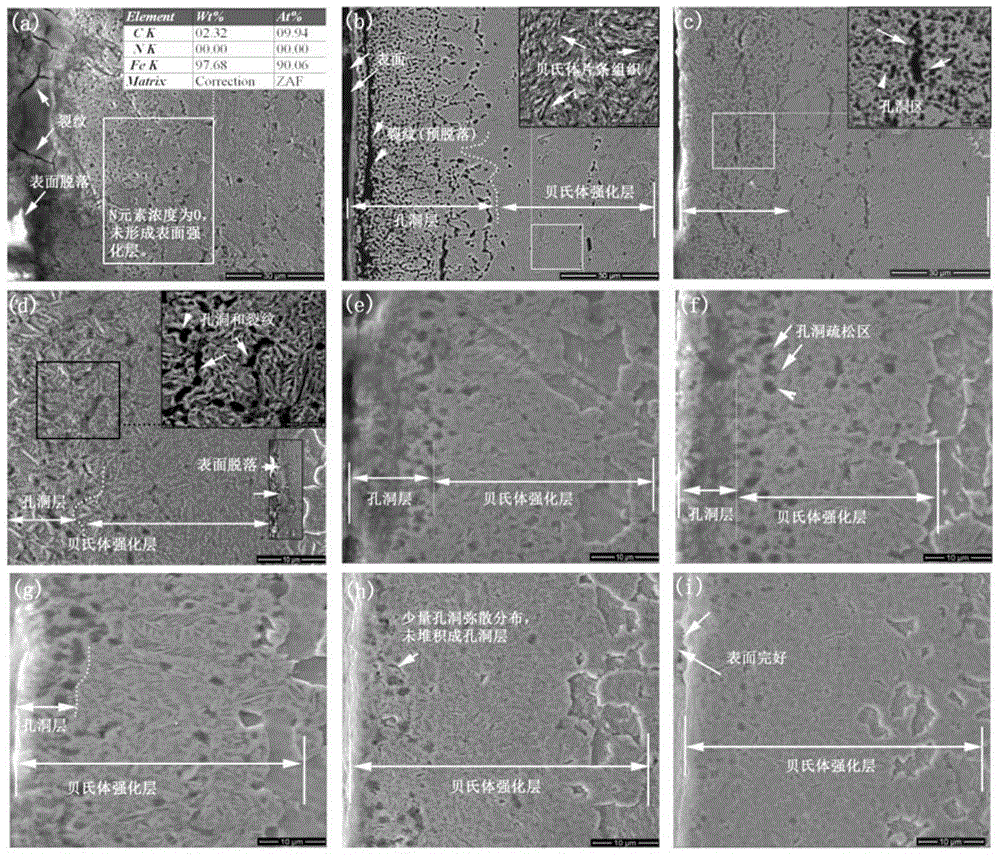

Composite heat treatment process for improving surface compactness of nitro-carburizing strengthened layer

ActiveCN104651858AImprove toughnessImprove wear resistanceSolid state diffusion coatingLow nitrogenHardness

The invention discloses a composite heat treatment process for improving the surface compactness of a nitro-carburizing strengthened layer, which is a heat treatment process for improving the surface compactness of the strengthened layer after the properties of the nitro-carburizing steel workpiece strengthened layer are improved and achieves the integration of nitro-carburizing treatment and austenitizing treatment. The process comprises the following steps: performing the composite process of short-time low nitrogen potential nitro-carburizing at 580 DEG C+ / -10 DEG C with the experimental nitriding potential value of 0.40-0.80 atm<-1 / 2> for 0.5-1.5 hours and austenitizing treatment at 680 DEG C+ / -10 DEG C, and performing isothermal aging treatment at 180 DEG C+ / -10 DEG C. The heat treatment disclosed by the invention is simple and convenient to operate and easy to implement, effectively restrains denitrification during austenitizing treatment, solves the problem that nitro-carburizing strengthened layer gets loose due to pores, and obtains the fully compact surface strengthened layer; and the surface hardness, toughness, smoothness and abrasion resistance of steel workpieces treated by the heat treatment process disclosed by the invention are further improved.

Owner:HUNAN UNIV

Fireproof cooling hydrogel and preparation method thereof

The invention relates to the fields of manufacturing and application of heat-resistant, heat-insulating, flame-retardant and high-temperature expansion materials, specifically to a hydrogel with fireproof and cooling functions and a preparation method thereof. The hydrogel comprises the following components in parts by mass: 0.05-20 parts of a hydrogel thickening agent, 5-35 parts of a freezing point depressant, 1-30 parts of an expanded foam material, 1-15 parts of an expanded flame retardant, 0.01-1 part of a foaming agent, 1-15 parts of a gas generating agent and 0.01-1 part of a bactericide. The hydrogel provided by the invention has the following innovations: when the hydrogel directly acts on the surface of a comburent, the hydrogel can be adhered to the surface of the comburent; meanwhile, foams can be generated on the surface of the comburent and contain water, so the water can be sealed in the foams to continuously exert cooling and fire extinguishing effects; after the wateris dried, an expansion flame-retardant layer can be formed to provide continuous heat-insulation and flame-retardant functions; and the functions of fire extinguishing, cooling, heat insulation and fire reburning prevention are achieved.

Owner:THE SECOND RES INST OF CIVIL AVIATION ADMINISTRATION OF CHINA

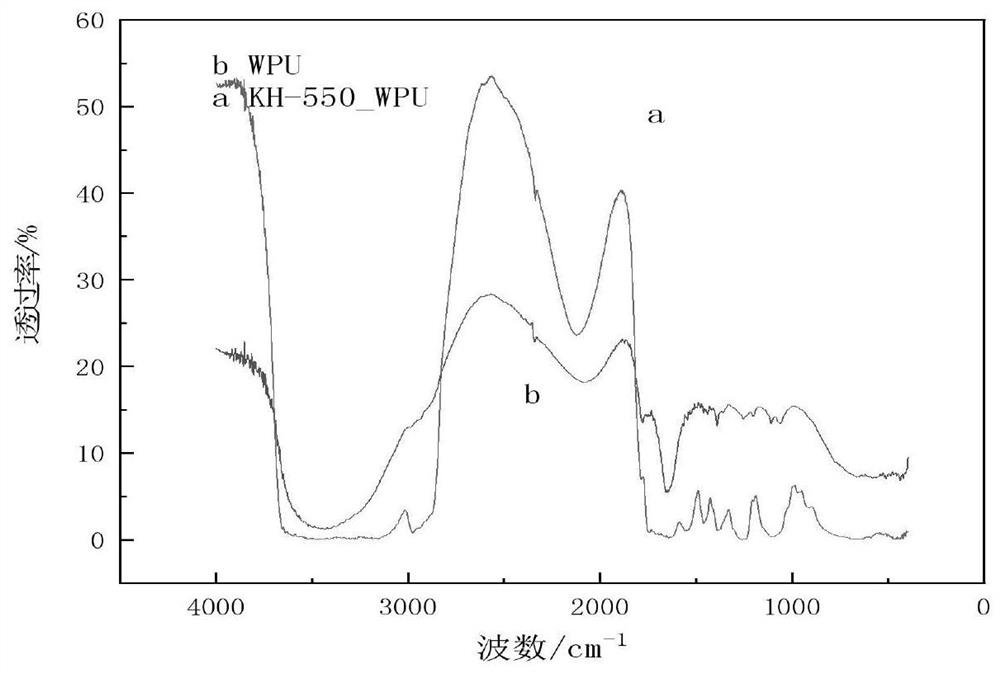

Organic silicon modified waterborne polyurethane waterproof coating and preparation method thereof

