A kind of sb‑te‑w phase change target material for phase change storage and its preparation method

A phase change storage and target technology, applied in metal material coating process, ion implantation plating, coating and other directions, can solve problems such as difficult and complicated operation, achieve uniform composition, improve grain size, and reduce sintering temperature Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

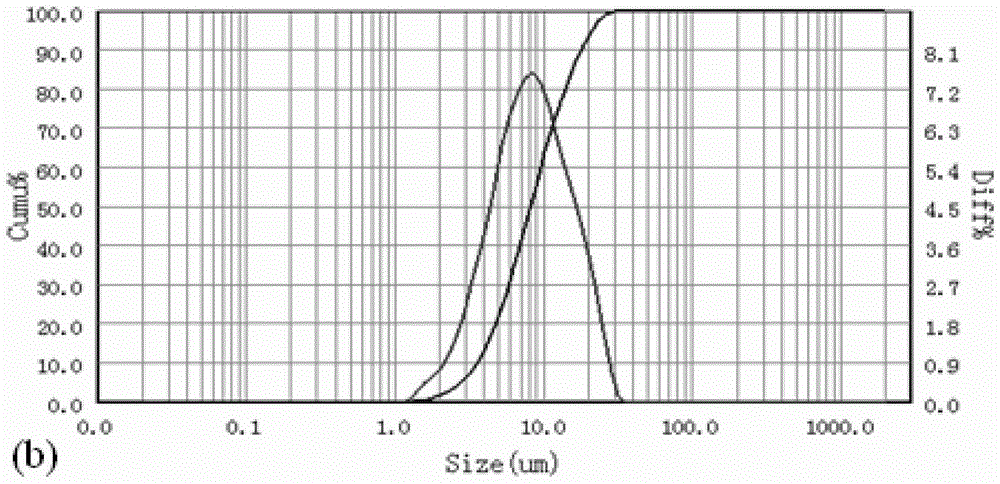

[0028] In this embodiment, the phase change target is Sb 0.398 Te 0.597 W 0.005 (Mass fraction of tungsten is about 0.7%). The specific preparation conditions are as follows: W powder (-300 mesh) with a mass fraction of 0.5%~1.5% is mixed with Sb powder (-200 mesh) and Te powder (-200 mesh) respectively, then pressed and molded, and packed into a bag Vacuum sealing, smelting, crushing and ball milling to obtain intermediate compound powder of WSb and WTe. Melting parameters: heating rate 15~20°C / min, melting temperatures of WSb and WTe respectively 650°C and 550°C, melting time 15min. Crushed and ball milled for 24 hours and 30 hours respectively, the intermediate compounds of WSb and WTe were obtained, with median diameters of about 8.378 μm and 8.182 μm. Table 1(a) and Table 1(b) are the laser particle size distributions of WSb and WTe intermediate compound powders in Example 1, Table 1(a): WSb, Table 1(b): WTe. Figure 1(a) and Figure 1(b) are the laser particle size di...

Embodiment 2

[0034] In this embodiment, the phase change target is Sb 0.654 Te 0.327 W 0.019 (The mass fraction of tungsten is about 3%). The specific preparation conditions are as follows: W powder with a mass fraction of 1%~2.5% is mixed with Sb powder and Te powder respectively, then pressed into shape, put into a bag, vacuum sealed, smelted, crushed, and ball milled to obtain the intermediate compound of WSb and WTe powder. Melting parameters: heating rate 15~20°C / min, melting temperatures of WSb and WTe respectively 660°C and 595°C, melting time 20min. Crushed and ball milled for 30h and 36h respectively, the intermediate compounds of WSb and WTe were obtained, with median diameters of about 11.352μm and 13.861μm.

[0035] According to the general formula Sb 0.654 Te 0.327 W 0.019 Proportion, mix the two intermediate compound powders evenly, after mixing for 48 hours, double-way press vacuum hot pressing sintering, pressure 15MPa, vacuum degree 1.0×10 -3 Pa, sintering temperat...

Embodiment 3

[0038] In this embodiment, the phase change target is Sb 0.756 Te 0.189 W 0.055 (Mass fraction of tungsten is about 8%). The specific preparation conditions are as follows: W powder (-300 mesh) with a mass fraction of 2%~4% is mixed with Sb powder (-200 mesh) and Te powder (-200 mesh) evenly, then pressed into shape, put into a bag and vacuumize Sealing, smelting, crushing and ball milling to obtain WSb and WTe intermediate compound powder. Melting parameters: heating rate 10~15°C / min, melting temperatures of WSb and WTe respectively 665°C and 603°C, melting time 20min. Crushed and ball milled for 36 hours respectively, the intermediate compounds of WSb and WTe were obtained, and the median particle size diameters were about 13.42 μm and 12.169 μm.

[0039] According to the general formula Sb 0.756 Te 0.189 W 0.055 Proportion, mix the two intermediate compound powders evenly, after mixing for 48 hours, double-way press vacuum hot pressing sintering, the pressure is 12MPa,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com