Phase change heat storage material and preparation method and application thereof

A phase change heat storage material and a heat storage technology, which are applied in the field of phase change heat storage materials and their preparation, can solve the problems of low thermal conductivity, low thermal conductivity, and low heat storage density of materials, so as to improve heat storage capacity and thermal conductivity. The effect of large coefficient and high heat storage density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] The phase change heat storage material 1 is prepared by the following steps:

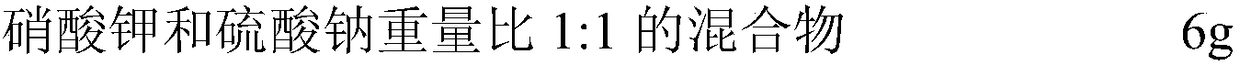

[0038] Mix the following components into a mixture:

[0039]

[0040]

[0041] A stirrer was used to stir the mixture at a speed of 800 rpm for 6 minutes to obtain the phase-change heat storage material 1 .

Embodiment 2

[0043] The only difference with Example 1 is that the components and content of the mixed solution are as follows:

[0044]

[0045] Example 2 Obtain variable heat storage material 2.

Embodiment 3

[0047] The only difference with Example 1 is that the components and content of the mixed solution are as follows:

[0048]

[0049] Example 3 Obtain variable heat storage material 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| heat storage density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| heat storage density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com