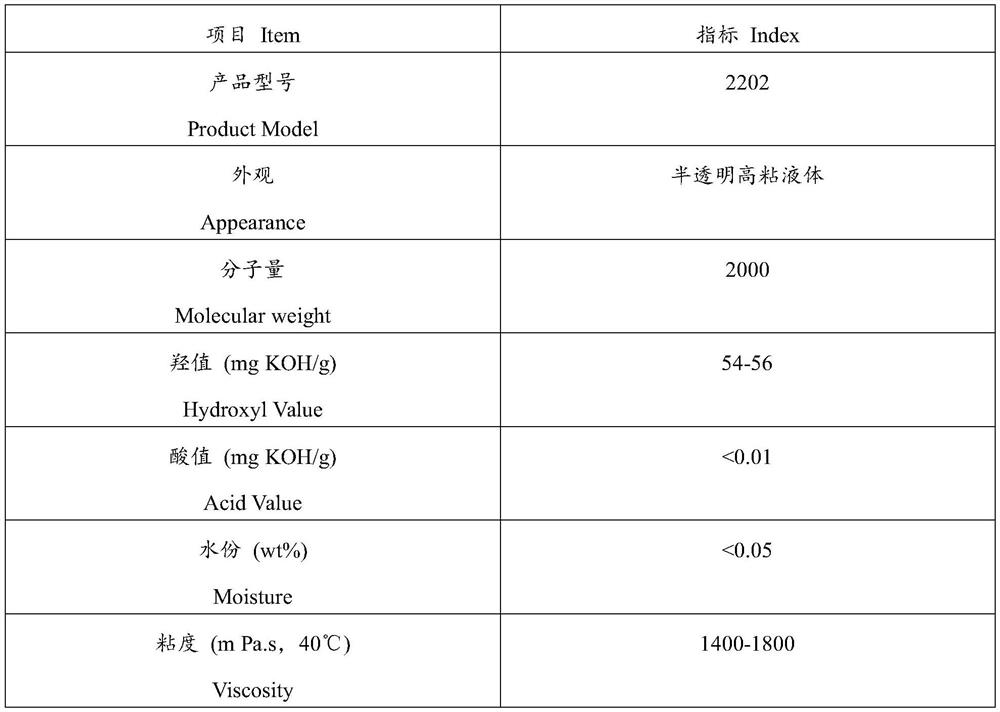

ActiveCN111995943AIncrease elasticityImprove mechanical propertiesAntifouling/underwater paintsPaints with biocidesPolymer sciencePolyol

The invention relates to the technical field of waterproof coatings, and provides an organic silicon modified waterborne polyurethane waterproof coating, which is prepared from the following raw materials in parts by mass: 100 parts of polyhydric alcohols and polyisocyanates; 4-6 parts of a hydrophilic chain extender; 3-7 parts of a post-chain extender; 0.05 to 0.3 part of a neutralizing agent; 0.1 to 1.0 part of a neutralizing agent; 1.5 to 2 parts of a KH-550 coupling agent, 10 to 25 parts of an auxiliary agent, 20 to 50 parts of a filling material, and 25 to 40 parts of water; the present invention defines the isocyanate index during dosing, and defines the composition of the polyols. When the addition amount of the KH-550 coupling agent is 1.8%, the organosilicon modified waterborne polyurethane waterproof coating provided by the invention can ensure that the water absorption rate of an adhesive film is 4.7% under the condition of ensuring emulsion stability, and has excellent water resistance, stain resistance, mechanical properties, weather resistance, waterproofness, wear resistance and corrosion resistance.

Owner:INST OF APPLIED CHEM JIANGXI ACAD OF SCI

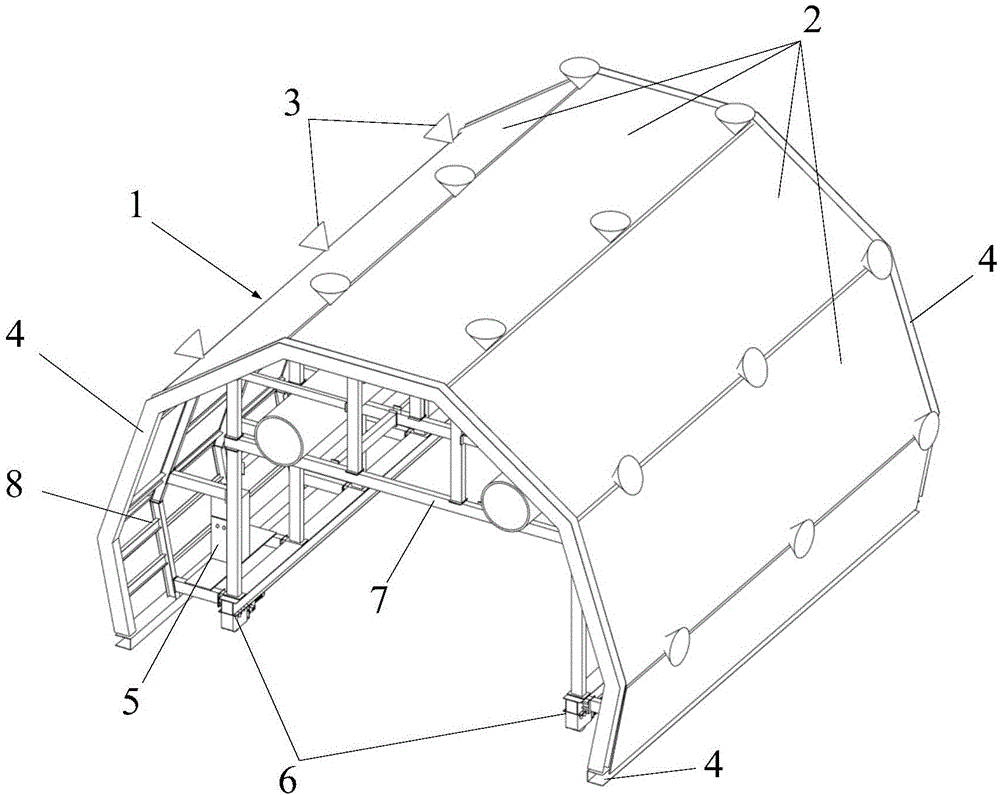

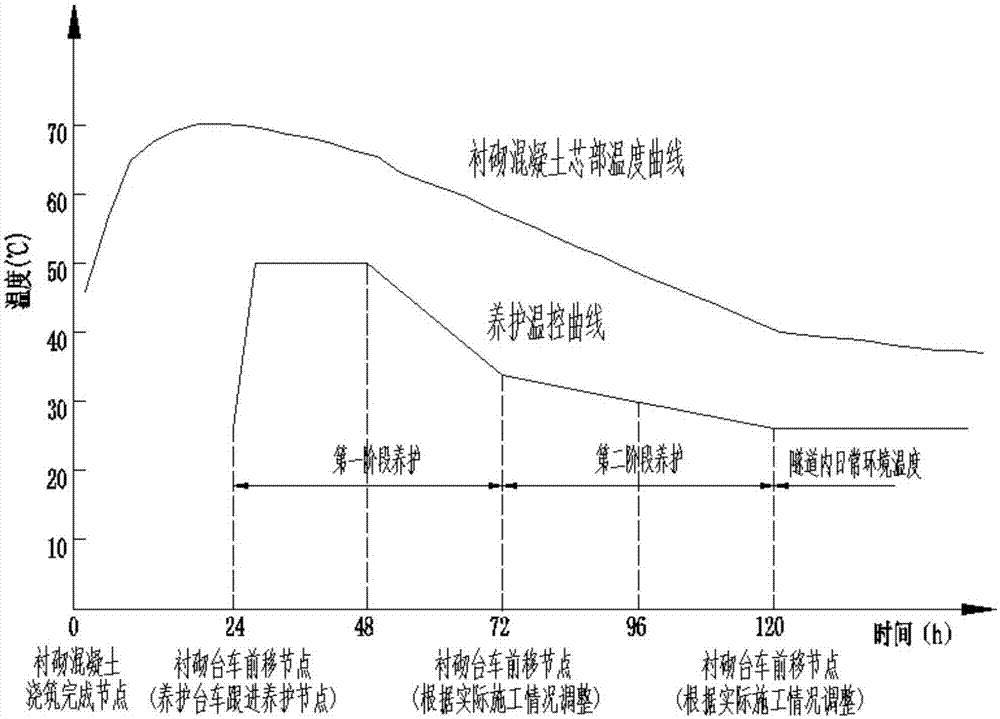

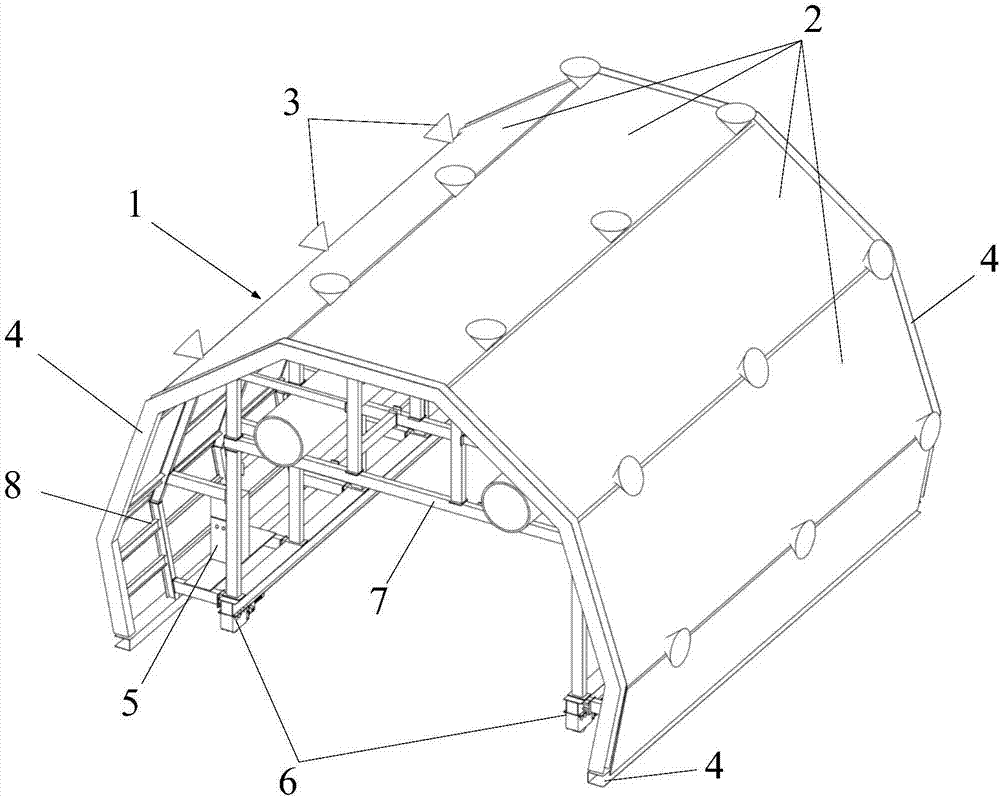

Intelligent tunnel lining curing trolley

PendingCN107435546AQuality improvementHigh strengthUnderground chambersTunnel liningThermal radiationElectrical and Electronics engineering

The invention relates to the technical field of tunnel lining curing and provides a tunnel lining curing trolley. The curing trolley comprises an outer arch and a controller. A plurality of heating devices, a plurality of spraying devices, a plurality of temperature detecting devices and a plurality of humidity detecting devices are arranged on the outer side of the outer arch, wherein the multiple temperature detecting devices and the multiple humidity detecting devices are arranged corresponding to the multiple heating devices and the multiple spraying devices. The heating devices are used for heating the inner wall of a tunnel lining in a heat radiation mode; the spraying devices are used for spraying the inner wall of the tunnel lining; and the controller is used for controlling the heating temperatures and the spraying amounts of the heating devices and the spraying devices according to information fed back by the temperature and humidity devices correspondingly. According to the curing trolley, the temperature and the humidity can be intelligently controlled, the heating curing measure and the humidifying curing measure are mutually independently, and the temperature curing condition and the humidity curing condition are not affected by each other, therefore the temperatures and humidity of areas can be controlled accurately according to the different requirements of the different areas, and finally the tunnel lining quality, concrete strength and surface compactness can be improved significantly.

Owner:CHINA RAILWAY ECONOMIC & PLANNING RES INST +2

Method for producing high thermal conductivity ceramic circuit board

InactiveCN101699932AAvoid breakage damageGuaranteed YieldConductive material chemical/electrolytical removalSolder maskThermal conductivity

The invention discloses a method for producing a high thermal conductivity ceramic circuit board, which comprises the following steps: a, pre-processing of a substrate; b, pattern transfer; c, manufacturing of conducting holes; d, printing of solder mask; e, silk screen printing of characters; f, chemical deposition of nickel, gold; and g, formation by cutting; the objective of the invention is to overcome the deficiencies in the prior art and provide a method for producing a high thermal conductivity ceramic circuit board with simple technology and good thermal conduction and radiating effects of the product.

Owner:广东达进电子科技有限公司

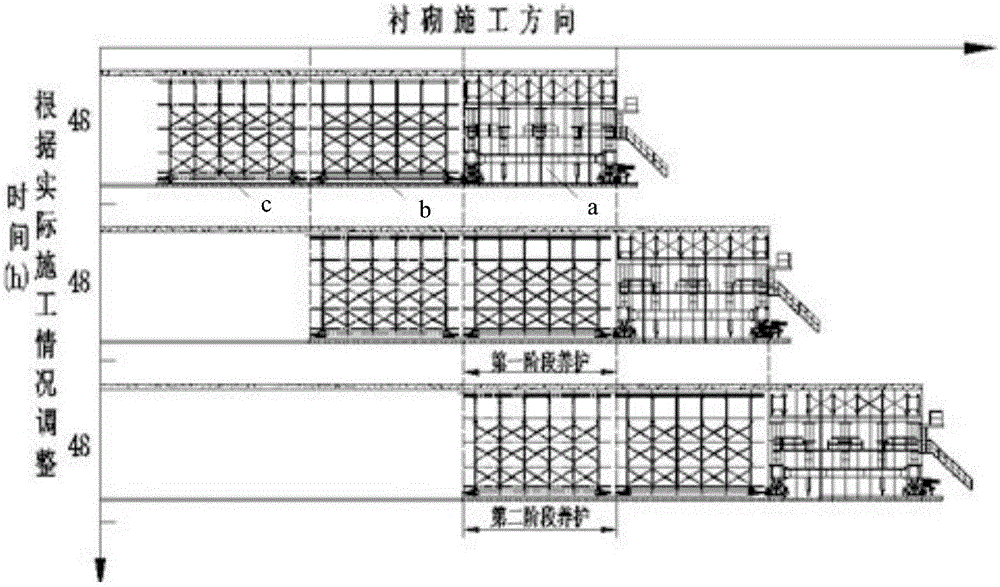

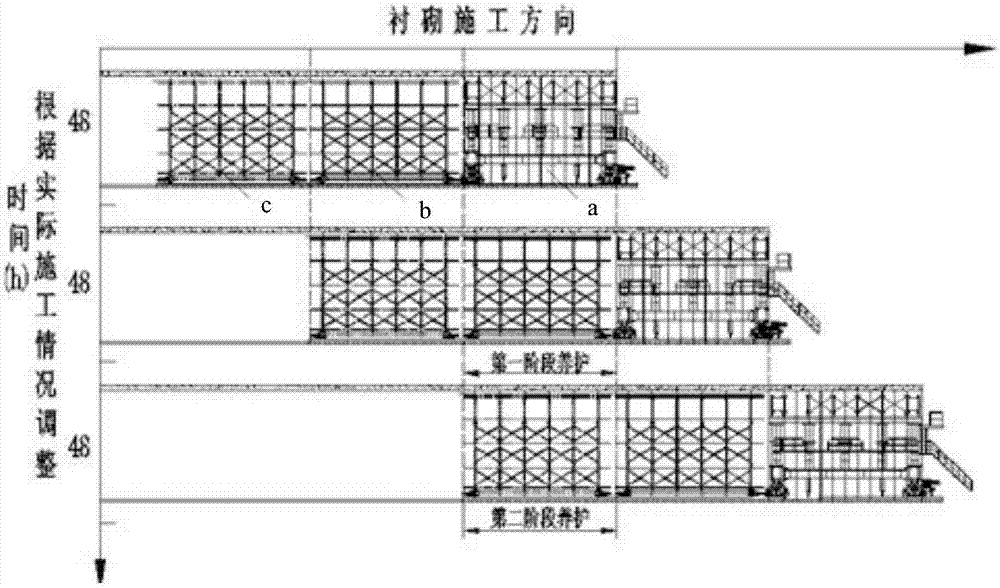

Tunnel lining concrete curing construction process

InactiveCN107387124AQuality improvementHigh strengthUnderground chambersTunnel liningThermal radiationUltimate tensile strength

The invention relates to the technical field of tunnel lining curing and provides a tunnel lining concrete curing construction process. According to the process, a tunnel lining is axially divided into multiple to-be-cured segments, each to-be-cured segment is divided into multiple to-be-cured areas, curing operation including monitoring the temperature and the humidity of each to-be-cured area is performed on all the to-be-cured segments one by one, and each to-be-cured area is subjected to spraying treatment and thermal radiation treatment to enable the temperature and the humidity of each to-be-cured area to conform to a set temperature variation curve and a set humidity variation curve. The curing process can realize intelligent control on temperature and humidity, two curing ways of heating and humidifying are independent from each other, temperature curing conditions and humidity curing conditions do not affect each other, and accordingly accurate control on the temperature and humidity of each area is realized according to different demands of different areas, and tunnel lining quality, concrete strength and surface compactness can be improved significantly.

Owner:CHINA RAILWAY ECONOMIC & PLANNING RES INST +2

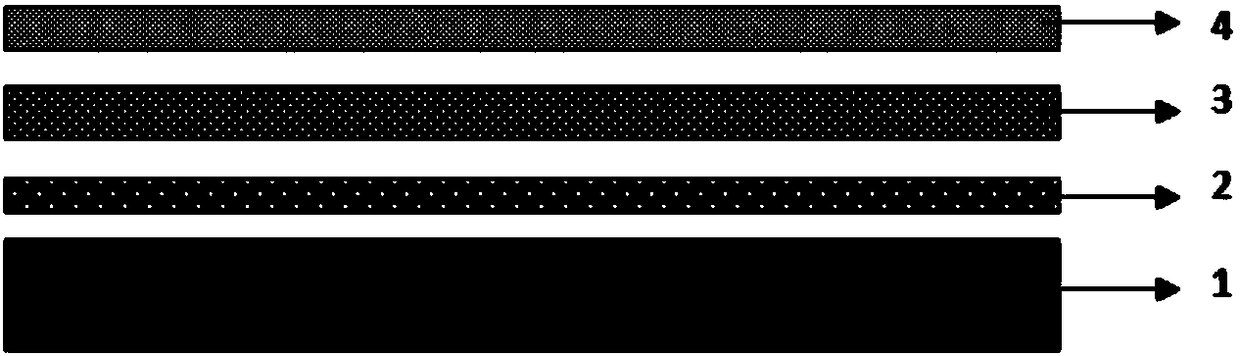

Nano barrier film and preparation method thereof

PendingCN108084474AIncreasing the thicknessImprove water and gas barrier performanceVacuum evaporation coatingSputtering coatingPolyurethane coatingSolid content

The invention provides a nano barrier film and a preparation method thereof. The nano barrier film is sequentially provided with an aluminizing base film layer , a bottom coating layer, a barrier coating layer and a nano clad layer from bottom to top. The bottom coating layer refers to acrylate or polyurethane coating, and the solid content is 30-40%; the barrier coating layer refers to acrylate or polyurethane coating, and the solid content is 50-70%. The invention further provides the preparation method of the nano barrier film, The thickness of the prepared nano barrier film is not significantly increased, the aluminizing base film layer is good in aluminum layer adhesion, excellent in water blocking and air blocking performance, meanwhile the durability of the film is good, and the service life is very long.

Owner:福建菲尔姆科技有限公司

Preparation process of terrazzo floor

InactiveCN107178196AReduce bleedingImprove surface compactnessBuilding material handlingFlooringTerrazzoEngineering

The invention relates to a preparation process of a terrazzo floor and belongs to the technical field of floor construction. According to the preparation process of the terrazzo floor, dry grinding is adopted to replace a water grinding process in the prior art, and a super nanometer lithium-based sealing curing agent is used, so that the terrazzo floor which is ground and polished through the preparation process is better in glossiness, abrasion resistance, compactness and oil stain resistance and more durable in use. According to the process, the steps of water sucking and waste slurry discharge treatment are omitted, construction operation is easy and convenient, and more energy conservation and environmental friendliness are achieved. The glossiness of the new terrazzo floor which is ground and polished through the process or a polishing of refurbished terrazzo floor can achieve the effect of high-grade marble or a high-grade polished brick.

Owner:SHENZHEN NANOFRONT TECH CO LTD

Blocking film with low heat bridge effect and vacuum heat insulation plate with blocking film

PendingCN108081713AImprove surface compactnessImprove barrier propertiesSynthetic resin layered productsCoatingsBlock layerBlocking layer

The invention discloses blocking film with a low heat bridge effect. The film is formed by bonding a waterproof layer, a protection layer and a blocking layer through an adhesive in sequence. The blocking layer is at least one layer of nano blocking thin film, and the nano blocking thin film is formed by laminating aluminizing base film, a bottom coating, a blocking coating and a nano plating layer in sequence. The invention provides a vacuum heat insulation plate which is formed in the mode that the blocking film with the low heat bridge effect wraps a cladding core material and a getter. Theprepared blocking film with the low heat bridge effect contains no aluminum foil, the edge heat bridge effect is low, the blocking performance is excellent, the durability under the warm and wet environment is good, the heat insulation and heat preservation performance and use durability of the vacuum heat insulation plate are greatly improved, and the vacuum heat insulation plate is effective under the high-temperate high-humidity environment for a long time.

Owner:福建菲尔姆科技有限公司

Production method of bright-copper-face high-heat-conductivity ceramic circuit board capable of locating

InactiveCN101699936AAvoid breakage damageGuaranteed YieldConductive material chemical/electrolytical removalCeramicMetallic Nickel

The invention discloses a production method of a bright-copper-face high-heat-conductivity ceramic circuit board capable of locating, which comprises the following steps: (a) pretreating a base board; (b) transferring a pattern; (c) making a locating hole; (d) printing solder-resisting ink; (e) screen-printing the text; (f) chemically depositing nickel and gold; (g) and forming by cutting. The invention aims to overcome the defects in the prior art and provide a production method of the bright-copper-face high-heat-conductivity ceramic circuit board capable of locating. The invention has the advantages of simple technique and favorable effects of heat conduction and dissipation of the product.

Owner:广东达进电子科技有限公司

Preparation method of ceramic-based electronic substrate material

The invention discloses a preparation method of a ceramic-based electronic substrate material, and belongs to the technical field of the preparation of ceramic substrate materials. The method comprises the following steps: mixing and ultrasonically dispersing yttrium nitrate and calcium nitrate, drying to constant weight, sintering and nitriding to prepare nanometer aluminum nitride, mixing with dehydrated and milled samarium nitrate, carrying out ball milling, drying to constant weight, grinding, screening and then calcining, mixing with the paraffin, extruding and pelleting, drily pressing to prepare a blank body, degumming, and sintering to obtain the ceramic-based electronic substrate material. The method disclosed by the invention has the beneficial effects that the preparation step is simple, the obtained product is good in sintering performance, the pore is avoided in the sintering, the material flexure strength is high; the surface compactness is good, and the phenomena of moisture absorption and electrode slurry penetration are avoided.

Owner:郭迎庆

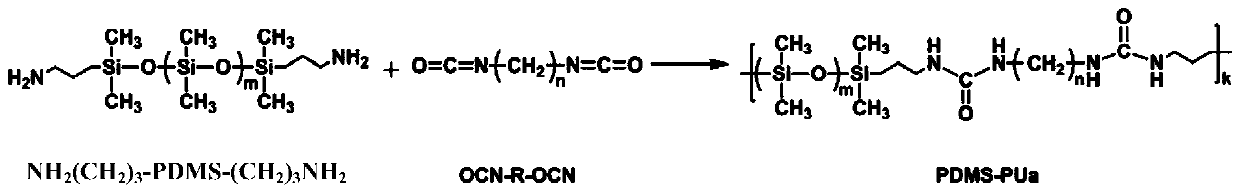

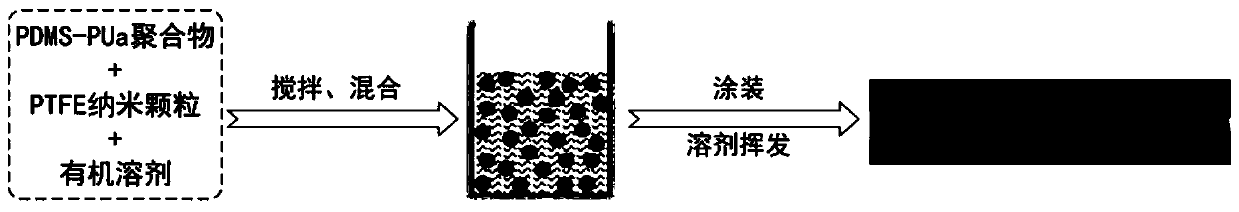

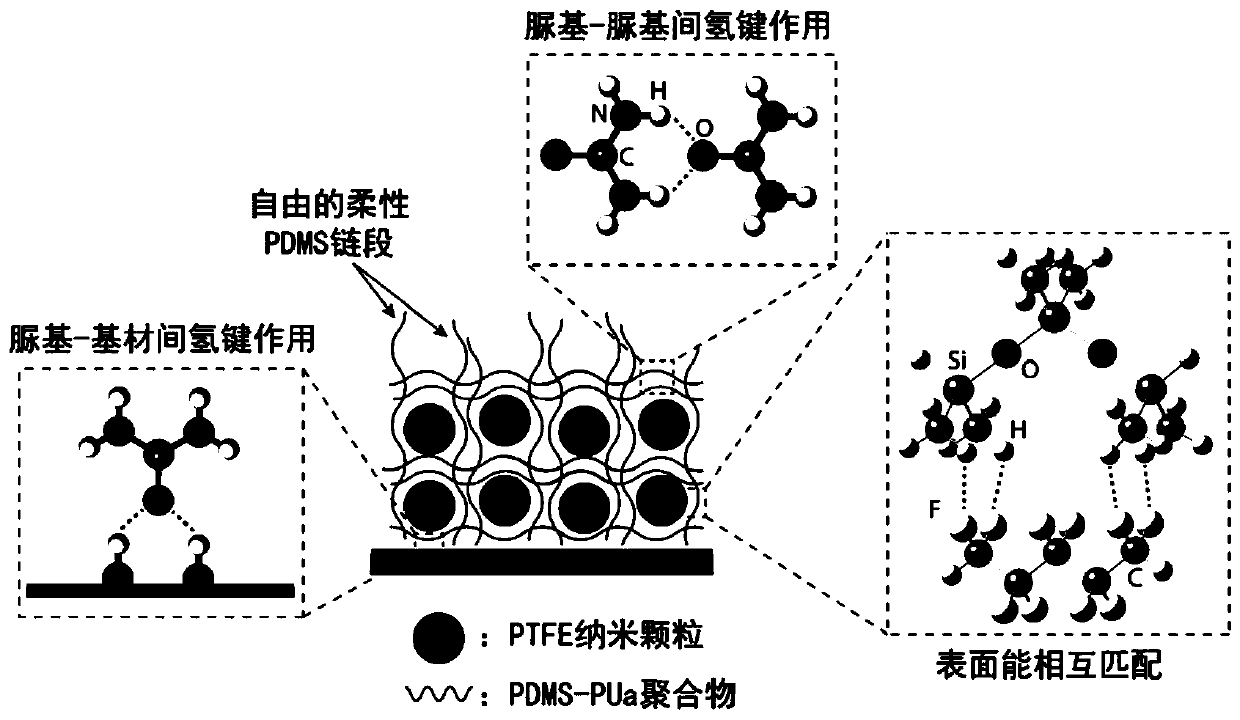

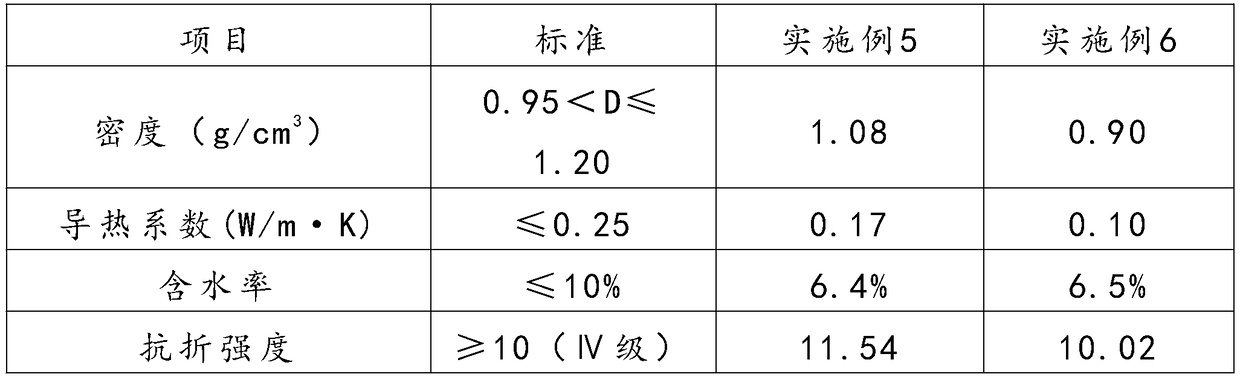

Antifouling coating material and preparation method and application thereof

ActiveCN110804380AImprove mechanical propertiesGood adhesionAntifouling/underwater paintsPaints with biocidesPolymer scienceOrganic solvent

The invention provides an antifouling coating material and a preparation method and application thereof, the coating material comprises the following raw materials: PDMS-PUa, PTFE nanoparticles and anorganic solvent A, and the coating material is obtained by mixing and crosslinking PTFE dispersion liquid dispersed in the organic solvent A and PDMS-PUa. The antifouling coating material and an antifouling material prepared from the antifouling coating material disclosed by the invention have relatively good flexibility and fluidity, a glossy surface and a low elastic modulus, The antifouling property is achieved while good mechanical property is guaranteed, certain self-repairing property is achieved, service life of antifouling material can be prolonged, durable and efficient antifouling purpose is achieved, and a wide application prospect is achieved.

Owner:NAT INNOVATION INST OF DEFENSE TECH PLA ACAD OF MILITARY SCI

NANO modified silicate capillary crystalline material and use method thereof

ActiveUS20220041518A1Increase effective free calcium ionImprove surface compactnessCrazingCapillary Tubing

A concrete durability protection method is provided, including following steps: Step one: rinsing the concrete surface; Step two: spraying agent A material or alternately spraying agent B material and agent A material at the wet surface of the concrete; Step three: repeating step two. The beneficial effects of the present invention include: nanoscale active silicate penetrates into the concrete surface layer within a certain depth and reacts with free calcium ions within the concrete to form C—S—H crystalline, thereby improving the compactness of the concrete surface layer within a certain depth, repairing defects in the concrete surface layer within a certain depth, such as the capillary interstices, pores, microcracks, etc., so as to effectively improve the durability of concrete. The unreacted nanoscale active silicate material has permanent activity. It could recover its activity when the concrete absorbs moisture, and continue to react with free calcium ions in the concrete to quickly form C—S—H crystals, realizing the permanent concrete durability protection.

Owner:ZHAN YANGDONG

Surface dense enhancement concrete heat preservation and moisturizing composite curing method

ActiveCN110173122AImprove surface compactnessImprove early strengthBuilding material handlingWater storageSilicon

The invention relates to a surface dense enhancement concrete heat preservation and moisturizing composite curing method. Nanometer silicon sol and a heat preservation and moisturizing curing film arecombined for concrete curing; in the composite curing method, the particle size range, the spraying using amount and the spraying opportunity of the nanometer silicon sol are defined, and the heat preservation and moisturizing curing film has the specific water storage and release structure characteristics. The surface dense enhancement effect of the nanometer silicon sol and the heat preservation and moisturizing effect of the curing film are combined, the early stage self hydration and heat release characteristics of the cast-in-place concrete structure are fully utilized, concrete surfacedense enhancement is achieved, and the durability of the structure is improved.

Owner:RAILWAY ENG RES INST CHINA ACADEMY OF RAILWAY SCI +2

Coating and glazing process for inorganic decorative sheets and preparation method of coatings

InactiveCN107286817AIncrease productivityWork quicklyAntifouling/underwater paintsPaints with biocidesAging resistanceSpray coating

The invention discloses a coating and glazing process for inorganic decorative sheets and a preparation method of coatings. The coating and glazing process and the coatings are mainly used for protecting and decorating coatings formed in early coating stage of the inorganic decorative sheets. Compared with traditional spraying, brush coating and roller coating processes, the coating and glazing process has the advantages of high production efficiency, good paint film build, high yield and low coating waste rate; the coatings for the coating and glazing process include a UV spray coating, a water spray coating and a fluorine-modified PU spray coating, and formed coating and glazing paint is good in water resistance, pollution resistance, ageing resistance and scrub resistance.

Owner:HUNAN JINHAI SCI & TECH

Graphene aldehyde removing diatom board and preparation method thereof

The invention belongs to the field of diatom boards, and especially relates to a graphene aldehyde removing diatom board and a preparation method thereof. The diatom board comprises following components: diatomite, a calcium material, a mineral material, an aqueous fiber, a thickening fiber, a graphene modified aldehyde removing agent, and water. The preparation method comprises following steps: mixing and stirring all components together, extruding the mixture in demoulding cloth, allowing the mixture to stand still, drying, and baking to obtain the graphene aldehyde removing diatom board. Diatomite and the calcium material are taken as the basic materials, at the same time, the graphene modified aldehyde removing agent is added so that harmful gas that is absorbed by the diatomite can berapidly decomposed into carbon dioxide and water, the surface compactness of the diatom board is greatly improved, the toughness and strength of the diatom board are enhanced; the added fibers can prevent the cracking and deformation of the diatom board, when the diatom board shrinks in a dry environment, the strength of the diatom board is further strengthened, and thus the service life of the diatom board is prolonged.

Owner:QINGDAO REALEADER ADVANCED MATERIALS TECH

Bare concrete and preparation method thereof

The invention discloses bare concrete. The bare concrete is characterized by being prepared from, by weight, 5-10 parts of surface modified nano-boron fiber, 5-10 parts of kaolin, 10-15 parts of illite powder, 20-30 parts of gravel, 5-10 parts of vermiculite sand, 20-30 parts of silver sand, 40-50 parts of Portland cement, 1-5 parts of a compound additive and 20-30 parts of water. The compound additive comprises, by weight, 20-25 parts of a phosphate borate copolymer, 2-5 parts of zinc citrate, 1-3 parts of pyrophyllite powder, 1-3 parts of wollastonite powder, 2-4 parts of porous magnesium silicate, 0.5-1 part of a defoaming agent, 0.8-1.5 parts of polyaminopropyl biguanide, 0.5-2 parts of hydroxypropyl cyclodextrin, 1-3 parts of an activator and 80-100 parts of water. The invention further discloses a preparation method of the bare concrete. The bare concrete is high in compressive strength, good in corrosion resistance, impermeability and crack resistance and excellent in comprehensive performance, and production and application are safe and environmentally friendly.

Owner:佛山市政通混凝土有限公司

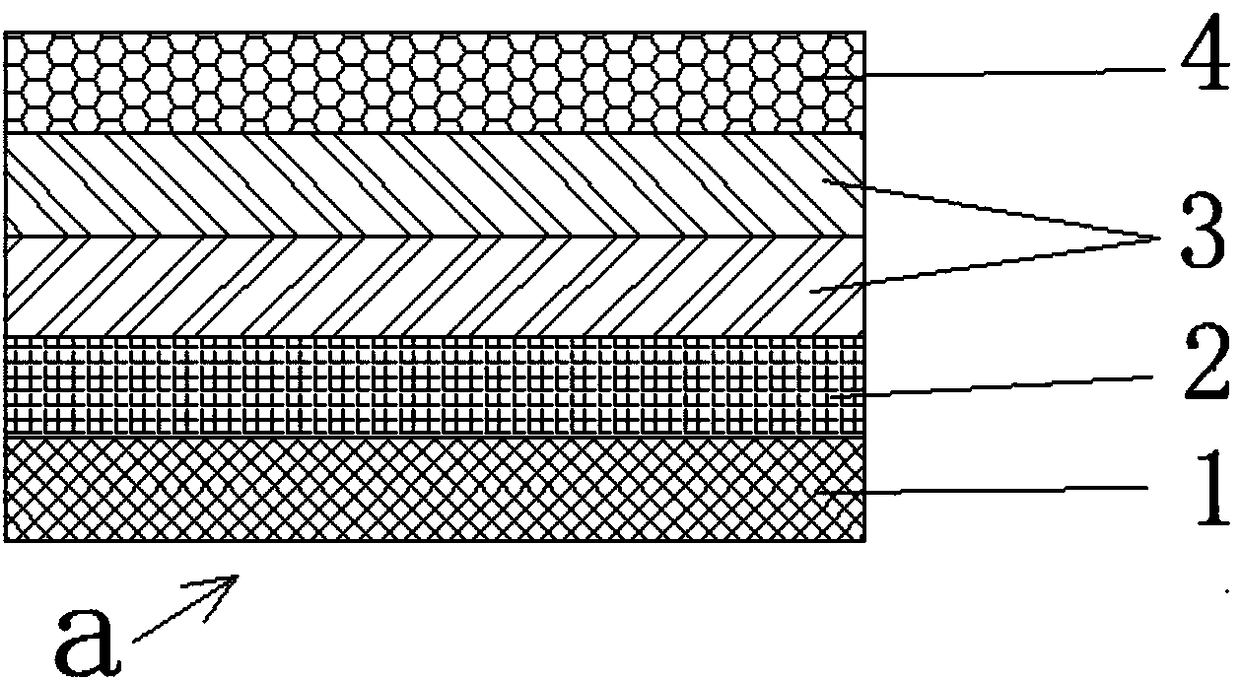

Composite absorbing layer pyroelectric infrared detector

ActiveCN105789428AControllable thicknessDense coating layerThermoelectric device with dielectric constant thermal changePyrometry using electric radation detectorsTitanium metalInfrared detector

The invention discloses a composite absorbing layer pyroelectric infrared detector, and belongs to the technical field of pyroelectric detectors. According to the pyroelectric infrared detector, an absorbing layer comprises a titanium metal layer (1), a dielectric layer (2), a nichrome alloy layer (3), a lithium tantalate crystal layer (4) and a reflecting layer (5) which are arranged from the top layer to the bottom layer in turn. The nichrome alloy layer (3) is deposited on the top surface of the lithium tantalate crystal layer (4). The reflecting layer (5) is deposited on the bottom surface of the lithium tantalate crystal layer (4). The titanium metal layer (1) is deposited on the top surface of the dielectric layer (2). Compared with a single metal absorbing layer film acting as a heat sensitive layer, the prepared composite absorbing layer of the pyroelectric infrared detector has better surface compactness, high absorption coefficient and low heat loss and can acquire high performance heat response so as to be favorable for preparation of the high-precision pyroelectric infrared detector.

Owner:UNIV OF ELECTRONIC SCI & TECH OF CHINA

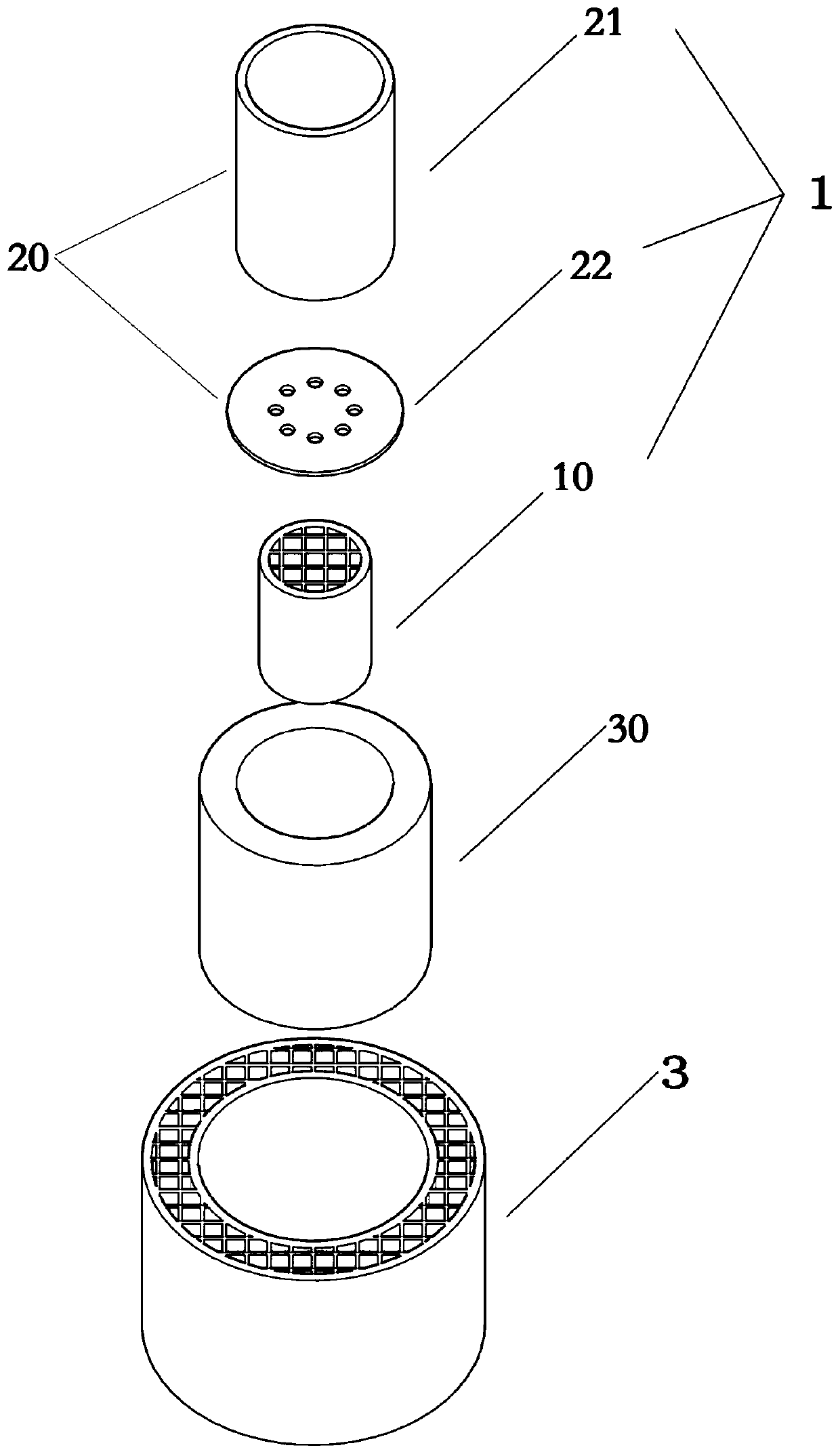

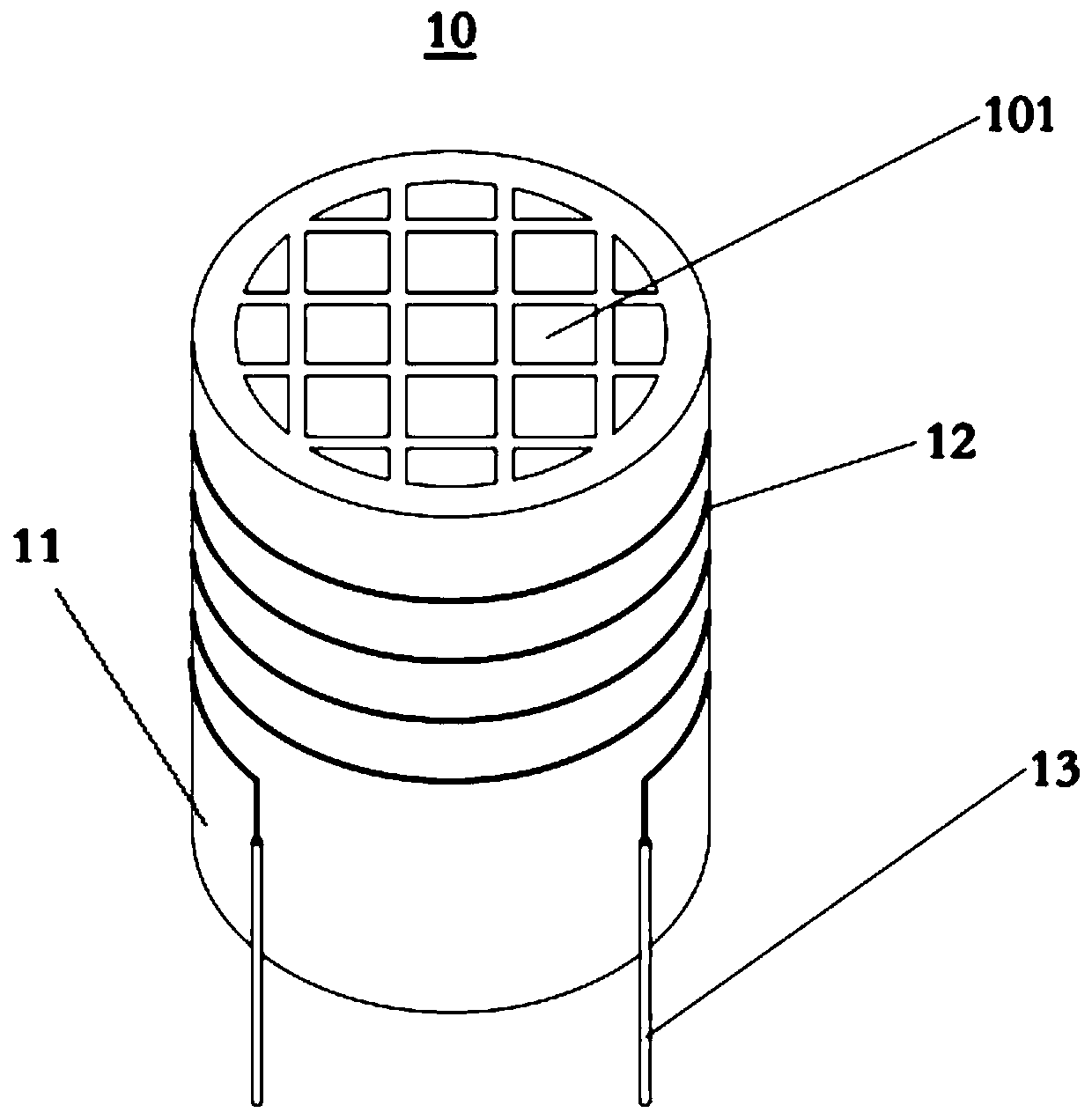

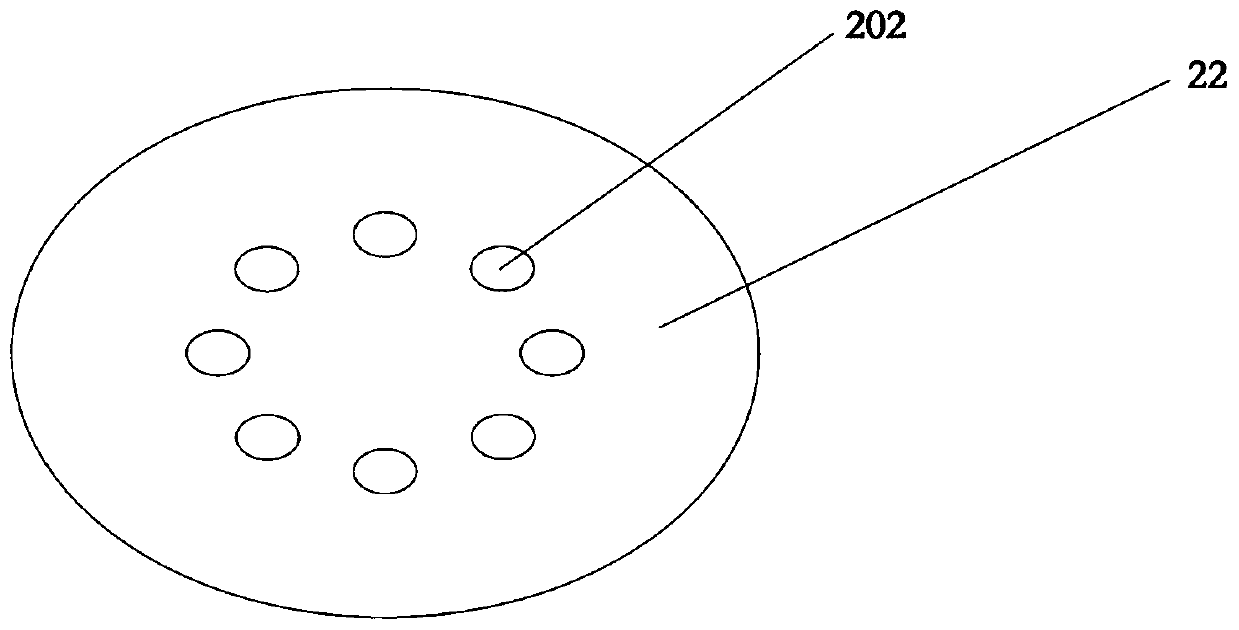

Ceramic heating element and non-contact electronic cigarette heater with ceramic heating element

PendingCN110710726AFully heatedControl flow rateOhmic-resistance heating circuitsTobacco smoke filtersElectronic cigarettePorous channel

The invention discloses a ceramic heating element. The ceramic heating element includes a heating body and a heating circuit; the heating body is columnar, and a porous channel is arranged in the heating body; and the heating circuit is arranged on the heating body to heat air passing through the porous channel. The ceramic heating element disclosed by the embodiment of the invention can increasethe contact area between the heating body and the air, and realize sufficient heating of the air, which not only has high heating efficiency and high thermal conductivity, and realizes energy saving and power saving, but also has good compactness and does not adsorb smoke particles, thereby having no abnormal odor. The invention also discloses a non-contact electronic cigarette heater with the ceramic heating element.

Owner:XIAMEN FENGTAO CERAMICS CO LTD

Strip steel surface appearance control method

The invention discloses a strip steel surface appearance control method, and relates to the technical field of steel rolling, and is applied to a wet leveling process of a double-rack temper mill. The method comprises the following step that target strip steel is controlled to sequentially pass through a first working roller on a first rack of the double-rack temper mill and a second working roller on a second rack of the double-rack temper mill at the speed of 300-600 m / min according to a preset condition for continuous rolling, wherein the roughness of the first working roller is 2.0-4.0 microns, the roughness of the second working roller is 1.0-3.0 microns, and the roughness of the first working roller is larger than the roughness of the second working roller. The strip steel surface appearance control method solves the problems that in the prior art, in the case of strip steel which is rolled by using a double-rack temper mill wet leveling process, rolling force lines exist on the surface of the strip steel after the strip steel is leveled, and the compactness of the surface of the strip steel is poor.

Owner:SHOUGANG CORPORATION

Preparation method of rear-earth magnesium alloy product

The invention relates to a preparation method of a rear-earth magnesium alloy product. The preparation method comprises the following steps of: placing dehydrated rear-earth chlorate in a melting electrolysis device; adding dehydrated magnesium chloride, potassium chloride and titanium dichloride for dispersing, mixing and carrying out melting electrolysis, so that rear-earth magnesium intermediate alloy is generated by co-electrodeposition of rear-earth ion and magnesium ion at a negative electrode; burdening and mixing the rear-earth magnesium intermediate alloy and the metal magnesium in a smelting device, wherein a molar ratio of the rear-earth metal to the magnesium is (0.1-1.0):100; heating up the rear-earth magnesium alloy mixture for melting, immersing the smelting agent inside the melt and stirring, increasing the temperature to 780 DEG C and stewing for 20 minutes for dividing the melt into an upper layer, a middle layer and a lower layer, wherein the middle melt layer is used as the rear-earth magnesium alloy melt; casting after pre-cooling, cooling and forming, and carrying out surface treatment after carrying out mechanical processing and thermal processing, so that a compact proactive film layer is covered on the surface of the rear-earth magnesium alloy product. The preparation method of the rear-earth magnesium alloy product is high in preparation efficiency, safe and reliable in process, environment-friendly and low in energy consumption.

Owner:YANGZHOU FENG MING METAL PROD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com